Study on Failure Mechanism of Roadway Surrounding Rock and Hierarchical Continuous Support Technology in Unidirectional Fault Area

Abstract

1. Introduction

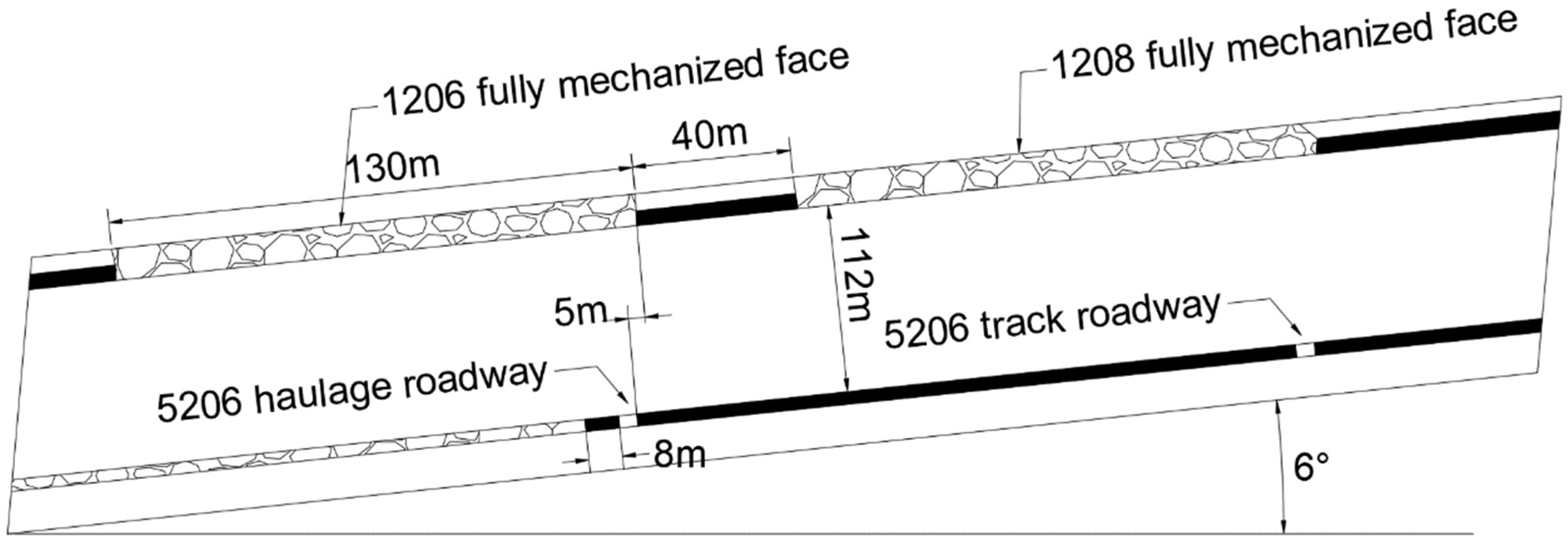

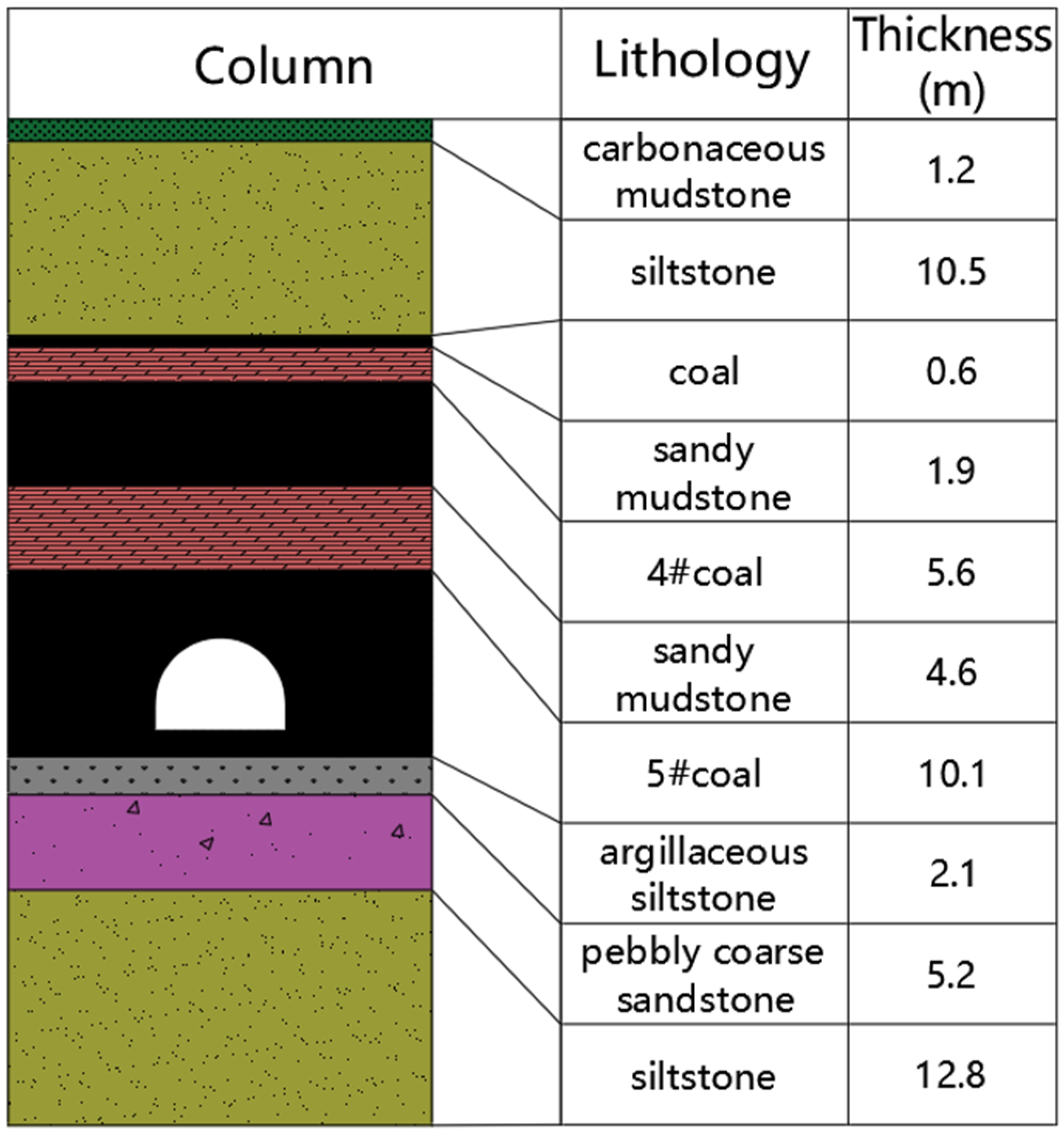

2. Engineering Geology Overview

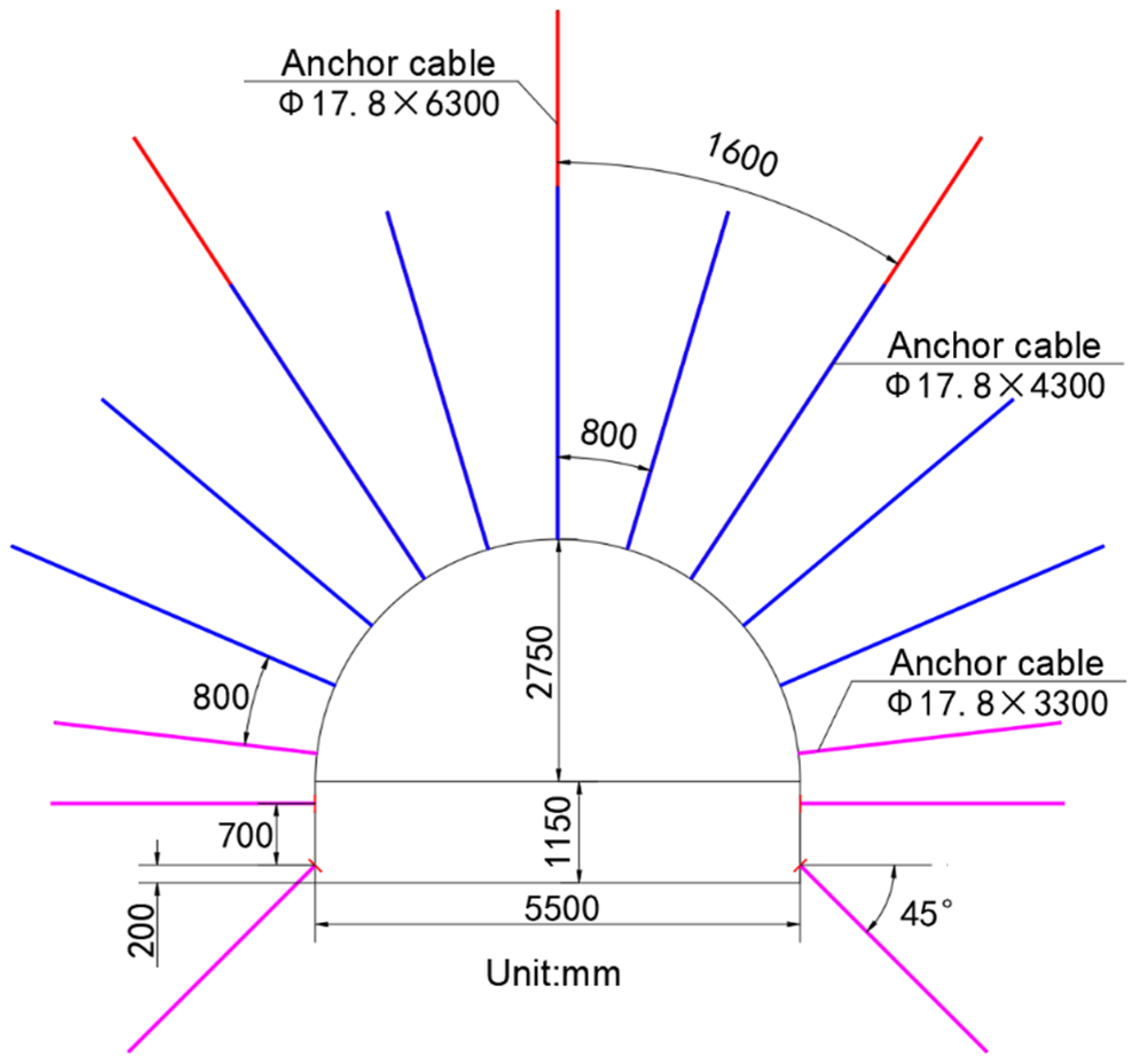

2.1. Occurrence Characteristics and Support Scheme

2.2. Deformation Characteristics and Deterioration Analysis of Surrounding Rock

- (1)

- The shallow coal rock mass is broken, and the overall subsidence of the roof is rather significant. The roof in the fault-concentrated area presents bulging deformation of different degrees. According to the degree of deformation, the area is divided into two categories. In the range of 130~200 m, the roof subsidence is the most severe in the medium fault drop area, which is about 800 mm. However, in the 50 m~130 m area, there are few faults, and the fault drop is small; and the roof deformation is relatively small. Therefore, it can be concluded that high ground stress and tectonic stress are the main causes of roof breakage and subsidence;

- (2)

- The synergy effect of the original supporting components is poor, and the supporting quality is insufficient. ① With low stiffness and a poor prestress diffusion effect, the metal mesh cannot cooperate with the anchor cable, thus failing to strengthen the constraints actively. ② The coordination between the 4.3 m-long cables and 6.3 m-long cables is rather poor, thus failing to provide a continuous strengthening control over the surrounding rock. As revealed by the field investigation, the prestress of the anchor cable is generally between 40 kN and 110 kN, which is relatively low. Accordingly, its reinforcement effect on the rock mass in a large range is rather limited. In this case, the two-stage support system is gradually destroyed, which is another reason for the large deformation of the surrounding rock;

- (3)

- The damage degree of the surrounding rock in fault area is high, and the long-term control of the surrounding rock cannot be realized without modification. The failure effects of the different fault drops are different, but the common feature is that the shallow surrounding rock is relatively prone to be fractured, which will reduce the strength and flexural stiffness of the anchorage zone and is not conducive to long-term control of the surrounding rock.

3. Distinct Element Numerical Model and Monitoring Scheme

3.1. The Determination of Model Parameters

- (1)

- The determination of rock mass parameters

- (2)

- The validation of model parameters

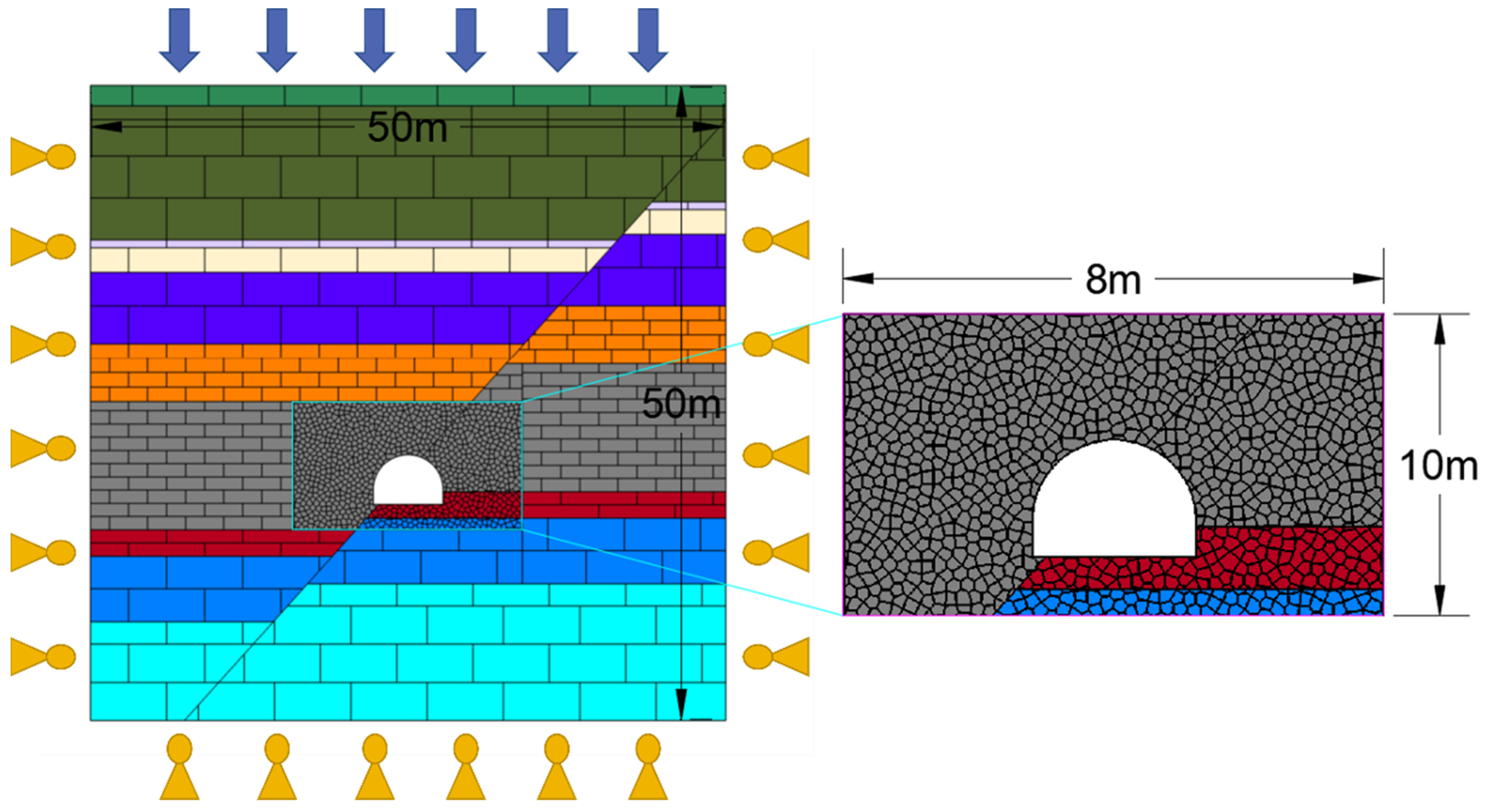

3.2. The Establishment of Distinct Element Numerical Model

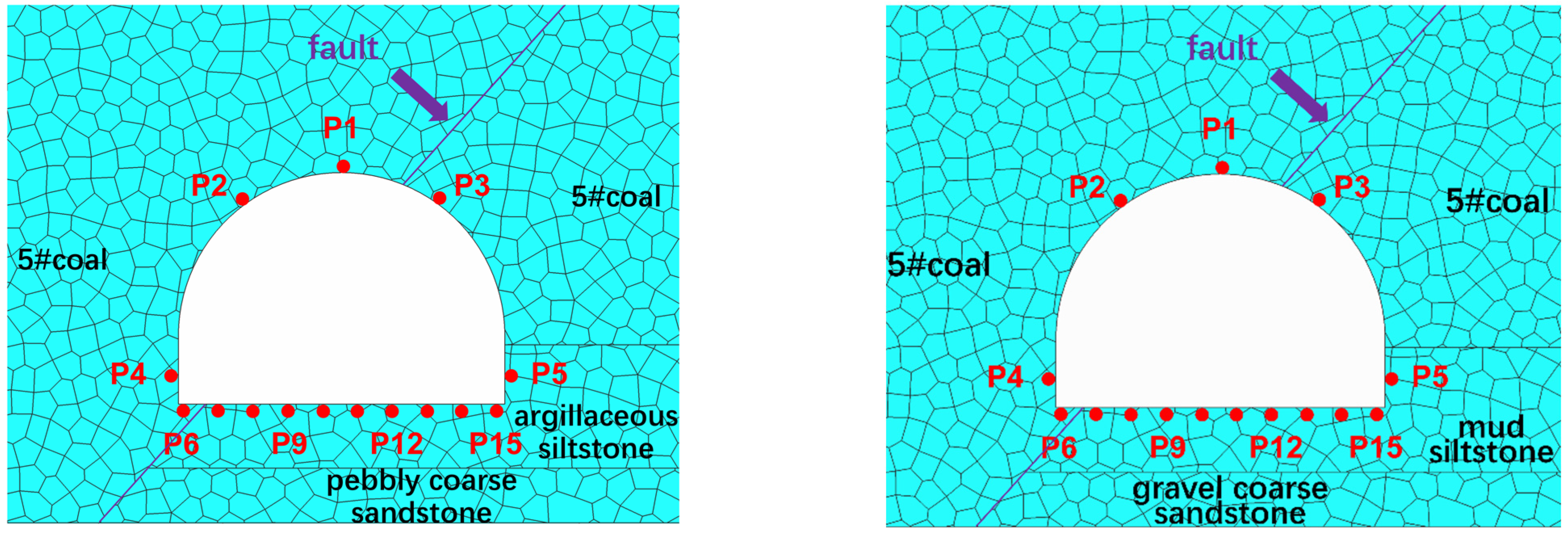

3.3. Model Monitoring Scheme

- (1)

- Stress Monitoring

- (2)

- Displacement Monitoring

4. Deformation Mechanism of Roadway Surrounding Rock under Influence of Unidirectional Fault Structure

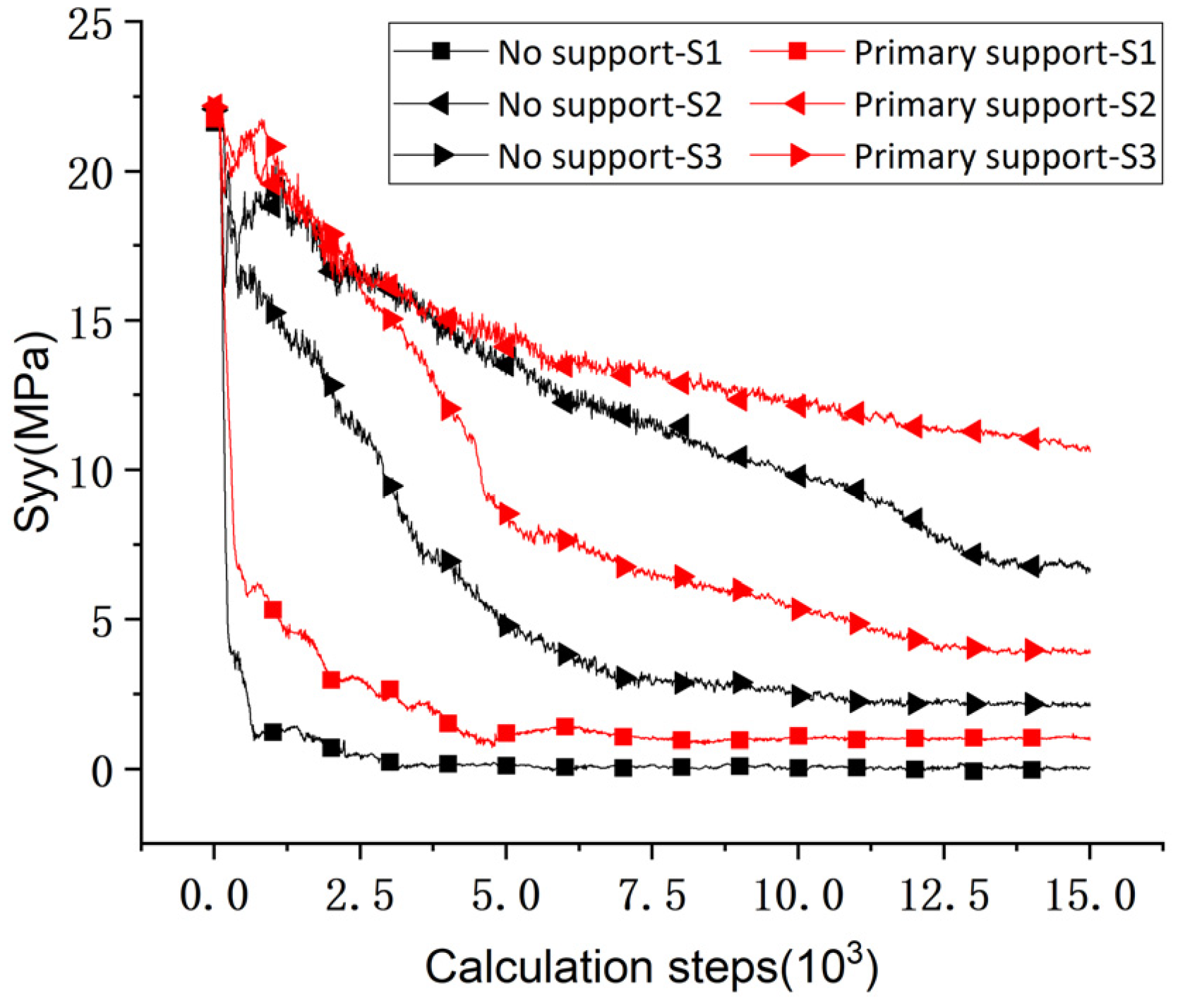

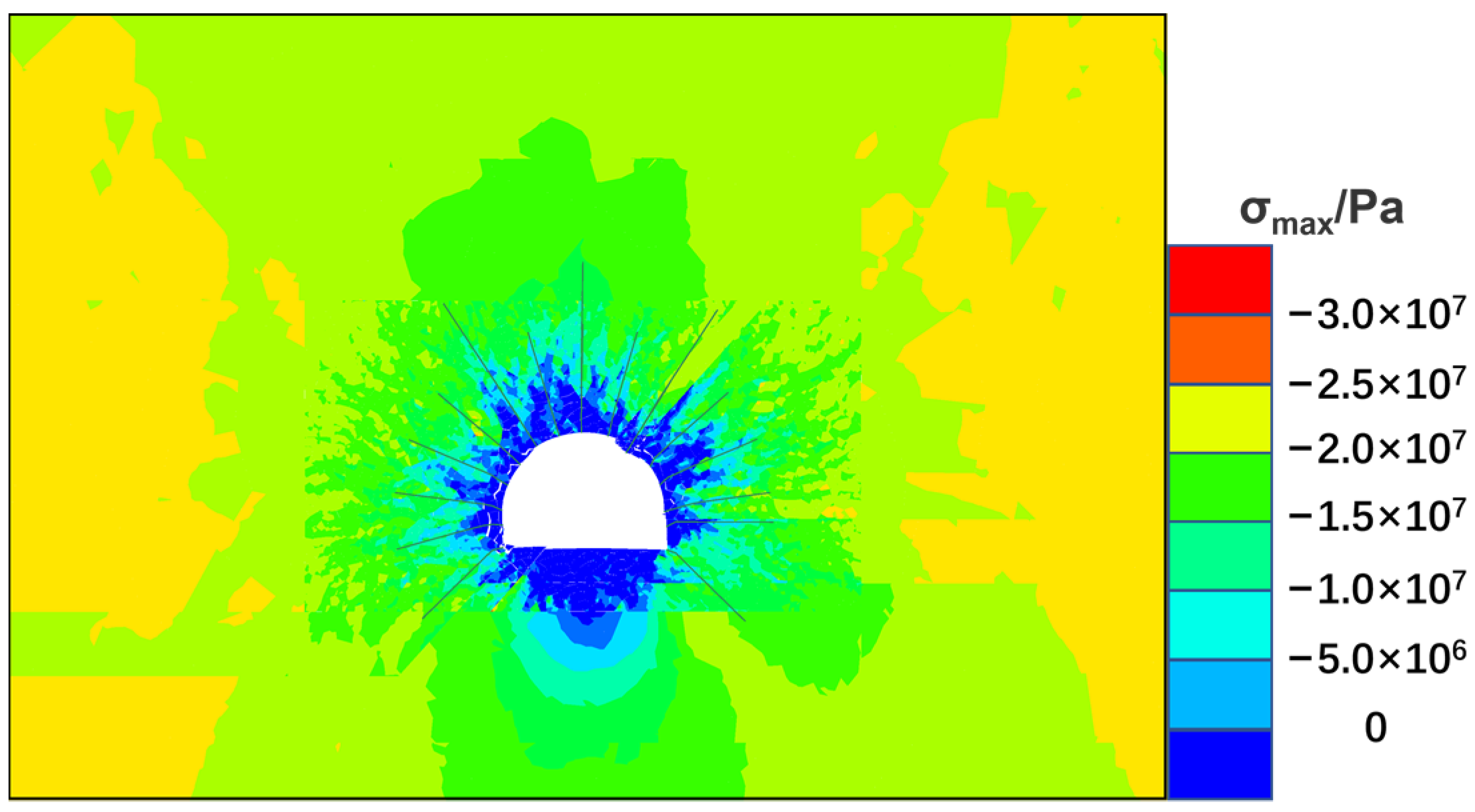

4.1. Stress Analysis of Surrounding Rock

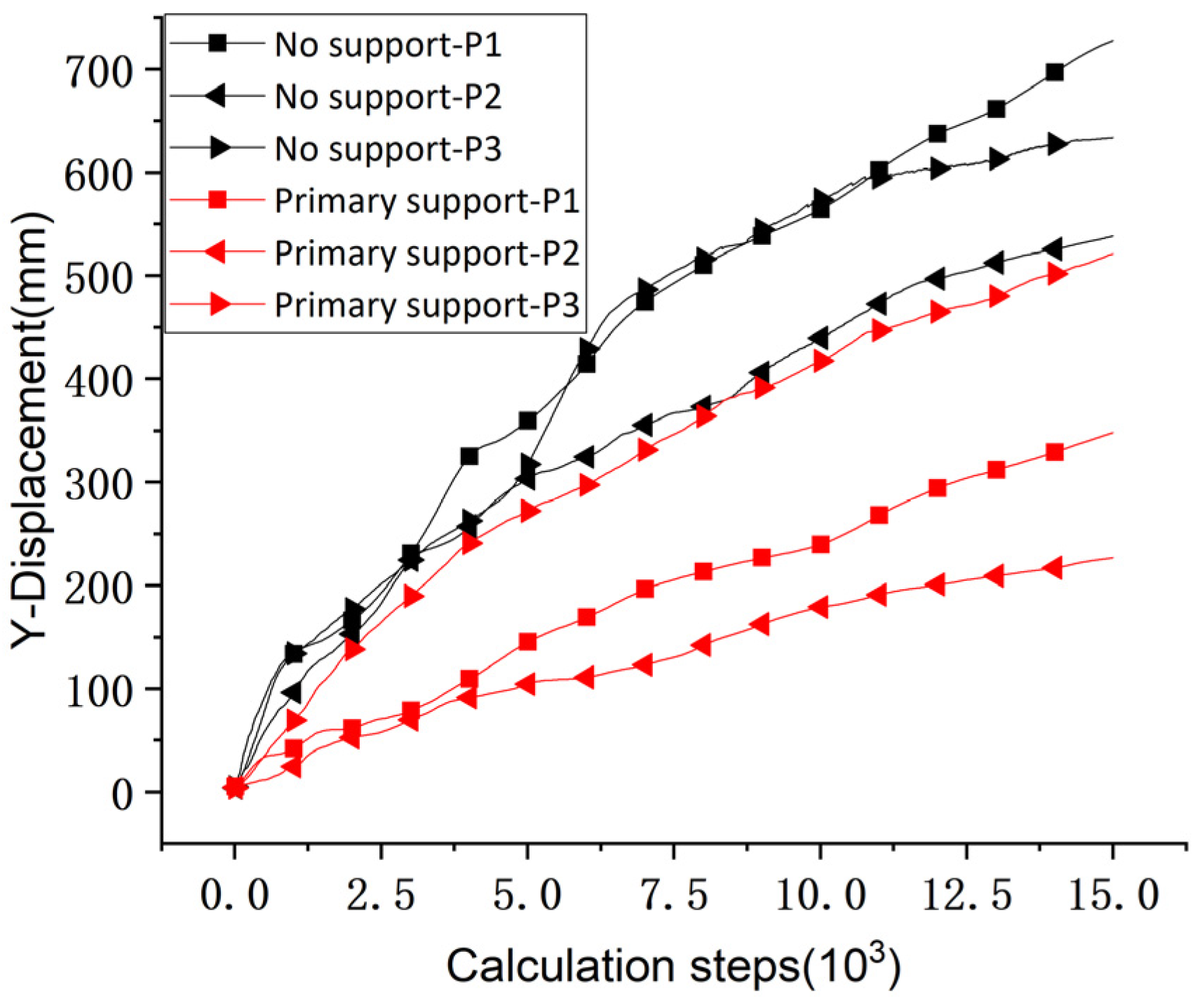

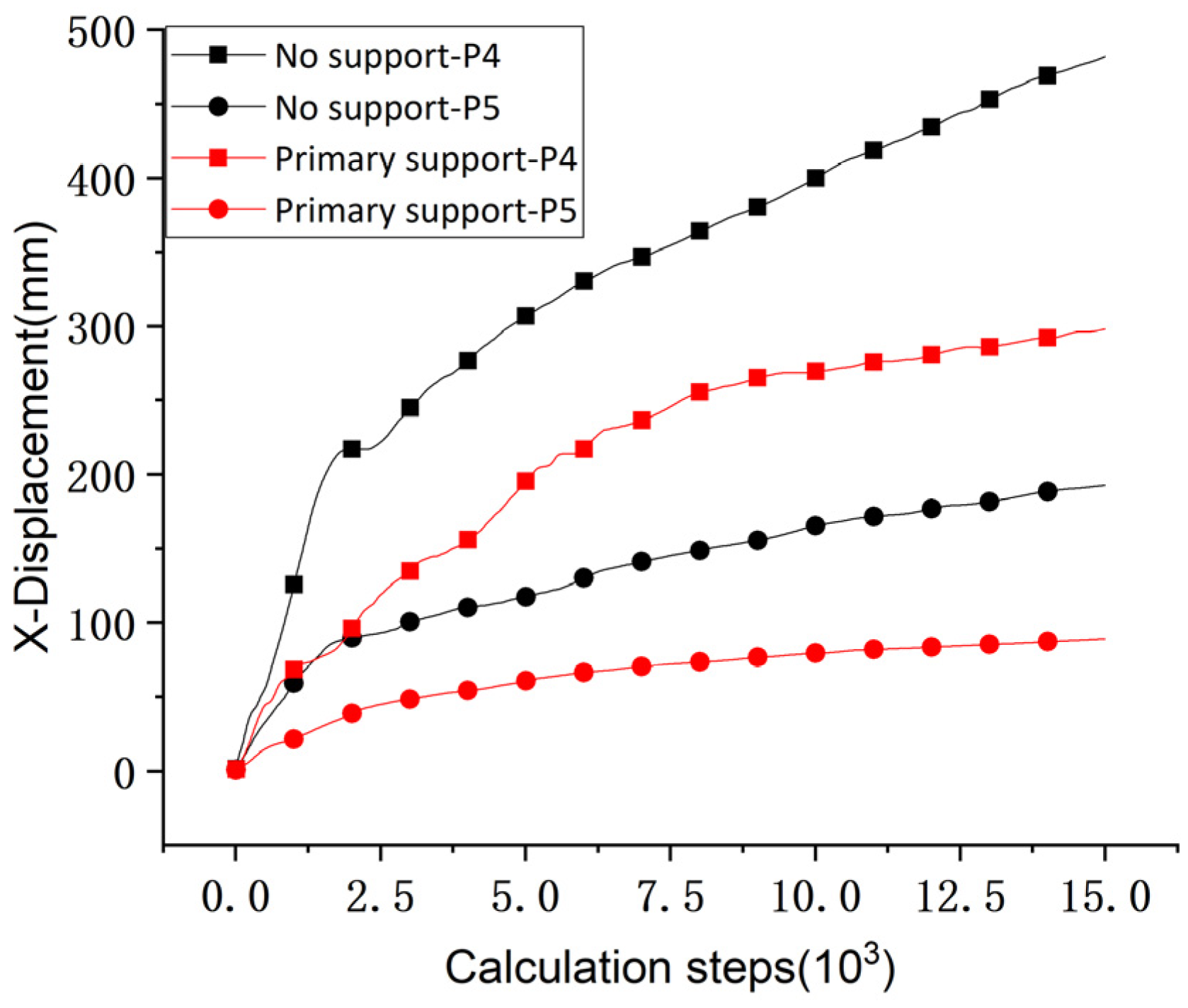

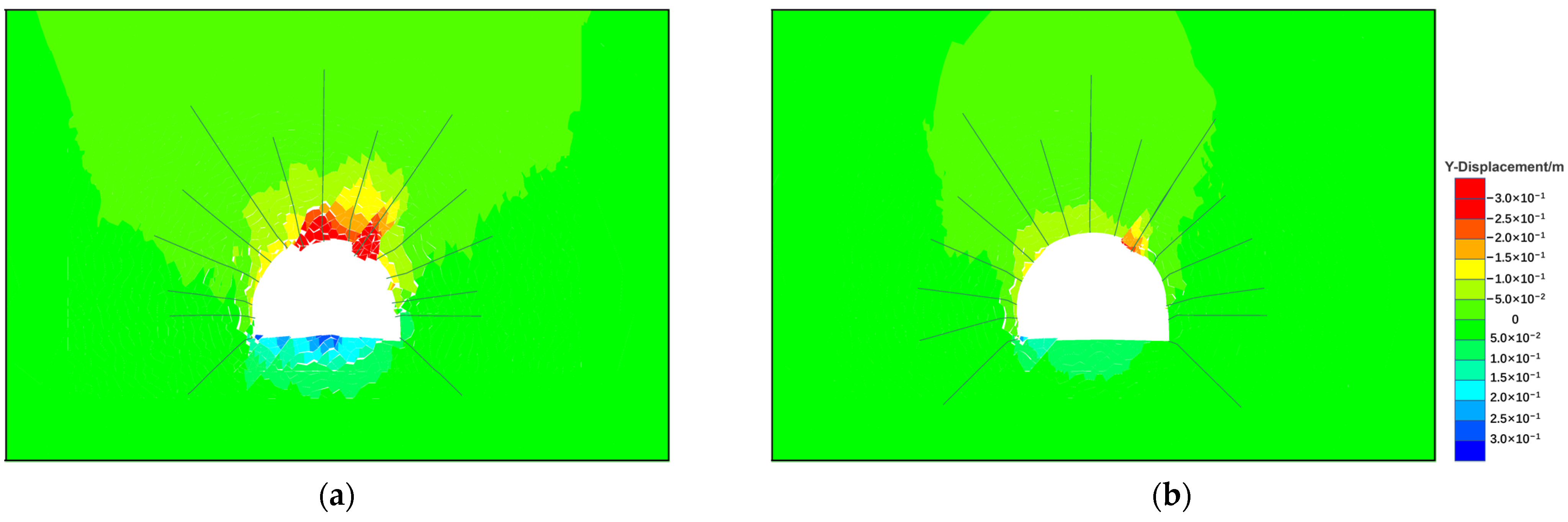

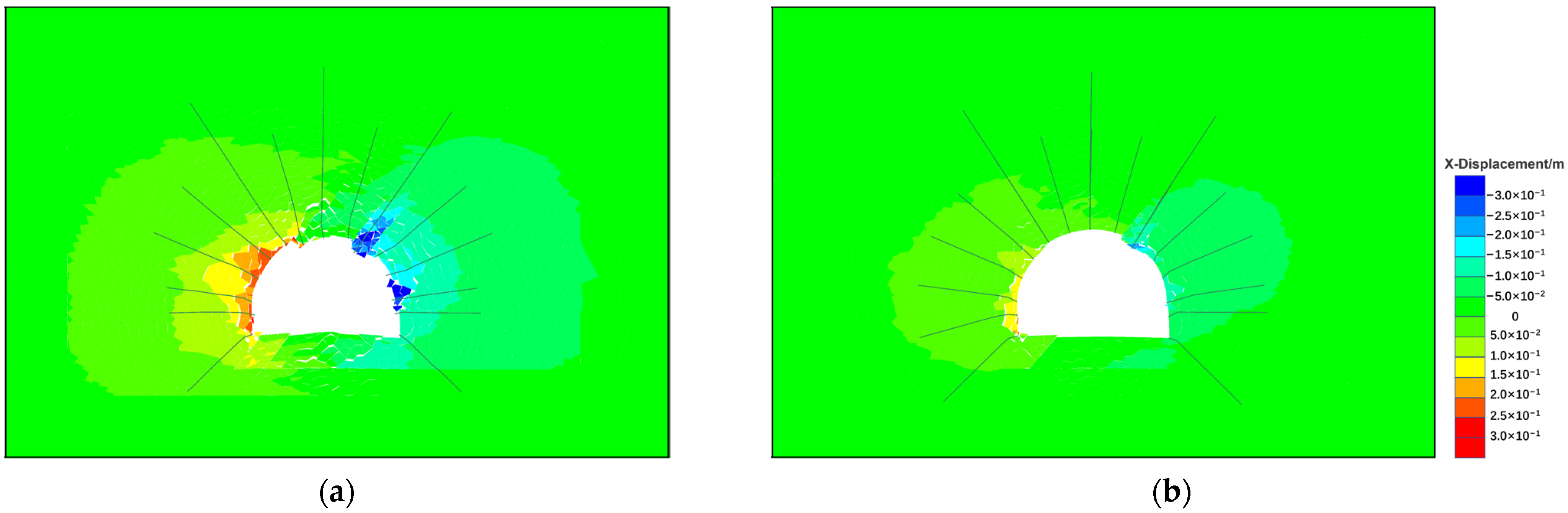

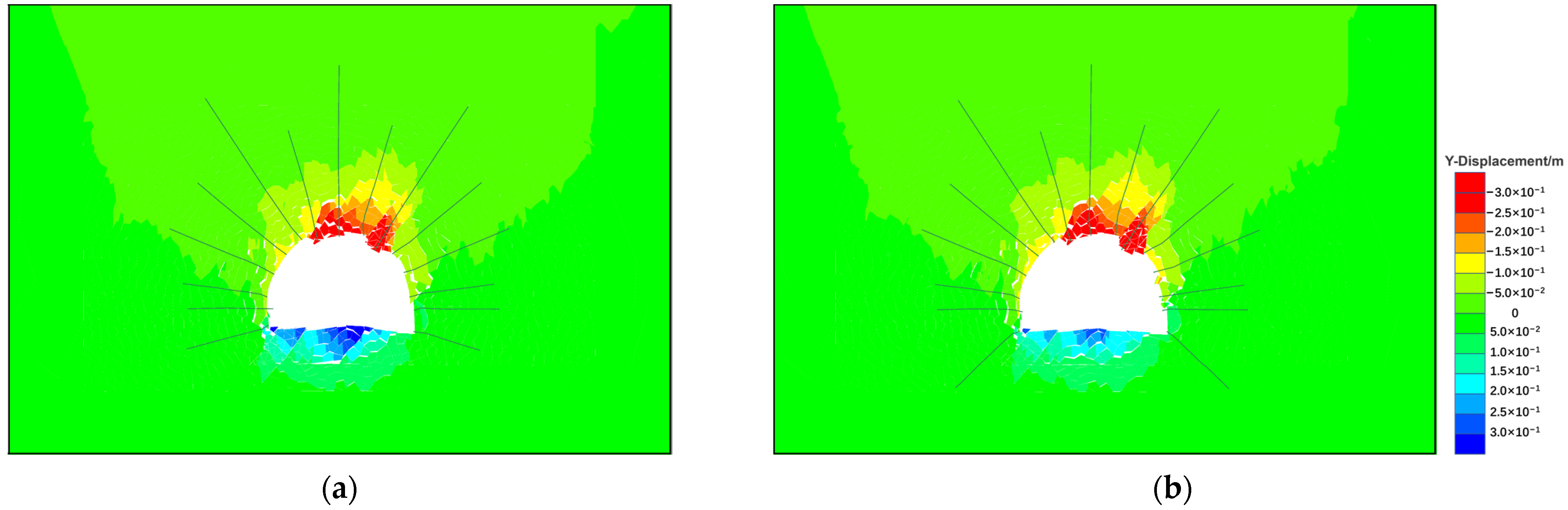

4.2. Displacement Analysis of Surrounding Rock

4.3. Failure Mechanism of Surrounding Rock under the Influence of Unidirectional Fault Structure

- (1)

- The redistribution of stress

- (2)

- Dynamic stress response

- (3)

- Fracture expansion

5. Hierarchical Continuous Anchorage Technology

5.1. Transboundary Bolt-Grouting Hierarchical Continuous Support

5.2. New Support Scheme

- (1)

- Differentiated support principle

- (2)

- Surrounding rock modification principle

- (3)

- Two-stage coordinated anchorage principle

- (4)

- Reinforced protection principle

- ①

- Basic support for the roof: High strength grouting anchor cables with a diameter of 22 mm are used jointly with ordinary anchor cables whose diameter is 21.6 mm to provide joint support. The length of both types of cables is 3.8 m. The row distance between the anchor cables is 800 mm × 800 mm; for each row, there are five grouting cables and six ordinary cables; the preload is not less than 150 kN; and the five cables in the middle are reinforced with a steel ladder beam whose length is 3300 mm and bar diameter is 14 mm;

- ②

- Secondary reinforced support for the roof: The ordinary anchor cables with Φ21.6 mm are used for the secondary reinforced support. The cables are 5.8 m long, and the distance between two anchor cables in the same row is 800 mm × 1600 mm, and the preload is not less than 180 kN;

- ③

- Support for the sides: for the left side, two Φ22 mm × 3800 mm high-strength grouting anchor cables are used; for the right side, two Φ21.6 mm × 3800 mm ordinary anchor cables are used at a row distance of 700 × 800 mm. The anchor cable near the shoulder socket of the left side is placed at a depression angle of 15°, while the anchor cable near the shoulder socket of the right side is placed vertical to the side. The anchor cables near the floor are arranged at a depression angle of 45° and a distance of 200 mm to the floor. For each row, there are four anchor cables in total with a preload no less than 150 kN; two steel ladder beams whose length is 2500 mm and bar diameter is 12 mm are equipped for each row.

5.3. Numerical Simulation of New Support Scheme

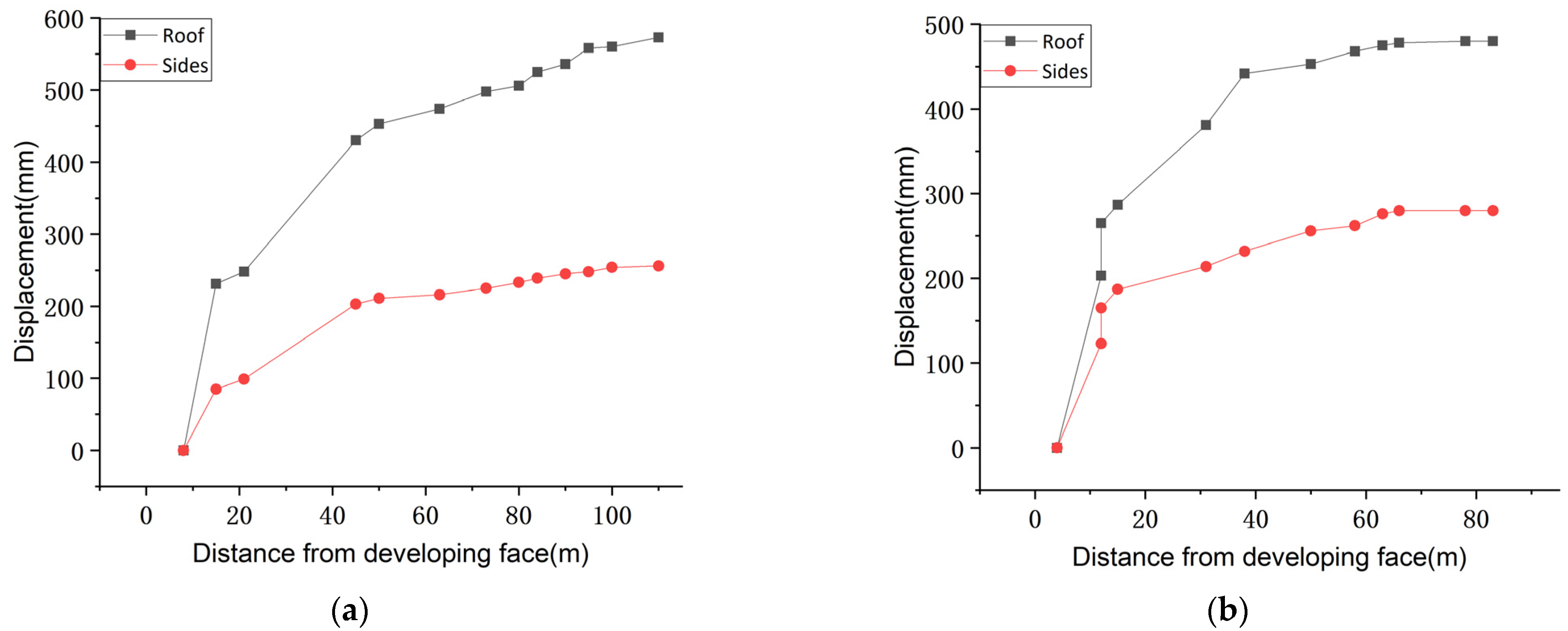

5.4. Engineering Practice

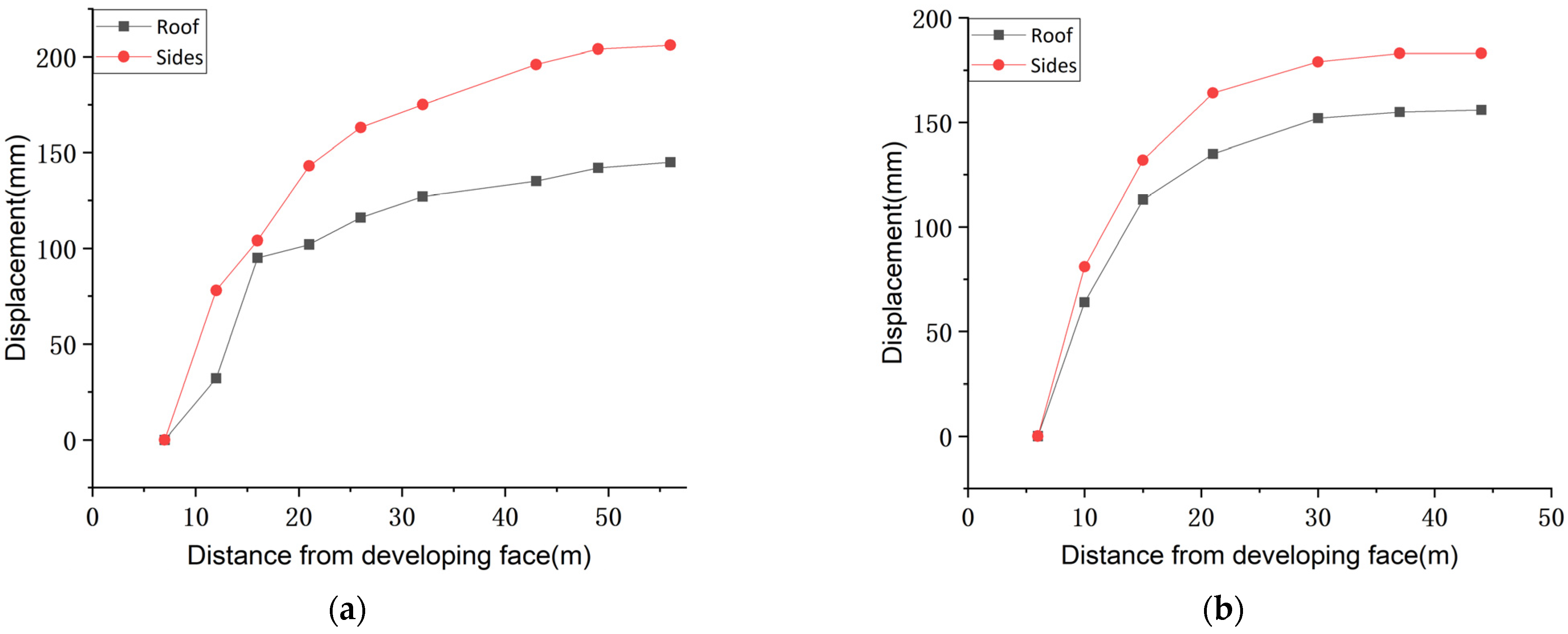

5.4.1. Monitoring of Roadway Surface Displacement

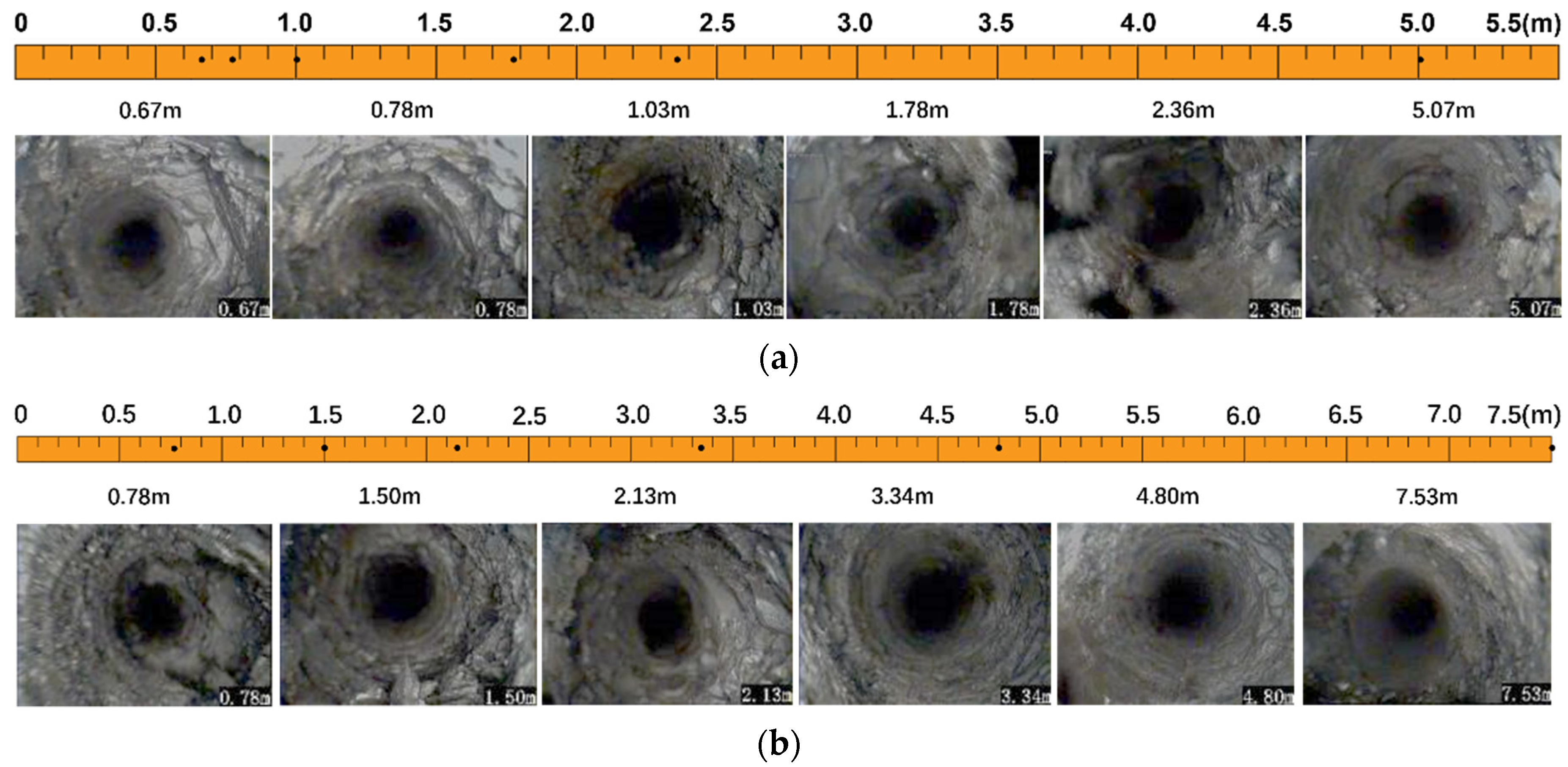

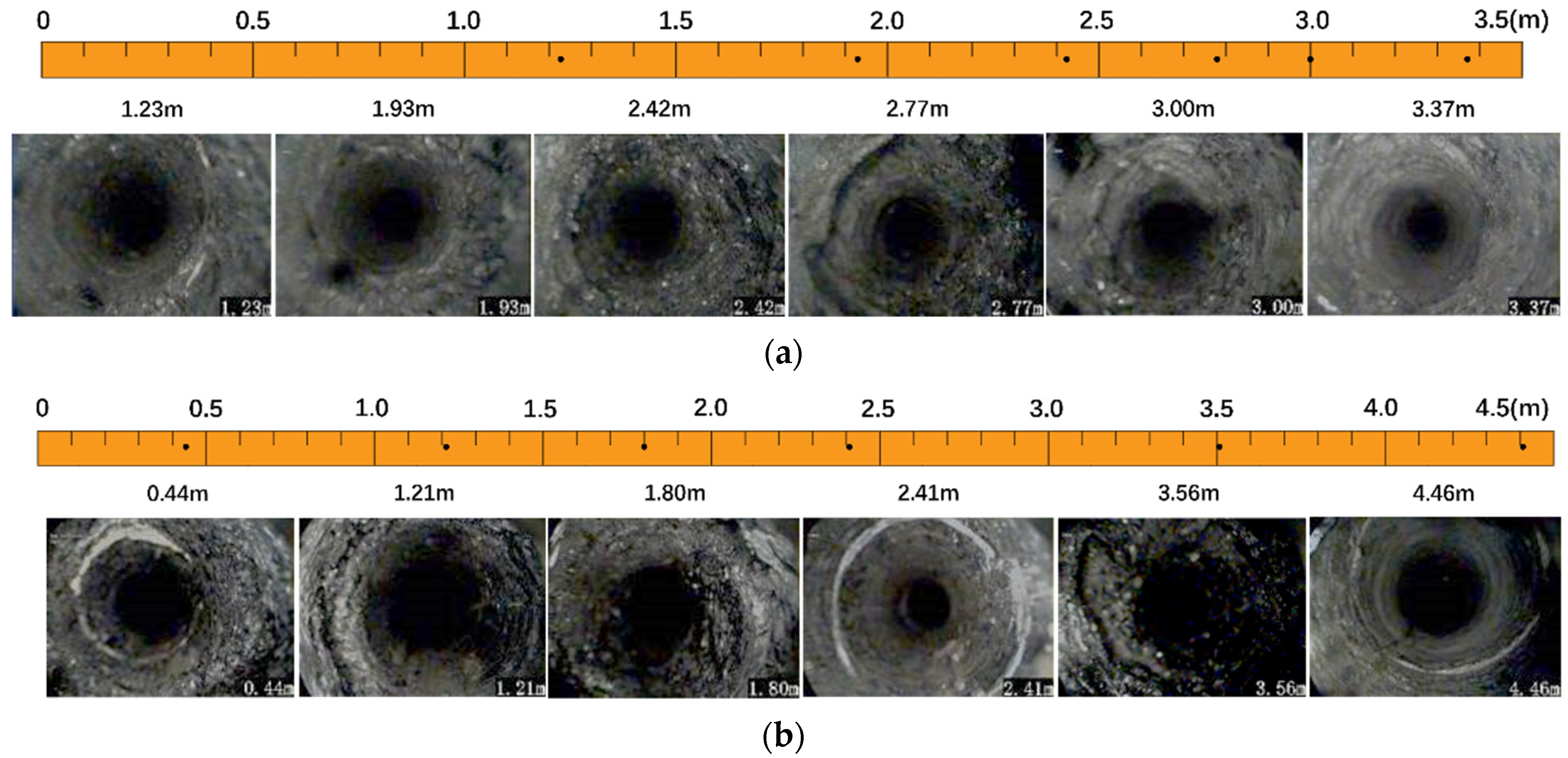

5.4.2. Monitoring of Fracture Development in Surrounding Rock

5.4.3. Photos of Roadway Maintenance and Control

6. Discussion

6.1. Necessity Analysis of Wedge Anchorage for Corner Anchor Cable

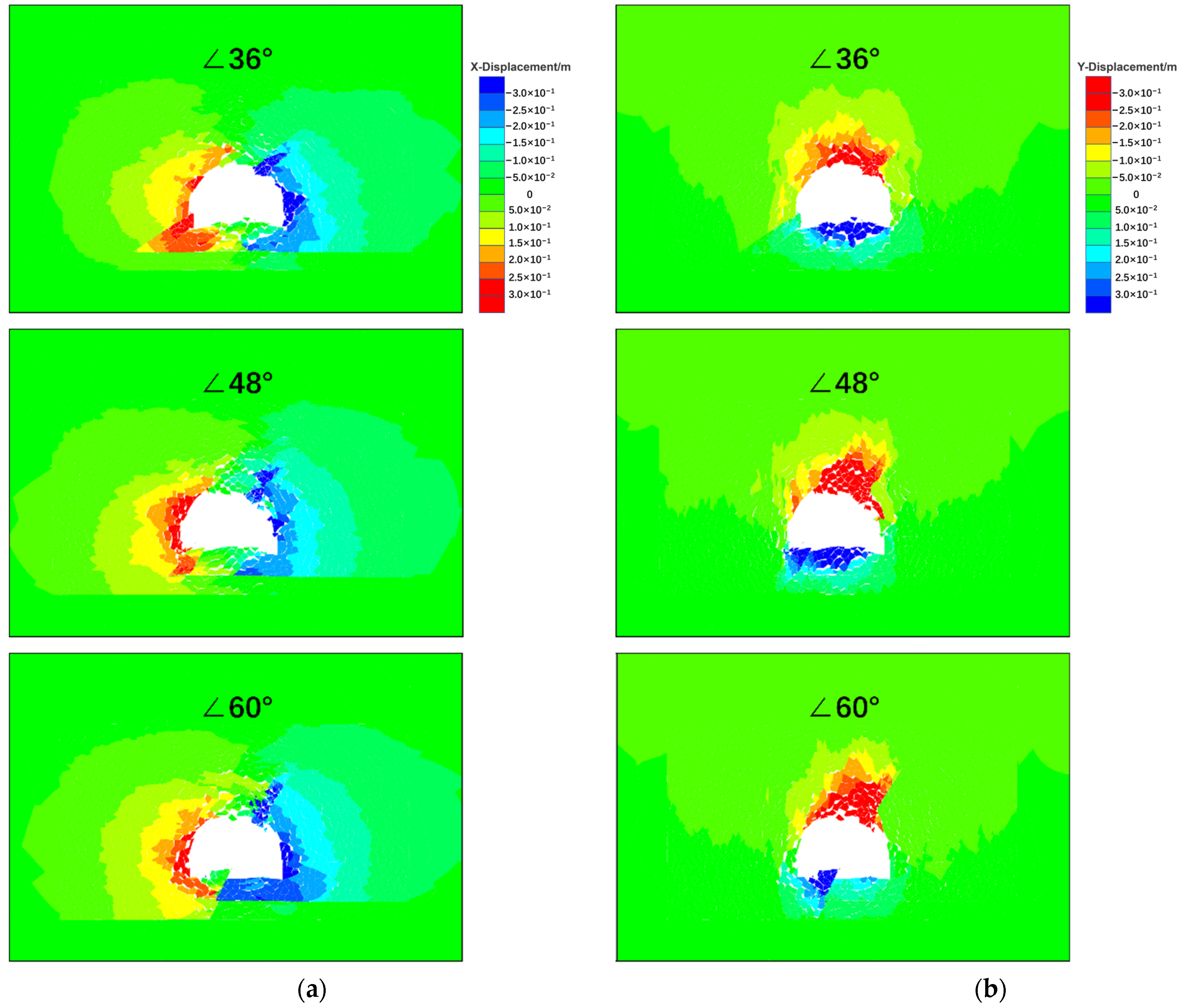

6.2. Discussion on Surrounding Rock Deformation under Different Fault Angles

7. Conclusions

- (1)

- According to the simulation analysis of UDEC discrete element software, under the influence of deep roadway excavation disturbance, the rock mass in the fault area is subjected to dynamic stress response, thus inducing dislocation and deformation in the weak plane of the fault. Consequently, the stress deterioration is further aggravated, and the cracks of surrounding rock extend towards the deep, while the roof loses its effective bearing capacity, which intensifies the deformation in the two sides and floor;

- (2)

- The mechanisms of thick layer transboundary anchorage and hierarchical continuous anchorage were demonstrated. On this basis, a differentiated two-stage continuous support technology is proposed for the roadway support in a unidirectional fault structure. To be specific, this technology can be expressed as “first-stage grouting anchor cable/ordinary anchor cable; second-stage high strength anchor cable”. The first-stage grouting can improve the mechanical properties of fractured rock mass in the fault; the second-stage coordinated anchorage can enhance the deformation resistance of the surrounding rock and its long-term stability;

- (3)

- The importance of the wedge anchoring of the bottom corner anchor cable under the influence of the fault structure was analyzed. When the bottom corner anchor cable is constructed 45° horizontally downward and modified by grouting, a high-quality wedge anchoring structure can be formed in the broken surrounding rock, which greatly improves the stress condition of the surrounding rock. The deformation characteristics of the roadway surrounding rock under 36°, 48° and 60° fault dip angles were discussed, and it is concluded that the differential two-stage continuous support technology can adapt to the maintenance and control of the roadway surrounding rock under different fault dip angles;

- (4)

- The field tests show that compared with the original scheme, the new scheme significantly reduces the deformation of the surrounding rock in the roof and two sides by 68.47% and 35.4%, respectively. According to the peephole results, under the new support condition, the maximum roof crack depth is reduced from 7.5 m to 3.5 m, and the number of cracks is also reduced by 76.6%. The integrity of the roadway surrounding rock in the fault area is significantly improved. This study provides an important reference for the safety maintenance and control of similar roadway engineering.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xie, H.P.; Gao, M.Z.; Zhang, R.; Peng, G.Y.; Wang, W.Y.; Li, A.Q. Study on the Mechanical Properties and Mechanical Response of Coal Mining at 1000 m or Deeper. Rock Mech. Rock Eng. 2019, 52, 1475–1490. [Google Scholar] [CrossRef]

- Ranjith, P.G.; Zhao, J.; Ju, M.H.; De Silva, R.V.S.; Rathnaweera, T.D.; Bandara, A. Opportunities and Challenges in Deep Mining: A Brief Review. Engineering 2017, 3, 546–551. [Google Scholar] [CrossRef]

- Yang, H.Q.; Zhang, N.; Han, C.L.; Sun, C.L.; Song, G.H.; Sun, Y.N.; Sun, K. Stability Control of Deep Coal Roadway under the Pressure Relief Effect of Adjacent Roadway with Large Deformation: A Case Study. Sustainability 2021, 13, 4412. [Google Scholar] [CrossRef]

- Gao, M.Z.; Xie, J.; Guo, J.; Lu, Y.Q.; He, Z.Q.; Li, C. Fractal evolution and connectivity characteristics of mining-induced crack networks in coal masses at different depths. Geomech. Geophys. Geo-Energy Geo-Resour. 2021, 7, 9. [Google Scholar] [CrossRef]

- Wang, Q.; Qin, Q.; Jiang, B.; Jiang, Z.H.; He, M.C.; Li, S.C.; Wang, Y. Geomechanics model test research on automatically formed roadway by roof cutting and pressure releasing. Int. J. Rock Mech. Min. Sci. 2020, 135, 104506. [Google Scholar] [CrossRef]

- Xie, Z.Z.; Zhang, N.; Yuan, Y.X.; Xu, G.; Wei, Q. Study on Safety Control of Composite Roof in Deep Roadway Based on Energy Balance Theory. Sustainability 2019, 11, 3688. [Google Scholar] [CrossRef]

- Zhang, B.; Zhou, H.Q.; Chang, Q.L.; Zhao, X.; Sun, Y.T. The Stability Analysis of Roadway near Faults under Complex High Stress. Adv. Civ. Eng. 2020, 2020, 8893842. [Google Scholar] [CrossRef]

- Jiang, J.Q.; Wu, Q.L.; Qu, H. Evolutionary characteristics of mining stress near the hard-thick overburden normal faults. J. Min. Saf. Eng. 2014, 31, 881. [Google Scholar] [CrossRef]

- Kong, P.; Jiang, L.S.; Shu, J.M.; Wang, L. Mining Stress Distribution and Fault-Slip Behavior: A Case Study of Fault-Influenced Longwall Coal Mining. Energies 2019, 12, 2494. [Google Scholar] [CrossRef]

- Kang, Y.S.; Hou, C.C.; Liu, J.Y.; Geng, Z.; Chen, J.B.; Liu, B. Numerical Analyses on the Stability of a Deep Coalmine Roadway Passing through a Fault Zone: A Case Study of the Gugui Coalfield in China. Energies 2021, 14, 2114. [Google Scholar] [CrossRef]

- Zeng, C.L.; Zhou, Y.J.; Zhang, L.M.; Mao, D.G.; Bai, K.X. Study on overburden failure law and surrounding rock deformation control technology of mining through fault. PLoS ONE 2022, 17, e0262243. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.T.; Zhang, C.; Wei, S.F.; Zhang, X.G.; Guo, S.H. Whole section anchor-grouting reinforcement technology and its application in underground roadways with loose and fractured surrounding rock. Tunn. Undergr. Space Technol. 2016, 51, 133–143. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, D.S.; Wang, H.Z.; Liang, S.S. Discrete element simulation of the control technology of large section roadway along a fault to drivage under strong mining. J. Geophys. Eng. 2018, 15, 2642–2657. [Google Scholar] [CrossRef]

- Yang, S.Q.; Chen, M.; Jing, H.W.; Chen, K.F.; Meng, B. A case study on large deformation failure mechanism of deep soft rock roadway in Xin’An coal mine, China. Eng. Geol. 2017, 217, 89–101. [Google Scholar] [CrossRef]

- Meng, Z.P.; Peng, S.P.; Feng, Y.; Lei, Z.Y. Influence of fracture structure plane on underground pressure and roof stability of working face. Coal Geol. Explor. 2006, 34, 24–27. [Google Scholar]

- Gou, P.F.; Hu, Y.G. Effect of faults on movement of roof rock strata in gateway. J. Min. Saf. Eng. 2006, 23, 285–289. [Google Scholar]

- Wang, X.Y.; Bai, J.B.; Li, L.; Han, Z.T. Deformation failure mechanism and control technology of mining-induced roadway near a fault. J. Min. Saf. Eng. 2014, 31, 674. [Google Scholar] [CrossRef]

- Islam, M.R.; Shinjo, R. Mining-induced fault reactivation associated with the main conveyor belt roadway and safety of the Barapukuria Coal Mine in Bangladesh: Constraints from BEM simulations. Int. J. Coal Geol. 2009, 79, 115–130. [Google Scholar] [CrossRef]

- Mark, C.; Gale, W.; Oyler, D.; Chen, J. Case history of the response of a longwall entry subjected to concentrated horizontal stress. Int. J. Rock Mech. Min. Sci. 2007, 44, 210–221. [Google Scholar] [CrossRef]

- Marcak, H.; Mutke, G. Seismic activation of tectonic stresses by mining. J. Seismol. 2013, 17, 1139–1148. [Google Scholar] [CrossRef]

- Naoi, M.; Nakatani, M.; Otsuki, K.; Yabe, Y.; Kgarume, T.; Murakami, O.; Masakale, T.; Ribeiro, L.; Ward, A.; Moriya, H.; et al. Steady activity of microfractures on geological faults loaded by mining stress. Tectonophysics 2015, 649, 100–114. [Google Scholar] [CrossRef]

- Sainoki, A.; Mitri, H. Dynamic modelling of a mining-induced fault slip. In Proceedings of the ISRM International Symposium (EUROCK), Wroclaw, Poland, 23–26 September 2013; pp. 763–768. [Google Scholar]

- Celico, F.; Petrella, E.; Celico, P. Hydrogeological behaviour of some fault zones in a carbonate aquifer of Southern Italy: An experimentally based model. Terra Nova 2006, 18, 308–313. [Google Scholar] [CrossRef]

- Liu, C.W. Relation between bolting-shotcrete support and NATM metmod forsoft rock driftsin coal mines. ChinaMining Mag. 2000, 9, 61–64. [Google Scholar]

- Kang, H.P.; Jiang, P.F.; Wu, Y.Z.; Gao, F.Q. A combined “ground support-rock modification-destressing” strategy for 1000-m deep roadways in extreme squeezing ground condition. Int. J. Rock Mech. Min. Sci. 2021, 142, 104746. [Google Scholar] [CrossRef]

- Kang, H.P.; Yang, J.H.; Gao, F.Q.; Li, J.Z. Experimental Study on the Mechanical Behavior of Rock Bolts Subjected to Complex Static and Dynamic Loads. Rock Mech. Rock Eng. 2020, 53, 4993–5004. [Google Scholar] [CrossRef]

- Zhang, N.; Xu, X.L.; Chen, Z.F.; Wang, C. Geological guarantee and construction controlling technique of main roadway crossing fault zone with 435 m fall. Chin. J. Rock Mech. Eng. 2008, 27, 3292–3297. [Google Scholar]

- Xie, Z.Z.; Zhang, N.; Feng, X.W.; Liang, D.X.; Wei, Q.; Weng, M.Y. Investigation on the evolution and control of surrounding rock fracture under different supporting conditions in deep roadway during excavation period. Int. J. Rock Mech. Min. Sci. 2019, 123, 104122. [Google Scholar] [CrossRef]

- An, Y.P.; Zhang, N.; Zhao, Y.M.; Xie, Z.Z. Field and numerical investigation on roof failure and fracture control of thick coal seam roadway. Eng. Fail. Anal. 2021, 128, 105594. [Google Scholar] [CrossRef]

- Xiao, T.Q.; Bai, J.B.; Li, J.P.; Wang, X.Y.; Yan, S. Stabilization mechanism of crushed surrounding rock in coal roadway with bolt support near fault. J. Min. Saf. Eng. 2010, 27, 482–486. [Google Scholar]

- Li, X.H.; Ju, M.H.; Yao, Q.L.; Zhou, J.; Chong, Z.H. Numerical Investigation of the Effect of the Location of Critical Rock Block Fracture on Crack Evolution in a Gob-side Filling Wall. Rock Mech. Rock Eng. 2016, 49, 1041–1058. [Google Scholar] [CrossRef]

- Zhang, L.Y.; Einstein, H.H. Using RQD to estimate the deformation modulus of rock masses. Int. J. Rock Mech. Min. Sci. 2004, 41, 337–341. [Google Scholar] [CrossRef]

- Singh, M.; Rao, K.S. Empirical methods to estimate the strength of jointed rock masses. Eng. Geol. 2005, 77, 127–137. [Google Scholar] [CrossRef]

- Hoek, E.; Brown, E.T. Practical estimates of rock mass strength. Int. J. Rock Mech. Min. Sci. 1997, 34, 1165–1186. [Google Scholar] [CrossRef]

- Yang, H.Q.; Han, C.L.; Zhang, N.; Sun, Y.T.; Pan, D.J.; Sun, C.L. Long High-Performance Sustainable Bolt Technology for the Deep Coal Roadway Roof: A Case Study. Sustainability 2020, 12, 1375. [Google Scholar] [CrossRef]

- Zhou, X.M.; Wang, S.; Li, X.L.; Meng, J.J.; Li, Z.; Zhang, L.H.; Pu, D.D.; Wang, L.K. Research on Theory and Technology of Floor Heave Control in Semicoal Rock Roadway: Taking Longhu Coal Mine in Qitaihe Mining Area as an Example. Lithosphere 2022, 2022, 3810988. [Google Scholar] [CrossRef]

- Lai, X.P.; Xu, H.C.; Shan, P.F.; Kang, Y.L.; Wang, Z.Y.; Wu, X. Research on Mechanism and Control of Floor Heave of Mining-Influenced Roadway in Top Coal Caving Working Face. Energies 2020, 13, 381. [Google Scholar] [CrossRef]

- Xu, Y.C.; Zhang, E.M.; Luo, Y.Q.; Zhao, L.; Yi, K. Mechanism of Water Inrush and Controlling Techniques for Fault-Traversing Roadways with Floor Heave Above Highly Confined Aquifers. Mine Water Environ. 2020, 39, 320–330. [Google Scholar] [CrossRef]

| Fault Name | Inclination | Dip Angle (°) | Drop Height (m) | Property | Distance from Lanehead (m) |

|---|---|---|---|---|---|

| F1 | south | 48 | 5.5 | reverse fault | 1 |

| F2 | north | 48 | 3 | normal fault | 16 |

| F3 | south | 65 | 1 | normal fault | 33 |

| F4 | south | 60 | 1.2 | normal fault | 45 |

| F5 | south | 50 | 0.4 | normal fault | 52 |

| F6 | south | 36 | 0.7 | normal fault | 57 |

| F7 | south | 40 | 2.4 | normal fault | 68 |

| F8 | north | 85 | 0.5 | normal fault | 71 |

| F9 | north | 55 | 1.5 | normal fault | 94 |

| F10 | north | 55 | 0.3 | normal fault | 102 |

| F11 | south | 55 | 0.15 | normal fault | 113 |

| F12 | south | 48 | 1.0 | normal fault | 131 |

| F13 | north | 45 | 1.2 | normal fault | 143 |

| F14 | south | 60 | 2.5 | normal fault | 173 |

| F15 | north | 45 | 1.4 | normal fault | 198 |

| Lithology | Intact Rock Characteristics | RQD | Rock Mass Characteristics | |||

|---|---|---|---|---|---|---|

| Coal | 9.8 | 1.6 | 69 | 5.3 | 0.5 | 0.7 |

| Sandy mudstone | 18.2 | 4.4 | 80 | 12.8 | 2.6 | 1.6 |

| Carbonaceous mudstone | 15.3 | 3.1 | 76 | 10.2 | 1.4 | 1.1 |

| Siltstone | 42.3 | 16.7 | 93 | 32.9 | 10.3 | 3.2 |

| Pebbly coarse sandstone | 46.4 | 23.9 | 97 | 36.1 | 15.8 | 3.6 |

| Argillaceous siltstone | 37.9 | 14.6 | 82 | 27.3 | 8.1 | 2.2 |

| Lithology | Block Properties | Contact Properties | |||||

|---|---|---|---|---|---|---|---|

| Density (kg/m3) | Elastic Modulus (GPa) | Kn (GPa/m) | Ks (GPa/m) | φ (°) | C (MPa) | σt (MPa) | |

| Coal | 1400 | 0.8 | 293 | 121 | 17 | 2.3 | 0.7 |

| Sandy mudstone | 1980 | 2.9 | 540 | 216 | 23 | 3.8 | 1.5 |

| Carbonaceous mudstone | 1860 | 1.6 | 492 | 184 | 21 | 3.2 | 1.0 |

| Siltstone | 2330 | 8.6 | 1061 | 421 | 31 | 12.6 | 3.6 |

| Pebbly coarse sandstone | 2600 | 10.0 | 1342 | 468 | 33 | 15.3 | 5.2 |

| Argillaceous siltstone | 2120 | 8.2 | 844 | 356 | 30 | 10.8 | 3.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, Z.; Mu, F.; Guo, F.; Zhang, N.; Li, Y.; Chen, R.; Chen, Q. Study on Failure Mechanism of Roadway Surrounding Rock and Hierarchical Continuous Support Technology in Unidirectional Fault Area. Processes 2023, 11, 1453. https://doi.org/10.3390/pr11051453

Xie Z, Mu F, Guo F, Zhang N, Li Y, Chen R, Chen Q. Study on Failure Mechanism of Roadway Surrounding Rock and Hierarchical Continuous Support Technology in Unidirectional Fault Area. Processes. 2023; 11(5):1453. https://doi.org/10.3390/pr11051453

Chicago/Turabian StyleXie, Zhengzheng, Fengchun Mu, Feng Guo, Nong Zhang, Yongle Li, Ruiji Chen, and Qinghua Chen. 2023. "Study on Failure Mechanism of Roadway Surrounding Rock and Hierarchical Continuous Support Technology in Unidirectional Fault Area" Processes 11, no. 5: 1453. https://doi.org/10.3390/pr11051453

APA StyleXie, Z., Mu, F., Guo, F., Zhang, N., Li, Y., Chen, R., & Chen, Q. (2023). Study on Failure Mechanism of Roadway Surrounding Rock and Hierarchical Continuous Support Technology in Unidirectional Fault Area. Processes, 11(5), 1453. https://doi.org/10.3390/pr11051453