Green Extraction Techniques of Bioactive Compounds: A State-of-the-Art Review

Abstract

:1. Introduction

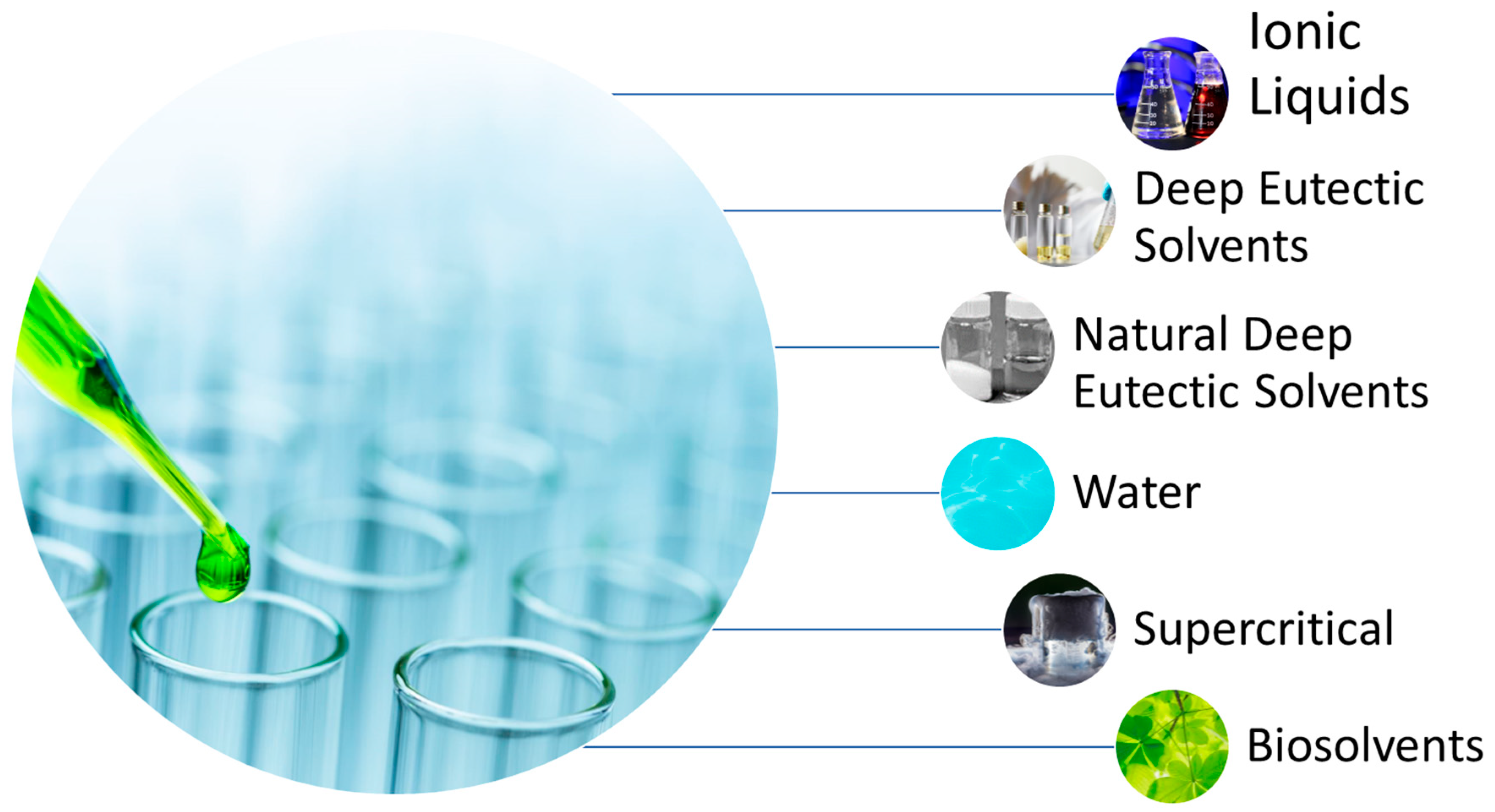

2. Green Solvents

3. Extraction Methods

3.1. Conventional Methods

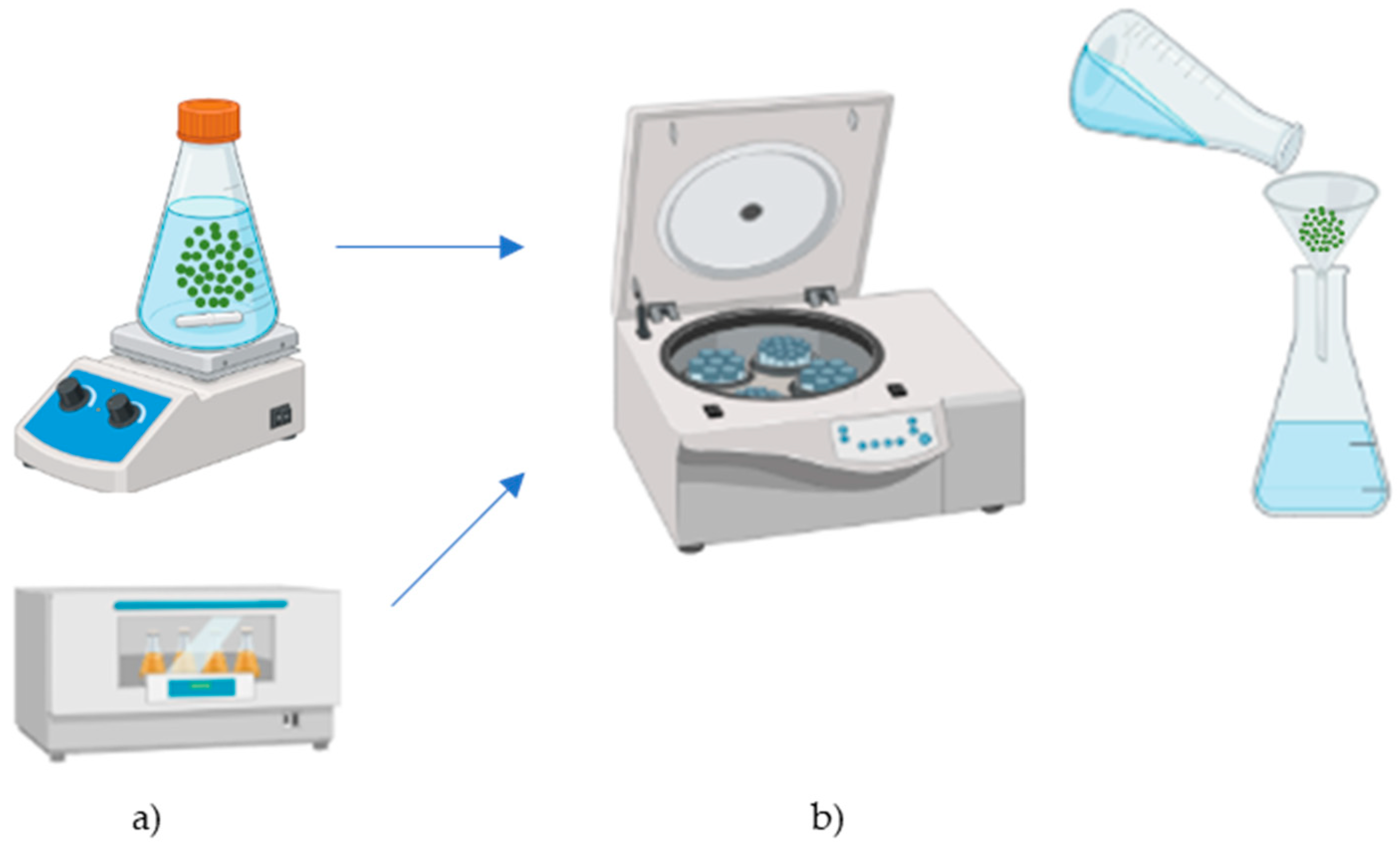

3.1.1. Maceration

Feed and Food Waste and Non-Compliance

| Biomass Source | Maceration Conditions | Yield | Ref. |

|---|---|---|---|

| Tomato peels | Ethyl lactate:ethanol (0.667:0.333), 40 °C, 30 min, solvent to biomass ratio (SB): 1:30 (w:v), 350 rpm | Lycopene (0.856 mg/g DW) | [45] |

| Tomato peels | Refined olive oil, 80 °C, 30 min, solvent to biomass ratio: 2.5% (w:v), 400 rpm | Lycopene (0.123 mg/g DW) | [44] |

| Tomato peels | Hydrogen-rich water, 25 °C, 24 h, SB: 1:20 (w:v), 120 rpm | Gallic acid (7.89 µg/g extract) Chlorogenic acid (1.11 µg/g extract) Caffeic acid (1.69 µg/g extract) Catechin (41.12 µg/g extract) Rutin (4.49 µg/g extract) | [50] |

| Onion peels | Hot water, 70 °C, 2 h, SB: 4:100; 500 rpm | Phenolics (21.24 mg GAE/g DW) Flavonoids (20.75 mg QE/g extract) | [48] |

| Onion waste | Glycerol:sodium propionate, 80 °C, 150 min, 900 rpm, SB: 1:100 (w:v) | Phenolics (137.50 mg GAE/g DW) | [47] |

| Banana peels | Ethanol 50% (v/v), 40 °C, 20 h, SB: 3:40 (w:v) | Phenolics (28.41 mg GAE/g) Flavonoids (19.07 mg QE/g) | [52] |

| Watermelon rind | Water, 60 °C, 80 min, SB: 1:10 (w:v) | Polysaccharides (34.4%) (Galactose, arabinose, glucose, galacturonic acid, mannose, rhamnose, xylose, and glucuronic acid) | [51] |

Microalgae

Lignocellulosic Biomass Sources

| Biomass Source | Maceration Conditions | Yield | Ref. |

|---|---|---|---|

| Pinus pinaster | Acidified water, SB: 1:17 (w:v), 40 °C | Yield of catechin: 2.34 mg/g of wood | [59] |

| Robinia pseudoacacia L. | Ethanol (80%), 250 rpm, 4 h | Flavonoids: 3670 mg/L | [61] |

| Populus nigra L. | Ethanol (70%), SB: 1:12 (w:v), 1 h | Total phenolic content (TPC): 334.87 mg of GAE/g extract | [62] |

| Quercus humboldtii Bonpl. | Ethanol (70%), SB: 1:5 (w:v) RT, 1 h | Yield: 1.09% TPC: 270.41 mg of GAE/g extract | [63] |

| Eucalyptus globulus Labill. | Ethanol, SB: 1:10 (w:v), 50 °C, 90 min | TPC: 85.71 g of GAE/100 g extract | [64] |

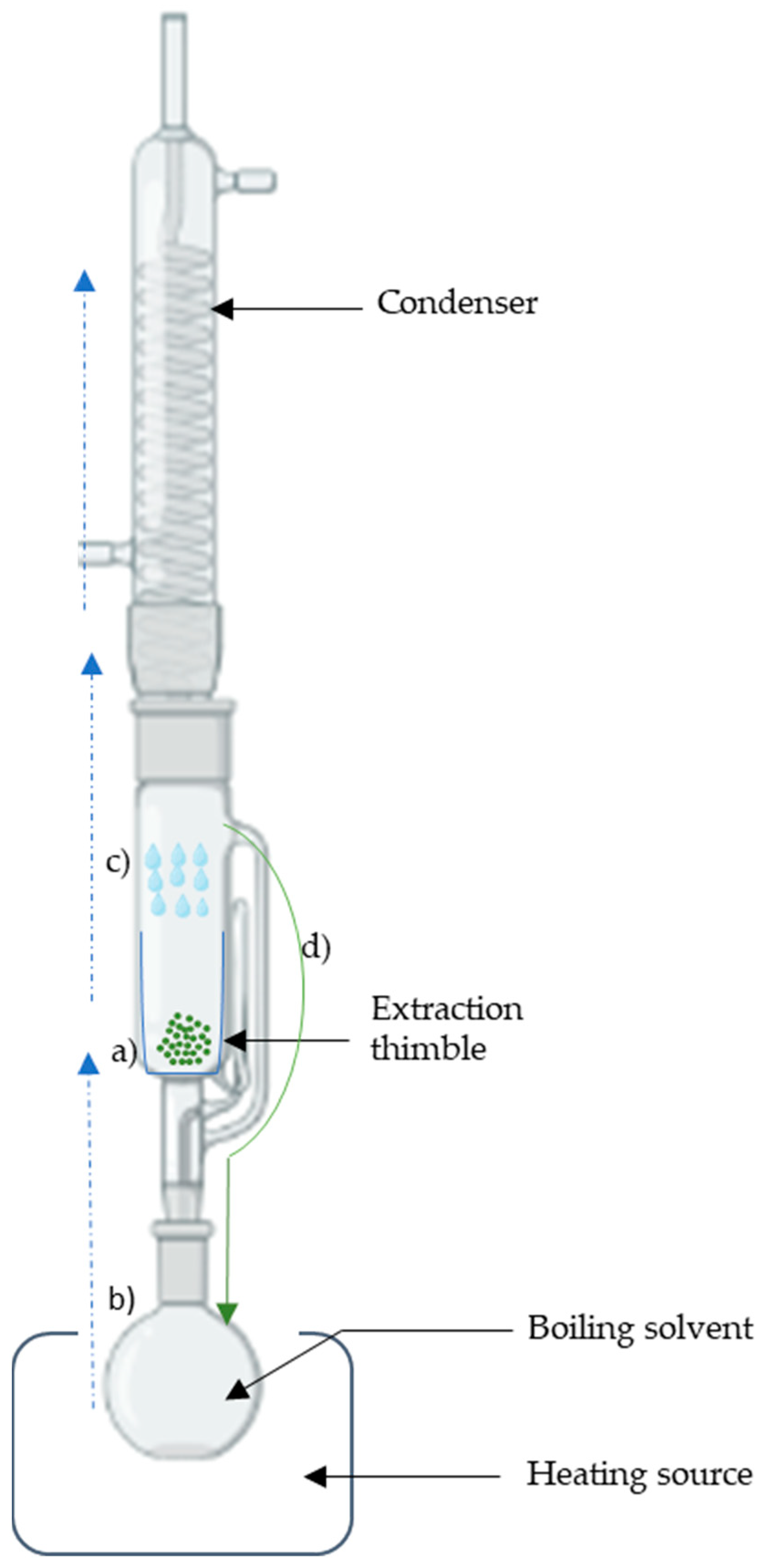

3.1.2. Soxhlet

Feed and Food Waste and Non-Compliance

Microalgae

Lignocellulosic Biomass Sources

3.2. Unconventional Methods

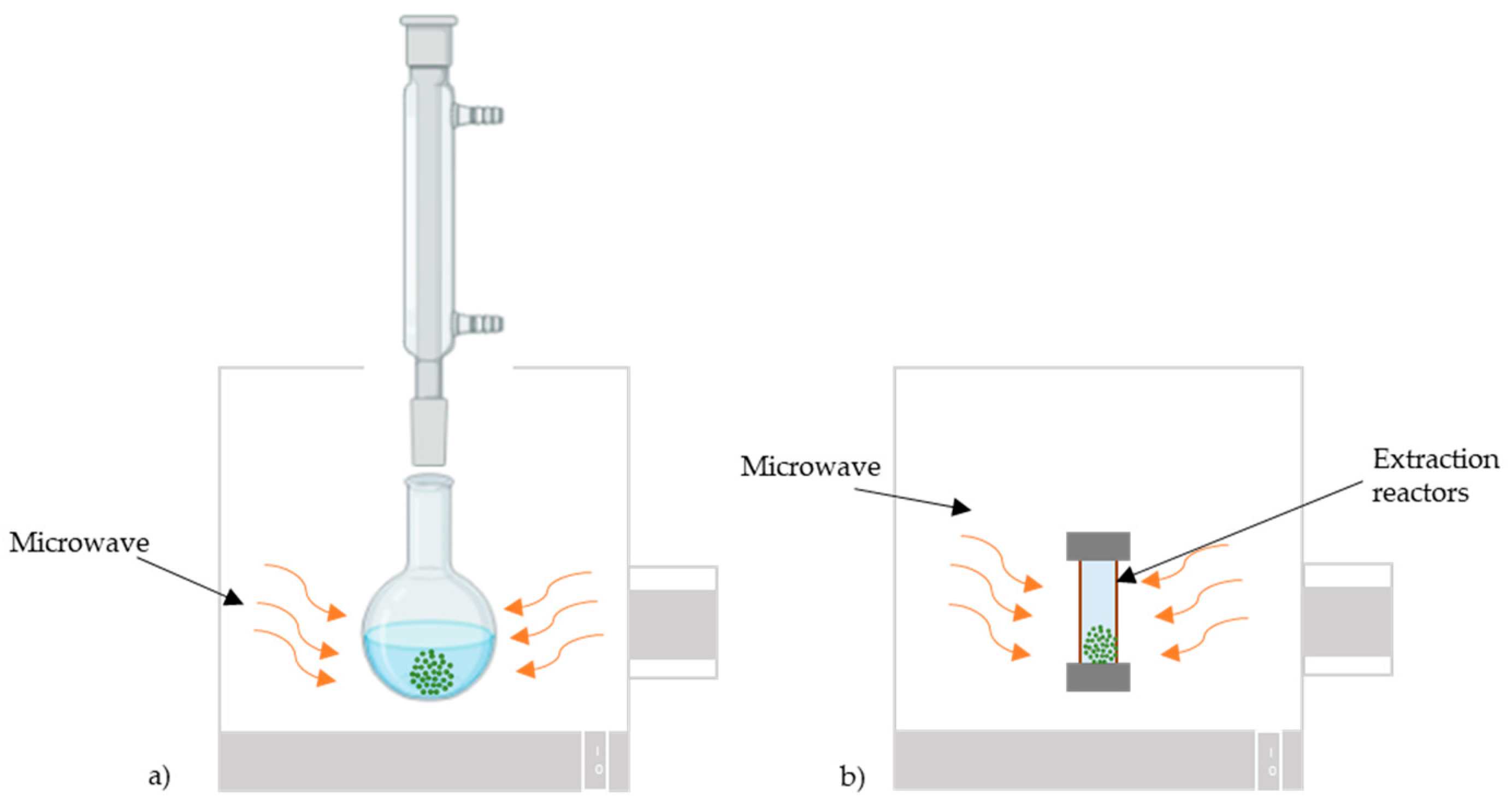

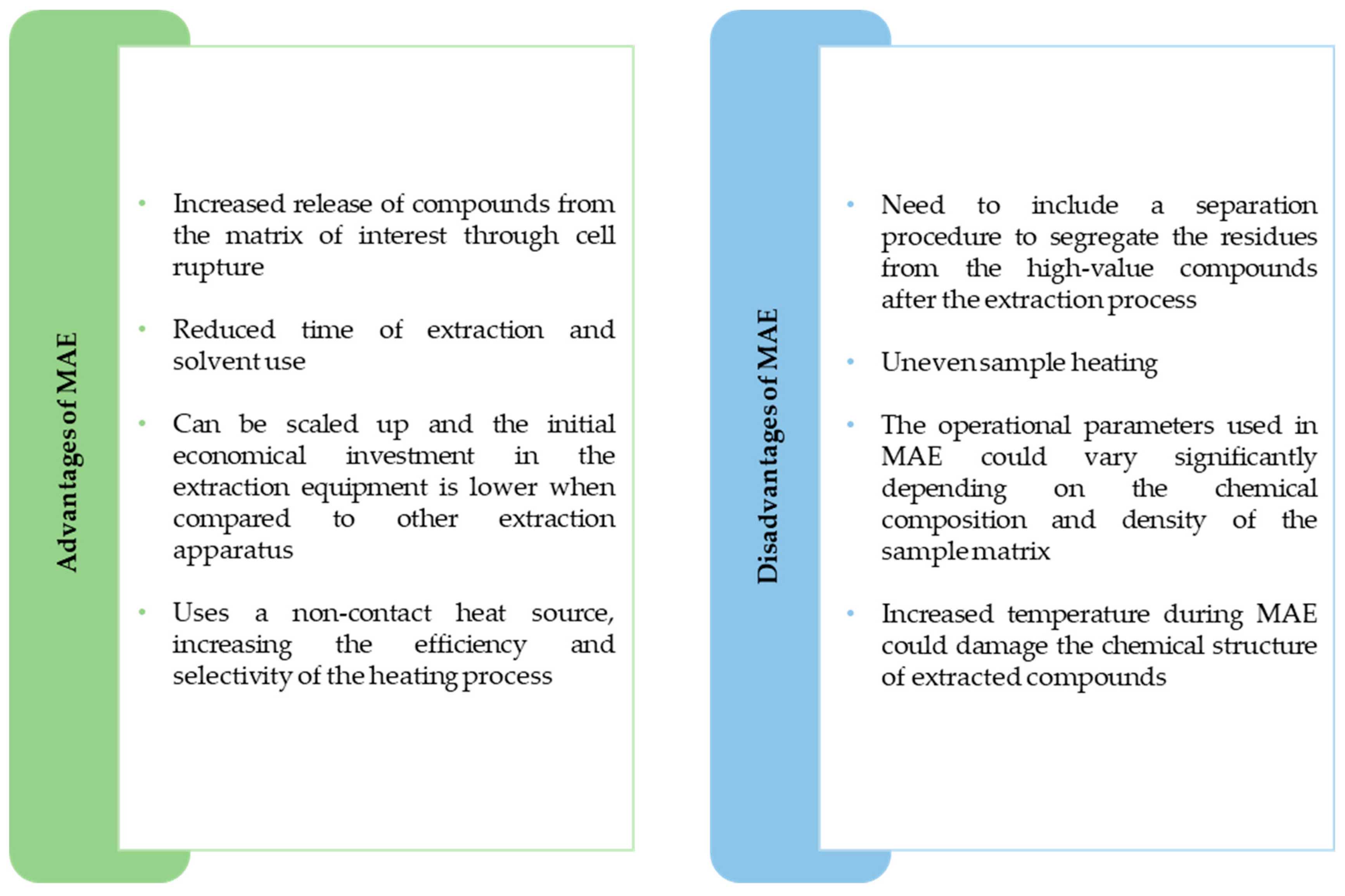

3.2.1. Microwave-Assisted Extraction (MAE)

Feed and Food Waste and Non-Compliance

Microalgae

| Biomass Source | MAE Conditions | Yield | Ref. |

|---|---|---|---|

| Phaeodactylum tricornutum | Ethanol, 2.45 GHz, 850 W, 30 °C, 2 min | 4.51% DW carotenoids and 0.46% DW fucoxanthin (32.26% recovery) | [56] |

| Spirulina sp. | Distilled water, 120 s, 1400 W, 2.450 MHz | Phycocyanin: 85.43 ± 0.60 mg/g | [96] |

| A. platensis | Water, 20 min, 434 W, SB: 1:30 | 127 ± 5 mg of carbohydrate/g of biomass | [93] |

| Chlorella sp. | Ethanol, 700 W, 78 °C, 6 min | 17.11% DW lipid | [94] |

| Spirulina sp. | Distilled water, 2.74 min, 40 ± 2 °C, 133 W | Phycocyanin: 28.90 mg/g | [95] |

Lignocellulosic Biomass Sources

| Biomass Source | MAE Conditions | Yield | Ref. |

|---|---|---|---|

| Eucalyptus globulus Labill. | Ethanol, SB: 1:10 (w:v), 50 °C, 10 min | TPC: 67.49 g GAE/100 g extract | [64] |

| Pinus pinaster | Solvent-free, 668 W, 43 min | Yield: 0.43% TPC: 74.62 mg GAE/g extract | [99] |

| Solvent-free, 600 W, 60 min | Yield: 0.27% (β-caryophyllene, longifolene, and α-terpineol) | [98] |

3.2.2. Ultrasound-Assisted Extraction (UAE)

Feed and Food Waste and Non-Compliance

Microalgae

Lignocellulosic Biomass Sources

| Biomass Source | UAE Conditions | Yield | Ref. |

|---|---|---|---|

| Pinus pinaster | Acidified water, SB: 1:17 (w:v), 40 °C, 43 min | Yield of catechin: 3.42 mg/g of wood | [98] |

| Olea europaea L. | Ethanol (70%), SB: 1:5 (w:v), RT, 1 h | Yield: 9.0% TPC: 156.04 mg GAE/g extract | [112] |

| Acer saccharum Marsh | Ethanol (95%), SB: 1:10 (w:v), 30 min | Yield: 2.3% TPC: 286 mg GAE/g extract | [111] |

| Quercus cerris L. | Ethanol (70%), SB: 1:5 (w:v), 1 h | Yield: 1.20% TPC: 350.28 mg GAE/g extract | [113] |

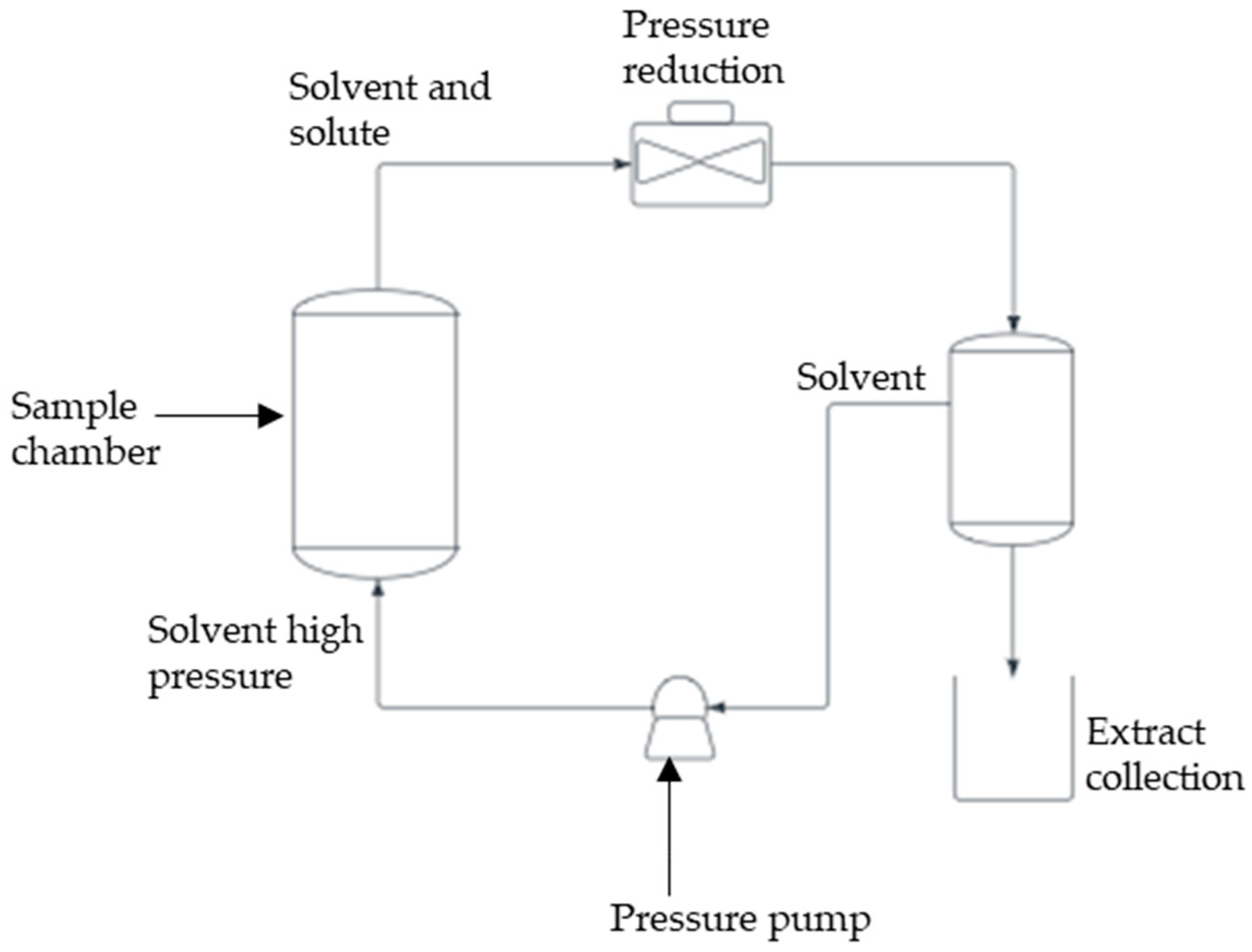

3.2.3. Supercritical Extraction (SC)

Feed and Food Waste and Non-Compliance

Microalgae

Lignocellulosic Biomass Sources

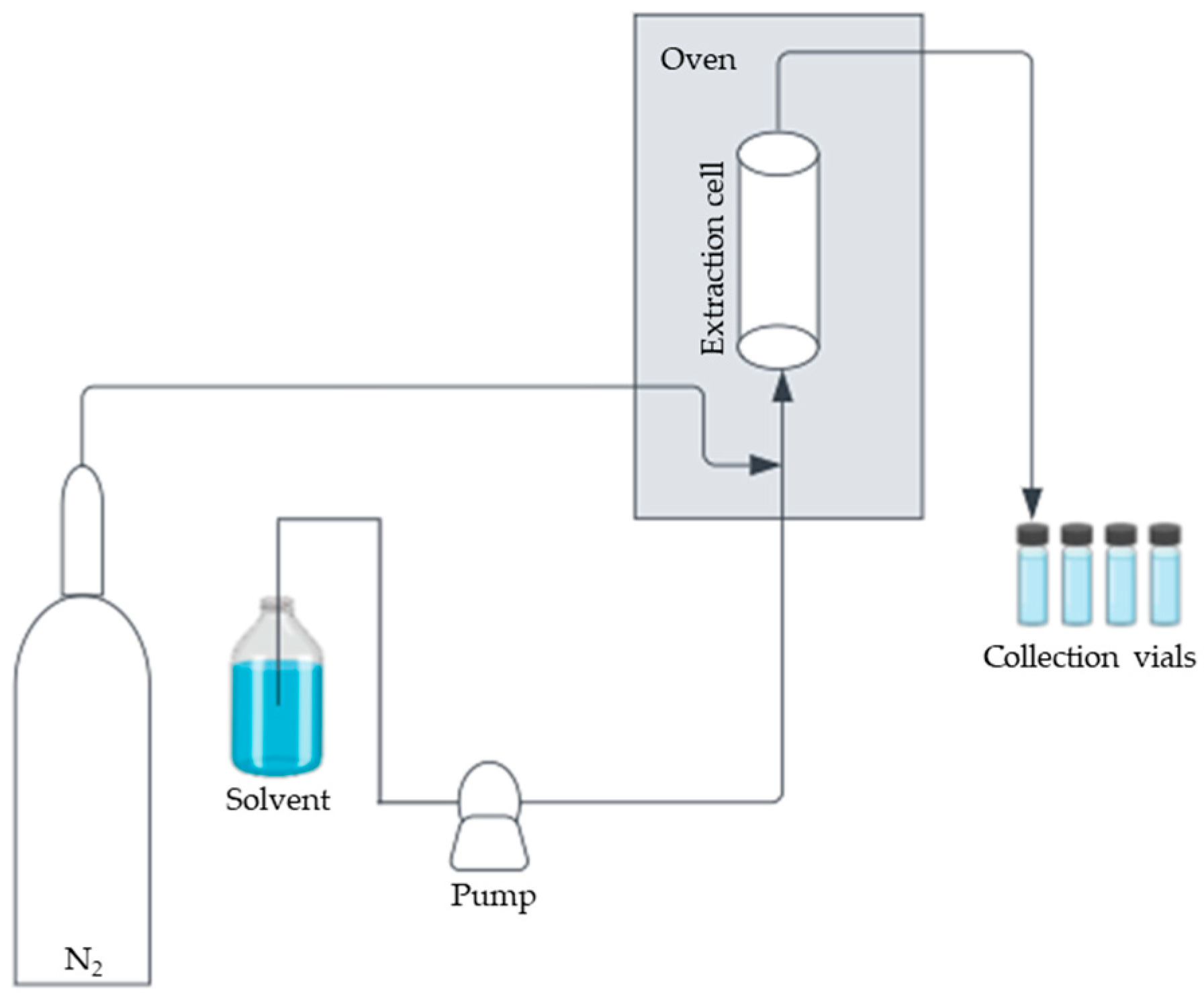

3.2.4. Pressurized Liquid Extraction (PLE)

Feed and Food Waste and Non-Compliance

Microalgae

Lignocellulosic Biomass Sources

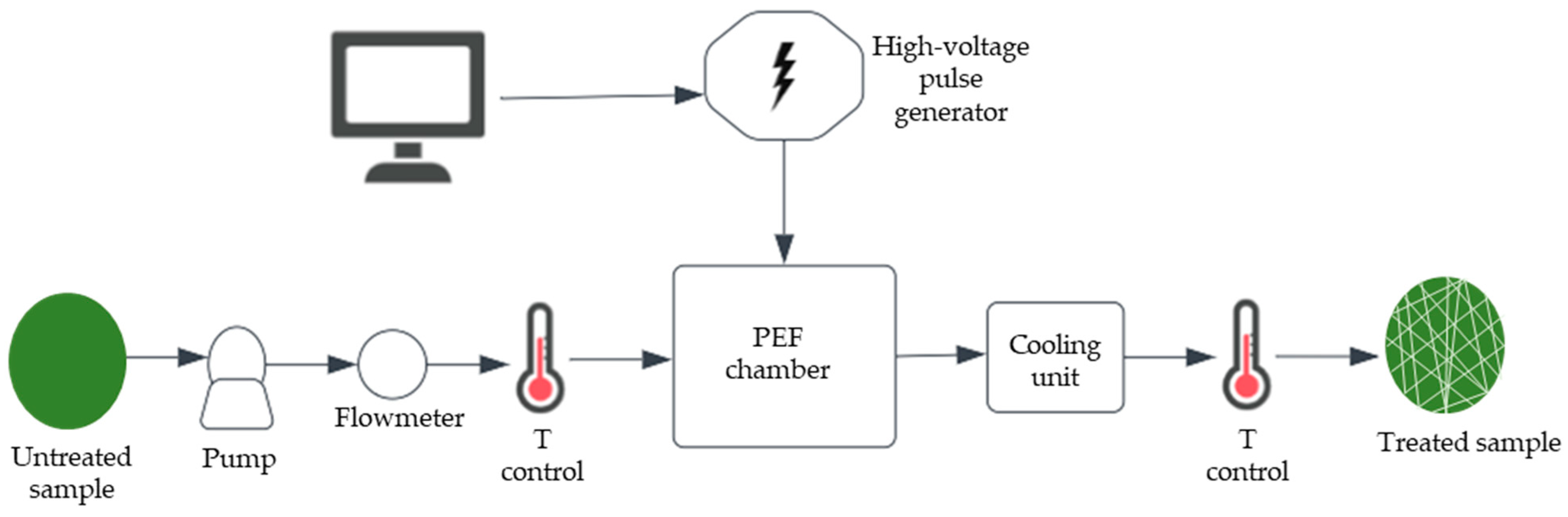

3.2.5. Pulsed Electric Fields (PEFs)

Feed and Food Waste and Non-Compliance

Microalgae

Lignocellulosic Biomass Sources

4. Conclusions and Future Perspectives

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AA | acid ascorbic |

| AAE | ascorbic acid equivalent |

| ABTS | 2,2′-azino-bis-3-ethylbenzthiazoline-6-sulphonic acid |

| AGREE | analytical greenness metric |

| ChCl | choline chloride |

| DES | deep eutectic solvents |

| DHA | docosahexaenoic acid |

| DPPH | 2,2-diphenyl-1-picrylhydrazyl |

| DW | dry weight |

| EPA | eicosapentaenoic acid |

| FAO | food and agricultural organization |

| Fen-Thy | fenchyl alcohol-thymol |

| GAE | gallic acid equivalents |

| GAPI | green analytical procedure index |

| GHCs | green house emissions |

| HRW | hydrogen-rich water |

| LCA | life cycle assessment |

| NADES | natural deep eutectic solvents |

| NEMI | national environmental methods index |

| MAE | microwave-assisted extraction |

| MHG | microwave hydrodiffusion and gravity |

| PLE | pressurized liquid extraction |

| PEF | pulsed electric fields |

| PUFAs | poly-unsaturated fatty acids |

| QE | quercetin equivalents |

| QSAR | quantitative structure acitivity relationship |

| ROS | reactive oxygen species |

| SB | solvent to biomass ratio |

| SC | supercritical fluid extraction |

| SC-CO2 | supercritical carbon dioxide |

| SFMH | solvent-free microwave hydrodistillation |

| TE | trolox equivalent |

| TPC | total phenolic content |

| UAE | ultrasound-assisted extraction |

| UFAs | unsaturated fatty acids |

| UN | united nations |

References

- ACS—American Chemical Society Green Chemistry. Available online: https://www.acs.org/greenchemistry/principles/12-principles-of-green-chemistry.html (accessed on 12 June 2023).

- Picot-Allain, C.; Mahomoodally, M.F.; Ak, G.; Zengin, G. Conventional versus green extraction techniques—A comparative perspective. Curr. Opin. Food Sci. 2021, 40, 144–156. [Google Scholar] [CrossRef]

- Chemat, F.; Vian, M.A.; Cravotto, G. Green Extraction of Natural Products: Concept and Principles. Int. J. Mol. Sci. 2012, 13, 8615–8627. [Google Scholar] [CrossRef] [Green Version]

- Benvenutti, L.; Zielinski, A.A.F.; Ferreira, S.R.S. Which is the best food emerging solvent: IL, DES or NADES? Trends Food Sci. Technol. 2019, 90, 133–146. [Google Scholar] [CrossRef]

- United Nation. Transforming Our World: The 2030 Agenda for Sustainable Development; United Nations: New York, NY, USA, 2015.

- Santos, D.I.; Saraiva, J.M.A.; Vicente, A.A.; Moldão-Martins, M. 2—Methods for Determining Bioavailability and Bioaccessibility of Bioactive Compounds and Nutrients. In Innovative Thermal and Non-Thermal Processing, Bioaccessibility and Bioavailability of Nutrients and Bioactive Compounds; Barba, F.J., Saraiva, J.M.A., Cravotto, G., Lorenzo, J.M., Eds.; Woodhead Publishing Series in Food Science, Technology and Nutrition; Woodhead Publishing: Cambridge, UK, 2019; pp. 23–54. ISBN 978-0-12-814174-8. [Google Scholar]

- Korga-Plewko, A.; Zgórka, G.; Józefczyk, A.; Grzegorczyk, A.; Biernasiuk, A.; Boguszewska, A.; Rajtar, B.; Świątek, Ł.; Polz-Dacewicz, M.; Kołodziej, P.; et al. Phytochemical profiling and biological activity of the extracts obtained from green biomass of three Miscanthus L. species using supercritical carbon dioxide extraction. Ind. Crops Prod. 2022, 189, 115641. [Google Scholar] [CrossRef]

- Kamiloglu, S.; Tomas, M.; Ozdal, T.; Yolci-Omeroglu, P.; Capanoglu, E. Chapter 2—Bioactive Component Analysis. In Innovative Food Analysis; Galanakis, C.M., Ed.; Academic Press: Cambridge, MA, USA, 2021; pp. 41–65. ISBN 978-0-12-819493-5. [Google Scholar]

- Sánchez-Muñoz, S.; Mariano-Silva, G.; Leite, M.O.; Mura, F.B.; Verma, M.L.; Da Silva, S.S.; Chandel, A.K. Production of Fungal and Bacterial Pigments and Their Applications. In Biotechnological Production of Bioactive Compounds; Elsevier: Amsterdam, The Netherlands, 2019; pp. 327–361. ISBN 9780444643230. [Google Scholar]

- Ravindran, R.; Jaiswal, A.K. Exploitation of Food Industry Waste for High-Value Products. Trends Biotechnol. 2016, 34, 58–69. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Majid, I.; Khan, S.; Aladel, A.; Dar, A.H.; Adnan, M.; Khan, M.I.; Mahgoub Awadelkareem, A.; Ashraf, S.A. Recent insights into green extraction techniques as efficient methods for the extraction of bioactive components and essential oils from foods. CyTA-J. Food 2023, 21, 101–114. [Google Scholar] [CrossRef]

- Rodríguez García, S.L.; Raghavan, V. Green extraction techniques from fruit and vegetable waste to obtain bioactive compounds—A review. Crit. Rev. Food Sci. Nutr. 2022, 62, 6446–6466. [Google Scholar] [CrossRef]

- Sharma, M.; Usmani, Z.; Gupta, V.K.; Bhat, R. Valorization of fruits and vegetable wastes and by-products to produce natural pigments. Crit. Rev. Biotechnol. 2021, 41, 535–563. [Google Scholar] [CrossRef]

- Martins, R.; Sales, H.; Pontes, R.; Nunes, J.; Gouveia, I. Food Wastes and Microalgae as Sources of Bioactive Compounds and Pigments in a Modern Biorefinery: A Review. Antioxidants 2023, 12, 328. [Google Scholar] [CrossRef]

- Saadaoui, I.; Rasheed, R.; Abdulrahman, N.; Bounnit, T.; Cherif, M.; Al Jabri, H.; Mraiche, F. Algae-Derived Bioactive Compounds with Anti-Lung Cancer Potential. Mar. Drugs 2020, 18, 197. [Google Scholar] [CrossRef] [Green Version]

- Martins, R.; Mouro, C.; Pontes, R.; Nunes, J.; Gouveia, I. NADES Extraction of Bioactive Pigments from Spirulina platensis and Electrospinning Ability Evaluation. Polymers 2023, 15, 1574. [Google Scholar] [CrossRef]

- Ben-Othman, S.; Jõudu, I.; Bhat, R. Bioactives from Agri-Food Wastes: Present Insights and Future Challenges. Molecules 2020, 25, 510. [Google Scholar] [CrossRef] [Green Version]

- More, P.R.; Jambrak, A.R.; Arya, S.S. Green, environment-friendly and sustainable techniques for extraction of food bioactive compounds and waste valorization. Trends Food Sci. Technol. 2022, 128, 296–315. [Google Scholar] [CrossRef]

- Socas-Rodríguez, B.; Álvarez-Rivera, G.; Valdés, A.; Ibáñez, E.; Cifuentes, A. Food By-Products and Food Wastes: Are They Safe Enough for Their Valorization? Trends Food Sci. Technol. 2021, 114, 133–147. [Google Scholar] [CrossRef]

- Nogueira, G.P.; McManus, M.C.; Leak, D.J.; Franco, T.T.; Oliveira de Souza Dias, M.; Nakao Cavaliero, C.K. Are eucalyptus harvest residues a truly burden-free biomass source for bioenergy? A deeper look into biorefinery process design and Life Cycle Assessment. J. Clean. Prod. 2021, 299, 126956. [Google Scholar] [CrossRef]

- Wei, H.; Yan, Y.; Gu, J.; Yi, W.; Tang, J. Lignocellulosic Biomass Valorization: Production of Ethanol. In Encyclopedia of Sustainable Technologies; Abraham, M.A., Ed.; Elsevier: Oxford, UK, 2017; pp. 601–604. ISBN 978-0-12-804792-7. [Google Scholar]

- Malolan, R.; Gopinath, K.P.; Vo, D.V.N.; Jayaraman, R.S.; Adithya, S.; Ajay, P.S.; Arun, J. Green ionic liquids and deep eutectic solvents for desulphurization, denitrification, biomass, biodiesel, bioethanol and hydrogen fuels: A review. Environ. Chem. Lett. 2021, 19, 1001–1023. [Google Scholar] [CrossRef]

- Bitwell, C.; Indra, S.S.; Luke, C.; Kakoma, M.K. A review of modern and conventional extraction techniques and their applications for extracting phytochemicals from plants. Sci. Afr. 2023, 19, e01585. [Google Scholar] [CrossRef]

- Dardavila, M.M.; Pappou, S.; Savvidou, M.G.; Louli, V.; Katapodis, P.; Stamatis, H.; Magoulas, K.; Voutsas, E. Extraction of Bioactive Compounds from C. vulgaris Biomass Using Deep Eutectic Solvents. Molecules 2023, 28, 415. [Google Scholar] [CrossRef]

- Yilmaz, E.; Soylak, M. Type of Green Solvents Used in Separation and Preconcentration Methods. In New Generation Green Solvents for Separation and Preconcentration of Organic and Inorganic Species; Elsevier: Amsterdam, The Netherlands, 2020; pp. 207–266. ISBN 9780128185698. [Google Scholar]

- Muralikrishna, I.V.; Manickam, V. Chapter Five—Life Cycle Assessment. In Environmental Management; Muralikrishna, I.V., Manickam, V., Eds.; Butterworth-Heinemann: Oxford, UK, 2017; pp. 57–75. ISBN 978-0-12-811989-1. [Google Scholar]

- Van Aken, K.; Strekowski, L.; Patiny, L. EcoScale, a semi-quantitative tool to select an organic preparation based on economical and ecological parameters. Beilstein J. Org. Chem. 2006, 2, 3. [Google Scholar] [CrossRef] [Green Version]

- Nash, D.B. In Silico Pharmacology. Am. Health Drug Benefits 2023, 9, 126. [Google Scholar] [CrossRef]

- Gamal, M.; Naguib, I.A.; Panda, D.S.; Abdallah, F.F. Comparative study of four greenness assessment tools for selection of greenest analytical method for assay of hyoscine N-butyl bromide. Anal. Methods 2021, 13, 369–380. [Google Scholar] [CrossRef] [PubMed]

- Giner, B.; Lafuente, C.; Lapeña, D.; Errazquin, D.; Lomba, L. QSAR study for predicting the ecotoxicity of NADES towards Aliivibrio fischeri. Exploring the use of mixing rules. Ecotoxicol. Environ. Saf. 2020, 191, 110004. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Li, H.; An, H.; Guan, J.; Shi, J.; Han, X. Are the environmental impacts, resource flows and economic benefits proportional? Analysis of key global trade routes based on the steel life cycle. Ecol. Indic. 2021, 122, 107306. [Google Scholar] [CrossRef]

- Clarke, C.J.; Tu, W.-C.; Levers, O.; Bröhl, A.; Hallett, J.P. Green and Sustainable Solvents in Chemical Processes. Chem. Rev. 2018, 118, 747–800. [Google Scholar] [CrossRef]

- Capello, C.; Fischer, U.; Hungerbühler, K. What is a green solvent? A comprehensive framework for the environmental assessment of solvents. Green Chem. 2007, 9, 927–934. [Google Scholar] [CrossRef]

- Winterton, N. The green solvent: A critical perspective. Clean Technol. Environ. Policy 2021, 23, 2499–2522. [Google Scholar] [CrossRef]

- Lei, Z.; Chen, B.; Koo, Y.-M.; MacFarlane, D.R. Introduction: Ionic Liquids. Chem. Rev. 2017, 117, 6633–6635. [Google Scholar] [CrossRef] [Green Version]

- Lajoie, L.; Fabiano-Tixier, A.S.; Chemat, F. Water as Green Solvent: Methods of Solubilisation and Extraction of Natural Products—Past, Present and Future Solutions. Pharmaceuticals 2022, 15, 1507. [Google Scholar] [CrossRef] [PubMed]

- Bandres, M.; De Caro, P.; Thiebaud-Roux, S.; Borredon, M.-E. Green syntheses of biobased solvents. C. R. Chim. 2011, 14, 636–646. [Google Scholar] [CrossRef]

- Popescu, M.; Iancu, P.; Plesu, V.; Todasca, M.C.; Isopencu, G.O.; Bildea, C.S. Valuable Natural Antioxidant Products Recovered from Tomatoes by Green Extraction. Molecules 2022, 27, 4191. [Google Scholar] [CrossRef]

- Prasad, W.; Wani, A.D.; Khamrui, K.; Hussain, S.A.; Khetra, Y. Green solvents, potential alternatives for petroleum based products in food processing industries. Clean. Chem. Eng. 2022, 3, 100052. [Google Scholar] [CrossRef]

- Viñas-Ospino, A.; López-Malo, D.; Esteve, M.J.; Frígola, A.; Blesa, J. Green Solvents: Emerging Alternatives for Carotenoid Extraction from Fruit and Vegetable By-Products. Foods 2023, 12, 863. [Google Scholar] [CrossRef]

- Nirmal, N.P.; Khanashyam, A.C.; Mundanat, A.S.; Shah, K.; Babu, K.S.; Thorakkattu, P.; Al-Asmari, F.; Pandiselvam, R. Valorization of Fruit Waste for Bioactive Compounds and Their Applications in the Food Industry. Foods 2023, 12, 556. [Google Scholar] [CrossRef] [PubMed]

- Salve, R.; Ray, S. Comprehensive Study of Different Extraction Methods of Extracting Bioactive Compounds from Pineapple Waste—A Review Ravindra R Salve and Subhajit Ray. Pharma Innov. J. 2020, 9, 327–340. [Google Scholar]

- Food and Agriculture Organization of the United Nations. FAOSTAT. Available online: https://www.fao.org/faostat/en/#data (accessed on 16 May 2023).

- Kehili, M.; Sayadi, S.; Frikha, F.; Zammel, A.; Allouche, N. Optimization of lycopene extraction from tomato peels industrial by-product using maceration in refined olive oil. Food Bioprod. Process. 2019, 117, 321–328. [Google Scholar] [CrossRef]

- Zuorro, A. Enhanced Lycopene Extraction from Tomato Peels by Optimized Mixed-Polarity Solvent Mixtures. Molecules 2020, 25, 2038. [Google Scholar] [CrossRef]

- Kumar, M.; Barbhai, M.D.; Hasan, M.; Punia, S.; Dhumal, S.; Rais, N.; Chandran, D.; Pandiselvam, R.; Kothakota, A.; Tomar, M.; et al. Onion (Allium cepa L.) peels: A review on bioactive compounds and biomedical activities. Biomed. Pharmacother. 2022, 146, 112498. [Google Scholar] [CrossRef]

- Stefou, I.; Grigorakis, S.; Loupassaki, S.; Makris, D.P. Development of sodium propionate-based deep eutectic solvents for polyphenol extraction from onion solid wastes. Clean Technol. Environ. Policy 2019, 21, 1563–1574. [Google Scholar] [CrossRef]

- Milea, Ș.A.; Crăciunescu, O.; Râpeanu, G.; Oancea, A.; Enachi, E.; Bahrim, G.E.; Stănciuc, N. Multifunctional Ingredient from Aqueous Flavonoidic Extract of Yellow Onion Skins with Cytocompatibility and Cell Proliferation Properties. Appl. Sci. 2021, 11, 7243. [Google Scholar] [CrossRef]

- Alwazeer, D.; Elnasanelkasim, M.A.; Çiçek, S.; Engin, T.; Çiğdem, A.; Karaoğul, E. Comparative study of phytochemical extraction using hydrogen-rich water and supercritical fluid extraction methods. Process. Biochem. 2023, 128, 218–226. [Google Scholar] [CrossRef]

- Alwazeer, D.; Elnasanelkasim, M.A. Hydrogen-rich water as a green solvent for the extraction of phytochemicals from agri-food wastes. Sustain. Chem. Pharm. 2023, 33, 101035. [Google Scholar] [CrossRef]

- Ben Romdhane, M.; Haddar, A.; Ghazala, I.; Ben Jeddou, K.; Helbert, C.B.; Ellouz-Chaabouni, S. Optimization of polysaccharides extraction from watermelon rinds: Structure, functional and biological activities. Food Chem. 2017, 216, 355–364. [Google Scholar] [CrossRef]

- Chaudhry, F.; Ahmad, M.L.; Hayat, Z.; Ranjha, M.M.A.N.; Chaudhry, K.; Elboughdiri, N.; Asmari, M.; Uddin, J. Extraction and Evaluation of the Antimicrobial Activity of Polyphenols from Banana Peels Employing Different Extraction Techniques. Separations 2022, 9, 165. [Google Scholar] [CrossRef]

- Naviglio, D.; Scarano, P.; Ciaravolo, M.; Gallo, M. Rapid Solid-Liquid Dynamic Extraction (RSLDE): A Powerful and Greener Alternative to the Latest Solid-Liquid Extraction Techniques. Foods 2019, 8, 245. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dianursanti; Nugroho, P.; Prakasa, M.B. Comparison of Maceration and Soxhletation Method for Flavonoid Production from Spirulina platensis as a Sunscreen’s Raw Material. In Proceedings of the AIP Conference Proceedings; American Institute of Physics Inc.: College Park, MD, USA, 2020; Volume 2230. [Google Scholar]

- Kim, S.M.; Jung, Y.J.; Kwon, O.N.; Cha, K.H.; Um, B.H.; Chung, D.; Pan, C.H. A Potential Commercial Source of Fucoxanthin Extracted from the Microalga Phaeodactylum tricornutum. Appl. Biochem. Biotechnol. 2012, 166, 1843–1855. [Google Scholar] [CrossRef] [PubMed]

- Gilbert-López, B.; Barranco, A.; Herrero, M.; Cifuentes, A.; Ibáñez, E. Development of new green processes for the recovery of bioactives from Phaeodactylum tricornutum. Food Res. Int. 2017, 99, 1056–1065. [Google Scholar] [CrossRef] [Green Version]

- Santos, M.B.; Sillero, L.; Gatto, D.A.; Labidi, J. Bioactive molecules in wood extractives: Methods of extraction and separation, a review. Ind. Crops Prod. 2022, 186, 115231. [Google Scholar] [CrossRef]

- Viñas, R.A.; Caudullo, G.; Oliveira, S.; De Rigo, D. Pinus pinaster in Europe: Distribution, Habitat, Usage and Threats. In European Atlas of Forest Tree Species; Publications Office of the EU: Luxembourg, 2016. [Google Scholar]

- Meullemiestre, A.; Petitcolas, E.; Maache-Rezzoug, Z.; Chemat, F.; Rezzoug, S.A. Impact of ultrasound on solid–liquid extraction of phenolic compounds from maritime pine sawdust waste. Kinetics, optimization and large scale experiments. Ultrason. Sonochem. 2016, 28, 230–239. [Google Scholar] [CrossRef]

- Wu, M.; Brown, A.C. Applications of Catechins in the Treatment of Bacterial Infections. Pathogens 2021, 10, 546. [Google Scholar] [CrossRef]

- Bostyn, S.; Destandau, E.; Charpentier, J.P.; Serrano, V.; Seigneuret, J.M.; Breton, C. Optimization and kinetic modelling of robinetin and dihydrorobinetin extraction from Robinia pseudoacacia wood. Ind. Crops Prod. 2018, 126, 22–30. [Google Scholar] [CrossRef]

- Todaro, L.; Russo, D.; Cetera, P.; Milella, L. Effects of thermo-vacuum treatment on secondary metabolite content and antioxidant activity of poplar (Populus nigra L.) wood extracts. Ind. Crops Prod. 2017, 109, 384–390. [Google Scholar] [CrossRef]

- Martínez-Gil, A.M.; del Alamo-Sanza, M.; Gutiérrez-Gamboa, G.; Moreno-Simunovic, Y.; Nevares, I. Volatile composition and sensory characteristics of Carménère wines macerating with Colombian (Quercus humboldtii) oak chips compared to wines macerated with American (Q. alba) and European (Q. petraea) oak chips. Food Chem. 2018, 266, 90–100. [Google Scholar] [CrossRef] [Green Version]

- Fernández-Agulló, A.; Freire, M.S.; González-Álvarez, J. Effect of the extraction technique on the recovery of bioactive compounds from eucalyptus (Eucalyptus globulus) wood industrial wastes. Ind. Crops Prod. 2015, 64, 105–113. [Google Scholar] [CrossRef]

- Zygler, A.; Słomińska, M.; Namieśnik, J. 2.04—Soxhlet Extraction and New Developments Such as Soxtec. In Comprehensive Sampling and Sample Preparation; Pawliszyn, J., Ed.; Academic Press: Oxford, UK, 2012; pp. 65–82. ISBN 978-0-12-381374-9. [Google Scholar]

- Pawliszyn, J. Comprehensive Sampling and Sample Preparation: Analytical Techniques for Scientists; Elsevier: Amsterdam, The Netherlands, 2012; ISBN 9780123813732. [Google Scholar]

- Al-Ansari, M.M.; Al-Humaid, L.; Aldawsari, M.; Abid, I.F.; Jhanani, G.K.; Shanmuganathan, R. Quercetin extraction from small onion skin (Allium cepa L. var. aggregatum Don.) and its antioxidant activity. Environ. Res. 2023, 224, 115497. [Google Scholar] [CrossRef] [PubMed]

- Nasir, N.; Roslly, N.; Razali, Z. Phytochemical Screening and Potential DPPH Radical Scavenging Activity of Banana Peel Extract. In Proceedings of the Charting the sustainable future of ASEAN in Science and Technology: Proceeding from the 3rd International Conference on the Future of ASEAN (ICoFA); Alias, N., Yusof, R., Eds.; Springer: Singapore, 2019; Volume 2, pp. 249–258. [Google Scholar]

- Zhou, J.; Wang, M.; Saraiva, J.A.; Martins, A.P.; Pinto, C.A.; Prieto, M.A.; Simal-Gandara, J.; Cao, H.; Xiao, J.; Barba, F.J. Extraction of lipids from microalgae using classical and innovative approaches. Food Chem. 2022, 384, 132236. [Google Scholar] [CrossRef] [PubMed]

- Ramluckan, K.; Moodley, K.G.; Bux, F. An evaluation of the efficacy of using selected solvents for the extraction of lipids from algal biomass by the soxhlet extraction method. Fuel 2014, 116, 103–108. [Google Scholar] [CrossRef]

- Liau, B.-C.; Shen, C.-T.; Liang, F.-P.; Hong, S.-E.; Hsu, S.-L.; Jong, T.-T.; Chang, C.-M.J. Supercritical fluids extraction and anti-solvent purification of carotenoids from microalgae and associated bioactivity. J. Supercrit. Fluids 2010, 55, 169–175. [Google Scholar] [CrossRef]

- Sheng, J.; Vannela, R.; Rittmann, B.E. Evaluation of methods to extract and quantify lipids from Synechocystis PCC 6803. Bioresour. Technol. 2011, 102, 1697–1703. [Google Scholar] [CrossRef] [PubMed]

- do Nascimento, T.C.; Cazarin, C.B.B.; Maróstica, M.R.; Mercadante, A.Z.; Jacob-Lopes, E.; Zepka, L.Q. Microalgae carotenoids intake: Influence on cholesterol levels, lipid peroxidation and antioxidant enzymes. Food Res. Int. 2020, 128, 108770. [Google Scholar] [CrossRef]

- Santigosa, E.; Brambilla, F.; Milanese, L. Microalgae Oil as an Effective Alternative Source of EPA and DHA for Gilthead Seabream (Sparus aurata) Aquaculture. Animals 2021, 11, 971. [Google Scholar] [CrossRef]

- Charles, C.N.; Msagati, T.; Swai, H.; Chacha, M. Microalgae: An alternative natural source of bioavailable omega-3 DHA for promotion of mental health in East Africa. Sci. Afr. 2019, 6, e00187. [Google Scholar] [CrossRef]

- Rodríguez-Cabo, T.; Rodríguez, I.; Ramil, M.; Cela, R. Assessment of alcoholic distillates for the extraction of bioactive polyphenols from grapevine canes. Ind. Crops Prod. 2018, 111, 99–106. [Google Scholar] [CrossRef]

- Setiawan, H.; Angela, I.L.; Rohmah, N.; Wijaya, O.; Mun’Im, A. Application of Natural Deep Eutectic Solvents (NADES) for Sappan Wood (Caesalpinia sappan L.) Extraction to Test for Inhibition of DPP IV Activity. J. Res. Pharm. 2020, 24, 380–388. [Google Scholar] [CrossRef]

- Ngamwonglumlert, L.; Devahastin, S. Brazilein as an alternative pigment: Isolation, characterization, stability enhancement and food applications. Food Chem. 2023, 398, 133898. [Google Scholar] [CrossRef] [PubMed]

- Zhao, S.; Zhang, D. Supercritical CO2 extraction of Eucalyptus leaves oil and comparison with Soxhlet extraction and hydro-distillation methods. Sep. Purif. Technol. 2014, 133, 443–451. [Google Scholar] [CrossRef]

- Lopez-Avila, V.; Luque de Castro, M.D. Microwave-Assisted Extraction. In Reference Module in Chemistry, Molecular Sciences and Chemical Engineering; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Gomez, L.; Tiwari, B.; Garcia-Vaquero, M. Emerging Extraction Techniques: Microwave-Assisted Extraction. In Sustainable Seaweed Technologies: Cultivation, Biorefinery, and Applications; Elsevier: Amsterdam, The Netherlands, 2020; pp. 207–224. ISBN 9780128179437. [Google Scholar]

- Luque-García, J.L.; Luque De Castro, M.D. Where Is Microwave-Based Analytical Equipment for Solid Sample Pre-Treatment Going? TrAC-Trends Anal. Chem. 2003, 22, 90–98. [Google Scholar] [CrossRef]

- Zhi, W.J.; Wang, L.F.; Hu, X.J. Recent advances in the effects of microwave radiation on brains. Mil. Med. Res. 2017, 4, 29. [Google Scholar] [CrossRef] [Green Version]

- Veggi, P.C.; Martinez, J.; Meireles, M.A.A. Fundamentals of Microwave Extraction. In Food Engineering Series; Springer: Berlin/Heidelberg, Germany, 2013; pp. 15–52. [Google Scholar]

- Feller, R.; Matos, Â.P.; Mazzutti, S.; Moecke, E.H.S.; Tres, M.V.; Derner, R.B.; Oliveira, J.V.; Junior, A.F. Polyunsaturated ω-3 and ω-6 fatty acids, total carotenoids and antioxidant activity of three marine microalgae extracts obtained by supercritical CO2 and subcritical n-butane. J. Supercrit. Fluids 2018, 133, 437–443. [Google Scholar] [CrossRef]

- Belwal, T.; Bhatt, I.D.; Rawal, R.S.; Pande, V. Microwave-assisted extraction (MAE) conditions using polynomial design for improving antioxidant phytochemicals in Berberis asiatica Roxb. ex DC. leaves. Ind. Crops Prod. 2017, 95, 393–403. [Google Scholar] [CrossRef]

- Hu, B.; Xi, X.; Li, H.; Qin, Y.; Li, C.; Zhang, Z.; Liu, Y.; Zhang, Q.; Liu, A.; Liu, S.; et al. A comparison of extraction yield, quality and thermal properties from Sapindus mukorossi seed oil between microwave assisted extraction and Soxhlet extraction. Ind. Crops Prod. 2021, 161, 113185. [Google Scholar] [CrossRef]

- Lasunon, P.; Sengkhamparn, N. Effect of Ultrasound-Assisted, Microwave-Assisted and Ultrasound-Microwave-Assisted Extraction on Pectin Extraction from Industrial Tomato Waste. Molecules 2022, 27, 1157. [Google Scholar] [CrossRef] [PubMed]

- Pal, C.B.T.; Jadeja, G.C. Microwave-assisted deep eutectic solvent extraction of phenolic antioxidants from onion (Allium cepa L.) peel: A Box–Behnken design approach for optimization. J. Food Sci. Technol. 2019, 56, 4211–4223. [Google Scholar] [CrossRef]

- Vu, H.T.; Scarlett, C.J.; Vuong, Q.V. Maximising recovery of phenolic compounds and antioxidant properties from banana peel using microwave assisted extraction and water. J. Food Sci. Technol. 2019, 56, 1360–1370. [Google Scholar] [CrossRef] [PubMed]

- Chada, P.S.N.; Santos, P.H.; Rodrigues, L.G.G.; Goulart, G.A.S.; Azevedo dos Santos, J.D.; Maraschin, M.; Lanza, M. Non-conventional techniques for the extraction of antioxidant compounds and lycopene from industrial tomato pomace (Solanum lycopersicum L.) using spouted bed drying as a pre-treatment. Food Chem. X 2022, 13, 100237. [Google Scholar] [CrossRef] [PubMed]

- Yao, S.; Mettu, S.; Law, S.Q.K.; Ashokkumar, M.; Martin, G.J.O. The effect of high-intensity ultrasound on cell disruption and lipid extraction from high-solids viscous slurries of Nannochloropsis sp. biomass. Algal Res. 2018, 35, 341–348. [Google Scholar] [CrossRef]

- Larrosa, A.P.Q.; Camara, Á.S.; Moura, J.M.; Pinto, L.A.A. Spirulina sp. biomass dried/disrupted by different methods and their application in biofilms production. Food Sci. Biotechnol. 2018, 27, 1659–1665. [Google Scholar] [CrossRef]

- de Sousa eSilva, A.; de Magalhães, W.T.; Moreira, L.M.; Rocha, M.V.P.; Bastos, A.K.P. Microwave-assisted extraction of polysaccharides from Arthrospira (Spirulina) platensis using the concept of green chemistry. Algal Res. 2018, 35, 178–184. [Google Scholar] [CrossRef]

- Kapoore, R.V.; Butler, T.O.; Pandhal, J.; Vaidyanathan, S. Microwave-Assisted Extraction for Microalgae: From Biofuels to Biorefinery. Biology 2018, 7, 18. [Google Scholar] [CrossRef] [Green Version]

- İlter, I.; Akyıl, S.; Demirel, Z.; Koç, M.; Conk-Dalay, M.; Kaymak-Ertekin, F. Optimization of phycocyanin extraction from Spirulina platensis using different techniques. J. Food Compos. Anal. 2018, 70, 78–88. [Google Scholar] [CrossRef]

- Cheng, J.; Sun, J.; Huang, Y.; Feng, J.; Zhou, J.; Cen, K. Dynamic microstructures and fractal characterization of cell wall disruption for microwave irradiation-assisted lipid extraction from wet microalgae. Bioresour. Technol. 2013, 150, 67–72. [Google Scholar] [CrossRef]

- Meullemiestre, A.; Petitcolas, E.; Maache-Rezzoug, Z.; Ginies, C.; Chemat, F.; Rezzoug, S.-A. Isolation of volatils from maritime pine sawdust waste by different processes: Ultrasound, microwave, turbohydrodistillation, and hydrodistillation. Wood Mater. Sci. Eng. 2014, 9, 76–83. [Google Scholar] [CrossRef]

- Meullemiestre, A.; Maache-Rezzoug, Z.; Chemat, F.; Rezzoug, S.A. Optimization of Solvent Free Microwave Extraction of Natural Antioxidant from Wood Waste. J. Mater. 2017, 8, 2608–2618. [Google Scholar]

- Kumar, K.; Srivastav, S.; Sharanagat, V.S. Ultrasound assisted extraction (UAE) of bioactive compounds from fruit and vegetable processing by-products: A review. Ultrason. Sonochem. 2021, 70, 105325. [Google Scholar] [CrossRef]

- Szabo, K.; Teleky, B.E.; Ranga, F.; Roman, I.; Khaoula, H.; Boudaya, E.; Ben Ltaief, A.; Aouani, W.; Thiamrat, M.; Vodnar, D.C. Carotenoid Recovery from Tomato Processing By-Products through Green Chemistry. Molecules 2022, 27, 3771. [Google Scholar] [CrossRef]

- Diacon, A.; Călinescu, I.; Vinatoru, M.; Chipurici, P.; Vlaicu, A.; Boscornea, A.C.; Mason, T.J. Fatty Acid Ethyl Esters (FAEE): A New, Green and Renewable Solvent for the Extraction of Carotenoids from Tomato Waste Products. Molecules 2021, 26, 4388. [Google Scholar] [CrossRef] [PubMed]

- de los Fernández, M.Á.; Espino, M.; Gomez, F.J.V.; Silva, M.F. Novel approaches mediated by tailor-made green solvents for the extraction of phenolic compounds from agro-food industrial by-products. Food Chem. 2018, 239, 671–678. [Google Scholar] [CrossRef] [PubMed]

- Fadimu, G.J.; Ghafoor, K.; Babiker, E.E.; Al-Juhaimi, F.; Abdulraheem, R.A.; Adenekan, M.K. Ultrasound-assisted process for optimal recovery of phenolic compounds from watermelon (Citrullus lanatus) seed and peel. J. Food Meas. Charact. 2020, 14, 1784–1793. [Google Scholar] [CrossRef]

- Rodrigues, R.D.P.; de Castro, F.C.; de Santiago-Aguiar, R.S.; Rocha, M.V.P. Ultrasound-assisted extraction of phycobiliproteins from Spirulina (Arthrospira) platens is using protic ionic liquids as solvent. Algal Res. 2018, 31, 454–462. [Google Scholar] [CrossRef]

- Wils, L.; Leman-Loubière, C.; Bellin, N.; Clément-Larosière, B.; Pinault, M.; Chevalier, S.; Enguehard-Gueiffier, C.; Bodet, C.; Boudesocque-Delaye, L. Natural deep eutectic solvent formulations for spirulina: Preparation, intensification, and skin impact. Algal Res. 2021, 56, 102317. [Google Scholar] [CrossRef]

- Fan, C.; Liu, Y.; Shan, Y.; Cao, X. A priori design of new natural deep eutectic solvent for lutein recovery from microalgae. Food Chem. 2022, 376, 131930. [Google Scholar] [CrossRef] [PubMed]

- Zou, T.B.; Jia, Q.; Li, H.W.; Wang, C.X.; Wu, H.-F. Response Surface Methodology for Ultrasound-Assisted Extraction of Astaxanthin from Haematococcus pluvialis. Mar. Drugs 2013, 11, 1644–1655. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ojha, K.S.; Aznar, R.; O’Donnell, C.; Tiwari, B.K. Ultrasound technology for the extraction of biologically active molecules from plant, animal and marine sources. TrAC-Trends Anal. Chem. 2020, 122, 115663. [Google Scholar] [CrossRef]

- Pez Jaeschke, D.; Rocha Teixeira, I.; Damasceno Ferreira Marczak, L.; Domeneghini Mercali, G. Phycocyanin from Spirulina: A Review of Extraction Methods and Stability. Food Res. Int. 2021, 143, 110314. [Google Scholar] [CrossRef] [PubMed]

- St-Pierre, F.; Achim, A.; Stevanovic, T. Composition of ethanolic extracts of wood and bark from Acer saccharum and Betula alleghaniensis trees of different vigor classes. Ind. Crops Prod. 2013, 41, 179–187. [Google Scholar] [CrossRef]

- Faraone, I.; Russo, D.; Bruno, M.R.; Todaro, L.; D’Auria, M.; Milella, L. Focus on Olea europaea L. pruning by-products: Extraction techniques, biological activity, and phytochemical profile. Biofuels Bioprod. Biorefin. 2021, 15, 1835–1849. [Google Scholar] [CrossRef]

- Cetera, P.; Russo, D.; Milella, L.; Todaro, L. Thermo-treatment affects Quercus cerris L. wood properties and the antioxidant activity and chemical composition of its by-product extracts. Ind. Crops Prod. 2019, 130, 380–388. [Google Scholar] [CrossRef]

- Chen, M.; Wen, S.S.; Wang, R.; Ren, Q.X.; Guo, C.W.; Li, P.; Gao, W. Advanced Development of Supercritical Fluid Chromatography in Herbal Medicine Analysis. Molecules 2022, 27, 4159. [Google Scholar] [CrossRef]

- Belo, Y.N.; Al-Hamimi, S.; Chimuka, L.; Turner, C. Ultrahigh-pressure supercritical fluid extraction and chromatography of Moringa oleifera and Moringa peregrina seed lipids. Anal. Bioanal. Chem. 2019, 411, 3685–3693. [Google Scholar] [CrossRef] [Green Version]

- Rosas-Quina, Y.E.; Mejía-Nova, F.C. Supercritical fluid extraction with cosolvent of alkaloids from Lupinus mutabilis Sweet and comparison with conventional method. J. Food Process. Eng. 2021, 44, e13657. [Google Scholar] [CrossRef]

- Zhang, H.; Li, Q.; Qiao, G.; Qiu, Z.; Wen, Z.; Wen, X. Optimizing the supercritical carbon dioxide extraction of sweet cherry (Prunus avium L.) leaves and UPLC-MS/MS analysis. Anal. Methods 2020, 12, 3004–3013. [Google Scholar] [CrossRef]

- de Lima, M.A.; Andreou, R.; Charalampopoulos, D.; Chatzifragkou, A. Supercritical Carbon Dioxide Extraction of Phenolic Compounds from Potato (Solanum tuberosum) Peels. Appl. Sci. 2021, 11, 3410. [Google Scholar] [CrossRef]

- Vági, E.; Balázs, M.; Komoczi, A.; Mihalovits, M.; Székely, E. Fractionation of phytocannabinoids from industrial hemp residues with high-pressure technologies. J. Supercrit. Fluids 2020, 164, 104898. [Google Scholar] [CrossRef]

- Uquiche, E.; Campos, C.; Marillán, C. Assessment of the bioactive capacity of extracts from Leptocarpha rivularis stalks using ethanol-modified supercritical CO2. J. Supercrit. Fluids 2019, 147, 1–8. [Google Scholar] [CrossRef]

- Goyeneche, R.; Fanovich, A.; Rodriguez Rodrigues, C.; Nicolao, M.C.; Di Scala, K. Supercritical CO2 extraction of bioactive compounds from radish leaves: Yield, antioxidant capacity and cytotoxicity. J. Supercrit. Fluids 2018, 135, 78–83. [Google Scholar] [CrossRef] [Green Version]

- Kassama, L.S.; Shi, J.; Mittal, G.S. Optimization of supercritical fluid extraction of lycopene from tomato skin with central composite rotatable design model. Sep. Purif. Technol. 2008, 60, 278–284. [Google Scholar] [CrossRef]

- Yi, C.; Shi, J.; Xue, S.J.; Jiang, Y.; Li, D. Effects of supercritical fluid extraction parameters on lycopene yield and antioxidant activity. Food Chem. 2009, 113, 1088–1094. [Google Scholar] [CrossRef]

- Prasad, K.N.; Yang, B.; Shi, J.; Yu, C.; Zhao, M.; Xue, S.; Jiang, Y. Enhanced antioxidant and antityrosinase activities of longan fruit pericarp by ultra-high-pressure-assisted extraction. J. Pharm. Biomed. Anal. 2010, 51, 471–477. [Google Scholar] [CrossRef]

- Ferrentino, G.; Giampiccolo, S.; Morozova, K.; Haman, N.; Spilimbergo, S.; Scampicchio, M. Supercritical fluid extraction of oils from apple seeds: Process optimization, chemical characterization and comparison with a conventional solvent extraction. Innov. Food Sci. Emerg. Technol. 2020, 64, 102428. [Google Scholar] [CrossRef]

- Hatami, T.; Meireles, M.A.A.; Ciftci, O.N. Supercritical carbon dioxide extraction of lycopene from tomato processing by-products: Mathematical modeling and optimization. J. Food Eng. 2019, 241, 18–25. [Google Scholar] [CrossRef]

- Constantin, O.E.; Milea, A.S.; Bolea, C.; Mihalcea, L.; Enachi, E.; Copolovici, D.M.; Copolovici, L.; Munteanu, F.; Bahrim, G.E.; Râpeanu, G. Onion (Allium cepa L.) peel extracts characterization by conventional and modern methods. Int. J. Food Eng. 2020, 17, 485–493. [Google Scholar] [CrossRef]

- Obeid, S.; Beaufils, N.; Camy, S.; Takache, H.; Ismail, A.; Pontalier, P.Y. Supercritical carbon dioxide extraction and fractionation of lipids from freeze-dried microalgae Nannochloropsis oculata and Chlorella vulgaris. Algal Res. 2018, 34, 49–56. [Google Scholar] [CrossRef] [Green Version]

- Di Sanzo, G.; Mehariya, S.; Martino, M.; Larocca, V.; Casella, P.; Chianese, S.; Musmarra, D.; Balducchi, R.; Molino, A. Supercritical Carbon Dioxide Extraction of Astaxanthin, Lutein, and Fatty Acids from Haematococcus pluvialis Microalgae. Mar. Drugs 2018, 16, 334. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Viguera, M.; Marti, A.; Masca, F.; Prieto, C.; Calvo, L. The process parameters and solid conditions that affect the supercritical CO2 extraction of the lipids produced by microalgae. J. Supercrit. Fluids 2016, 113, 16–22. [Google Scholar] [CrossRef]

- Bong, S.C.; Loh, S. A study of fatty acid composition and tocopherol content of lipid extracted from marine microalgae, Nannochloropsis oculata and Tetraselmis suecica, using solvent extraction and supercritical fluid extraction. Int. Food Res. J. 2013, 20, 721–729. [Google Scholar]

- Lorenzen, J.; Igl, N.; Tippelt, M.; Stege, A.; Qoura, F.; Sohling, U.; Brück, T. Extraction of microalgae derived lipids with supercritical carbon dioxide in an industrial relevant pilot plant. Bioprocess Biosyst. Eng. 2017, 40, 911–918. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Davinelli, S.; Nielsen, M.E.; Scapagnini, G. Astaxanthin in Skin Health, Repair, and Disease: A Comprehensive Review. Nutrients 2018, 10, 522. [Google Scholar] [CrossRef] [Green Version]

- Molino, A.; Mehariya, S.; Iovine, A.; Larocca, V.; Di Sanzo, G.; Martino, M.; Casella, P.; Chianese, S.; Musmarra, D. Extraction of Astaxanthin and Lutein from Microalga Haematococcus pluvialis in the Red Phase Using CO2 Supercritical Fluid Extraction Technology with Ethanol as Co-Solvent. Mar. Drugs 2018, 16, 432. [Google Scholar] [CrossRef] [Green Version]

- Higuera-Ciapara, I.; Félix-Valenzuela, L.; Goycoolea, F.M. Astaxanthin: A Review of its Chemistry and Applications. Crit. Rev. Food Sci. Nutr. 2006, 46, 185–196. [Google Scholar] [CrossRef]

- Rodrigues, V.H.; Portugal, I.; Silva, C.M. Experimental optimization of the supercritical fluid extraction of triterpenoids from Acacia dealbata Link. Leaves. Sep. Purif. Technol. 2023, 306, 122637. [Google Scholar] [CrossRef]

- Xu, F.; Huang, X.; Wu, H.; Wang, X. Beneficial health effects of lupenone triterpene: A review. Biomed. Pharmacother. 2018, 103, 198–203. [Google Scholar] [CrossRef]

- Bukhanko, N.; Attard, T.; Arshadi, M.; Eriksson, D.; Budarin, V.; Hunt, A.J.; Geladi, P.; Bergsten, U.; Clark, J. Extraction of cones, branches, needles and bark from Norway spruce (Picea abies) by supercritical carbon dioxide and soxhlet extractions techniques. Ind. Crops Prod. 2020, 145, 112096. [Google Scholar] [CrossRef]

- Ribas, M.C.; Mantovani, D.; Awadallak, J.A.; Canevesi, R.L.; Tazinafo, N.M.; Cardozo Filho, L.; Palú, F.; da Silva, E.A. Study of candeia oil extraction using pressurized fluids and purification by adsorption process. J. Supercrit. Fluids 2014, 92, 177–182. [Google Scholar] [CrossRef]

- Kim, J.; Choi, K.; Chung, D.S. 3.35—Sample Preparation for Capillary Electrophoretic Applications. In Comprehensive Sampling and Sample Preparation; Pawliszyn, J., Ed.; Academic Press: Oxford, UK, 2012; pp. 701–721. ISBN 978-0-12-381374-9. [Google Scholar]

- Mandal, S.C.; Mandal, V.; Das, A.K. Classification of Extraction Methods. In Essentials of Botanical Extraction; Elsevier: Amsterdam, The Netherlands, 2015; pp. 83–136. [Google Scholar]

- De La Guardia, M.; Armenta, S. Chapter 5—Greening Sample Treatments. In Green Analytical Chemistry: Theory and Practice; Elsevier: Amsterdam, The Netherlands, 2011; Volume 57, pp. 87–120. [Google Scholar]

- Baiano, A. Recovery of Biomolecules from Food Wastes—A Review. Molecules 2014, 19, 14821–14842. [Google Scholar] [CrossRef] [Green Version]

- Herrero, M.; Cifuentes, A.; Ibáñez, E. 4.09—Extraction Techniques for the Determination of Carotenoids and Vitamins in Food. In Comprehensive Sampling and Sample Preparation; Pawliszyn, J., Ed.; Academic Press: Oxford, UK, 2012; pp. 181–201. ISBN 978-0-12-381374-9. [Google Scholar]

- Savic, I.M.; Savic Gajic, I.M. Development of the Sustainable Extraction Procedures of Bioactive Compounds from Industrial Food Wastes and Their Application in the Products for Human Uses. Sustainability 2023, 15, 2102. [Google Scholar] [CrossRef]

- Gallego, R.; Montero, L.; Cifuentes, A.; Ibáñez, E.; Herrero, M. Green Extraction of Bioactive Compounds from Microalgae. J. Anal. Test. 2018, 2, 109–123. [Google Scholar] [CrossRef]

- Pieber, S.; Schober, S.; Mittelbach, M. Pressurized fluid extraction of polyunsaturated fatty acids from the microalga Nannochloropsis oculata. Biomass Bioenergy 2012, 47, 474–482. [Google Scholar] [CrossRef]

- Golmakani, M.-T.; Mendiola, J.A.; Rezaei, K.; Ibáñez, E. Pressurized limonene as an alternative bio-solvent for the extraction of lipids from marine microorganisms. J. Supercrit. Fluids 2014, 92, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Koo, S.Y.; Cha, K.H.; Song, D.G.; Chung, D.; Pan, C.H. Optimization of pressurized liquid extraction of zeaxanthin from Chlorella ellipsoidea. J. Appl. Phycol. 2012, 24, 725–730. [Google Scholar] [CrossRef]

- D’auria, M.; Mecca, M.; Bruno, M.R.; Todaro, L. Extraction Methods and Their Influence on Yield When Extracting Thermo-Vacuum-Modified Chestnut Wood. Forests 2021, 12, 73. [Google Scholar] [CrossRef]

- Bocker, R.; Silva, E.K. Pulsed electric field assisted extraction of natural food pigments and colorings from plant matrices. Food Chem. X 2022, 15, 100398. [Google Scholar] [CrossRef]

- Taha, A.; Casanova, F.; Šimonis, P.; Stankevič, V.; Gomaa, M.A.E.; Stirkė, A. Pulsed Electric Field: Fundamentals and Effects on the Structural and Techno-Functional Properties of Dairy and Plant Proteins. Foods 2022, 11, 1556. [Google Scholar] [CrossRef]

- Nowosad, K.; Sujka, M.; Pankiewicz, U.; Kowalski, R. The application of PEF technology in food processing and human nutrition. J. Food Sci. Technol. 2021, 58, 397–411. [Google Scholar] [CrossRef] [PubMed]

- Pataro, G.; Carullo, D.; Falcone, M.; Ferrari, G. Recovery of lycopene from industrially derived tomato processing by-products by pulsed electric fields-assisted extraction. Innov. Food Sci. Emerg. Technol. 2020, 63, 102369. [Google Scholar] [CrossRef]

- Kim, H.-S.; Ko, M.-J.; Park, C.-H.; Chung, M.-S. Application of Pulsed Electric Field as a Pre-Treatment for Subcritical Water Extraction of Quercetin from Onion Skin. Foods 2022, 11, 1069. [Google Scholar] [CrossRef] [PubMed]

- Goettel, M.; Eing, C.; Gusbeth, C.; Straessner, R.; Frey, W. Pulsed Electric Field Assisted Extraction of Intracellular Valuables from Microalgae. Algal Res. 2013, 2, 401–408. [Google Scholar] [CrossRef]

- Eleršek, T.; Flisar, K.; Likozar, B.; Klemenčič, M.; Golob, J.; Kotnik, T.; Miklavčič, D. Electroporation as a Solvent-Free Green Technique for Non-Destructive Extraction of Proteins and Lipids From Chlorella vulgaris. Front. Bioeng. Biotechnol. 2020, 8, 443. [Google Scholar] [CrossRef] [PubMed]

- Käferböck, A.; Smetana, S.; de Vos, R.; Schwarz, C.; Toepfl, S.; Parniakov, O. Sustainable extraction of valuable components from Spirulina assisted by pulsed electric fields technology. Algal Res. 2020, 48, 101914. [Google Scholar] [CrossRef]

- Martínez, J.M.; Luengo, E.; Saldaña, G.; Álvarez, I.; Raso, J. C-phycocyanin extraction assisted by pulsed electric field from Artrosphira platensis. Food Res. Int. 2017, 99, 1042–1047. [Google Scholar] [CrossRef]

- Jaeschke, D.P.; Menegol, T.; Rech, R.; Mercali, G.D.; Marczak, L.D.F. Carotenoid and lipid extraction from Heterochlorella luteoviridis using moderate electric field and ethanol. Process. Biochem. 2016, 51, 1636–1643. [Google Scholar] [CrossRef]

- Golberg, A.; Sack, M.; Teissie, J.; Pataro, G.; Pliquett, U.; Saulis, G.; Stefan, T.; Miklavcic, D.; Vorobiev, E.; Frey, W. Energy-efficient biomass processing with pulsed electric fields for bioeconomy and sustainable development. Biotechnol. Biofuels 2016, 9, 94. [Google Scholar] [CrossRef] [Green Version]

- Bouras, M.; Grimi, N.; Bals, O.; Vorobiev, E. Impact of pulsed electric fields on polyphenols extraction from Norway spruce bark. Ind. Crops Prod. 2016, 80, 50–58. [Google Scholar] [CrossRef]

| Biomass Source | Maceration Conditions | Yield | Ref. |

|---|---|---|---|

| Spirulina platensis | Ethanol, 48 h | Flavonoid: 2.68% | [54] |

| Phaeodactylum tricornutum | Ethanol, 30 min | Fucoxanthin: 15.71 mg/g DW | [55] |

| Biomass Source | Soxhlet Conditions | Yield | Ref. |

|---|---|---|---|

| Tomato pomace (pulp, seeds, and peels) | Ethyl acetate, 6 h, SB: 2:25 (w:v) | Lycopene (454.64 mg/100 g extract) Beta-carotene (580.96 mg/100 g extract) Phenolics (25.25 mg GAE/g extract) | [38] |

| Onion peels | Ethanol 70% (v/v) and 90% (v/v), 72 h | Phenolics (301.03 mg GAE/g) Flavonoids (156 QE mg/g) | [67] |

| Banana peels | Ethanol 95% (v/v), 6 h | 2-pentenoic acid, 3-ethyl-methyl ester, 4-amino-1-methyl-3-nitropyrazole, Thiophene-2-carboxamide, 3-ethoxy-N-(4-chlorophenyl Pentadecane, 1-methoxy-13-methyl-3-Hexadecane, (Z)- 4-Heptafluorobutyryloxyhexadecane 1-Hexadecene, 2-Tetradecene, Pentafluoropropionic acid, 4-hexadecyl ester | [68] |

| Biomass Source | Soxhlet Conditions | Yield | Ref. |

|---|---|---|---|

| Spirulina platensis | Ethanol, 60–80 °C, 4 h | Flavonoid: 5.26% | [54] |

| Chlorella sp. | Ethanol, 78 °C, 3 h | Lipid: 9.40% | [70] |

| Nannochloropsis oculata | Ethanol, 40 °C, 0.1 MPa, 18 h | Lipid: 40.90% | [71] |

| Synechocystis | Ethanol, 40 °C, 0.1 MPa, 18 h | Lipid: 48% | [72] |

| Biomass Source | Soxhlet Conditions | Yield | Ref. |

|---|---|---|---|

| Vitis vinifera canes | Ethanol (50%), SB: 1:20 (w:v), 3 h | Catechin yield: 0.65 mg/g | [76] |

| Caesalpinia sappan L. | Ethanol (96%), SB: 1:20 (w:v), 3 h | Yield of brazilin: 5.43 mg/g of extract | [77] |

| Eucalyptus loxophleba ssp. lissophloia leaves | Ethanol, 90 °C, 0.5–8 h | Oil: 36.33% | [79] |

| Biomass Source | MAE Conditions | Yield | Ref. |

|---|---|---|---|

| Tomato pomace (peels and seeds) | Citric acid solution, 2450 MHz, 600 W, 10 min | Pectin (28.28%), galacturonic acid (22.44 µg/L), lycopene (27.16 µg/g pectin) | [88] |

| Onion peels | ChCl:Urea:water, 100 W, 15.03 min 1:54.97 (w:v) | Phenolics (80.45 mg GAE/g) | [89] |

| Banana peels | Water; 2:100 (w:v); 6 min | Phenolics (50.55 mg GAE/g) | [90] |

| Tomato pomace | Ethanol:ethyl acetate 90:10 (v/v), 3 min, 90 °C | Lycopene (59.66 µg/g) Beta-carotene (39.82%) | [91] |

| Biomass Source | UAE Conditions | Yield | Ref. |

|---|---|---|---|

| Onion seeds | NADES—Lactic acid, glucose, and 15% water (LGH-15), 40 °C, 30 min, SB: 75 mg/mL | Rutein (67.169 µg/g DW) Tyrosin (139.012 µg/g DW) Cafeic acid (136.314 µg/g DW) Quercetin (2.056 µg/g DW) | [52] |

| Tomato pomace (peels, seeds, and pulp) | Ethyl acetate:ethyl lactate 1:3 (v/v), SB: 1:20 (w:v), 10 min, 35 °C | Lycopene (254.08 µg/g DW) Beta-carotene (78.74 µg/g DW) Lutein (31.16 µg/g DW) | [101] |

| Tomato peels | Fatty acid ethyl esters, SB: 2:40 (w:v); 15 min | Lycopene (101.4 mg/100 g) | [102] |

| Tomato peels and seeds | NADES—Lactic acid, glucose, and 15% water (LGH-15), 40 °C, 30 min, SB: 75 mg/mL | Rutein (325.132 µg/g DW) Caffeic acid (98.087 µg/g DW) Quercetin (62.605 µg/g DW) | [103] |

| Banana peels | Ethanol (50%), 1:20, 45 °C, SB: 3:60 (w:v), 1 h | Phenolics (31.45 mg GAE/g) Flavonoids (22.11 mg GAE/g) | [104] |

| Watermelon peels | Ethanol (43.28%), 40 kHz, 44 °C, 110 W, 32 min | Phenolics (8.35 mg GAE/g) | [104] |

| Watermelon seeds | Ethanol (39.18%), 40 kHz, 50 °C, 38 min | Phenolics (32.2 mg GAE/g) Syringic acid (18.21 µg/mL) Caffeic acid (24.22 µg/mL) Sinapic acid 152.30 µg/mL) Ferrulic acid (68.28 µg/mL) Vanillic acid (22.64 µg/mL) Gallic acid (2.56 µg/mL) 4-hydroxy benzoic acid (59.71 µg/mL) | [101] |

| Biomass Source | UAE Conditions | Yield | Ref. |

|---|---|---|---|

| Spirulina platensis | DES/IL, 25 °C, 25 kHz, and 30 min | Allophycocyanin: 6.34 mg g−1 Phycocyanin: 5.95 mg g−1 Phycoerythrin: 2.62 mg g−1 | [105] |

| Spirulina sp. | NADES: glycerol/glucose/water (1:2:4 molar ratio) | Chlorophylls: 0.50 mg/g Carotenoids: 0.22 mg/g Phycocyanin: 3.96 mg/g | [106] |

| Scenedesmus sp. | NADES: Fen-Thy, 70 min, 60 °C, 40 kHz, 300 W | Carotenoid (lutein): 4.4 mg/g | [107] |

| Haematococcus pluvialis | Ethanol:ethyl acetate (1:1 (v/v)), 200 W, 16 min | Astaxanthin: 27.58 ± 0.40 (mg/g) | [108] |

| Biomass Source | SC Conditions | Yield | Ref. |

|---|---|---|---|

| Tomato peels | CO2, 30 °C, 7 MPa, 2 h | Gallic acid (2.77 µg/g) Chlorogenic acid (2.35 µg/g) P-coumaric acid (1.64 µg/g) Catechin (23.71 µg/g) Rutin (1.69 µg/g) | [49] |

| Tomato peels and seeds | CO2, 50 Mpa, 80 °C, 220 min | Lycopene (55%, 1.32 mg/kg raw material) | [126] |

| Tomato pomace | CO2, 45 MPa, 70 °C, 11 kg/h | Lycopene (1016.94 mg/100 g extract) Beta-carotene (154.87 mg/100 g extract) Phenolics (35.25 mg GAE/G extract) | [38] |

| Onion peels | CO2, 40 MPa, 55 °C, ethanol as co-solvent (2.5 to 4 h), SB: 1:8 (w:v) | Phenolics (212.56 mg GAE/g) Flavonoids (211.51 mg QE/g) Quercetin 7,4-diglycoside (6.63%) Quercetin 3,4-diglycoside (45.19%) Quercetin 4-glucoside (0.12%) Quercetin (2.41%) Kaempferol (1.00%) | [127] |

| CO2, 40 MPa, 55 °C, ethanol as co-solvent (2.5 to 4 h), SB: 1:8 (w:v) | Phenolics (202.31 mg GAE/g) Flavonoids (282.80 mg QE/g) Quercetin 7,4-diglycoside (1.39%) Quercetin 3,4-diglycoside (3.99%) Quercetin 4-glucoside (5.60%) Quercetin (39.94%) Kaempferol (1.27%) | [127] |

| Biomass Source | SC Conditions | Yield | Ref. |

|---|---|---|---|

| Nannochloropsis oculata | CO2 and ethanol, 45 bar, 50 °C, 250 min | Lipid: 83% | [128] |

| Haematococcus pluvialis | CO2, 55 MPa, 50 °C, 120 min | Astaxanthin: 98.6% | [129] |

| Chlorella protothecoides | CO2, 30 MPa, 70 °C | Lipid: 21% | [130] |

| Nannochloropsis oculata | CO2, 80 °C, 20.7 MPa, 240 min | Lipid: 71% | [131] |

| Scenedesmus obliquus | CO2, 20 °C, 12 MPa, 540 min | Lipid: 59% | [132] |

| Biomass Source | SC Conditions | Yield | Ref. |

|---|---|---|---|

| Picea abies branches | CO2, 50 °C, 2 h, 30 MPa | Yield: 5.3% | [138] |

| Eremanthus erythropappus | CO2, 60 °C, 1 h, 12 MPa, Flow rate: 3 mL/min | Yield: 0.36% α-Bisabolol: 58.02% | [139] |

| Acacia dealbata Link. | 25 MPa, 40 °C, no cosolvent | Lupenone: 0.4748% | [136] |

| Biomass Source | PLE Conditions | Yield | Ref. |

|---|---|---|---|

| Tomato pomace | Ethanol:ethyl acetate 50:50 (v/v), SB: 1:20 (w:v), 90 °C, 10 MPa, 2 mL/min | Lycopene (20.09 µg/g) Beta-carotene (46.51%) | [91] |

| Biomass Source | PLE Conditions | Yield | Ref. |

|---|---|---|---|

| Nannochloropsis oculata | Ethanol, 60 °C, 10–12 MPa, 10 min | Lipid: 36% | [147] |

| Nannochloropsis oculata | Ethanol, 60 °C, 10–12 MPa, 48 min | Lipid: 36.4% | [147] |

| Arthrospira platensis | Limonene/ethanol, 200 °C, 20.7 MPa, 15 min | Lipid: 70% | [148] |

| Chlorella ellipsoidea | Ethanol, 115.4 °C, 10.3 MPa, 23.3 min | Zeaxanthin: 4.28 mg g−1 | [149] |

| Scenedesmus obliquus | Water, 50 °C, 10 MPa, 45 min | Lutein: 7.50 ± 0.8% | [56] |

| Biomass Source | PLE Conditions | Yield | Ref. |

|---|---|---|---|

| Castanea sativa Mill. | Ethanol (70%), 110 °C, 3 cycles of 5 min, 1 MPa | Yield: 12.5% | [150] |

| Quercus cerris L. | Ethanol (70%), SB: 1:5 (w:v), 1 h | Yield: 1.20% TPC: 350.28 mg GAE/g extract | [113] |

| Populus nigra | Ethanol (70%), 100 °C, 3 cyles of 5 min, 10.34 MPa | - | [62] |

| Biomass Source | PEF Conditions | Yield | Ref. |

|---|---|---|---|

| Tomato peels | 3 kV/cm, 10 kJ/kg, ethyl lactate 1:20 (w:v) | Lycopene (10,140 mg/kg DW) | [154] |

| Onion peels | 2.5 kV/cm, 25 Hz, 25 µs, 15 s | Total quercetin (19.25 mg/g DW) | [155] |

| Biomass Source | PEF Conditions | Yield | Ref. |

|---|---|---|---|

| Spirulina sp. | Deionized water, 2 h, 41 °C, 20–25 kV cm−1, 300 Hz, 100 kJ kg−1 | Phycocyanin: 119.48 ± 6.7 mg g−1 | [158] |

| Distilled water, 360 min, 40 °C, 25 kV cm−1, 150 μs, 110 kJ kg−1 | Phycocyanin: 151.94 ± 14.22 mg g−1 | [159] | |

| Heterochlorella luteoviridis | Ethanol/water, 180 V, 50 min | Carotenoids: 73% | [160] |

| Ethanol/water, 180 V, 50 min | Lipid: 83% |

| Biomass Source | PEF Conditions | Yield | Ref. |

|---|---|---|---|

| Picea abies (L.) Karst. | 20 kV/cm, SB: 10 (w/w) | Polyphenols | [162] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martins, R.; Barbosa, A.; Advinha, B.; Sales, H.; Pontes, R.; Nunes, J. Green Extraction Techniques of Bioactive Compounds: A State-of-the-Art Review. Processes 2023, 11, 2255. https://doi.org/10.3390/pr11082255

Martins R, Barbosa A, Advinha B, Sales H, Pontes R, Nunes J. Green Extraction Techniques of Bioactive Compounds: A State-of-the-Art Review. Processes. 2023; 11(8):2255. https://doi.org/10.3390/pr11082255

Chicago/Turabian StyleMartins, Rodrigo, Ana Barbosa, Bárbara Advinha, Hélia Sales, Rita Pontes, and João Nunes. 2023. "Green Extraction Techniques of Bioactive Compounds: A State-of-the-Art Review" Processes 11, no. 8: 2255. https://doi.org/10.3390/pr11082255

APA StyleMartins, R., Barbosa, A., Advinha, B., Sales, H., Pontes, R., & Nunes, J. (2023). Green Extraction Techniques of Bioactive Compounds: A State-of-the-Art Review. Processes, 11(8), 2255. https://doi.org/10.3390/pr11082255