Characterization of Extra Low-Permeability Conglomerate Reservoir and Analysis of Three-Phase Seepage Law

Abstract

:1. Introduction

2. Methodology

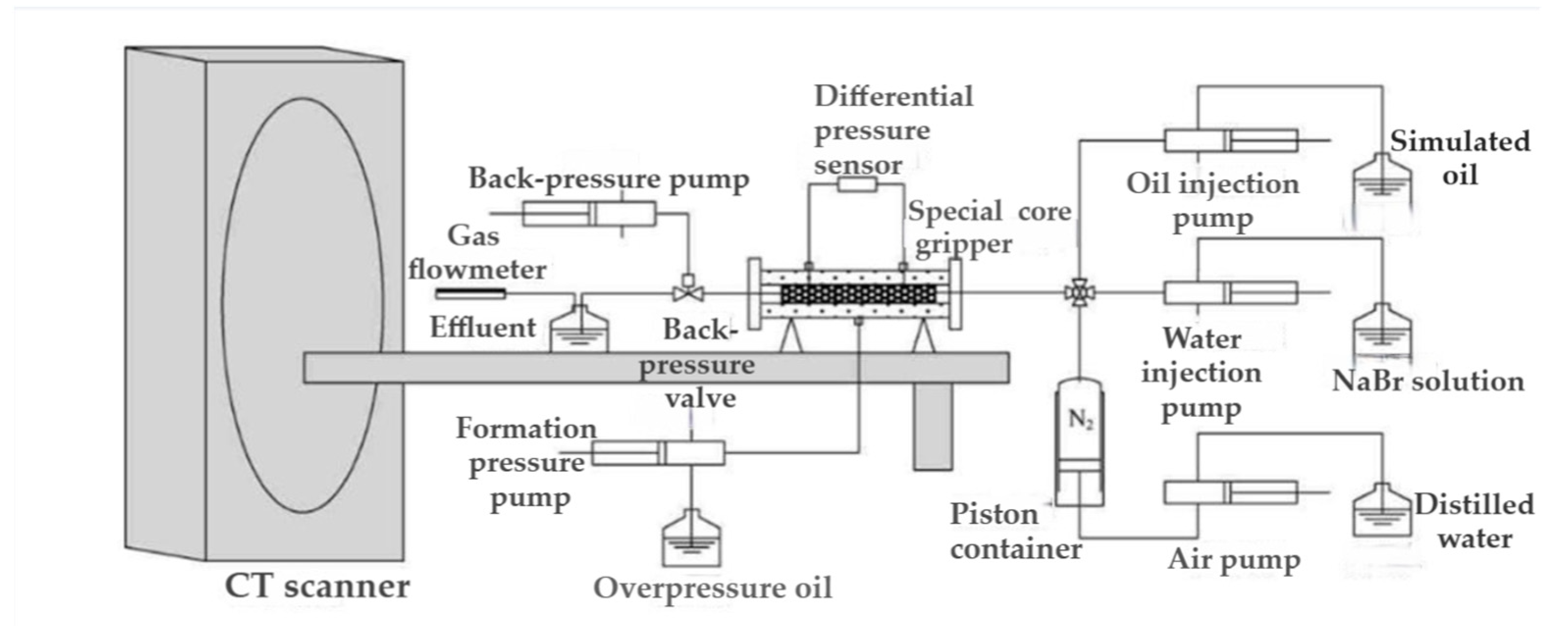

2.1. Three-Phase Relative Permeability Curve Test

2.2. Simulation Calculation Method of Three-Phase Relative Permeability Curve

- (1)

- Take the fully dried sample and place it in the experimental device. Calculate the permeability of different saturations through different pressure differences and flow rates. Based on experimental data, the permeability curves of the unstable oil-water phase of the ultra-low permeability conglomerate are obtained by statistical analysis and organization of permeability under different saturations.

- (2)

- Take the sample from the ultra low-permeability conglomerate and dry it thoroughly before conducting the test. Place the sample in the experimental device and first inject water to fully saturate the sample. Then, continuously inject gas and record saturation and permeability data over time. Analyze and organize the saturation and permeability at different time points based on experimental data, and obtain the non-stationary oil- and gas-phase permeability curve of ultra low-permeability conglomerate.

- (3)

- Place the dried sample into the experimental device and continuously inject different fluids (water, oil, gas) and record the corresponding CT images to derive the distribution of fluid saturation during the process. Based on experimental data, the distribution of fluid saturation along the process is modeled and analyzed using Eclipse and compared and validated with experimental results.

- (4)

- Based on the previous experimental results, establish a three-phase permeability model for ultra low-permeability conglomerate, including permeability calculations at both macro and micro scales. Simulate and calculate the three-phase permeability of ultra low-permeability conglomerate using computer software, and obtain the three-phase permeability curve of ultra low-permeability conglomerate.

- (5)

- Select representative samples and place them in the experimental device. Inject CO2 gas and control the injection flow rate and time under different pressure and temperature conditions, and measure recovery rate and remaining oil quantity. Calculate and analyze the recovery efficiency of CO2 flooding based on experimental data, providing a reference basis for the application and implementation of CO2 flooding.

2.3. Establishment and Characterization of Conglomerate Reservoir Pore Network Model

2.4. Three-Phase Seepage Simulation Parameter Optimization Based on Pore Network Model

- (1)

- Geological data are obtained through seismic exploration and well location data, and modeling and visualization are carried out using Eclipse software.

- (2)

- An adaptive mesh partitioning method is adopted to ensure the high accuracy and reliability of the model.

- (3)

- The boundary conditions of the pore network model are set, including information such as the inlet pressure and outlet pressure of each layer.

- (4)

- A three-phase seepage simulation program is run, and Eclipse simulation calculations are performed. During the calculation process, adjustments and optimizations can be made as needed.

- (5)

- The calculation results are to be analyzed, and problems that arise in the simulation are optimized and improved. Result analysis helps to understand the movement patterns of three-phase fluids in the reservoir and provides support for subsequent decision-making.

3. Results and Discussion

3.1. Reservoir Physical Properties

3.2. Reservoir Pore Structure Characteristics

3.2.1. Reservoir Pore Type and Size

3.2.2. Reservoir Pore Throat Structure Parameters

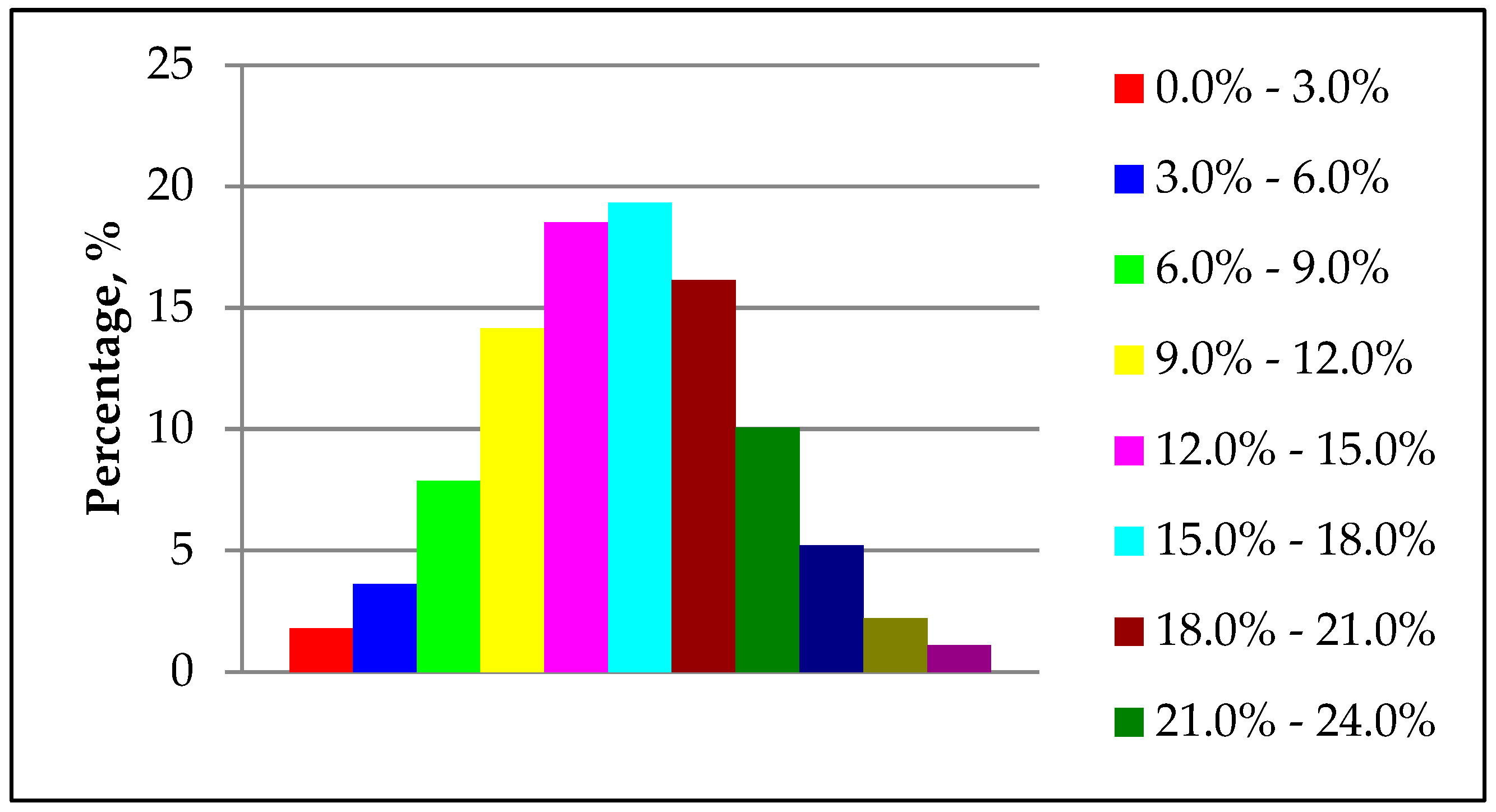

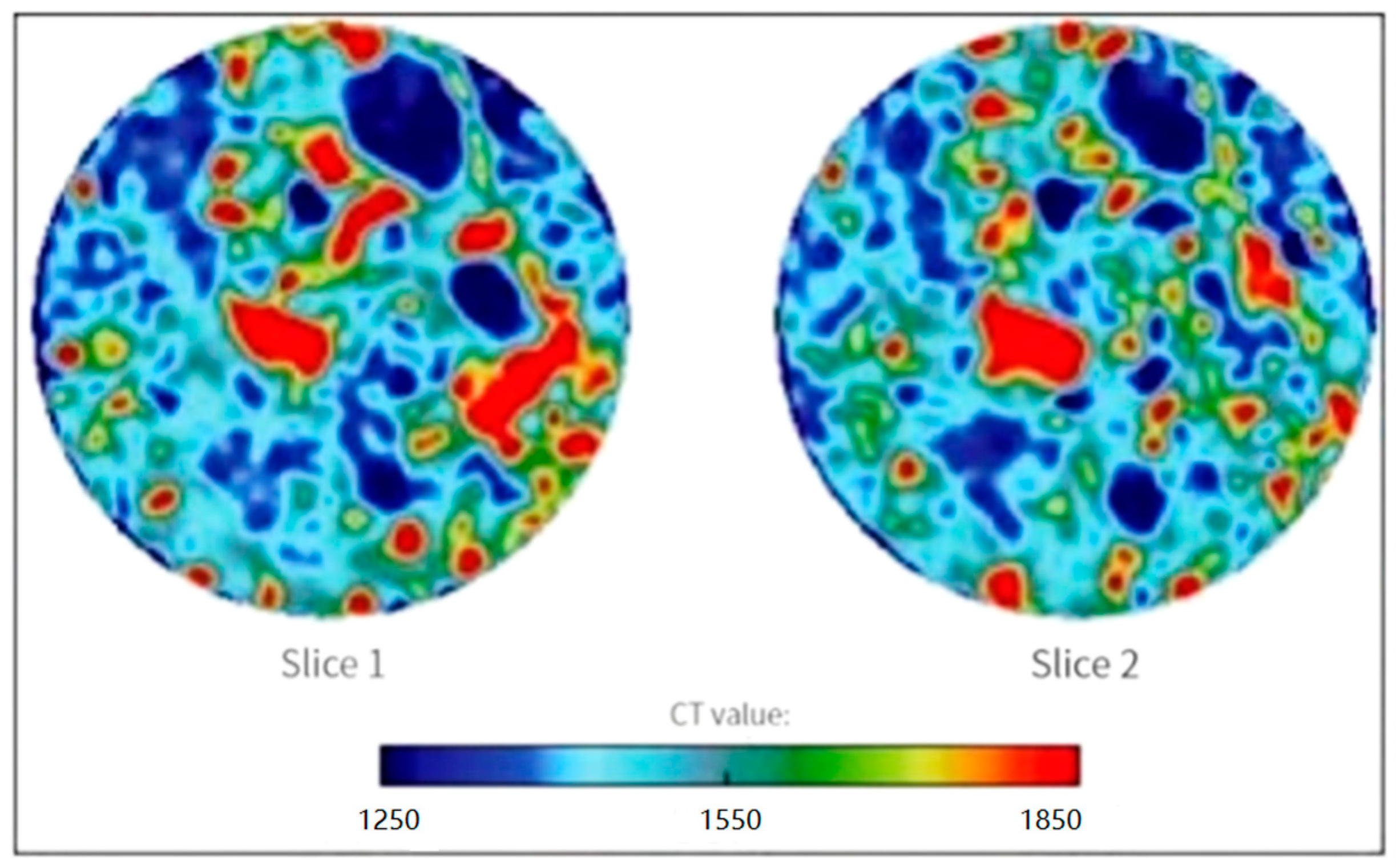

3.2.3. CT Scan Porosity Analysis

3.3. Three-Phase Seepage Characteristics of Extra Low–Permeability Conglomerate Reservoirs and the Influence of Different Factors

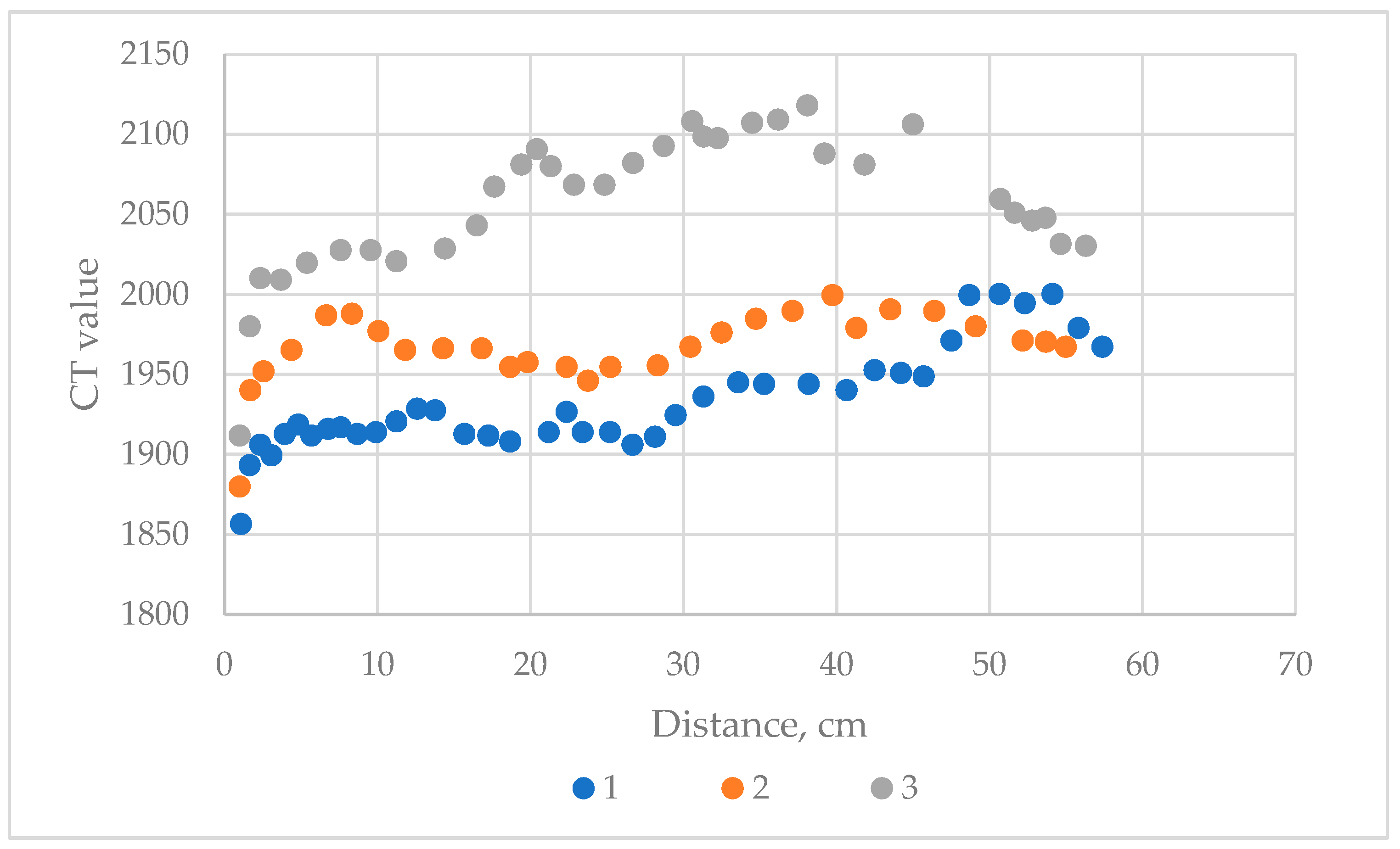

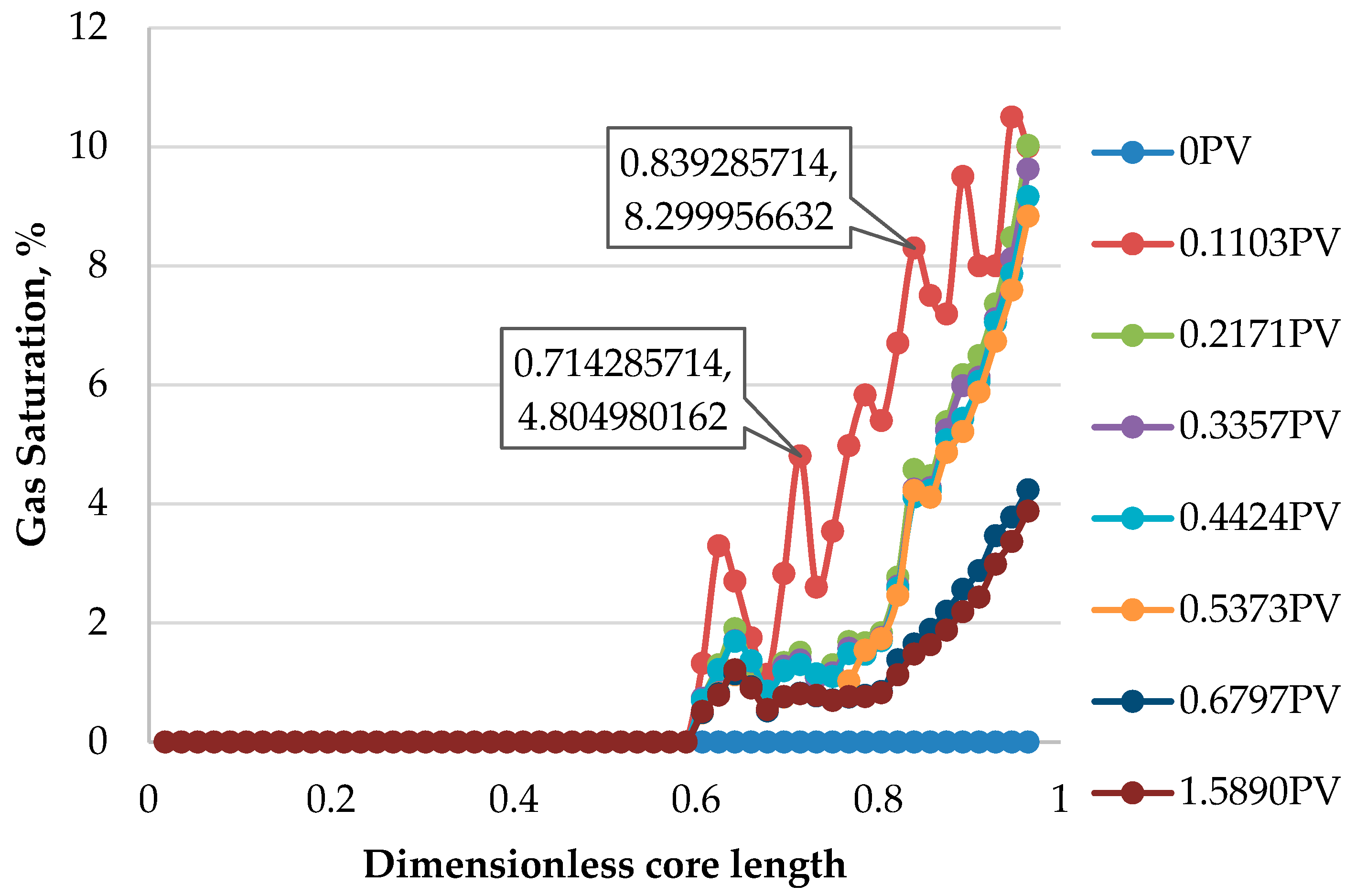

3.3.1. Change Characteristics of Saturation Distribution along the Way

3.3.2. Variation Characteristics of Three-Phase Saturation History

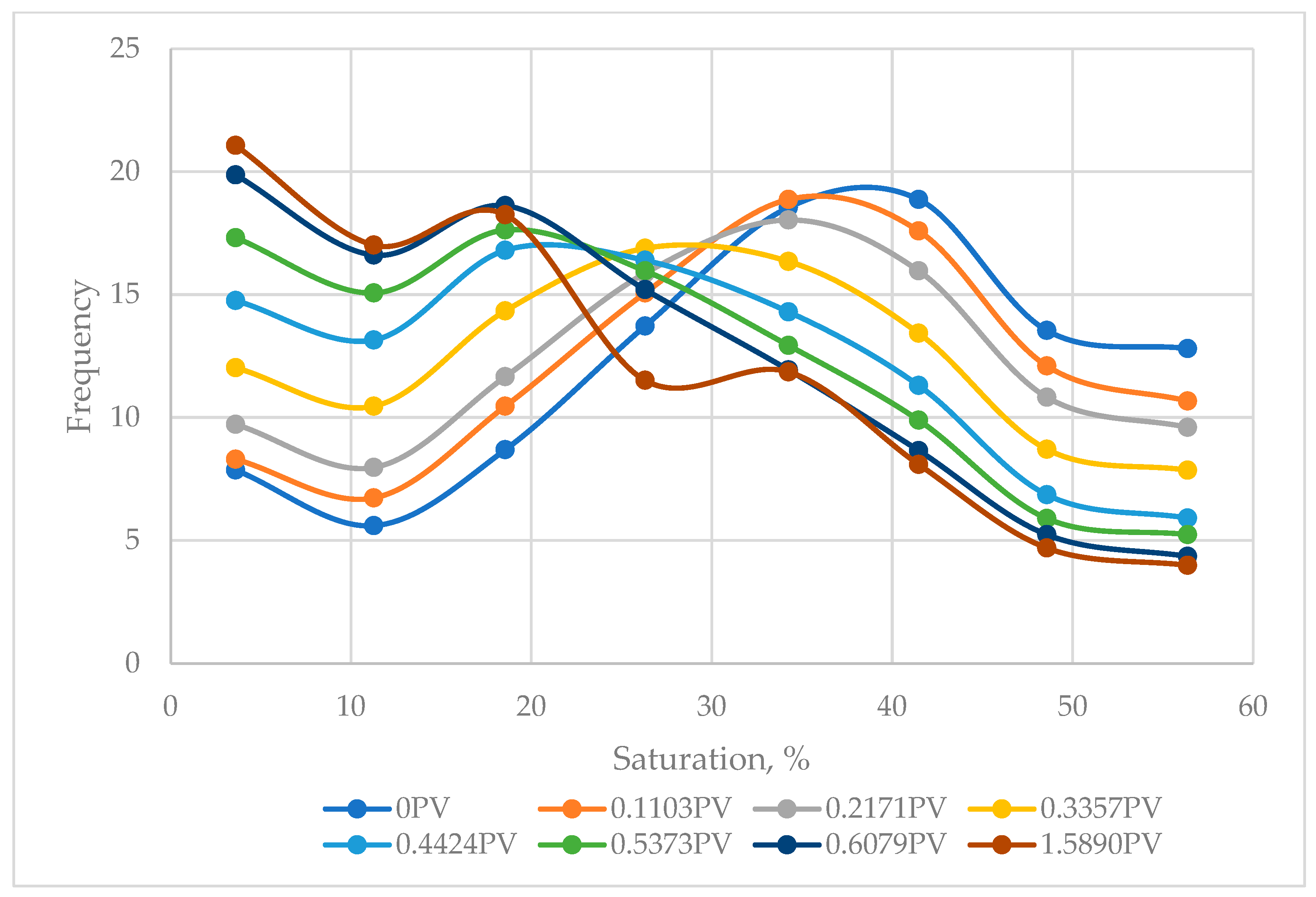

3.3.3. Distribution Characteristics of Remaining Oil

3.3.4. Influence of Different Original Oil Saturation

3.3.5. Influence of Different Core Permeability

4. Conclusions

- (1)

- The reservoir cores in the study area are all of low porosity and low permeability, and the permeability of the core samples is distributed in an inverse rhythm pattern with layer depth. This reservoir is a thick conglomerate reservoir with low porosity (porosity 12%), ultra-low permeability (permeability 1.2 mD), burial depth (average burial depth of 2623 m), and microfractures.

- (2)

- CT core analysis and mercury intrusion experiments indicate that the area with porosity ranging from 9% to 21% accounts for 79%, making it the main seepage channel area. Larger pores play a major role in seepage.

- (3)

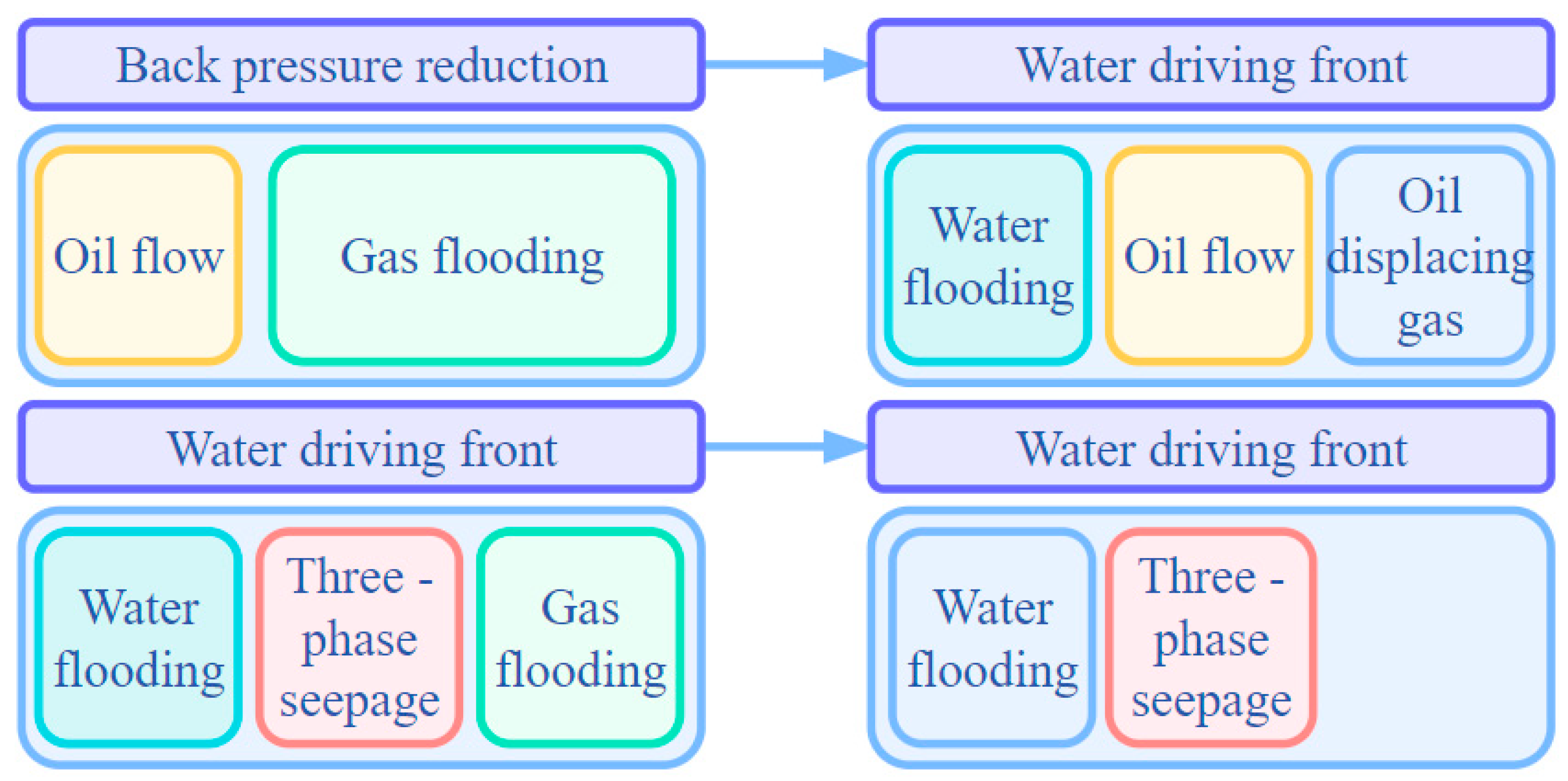

- The CT scanning core displacement system achieves real-time dynamic detection of the multiphase saturation field in the core. At the beginning of the waterdrive process, there are two saturated historical regions along the core. After the displacement front enters the dissolved gas precipitation zone, there are three saturation history zones, at which time there is three-phase seepage near the core outlet.

- (4)

- In terms of the remaining oil distribution characteristics, the distribution frequency of oil saturation decreased from the initial peak of 41% to a peak of 20% after water flooding. Different original oil content has great influence on oil–water relative permeability and residual oil saturation. The degassing phenomenon of rock samples with different permeability is also different. The degassing phenomenon is more severe in rock samples with low permeability. It is necessary to comprehensively consider factors such as reservoir porosity and permeability to comprehensively reflect and characterize waterdrive efficiency.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CT | Computed Tomography |

| k | Permeability; mD |

| PV | the pore volume; non-dimensional |

References

- Shun, G.; Chao, D.; Jianshan, Q.; Lan, G.; Yongping, W.; Qing, Z.; Baojun, W. Development strategy of proved un-developed geological reserves in the Yanchang oil region, Ordos Basin#br#. China Pet. Explor. 2021, 26, 85. [Google Scholar] [CrossRef]

- Fan, Y.M. Classification and evaluation of undeveloped reserves in low permeability reservoirs based on development technology. Pet. Exp. Geol. 2022, 44, 337–341. [Google Scholar]

- Kang, X.; Hu, W.; Cao, J.; Jin, J.; Wu, H.; Zhao, Y.; Wang, J. Selective dissolution of alkali feldspars and its effect on Lower Triassic sandy conglomerate reservoirs in the Junggar Basin, northwestern China. Geol. J. 2018, 53, 475–499. [Google Scholar] [CrossRef]

- Zhou, Y.; Wu, S.; Li, Z.; Zhu, R.; Xie, S.; Jing, C.; Lei, L. Multifractal Study of Three-Dimensional Pore Structure of Sand-Conglomerate Reservoir Based on CT Images. Energy Fuels 2018, 32, 4797–4807. [Google Scholar] [CrossRef]

- Wang, H.-X.; Wang, G.; Chen, Z.X.J.; Wong, R.C. Deformational characteristics of rock in low permeable reservoir and their effect on permeability. J. Pet. Sci. Eng. 2010, 75, 240–243. [Google Scholar] [CrossRef]

- Qin, Q.; Cheng, H.; Wang, M.; Sun, M.; Zhao, L. Analyzing the wettability of tight sandstone of Taiyuan formation in Shenfu block, eastern margin of ordos basin. IOP Conf. Ser. Earth Environ. Sci. 2021, 671, 012022. [Google Scholar] [CrossRef]

- Kang, W.-L.; Zhou, B.-B.; Issakhov, M.; Gabdullin, M. Advances in enhanced oil recovery technologies for low permeability reservoirs. Pet. Sci. 2022, 19, 1622–1640. [Google Scholar] [CrossRef]

- Li, X.; Yang, Z.; Li, S.; Huang, W.; Zhan, J.; Lin, W. Reservoir characteristics and effective development technology in typical low-permeability to ultralow-permeability reservoirs of China National Petroleum Corporation. Energy Explor. Exploit. 2021, 39, 1713–1726. [Google Scholar] [CrossRef]

- Clarke, R.H. Reservoir Properties of Conglomerates and Conglomeratic Sandstones: GEOLOGIC NOTES. AAPG Bull. 1979, 63, 799–803. [Google Scholar] [CrossRef]

- Sneider, R.M.; King, H.R.; Hawkes, H.E.; Davis, T.B. Methods for Detection and Characterization of Reservoir Rock, Deep Basin Gas Area, Western Canada. J. Pet. Technol. 1983, 35, 1725–1734. [Google Scholar] [CrossRef]

- Yin, S.; Chen, Y.; Wu, X. Different pore structure modalities in sandy conglomerate reservoirs and their forming mechanisms. Arab. J. Geosci. 2018, 11, 654. [Google Scholar] [CrossRef]

- Sneider, R.; Richardson, F.; Paynter, D.; Eddy, R.; Wyant, I. Predicting Reservoir Rock Geometry and Continuity in Pennsylvanian Reservoirs, Elk City Field, Oklahoma. J. Pet. Technol. 1977, 29, 851–866. [Google Scholar] [CrossRef]

- Zhang, D.; Ma, S.; Zhang, J.; Zhu, Y.; Bin Wang, B.; Zhu, J.; Fan, X.; Yang, H.; Liang, T. Field experiments of different fracturing designs in tight conglomerate oil reservoirs. Sci. Rep. 2022, 12, 3220. [Google Scholar] [CrossRef] [PubMed]

- Wei, X.; Guo, Y.; Cheng, H.; Meng, X.; Cheng, M.; Yang, T.; Xu, C. Rock mass characteristics in Beishan, a preselected area for China’s high-level radioactive waste disposal. Acta Geol. Sin. 2019, 93, 116–126. [Google Scholar] [CrossRef]

- Xiong, J.; Wang, H.; Huang, L.; Zhang, H.; Liu, X.; Yin, G. Rock stress sensitivity in low-permeability gas reservoirs and its impact on productivity. IOP Conf. Ser. Earth Environ. Sci. 2020, 570, 022021. [Google Scholar] [CrossRef]

- Krause, F.F.; Collins, H.N.; Nelson, D.A.; Machemer, S.D.; French, P.R. Multiscale anatomy of a reservoir: Geological characterization of Pembina-Cardium pool, west-central Alberta, Canada. Aapg Bull. 1987, 71, 1233–1260. [Google Scholar]

- Afzali, S.; Zendehboudi, S.; Mohammadzadeh, O.; Rezaei, N. Hybrid mathematical modelling of three-phase flow in porous media: Application to water-alternating-gas injection. J. Nat. Gas Sci. Eng. 2021, 94, 103966. [Google Scholar] [CrossRef]

- Schäfer, G.; Roupert, R.D.C.; Alizadeh, A.H.; Piri, M. On the prediction of three-phase relative permeabilities using two-phase constitutive relationships. Adv. Water Resour. 2020, 145, 103731. [Google Scholar] [CrossRef]

- Zhu, X.; Wang, S.; Feng, Q.; Zhang, L.; Chen, L.; Tao, W. Pore-scale numerical prediction of three-phase relative permeability in porous media using the lattice Boltzmann method. Int. Commun. Heat Mass Transf. 2021, 126, 105403. [Google Scholar] [CrossRef]

- Zheng, M.; Li, J.; Wu, X.; Li, P.; Wang, W.; Wang, S.; Xie, H. Physical modeling of oil charging in tight reservoirs: A case study of Permian Lucaogou Formation in Jimsar Sag, Junggar Basin, NW China. Pet. Explor. Dev. 2016, 43, 241–250. [Google Scholar] [CrossRef]

- Wang, J.; Ge, H.; Liu, J.; Shen, Y.; Zhang, Z.; Luo, S.; Liu, D. Effects of Gravel Size and Content on the Mechanical Properties of Conglomerate. Rock Mech. Rock Eng. 2022, 55, 2493–2502. [Google Scholar] [CrossRef]

- Tan, F.; Li, H.; Xu, C.; Li, Q.; Peng, S. Quantitative evaluation methods for water-flooded layers of conglomerate reservoir based on well logging data. Pet. Sci. 2010, 7, 485–493. [Google Scholar] [CrossRef] [Green Version]

- Liu, Z.; Li, Y.; Chen, X.; Chen, Y.; Lyu, J.; Sui, M. The Optimal Initiation Timing of Surfactant-Polymer Flooding in a Waterflooded Conglomerate Reservoir. SPE J. 2021, 26, 2189–2202. [Google Scholar] [CrossRef]

- Malvić, T.; Sučić, A.; Cvetković, M.; Resanović, F.; Velić, J. Low permeability Neogene lithofacies in Northern Croatia as potential unconventional hydrocarbon reservoirs. Open Geosci. 2014, 6, 182–194. [Google Scholar] [CrossRef]

- Kaminskaite, I.; Fisher, Q.; Michie, E. Impact of Laboratory-Induced Deformation and Naturally-Occurring Faults on Fluid Flow in Carbonates. In Proceedings of the Fifth International Conference on Fault and Top Seals, Palermo, Italy, 8–12 September 2019; pp. 1–5. [Google Scholar] [CrossRef]

- Liu, C.; Yin, C.; Lu, J.; Sun, L.; Wang, Y.; Hu, B.; Li, J. Pore structure and physical properties of sandy conglomerate reservoirs in the Xujiaweizi depression, northern Songliao Basin, China. J. Pet. Sci. Eng. 2020, 192, 107217. [Google Scholar] [CrossRef]

| Pore Structures | ||||||

|---|---|---|---|---|---|---|

| Core Number | T01251 | T07252 | T14251 | T23251 | T28252 | T36251 |

| Depth, m | 2532.67 | 2544.08 | 2556.49 | 2591.6 | 2605.1 | 2613.7 |

| Primary pores | - | - | - | - | 10% | - |

| Secondary intragranular dissolution pores | 35% | 35% | 32% | 30% | 30% | 30% |

| Intergranular pores | 55% | 65% | 58% | 50% | 50% | 60% |

| Hetero group sparingly soluble pores | 10% | 10% | 10% | 20% | 10% | 10% |

| Pore surface rate, % | 8 | 9 | 11 | 5 | 10 | 6 |

| Total pore surface rate, % | 8 | 9 | 11 | 5 | 10 | 6 |

| Average pore diameter, μm | 256 | 186 | 355 | 108 | 160 | 430 |

| Average throat width, μm | 32 | 30 | 40 | 31 | 62 | 84 |

| Average pore-throat ratio | 8.28 | 6.2 | 8.88 | 3.48 | 2.58 | 5.1 |

| Average coordination number | 0.4 | 0.4 | 0.4 | 0.4 | 0.8 | 0.4 |

| Core Sample | Permeability (mD) | Whether Overpressure | Oil Displacement Rate (%) |

|---|---|---|---|

| T08251 | 1.04 | No | 50.1 |

| T25251 | 0.57 | No | 44.3 |

| T30251 | 0.36 | No | 42.1 |

| T27251 | 0.27 | No | 28.8 |

| T18251 | 0.19 | Yes | 11.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, Z.; Tang, H.; Wang, J.; Zhang, L.; Wang, X. Characterization of Extra Low-Permeability Conglomerate Reservoir and Analysis of Three-Phase Seepage Law. Processes 2023, 11, 2054. https://doi.org/10.3390/pr11072054

Jiang Z, Tang H, Wang J, Zhang L, Wang X. Characterization of Extra Low-Permeability Conglomerate Reservoir and Analysis of Three-Phase Seepage Law. Processes. 2023; 11(7):2054. https://doi.org/10.3390/pr11072054

Chicago/Turabian StyleJiang, Zhibin, Hongming Tang, Jie Wang, Lin Zhang, and Xiaoguang Wang. 2023. "Characterization of Extra Low-Permeability Conglomerate Reservoir and Analysis of Three-Phase Seepage Law" Processes 11, no. 7: 2054. https://doi.org/10.3390/pr11072054