A Study on the Mechanism of Casing Deformation and Its Control Strategies in Shale Oil Hydraulic Fracturing

Abstract

:1. Introduction

2. Analysis of the Casing Deformation Mechanism

2.1. Analysis of the Impact of Casing Strength on Casing Deformation

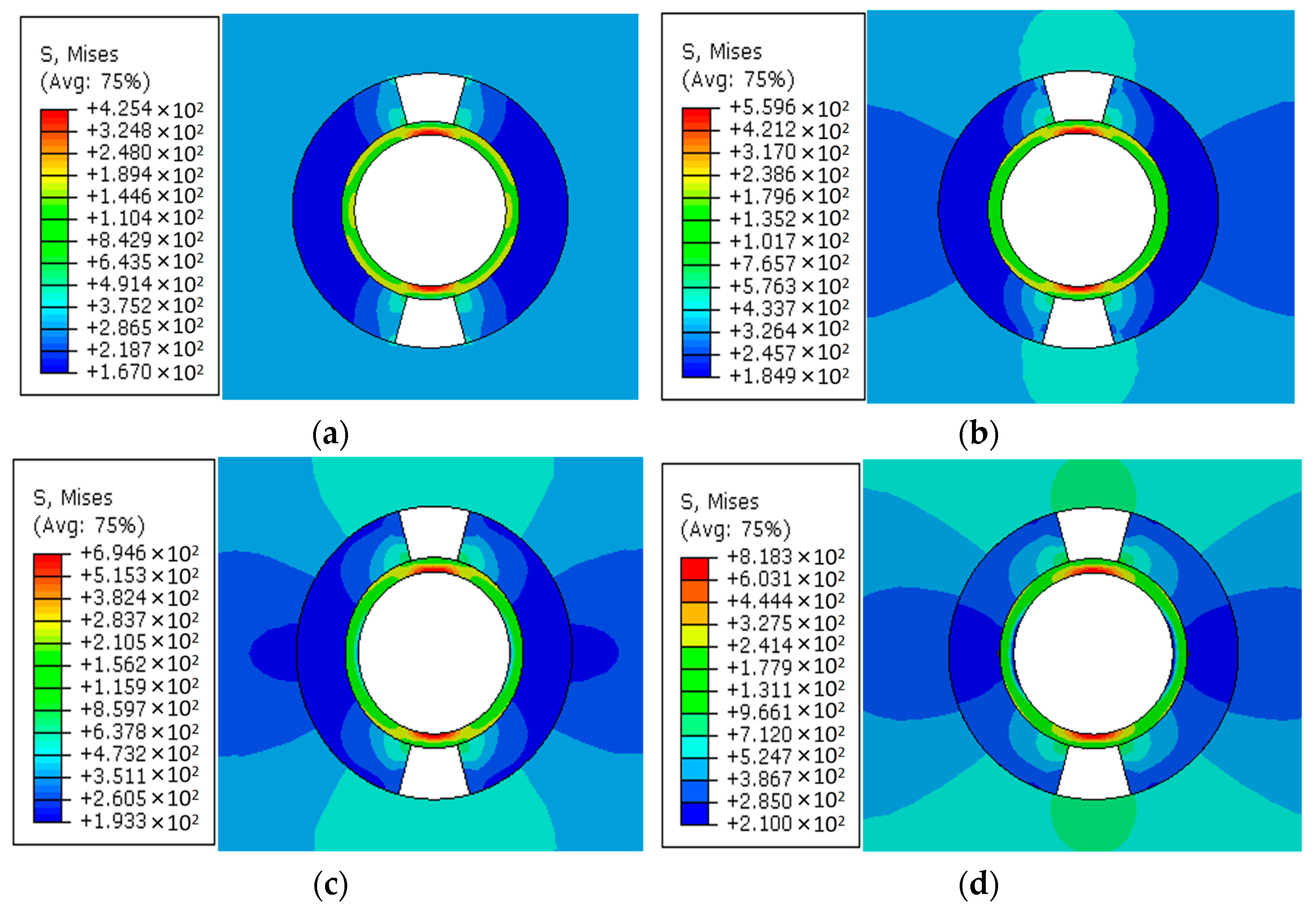

2.2. Analysis of the Impact of Cementing Quality on Casing Deformation

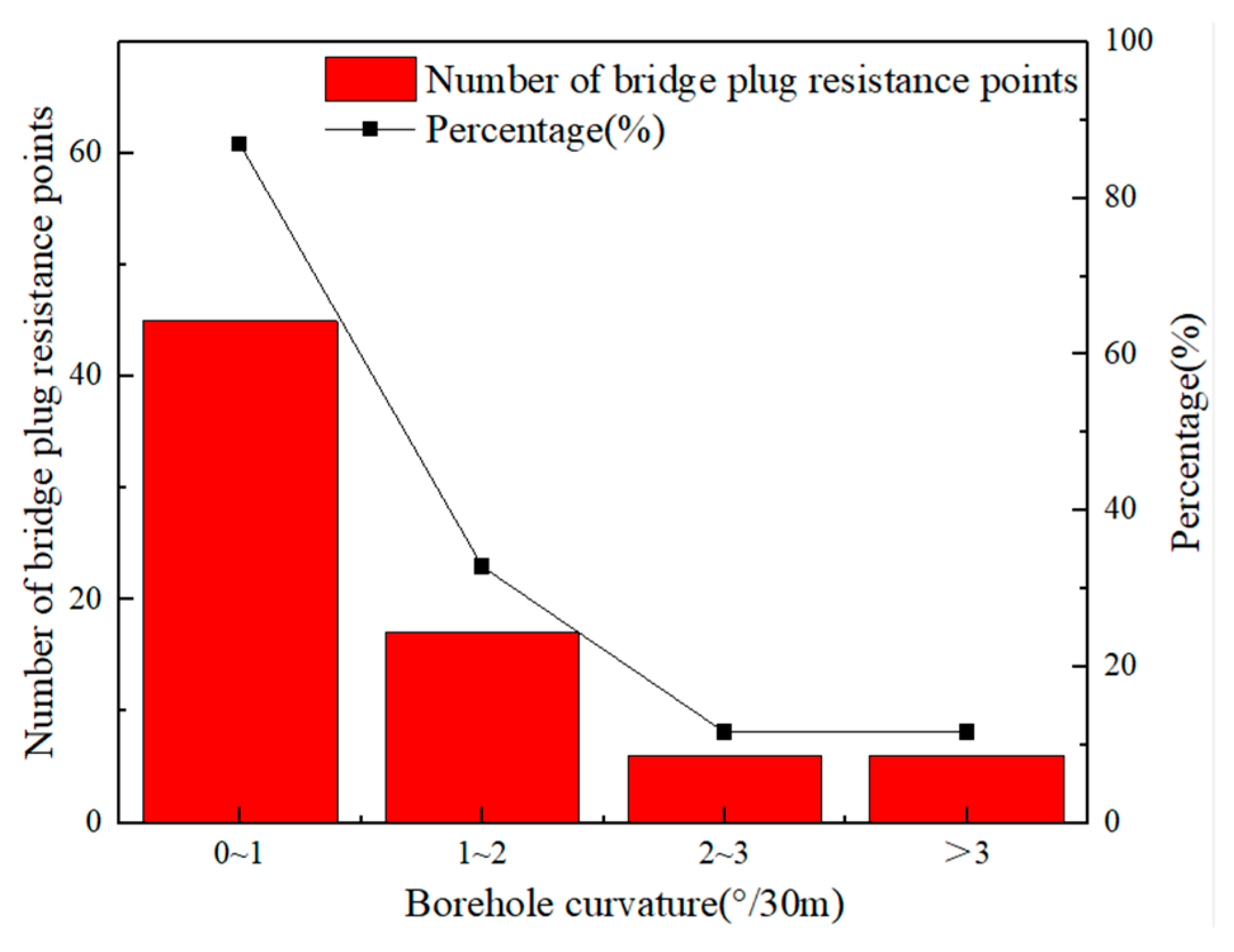

2.3. Analysis of the Impact of Wellbore Curvature on Casing Deformation

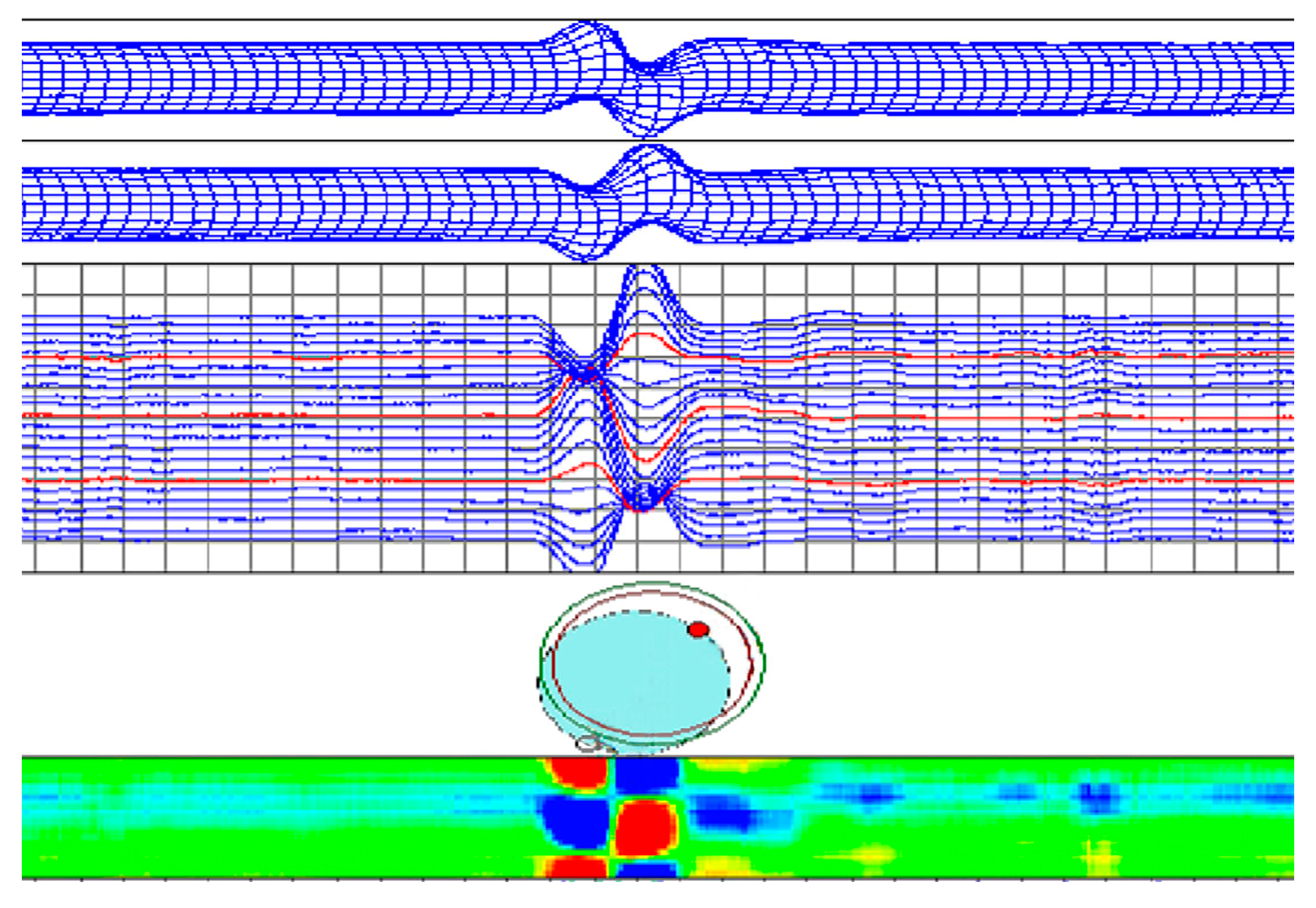

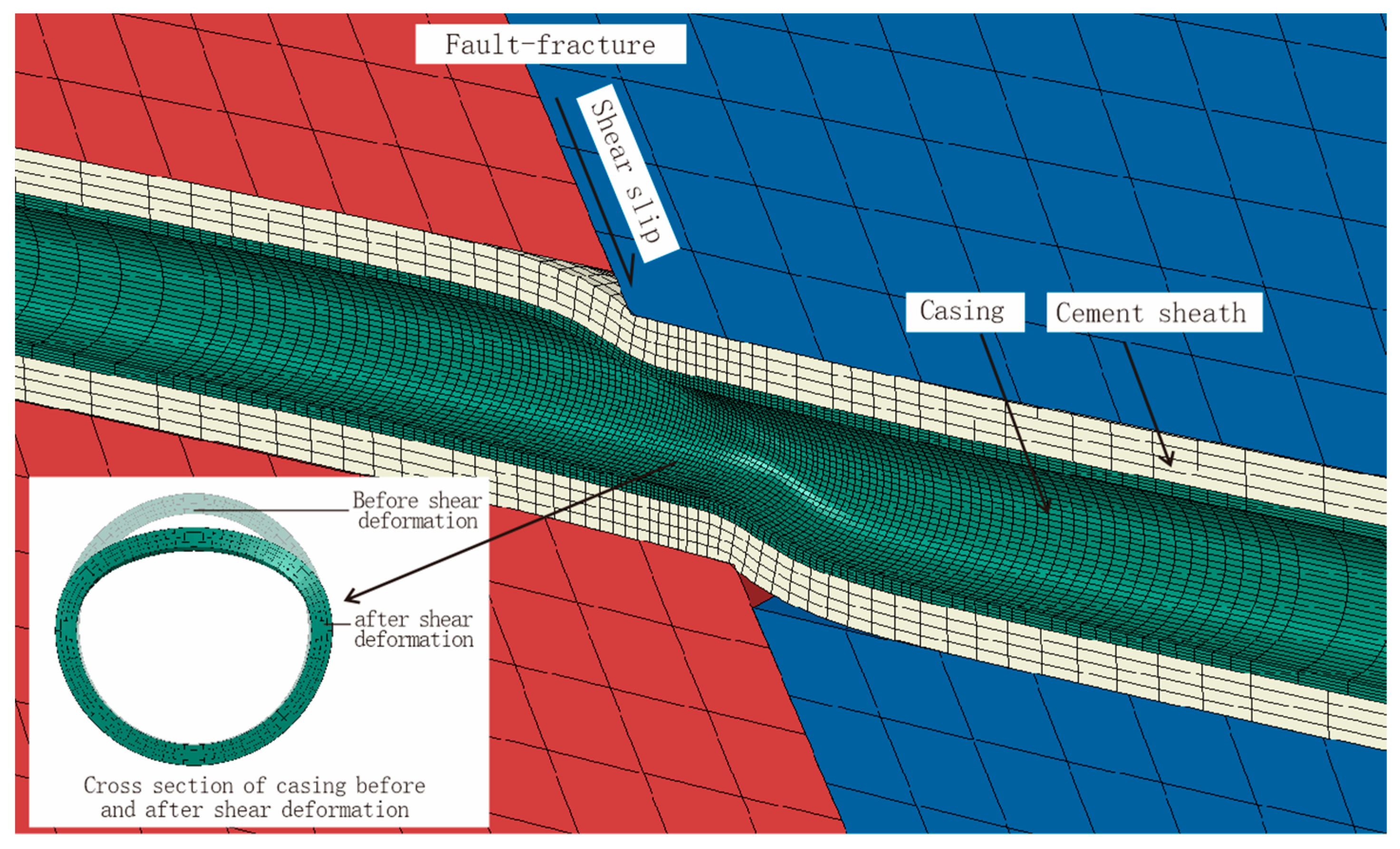

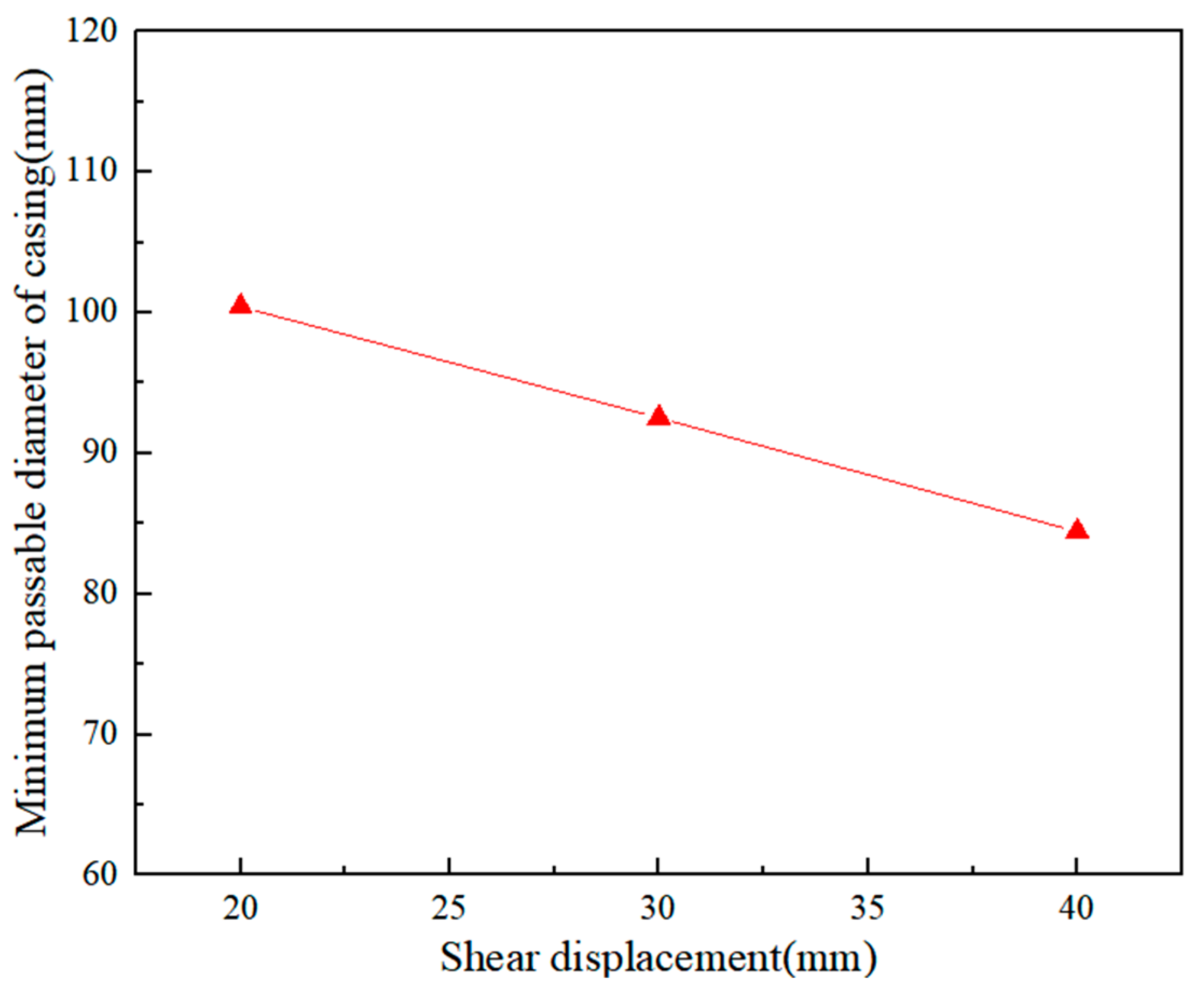

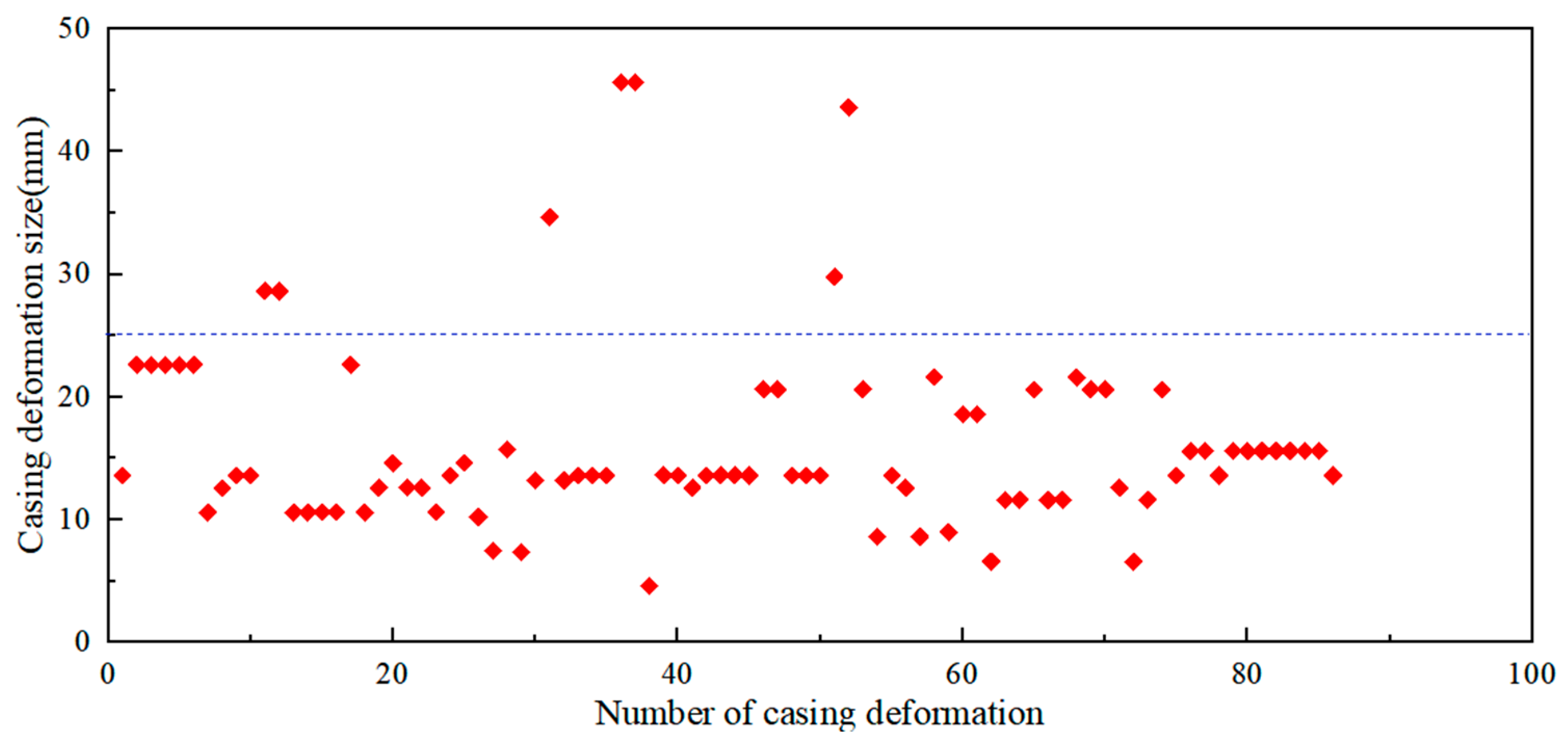

2.4. Analysis of the Morphological Characteristics of Casing Deformation

2.5. Fracture Stability Analysis

2.6. The Correlation between the Distribution of Casing Deformation Points and Fractures

3. Risk Prevention and Control Measures for Casing Deformation

3.1. Casing Deformation Prevention and Control Method Based on Temporary Plugging and Pumping Rate Optimization

3.1.1. Theoretical Analysis of Casing Deformation Prevention and Control through Temporary Plugging

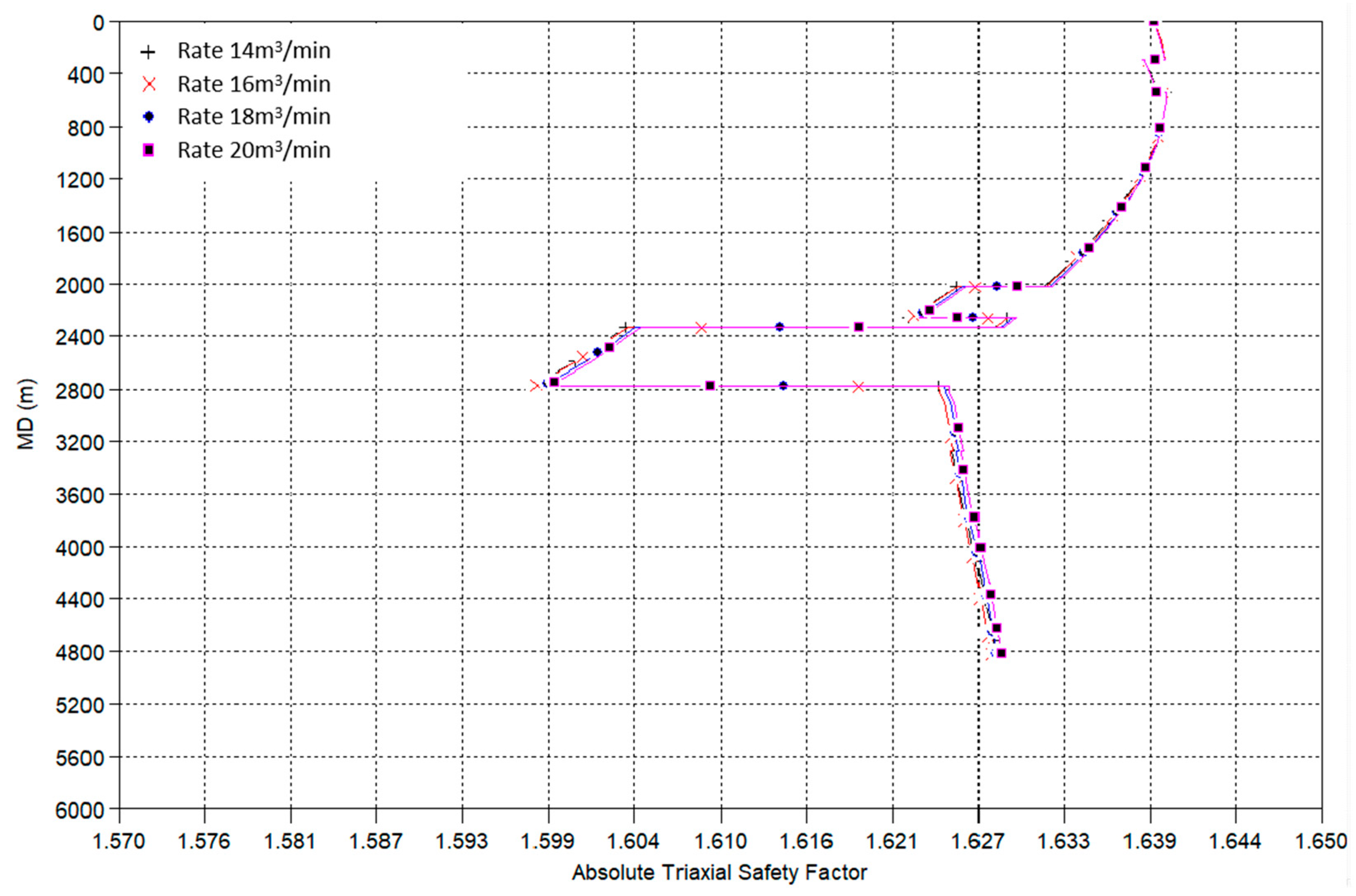

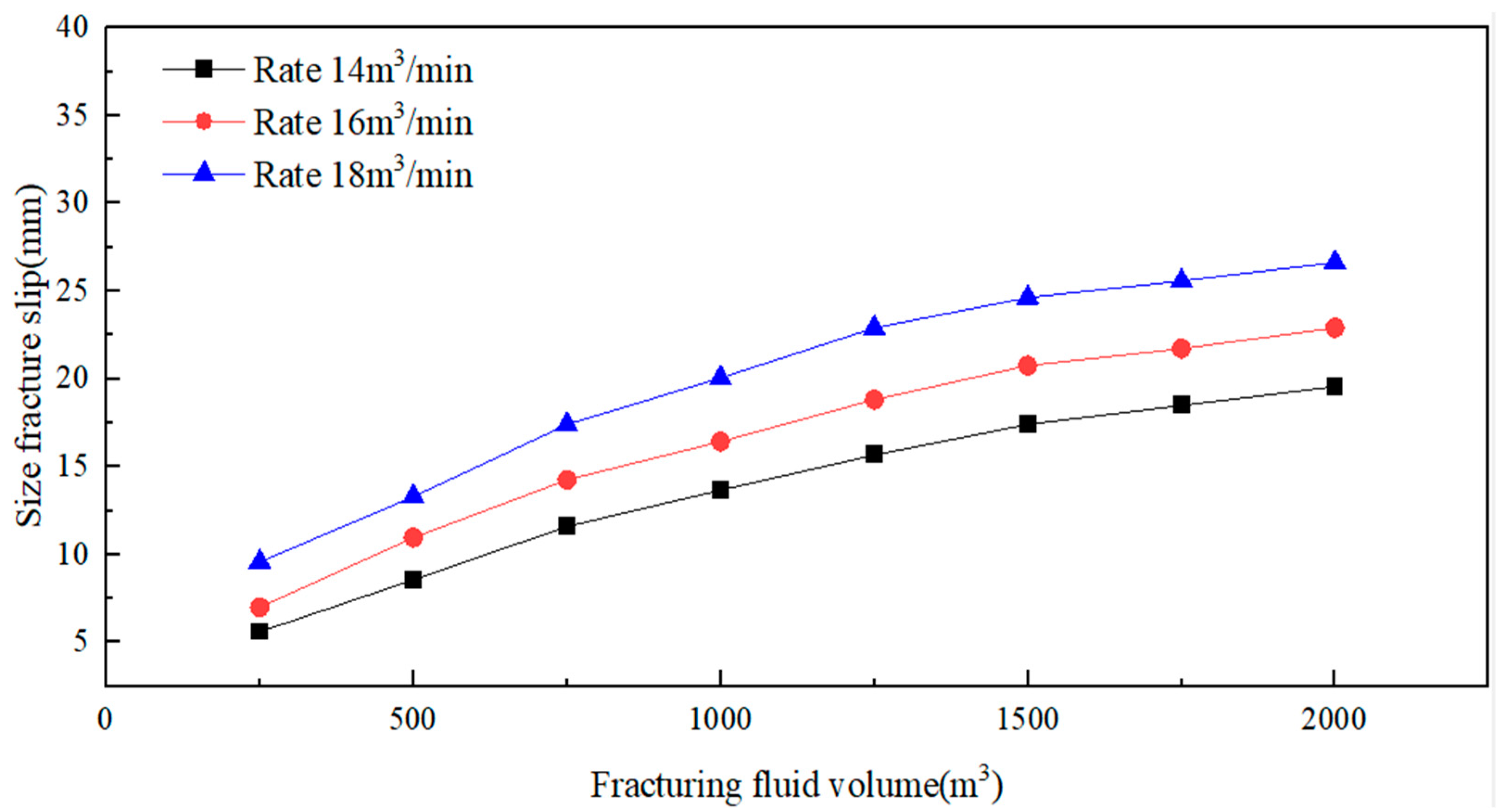

3.1.2. Theory Analysis of Fracture Pumping Rate Optimization in Hydraulic Fracturing

3.1.3. Fracturing Temporary Plugging Timing and Pumping Rate Optimization

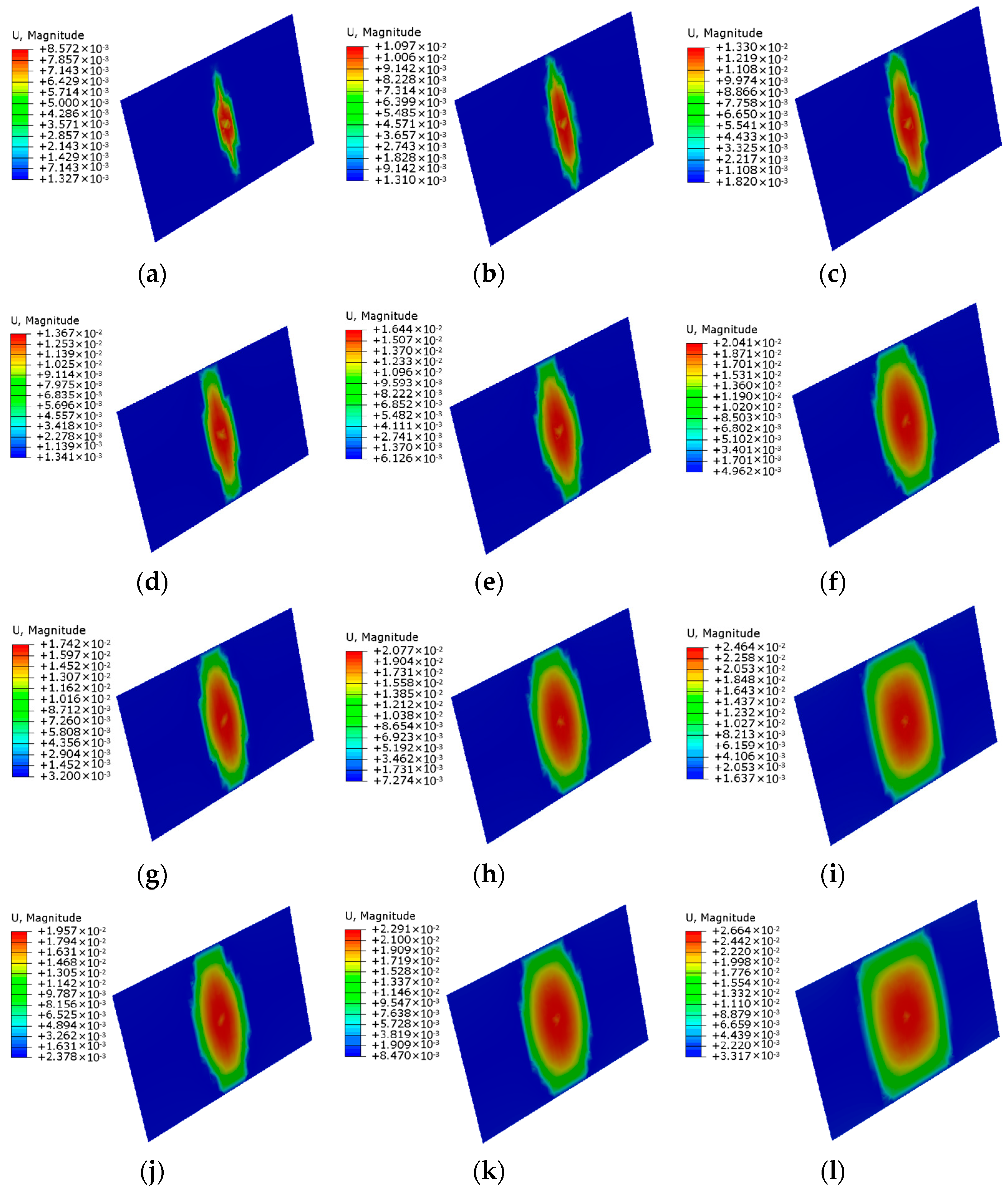

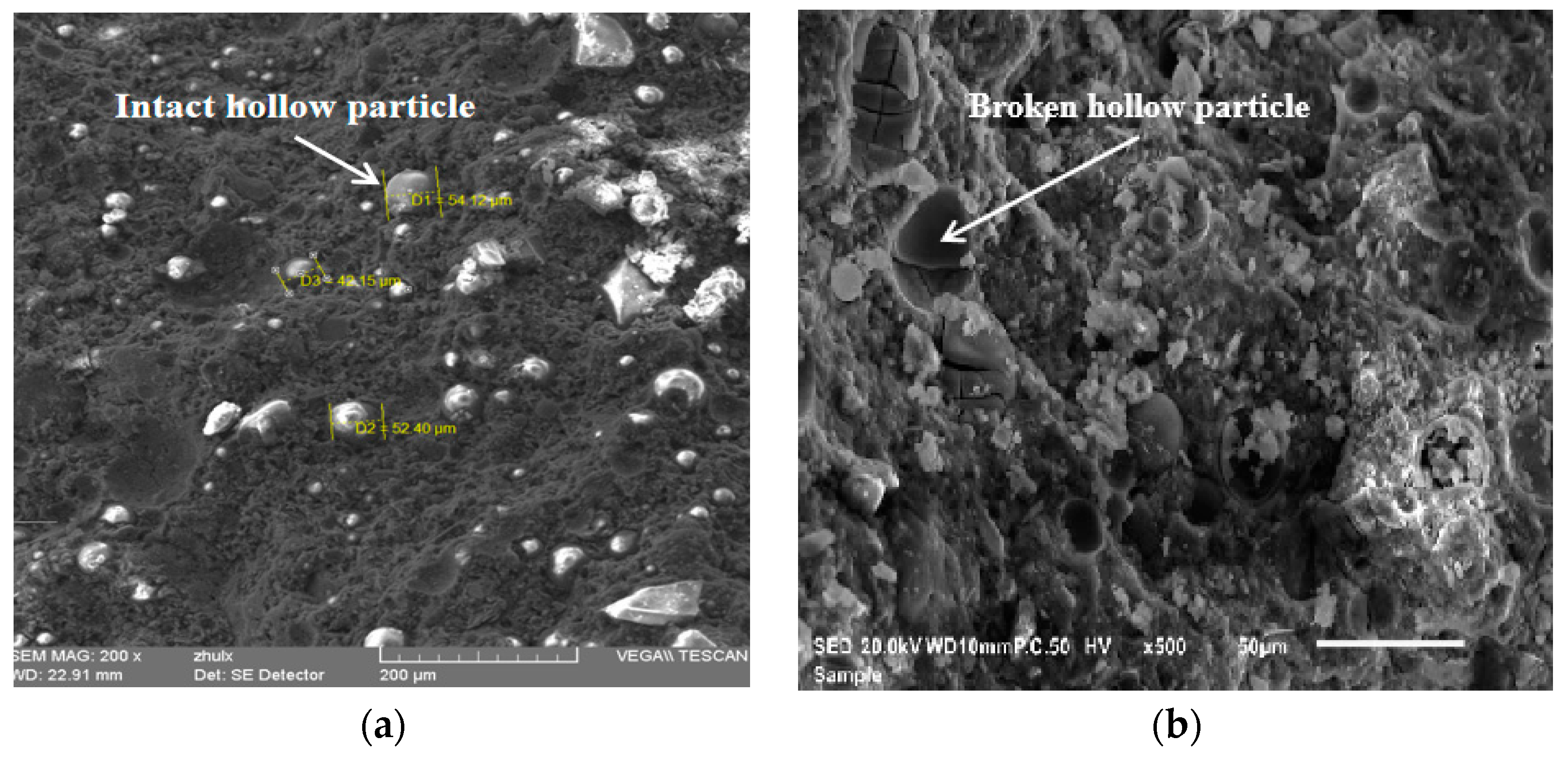

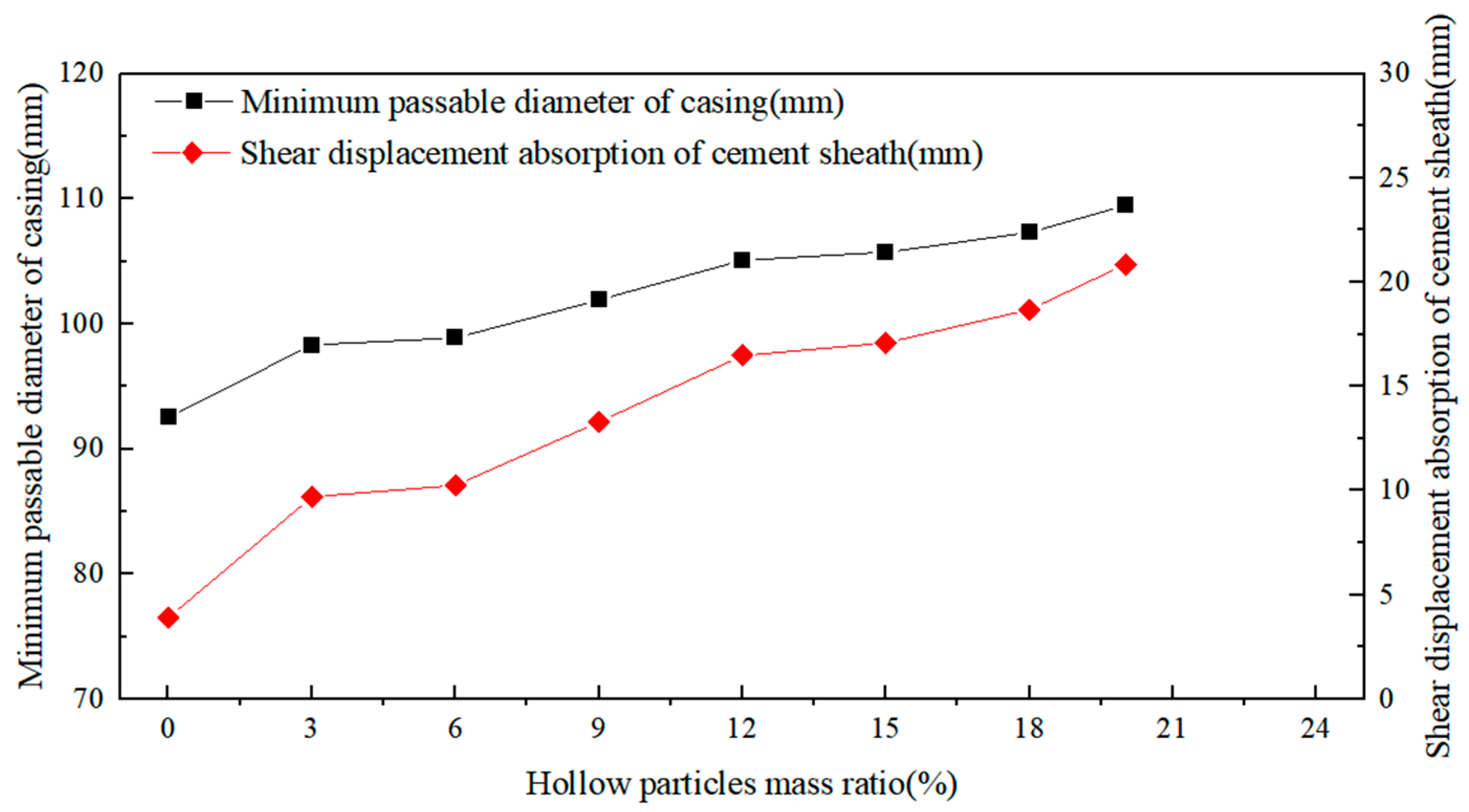

3.2. Casing Deformation Prevention Based on Cement System Optimization

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xi, Y.; Li, J.; Liu, G.H.; Zeng, Y.J.; Li, J.P. Overview of Casing Deformation in Multistage Fracturing of Shale Gas Horizontal Wells. Spec. Oil Gas Reserv. 2019, 26, 1–6. [Google Scholar]

- Li, J.; Ding, S.D.; Han, L.H.; Tao, Q. Research progress in failure mechanism and control methods if wellbore integrity during multi-stage fracturing of shale gas. Pet. Tubul. Goods Instrum. 2020, 48, 126–134. [Google Scholar]

- Zhang, L.P.; Du, J.L.; Tian, Z.H.; Xu, W.L.; Zhao, Y.F.; Aliyaha, A.S.L.B.K.; Zhang, Y. Application of Seismic-Based Casing Deformation Prediction Technology in Xinjiang Oil Field. Xinjiang Oil Gas 2022, 18, 86–91. [Google Scholar]

- Jiang, K.; Li, Q.; Chen, Y.L.; Guo, X.L.; Fu, Y.Q.; Li, J. Influence of cementing quality on casing failures in horizontal shale gas wells. Nat. Gas Ind. 2015, 35, 77–82. [Google Scholar]

- Yu, H.; Lian, Z.H.; Lin, T.J. Numerical simulation if influence of cementing quality on casing failure for oil field. Comput. Simul. 2014, 31, 161–164. [Google Scholar]

- Wu, J.Z.; Zhang, X.J.; Li, J.; Zhang, H.; Lian, W.; Liu, P.L. Influence of In-stiu Stress Variation on Casing Load During Multi-stage Fracturing of Shale Gas Wells. Pet. Tubul. Goods Instrum. 2022, 8, 23–29. [Google Scholar]

- Lian, Z.H.; Yu, H.; Lin, T.J.; Guo, J.H. A study on casing deformation failure during multi-stage hydraulic fracturing for the stimulated reservoir volume of horizontal shale wells. J. Nat. Gas Sci. Eng. 2015, 23, 538–546. [Google Scholar] [CrossRef]

- Fan, M.T.; Li, J.; Liu, G.H.; Chen, X.X. Study on Casing Damage Mechanism in volume Fracturing of Shale Gas Horizontal Well. Pet. Mach. 2018, 46, 82–87. [Google Scholar]

- Tian, Z.L.; Shi, L.; Qiao, L. Research of and countermeasure for wellbore integrity of shale gas horizontal well. Nat. Gas Ind. 2015, 35, 70–76. [Google Scholar]

- Gao, L.J.; Liu, Z.L.; Qiao, L.; Zhuang, Z.; Yang, H.L. Mechanism Analysis and Numerical Simulation if Casing Failure in Hydraulic Fracturing of Shale Gas Formation. Pet. Mach. 2017, 45, 75–80. [Google Scholar]

- Chen, Z.W.; Cao, H.; Zhou, X.J.; Gou, Q.Y.; Zhang, H.Z. Correlation between casing deformation and fracture zones in Changning shale gas block, Sichuan Basin. Nat. Gas Explor. Dev. 2020, 43, 123–130. [Google Scholar]

- Chen, Z.W.; Xiang, D.G.; Zhang, F.S.; An, M.K.; Yin, Z.R.; Jiang, Z.Y. Fault slip and casing deformation caused by hydraulic fracturing in Chang-ning-Weiyuan Blocks, Sichuan: Mechanism and prevention strategy. Pet. Sci. Bull. 2019, 4, 364–377. [Google Scholar]

- Li, L.W.; Wang, G.C.; Lian, Z.H.; Zhang, L.; Mei, Y.; He, Y.L. Deformation mechanism of horizontal shale gas well production casing and its en-gineering solution: A case study on the Huangjinba Block of the Zhaotong National Shale Gas Demonstration Zone. Nat. Gas Ind. 2017, 37, 91–99. [Google Scholar]

- Zhang, F.S.; Yin, Z.R.; Chen, Z.W.; Shawn, M.; Zhang, L.Y.; Wu, Y.H. Fault reactivation and induced seismicity during multi-stage hydraulic fracturing: Field microseismic analysis and geomechanical modeling. SPE J. 2020, 25, 692–711. [Google Scholar] [CrossRef]

- Liu, W.; Tao, C.Z.; Wan, Y.Y.; Chi, X.M.; Li, Y.; Lin, H.; Deng, J.G. Numerical analysis of casing deformation during massive hydraulic fracturing of horizontal wells in a tight-oil reservoir. Pet. Sci. Bull. 2017, 4, 466–477. [Google Scholar]

- Fan, Y.; Huang, R.; Zeng, B.; Chen, Z.W.; Zhou, X.J.; Xiang, D.G.; Song, Y. Fault slip induced by hydraulic fracturing and risk assessment of casing deformation in the Sichuan Basin. Pet. Sci. Bull. 2020, 5, 366–375. [Google Scholar]

- Chen, Z.W.; Fang, C.; Yong, Z.; Xiang, D.G. Deformation Characteristics and Stress Modes of Casings for Shale Gas Wells in Sichuan. China Pet. Mach. 2020, 48, 126–134. [Google Scholar]

- Twiss, R.J.; Moores, E.M. Structural Geology; Freeman and Company: New York, NY, USA, 1992; p. 532. [Google Scholar]

- Jaeger, J.C.; Cook, N.G.W. Fundamentals of Rock Mechanics, 3rd ed.; Chapman and Hall: London, UK, 1979; p. 593. [Google Scholar]

- Tong, H.M.; Wang, J.J.; Zhao, H.T.; Li, B.; Hao, H.W.; Wang, M.Y. “Molar space” and its application to prediction of activity of pre-existing structures. China Sci. Earth Sci. 2014, 44, 1948–1957. [Google Scholar]

- Tong, H.M.; Zhang, P.; Zhang, H.X.; Liu, Z.P.; Ren, X.H.; Xiao, K.Z.; Zhou, Y.B.; Deng, C. Geomechanical mechanisms and prevention countermeasures of casing deformation in shale gas horizontal wells. Nat. Gas Ind. 2021, 41, 189–197. [Google Scholar]

- ZOBACK, M.D. Reservoir Geomechanics; Cambridge University Press: Cambridge, UK, 2007. [Google Scholar]

- Tong, H.M.; Liu, Z.P.; Zhang, H.X.; Zhang, P.; Deng, C.; Ren, X.H.; Xiao, K.Z.; Zhou, Y.B. Theory and method of temporary macrofracture plugging to prevent casing deformation in shale gas horizontal wells. Nat. Gas Ind. 2021, 41, 92–100. [Google Scholar]

- Zhang, F.S.; Jiang, Z.Y.; Chen, Z.W.; Yin, Z.R.; Tang, J.Z. Hydraulic fracturing induced fault slip and casing shear in Sichuan Basin: A multi-scale numerical investigation. J. Pet. Sci. Eng. 2020, 195, 107797. [Google Scholar] [CrossRef]

| Parameters of casing | |

| Young’s modulus | 210 GPa |

| Poisson’s ratio | 0.3 |

| Outside diameter | 139.7 |

| Thickness | 10.54 |

| Parameters of cement sheath | |

| Young’s modulus | 7 GPa |

| Poisson’s ratio | 0.2 |

| Thickness | 38.1 mm |

| Parameters of rock | |

| Young’s modulus | 20 GPa |

| Poisson’s ratio | 0.2 |

| Parameters of casing | |

| Young’s modulus | 210 GPa |

| Poisson’s ratio | 0.3 |

| Outside diameter | 139.7 |

| Thickness | 10.54 |

| Parameters of cement sheath | |

| Young’s modulus | 7 GPa |

| Poisson’s ratio | 0.2 |

| Thickness | 38.1 mm |

| Parameters of rock | |

| Young’s modulus | 20 GPa |

| Poisson’s ratio | 0.2 |

| Parameters of fracture | |

| Dip | 75° |

| Parameters of Rock | |

|---|---|

| Young’s modulus | 20 GPa |

| Poisson’s ratio | 0.2 |

| Parameters of fracture surface | |

| Length | 800 m |

| Dip | 75° |

| Cohesion | 1 MPa |

| Parameters of hydraulic fracturing | |

| Pumping rate | 14~18 m3/min |

| Injection volume | 250~2000 m3 |

| Viscosity | 2 mP.s |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, N.; Wang, P.; Li, J.; Ma, W.; Zhang, X.; Zhang, H.; Jiang, C.; Huang, W.; Feng, X.; Liu, S. A Study on the Mechanism of Casing Deformation and Its Control Strategies in Shale Oil Hydraulic Fracturing. Processes 2023, 11, 2437. https://doi.org/10.3390/pr11082437

Zhang N, Wang P, Li J, Ma W, Zhang X, Zhang H, Jiang C, Huang W, Feng X, Liu S. A Study on the Mechanism of Casing Deformation and Its Control Strategies in Shale Oil Hydraulic Fracturing. Processes. 2023; 11(8):2437. https://doi.org/10.3390/pr11082437

Chicago/Turabian StyleZhang, Nan, Peng Wang, Junliang Li, Wenhai Ma, Xiaochuan Zhang, Hongtao Zhang, Chenggang Jiang, Weiming Huang, Xinzhu Feng, and Shuwei Liu. 2023. "A Study on the Mechanism of Casing Deformation and Its Control Strategies in Shale Oil Hydraulic Fracturing" Processes 11, no. 8: 2437. https://doi.org/10.3390/pr11082437

APA StyleZhang, N., Wang, P., Li, J., Ma, W., Zhang, X., Zhang, H., Jiang, C., Huang, W., Feng, X., & Liu, S. (2023). A Study on the Mechanism of Casing Deformation and Its Control Strategies in Shale Oil Hydraulic Fracturing. Processes, 11(8), 2437. https://doi.org/10.3390/pr11082437