Research and Development of Anti-High-Pressure Sealing Material and Its Bonding Performance

Abstract

:1. Introduction

2. Material Preparation

2.1. Basic Performance Indicators for Anti-High-Pressure Sealing Materials

2.2. Effect of Different Materials on Basic Sealing Material Properties

2.2.1. Test Method

- (1)

- To make the cement slurry more homogeneous, with consistent mixing conditions for each ratio, each slurry was mixed for 3 min using a mixer.

- (2)

- The setting time of the cement slurry was determined according to GB1346-2001 [14] (“Cement Standard Consistency, Setting Time, Stability Test Method”) using the cement standard consistency and a setting time tester.

- (3)

- (4)

- The compressive strength of the cement specimens was tested in 70 mm × 70 mm × 70 mm test molds; the slurry was injected into the test molds and placed in a curing box at an ambient temperature of 20 ± 2 °C and a humidity higher than 90%. The molds were removed after 1 d, 2 d, 3 d, and 7 d for compressive strength tests.

- (5)

- A water–cement ratio of 0.5 at 20 ± 2 °C was chosen for the development of the sealing material.

2.2.2. Influence of Different Cement Components on the Performance of Hole-Sealing Materials

2.2.3. Effect of Expansion Agent Components on Material Properties

2.2.4. Effect of Stabilizers on Sealing Material Performance

- (1)

- The cement precipitation of the composite grout was lower, making the overall grout more uniform.

- (2)

- The water loss from the grout surface was reduced; the grout had high stability and could fully penetrate the microcracks in coal-rock pores, improving the sealing quality.

- (3)

- After adding the stabilizer, the overall structure of the slurry was dense, the mechanical strength was improved, and the slurry could better resist external loads.

2.2.5. Effect of Fibers on Material Properties

3. Bonding Performance Test of Hole-Sealing Materials

3.1. Cracking Pressure and Mechanical Property Test Method Selection

3.2. Calculation Method for Fractional Dimension

3.3. Specimen Cut after Fracturing

- (1)

- Fifteen rock samples (five samples from each type of rock) and 12 coal samples (three coal samples from each mine) that met the test requirements were collected and numbered.

- (2)

- The selected coal-rock samples were sheared into two parts using a universal material-testing machine to perform oblique shear tests at a shear angle of α = 50°.

- (3)

- The shear surfaces of the coal-rock body samples sheared into two parts were moderately polished with sandpaper. After removing the broken particles, 30 rock samples and 16 coal block samples were selected after shearing (some coal samples were damaged after shearing; four samples were selected from each of the four coal samples), and the fractional dimension D of the shear surface of the coal-rock body was tested using a homemade fractional dimension meter.

- (4)

- Thirty rock samples and 16 coal samples were placed into the standard mold, and a new high-pressure-resistant drilling seal material was formulated with a suitable water–cement ratio. The seal material was injected into the standard mold and demolded after 3 d of standard maintenance; 46 samples of the combined seal material and coal-rock body were obtained.

- (5)

- A universal material-testing machine was used to perform a shear test with a shear angle of α = 50° on a sample of the bond between the sealing material and the coal-rock body to determine the minimum stress when the bond interface between the sealing material and the coal-rock body was broken.

- (6)

- According to the measured fractional dimension, D, and the bond strength, a similar curve between the bond strength and roughness was fitted, and the function equation of the bond strength between the sealing material and the coal-rock body was analyzed.

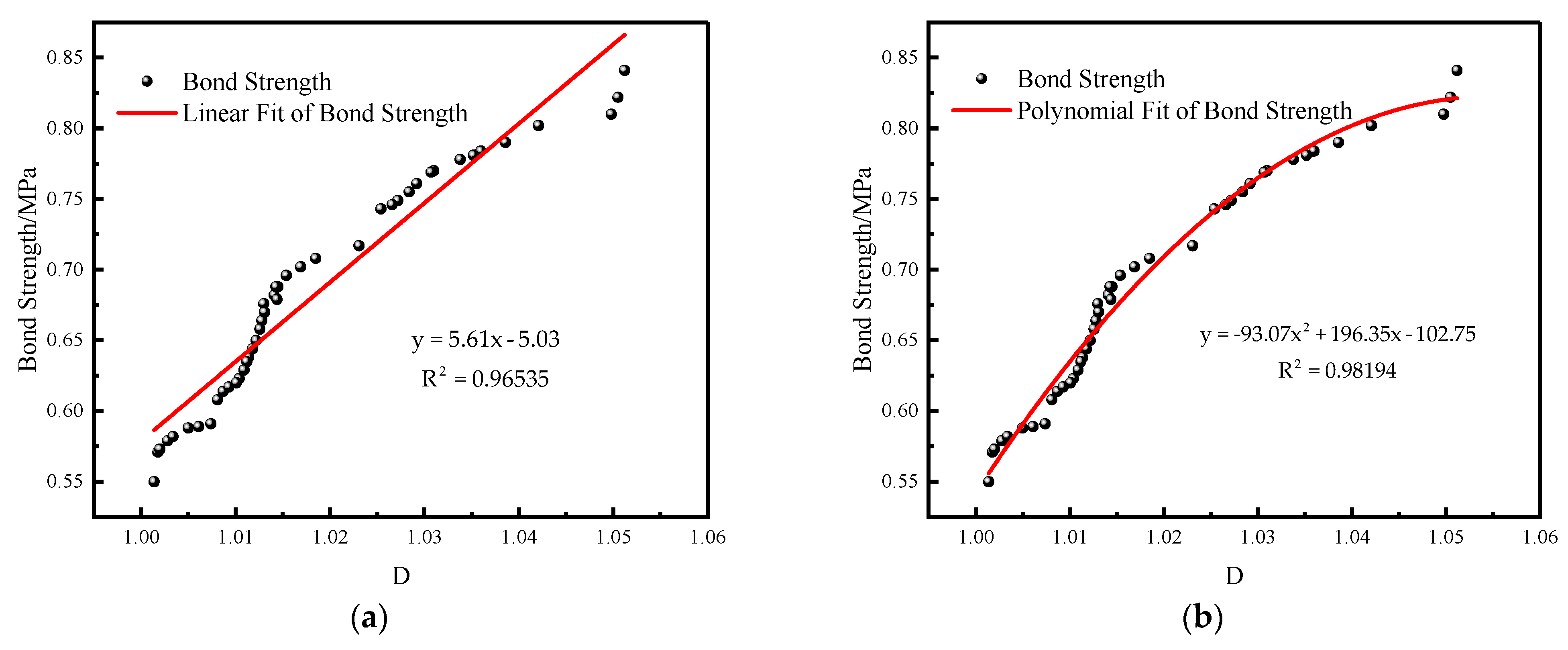

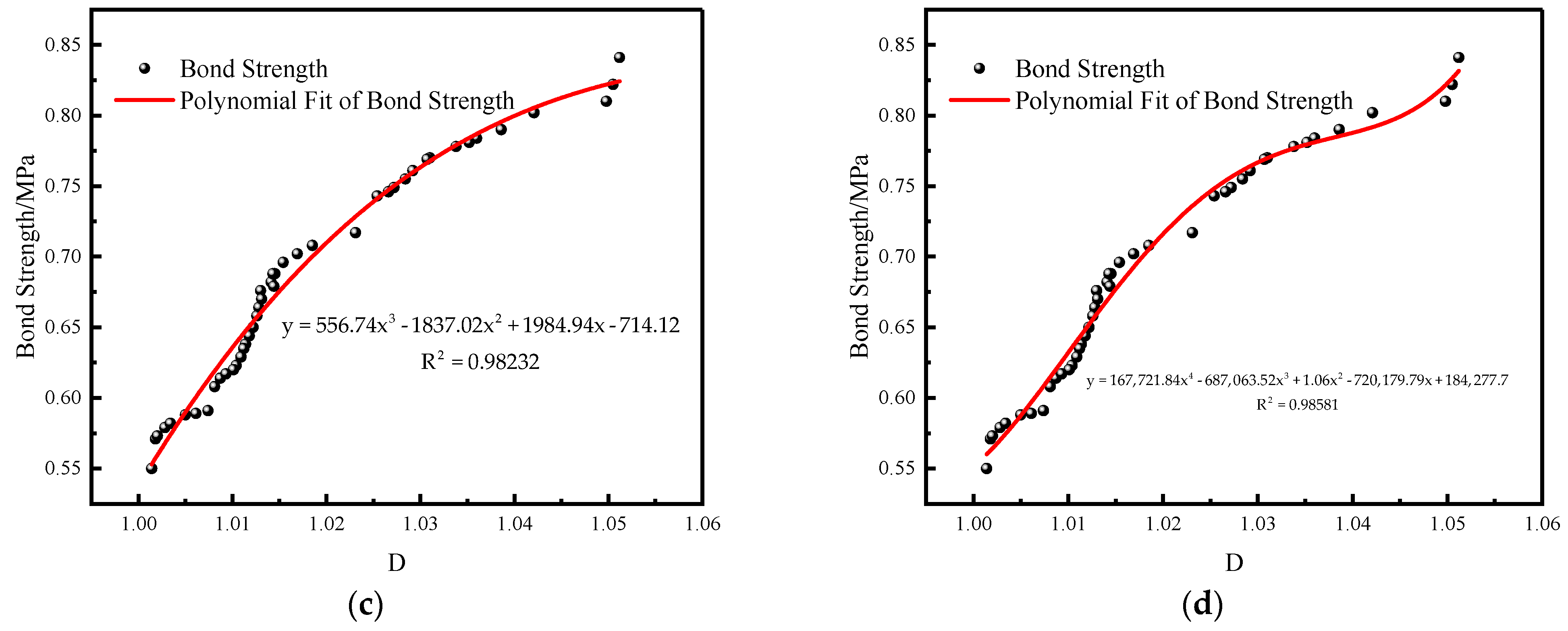

3.4. Test Data and Curve-Fitting Function

4. Conclusions

- (1)

- Considering the influence of different materials on the basic performance of the sealing materials, the integration of the setting time of composite cement slurry sealing materials, and the actual underground coal mine conditions, the best water–cement ratio was determined to be 0.5. The admixture of special cement was most suitable between 20% and 25%; the admixture of composite expansion agent was best at 4%. By adding 1% of 8 mm polyvinyl alcohol fibers, the surface area of the cement matrix was increased; the integrity and compressive strength of the material were increased due to the increased surface area of the cement matrix.

- (2)

- The variable-angle shear (oblique shear) test was used to integrate the compressive shear strength, tensile shear strength, and bending shear strength to accurately reflect the bonding performance of the sealing material and the coal-rock body. The results were in line with those from an actual coal mine. The oblique shear method with a fixed horizontal angle of τ = 50° was used to measure the bonding performance of the sealing material and the bonding interface of the coal-rock body, using the shear stress, τ, at the breaking interface.

- (3)

- The roughness of the coal-rock body around the borehole has a direct influence on the bonding strength of the sealing material, the bonding interface of the coal-rock body in the borehole, and the roughness of the coal-rock body. The measured fractional dimension, D, and the bond strength results were analyzed and fitted with a primary linear function and polynomial functions to obtain the fitted curves. Comparing the fitting degrees of the fitted curves, it was found that the change curve of the bond strength between the seal material and the coal-rock body with the fractional dimension, D, follows the change law of a binomial function.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zheng, K. Permeability improving technology by sectional hydraulic fracturing for comb-like long drilling in the floor of crushed and soft coal seam with low permeability. J. Min. Saf. Eng. 2020, 37, 272–281. [Google Scholar]

- Zhang, C.; Yan, J.; Li, S. Experimental study on dynamic sealing of mucilage material in gas extraction borehole. J. Min. Saf. Eng. 2022, 39, 1033–1040. [Google Scholar]

- Wang, S. A new pressure maintaining and sealing technology for gas drainage borehole. Saf. Coal Mines 2021, 52, 61–66. [Google Scholar]

- Yang, W.; Huo, Z.; Shu, L. Analysis of the whole process of grouting sealing for gas extraction drilling hole sealing section. Saf. Coal Mines 2021, 52, 1–6. [Google Scholar]

- Liu, A.; Ju, W.; Zhang, Z. Key factors in hole-sealing and pressure-relief failure of hydraulic fracturing straddle packer in coal mine. Eng. Fail. Anal. 2023, 149, 107243. [Google Scholar] [CrossRef]

- Klishin, S.V.; Klishin, V.I. Packer Sealing–Wellbore Interaction in Hydraulic Fracturing in Coal Seams. J. Min. Sci. 2020, 56, 547–556. [Google Scholar] [CrossRef]

- Xiao, Q.; Yu, X.; Feng, K. Research and application of “double-sealing and single-grouting” hole sealing technique with pressure in Longmen Gorge South Coal Mine. China Coal 2020, 46, 52–56. [Google Scholar]

- Pakravan, H.R.; Latifi, M.; Jamshidi, M. Hybrid short fiber reinforcement system in concrete: A review. Constr. Build. Mater. 2017, 142, 280–294. [Google Scholar] [CrossRef]

- Furlan, S.; Hanai, J. Shear behavior of fiber reinforced concrete beams. Cem. Concr. Compos. 1997, 19, 359–366. [Google Scholar] [CrossRef]

- American Concrete Institute. ACI 546.3R-14: Guide to Materials Selection for Concrete Repair; American Concrete Institute: Indianapolis, IN, USA, 2014. [Google Scholar]

- Li, S. Durability and Bond of High-Performance Concrete and Repaired Portland Cement Concrete; University of Connecticut: Storrs, CT, USA, 1997. [Google Scholar]

- Tabor, L.J. The Evaluation of Resin Systems for Concrete Repair. Mag. Concr. Res. 1978, 30, 221–225. [Google Scholar] [CrossRef]

- Li, C.; Ke, L.; Chen, Z. Experimental study and numerical simulation for bond behavior of interface between CFRP and steel. Acta Mater. Compos. Sin. 2018, 35, 3534–3536. [Google Scholar]

- GB1346-2001; Test Methods for Water Requirement of Normal Consistency, Setting Time and Soundness of the Portland Cements. GAQSIQ: Beijing, China, 2001.

- GB/T2419-2005; Method for Determining the Flow of Cementitious Sand. National Institutes of Health: Bethesda, MD, USA, 2005.

- Gou, M.; Guan, X.; Zhang, A. Study on a New Cement-Based Plugging Grouting Material. Coal Technol. 2007, 119–121. [Google Scholar] [CrossRef]

- Feng, Q.; Jia, F.; Peng, Z. Preparation, characterization, and evaluation of suspension stabilizer for low-density cement slurry for cementing. J. Appl. Polym. Sci. 2022, 139, e53058. [Google Scholar] [CrossRef]

- Nassiri, S.; Chen, Z.; Jian, G. Comparison of unique effects of two contrasting types of cellulose nanomaterials on setting time, rheology, and compressive strength of cement paste. Cem. Concr. Compos. 2021, 123, 104201. [Google Scholar] [CrossRef]

- Kim, S.; Park, C. Flexural Behavior Characteristics of High Performance Slurry Infiltrated Fiber Reinforced Cementitious Composite with Respect to Exposure to High Temperature. J. Korea Concr. Inst. 2019, 31, 139–146. [Google Scholar] [CrossRef]

- Yang, G.; Dong, Z.; Bi, J. Experimental study on the dynamic splitting tensile properties of polyvinyl-alcohol-fiber-reinforced cementitious composites. Constr. Build. Mater. 2023, 383, 131233. [Google Scholar] [CrossRef]

- Gomes, T.A.; de Resende, T.L.; Cardoso, D.C.T. Shear-transfer mechanisms in reinforced concrete beams with GFRP bars and basalt fibers. Eng. Struct. 2023, 289, 116299. [Google Scholar] [CrossRef]

- Liu, J.; Nie, Z.; Yu, B. Analysis of the mechanism and influencing factors of supercritical carbon dioxide on coal permeability enhancement. Coal Sci. Technol. 2023, 51, 204–216. [Google Scholar]

- Sannma, V.E. Fractal characterization of fracture surfaces in concrete. Eng. Fraerure Meehanies 1990, 35, 47–53. [Google Scholar]

| Ordinary Silicate Cement Content/% | Special Cement Content/% | Flow/mm | Solidification Time/min | Compressive Strength/MPa | ||

|---|---|---|---|---|---|---|

| Initial Condensation | Final Condensation | 1 d | 3 d | |||

| 95 | 5 | 279 | 410 | 664 | 6.8 | 8.8 |

| 90 | 10 | 281 | 230 | 342 | 13.0 | 16.7 |

| 85 | 15 | 288 | 118 | 159 | 17.9 | 22.5 |

| 80 | 20 | 293 | 82 | 98 | 22.8 | 31.3 |

| 75 | 25 | 292 | 72 | 88 | 24.1 | 32.7 |

| 70 | 30 | 292 | 60 | 76 | 23.4 | 32.1 |

| 65 | 35 | 291 | 50 | 63 | 22.6 | 29.8 |

| 60 | 40 | 287 | 38 | 46 | 21.8 | 28.8 |

| 55 | 45 | 282 | 28 | 34 | 20.2 | 26.5 |

| Amount of Expansion Agent Added/% | Flow/mm | Solidification Time/min | Expansion Multiplier/% | |

|---|---|---|---|---|

| Initial Condensation | Final Condensation | |||

| 1 | 282 | 71 | 83 | 5 |

| 2 | 261 | 67 | 77 | 10 |

| 3 | 245 | 62 | 70 | 15 |

| 4 | 223 | 55 | 61 | 16 |

| 5 | 194 | 54 | 57 | 18 |

| 6 | 171 | 51 | 55 | 22 |

| Length/mm | Fiber Content/% | |||

|---|---|---|---|---|

| 0.5 | 1.0 | 1.5 | 2.0 | |

| 6 | 294 | 270 | 242 | 205 |

| 8 | 300 | 278 | 250 | 215 |

| 12 | 305 | 285 | 256 | 225 |

| Sample Number | Applied Load/kN | Bond Strength/MPa | D | Sample Number | Applied Load/kN | Bond Strength/MPa | D |

|---|---|---|---|---|---|---|---|

| Coal sample 1 | 2.00 | 0.600 | 1.0076 | Rock sample 8 | 4.95 | 0.778 | 1.0338 |

| Coal sample 2 | 1.93 | 0.588 | 1.0050 | Rock sample 9 | 4.54 | 0.682 | 1.0141 |

| Coal sample 3 | 2.11 | 0.638 | 1.0114 | Rock sample 10 | 4.95 | 0.755 | 1.0284 |

| Coal sample 4 | 1.86 | 0.579 | 1.0028 | Rock sample 11 | 4.47 | 0.679 | 1.0144 |

| Coal sample 5 | 2.08 | 0.623 | 1.0104 | Rock sample 12 | 4.47 | 0.696 | 1.0154 |

| Coal sample 6 | 1.95 | 0.614 | 1.0087 | Rock sample 13 | 4.70 | 0.702 | 1.0169 |

| Coal sample 7 | 1.85 | 0.571 | 1.0018 | Rock sample 14 | 4.29 | 0.664 | 1.0128 |

| Coal sample 8 | 2.11 | 0.644 | 1.0118 | Rock sample 15 | 4.67 | 0.717 | 1.0231 |

| Coal sample 9 | 1.79 | 0.550 | 1.0014 | Rock sample 16 | 4.52 | 0.688 | 1.0143 |

| Coal sample 10 | 2.03 | 0.620 | 1.0101 | Rock sample 17 | 5.10 | 0.790 | 1.0386 |

| Coal sample 11 | 1.89 | 0.591 | 1.0074 | Rock sample 18 | 4.90 | 0.749 | 1.0272 |

| Coal sample 12 | 1.87 | 0.573 | 1.0020 | Rock sample 19 | 4.30 | 0.670 | 1.0131 |

| Coal sample 13 | 2.02 | 0.617 | 1.0093 | Rock sample 20 | 4.94 | 0.761 | 1.0292 |

| Coal sample 14 | 1.90 | 0.582 | 1.0034 | Rock sample 21 | 5.04 | 0.769 | 1.0307 |

| Coal sample 15 | 1.96 | 0.608 | 1.0081 | Rock sample 22 | 5.50 | 0.841 | 1.0512 |

| Coal sample 16 | 1.91 | 0.589 | 1.0061 | Rock sample 23 | 4.30 | 0.629 | 1.0109 |

| Rock sample 1 | 5.36 | 0.802 | 1.0421 | Rock sample 24 | 4.82 | 0.746 | 1.0266 |

| Rock sample 2 | 4.22 | 0.635 | 1.0112 | Rock sample 25 | 5.14 | 0.784 | 1.0360 |

| Rock sample 3 | 4.12 | 0.650 | 1.0122 | Rock sample 26 | 5.18 | 0.781 | 1.0352 |

| Rock sample 4 | 5.41 | 0.822 | 1.0505 | Rock sample 27 | 4.22 | 0.658 | 1.0126 |

| Rock sample 5 | 4.53 | 0.688 | 1.0145 | Rock sample 28 | 5.31 | 0.810 | 1.0498 |

| Rock sample 6 | 5.16 | 0.770 | 1.0310 | Rock sample 29 | 4.87 | 0.743 | 1.0254 |

| Rock sample 7 | 4.34 | 0.676 | 1.0130 | Rock sample 30 | 4.58 | 0.708 | 1.0185 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hao, S.; Li, X.; Wu, T.; Zhou, W.; Zhang, J. Research and Development of Anti-High-Pressure Sealing Material and Its Bonding Performance. Processes 2023, 11, 2270. https://doi.org/10.3390/pr11082270

Hao S, Li X, Wu T, Zhou W, Zhang J. Research and Development of Anti-High-Pressure Sealing Material and Its Bonding Performance. Processes. 2023; 11(8):2270. https://doi.org/10.3390/pr11082270

Chicago/Turabian StyleHao, Shigang, Xianzhong Li, Tao Wu, Weilong Zhou, and Jinhao Zhang. 2023. "Research and Development of Anti-High-Pressure Sealing Material and Its Bonding Performance" Processes 11, no. 8: 2270. https://doi.org/10.3390/pr11082270

APA StyleHao, S., Li, X., Wu, T., Zhou, W., & Zhang, J. (2023). Research and Development of Anti-High-Pressure Sealing Material and Its Bonding Performance. Processes, 11(8), 2270. https://doi.org/10.3390/pr11082270