Evaluating the Efficiency of the Process Safety Management System through Analysis of Major Industrial Accidents in South Korea

Abstract

:1. Introduction

2. Methods

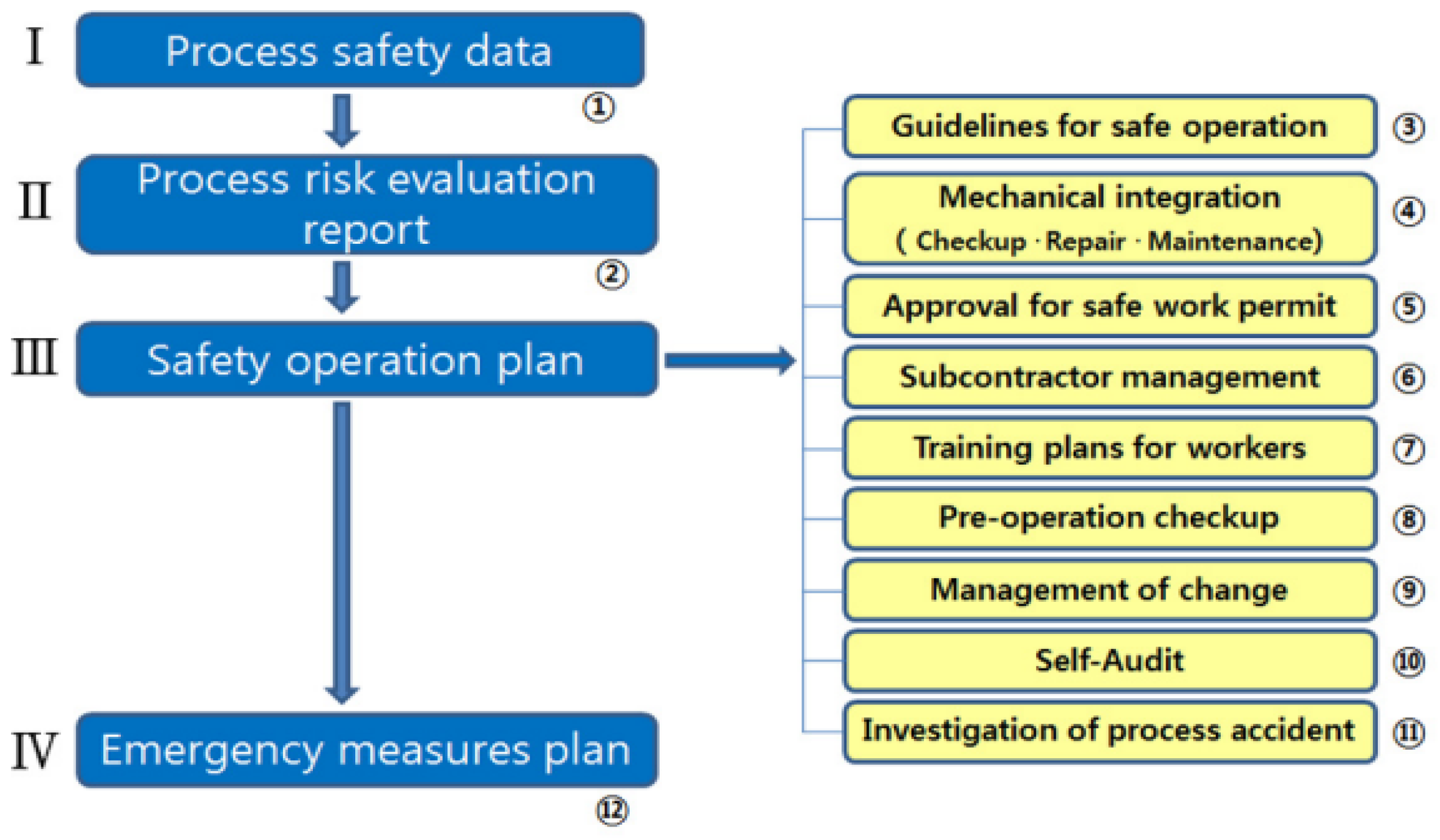

3. Law of Process Safety Management in South Korea

- -

- Refineries

- -

- Reprocessing of petroleum refining byproducts.

- -

- Petrochemical organic chemicals or synthetic resins

- -

- Fertilizer industry

- -

- Pesticide/herbicide industry

- -

- Explosive powder/fireworks products

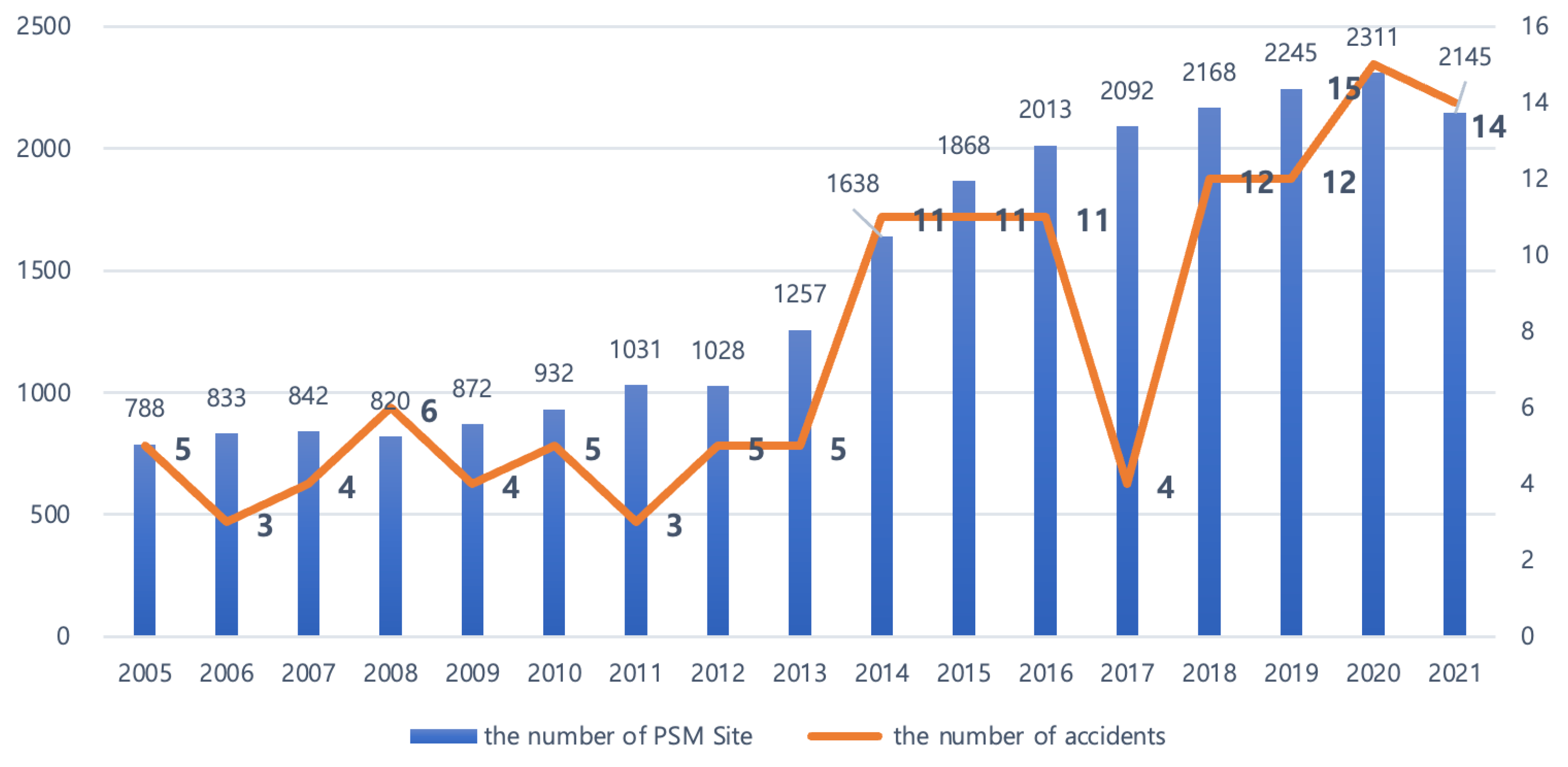

4. Analysis of the Operating Status of PSM

5. Analysis of the Correlation between Major Industrial Accidents and PSM Grades

5.1. Analysis of Major Industrial Accidents by Company Size

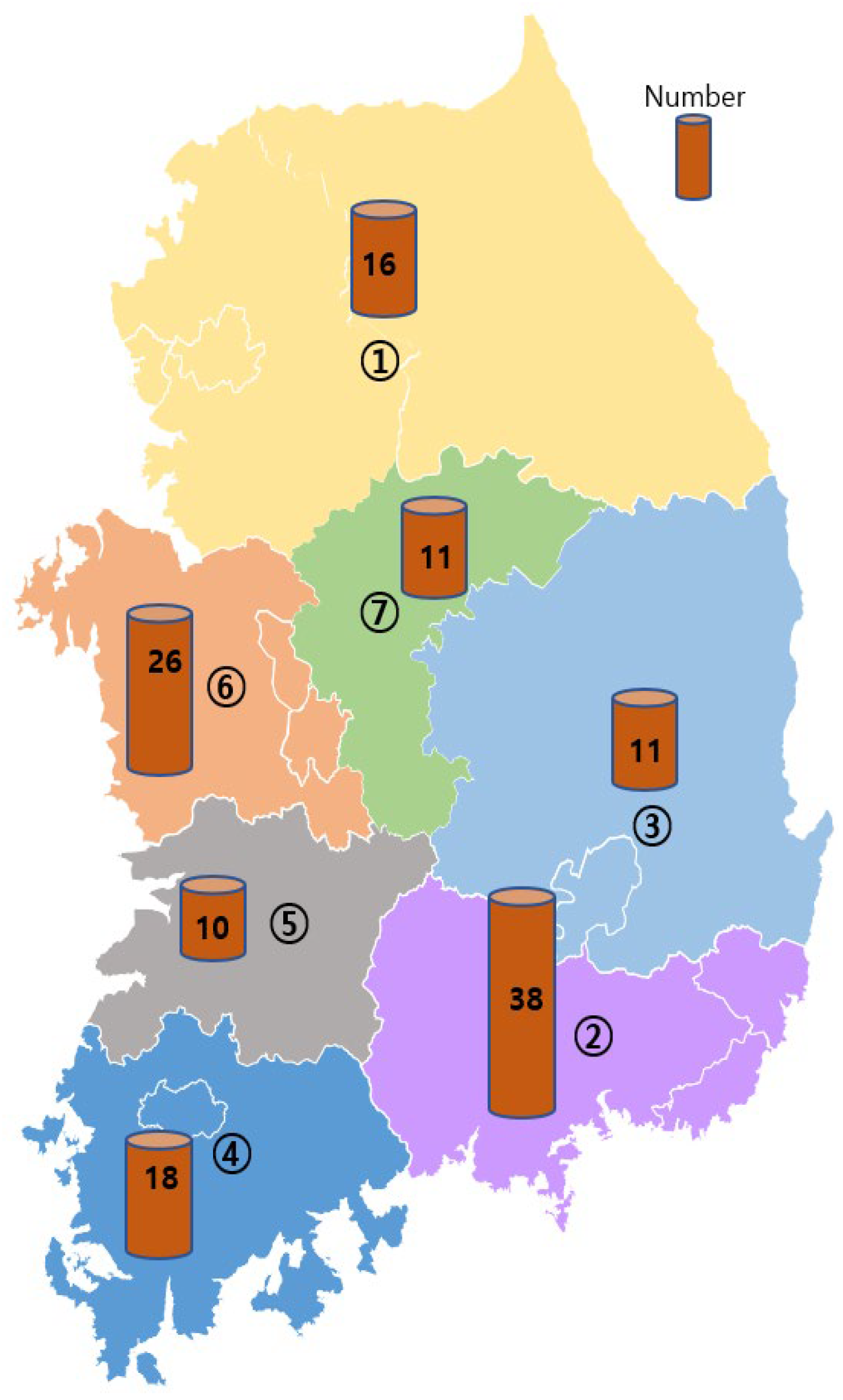

5.2. Analysis of Major Industrial Accidents by Region

5.3. Analysis of Major Causes of Major Industrial Accidents

6. Results and Discussion

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- EC Council Directive. 96/82/EEC of 9 December 1996 on the control of major accident hazards involving dangerous substances. Off. J. Eur. Communities 1997, 10, 13–33. [Google Scholar]

- Wettig, J.; Porter, S.; Kirchsteiger, C. Major industrial accidents regulation in the European Union. J. Loss Prev. Process Ind. 1999, 12, 19–28. [Google Scholar] [CrossRef]

- 29 CFR 1910.119; Process Safety Management of Highly Hazardous Chemicals. Occupational safety and health administration, U.S. Department of Labor: Washington, DC, USA, 2013.

- Steve, A. Continuously improving PSM effectiveness—A practical roadmap. Process Saf. Prog. 2006, 25, 86–93. [Google Scholar] [CrossRef]

- CCPS. Guidelines for Technical Management of Chemical Process Safety; American Institute of Chemical Engineers: New York, NY, USA, 1989. [Google Scholar]

- CCPS. Process Safety Leading and Lagging Metrics: You Don’t Improve What You Don’t Measure; An AIChE Industry Technology Alliance: New York, NY, USA, 2011. [Google Scholar]

- MacDonald, G.; Varney, L. The control of major accident hazards regulations 1999 (COMAH). IChem Symp. 1999, 144, 1–9. [Google Scholar]

- Hans, J.; Norbert, W. Central collecting and evaluating of major accidents and near-miss-events in the Federal Republic of Germany—Results, experiences, perspectives. J. Hazard. Mater. 2004, 111, 139–145. [Google Scholar] [CrossRef]

- Casebook of Major Industrial Accidents in 2021; Korea Occupational Safety and Health Agency: Ulsan, Republic of Korea, 2021.

- Kwon, H.M. The effectiveness of process safety management (PSM) regulation for chemical industry in Korea. J. Loss Prev. Process Ind. 2006, 19, 13–16. [Google Scholar] [CrossRef]

- Lee, Y.S.; Kim, T.O.; Han, J.M.; Kang, M.J. Performance Measurement and Effectiveness Analysis of PSM Regulation; Occupational Safety and Health Research Institute: Ulsan, Republic of Korea, 2006. [Google Scholar]

- No. 32873. Enforcement Decree of the Occupational Safety and Health Act. Available online: https://www.law.go.kr/LSW/eng/engLsSc.do?menuId=2§ion=lawNm&query=Enforcement+Decree+of+the+Occupational+Safety+and+Health+Act.&x=0&y=0#liBgcolor0 (accessed on 15 March 2023).

- Kletz, T. Lessons from Disaster: How Organisations Have No Memory and Accidents Occur; Institute of Chemical Engineers: Rugby, UK, 1993. [Google Scholar]

- Chizaram, D.N.; Stephen, C.T.; Andrew, O.A. A comparative analysis of process safety management (PSM) systems in the process industry. J. Loss Prev. Process Ind. 2020, 66, 104171. [Google Scholar] [CrossRef]

- Cheng, C.W.; Yao, H.Q.; Wu, T.C. Applying data mining techniques to analyze the causes of major occupational accidents in the petrochemical industry. J. Loss Prev. Process Ind. 2013, 26, 1269–1278. [Google Scholar] [CrossRef]

- CCPS. Guidelines for Risk Based Process Safety; Wiley: Hoboken, NJ, USA, 2007. [Google Scholar]

- CCPS. Guidelines for Technical Management of Chemical Process; Wiley: Hoboken, NJ, USA, 1991. [Google Scholar]

- Lee, K.H.; Kwon, H.M.; Cho, S.S.; Kim, J.Y.; Moon, I. Improvements of safety management system in Korean chemical industry after a large chemical accident. J. Loss Prev. Process Ind. 2016, 42, 6–13. [Google Scholar] [CrossRef]

- Theophilus, S.C.; Nwankwo, C.D.; Acquah, A.; Bassey, E.; Umoren, U. Integrating human factors (HF) into a process safety management system (PSMS). Process Saf. Prog. 2018, 37, 67–85. [Google Scholar] [CrossRef]

- Lee, J.Y.; Lee, K.W.; Kim, K.J.; Kim, T.O. A Study on Improvement of Safety Management in Subcontractor through Process Safety Management. J. Korean Inst. Gas 2015, 19, 15–21. [Google Scholar] [CrossRef] [Green Version]

- Kwon, W.T.; Sung, S.H.; Gal, W.M. A reasonal improvement method for the effective PSM system. J. Korean Inst. Plant Eng. 2017, 22, 49–54. Available online: https://kiss.kstudy.com/ExternalLink/Ar?key=3549857 (accessed on 26 April 2023).

- Zhou, A.; Fan, L.; Ma, M.; Tao, B. Chinese process safety management core elements and control measures. Process Saf. Prog. 2017, 36, 378–381. [Google Scholar] [CrossRef]

- Zhao, J.; Suikkanen, J.; Wood, M. Lessons learned for process safety management in China. J. Loss Prev. Process Ind. 2014, 29, 170–176. [Google Scholar] [CrossRef]

- Jacobsson, A.; Sales, J.; Mushtaq, F. A sequential method to identify underlying causes from industrial accidents reported to the MARS database. J. Loss Prev. Process Ind. 2009, 22, 197–203. [Google Scholar] [CrossRef]

- Kwon, H.M.; Lee, C.J.; Seo, D.H.; Moon, I. Korean experience of process safety management (PSM) regulation for chemical industry. J. Loss Prev. Process Ind. 2016, 42, 2–5. [Google Scholar] [CrossRef]

- Lee, J.Y.; Lee, K.W.; Kim, T.O. A Study on Reforming Threshold Quantities of Toxic Substances in Process Safety Management. J. Korean Inst. Gas 2017, 21, 6–15. [Google Scholar] [CrossRef]

- Lee, J.Y.; Lee, K.W.; Ahn, B.J.; Kim, T.O. Improvement Plan of Implementing Condition Assessment in Process Safety Management (PSM) System. J. Korean Inst. Gas 2016, 31, 27–34. [Google Scholar] [CrossRef]

- Ministry Employment of Labor, Introduction to Process Safety Management (PSM) System. Available online: https://www.moel.go.kr/policy/policydata/view.do;jsessionid=Z9nYIbCKACkXLABVBy4mqinyFb7fVbxAcWZGrQAyxLP1iK15JOpeo9nIQoaomq8v.moel_was_outside_servlet_www1?bbs_seq=1476237136554 (accessed on 1 April 2023).

- KOSHA. Review and Confirmation of Process Safety Report. Available online: https://www.kosha.or.kr/english/reviewandconfirmationofprocesssafetyreport.do (accessed on 19 May 2023).

- Lee, Y.S.; Kang, M.J.; Yang, H.S. A Study on the Rationalization Plan of the Coverage Basis of PSM Regulation in Korea; Occupational Safety and Health Research Institute: Ulsan, Republic of Korea, 2008. [Google Scholar]

- Lee, Y.S.; Lee, K.W.; Kang, M.J. Study on Expansion of Substance to Be Applied to PSM System; Occupational Safety and Health Research Institute: Ulsan, Republic of Korea, 2011. [Google Scholar]

- No. 18426. Occupational Safety and Health Act. Available online: https://www.law.go.kr/LSW/eng/engLsSc.do?menuId=2§ion=lawNm&query=Occupational+Safety+and+Health+Act&x=0&y=0 (accessed on 10 March 2023).

- Enforcement Decree of the Occupational Safety and Health Act; Ministry of Employment and Labor of Korea: Sejong-si, Republic of Korea, 2022.

- Major Industrial Accident Prevention Center. Available online: https://www.kosha.or.kr/epsm (accessed on 10 March 2023).

- Serious Industrial Accident Prevention Center Operating Regulations; Ministry of Employment and Labor of Korea: Sejong, Republic of Korea, 2019.

- Cho, Y.J.; Park, J.W. Effects of PSM on Attitudes of Firefighters in Korea: Exploring a Moderation Role of Communication. In Proceedings of the 21st Annual International Research Society for Public Management (IRSPM), Budapest, Hungary, 19–21 April 2017. [Google Scholar]

- Kwon, H.Y. Development of An Integrated Risk Management System for The Prevention of Major Industrial Accidents. Ph.D. Thesis, Yonsei University, Seoul, Republic of Korea, 2003. [Google Scholar]

- Data on the Serious Accident Punishment Act. Available online: https://www.moel.go.kr/local/chungju/info/dataroom/view.do?bbs_seq=20220100371 (accessed on 1 April 2023).

- Ferjencik, M. Practical safety management for small or medium enterprises. J. Loss Prev. Process Ind. 2020, 68, 104281. [Google Scholar] [CrossRef]

| Grade | Implementing Condition Assessment |

|---|---|

| P (Progressive) (Excellent) | Inspection once every four years after a rating evaluation |

| S (Stagnant) (Good) | Inspection once every two years |

| M+ (Mismanagement) (Normal) | Inspection and consulting once a year |

| M− (Mismanagement) (Bad) | Inspection twice a year, or inspection once a year |

| No. of Employees | Petroleum Refinery | Petro Chemical | Fertilizer | Pesticide | Explosive | Harmful or Dangerous Substances | Total |

|---|---|---|---|---|---|---|---|

| P | 13 | 27 | 0 | 0 | 1 | 45 | 86 |

| S | 9 | 62 | 3 | 2 | 6 | 614 | 696 |

| M+ | 1 | 46 | 0 | 0 | 6 | 776 | 829 |

| M− | 0 | 22 | 0 | 1 | 1 | 179 | 203 |

| Total | 23 | 157 | 3 | 3 | 14 | 1614 | 1814 |

| No. of Employees | P | S | M+ | M− | Total |

|---|---|---|---|---|---|

| <100 | 34 | 333 | 576 | 170 | 1113 |

| 100–299 | 32 | 202 | 158 | 26 | 418 |

| 300–500 | 6 | 62 | 43 | 1 | 112 |

| >500 | 14 | 99 | 52 | 6 | 171 |

| Total | 86 | 696 | 829 | 203 | 1814 |

| No. of Employees | No. of Accident | Percent (%) |

|---|---|---|

| Total | 130 | 100% |

| <50 | 18 | 13.8% |

| 50–100 | 29 | 22.3% |

| 100–300 | 32 | 24.6% |

| 300–1000 | 24 | 18.5% |

| >1000 | 27 | 20.8% |

| Region | Characteristics |

|---|---|

| ① Metropolitan Area |

|

| ② South Gyeongsang Province |

|

| ③ North Gyeongsang Province |

|

| ④ South Jeolla Province |

|

| ⑤ North Jeolla Province |

|

| ⑥ South Chung cheong Province |

|

| ⑦ North Chung cheong Province |

|

| Classify | Sum | ① Metropolitan Area | ② South Gyeongsang Province | ③ North Gyeongsang Province | ④ South Jeolla Province | ⑤ North Jeolla Province | ⑥ South Chungcheong Province | ⑦ North Chungcheong Province |

|---|---|---|---|---|---|---|---|---|

| Year | 130 | 16 | 38 | 11 | 18 | 10 | 26 | 11 |

| 2005 | 5 | 2 | 1 | - | 1 | - | 1 | - |

| 2006 | 3 | 1 | 1 | - | - | - | 1 | - |

| 2007 | 4 | 1 | 1 | - | 1 | 1 | - | - |

| 2008 | 6 | - | 1 | 1 | 2 | 1 | 1 | - |

| 2009 | 4 | - | 3 | - | - | - | 1 | - |

| 2010 | 5 | - | 2 | 2 | 1 | - | - | - |

| 2011 | 3 | - | 2 | 1 | - | - | - | - |

| 2012 | 5 | - | - | 3 | - | 1 | - | 1 |

| 2013 | 5 | 1 | 1 | - | 2 | 1 | - | - |

| 2014 | 11 | 1 | 2 | 2 | 2 | 1 | 2 | 1 |

| 2015 | 11 | 2 | 4 | - | 2 | 1 | 1 | 1 |

| 2016 | 11 | 1 | 4 | - | 2 | - | 3 | 1 |

| 2017 | 4 | - | 3 | - | - | - | - | 1 |

| 2018 | 12 | 2 | 2 | - | 2 | - | 5 | 1 |

| 2019 | 12 | 1 | 3 | - | 1 | 1 | 4 | 2 |

| 2020 | 15 | 1 | 6 | - | - | 1 | 6 | 1 |

| 2021 | 14 | 3 | 2 | 2 | 2 | 2 | 1 | 2 |

| Classification | 1998 | 2000 | 2003 | 2007 | 2021 | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| No. | % | No. | % | No. | % | No. | % | No. | % | |

| ① Risk assessment | 55 | 32.7% | 58 | 31.9% | 13 | 17.3% | 25 | 20.2% | 15 | 11.5% |

| ② Safety Operation Procedure | 23 | 13.7% | 26 | 14.3% | 23 | 30.7% | 31 | 25.0% | 64 | 49.2% |

| ③ Facility maintenance | 8 | 4.8% | 10 | 5.5% | 8 | 10.7% | 16 | 12.9% | 14 | 10.8% |

| ④ Safety work permit | 66 | 39.3% | 71 | 39.0% | 29 | 38.7% | 46 | 37.1% | 33 | 25.4% |

| ⑤ Management of chance | 15 | 8.9% | 16 | 8.8% | 2 | 2.7% | 4 | 3.2% | 3 | 2.3% |

| ⑥ Emergency control plan | 1 | 0.6% | 1 | 0.5% | 0 | 0.0% | 2 | 1.6% | 1 | 0.8% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yoo, B.-T.; Shim, W.S. Evaluating the Efficiency of the Process Safety Management System through Analysis of Major Industrial Accidents in South Korea. Processes 2023, 11, 2022. https://doi.org/10.3390/pr11072022

Yoo B-T, Shim WS. Evaluating the Efficiency of the Process Safety Management System through Analysis of Major Industrial Accidents in South Korea. Processes. 2023; 11(7):2022. https://doi.org/10.3390/pr11072022

Chicago/Turabian StyleYoo, Byung-Tae, and Woo Sub Shim. 2023. "Evaluating the Efficiency of the Process Safety Management System through Analysis of Major Industrial Accidents in South Korea" Processes 11, no. 7: 2022. https://doi.org/10.3390/pr11072022

APA StyleYoo, B.-T., & Shim, W. S. (2023). Evaluating the Efficiency of the Process Safety Management System through Analysis of Major Industrial Accidents in South Korea. Processes, 11(7), 2022. https://doi.org/10.3390/pr11072022