Application of Life Cycle of Aeroengine Mainshaft Bearing Based on Digital Twin

Abstract

1. Introduction

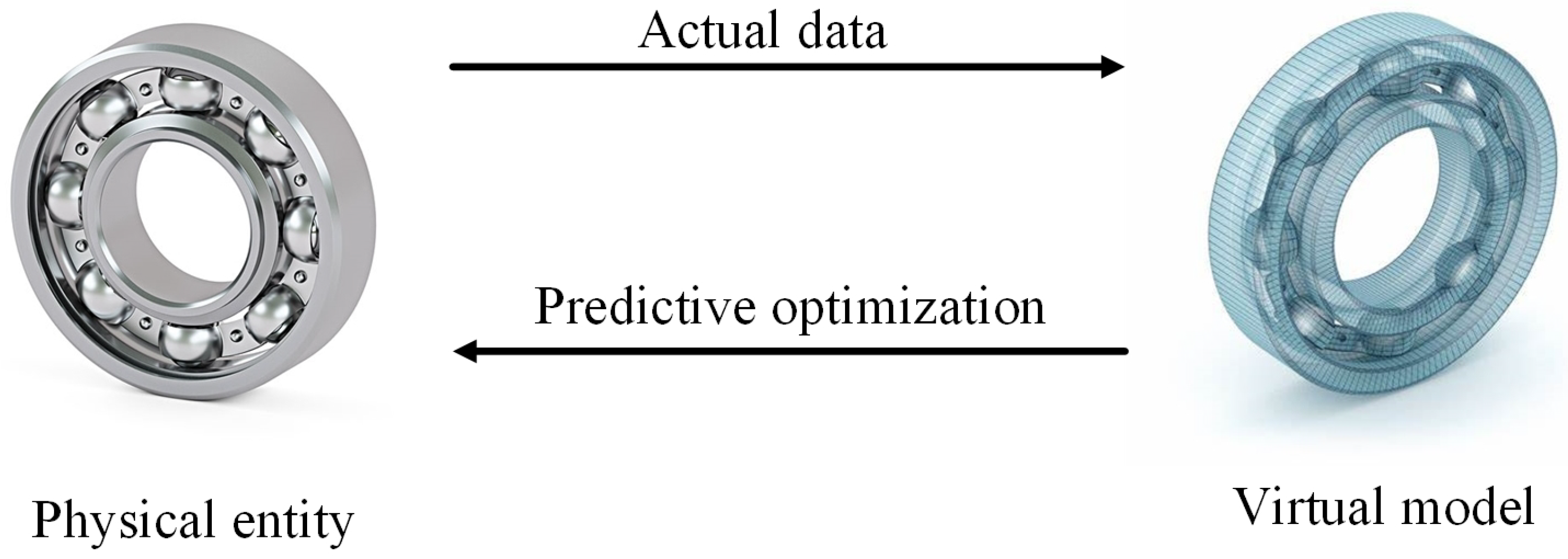

2. The Development and Significance of Digital Twins

3. Manufacture of Aeroengine Mainshaft Bearing Based on Digital Twin

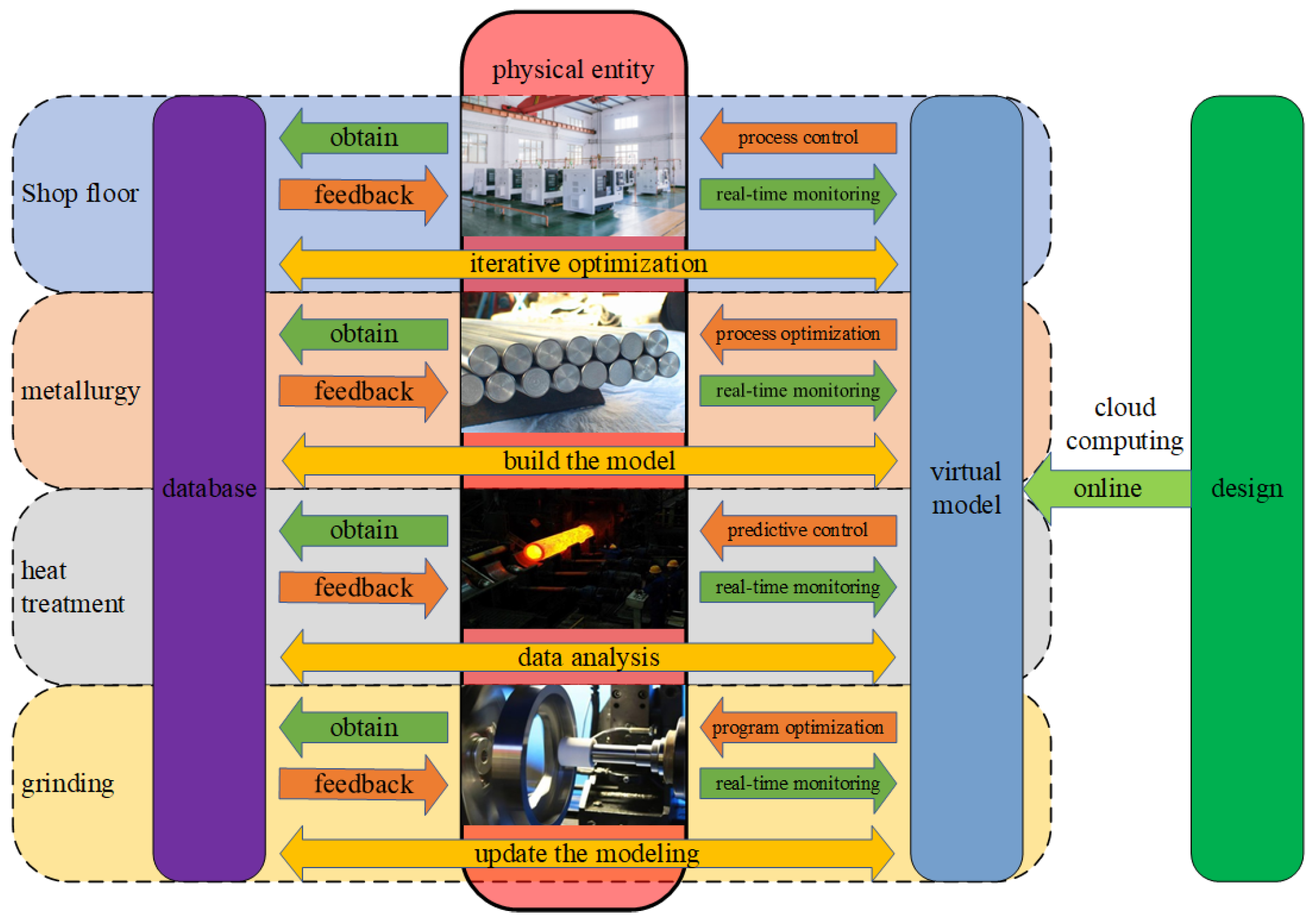

3.1. Operation Mode of Digital Twin Shop Floor

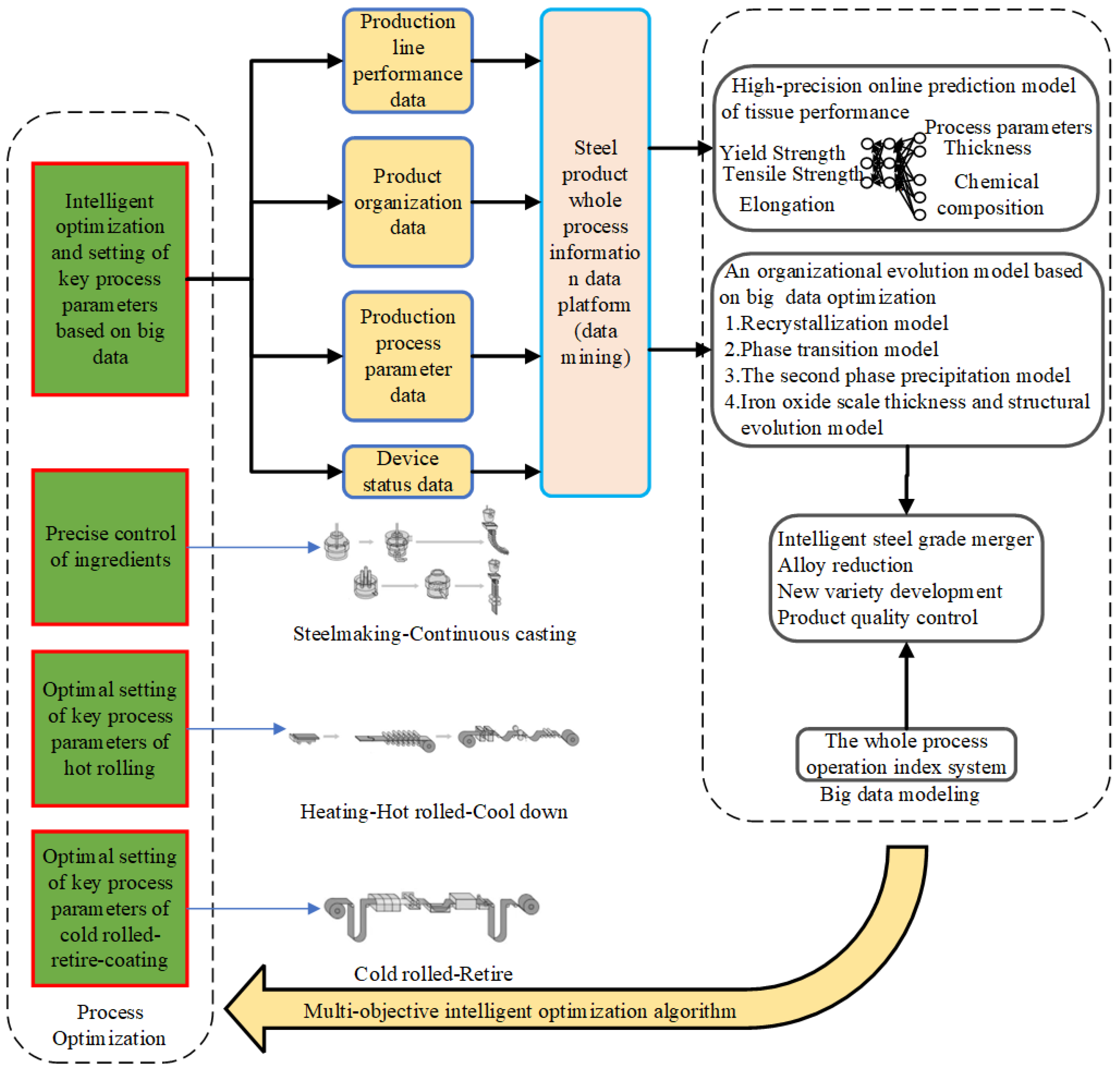

3.2. Metallurgical Process of Bearing Steel Based on Digital Twin

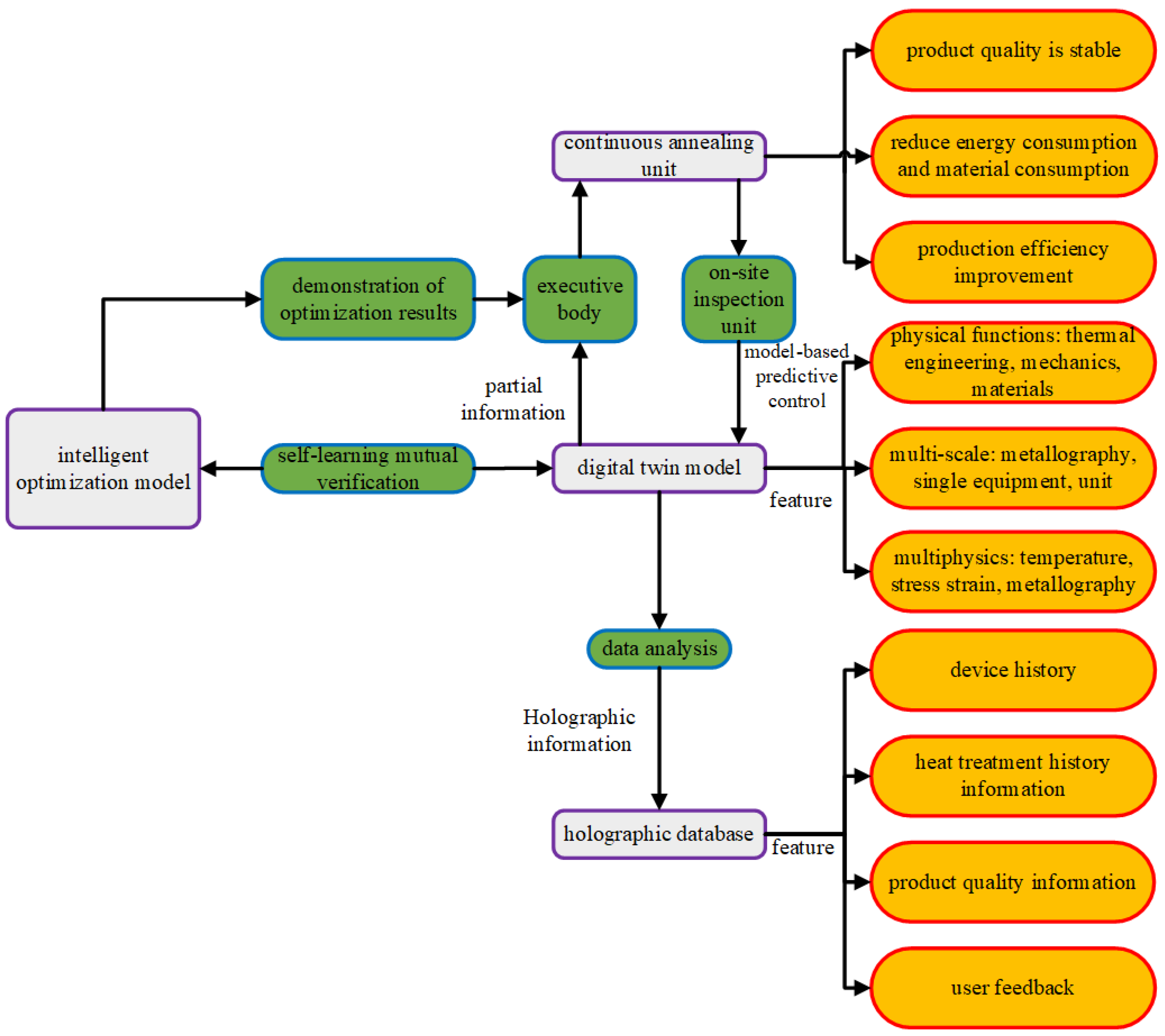

3.3. Heat Treatment Process of Bearing Steel Based on Digital Twin

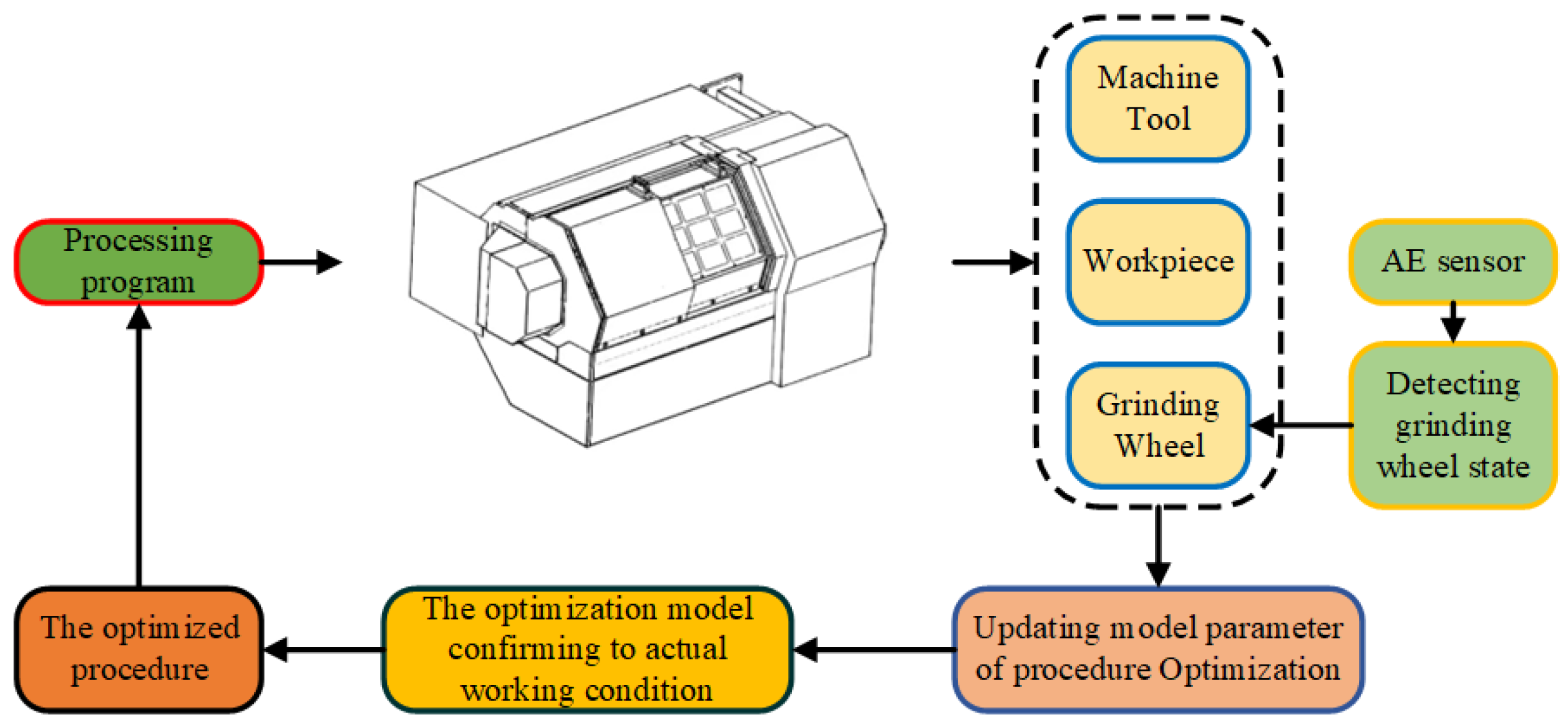

3.4. The Mainshaft Bearing Grinding Technology Based on Digital Twin

4. Fault Diagnosis and Life Analysis of Aeroengine Mainshaft Bearings Based on Digital Twin

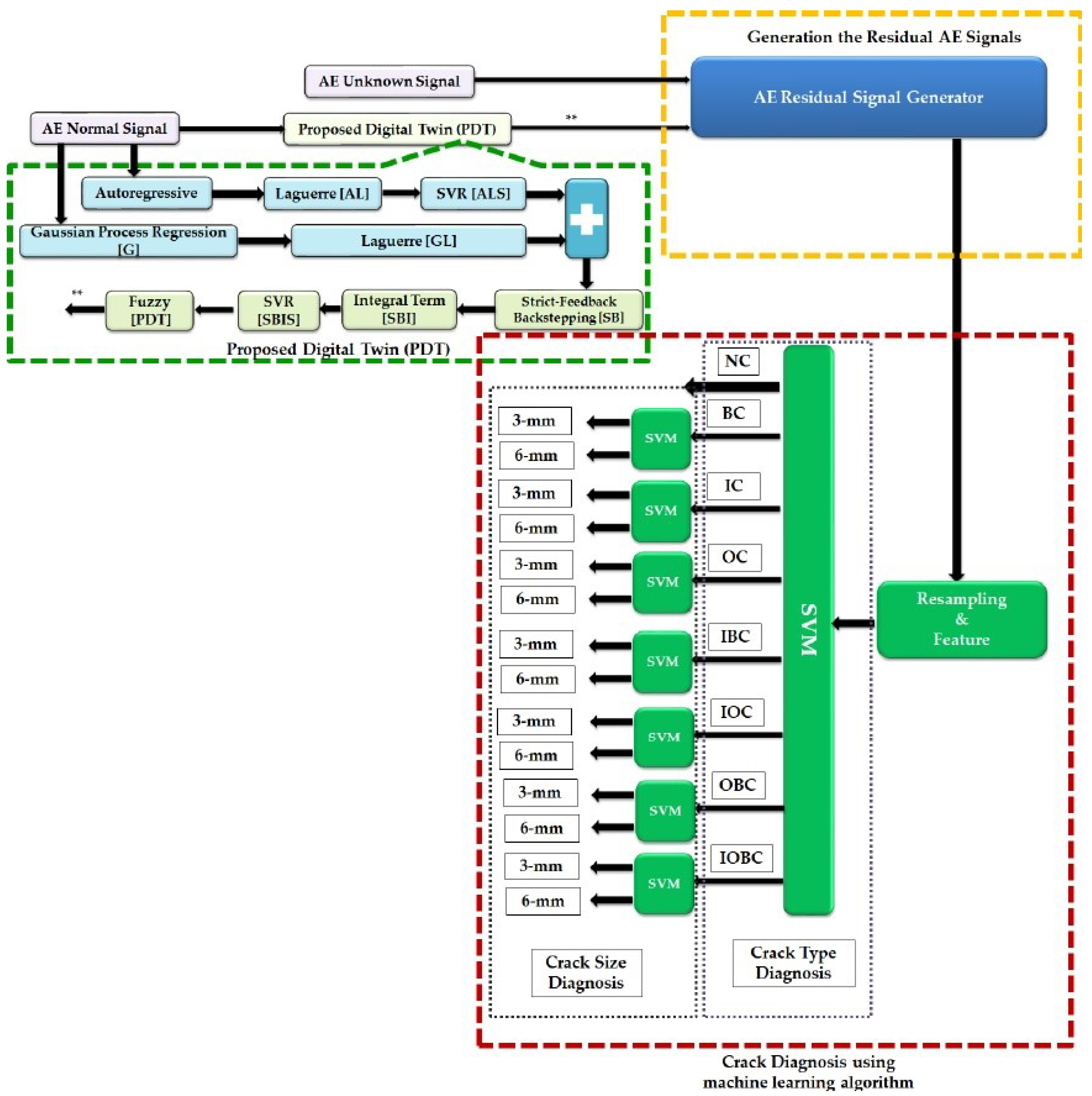

4.1. Fault Diagnosis of the Mainshaft Bearing Based on Digital Twin

4.2. The Mainshaft Bearing Life Analysis Based on Digital Twin

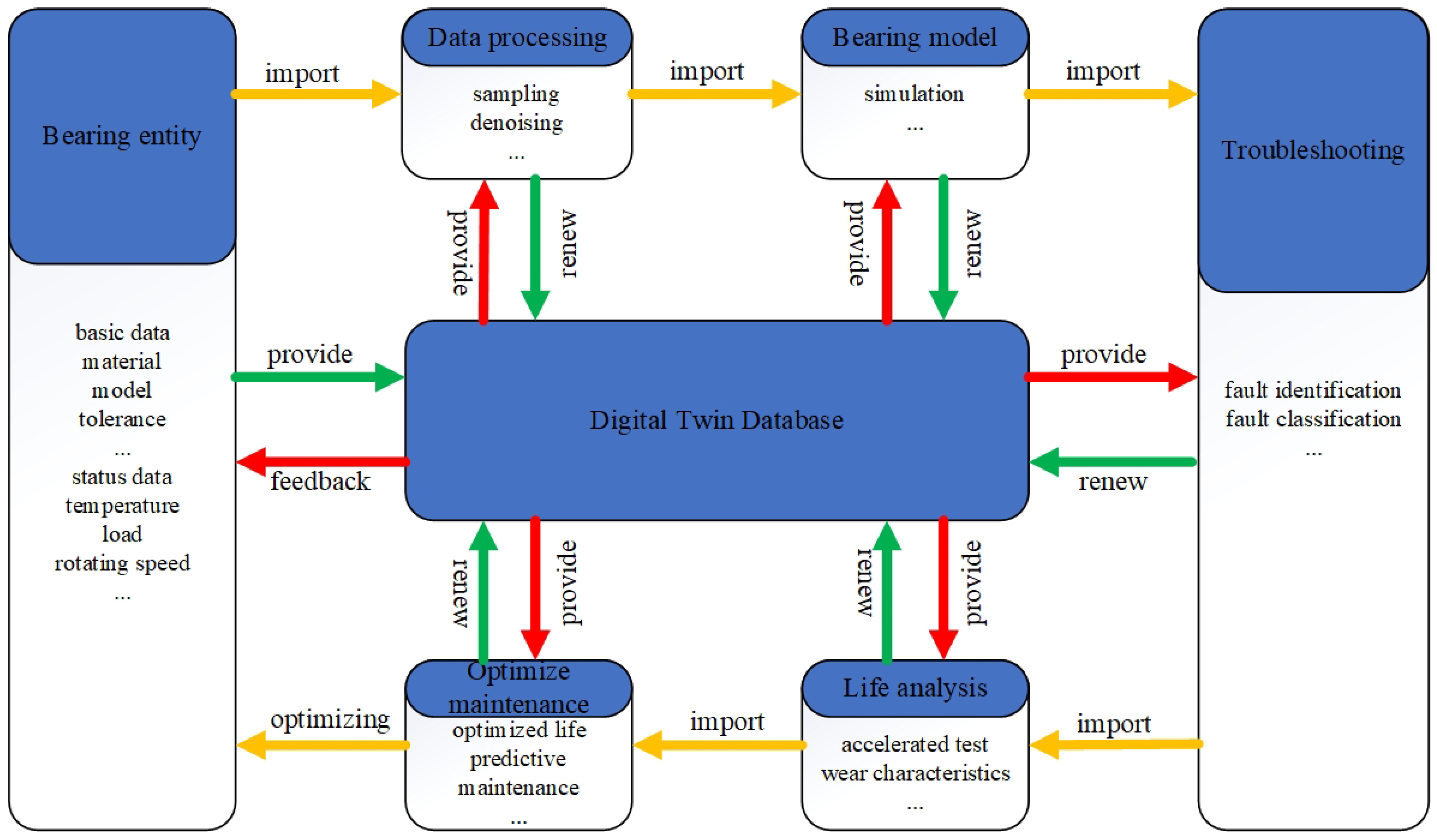

4.3. A Digital Twin Framework for Fault Diagnosis of Aeroengine Mainshaft Bearings

- Bearing entity: This is the actual entity of the aeroengine mainshaft bearing. It is necessary to input the parameters of the mainshaft bearing in various states into the digital twin framework, and it will be optimized and maintained according to the recommendations given by the digital twin framework. It is the basic data source and the final executed object of the digital twin framework.

- Data processing module: Due to the large number of mainshaft bearing state parameters monitored by various sensors, such as temperature, speed, vibration, flow, displacement, sound and other parameters, some parameters contain a lot of noise, such as vibration signal and audio signal. The data processing module needs to perform multi-parameter integration and data processing, such as denoising the signal containing noise, extracting fault features and simplifying the signal to be analyzed, to facilitate data transmission and analysis.

- Bearing model: Mapping of bearing entities. The status data of the bearing entity can simulate the status of the mainshaft bearing in real time, or simulate the status of the mainshaft bearing at any time according to the parameters of the mainshaft bearing in the database, such as the mainshaft bearing dynamics simulation, lubricating fluid dynamics simulation, etc.

- Troubleshooting Module: The data of the mainshaft bearing are analyzed, numerical algorithms, such as convolutional neural network, support vector machine, etc., are used to intelligently identify the fault type of the mainshaft bearing and classify the fault.

- Digital Twin Database: The basic dimensional data of the mainshaft bearing are stored, such as material, model, tolerance, etc., as well as all data under working conditions such as temperature, speed, etc. Data are analyzed by all modules in the digital twin framework, such as failure frequency, life, etc. This provides parameter information for the mainshaft bearing simulation model and is the data source for the operation of all other modules.

- Life Analysis Module: According to the accelerated life experiment of the mainshaft bearing state simulation, the wear characteristics of the mainshaft bearing are analyzed and the influence of each parameter of the mainshaft bearing on the wear life of the mainshaft bearing is evaluate, such as speed, load, clearance, etc., to improve the life prediction accuracy of the mainshaft bearing.

- Optimize Maintenance Module: According to the results of the life analysis module, a set of maintenance strategies for the existing mainshaft bearings are formulated to optimize the life of the mainshaft bearings. The digital twin framework can also simulate according to the maintenance strategy, find out the deficiencies of the existing strategy and iteratively optimize it to obtain the optimal maintenance strategy and achieve predictive maintenance.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, Z.; Lei, J.; Xu, H.; Yu, F.; Dong, H.; Cao, W. Current status and development trend of bearing steel in China and abroad. J. Iron Steel Res. 2016, 28, 1–12. [Google Scholar] [CrossRef]

- Zhang, F.; Yang, Z. Development of and Perspective on High-Performance Nanostructured Bainitic Bearing Steel. Engineering 2019, 5, 319–328. [Google Scholar] [CrossRef]

- Cao, H.; Peng, C.; Chen, X. Rolling Bearing Modeling and Model Updating Method and System Based on Digital Twinning. Chinese Patent CN113221280A, 9 December 2022. [Google Scholar]

- Cao, H.; Wang, L.; Qiao, B.; Chen, X. Bearing Performance Degradation Evaluation Method and System Based on Digital Twinborn Model. Chinese Patent CN113221277A, 9 December 2022. [Google Scholar]

- Cao, H.; Su, S.; Fu, Y.; Qiao, B.; Chen, X. Digital Twin-Based Method for Detecting and Diagnosing Damage of Main Bearing of Aero-Engine. Chinese Patent CN110530638B, 27 October 2020. [Google Scholar]

- Cao, H.; Su, S.; Fu, Y.; Qiao, B.; Chen, X. Aero-Engine Main Bearing Residual Life Prediction Method Based on Digital Twinning. Chinese Patent CN110532626B, 19 January 2021. [Google Scholar]

- Zhao, Y.; Zhang, J.; Zhou, E. Bearing Full Life Cycle Monitoring Method Based on Digital Twins. Chinese Patent CN112762100B, 10 August 2021. [Google Scholar]

- Guo, L.; Zong, H.; Gao, H.; Han, J.; Li, S.; Zhang, J.; He, J.; You, C.; Pan, J.; Ma, G.; et al. Rolling Bearing Full-Life State Monitoring Method Based on Digital Twinning. Chinese Patent CN114383847B, 12 July 2022. [Google Scholar]

- Wu, L.; Leng, J.; Ju, B. Digital Twins-Based Smart Design and Control of Ultra-Precision Machining: A Review. Symmetry 2021, 13, 1717. [Google Scholar] [CrossRef]

- Grieves, M. Digital Twin: Manufacturing Excellence through Virtual Factory Replication; Michael W. Grieves, LLC.: Cocoa Beach, FL, USA, 2015. [Google Scholar]

- Tao, F.; Liu, W.; Liu, J.; Liu, X.; Liu, Q.; Qu, T.; Hu, T.; Zhang, Z.; Xiang, F.; Xu, W.; et al. Digital twin and its potential application exploration. Comput. Integr. Manuf. Syst. 2018, 24, 1–18. [Google Scholar] [CrossRef]

- Liu, F.; Cao, H.; He, N. On State-of-the-Art of Green Manufacturing. China Mech. Eng. 2000, Z1, 114–119+5. [Google Scholar]

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital twin-driven product design, manufacturing and service with big data. Int. J. Adv. Manuf. Technol. 2018, 94, 3563–3576. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, M.; Cheng, J.; Qi, Q. Digital twin workshop: A new paradigm for future workshop. Comput. Integr. Manuf. Syst. 2017, 23, 1–9. [Google Scholar] [CrossRef]

- Tao, F.; Liu, W.; Zhang, M.; Hu, T.; Qi, Q.; Zhang, H.; Sui, F.; Wang, T.; Xu, H.; Huang, Z.; et al. Five-dimension digital twin model and its ten applications. Comput. Integr. Manuf. Syst. 2019, 25, 1–18. [Google Scholar] [CrossRef]

- Yildiz, E.; Møller, C.; Bilberg, A. Conceptual foundations and extension of digital twin-based virtual factory to virtual enterprise. Int. J. Adv. Manuf. Technol. 2022, 121, 2317–2333. [Google Scholar] [CrossRef]

- Yu, H. Control and Research of Inclusions in the Refining Process of High-grade Bearing Steel. Metall Mater. 2022, 14, 39–40. [Google Scholar]

- Xu, X.; Liu, X.; Qin, G.; An, H.; Ren, Y.; Yin, Y. Control Technology for Domestic Bearing Steel in Production. Angang Technol. 2021, 5, 7–11+27. [Google Scholar]

- You, S. Status and research directions of bearing steels and heat processes in China. Heat Treat Met. 2012, 37, 119–125. [Google Scholar] [CrossRef]

- Wang, G.; Liu, Z.; Dianhua, Z. Research progress on the cyber-physical system of steel hot rolling in RAL. Steel Roll. 2021, 38, 1–7+13. [Google Scholar] [CrossRef]

- Yang, X. Criteria of Research and Development for Bearing Steel According to Chemical Composition Design of GCr15. Bearing 2022, 12, 28–31. [Google Scholar]

- Zhang, G.; Zhang, Z.; Wu, K. Progress of Research on Composition Design and Heat Treatment Process of High Carbon Chromium Bearing Steel. Spec. Steel 2015, 36, 9–13. [Google Scholar]

- Chen, Y.; Wu, Y.; Qin, Z.; Zhou, X.; Wang, H. Effect of Deep Cryogenic Treatment on Microstructure and Mechanical Properties of GCr15 Bearing Steel. Mater. Sci. Eng. 2018, 42, 55–58+62. [Google Scholar]

- Kong, Y.; Li, S.; Zhou, J.; Zhu, S. Effect of austempering process parameters on microstructure and wear resistance of GCr15 steel spinning ring. Heat. Treat. Met. 2016, 41, 95–99. [Google Scholar] [CrossRef]

- Zhang, G.; Cui, H.; Cheng, G. Friction and Wear Behaviors of Gas Nitriding and Quenching Compound Treatment of GCr15 Steels. China Surf. Eng. 2016, 29, 30–37. [Google Scholar]

- Cheng, G.; Li, W.; Zhang, X.; Zhang, L. Transformation of Inclusions in Solid GCr15 Bearing Steels During Heat Treatment. Metals 2019, 9, 642. [Google Scholar] [CrossRef]

- Wang, H.; Su, F.; Wen, Z. Study on Decarburization Mechanism and Law of GCr15 Bearing Steel during Heat Treatment. Adv. Mater. Sci. Eng. 2022, 2022, 3723680. [Google Scholar] [CrossRef]

- Dou, R. Application of Digital Twin Technology in Heat Treatment Furnace. In Proceedings of the 2021 China Industrial Furnace and Metallurgical Industry Thermal Technology Development Conference, Shanghai, China, 26 June 2021; pp. 10–30. [Google Scholar]

- Rudskoy, A.I.; Kolbasnikov, N.G. Digital Twins of Processes of Thermomechanical Treatment of Steel. Met. Sci. Heat. Treat. 2020, 62, 3–10. [Google Scholar] [CrossRef]

- Zhou, Q. A Study on the Dynamic Characteristics of Grinding Process System and Application. Ph.D. Thesis, Hunan University, Changsha, China, 2013. [Google Scholar]

- Wang, S. Development Status of Bearing Bing Grinding and Supermachining Technology. Machinery 2006, 07, 54–56. [Google Scholar]

- Ding, H.; Hang, L.; Chen, Y. Experimental Research of Surface Integrity for Precision Hard Turning Finished Bearing Rings. China Mech. Eng. 2016, 27, 1066–1071. [Google Scholar]

- Sun, X.; Yao, P.; Qu, S.; Yu, S.; Zhang, X.; Wang, W.; Huang, C.; Chu, D. Material properties and machining characteristics under high strain rate in ultra-precision and ultra-high-speed machining process: A review. Int. J. Adv. Manuf. Technol. 2022, 120, 7011–7042. [Google Scholar] [CrossRef]

- Li, W. Processing Technic Parameter Optimization Research of Bearing Strengthening and Polishing Processing. Master’s Thesis, Guangzhou University, Guangzhou, China, 2012. [Google Scholar]

- Monier, A.; Guo, B.; Zhao, Q.; Guo, Z.; Mahmoud, T.S.; El-mahallawi, I. The effects of structured grinding wheel designed parameters on the geometries of ground structured surfaces. Int. J. Adv. Manuf. Technol. 2022, 120, 5551–5571. [Google Scholar] [CrossRef]

- López, C.E.B. Real-time event-based platform for the development of digital twin applications. Int. J. Adv. Manuf. Technol. 2021, 116, 835–845. [Google Scholar] [CrossRef]

- Kannan, K.; Arunachalam, N. A Digital Twin for Grinding Wheel: An Information Sharing Platform for Sustainable Grinding Process. J. Manuf. Sci. Eng.-Trans. ASME 2019, 141, 021015. [Google Scholar] [CrossRef]

- Liu, H.; Shen, Z.; Wang, Y.; Qiu, M.; Lin, W. Application of Digital Twin Model in Grinding of Bearing Rings. J. Syst. Simul. 2023, 12, 557–567. [Google Scholar] [CrossRef]

- Zheng, Y.; Wang, C.; Zhang, Y.; Meng, F. Study on temperature of cylindrical wet grinding considering lubrication effect of grinding fluid. Int. J. Adv. Manuf. Technol. 2022, 121, 6095–6109. [Google Scholar] [CrossRef]

- Pereverzev, P.P.; Akintseva, A.V.; Alsigar, M.K.; Ardashev, D.V. Designing optimal automatic cycles of round grinding based on the synthesis of digital twin technologies and dynamic programming method. Mech. Sci. 2019, 10, 331–341. [Google Scholar] [CrossRef]

- Shen, N.; Wu, Y.; Li, J.; He, T.; Lu, Y.; Xu, Y. Research on procedure optimisation for composite grinding based on Digital Twin technology. Int. J. Prod. Res. 2022, 61, 1736–1754. [Google Scholar] [CrossRef]

- Zhang, Y. Research on Locally-Linear-Embedding-Based Fault Feature Extraction Technology for Rolling Bearing. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2020. [Google Scholar] [CrossRef]

- Li, N. Research on Rolling Bearing Fault Diagnosis Method Based on Deep Learning. Master’s Thesis, Shenyang Jianzhu University, Shenyang, China, 2021. [Google Scholar] [CrossRef]

- Gao, W.; Nelias, D.; Li, K.; Liu, Z.; Lyu, Y. A multiphase computational study of oil distribution inside roller bearings with under-race lubrication. Tribol. Int. 2019, 140, 105862. [Google Scholar] [CrossRef]

- Li, Z. Study on Wear Characteristics of Rolling Bearing under Rolling-sliding State. Master’s Thesis, Taiyuan University of Technology, Taiyuan, China, 2021. [Google Scholar] [CrossRef]

- Wang, F.; Zhu, Y.; Yan, K.; Liu, Y.; Hong, J. Wireless Monitoring Technology of Rolling Bearing Inner Ring Temperature. J. Mech. Eng. 2018, 54, 8–14. [Google Scholar] [CrossRef]

- Liu, J. Fatigue Life Reliability Research of High-Speed Railway Bearing Based on Multi-Source Information Fusion. Master’s Thesis, University of Electronic Science and Technology of China, Chengdu, China, 2021. [Google Scholar] [CrossRef]

- Fang, X.; Wang, H.; Liu, G.; Tian, X.; Ding, G.; Zhang, H. Industry application of digital twin: From concept to implementation. Int. J. Adv. Manuf. Technol. 2022, 121, 4289–4312. [Google Scholar] [CrossRef]

- Yang, J.; Huang, D.; Zhou, D.; Liu, H. Optimal IMF selection and unknown fault feature extraction for rolling bearings with different defect modes. Measurement 2020, 157, 107660. [Google Scholar] [CrossRef]

- Huang, H.; Baddour, N.; Liang, M. A method for tachometer-free and resampling-free bearing fault diagnostics under time-varying speed conditions. Measurement 2019, 134, 101–117. [Google Scholar] [CrossRef]

- Wang, B.; Feng, G.; Huo, D.; Kang, Y. A Bearing Fault Diagnosis Method Based on Spectrum Map Information Fusion and Convolutional Neural Network. Processes 2022, 10, 1426. [Google Scholar] [CrossRef]

- Lv, D.; Wang, H.; Che, C. Multiscale convolutional neural network and decision fusion for rolling bearing fault diagnosis. Ind. Lubr. Tribol. 2021, 73, 516–522. [Google Scholar] [CrossRef]

- Wang, Z.; Yin, Y.; Yin, R. Multi-tasking atrous convolutional neural network for machinery fault identification. Int. J. Adv. Manuf. Technol. 2022, 124, 4183–4191. [Google Scholar] [CrossRef]

- Plakias, S.; Boutalis, Y.S. Fault detection and identification of rolling element bearings with Attentive Dense CNN. Neurocomputing 2020, 405, 208–217. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, H.; Liu, J.; Qin, Y.; Peng, D. Multitask Learning Based on Lightweight 1DCNN for Fault Diagnosis of Wheelset Bearings. IEEE Trans. Instrum. Meas. 2021, 70, 3501711. [Google Scholar] [CrossRef]

- Abdeljaber, O.; Sassi, S.; Avci, O.; Kiranyaz, S.; Ibrahim, A.A.; Gabbouj, M. Fault Detection and Severity Identification of Ball Bearings by Online Condition Monitoring. IEEE Trans. Ind. Electron. 2019, 66, 8136–8147. [Google Scholar] [CrossRef]

- Han, S.; Zhang, S.; Li, Y.; Chen, L. The multilabel fault diagnosis model of bearing based on integrated convolutional neural network and gated recurrent unit. Int. J. Intell. Comput. Cybern. 2022, 15, 401–413. [Google Scholar] [CrossRef]

- Tang, X.; He, Q.; Gu, X.; Li, C.; Zhang, H.; Lu, J. A Novel Bearing Fault Diagnosis Method Based on GL-mRMR-SVM. Processes 2020, 8, 784. [Google Scholar] [CrossRef]

- Yang, C.; Jia, M. Hierarchical multiscale permutation entropy-based feature extraction and fuzzy support tensor machine with pinball loss for bearing fault identification. Mech. Syst. Signal Proc. 2021, 149, 107182. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, S.; Liu, S.; Liu, W.; Ding, A. A bearing fault diagnosis method for high-noise and unbalanced dataset. Smart Resilient Transp. 2022; ahead-of-print. [Google Scholar] [CrossRef]

- Piltan, F.; Toma, R.N.; Shon, D.; Im, K.; Choi, H.K.; Yoo, D.S.; Kim, J.M. Strict-Feedback Backstepping Digital Twin and Machine Learning Solution in AE Signals for Bearing Crack Identification. Sensors 2022, 22, 539. [Google Scholar] [CrossRef]

- Piltan, F.; Kim, J.M. Bearing Anomaly Recognition Using an Intelligent Digital Twin Integrated with Machine Learning. Appl. Sci. 2021, 11, 4602. [Google Scholar] [CrossRef]

- Piltan, F.; Kim, J.M. Crack Size Identification for Bearings Using an Adaptive Digital Twin. Sensors 2021, 21, 5009. [Google Scholar] [CrossRef]

- Qin, Y.; Wu, X.; Luo, J. Data-Model Combined Driven Digital Twin of Life-Cycle Rolling Bearing. IEEE Trans. Ind. Inform. 2022, 18, 1530–1540. [Google Scholar] [CrossRef]

- Zhu, J.Y.; Park, T.; Isola, P.; Efros, A.A. Unpaired Image-to-Image Translation using Cycle-Consistent Adversarial Networks. In Proceedings of the 16th IEEE International Conference on Computer Vision (ICCV), 2017, IEEE International Conference on Computer Vision, Venice, Italy, 22–29 October 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 2242–2251. [Google Scholar] [CrossRef]

- Shen, R.; Xu, H.; Jiao, Y.; Wu, J. Digital Twin and Its Application in Aircraft Field. J. Command. Control. 2021, 7, 241–248. [Google Scholar]

- Xue, B.; Xu, H.; Huang, X.; Zhu, K.; Xu, Z.; Pei, H. Similarity-based prediction method for machinery remaining useful life: A review. Int. J. Adv. Manuf. Technol. 2022, 121, 1501–1531. [Google Scholar] [CrossRef]

- Zhang, Q.; Ye, Z.; Shao, S.; Niu, T.; Zhao, Y. Remaining useful life prediction of rolling bearings based on convolutional recurrent attention network. Assem. Autom. 2022, 42, 372–387. [Google Scholar] [CrossRef]

- Nistane, V. Optimum prediction model of remaining useful life for rolling element bearing based on integrating optimize health indicator (OHI) and machine learning algorithm. World J. Eng. 2022; ahead-of-print. [Google Scholar] [CrossRef]

- Desai, P.S.; Granja, V.; Higgs, C.; Fred, I. Lifetime Prediction Using a Tribology-Aware, Deep Learning-Based Digital Twin of Ball Bearing-Like Tribosystems in Oil and Gas. Processes 2021, 9, 922. [Google Scholar] [CrossRef]

- Farah, S.O.; Guessasma, M.; Bellenger, E. Digital twin by DEM for ball bearing operating under EHD conditions. Mech. Ind. 2020, 21, 506. [Google Scholar] [CrossRef]

- Xiong, M.; Wang, H.; Fu, Q.; Xu, Y. Digital twin–driven aero-engine intelligent predictive maintenance. Int. J. Adv. Manuf. Technol. 2021, 114, 3751–3761. [Google Scholar] [CrossRef]

- Liu, Z.; Chen, W.; Zhang, C.; Yang, C.; Chu, H. Data Super-Network Fault Prediction Model and Maintenance Strategy for Mechanical Product Based on Digital Twin. IEEE Access 2019, 7, 177284–177296. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Li, M.; Yan, Z.; Li, R.; Tian, A.; Xu, X.; Zhang, H. Application of Life Cycle of Aeroengine Mainshaft Bearing Based on Digital Twin. Processes 2023, 11, 1768. https://doi.org/10.3390/pr11061768

Li Y, Li M, Yan Z, Li R, Tian A, Xu X, Zhang H. Application of Life Cycle of Aeroengine Mainshaft Bearing Based on Digital Twin. Processes. 2023; 11(6):1768. https://doi.org/10.3390/pr11061768

Chicago/Turabian StyleLi, Yunfeng, Ming Li, Zhong Yan, Ruoxuan Li, Ao Tian, Xinming Xu, and Hang Zhang. 2023. "Application of Life Cycle of Aeroengine Mainshaft Bearing Based on Digital Twin" Processes 11, no. 6: 1768. https://doi.org/10.3390/pr11061768

APA StyleLi, Y., Li, M., Yan, Z., Li, R., Tian, A., Xu, X., & Zhang, H. (2023). Application of Life Cycle of Aeroengine Mainshaft Bearing Based on Digital Twin. Processes, 11(6), 1768. https://doi.org/10.3390/pr11061768