Bearing Inner Ring Raceway Low-Temperature Aerosol Cooling Lubrication Grinding

Abstract

:1. Introduction

- Lubricating effect: cutting fluid plays a lubricating role in the cutting process, which can reduce the friction between the material and the tool, reduce the generation and accumulation of heat, and thus reduce the wear of the tool and prolong its service life;

- Cooling effect: cutting fluid can absorb and remove the heat generated in the cutting process and reduce the processing temperature, thus reducing the occurrence of thermal deformation and thermal cracking;

- Cleaning effect: cutting fluid can remove chips, cutting coatings, and other impurities in the cutting process to prevent them from reattaching to the workpiece surface during machining, which affects the machining accuracy and surface quality;

- Chemical effect: the chemical components in the cutting fluid can react with the workpiece surface to form a protective film to prevent oxidation and corrosion, thus improving the quality and machining accuracy of the workpiece surface;

- Grinding: the abrasive particles in the cutting fluid can rub against the workpiece surface to remove surface impurities such as oxidation and burrs, thus improving the finish and precision of the machined surface.

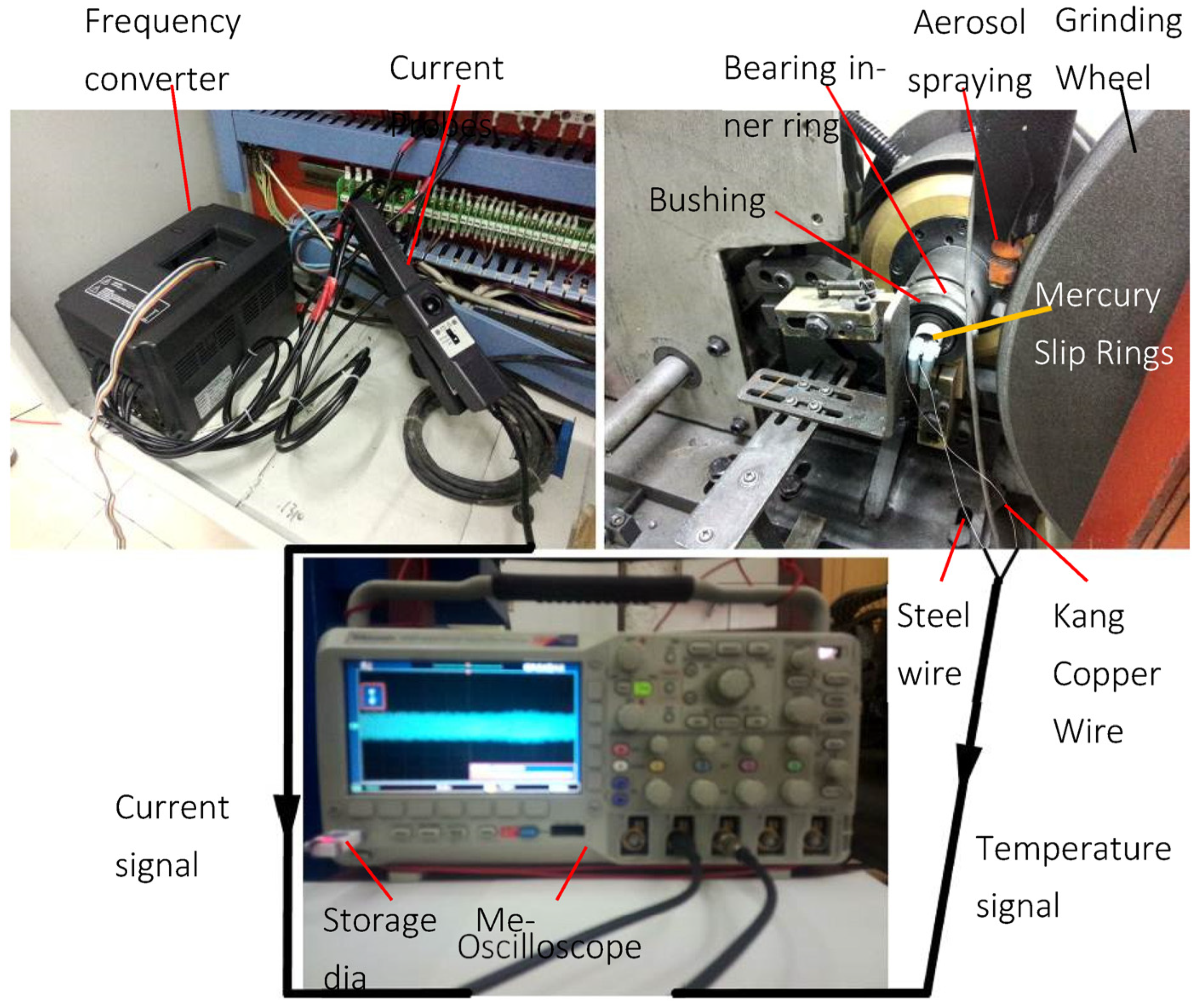

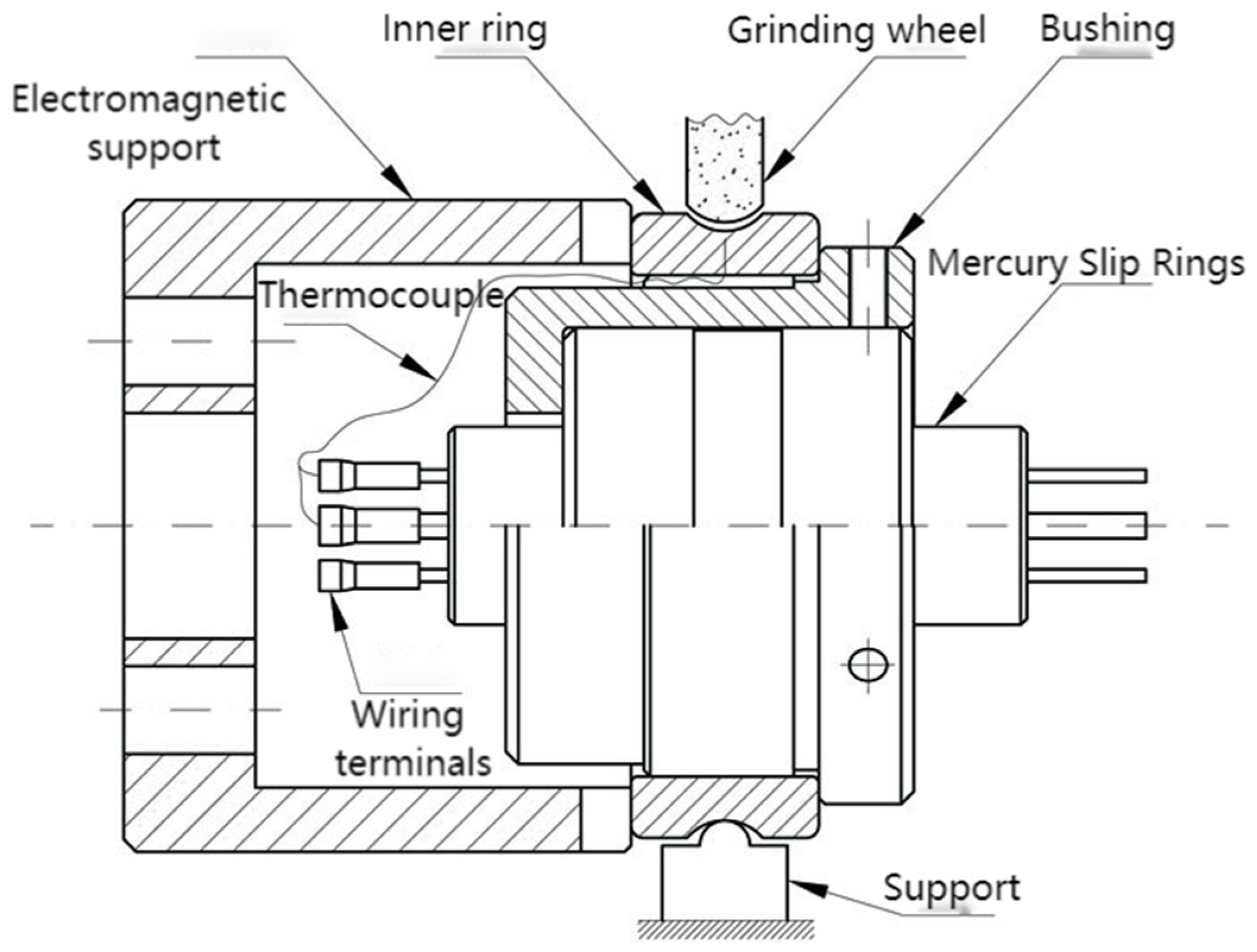

2. Bearing Inner Ring Raceway Low-Temperature Aerosol Cooling Lubrication Grinding Test Bench

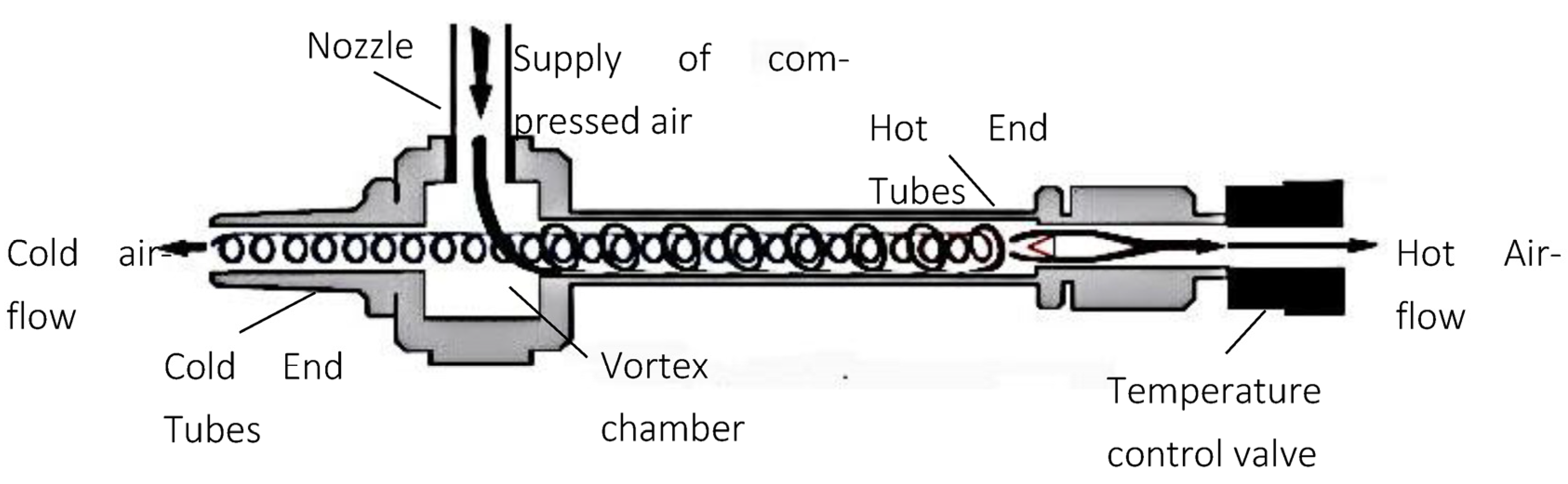

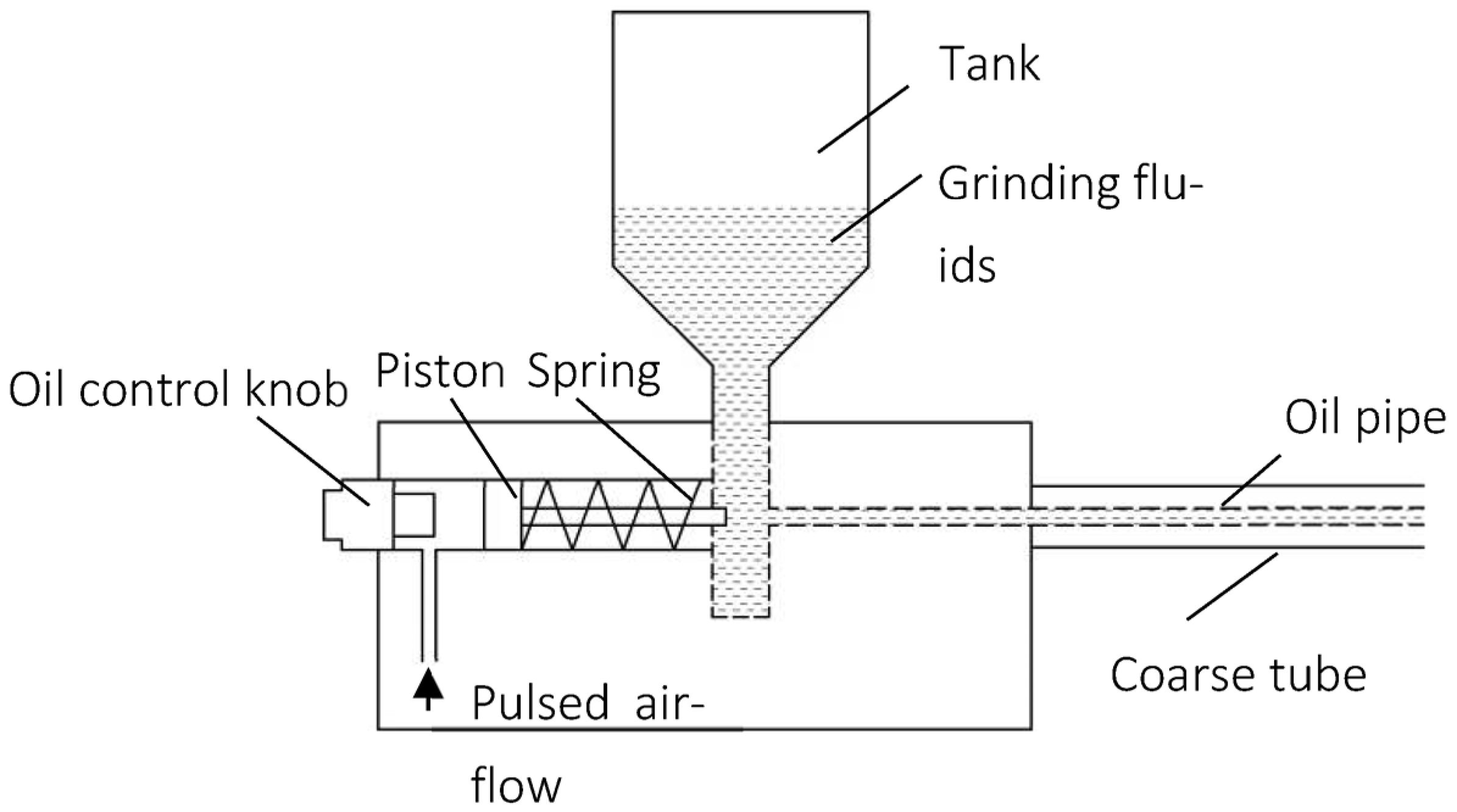

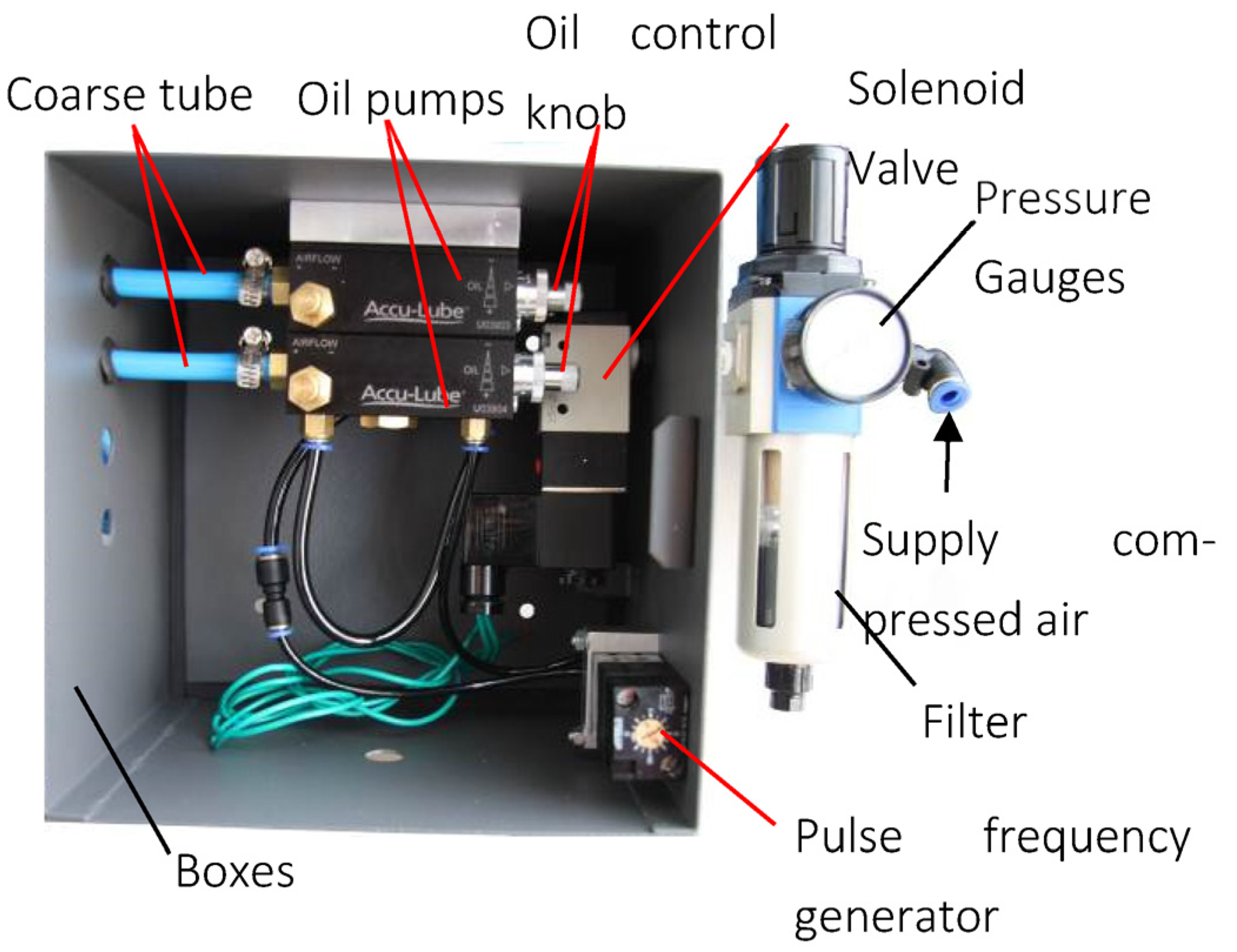

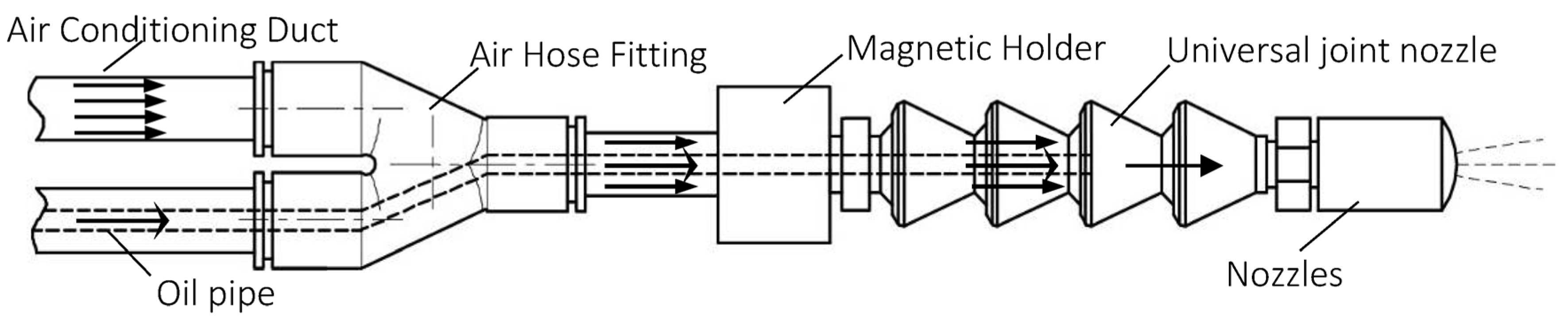

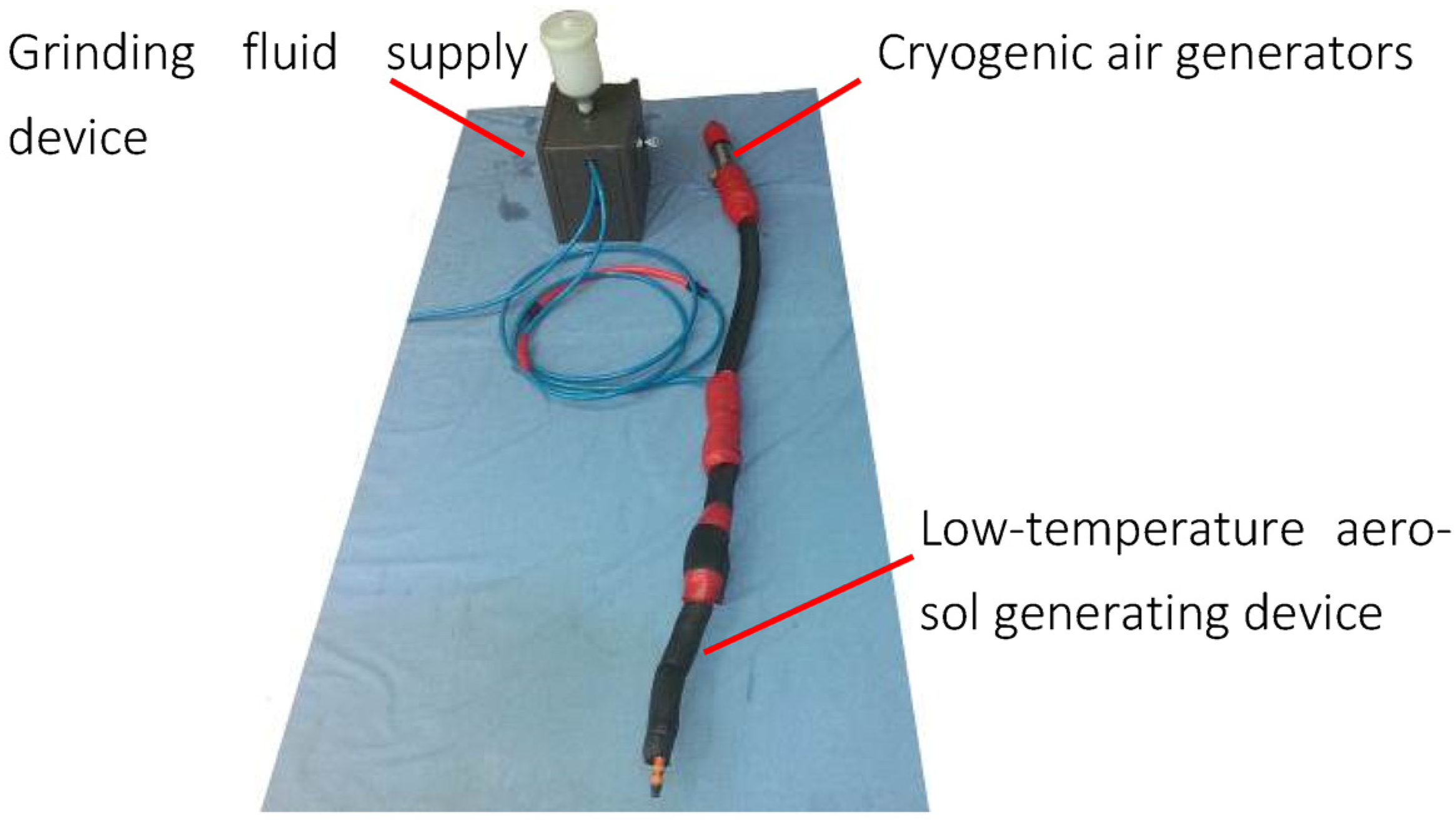

2.1. Low-Temperature Aerosol Supply System

2.2. Determination of Low-Temperature Aerosol Liquid Supply Parameters

3. Bearing Inner Ring Raceway Low-Temperature Aerosol Cooling Lubrication Grinding Experiment

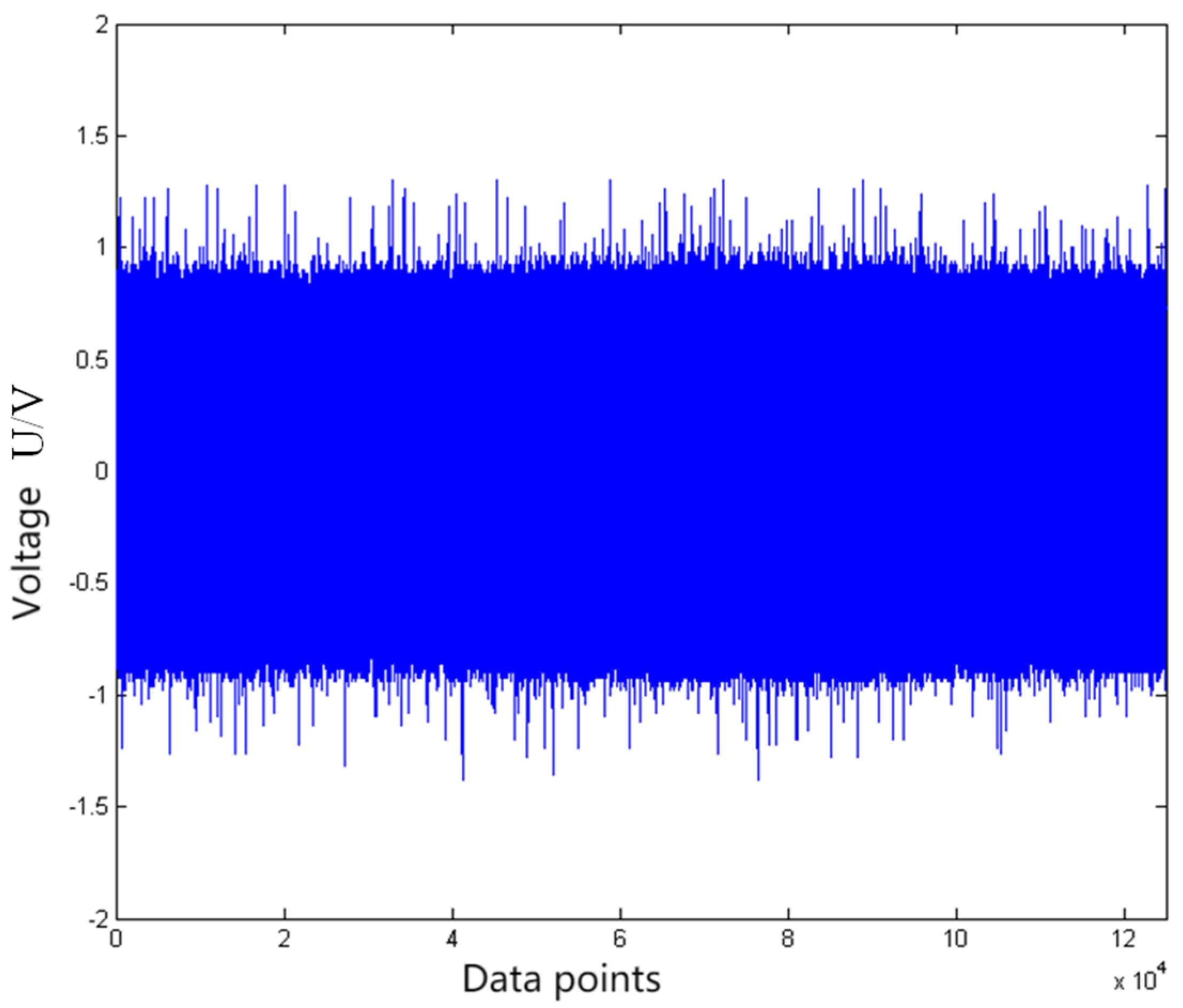

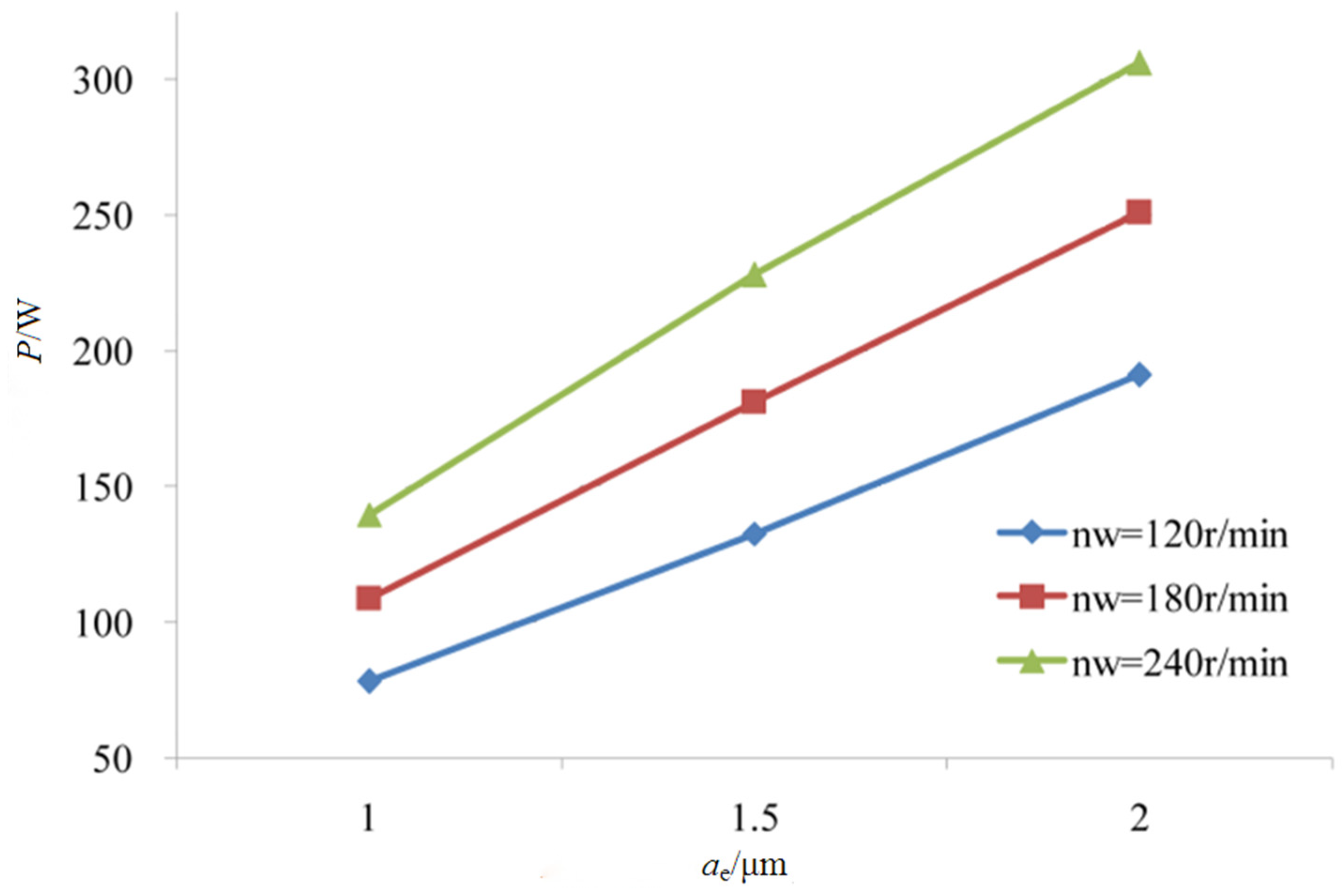

3.1. Grinding Force Test

3.2. Grinding Temperature Test

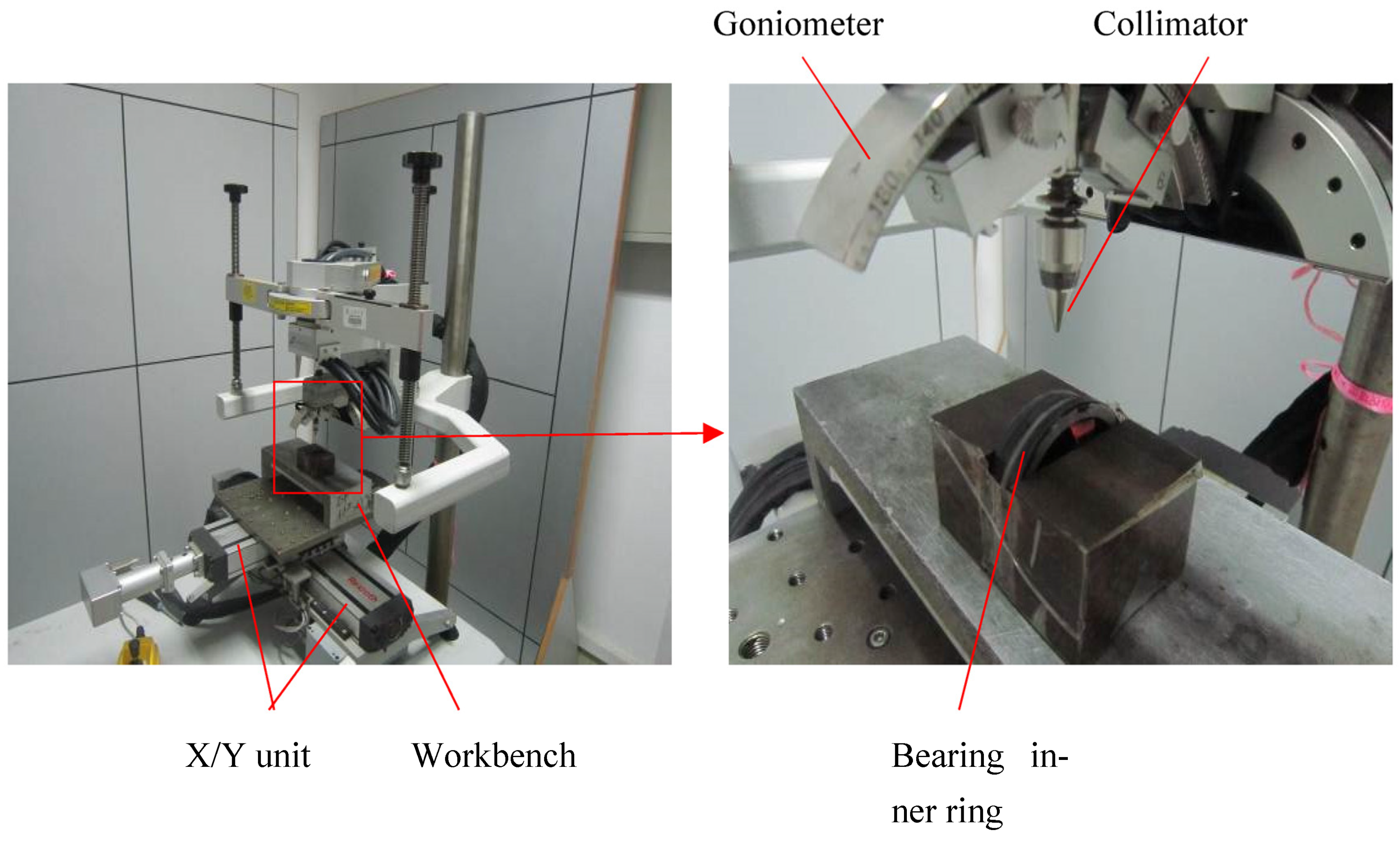

3.3. Residual Stress Measurement

4. Grinding Experimental Results and Analysis

4.1. Low-Temperature Aerosol Lubrication Performance Study

4.2. Low-Temperature Aerosol Cooling Performance Study

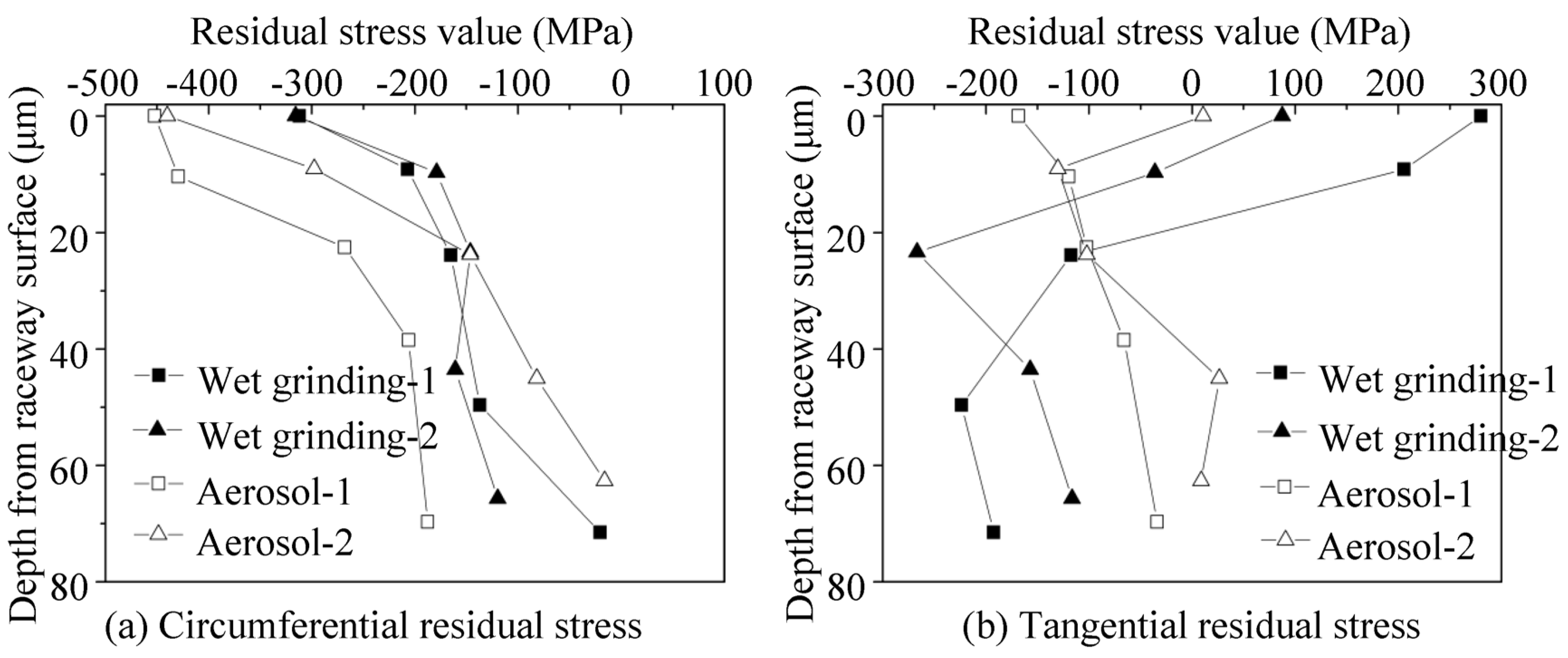

4.3. Effect of Cooling and Lubrication Conditions on the State of Residual Stress Distribution in the Raceway Surface Layer

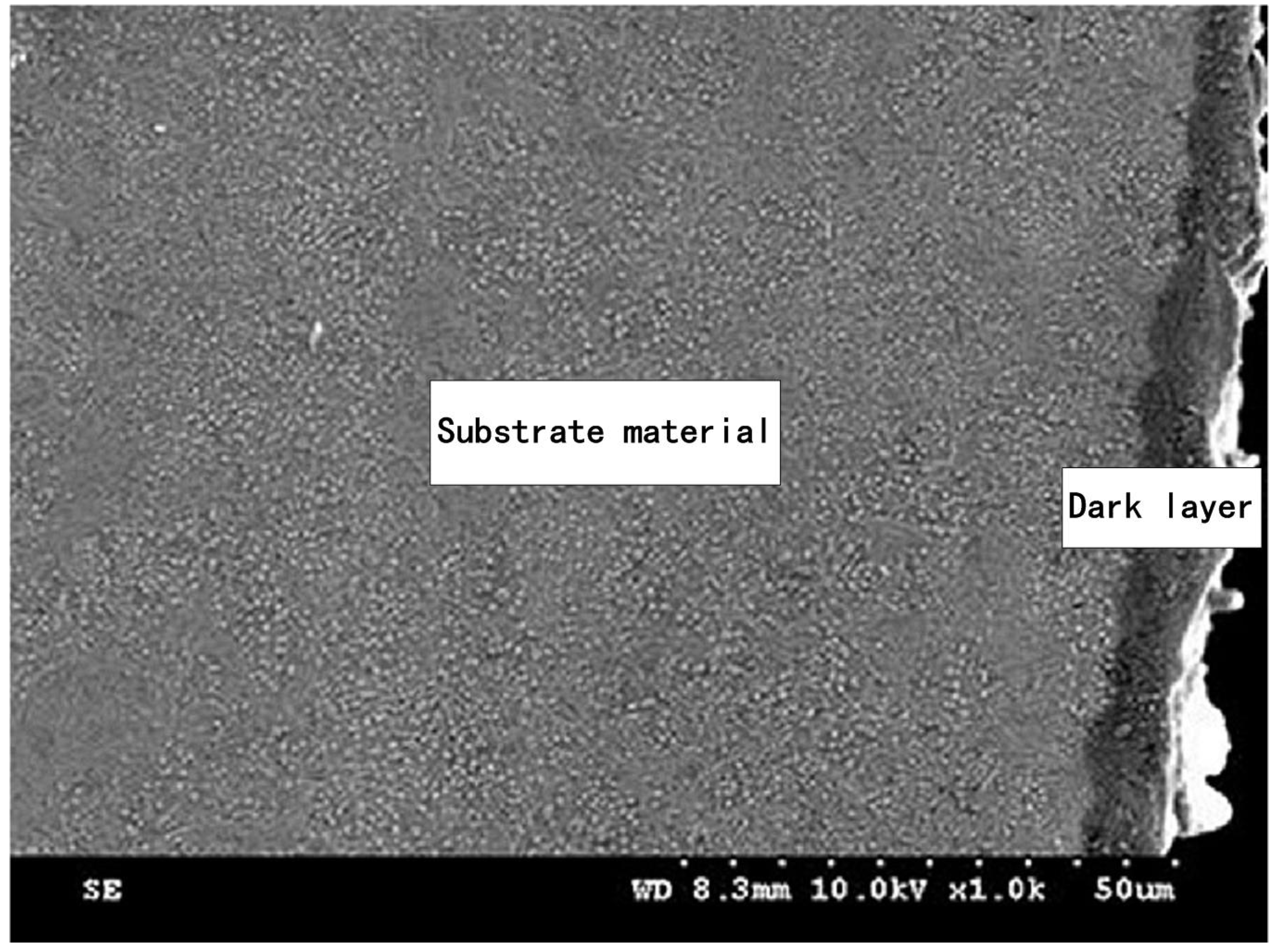

4.4. Thickness of the Layer Affected by Grinding

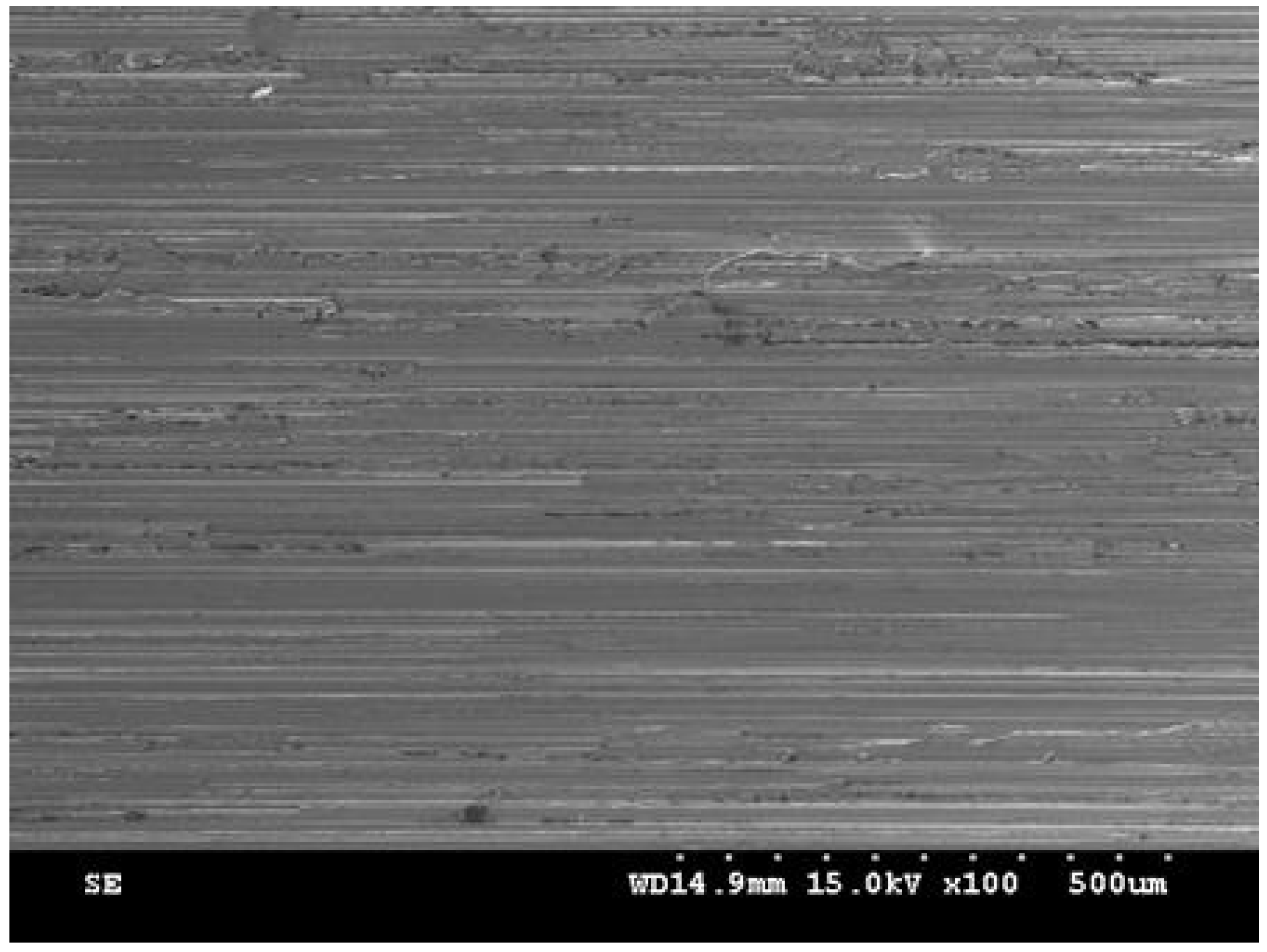

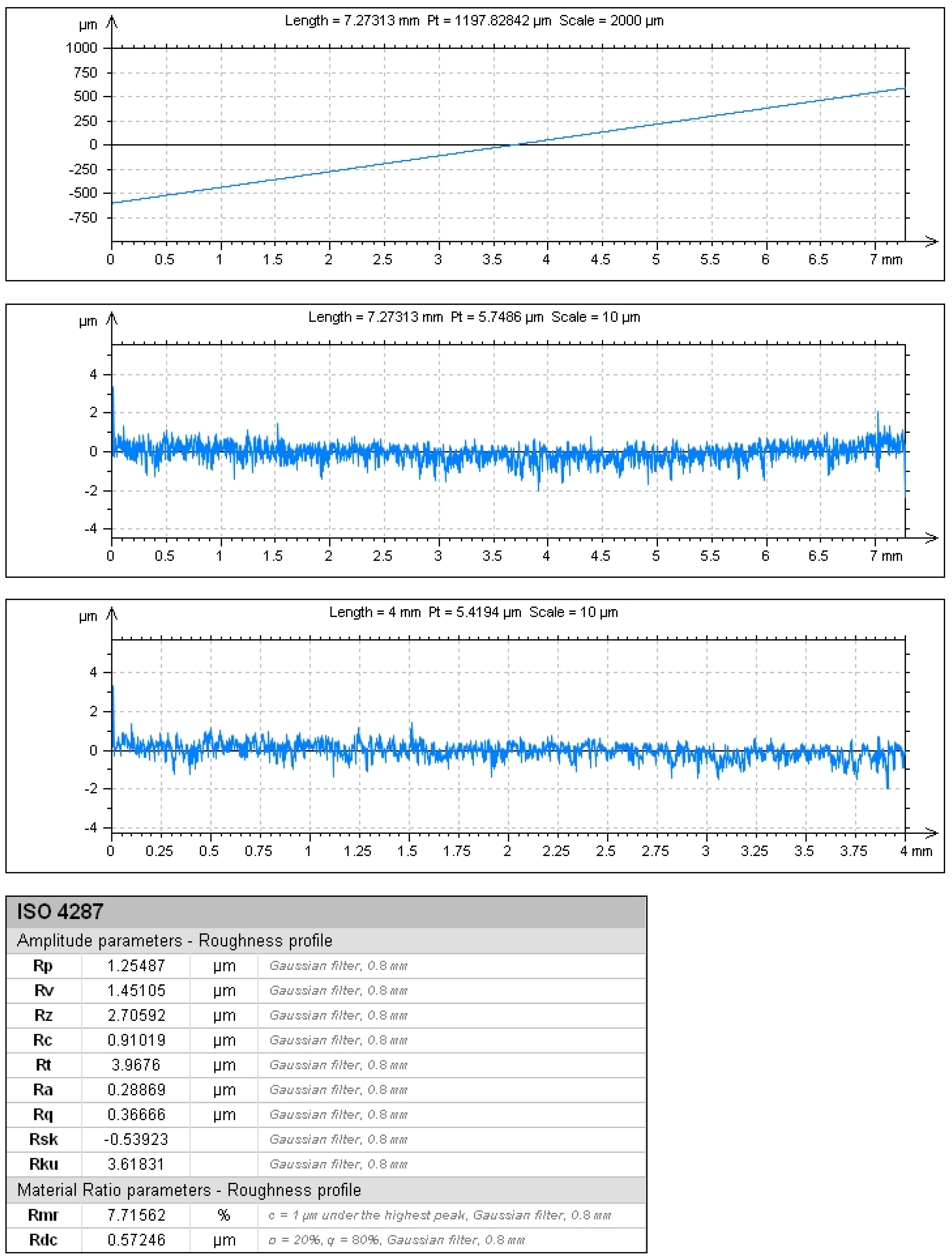

4.5. Roughness Measurement

- Definitions and symbols: defines the concepts of surface roughness, contour lines, contour surfaces and symbols;

- Measurement length and filter: specifies the selection of measurement length and the types and parameters of filters;

- Inspection lengths: specifies the selection and use of inspection lengths;

- Surface parameters: lists the parameters used to describe the surface roughness, including Ra, Rz, Rq, Rt, Rp, Rv, Rsk, Rku, etc.;

- Surface profile parameters: The parameters used to describe the surface profile are listed, including wavelength, wave height, wave number, waveform, etc.;

- Report form: specifies the report form and content of the surface roughness measurement results.

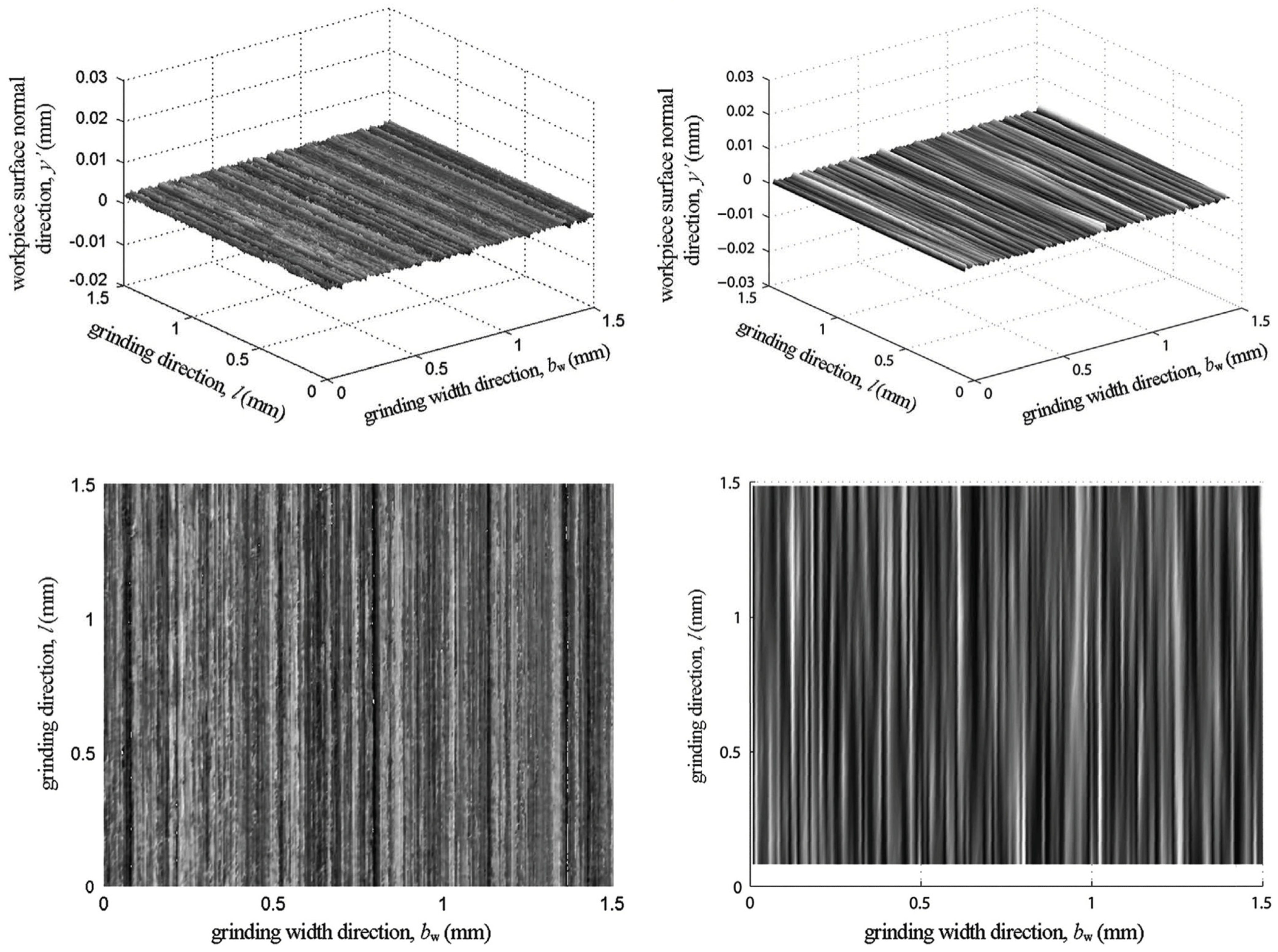

4.6. Roughness Analysis

- (1)

- The two-dimensional morphology of the grinding surface was simulated using contour lines, the height of each point was counted to be worth the grinding surface roughness, and the numerical relationship between the grinding parameters and the grinding surface coarse sugar content was established. The calculated results were in good agreement with the experimental data found in the literature, and when the change in the grinding parameters led to a decrease in the maximum undeformed chip thickness, the grinding surface roughness also decreased at the same time;

- (2)

- The dressing wear contour line was used to describe the factors such as the dressing parameters of the grinding wheel and the wear of the grinding wheel and dresser. The calculation results showed that the grinding surface profile obtained when the effects of dressing and wear were considered differed significantly from that obtained when the effects of dressing and wear were not considered. A single-factor grinding experiment with dressing guides was conducted to compare the theoretical calculation results with the experimental data, and the results showed that the prediction accuracy of the theoretical model considering the effects of dressing and wear was significantly improved, with a prediction error of less than 10%. The three-dimensional model was more accurate and obtained a grinding surface morphology close to the measured results, while the two-dimensional model was less computationally intensive and more suitable for application in production practice;

- (3)

- The bearing raceway grinding parameters were equated to the surface grinding process, and the influence of the grinding parameters on the raceway grinding roughness was analyzed. The results showed that within the range of the selected conventional bearing grinding parameters, the grinding roughness was influenced by the workpiece speed and increased with the increase in the workpiece speed.

5. Conclusions

- (1)

- The grinding force and grinding temperature were measured using a bearing inner ring raceway low-temperature aerosol cooling lubrication grinding experiment. The experimental results showed that there was a critical value of the grinding fluid flow rate, and after this value was exceeded, the tangential grinding force no longer changed when the grinding fluid flow rate continued to increase. Decreasing the low-temperature cold airflow rate caused an increase in the tangential grinding force. Compared with PC-621F water-soluble semi-synthetic cutting fluid, LB-2000 vegetable-based aerosol cutting oil exhibited better lubrication performance;

- (2)

- The cooling performance and lubricating performance of the aerosol were evaluated. Compared with PC-621F type water-soluble semi-synthetic cutting fluid in a wet grinding environment, spraying LB-2000-type vegetable-based spray cutting oil can obtain a better lubrication effect, but the cooling effect is insufficient;

- (3)

- Under different cooling and lubricating conditions, the state of residual stress distribution on the inner ring raceway surface was measured, and the effect of cooling and lubricating conditions on the state of residual stress distribution on the inner ring raceway surface was compared and analyzed. The results showed that the low-temperature aerosol cooling lubrication method was more beneficial to the generation of residual compressive stresses in the inner ring raceway surface layer of the bearing.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lambda, R. Finite element correction for stress relaxation in complex geometries. In Diffraction Notes; Lambda Research Inc.: Sinssinati, OH, USA, 1996; pp. 1–4. [Google Scholar]

- Tawakoli, T.; Hadad, M.J.; Sadeghi, M.H. Influence of oil mist parameters on minimum quantity lubrication–MQL grinding process. Int. J. Mach. Tools Manuf. 2010, 50, 521–531. [Google Scholar] [CrossRef]

- Malkin, S.; Guo, C. Thermal analysis of grinding. CIRP Ann.-Manuf. Technol. 2007, 56, 760–782. [Google Scholar] [CrossRef]

- Xi, F.; Zhou, D. Modeling Surface Roughness in the Stone Polishing Process. Int. J. Mach. Tools Manuf. 2005, 45, 365–372. [Google Scholar] [CrossRef]

- Chen, X.; Rowe, W.B. Analysis and Simulation of the Gring Process. Part I: Generation of the Grinding Wheel Surface. Int. J. Mach. Tools Manuf. 1996, 36, 871–882. [Google Scholar] [CrossRef]

- Jiang, J.L.; Ge, P.Q.; Hong, J. Study on Micro-interacting Mechanism Modeling in Grinding Process and Ground Surface Roughness Prediction. Int. J. Adv. Manuf. Technol. 2013, 67, 1035–1052. [Google Scholar] [CrossRef]

- Wang, D.; Ge, P.; Bi, W.; Jiang, J. Grain Trajectory and Grain Workpiece Contact Analyses for Modeling of Grinding Force and Energy Partition. Int. J. Adv. Manuf. Technol. 2014, 70, 2111–2123. [Google Scholar] [CrossRef]

- Malkin, S. Grinding Technology: Theory and Applications of Machining with Abrasives; Ellis Horwood: Chichester, UK, 1989. [Google Scholar]

- Zhou, X.; Xi, F. Modeling and Predicting Surface Roughness of the Grinding Process. Int. J. Mach. Tools Manuf. 2002, 42, 969–977. [Google Scholar] [CrossRef]

- Wang, G.; Wang, Y.; Xu, Z. Modeling and Analysis of the Material Removal Depth for Stone Polishing. J. Mater. Process. Technol. 2009, 209, 2453–2463. [Google Scholar] [CrossRef]

- Grum, J. A review of the Influence of Grinding Conditions on Resulting Residual Stresses after Induction Surface Hardening and Grinding. J. Mater. Process. Technol. 2001, 114, 212–226. [Google Scholar] [CrossRef]

- Davis, J.M.; Saei, M.; Mohanty, D.P.; Udupa, A.; Sugihara, T.; Chandrasekar, S. Cutting of tantalum: Why it is so difficult and what can be done about it. Int. J. Mach. Tools Manuf. 2020, 157, 103607. [Google Scholar] [CrossRef]

- Udupa, A.; Sugihara, T.; Viswanathan, K.; Latanision, R.M.; Chandrasekar, S. Surfacestress induced embrittlement of metals. Nano Lett. 2021, 21, 9502–9508. [Google Scholar] [CrossRef]

- Issahaq, M.N.; Udupa, A.; Sugihara, T.; Mohanty, D.P.; Mann, J.B.; Trumble, K.P.; Chandrasekar, S.; M’Saoubi, R. Enhancing surface quality in cutting of gummy metals using nanoscale organic films. CIRP Ann. 2022, 71, 93–96. [Google Scholar] [CrossRef]

- Lee, Y.J.; Wang, H. Current understanding of surface effects in microcutting. Mater. Des. 2020, 192, 108688. [Google Scholar] [CrossRef]

- Zhang, J.; Lee, Y.J.; Wang, H. Mechanochemical effect on the microstructure and mechanical properties in ultraprecision machining of AA6061 alloy. J. Mater. Sci. Technol. 2021, 69, 228–238. [Google Scholar] [CrossRef]

- Zhang, J.; Lee, Y.J.; Wang, H. Surface texture transformation in micro-cutting of AA6061-T6 with the rehbinder effect. Int. J. Precis. Eng. Manuf.-Green Technol. 2021, 8, 1151–1162. [Google Scholar] [CrossRef]

| Parameters | Data |

|---|---|

| Kinematic Viscosity | 37 mm2/s |

| Flash Point | 320 °C |

| Tipping Point | −20 °C |

| Water Soluble | Insoluble in water |

| Parameters | Data |

|---|---|

| Kinematic Viscosity | 51.8 mm2/s |

| Flash Point | 180 °C |

| Tipping Point | −30 °C |

| Water Soluble | Soluble in water |

| Frequency (Hz) | Flow Rate (mL/h) |

|---|---|

| 0.5 | 35.29 |

| 1 | 71.43 |

| 1.5 | 111.11 |

| 2 | 136.36 |

| 3 | 216.92 |

| 4 | 266.67 |

| 5 | 333.33 |

| Number of Laps | Flow Rate (m3/h) |

|---|---|

| 0 | 12.70 |

| 0.5 | 11.48 |

| 1 | 6.56 |

| 2 | 4.34 |

| 4 | 2.54 |

| Number of Laps | Temperature (°C) |

|---|---|

| 0 | 12.9 |

| 0.5 | 7.1 |

| 1 | 0.5 |

| 2 | −3.8 |

| 4 | −8.7 |

| Number | Technical Parameters | Values and Descriptions |

|---|---|---|

| 1 | Using the power supply | 50 Hz, 380 V |

| 2 | Grinding wheel motor | Y132S2-2B3, 7.5 Kw |

| 3 | Workpiece motors | Y906-4B3, 1.5 Kw |

| 4 | Grinding wheel size | Φ500 × B × Φ203 mm, Bmax = 40 mm |

| 5 | Grinding wheel line speed | 60 m/s |

| 6 | Grinding wheel speed | 2300 r/min |

| 7 | Feeding speed | 0–30 mm/min |

| Serial Number | Workpiece Shaft Speed nw (r/min) | Grinding Depth ae (μm) | Feeding Speed vf (μm/s) |

|---|---|---|---|

| 1 | 120 | 1 | 4 |

| 2 | 180 | 1 | 6 |

| 3 | 240 | 1 | 8 |

| 4 | 120 | 1.5 | 6 |

| 5 | 180 | 1.5 | 9 |

| 6 | 240 | 1.5 | 12 |

| 7 | 120 | 2 | 8 |

| 8 | 180 | 2 | 12 |

| 9 | 240 | 2 | 16 |

| Grinding Parameters | Parameter Value |

|---|---|

| Grinder | 3MKS1310 high-speed CNC bearing inner ring groove grinding machine |

| Grinding wheel | A80L6V |

| Grinding wheel diameter ds | 497.17~500 mm |

| Inner ring material | Hardened bearing steel GCr15, HRC 62 |

| Grinding wheel speed ns | 2300 r/min |

| Workpiece speed nw | 240 r/min |

| Feed rate vf | 16 μm/s |

| Grinding environment | Dry grinding, wet grinding, aerosol |

| Wet grinding | PC-621F type water-soluble semi-synthetic cutting fluid, concentration 5% |

| Aerosol | As shown in Table 1 and Table 2 |

| Grinding method | Smooth grinding |

| Trimmer | Single point diamond grain dresser |

| Trimming depth ad | 0.01 mm |

| Trimming speed fd | 0.0012 mm/r |

| Parameters | Parameter Value |

|---|---|

| Type of grinding fluid | LB-2000 type plant-based spray cutting oil. PC-621F type water-soluble semi-synthetic cutting fluid, concentration 5% |

| Grinding fluid flow | 35.29, 71.43, 111.11, 136.36, 216.92, 266.67, 333.33 mL/h |

| Low-temperature cooling airflow | 12.70, 11.48, 6.56, 4.34, 2.54 m3/h |

| Low-temperature aerosol outlet temperature | 12.9, 7.1, 0.5, −3.8, −8.7 °C |

| Nozzle distance from the grinding arc | 24.9 mm |

| Serial Number | Workpiece Shaft Speed nw (r/min) | Grinding Depth ae (μm) | Ft Experimental Value (N) | Ft Theoretical Value (N) | Error (%) |

|---|---|---|---|---|---|

| 1 | 120 | 1 | 1.30 | 1.21 | 7.17 |

| 2 | 180 | 1 | 1.81 | 1.78 | 1.67 |

| 3 | 240 | 1 | 2.32 | 2.26 | 2.62 |

| 4 | 120 | 1.5 | 2.21 | 2.08 | 6.06 |

| 5 | 180 | 1.5 | 3.02 | 2.92 | 3.37 |

| 6 | 240 | 1.5 | 3.80 | 3.60 | 5.41 |

| 7 | 120 | 2 | 3.18 | 2.98 | 6.49 |

| 8 | 180 | 2 | 4.18 | 3.98 | 4.90 |

| 9 | 240 | 2 | 5.10 | 4.90 | 4.00 |

| Cooling and Lubrication Conditions | Qa (m3/h) | Tf (°C) | Ft (N) | Tmax (°C) | εwb |

|---|---|---|---|---|---|

| Low-temperature aerosol (LB-2000) | 12.70 | 12.9 | 4.94 | 279.6 | 0.735 |

| 2.54 | −8.7 | 6.84 | 362.1 | 0.743 | |

| Wet grinding | --- | 13.5 | 5.97 | 315.8 | 0.648 |

| Cooling and Lubrication Conditions | Qa (m3/h) | Qf (mL/h) | Tf (°C) |

|---|---|---|---|

| Low-temperature aerosol (LB-2000) | 12.70 | 136.36 | 12.9 |

| Wet grinding | --- | --- | 13.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, Z.; Hu, L. Bearing Inner Ring Raceway Low-Temperature Aerosol Cooling Lubrication Grinding. Processes 2023, 11, 1546. https://doi.org/10.3390/pr11051546

Chang Z, Hu L. Bearing Inner Ring Raceway Low-Temperature Aerosol Cooling Lubrication Grinding. Processes. 2023; 11(5):1546. https://doi.org/10.3390/pr11051546

Chicago/Turabian StyleChang, Zhou, and Lai Hu. 2023. "Bearing Inner Ring Raceway Low-Temperature Aerosol Cooling Lubrication Grinding" Processes 11, no. 5: 1546. https://doi.org/10.3390/pr11051546

APA StyleChang, Z., & Hu, L. (2023). Bearing Inner Ring Raceway Low-Temperature Aerosol Cooling Lubrication Grinding. Processes, 11(5), 1546. https://doi.org/10.3390/pr11051546