A Fault Diagnosis Method for Drilling Pump Fluid Ends Based on Time–Frequency Transforms

Abstract

1. Introduction

2. Preparations

2.1. Time–Frequency Transform Method

2.1.1. Generalized S Transform

2.1.2. Short-Time Fourier Transform

2.1.3. Wigner–Ville Distribution

2.1.4. Continuous Wavelet Transform

2.2. Convolutional Neural Networks

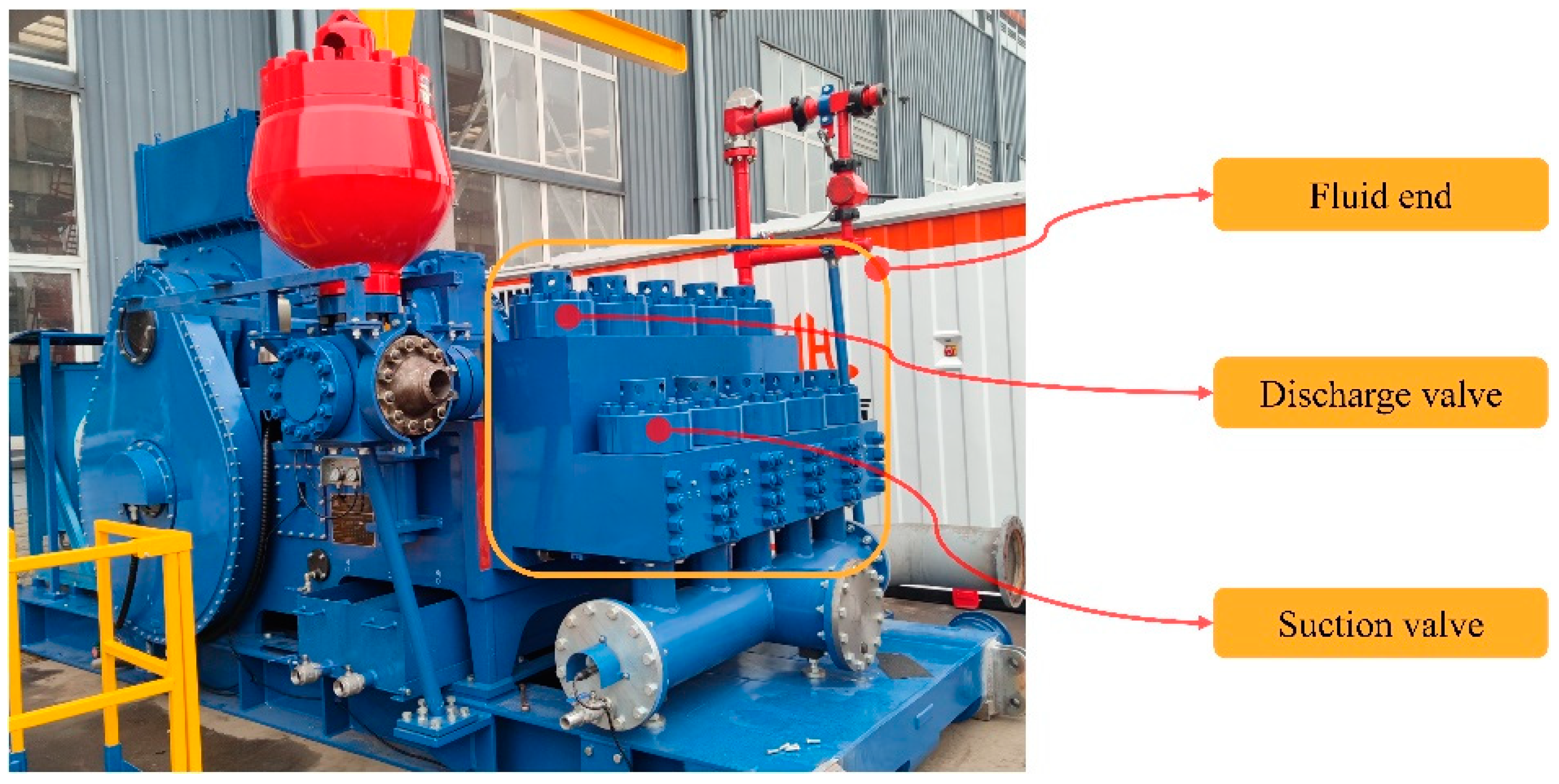

3. Drilling Pump Fluid End Fault Diagnosis

3.1. Time–Frequency Image Generation

3.2. Network Structure Optimization

3.3. Fluid End Fault Diagnosis Process

- (1)

- Collecting vibration signals from the fluid end valve box of the drilling pump under different damage degrees of the SV and the DV at the fluid end.

- (2)

- Converting the vibration signals of valve boxes in different states into time–frequency images, using GST to form image datasets.

- (3)

- Dividing the dataset into training and test sets, inputting them into the optimized AlexNet model for training and prediction, calculating the accuracy rate, outputting the confusion matrix, and visualizing the diagnosis results.

4. Fluid End Diagnosis Results and Analysis

4.1. Signal Acquisition Experiment

4.2. Experimental Data Process

4.3. Comparison of Diagnostic Results

5. Conclusions

- (1)

- A GST-CNN-based fault diagnosis method is proposed for the fluid end, which achieves higher fault diagnosis accuracy compared to traditional machine learning methods.

- (2)

- This study explores the optimization of the AlexNet model by incorporating a batch normalization layer (BN) and adjusting the number of neurons. The findings suggest that adding the BN layer to the AlexNet model, along with an appropriate number of fully connected layer neurons, can improve the accuracy of fault diagnosis.

- (3)

- The diagnostic model proposed in this approach has been shown to achieve an impressive average accuracy rate of 99.21% for diagnosing the nine categories of the fluid end. This surpasses the performance of many other available diagnostic methods and provides a fast and reliable alternative in the diagnosis of the fluid end. This development provides a useful tool for ensuring optimal performance and efficiency of fluid ends.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yang, Q.J.; Pei, J.F.; Tian, J.H. Working condition monitoring and fault diagnosis of valves in triplex drilling pump. J. Univ. Pet. China Ed. Nat. Sci. 1998, 22, 60–62. [Google Scholar]

- Junfeng, P.; Siwei, Z.; Mingxia, Q.; Guangwei, W.A.N. A new method for fault diagnosis of fluid end in drilling pump. Acta Pet. Sin. 2009, 30, 617–620. [Google Scholar]

- Zhang, Z.D.; Ai, Z.J.; Zheng, W.; Li, B.; Zhong, G.X. Study on Fault Diagnosis Technology for Fluid End of Drilling Pump. J. Southwest Pet. Univ. Sci. Technol. Ed. 2015, 37, 167–173. [Google Scholar]

- Gao, J.F.; Shi, W.G. Support Vector Machines Based Approach for Fault Reciprocating Pumps. In Proceedings of the 2002 IEEE Canadian Conference on Electrical and Computer Engineering, Winnipeg, MB, Canada, 12–15 May 2002; pp. 1622–1627. [Google Scholar]

- Li, G.; Hu, J.; Shan, D.; Ao, J.X.; Huang, B.K.; Huang, Z.Q. A CNN model based on innovative expansion operation improving the fault diagnosis accuracy of drilling pump fluid end. Mech. Syst. Signal Process. 2023, 187, 109974. [Google Scholar] [CrossRef]

- Li, B.; Huang, H.; Wang, T.; Wang, P.; Wang, M.; Shi, J.; Xue, S. Research on seismic signal classification and recognition based on STFT and CNN. Geophysics 2021, 36, 1404–1411. [Google Scholar]

- Cai, K.; Cao, W.; Aarniovuori, L.; Pang, H.; Lin, Y.; Li, G. Classification of power quality disturbances using Wigner-Ville distribution and deep convolutional neural networks. IEEE Access 2019, 7, 119099–119109. [Google Scholar] [CrossRef]

- Miao, R.; Gao, Y.; Ge, L.; Jiang, Z.; Zhang, J. Online defect recognition of narrow overlap weld based on a two-stage recognition model combining continuous wavelet transform and convolutional neural network. Comput. Ind. 2019, 112, 103115. [Google Scholar] [CrossRef]

- Luo, J.H.; Huang, G.Y. Check valve fault diagnosis based on generalized S transform and deep belief network. J. Electron. Meas. Instrum. 2019, 33, 192–198. [Google Scholar]

- Chen, H.; Yi, Y.; Chen, W.; Chen, P.; Shen, J. Fault Diagnosis Method of Gearbox Bearings Based on Generalized S-transform. China Mech. Eng. 2017, 28, 51–56. [Google Scholar]

- Liu, M.; Chen, J.; Zhang, Y.; Chen, Y.; Fan, H.; Zhang, Y. Engine Fault Diagnosis Based on Synchrosqueezing Generalized S-transform. J. Vib. Meas. Diagn. 2021, 41, 984–990. [Google Scholar]

- Wang, C.J.; Yang, P.J.; Luo, H.M.; Xu, X.K. Time-variable frequency division based on generalized S transform. Geophys. Prospect. Pet. 2013, 52, 489–494. [Google Scholar]

- Stockwell, R.G.; Mansinha, L.; Lowe, R.P. Localization of the complex spectrum: The S transform. IEEE Trans. Signal Process. 1996, 44, 998–1001. [Google Scholar] [CrossRef]

- Cai, J.H.; Xiao, Y.L. Denoising of MT Data by Time-Frequency Filtering Based on the Generalized S transform. Geol. Explor. 2021, 57, 1383–1390. [Google Scholar]

- McFadden, P.D.; Cook, J.G.; Forster, L.M. Decomposition of gear vibration signals by the generalised S transform. Mech. Syst. Signal Process. 1999, 13, 691–707. [Google Scholar] [CrossRef]

- Pinnegar, C.R.; Mansinha, L. The S transform with windows of arbitrary and varying shape. Geophysics 2003, 68, 381–385. [Google Scholar] [CrossRef]

- Gabor, D. Theory of communication. Part 1: The analysis of information. J. Inst. Electr. Eng.—Part III Radio Commun. Eng. 1946, 93, 429–441. [Google Scholar] [CrossRef]

- Wigner, E.P. On the quantum correction for thermodynamic equilibrium. In Part I: Physical Chemistry. Part II: Solid State Physics; Springer: Berlin/Heidelberg, Germany, 1997; pp. 110–120. [Google Scholar]

- Grossmann, A.; Morlet, J. Decomposition of Hardy functions into square integrable wavelets of constant shape. SIAM J. Math. Anal. 1984, 15, 723–736. [Google Scholar] [CrossRef]

- Hubel, D.H.; Wiesel, T.N. Receptive fields, binocular interaction and functional architecture in the cat’s visual cortex. J. Physiol. 1962, 160, 106–154. [Google Scholar] [CrossRef] [PubMed]

- Kiranyaz, S.; Avci, O.; Abdeljaber, O.; Ince, T.; Gabbouj, M.; Inman, D.J. 1D convolutional neural networks and applications: A survey. Mech. Syst. Signal Process. 2021, 151, 107398. [Google Scholar] [CrossRef]

- Lei, Y.; Yang, B.; Jiang, X.; Jia, F.; Li, N.; Nandi, A.K. Applications of machine learning to machine fault diagnosis: A review and roadmap. Mech. Syst. Signal Process. 2020, 138, 106587. [Google Scholar] [CrossRef]

- Krizhevsky, A.; Sutskever, I.; Hinton, G.E. Imagenet classification with deep convolutional neural networks. Adv. Neural Inf. Process. Syst. 2017, 60, 84–90. [Google Scholar] [CrossRef]

- Glorot, X.; Bordes, A.; Bengio, Y. Deep sparse rectifier neural networks. In Proceedings of the Fourteenth International Conference on Artificial Intelligence and Statistics, Fort Lauderdale, FL, USA, 11–13 April 2011; pp. 315–323. [Google Scholar]

- Shanthi, T.; Sabeenian, R.S. Modified Alexnet architecture for classification of diabetic retinopathy images. Comput. Electr. Eng. 2019, 76, 56–64. [Google Scholar] [CrossRef]

- Ioffe, S.; Szegedy, C. Batch normalization: Accelerating deep network training by reducing internal covariate shift. In Proceedings of the International Conference on Machine Learning, Lille, France, 6–11 July 2015; pp. 448–456. [Google Scholar]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Deep residual learning for image recognition. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Las Vegas, NV, USA, 27–30 June 2016; pp. 770–778. [Google Scholar]

- Iandola, F.N.; Han, S.; Moskewicz, M.W.; Ashraf, K.; Dally, W.J.; Keutzer, K. SqueezeNet: AlexNet-level accuracy with 50x fewer parameters and <0.5 MB model size. arXiv 2016, arXiv:1602.07360. [Google Scholar]

- LeCun, Y.; Bottou, L.; Bengio, Y.; Haffner, P. Gradient-based learning applied to document recognition. Proc. IEEE 1998, 86, 2278–2324. [Google Scholar] [CrossRef]

- Hochreiter, S.; Schmidhuber, J. Long short-term memory. Neural Comput. 1997, 9, 1735–1780. [Google Scholar] [CrossRef]

- McDonald, G.L.; Zhao, Q.; Zuo, M.J. Maximum correlated Kurtosis deconvolution and application on gear tooth chip fault detection. Mech. Syst. Signal Process. 2012, 33, 237–255. [Google Scholar] [CrossRef]

| No | CNN-128 | CNN-256 | CNN-512 | CNN-1024 | CNN-2048 | CNN-3072 | CNN-4096 | CNN-5120 |

|---|---|---|---|---|---|---|---|---|

| GST | 97.65 | 97.82 | 98.21 | 98.46 | 98.43 | 98.33 | 98.46 | 98.30 |

| STFT | 97.30 | 97.81 | 97.86 | 98.09 | 98.25 | 98.39 | 98.17 | 98.17 |

| WVD | 95.23 | 96.12 | 96.03 | 96.65 | 96.64 | 96.44 | 96.74 | 96.76 |

| CWT | 94.25 | 94.59 | 95.11 | 95.34 | 95.61 | 95.87 | 95.88 | 95.65 |

| No | CNN-128 | CNN-256 | CNN-512 | CNN-1024 | CNN-2048 | CNN-3072 | CNN-4096 | CNN-5120 |

|---|---|---|---|---|---|---|---|---|

| GST | 98.97 | 99.10 | 99.15 | 99.21 | 99.10 | 98.91 | 99.00 | 99.05 |

| STFT | 99.02 | 99.02 | 99.01 | 99.02 | 99.14 | 99.10 | 99.03 | 99.04 |

| WVD | 97.55 | 97.63 | 97.47 | 97.41 | 97.44 | 97.48 | 97.51 | 97.23 |

| CWT | 96.14 | 96.34 | 96.63 | 96.69 | 96.63 | 96.54 | 96.80 | 96.70 |

| Image Datasets | Methods | Accuracy (%) |

|---|---|---|

| GST | AlexNet-1024 | 99.21 |

| ResNet-18 | 98.56 | |

| SqueezeNet | 92.97 | |

| LeNet | 86.01 | |

| WVD | AlexNet-256 | 97.63 |

| ResNet-18 | 98.42 | |

| SqueezeNet | 90.64 | |

| LeNet | 84.17 | |

| STFT | AlexNet-2048 | 99.14 |

| ResNet-18 | 99.09 | |

| SqueezeNet | 92.33 | |

| LeNet | 78.42 | |

| CWT | AlexNet-4096 | 96.80 |

| ResNet-18 | 96.71 | |

| SqueezeNet | 82.78 | |

| LeNet | 68.67 | |

| One-dimensional signals | CNN-LSTM | 70.32 |

| MCKD-CNN | 92.36 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, A.; Zhao, W. A Fault Diagnosis Method for Drilling Pump Fluid Ends Based on Time–Frequency Transforms. Processes 2023, 11, 1996. https://doi.org/10.3390/pr11071996

Tang A, Zhao W. A Fault Diagnosis Method for Drilling Pump Fluid Ends Based on Time–Frequency Transforms. Processes. 2023; 11(7):1996. https://doi.org/10.3390/pr11071996

Chicago/Turabian StyleTang, Aimin, and Wu Zhao. 2023. "A Fault Diagnosis Method for Drilling Pump Fluid Ends Based on Time–Frequency Transforms" Processes 11, no. 7: 1996. https://doi.org/10.3390/pr11071996

APA StyleTang, A., & Zhao, W. (2023). A Fault Diagnosis Method for Drilling Pump Fluid Ends Based on Time–Frequency Transforms. Processes, 11(7), 1996. https://doi.org/10.3390/pr11071996