Monitoring and Characterizing the Flame State of a Bluff-Body Stabilized Burner by Electrical Capacitance Tomography

Abstract

1. Introduction

2. Methodology

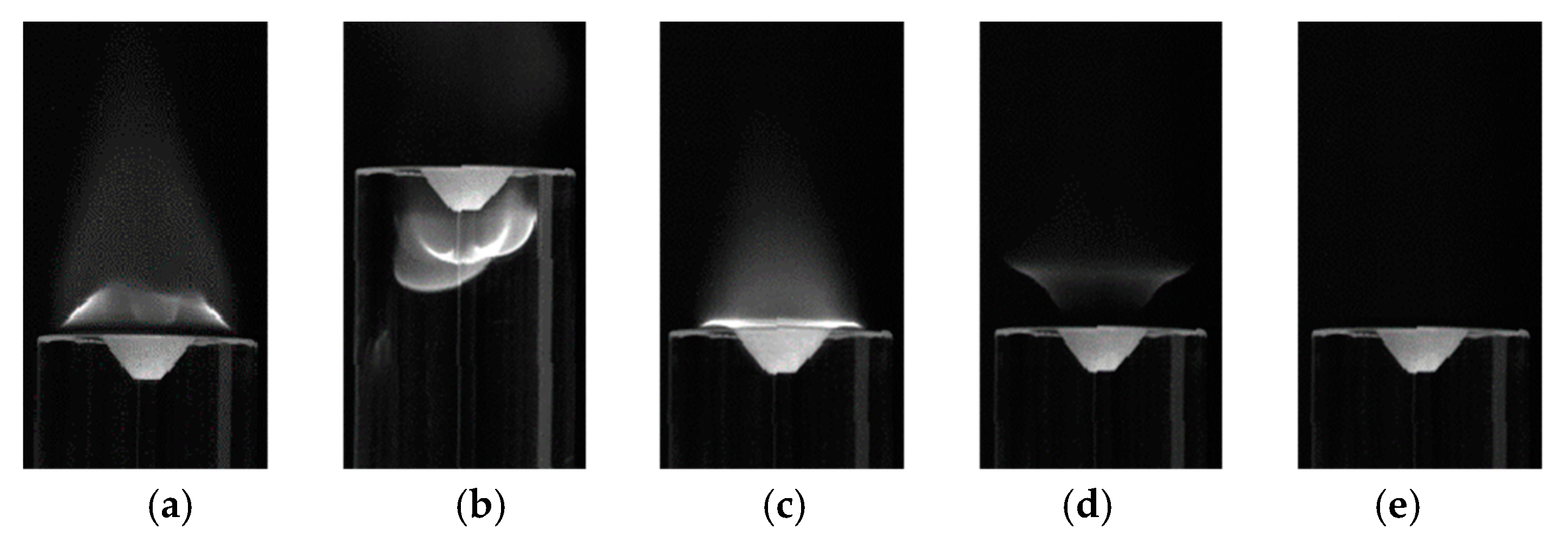

2.1. Flame State of Bluff-Body Stabilized Burner

2.2. Flame State Monitoring

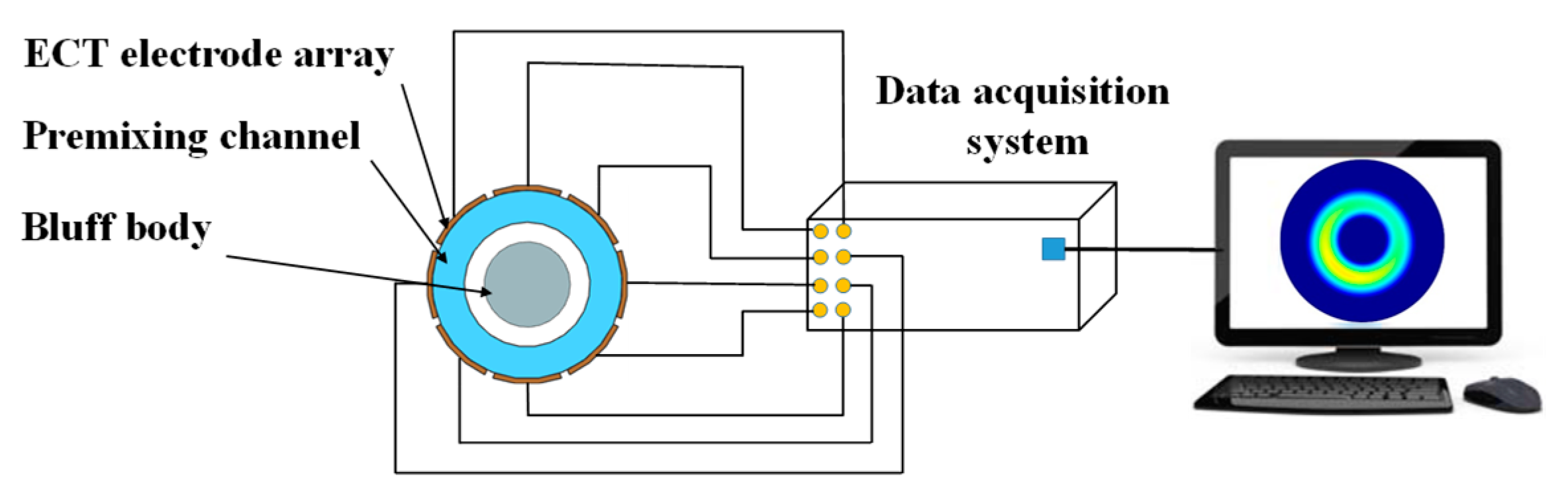

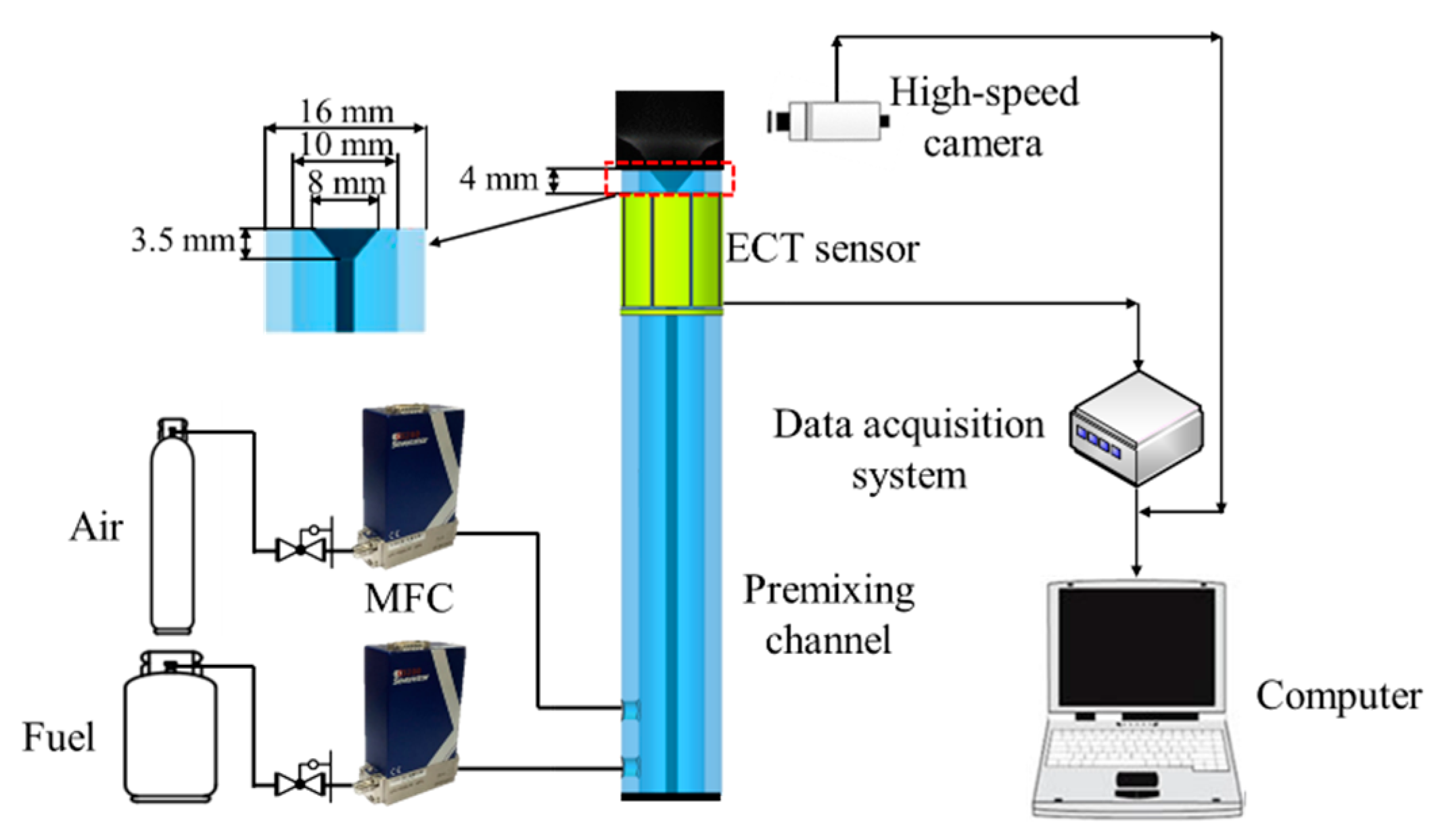

2.2.1. Electrical Capacitance Tomography System and the Modified Reconstruction Method

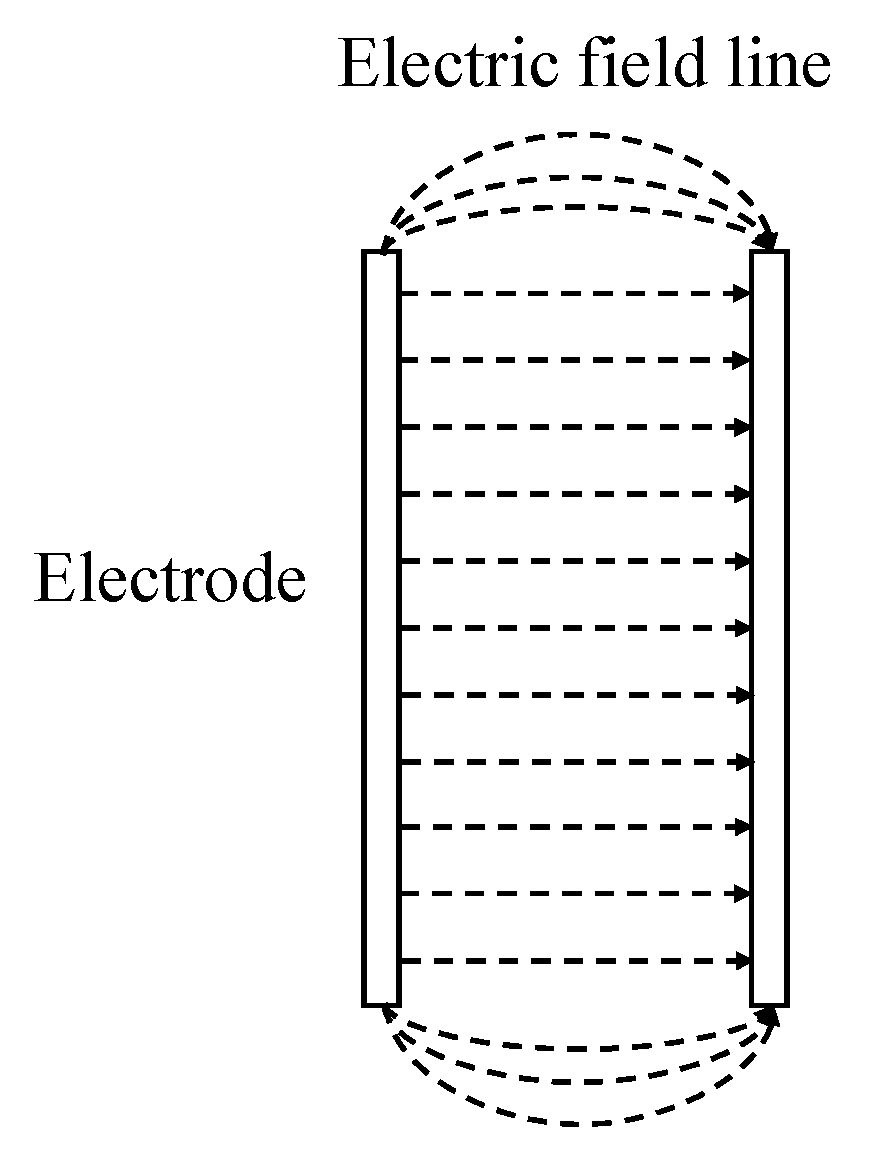

2.2.2. Fringe Effect of Electrical Capacitance Tomography Sensor

2.3. Flame State Characterization

3. Experiment

4. Results and Discussion

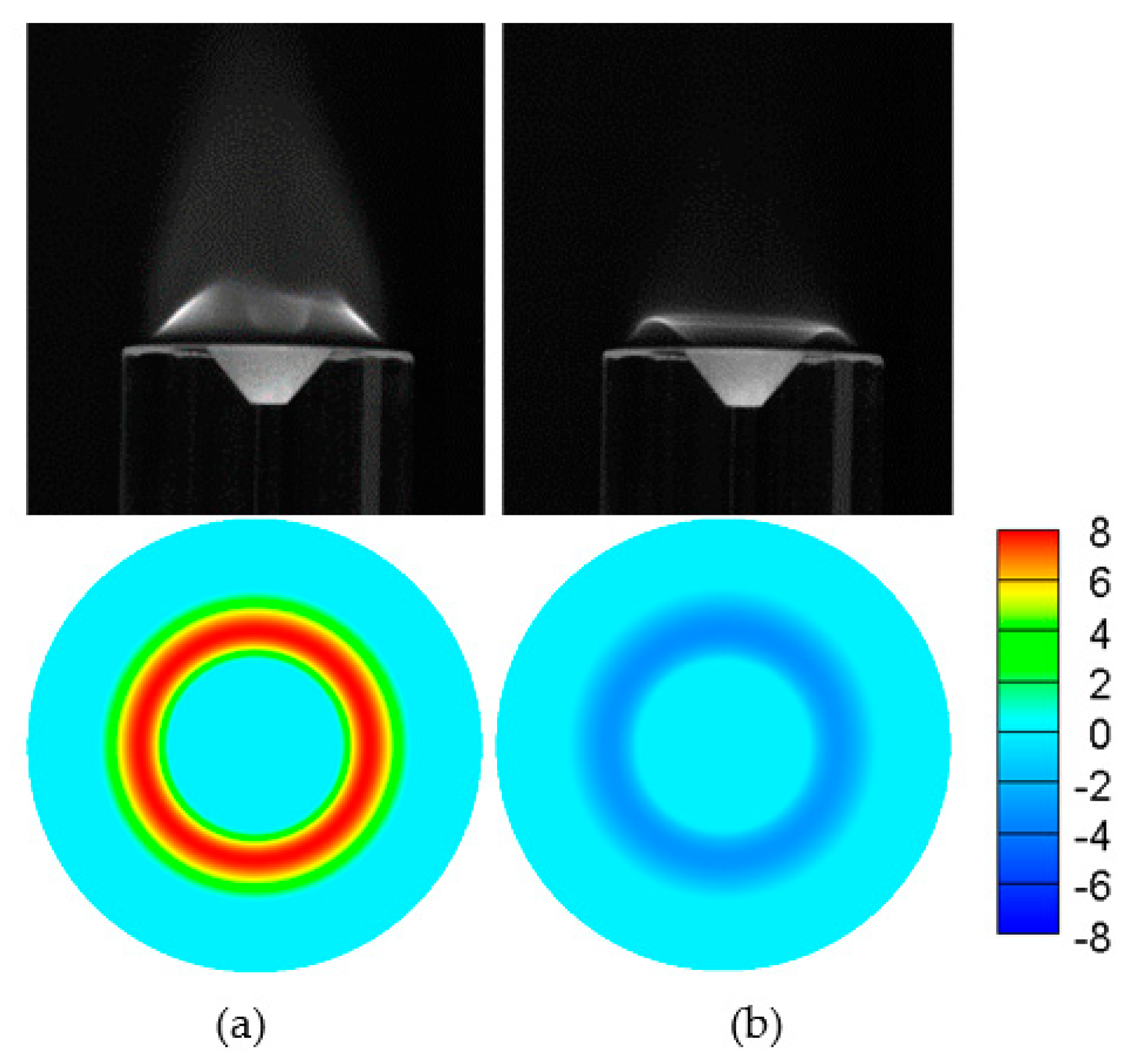

4.1. Flame Images Reconstructed by ECT System at Different Flame States

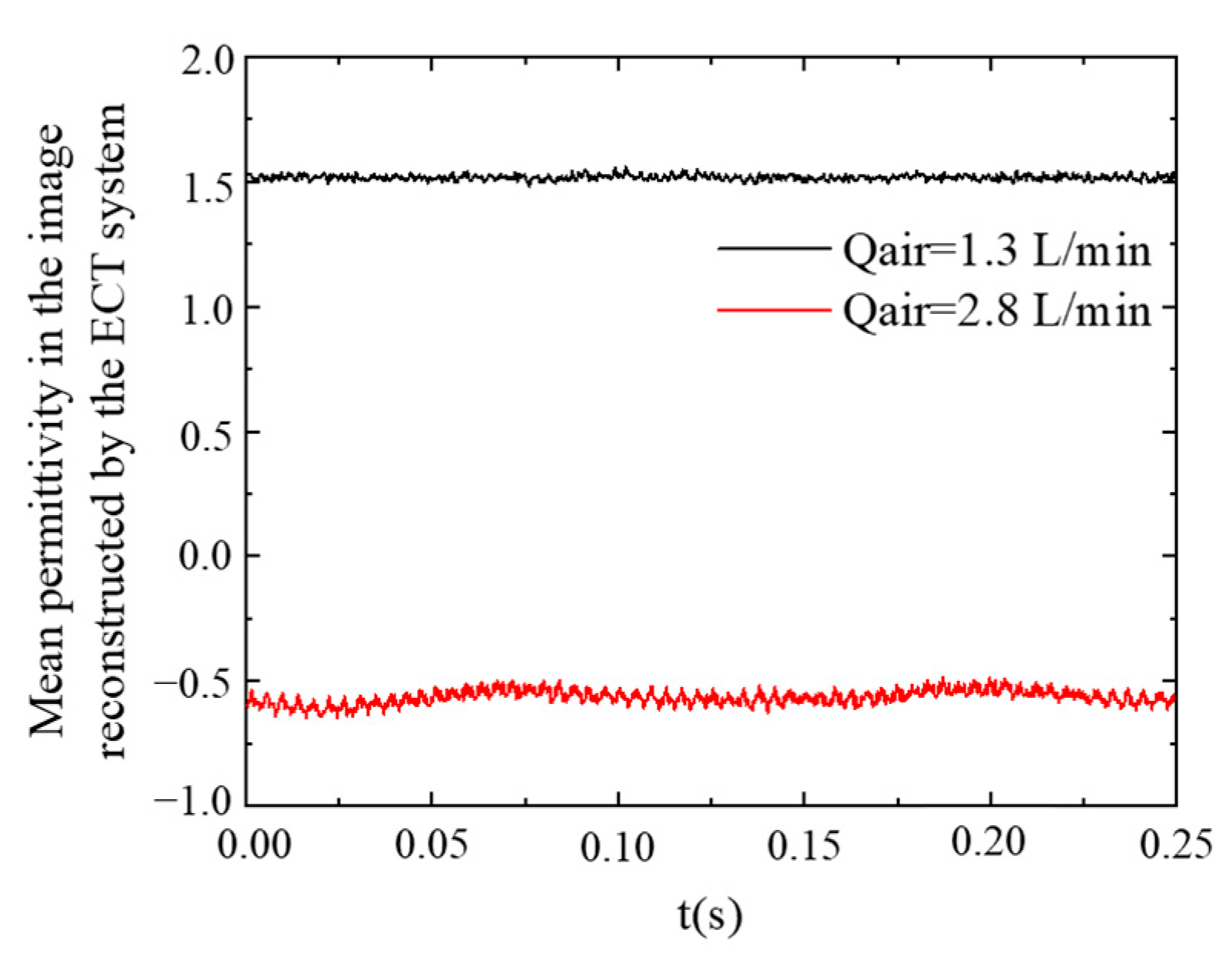

4.1.1. Flame Images Reconstructed by ECT System at Fuel-Rich and Fuel-Lean Stable States

4.1.2. Flame Images Reconstructed by ECT System at Flashback and Extinction States

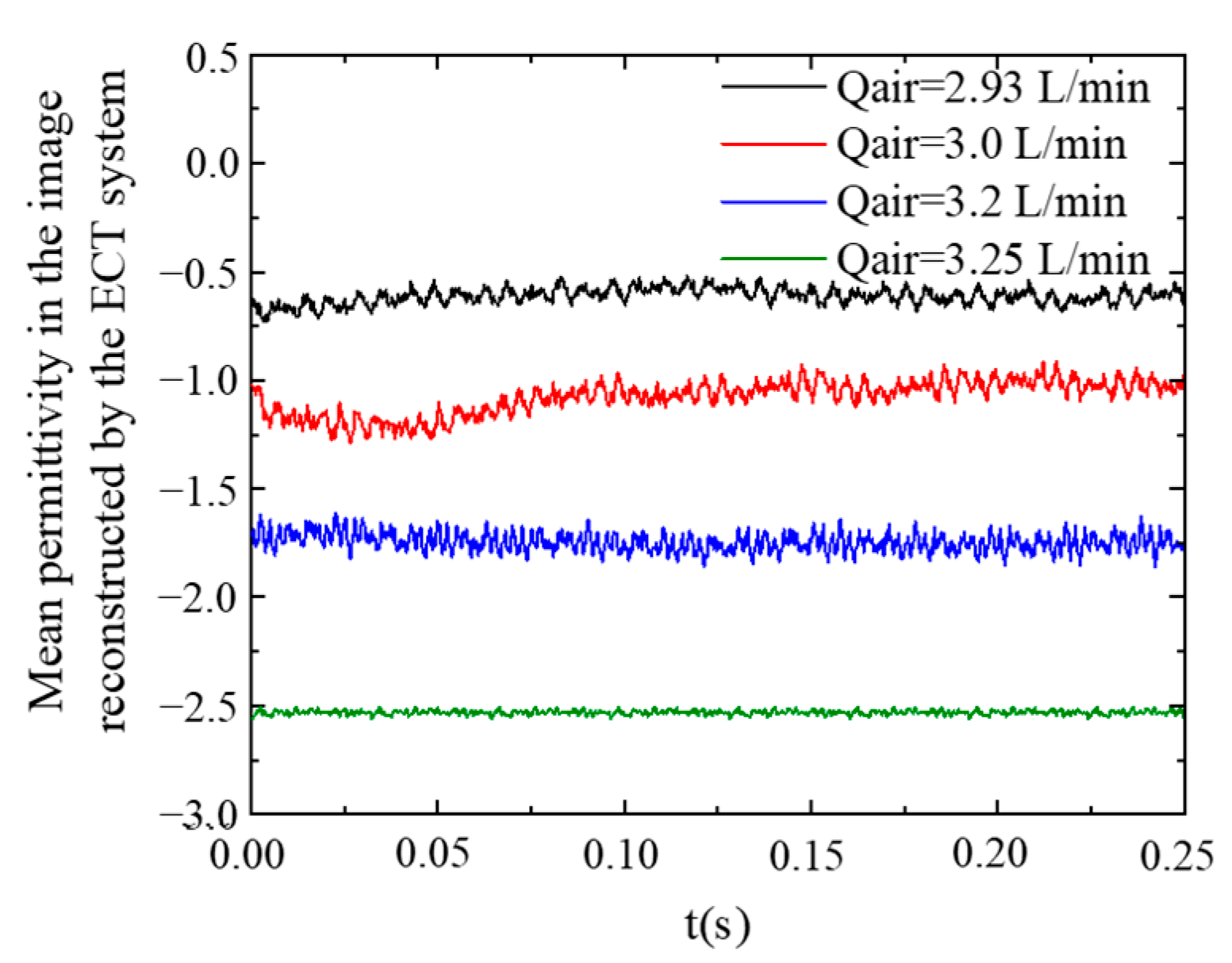

4.1.3. Flame Images Reconstructed by ECT System at Liftoff and Blowout States

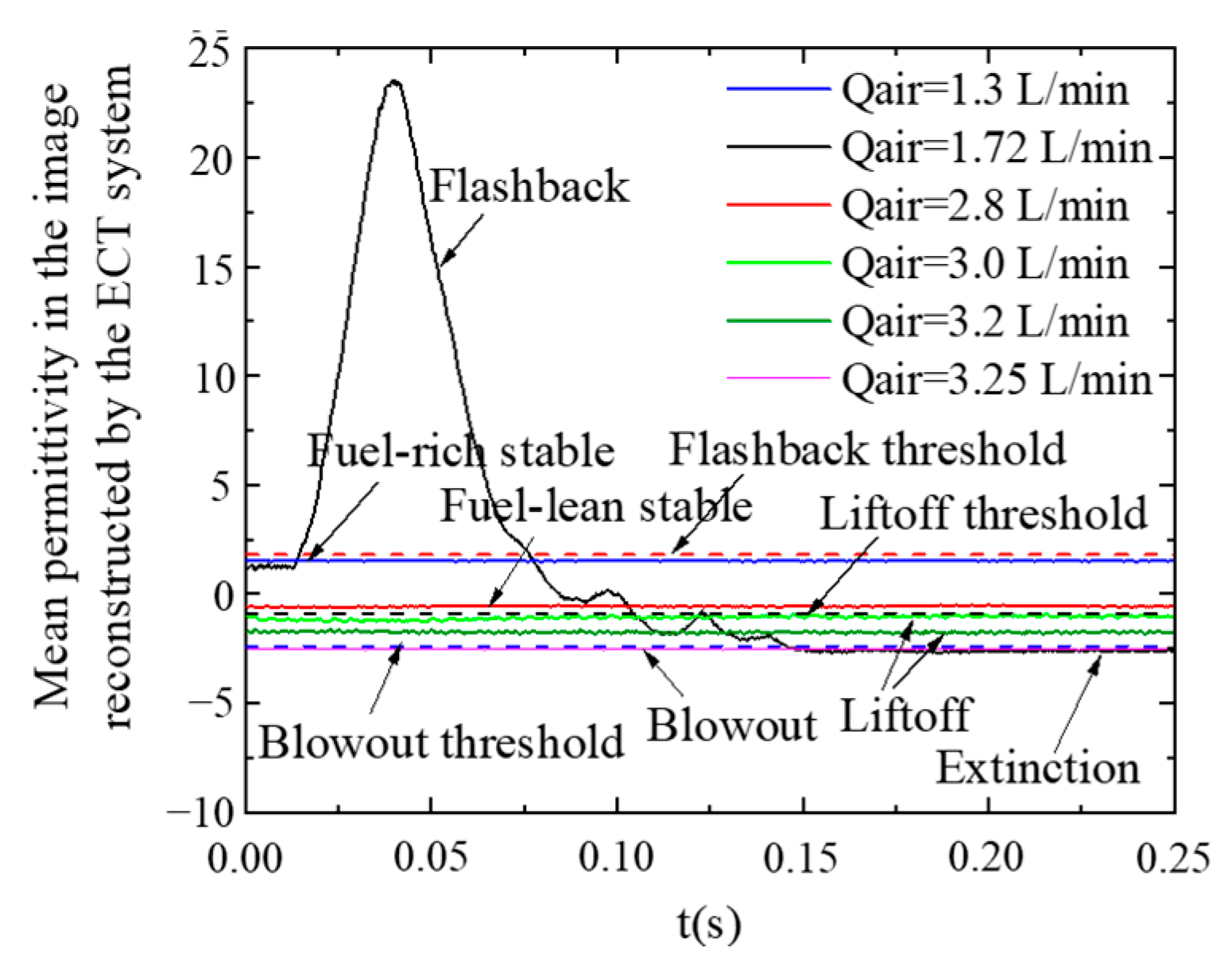

4.2. Determination of Flame State Index

4.3. Characterization of Different Flame States

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tong, Y.; Liu, X.; Wang, Z.; Richter, M.; Klingmann, J. Experimental and numerical study on bluff-body and swirl stabilized diffusion flames. Fuel 2018, 217, 352–364. [Google Scholar] [CrossRef]

- Khateeb, A.A.; Guiberti, T.F.; Zhu, X.; Younes, M.; Jamal, A.; Roberts, W.L. Stability limits and exhaust NO performances of ammonia-methane-air swirl flames. Exp. Therm. Fluid Sci. 2020, 114, 110058. [Google Scholar] [CrossRef]

- Dam, B.; Love, N.; Choudhuri, A. Flashback propensity of syngas fuels. Fuel 2011, 90, 618–625. [Google Scholar] [CrossRef]

- Kim, W.; Im, S.-K.; Do, H.; Mungal, M.G. Flame liftoff height dependence on geometrically modified bluffbodies in a vitiated flow. Exp. Fluids 2009, 49, 27–41. [Google Scholar] [CrossRef]

- Li, F.; Xu, L.; Du, M.; Yang, L.; Cao, Z. Ion current sensing-based lean blowout detection for a pulse combustor. Combust. Flame 2016, 176, 263–271. [Google Scholar] [CrossRef]

- Kurdyumov, V.; Fernández-Tarrazo, E.; Truffaut, J.-M.; Quinard, J.; Wangher, A.; Searby, G. Experimental and numerical study of premixed flame flashback. Proc. Combust. Inst. 2007, 31, 1275–1282. [Google Scholar] [CrossRef]

- Kedia, K.S.; Ghoniem, A.F. The blow-off mechanism of a bluff-body stabilized laminar premixed flame. Combust. Flame 2015, 162, 1304–1315. [Google Scholar] [CrossRef]

- Li, S.; Yao, Q.; Law, C.K.; Liang, W.; Zhuo, J. Liftoff and blowout of the Emmons flame: Analysis of the triple flame. Combust. Flame 2020, 215, 184–192. [Google Scholar] [CrossRef]

- De, S.; Bhattacharya, A.; Mukhopadhyay, A.; Sen, S. Early detection of lean blowout in a combustor using symbolic analysis of colour images. Measurement 2021, 186, 110113. [Google Scholar] [CrossRef]

- Christodoulou, L.; Kabiraj, L.; Saurabh, A.; Karimi, N. Characterizing the signature of flame flashback precursor through recurrence analysis. Chaos Interdiscip. J. Nonlinear Sci. 2016, 26, 013110. [Google Scholar] [CrossRef]

- Eichler, C.; Sattelmayer, T. Premixed flame flashback in wall boundary layers studied by long-distance micro-PIV. Exp. Fluids 2011, 52, 347–360. [Google Scholar] [CrossRef]

- Ebi, D.; Clemens, N.T. Simultaneous high-speed 3D flame front detection and tomographic PIV. Meas. Sci. Technol. 2016, 27, 035303. [Google Scholar] [CrossRef]

- Yon, S.; Sautet, J.-C. Flame lift-off height, velocity flow and mixing of hythane in oxy-combustion in a burner with two separated jets. Appl. Therm. Eng. 2012, 32, 83–92. [Google Scholar] [CrossRef]

- Zheng, L.; Ma, X.; Wang, Z.; Wang, J. An optical study on liquid-phase penetration, flame lift-off location and soot volume fraction distribution of gasoline-diesel blends in a constant volume vessel. Fuel 2015, 139, 365–373. [Google Scholar] [CrossRef]

- Li, D.; He, Z.; Xuan, T.; Zhong, W.; Cao, J.; Wang, Q.; Wang, P. Simultaneous capture of liquid length of spray and flame lift-off length for second-generation biodiesel/diesel blended fuel in a constant volume combustion chamber. Fuel 2017, 189, 260–269. [Google Scholar] [CrossRef]

- Nair, S.; Lieuwen, T. Acoustic Detection of Blowout in Premixed Flames. J. Propuls. Power 2005, 21, 32–39. [Google Scholar] [CrossRef]

- Muruganandam, T.M.; Nair, S.; Scarborough, D.; Neumeier, Y.; Jagoda, J.; Lieuwen, T.; Seitzman, J.; Zinn, B. Active Control of Lean Blowout for Turbine Engine Combustors. J. Propuls. Power 2005, 21, 807–814. [Google Scholar] [CrossRef]

- Li, H.; Zhou, X.; Jeffries, J.; Hanson, R. Sensing and Control of Combustion Instabilities in Swirl-Stabilized Combustors Using Diode-Laser Absorption. AIAA J. 2007, 45, 390–398. [Google Scholar] [CrossRef]

- Docquier, N.; Candel, S. Combustion control and sensors: A review. Prog. Energy Combust. Sci. 2002, 28, 107–150. [Google Scholar] [CrossRef]

- Chang, L.; Cao, Z.; Fu, B.; Lin, Y.; Xu, L. Lean blowout detection for bluff-body stabilized flame. Fuel 2020, 266, 117008. [Google Scholar] [CrossRef]

- Hu, D.; Tian, Y.; Chang, L.; Sun, S.; Sun, J.; Cao, Z.; Xu, L. Estimation of Combustion Temperature Field from the Electrical Admittivity Distribution Obtained by Electrical Tomography. IEEE Trans. Instrum. Meas. 2020, 69, 6271–6280. [Google Scholar] [CrossRef]

- Sun, J.; Yang, W.; Tian, W. 3D imaging based on fringe effect of an electrical capacitance tomography sensor. Measurement 2015, 74, 186–199. [Google Scholar] [CrossRef]

- Calderón, A.P. On an inverse boundary value problem. Comput. Appl. Math. 2006, 25, 133–138. [Google Scholar] [CrossRef]

- Gut, Z.; Wolanski, P. Flame Imaging Using 3D Electrical Capacitance Tomography. Combust. Sci. Technol. 2010, 182, 1580–1585. [Google Scholar] [CrossRef]

- Waterfall, R.C.; He, R.; Beck, C.M. Visualizing combustion using electrical impedance tomography. Chem. Eng. Sci. 1997, 52, 2129–2138. [Google Scholar] [CrossRef]

- Chen, Q.; Jia, Y.; Mao, X.; Ju, Y. Direct Measurements of Permittivity of Plasma-Assisted Combustion Using Electrical Capacitance Tomography. IEEE Trans. Plasma Sci. 2016, 44, 3009–3016. [Google Scholar] [CrossRef]

- Sun, J.; Yang, W. Fringe effect of electrical capacitance and resistance tomography sensors. Meas. Sci. Technol. 2013, 24, 074002. [Google Scholar] [CrossRef]

- Wen, Y.; Zhao, L.; Zhang, Y.; Zhao, P.; Wang, H. Defect detection of the adhesive layer of composite component based on the ECT technology. Chinses J. Sci. Instrum. 2015, 36, 1783–1791. [Google Scholar]

- Ma, M.; Liu, H. Design of ECT system based on planar array electrode sensor. Trans. Microsyst. Technol. 2016, 36, 82–87. [Google Scholar]

| Airflow (L/min) | Equivalence Ratio | Flame State |

|---|---|---|

| <1.36 | >1.27 | Stable flame at fuel-rich condition |

| 1.36–2.48 | 0.72–1.27 | Flame flashback |

| 2.48–3.0 | 0.59–0.72 | Stable flame at fuel-lean condition |

| 3.0–3.25 | 0.54–0.59 | Flame liftoff |

| >3.25 | <0.54 | Blowout |

| Airflow (L/min) | Flame State | Flame State Index |

|---|---|---|

| 1.3 | Fuel-rich stable | 0 |

| 1.72 | Flashback | 0.8452 |

| 2.8 | Fuel-lean stable | 0 |

| 3.0 | Liftoff | −0.1176 |

| 3.2 | Liftoff | −0.4841 |

| 3.25 | Blowout | −0.6444 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, L.; Cui, B.; Zhang, C.; Xu, Z.; Li, G.; Chen, L. Monitoring and Characterizing the Flame State of a Bluff-Body Stabilized Burner by Electrical Capacitance Tomography. Processes 2023, 11, 2403. https://doi.org/10.3390/pr11082403

Chang L, Cui B, Zhang C, Xu Z, Li G, Chen L. Monitoring and Characterizing the Flame State of a Bluff-Body Stabilized Burner by Electrical Capacitance Tomography. Processes. 2023; 11(8):2403. https://doi.org/10.3390/pr11082403

Chicago/Turabian StyleChang, Liuyong, Boxuan Cui, Chenglin Zhang, Zheng Xu, Guangze Li, and Longfei Chen. 2023. "Monitoring and Characterizing the Flame State of a Bluff-Body Stabilized Burner by Electrical Capacitance Tomography" Processes 11, no. 8: 2403. https://doi.org/10.3390/pr11082403

APA StyleChang, L., Cui, B., Zhang, C., Xu, Z., Li, G., & Chen, L. (2023). Monitoring and Characterizing the Flame State of a Bluff-Body Stabilized Burner by Electrical Capacitance Tomography. Processes, 11(8), 2403. https://doi.org/10.3390/pr11082403