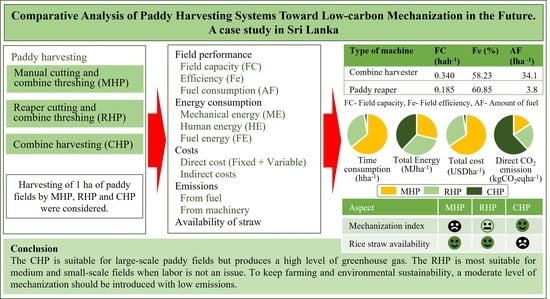

Comparative Analysis of Paddy Harvesting Systems toward Low-Carbon Mechanization in the Future: A Case Study in Sri Lanka

Abstract

:1. Introduction

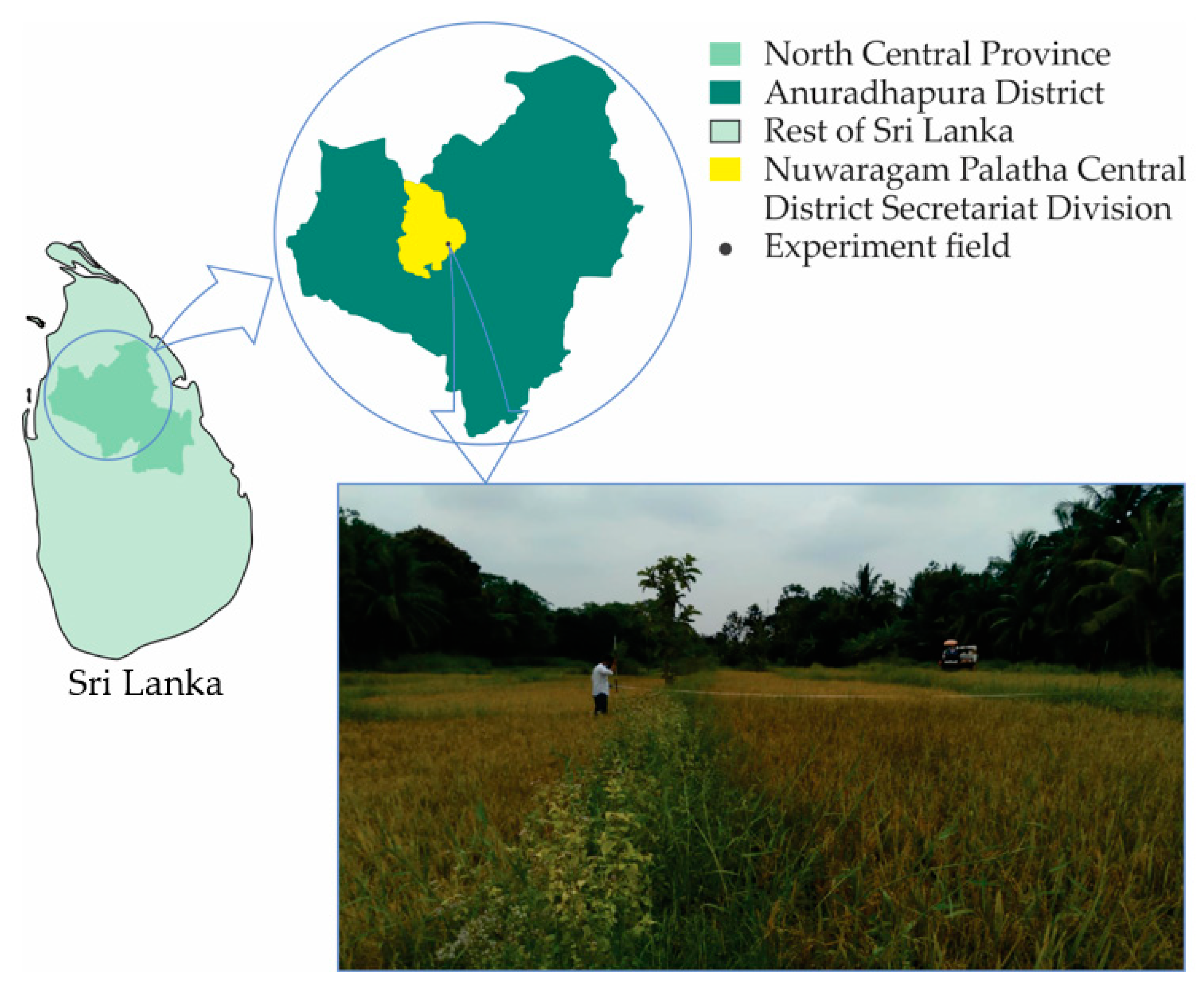

2. Materials and Methods

2.1. Overview of Harvesting Methods

2.1.1. Manual Cutting and Combine Threshing of Paddy (MHP)

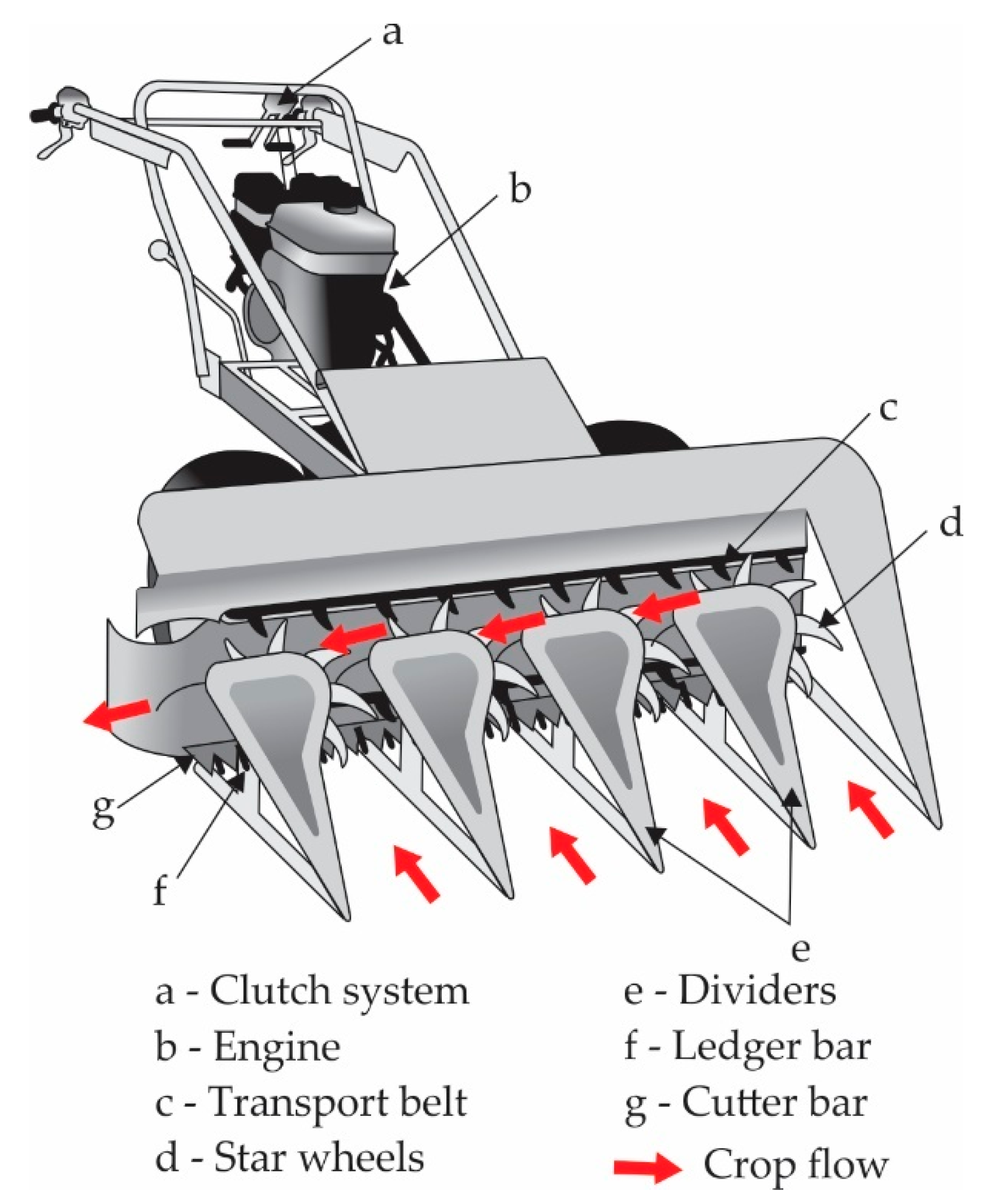

2.1.2. Reaper Cutting and Combine Threshing of Paddy (RHP)

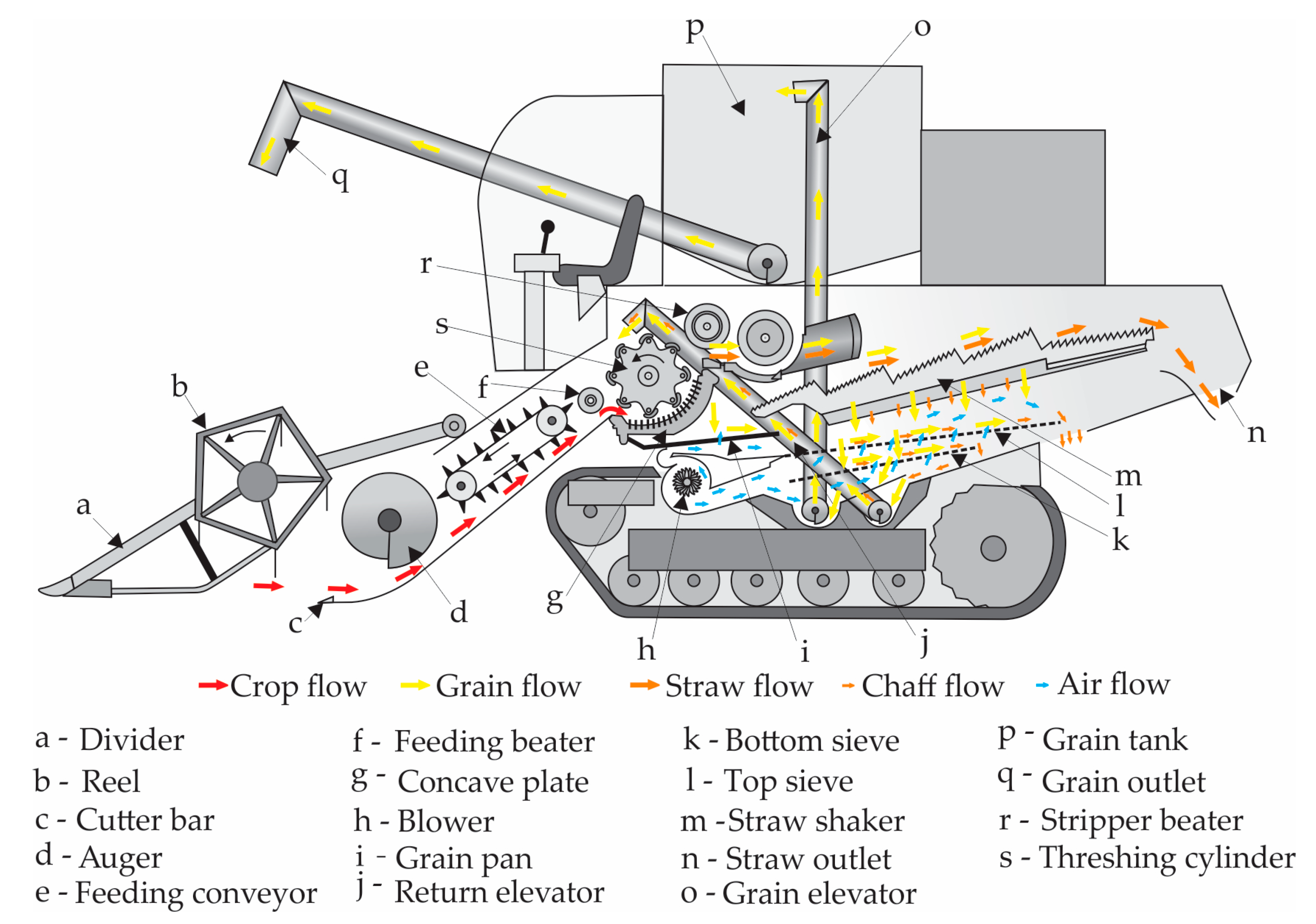

2.1.3. Combined Harvesting of Paddy (CHP)

2.2. Determination of Field Performance

2.2.1. Field and Ambient Conditions

2.2.2. Field Performance

Average Forward Speed (FS)

Field Capacity and Efficiency

Fuel Consumption (AF)

2.3. Total Energy Input for Paddy Harvesting (TEI)

2.3.1. Machinery Energy (ME)

2.3.2. Fuel Energy (FE)

2.3.3. Human Energy (HE)

2.3.4. Mechanization Index (MI)

2.4. Economic Analysis

2.5. Determination of Grain Loss in the Field

2.6. Determination of Greenhouse Gas Emissions from Harvesting Operations

3. Results

3.1. Field Performance of Harvesting Machinery

3.2. Human Involvement and Time Consumption of Each Harvesting System

3.3. Energy Consumption of Harvesting Systems

3.4. Machinery and Labor Cost of Harvesting

3.5. Grain Loss in the Field

3.6. Contribution to GHG Emissions

3.7. Indirect Costs of Harvesting Systems

4. Discussion

4.1. Field Performance

4.2. Human Involvement, Mechanization Index (MI), and Time Consumption

4.3. Energy Consumption

4.4. Direct Costs of Harvesting

4.5. Availability of Rice Straw, GHG Emissions, and Indirect Costs

5. Conclusions

- (1)

- CHP showed the highest field performance, lowest direct cost, lowest time consumption, lowest human input, and highest mechanization index (MI), making it the most suitable option for large-scale fields. Higher field performance and lower time consumption of CHP are mainly due to its higher MI. Integrating a rice straw compression mechanism is an alternative to reduce the indirect costs of combine harvesting to obtain maximum advantages of residual biomass while minimizing GHG emissions.

- (2)

- MHP was the most environment-friendly option with the highest availability of rice straw and lowest indirect cost, but the direct cost and time consumption were very high due to its lowest mechanization index and higher human involvement. RHP showed intermediate performance in all the considered aspects, providing equal availability of rice straw as MHP.

- (3)

- RHP exhibited a lower indirect cost showing good environmental friendliness and it is close to that of the MHP, which recorded the lowest indirect cost.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| A | Area |

| AF | Amount of fuel |

| ALq | Average loss within quadrant |

| BD | Bulk density |

| CEF | Carbon dioxide emission from fuel |

| CEM | Carbon dioxide emission from machine |

| CHP | Combine harvesting of paddy |

| CO2eq | Carbon dioxide equivalent |

| CW | Cutting width |

| D | Depreciation |

| EFC | Effective field capacity |

| FC | Fuel energy conversion coefficient |

| Fe | Field efficiency |

| FE | Fuel energy |

| FS | Forward speed |

| GHG | Greenhouse gas |

| GL | Grain loss |

| GWP | Global warming potential |

| h | Hour |

| ha | Hectare |

| HC | Energy conversion coefficient for human labor |

| HE | Human energy |

| I | Interest |

| i | Interest rate |

| L | Liter |

| LT | Lifetime |

| MC | Moisture content |

| ME | Mechanical energy |

| MEC | Energy conversion coefficient |

| MHP | Manual Harvesting of paddy |

| MI | Mechanical index |

| NLq | Natural loss of grain within quadrant |

| P | Value at purchasing |

| RF | Rainfall |

| RH | Relative humidity |

| RHP | Reaper harvesting of paddy |

| S | Salvage value |

| T | Temperature |

| t | Time |

| TEI | Total energy input |

| TFC | Theoretical field capacity |

| USD | United states dollar |

| W | Weight |

| WV | Wind velocity |

Appendix A

Appendix A.1. Statistical Analysis of Energy Consumption of Harvesting Systems

Appendix A.1.1. Human Energy—HE

| Source | Type III Sum of Squares | df | Mean Square | F | Sig. |

|---|---|---|---|---|---|

| Corrected Model | 99,401.726 a | 2 | 49,700.863 | 24,473.820 | 0.000 |

| Intercept | 167,174.318 | 1 | 167,174.318 | 82,320.385 | 0.000 |

| MH | 99,401.726 | 2 | 49,700.863 | 24,473.820 | 0.000 |

| Error | 24.369 | 12 | 2.031 | ||

| Total | 266,600.413 | 15 | |||

| Corrected Total | 99,426.095 | 14 |

| (I) MH | (J) MH | Mean Difference (I-J) | Std. Error | Sig. | 95% Confidence Interval | |

|---|---|---|---|---|---|---|

| Lower Bound | Upper Bound | |||||

| 1.00 | 2.00 | 105.8660 * | 0.90128 | 0.000 | 103.9023 | 107.8297 |

| 3.00 | 199.2710 * | 0.90128 | 0.000 | 197.3073 | 201.2347 | |

| 2.00 | 1.00 | −105.8660 * | 0.90128 | 0.000 | −107.8297 | −103.9023 |

| 3.00 | 93.4050 * | 0.90128 | 0.000 | 91.4413 | 95.3687 | |

| 3.00 | 1.00 | −199.2710 * | 0.90128 | 0.000 | −201.2347 | −197.3073 |

| 2.00 | −93.4050 * | 0.90128 | 0.000 | −95.3687 | −91.4413 | |

Appendix A.1.2. Machinery Energy—ME

| Source | Type III Sum of Squares | df | Mean Square | F | Sig. |

|---|---|---|---|---|---|

| Corrected Model | 382,034.616 a | 2 | 191,017.308 | 2151.453 | 0.000 |

| Intercept | 651,758.531 | 1 | 651,758.531 | 7340.840 | 0.000 |

| MH | 382,034.616 | 2 | 191,017.308 | 2151.453 | 0.000 |

| Error | 1065.423 | 12 | 88.785 | ||

| Total | 1,034,858.569 | 15 | |||

| Corrected Total | 383,100.039 | 14 |

| (I) MH | (J) MH | Mean Difference (I-J) | Std. Error | Sig. | 95% Confidence Interval | |

|---|---|---|---|---|---|---|

| Lower Bound | Upper Bound | |||||

| 1.00 | 2.00 | −32.6040 * | 5.95937 | 0.000 | −45.5884 | −19.6196 |

| 3.00 | −353.6640 * | 5.95937 | 0.000 | −366.6484 | −340.6796 | |

| 2.00 | 1.00 | 32.6040 * | 5.95937 | 0.000 | 19.6196 | 45.5884 |

| 3.00 | −321.0600 * | 5.95937 | 0.000 | −334.0444 | −308.0756 | |

| 3.00 | 1.00 | 353.6640 * | 5.95937 | 0.000 | 340.6796 | 366.6484 |

| 2.00 | 321.0600 * | 5.95937 | 0.000 | 308.0756 | 334.0444 | |

Appendix A.1.3. Fuel Energy—FE

| Source | Type III Sum of Squares | df | Mean Square | F | Sig. |

|---|---|---|---|---|---|

| Corrected Model | 3.465 × 106 | 2 | 1,732,464.717 | 11,232.970 | 0.000 |

| Intercept | 1.022 × 107 | 1 | 1.022 × 107 | 66,236.296 | 0.000 |

| MH | 3,464,929.433 | 2 | 1,732,464.717 | 11,232.970 | 0.000 |

| Error | 1850.764 | 12 | 154.230 | ||

| Total | 1.368 × 107 | 15 | |||

| Corrected Total | 3,466,780.197 | 14 |

| (I) MH | (J) MH | Mean Difference (I-J) | Std. Error | Sig. | 95% Confidence Interval | |

|---|---|---|---|---|---|---|

| Lower Bound | Upper Bound | |||||

| 1.00 | 2.00 | −170.1000 * | 7.85443 | 0.000 | −187.2133 | −152.9867 |

| 3.00 | −1093.9000 * | 7.85443 | 0.000 | −1111.0133 | −1076.7867 | |

| 2.00 | 1.00 | 170.1000 * | 7.85443 | 0.000 | 152.9867 | 187.2133 |

| 3.00 | −923.8000 * | 7.85443 | 0.000 | −940.9133 | −906.6867 | |

| 3.00 | 1.00 | 1093.9000 * | 7.85443 | 0.000 | 1076.7867 | 1111.0133 |

| 2.00 | 923.8000 * | 7.85443 | 0.000 | 906.6867 | 940.9133 | |

Appendix A.1.4. Total Energy—TE

| Source | Type III Sum of Squares | df | Mean Square | F | Sig. |

|---|---|---|---|---|---|

| Corrected Model | 4.822 × 106 | 2 | 2,411,218.024 | 7725.941 | 0.000 |

| Intercept | 1.947 × 107 | 1 | 1.947 × 107 | 62,382.136 | 0.000 |

| MH | 4,822,436.049 | 2 | 2,411,218.024 | 7725.941 | 0.000 |

| Error | 3745.125 | 12 | 312.094 | ||

| Total | 2.430 × 107 | 15 | |||

| Corrected Total | 4,826,181.174 | 14 |

| (I) MH | (J) MH | Mean Difference (I-J) | Std. Error | Sig. | 95% Confidence Interval | |

|---|---|---|---|---|---|---|

| Lower Bound | Upper Bound | |||||

| 1.00 | 2.00 | −96.8380 * | 11.17307 | 0.000 | −121.1820 | −72.4940 |

| 3.00 | −1248.2930 * | 11.17307 | 0.000 | −1272.6370 | −1223.9490 | |

| 2.00 | 1.00 | 96.8380 * | 11.17307 | 0.000 | 72.4940 | 121.1820 |

| 3.00 | −1151.4550 * | 11.17307 | 0.000 | −1175.7990 | −1127.1110 | |

| 3.00 | 1.00 | 1248.2930 * | 11.17307 | 0.000 | 1223.9490 | 1272.6370 |

| 2.00 | 1151.4550 * | 11.17307 | 0.000 | 1127.1110 | 1175.7990 | |

Appendix A.1.5. Mechanization Index—MI

| Source | Type III Sum of Squares | df | Mean Square | F | Sig. |

|---|---|---|---|---|---|

| Corrected Model | 1.277 a | 2 | 0.638 | 7975.441 | 0.000 |

| Intercept | 5.309 | 1 | 5.309 | 66,332.427 | 0.000 |

| MH | 1.277 | 2 | 0.638 | 7975.441 | 0.000 |

| Error | 0.001 | 12 | 8.003 × 10−5 | ||

| Total | 6.586 | 15 | |||

| Corrected Total | 1.278 | 14 |

| (I) MH | (J) MH | Mean Difference (I-J) | Std. Error | Sig. | 95% Confidence Interval | |

|---|---|---|---|---|---|---|

| Lower Bound | Upper Bound | |||||

| 1.00 | 2.00 | −0.2481 * | 0.00566 | 0.000 | −0.2604 | −0.2357 |

| 3.00 | −0.7044 * | 0.00566 | 0.000 | −0.7167 | −0.6921 | |

| 2.00 | 1.00 | 0.2481 * | 0.00566 | 0.000 | 0.2357 | 0.2604 |

| 3.00 | −0.4563 * | 0.00566 | 0.000 | −0.4687 | −0.4440 | |

| 3.00 | 1.00 | 0.7044 * | 0.00566 | 0.000 | 0.6921 | 0.7167 |

| 2.00 | 0.4563 * | 0.00566 | 0.000 | 0.4440 | 0.4687 | |

Appendix B

Appendix B.1. Statistical Analysis of Grain Losses of Harvesting Systems

Appendix B.1.1. Grain Losses at Cutting Operation—CUT GL

| Source | Type III Sum of Squares | df | Mean Square | F | Sig. |

|---|---|---|---|---|---|

| Corrected Model | 606.060 a | 2 | 303.030 | 3178.636 | 0.000 |

| Intercept | 4846.944 | 1 | 4846.944 | 50,842.074 | 0.000 |

| PHM | 606.060 | 2 | 303.030 | 3178.636 | 0.000 |

| Error | 0.572 | 6 | 0.095 | ||

| Total | 5453.576 | 9 | |||

| Corrected Total | 606.632 | 8 |

| (I) PHM | (J) PHM | Mean Difference (I-J) | Std. Error | Sig. | 95% Confidence Interval | |

|---|---|---|---|---|---|---|

| Lower Bound | Upper Bound | |||||

| 1 | 2 | 6.9000 * | 0.25210 | 0.000 | 6.2831 | 7.5169 |

| 3 | −12.9000 * | 0.25210 | 0.000 | −13.5169 | −12.2831 | |

| 2 | 1 | −6.9000 * | 0.25210 | 0.000 | −7.5169 | −6.2831 |

| 3 | −19.8000 * | 0.25210 | 0.000 | −20.4169 | −19.1831 | |

| 3 | 1 | 12.9000 * | 0.25210 | 0.000 | 12.2831 | 13.5169 |

| 2 | 19.8000 * | 0.25210 | 0.000 | 19.1831 | 20.4169 | |

Appendix B.1.2. Grain Loss Percentage—Perce GL

| Source | Type III Sum of Squares | df | Mean Square | F | Sig. |

|---|---|---|---|---|---|

| Corrected Model | 6.990 a | 2 | 3.495 | 606.087 | 0.000 |

| Intercept | 34.340 | 1 | 34.340 | 5954.844 | 0.000 |

| PHM | 6.990 | 2 | 3.495 | 606.087 | 0.000 |

| Error | 0.035 | 6 | 0.006 | ||

| Total | 41.364 | 9 | |||

| Corrected Total | 7.025 | 8 |

| (I) PHM | (J) PHM | Mean Difference (I-J) | Std. Error | Sig. | 95% Confidence Interval | |

|---|---|---|---|---|---|---|

| Lower Bound | Upper Bound | |||||

| 1 | 2 | 0.1500 | 0.06200 | 0.052 | −0.0017 | 0.3017 |

| 3 | 1.9400 * | 0.06200 | 0.000 | 1.7883 | 2.0917 | |

| 2 | 1 | −0.1500 | 0.06200 | 0.052 | −0.3017 | 0.0017 |

| 3 | 1.7900 * | 0.06200 | 0.000 | 1.6383 | 1.9417 | |

| 3 | 1 | −1.9400 * | 0.06200 | 0.000 | −2.0917 | −1.7883 |

| 2 | −1.7900 * | 0.06200 | 0.000 | −1.9417 | −1.6383 | |

References

- Mohidem, N.A.; Hashim, N.; Shamsudin, R.; Man, H.C. Rice for Food Security: Revisiting Its Production, Diversity, Rice Milling Process and Nutrient Content. Agriculture 2022, 12, 741. [Google Scholar] [CrossRef]

- Chandrajith, U.G.; Gunathilake, D.M.C.C.; Bandara, B.D.M.P.; Swarnasiri, D.P.C. Effects of Combine Harvesting on Head Rice Yield and Chaff Content of Long and Short Grain Paddy Harvest in Sri Lanka. Procedia Food Sci. 2016, 6, 242–245. [Google Scholar] [CrossRef] [Green Version]

- Muazu, A.; Yahya, A.; Ishak, W.I.W.; Khairunniza-Bejo, S. Machinery Utilization and Production Cost of Wetland, Direct Seeding Paddy Cultivation in Malaysia. Agric. Agric. Sci. Procedia 2014, 2, 361–369. [Google Scholar] [CrossRef] [Green Version]

- Gummert, M. When to Harvest—IRRI Rice Knowledge Bank. Available online: http://www.knowledgebank.irri.org/training/fact-sheets/item/when-to-harvest-fact-sheet (accessed on 14 August 2022).

- Mafakheri, F.; Nasiri, F. Modeling of biomass-to-energy supply chain operations: Applications, challenges and research directions. Energy Policy 2014, 67, 116–126. [Google Scholar] [CrossRef]

- Harun, S.N.; Hanafiah, M.M.; Aziz, N.I.H.A. An LCA-Based Environmental Performance of Rice Production for Developing a Sustainable Agri-Food System in Malaysia. Environ. Manag. 2021, 67, 146–161. [Google Scholar] [CrossRef]

- Jiang, M.; Hu, X.; Chunga, J.; Lin, Z.; Fei, R. Does the popularization of agricultural mechanization improve energy-environment performance in China’s agricultural sector? J. Clean. Prod. 2020, 276, 124210. [Google Scholar] [CrossRef]

- Lampridi, M.; Kateris, D.; Sørensen, C.G.; Bochtis, D. Energy footprint of mechanized agricultural operations. Energies 2020, 13, 769. [Google Scholar] [CrossRef] [Green Version]

- Mokhtor, S.A.; El Pebrian, D.; Johari, N.A.A. Actual field speed of rice combine harvester and its influence on grain loss in Malaysian paddy field. J. Saudi Soc. Agric. Sci. 2020, 19, 422–425. [Google Scholar] [CrossRef]

- Alam, S.; Rashedujjaman, M.; Hossain, M.; Hossain, K. Comparative Harvesting and Threshing Cost of Paddy by Combine Harvester and Self-propelled Reaper and Thresher. J. Environ. Sci. Nat. Resour. 2017, 10, 133–136. [Google Scholar] [CrossRef] [Green Version]

- Nadeem, M.; Ghani, M.U. Cost Analysis of Engine Operated Reaper and Its Comparison. J. Glob. Agric. Soc. Sci. 2018, 6, 2312–5225. [Google Scholar]

- Putri, R.E.; Santosa; Cahyani, G.A.; Fahmy, K.; Arlius, F.; Hasan, A. Comparison of Performance and Total Energy Requirement for Several Harvesting Method of Indonesian Farmers. IOP Conf. Ser. Earth Environ. Sci. 2020, 515, 012004. [Google Scholar] [CrossRef]

- Hasan, M.; Ali, M.; Saha, C.; Alam, M.; Hossain, M. Assessment of paddy harvesting practices of Southern Delta Region in Bangladesh. Progress. Agric. 2019, 30, 57–64. [Google Scholar] [CrossRef] [Green Version]

- Abeyrathna, R.M.R.D.; Nakaguchi, V.M.; Minn, A.; Ahamed, T. Recognition and Counting of Apples in a Dynamic State Using a 3D Camera and Deep Learning Algorithms for Robotic Harvesting Systems. Sensors 2023, 23, 3810. [Google Scholar] [CrossRef]

- Huang, Y.; Fu, J.; Xu, S.; Han, T.; Liu, Y. Research on Integrated Navigation System of Agricultural Machinery Based on RTK-BDS/INS. Agriculture 2022, 12, 1169. [Google Scholar] [CrossRef]

- Hasan, M.K.; Tanaka, T.S.T.; Alam, M.M.; Ali, M.R.; Saha, C.K. Impact of modern rice harvesting practices over traditional ones. Rev. Agric. Sci. 2020, 8, 89–108. [Google Scholar] [CrossRef] [PubMed]

- Islam, A.K.M.S.; Alam, M.A.; Ashik-E-Rabbani, M.; Bashir, M.S.; Rahman, M.M. Techno-Economic Feasibility of Zoomlion Combine Harvester in Haor Areas of Bangladesh. Agric. Sci. 2020, 11, 1170–1185. [Google Scholar] [CrossRef]

- Elsoragaby, S.; Yahya, A.; Mahadi, M.R.; Nawi, N.M.; Mairghany, M. Comparative field performances between conventional combine and mid-size combine in wetland rice cultivation. Heliyon 2019, 5, 1427. [Google Scholar] [CrossRef] [Green Version]

- ASAE Standards. ASAE D497.4 Agricultural Machinery Management Data; American Society of Agricultural Engineers: St. Joseph, MI, USA, 2000; Volume 85. [Google Scholar]

- Eurostat. Energy Balance Guide Methodology Guide for the Construction of Energy Balances & Operational Guide for the Energy Balance Builder Tool; European Commission: Ljubljana, Slovenia, 2019.

- Quilty, J.R.; McKinley, J.; Pede, V.O.; Buresh, R.J.; Correa, T.Q.; Sandro, J.M. Energy efficiency of rice production in farmers’ fields and intensively cropped research fields in the Philippines. Field Crop. Res. 2014, 168, 8–18. [Google Scholar] [CrossRef]

- Alam, M.A.; Hossen, A.; Islam, A.S.; Alam, M. Performance evaluation of power-operated reapers for harvesting rice at farmers’ field. J. Bangladesh Agric. Univ. 2018, 16, 144–150. [Google Scholar] [CrossRef] [Green Version]

- Edwards, W. Estimating Farm Machinery Costs. Available online: https://www.extension.iastate.edu/agdm/crops/html/a3-29.html (accessed on 18 August 2022).

- Schuler, R.T.; Frank, G.G. Estimating Agricultural Field Machinery Costs. Agric. Bull. Rm. 2010, 30, 1–12. [Google Scholar]

- Nabavi-Pelesaraei, A.; Abdi, R.; Rafiee, S. Neural network modeling of energy use and greenhouse gas emissions of watermelon production systems. J. Saudi Soc. Agric. Sci. 2016, 15, 38–47. [Google Scholar] [CrossRef] [Green Version]

- EIA Carbon Dioxide Emissions Coefficients. Available online: https://www.eia.gov/environment/emissions/co2_vol_mass.php (accessed on 22 August 2022).

- Bergh, J.V.D.; Botzen, W. Monetary valuation of the social cost of CO2 emissions: A critical survey. Ecol. Econ. 2015, 114, 33–46. [Google Scholar] [CrossRef]

- Hossain, M.; Hoque, M.; Wohab, M.; Miah, M.M.; Hassan, M. Technical and economic performance of combined harvester in farmers’ field. Bangladesh J. Agric. Res. 2015, 40, 291–304. [Google Scholar] [CrossRef]

- Wagiman, N.A.; Nawi, N.M.; Yahya, A.; Su, A.S.M.; Nasir, R.M. Field performance comparison of the combine harvesters utilized for rice harvesting in Malaysia. Food Res. 2019, 3, 177–181. [Google Scholar] [CrossRef] [PubMed]

- Durczak, K.; Rybacki, P.; Sujak, A. Application of a Selected Pseudorandom Number Generator for the Reliability of Farm Tractors. Appl. Sci. 2022, 12, 12452. [Google Scholar] [CrossRef]

- Kutelia, G.; Abuladze, I.; Beridze, G. Improving the Reliability of Agricultural Machinery, Using the Method of Restoration of Parts Under Submerged Arc Welding, and Its Technical and Economic Evaluation. Int. Sci. J. Sci. Tech. Union Mech. Eng. 2017, 310, 307–310. [Google Scholar]

- Tshotsho; Lippert, C.; Feuerbacher, A. Organic agriculture, labour exchange, and social networks: A case study of smallholder farming in Bhutan. Org. Agric. 2023, 13, 83–98. [Google Scholar] [CrossRef]

- Martins, F.; Felgueiras, C.; Smitkova, M.; Caetano, N. Analysis of fossil fuel energy consumption and environmental impacts in european countries. Energies 2019, 12, 964. [Google Scholar] [CrossRef] [Green Version]

- Rostom, A.; Hasan, K.; Saha, C.K.; Alam, M.; Kalita, P.K.; Hansen, A.C. Mechanized rice harvesting opportunity in Southern delta of Bangladesh. In Proceedings of the 2017 ASABE Annual International Meeting, St. Joseph, MI, USA, 15–19 July 2017. [Google Scholar]

- Lohan, S.K.; Jat, H.S.; Yadav, A.K.; Sidhu, H.S.; Jat, M.L.; Choudhary, M.; Peter, J.K.; Sharma, P.C. Burning issues of paddy residue management in north-west states of India. Renew. Sustain. Energy Rev. 2018, 81, 693–706. [Google Scholar] [CrossRef]

- Awad, M.; Fouda, O.; Fathy, W.; El Balkemy, W.; Egela, M.; El-Fakhrany, W.; Okasha, M. A combined machine for collecting and chopping rice straw. Heliyon 2022, 8, e10412. [Google Scholar] [CrossRef]

- Rennert, K.; Errickson, F.; Prest, B.C.; Rennels, L.; Newell, R.G.; Pizer, W.; Kingdon, C.; Wingenroth, J.; Cooke, R.; Parthum, B.; et al. Comprehensive evidence implies a higher social cost of CO2. Nature 2022, 610, 687–692. [Google Scholar] [CrossRef] [PubMed]

| Type of Machine | Specifications | ||||

|---|---|---|---|---|---|

| Power Output (hp) | Cutting Width/Threshing Drum Width (m) | Weight (kg) | Fuel Type | Capacity of Grain Tank (L) | |

| Combine harvester | 68 | 1.98 | 3200 | Diesel | 1250 |

| Paddy reaper | 2.7 | 1.2 | 130 | Gasoline | - |

| Combine thresher | 10 | 0.9 | 400 | Diesel | - |

| Parameter | Unit | Paddy Reaper | Combine Harvester | Combine Thresher |

|---|---|---|---|---|

| Purchase price | USD | 1142.86 | 14,257.14 | 1000 |

| Salvage value | USD | 114.28 | 1425.71 | 100 |

| Expected life | Years | 10 | 10 | 10 |

| Annual working time | h | 300 | 300 | 300 |

| Interest rate | % | 12 | 12 | 12 |

| Labor charges | USDh−1 | 0.57 | 0.57 | 0.57 |

| Fuel price | USDL−1 | 1.54 (Gasoline) | 1.23 (Diesel) | 1.23 (Diesel) |

| Parameter | MHP | RHP | CHP | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Avg. | Max. | Min. | Avg. | Max. | Min. | Avg. | Max. | Min. | |

| MC (%) | 15.96 | 20.47 | 13.31 | 13.38 | 14.16 | 12.3 | 13.39 | 15.84 | 11.73 |

| BD (gcm−3) | 1.19 | 1.22 | 1.15 | 1.13 | 1.2 | 1.03 | 1.12 | 1.16 | 0.95 |

| T (°C) | 35 | 36 | 34 | 34 | 34 | 33 | 35 | 36 | 33 |

| RH (%) | 55 | 57 | 53 | 55 | 57 | 53 | 59 | 61 | 56 |

| RF (mm) | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| WV (kmh−1) | 24.65 | 26.81 | 22.31 | 24.15 | 26.56 | 21.25 | 26.4 | 27.37 | 24.31 |

| Type of Machine | FS (ms−1) | TFC (hah−1) | EFC (hah−1) | Fe (%) | AF (lha −1) |

|---|---|---|---|---|---|

| Combine harvester | 0.82 a | 0.584 a | 0.340 a | 58.23 a | 34.1 a |

| (0.009) | (0.006) | (0.005) | (1.056) | (0.172) | |

| Paddy reaper | 0.70 b | 0.304 b | 0.185 b | 60.85 b | 3.8 b |

| (0.01) | (0.004) | (0.001) | (0.456) | (0.096) |

| Harvesting Method | HE (MJha−1) | ME (MJha−1) | FE (MJha−1) | Total Energy (MJha−1) | Mechanization Index (MI) |

|---|---|---|---|---|---|

| MHP | 207.28 a | 79.69 a | 403.92 a | 690.89 a | 0.28 a |

| (0.77) | (2.76) | (3.23) | (6.07) | (0.0006) | |

| RHP | 101.41 b | 112.29 b | 574.02 b | 787.73 b | 0.52 b |

| (0.44) | (0.23) | (5.01) | (4.75) | (0.0015) | |

| CHP | 8.01 c | 433.35 c | 1497.82 c | 1939.18 c | 0.98 c |

| (0.19) | (6.75) | (7.54) | (11.30) | (0.0006) |

| Cost Component | Unit | Paddy Reaper | Combine Harvester | Combine Thresher |

|---|---|---|---|---|

| Depreciation | USDh−1 | 0.34 | 4.28 | 0.30 |

| Interest | USDh−1 | 0.05 | 0.63 | 0.04 |

| Housing, taxes, and insurance | USDh−1 | 0.08 | 0.95 | 0.07 |

| Fuel cost | USDh−1 | 1.08 | 14.26 | 2.60 |

| Lubrication cost | USDh−1 | 0.16 | 2.14 | 0.39 |

| Repair and maintenance | USDh−1 | 0.57 | 7.13 | 0.50 |

| Total cost | USDh−1 | 2.29 | 29.38 | 3.90 |

| Harvesting Method | Cost of Machinery (USDha−1) | Labor Cost (USDha−1) | Total Cost (USDha−1) |

|---|---|---|---|

| MHP | 16.97 | 133.00 | 149.97 |

| RHP | 29.36 | 64.70 | 94.06 |

| CHP | 86.38 | 5.13 | 91.51 |

| Harvesting System | Grain Loss at the Field (kgha−1) | Grain Loss Percentage (%) | ||

|---|---|---|---|---|

| Cutting | Collecting and Transporting | Combine Threshing | ||

| MHP | 21.2 a | 22.4 a | 83.4 a | 2.65 a |

| (0.25) | (0.02) | (0.24) | (0.03) | |

| RHP | 14.3 b | 22.4 a | 83.4 a | 2.50 a |

| (0.06) | (0.04) | (0.17) | (0.04) | |

| CHP | 34.1 c | - | - | 0.71 b |

| (0.16) | (0.04) | |||

| Cost Component | MHP | RHP | CHP |

|---|---|---|---|

| Direct cost (USD) | |||

| Machinery cost | 16.97 | 29.36 | 86.38 |

| Labor cost | 133.00 | 64.70 | 5.13 |

| Indirect cost (USD) | |||

| SCC | 3.89 | 5.45 | 20.80 |

| Grain loss | 25.40 | 23.96 | 6.80 |

| Straw collection | - | - | 88.31 |

| Total | 179.26 | 123.47 | 207.42 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kahandage, P.D.; Piyathissa, S.D.S.; Ariesca, R.; Namgay; Ishizaki, R.; Kosgollegedara, E.J.; Weerasooriya, G.V.T.V.; Ahamed, T.; Noguchi, R. Comparative Analysis of Paddy Harvesting Systems toward Low-Carbon Mechanization in the Future: A Case Study in Sri Lanka. Processes 2023, 11, 1851. https://doi.org/10.3390/pr11061851

Kahandage PD, Piyathissa SDS, Ariesca R, Namgay, Ishizaki R, Kosgollegedara EJ, Weerasooriya GVTV, Ahamed T, Noguchi R. Comparative Analysis of Paddy Harvesting Systems toward Low-Carbon Mechanization in the Future: A Case Study in Sri Lanka. Processes. 2023; 11(6):1851. https://doi.org/10.3390/pr11061851

Chicago/Turabian StyleKahandage, P. D., S. D. S. Piyathissa, Reza Ariesca, Namgay, Riaru Ishizaki, E. J. Kosgollegedara, G. V. T. V. Weerasooriya, Tofael Ahamed, and Ryozo Noguchi. 2023. "Comparative Analysis of Paddy Harvesting Systems toward Low-Carbon Mechanization in the Future: A Case Study in Sri Lanka" Processes 11, no. 6: 1851. https://doi.org/10.3390/pr11061851

APA StyleKahandage, P. D., Piyathissa, S. D. S., Ariesca, R., Namgay, Ishizaki, R., Kosgollegedara, E. J., Weerasooriya, G. V. T. V., Ahamed, T., & Noguchi, R. (2023). Comparative Analysis of Paddy Harvesting Systems toward Low-Carbon Mechanization in the Future: A Case Study in Sri Lanka. Processes, 11(6), 1851. https://doi.org/10.3390/pr11061851