Conversion of Materials and Energy in Anaerobic Digestion of Sewage Sludge with High-Pressure Homogenization Pretreatment

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. HPH Pretreatment of Sewage Sludge

2.3. Sludge Anaerobic Digestion

2.4. Analysis Methods

2.5. Statistical Analysis

3. Results and Discussion

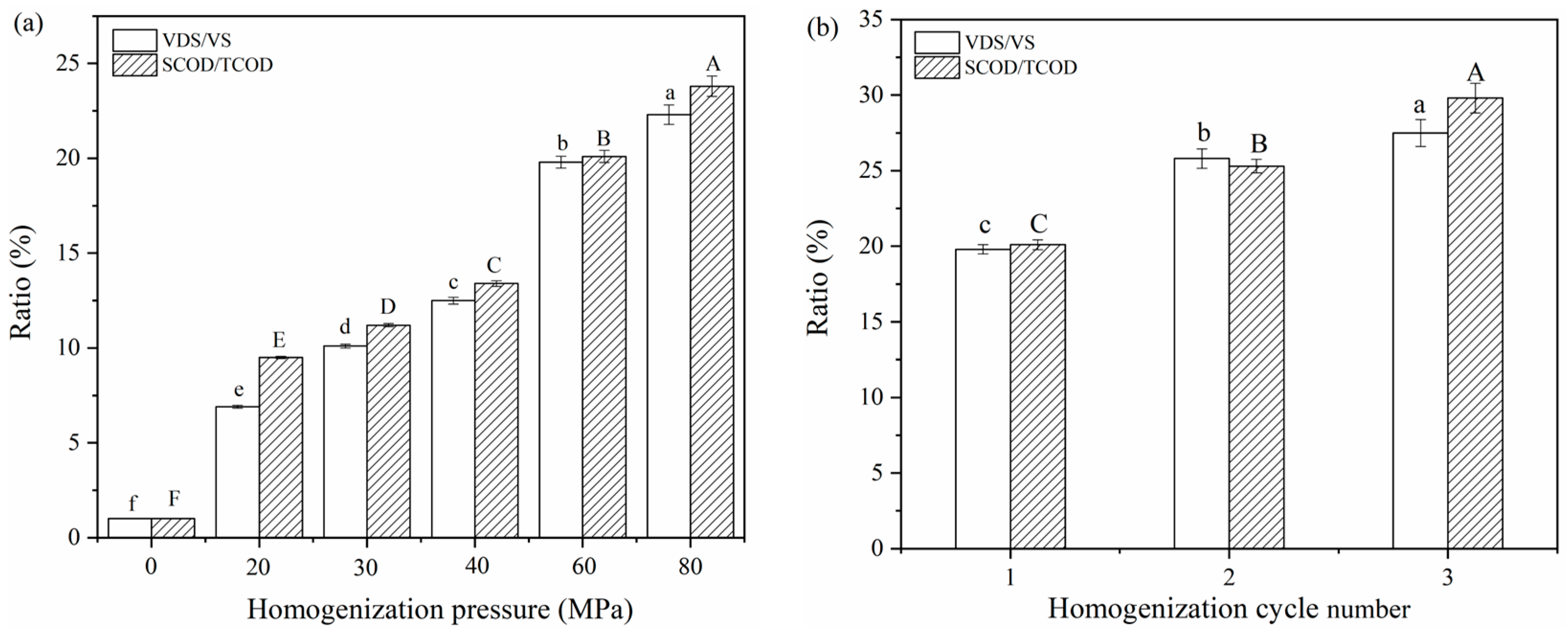

3.1. Change of HPH Pretreatment on Sludge Characteristics

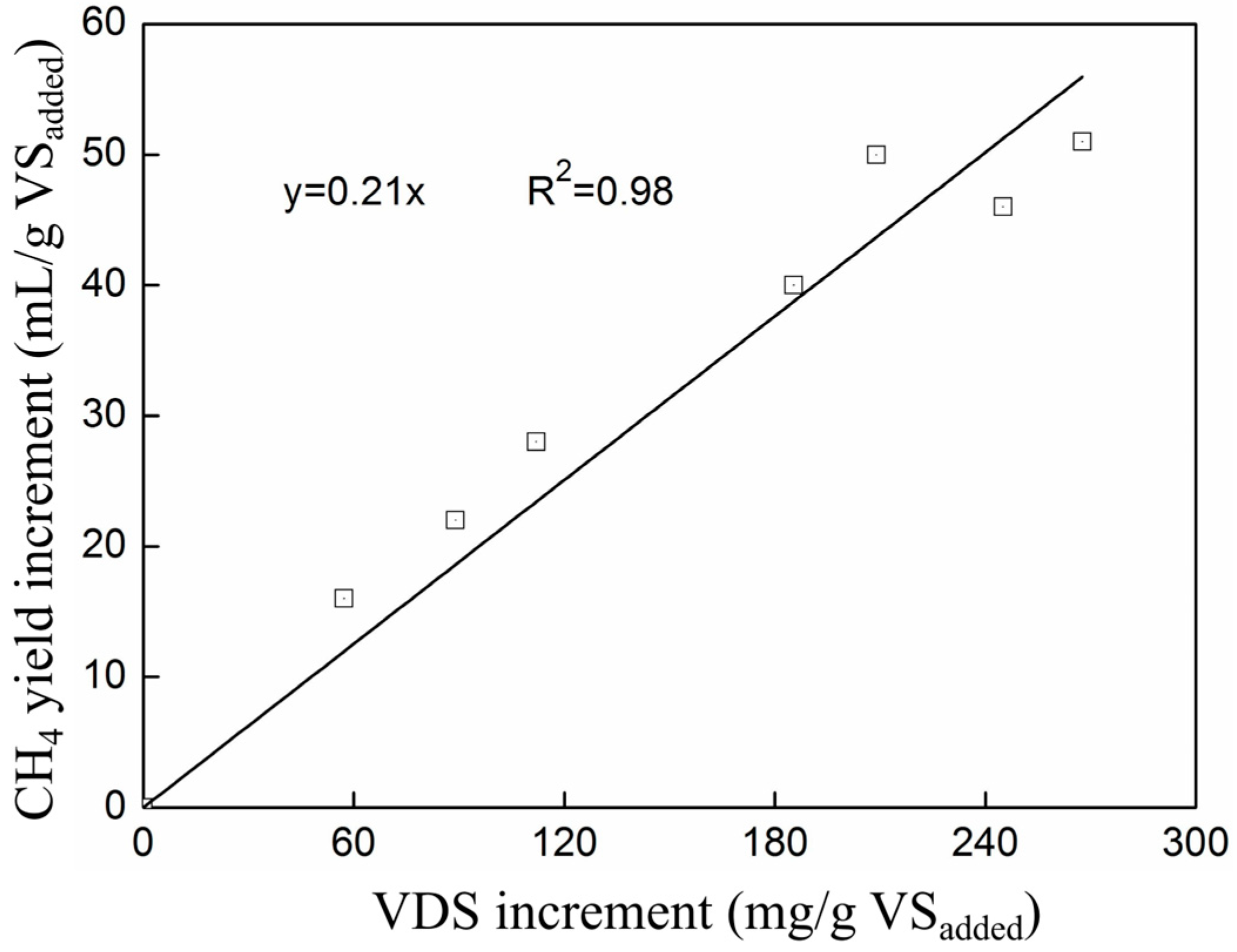

3.2. Effect of HPH Pretreatment on Biogas Yield and Rate of Sludge Anaerobic Digestion

3.3. Additive Energy Consumption of HPH Pretreatment for Improvement of Biogas Production

4. Practical Implication on HPH Pretreatment Enhancement in Anaerobic Sludge Digestion

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ding, A.; Zhang, R.R.; Ngo, H.H.; He, X.; Ma, J.; Nan, J.; Li, G. Life cycle assessment of sewage sludge treatment and disposal based on nutrient and energy recovery: A review. Sci. Total Environ. 2021, 769, 144451. [Google Scholar] [PubMed]

- El Hayany, B.; Rumpel, C.; Hafidi, M.; El Fels, L. Occurrence, analysis of microplastics in sewage sludge and their fate during composting: A literature review. J. Environ. Manag. 2022, 317, 115364. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.R.; Deng, Q.; Du, M.; Lu, Q.; Zhou, W.; Wang, D.B. Microplastics decrease the toxicity of cadmium to methane production from anaerobic digestion of sewage sludge. Sci. Total Environ. 2023, 869, 161780. [Google Scholar] [CrossRef] [PubMed]

- Xiao, J.; He, D.D.; Ye, Y.H.; Yang, B.; Duan, A.; Wang, D.B. Recent progress in persulfate to improve waste activated sludge treatment: Principles, challenges and perspectives. Chem. Eng. J. 2023, 469, 143956. [Google Scholar] [CrossRef]

- Chen, L.; Fang, W.; Liang, J.S.; Nabi, M.; Cai, Y.J.; Wang, Q.Y.; Zhang, P.Y.; Zhang, G.M. Biochar application in anaerobic digestion: Performances, mechanisms, environmental assessment and circular economy. Resour. Conser. Recy. 2023, 188, 106720. [Google Scholar]

- Junior, I.V.; Almeida, R.D.; Cammarota, M.C. A review of sludge pretreatment methods and co-digestion to boost biogas production and energy self-sufficiency in wastewater treatment plants. J. Water Process Eng. 2021, 40, 101857. [Google Scholar]

- Paranjpe, A.; Saxena, S.; Jain, P. A review on performance improvement of anaerobic digestion using co-digestion of food waste and sewage sludge. J. Environ. Manag. 2023, 338, 117733. [Google Scholar] [CrossRef]

- Liang, J.S.; Nabi, M.; Zhang, P.Y.; Zhang, G.M.; Cai, Y.Y.; Wang, Q.Y.; Zhou, Z.Y.; Ding, Y.R. Promising biological conversion of lignocellulosic biomass to renewable energy with rumen microorganisms: A comprehensive review. Renew. Sust. Energy Rev. 2020, 134, 110335. [Google Scholar]

- Liang, J.S.; Zheng, W.G.; Zhang, H.B. Transformation of bacterial community structure in rumen liquid anaerobic digestion of rice straw. Environ. Pollut. 2021, 269, 116130. [Google Scholar] [PubMed]

- Zhang, X.; Huang, X.; Li, X.; Zhang, J.; Tang, M.; Liu, X.; Wang, D.; Yang, Q.; Duan, A.; Liu, J. Performance and mechanisms of citric acid improving biotransformation of waste activated sludge into short-chain fatty acids. Bioresour. Technol. 2023, 373, 128754. [Google Scholar] [CrossRef]

- Liu, X.; Wang, D.; Chen, Z.; Wei, W.; Mannina, G.; Ni, B.J. Advances in pretreatment strategies to enhance the biodegradability of waste activated sludge for the conversion of refractory substances. Bioresour. Technol. 2022, 362, 127804. [Google Scholar] [CrossRef]

- Garlicka, A.; Umiejewska, K.; Halkjær Nielsen, P.; Muszyński, A. Hydrodynamic disintegration of thickened excess sludge and maize silage to intensify methane production: Energy effect and impact on microbial communities. Bioresour. Technol. 2023, 376, 128829. [Google Scholar] [CrossRef] [PubMed]

- Godvin Sharmila, V.; Kumar, G.; Sivashanmugham, P.; Piechota, G.; Park, J.H.; Adish Kumar, S.; Rajesh Banu, J. Phase separated pretreatment strategies for enhanced waste activated sludge disintegration in anaerobic digestion: An outlook and recent trends. Bioresour. Technol. 2022, 363, 127985. [Google Scholar] [PubMed]

- Wang, X.; Jiang, C.; Wang, H.; Xu, S.; Zhuang, X. Strategies for energy conversion from sludge to methane through pretreatment coupled anaerobic digestion: Potential energy loss or gain. J. Environ. Manag. 2023, 330, 117033. [Google Scholar]

- Nabi, M.; Gao, D.W.; Liang, J.; Cai, Y.J.; Zhang, P.Y. Combining high pressure homogenization with free nitrous acid pretreatment to improve anaerobic digestion of sewage sludge. J. Environ. Manag. 2022, 318, 115635. [Google Scholar] [CrossRef]

- Nguyen, V.K.; Chaudhary, D.K.; Dahal, R.H.; Trinh, N.H.; Kim, J.; Chang, S.W.; Hong, Y.; La, D.D.; Nguyen, X.C.; Ngo, H.H.; et al. Review on pretreatment techniques to improve anaerobic digestion of sewage sludge. Fuel 2021, 285, 119105. [Google Scholar] [CrossRef]

- Chen, Y.; Ping, Q.; Li, D.; Dai, X.; Li, Y. Comprehensive insights into the impact of pretreatment on anaerobic digestion of waste active sludge from perspectives of organic matter composition, thermodynamics, and multi-omics. Water Res. 2022, 226, 119240. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, P.Y.; Zhang, G.M.; Fan, J.; Zhang, Y. Enhancement of anaerobic sludge digestion by high-pressure homogenization. Bioresour. Technol. 2012, 118, 496–501. [Google Scholar]

- Nabi, M.; Liang, J.S.; Zhang, P.Y.; Wu, Y.; Fu, C.; Wang, S.Q.; Ye, J.P.; Gao, D.W.; Shah, F.A.; Dai, J.Q. Anaerobic digestion of sewage sludge pretreated by high pressure homogenization using expanded granular sludge blanket reactor: Feasibility, operation optimization and microbial community. J. Environ. Chem. Eng. 2021, 9, 104720. [Google Scholar] [CrossRef]

- Onyeche, T.I.; Schläfer, O.; Sievers, M. Advanced anaerobic digestion of sludge through high pressure homogenization. J. Solid Waste Technol. Manag. 2003, 29, 56–61. [Google Scholar]

- Onyeche, T.I. Sludge homogenisation for improved energy and reduced sludge productions. J. Solid Waste Technol. Manag. 2004, 30, 164–169. [Google Scholar]

- Zhang, Y.; Zhang, P.; Zhang, G.; Ma, W.; Wu, H.; Ma, B. Sewage sludge disintegration by combined treatment of alkaline + high pressure homogenization. Bioresour. Technol. 2012, 123, 514–519. [Google Scholar] [CrossRef] [PubMed]

- Apul, O.G.; Sanin, F.D. Ultrasonic pretreatment and subsequent anaerobic digestion under different operational conditions. Bioresour. Technol. 2010, 101, 8984–8992. [Google Scholar] [CrossRef] [PubMed]

- APHA. Standard Methods for the Examination of Water and Wastewater; American Public Health Association: Washington, DC, USA, 2012. [Google Scholar]

- Wang, S.Q.; Zhang, G.M.; Zhang, P.Y.; Ma, X.W.; Li, F.; Zhang, H.B.; Tao, X.; Ye, J.P.; Nabi, M. Rumen fluid fermentation for enhancement of hydrolysis and acidification of grass clipping. J. Environ. Manag. 2018, 220, 142–148. [Google Scholar] [CrossRef]

- Fang, W.; Zhang, P.Y.; Shang, R.; Ye, J.; Wu, Y.; Zhang, H.B.; Liu, J.B.; Gou, X.Y.; Zeng, G.M.; Zhou, S.Q. Effect of high pressure homogenization on anaerobic digestion of the sludge pretreated by combined alkaline and high pressure homogenization. Desalin. Water Treat. 2017, 62, 168–174. [Google Scholar] [CrossRef]

- Zhang, Y.X.; Zhang, P.Y.; Guo, J.B.; Ma, W.F.; Xiao, L.P. Spectroscopic analysis and biodegradation potential study of dissolved organic matters in sewage sludge treated with high-pressure homogenization. Bioresour. Technol. 2013, 135, 616–621. [Google Scholar] [CrossRef]

- Nabi, M.; Zhang, G.M.; Zhang, P.Y.; Tao, X.; Wang, S.Q.; Ye, J.P.; Zhang, Q.; Zubair, M.; Bao, S.; Wu, Y. Contribution of solid and liquid fractions of sewage sludge pretreated by high pressure homogenization to biogas production. Bioresour. Technol. 2019, 286, 121378. [Google Scholar] [CrossRef]

- Zhen, G.; Lu, X.; Kato, H.S.; Zhao, Y.; Li, Y. Overview of pretreatment strategies for enhancing sewage sludge disintegration and subsequent anaerobic digestion: Current advances, full-scale application and future perspectives. Renew. Sustain. Energy Rev. 2017, 69, 559–577. [Google Scholar] [CrossRef]

- Sun, Y.; Liu, Y.; Zhang, Y.; Huang, Y.; Wang, H. Hydrocyclone-induced pretreatment for sludge solubilization to enhance anaerobic digestion. Chem. Eng. J. 2019, 374, 1364–1372. [Google Scholar] [CrossRef]

- Nabi, M.; Zhang, G.M.; Li, F.; Zhang, P.Y.; Dai, J.Q. Enhancement of high pressure homogenization pretreatment on biogas production from sewage sludge: A review. Desalin. Water Treat. 2020, 175, 341–351. [Google Scholar] [CrossRef]

- Zhang, Y.X.; Zhang, P.Y.; Ma, B.Q.; Wu, H.; Zhang, S.; Xu, X. Sewage sludge disintegration by high-pressure homogenization: A sludge disintegration model. J. Environ. Sci. 2012, 24, 814–820. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Liang, L.; Xu, X. Advances in converting of meat protein into functional ingredient via engineering modification of high pressure homogenization. Trends Food Sci. Tech. 2020, 106, 12–29. [Google Scholar] [CrossRef]

| HPH Conditions | SCOD (mg/L) | VDS (mg/L) | VFA (mg CH3COOH/L) | pH | |

|---|---|---|---|---|---|

| Pressure (MPa) | Cycle Number | ||||

| 0 | 0 | 120.42 ± 8.19 | 99.10 ± 6.96 | 72.23 ± 5.24 | 7.31 ± 0.072 |

| 20 | 1 | 1434.3 ± 100.9 | 676.2 ± 44.4 | 222.4 ± 16.8 | 7.22 ± 0.064 |

| 30 | 1 | 1661.7 ± 112.3 | 994.8 ± 50.5 | 276.3 ± 13.2 | 7.14 ± 0.056 |

| 40 | 1 | 2005.8 ± 161.4 | 1223.6 ± 80.3 | 324.2 ± 20.7 | 7.04 ± 0.048 |

| 60 | 1 | 3018.9 ± 184.5 | 1963.4 ± 121.1 | 343.6 ± 30.8 | 6.95 ± 0.031 |

| 80 | 1 | 3498.2 ± 202.8 | 2183.8 ± 151.7 | 358.8 ± 26.6 | 6.80 ± 0.021 |

| 60 | 1 | 3018.3 ± 184.5 | 1963.3 ± 121.1 | 343.3 ± 30.8 | 6.95 ± 0.031 |

| 60 | 2 | 3844.5 ± 242.3 | 2530.2 ± 161.9 | 408.4 ± 40.4 | 6.85 ± 0.025 |

| 60 | 3 | 4496.2 ± 275.8 | 2742.6 ± 183.2 | 499.5 ± 45.9 | 6.78 ± 0.020 |

| HPH Conditions | Biogas Yield (mL/g VS) | CH4 Content (%) | CH4 Yield (mL/g VS) | |

|---|---|---|---|---|

| Pressure (MPa) | Cycle Number | |||

| 0 | 0 | 170.1± 6.5 | 53.2 ± 3.2 | 90.0 ± 4.2 |

| 20 | 1 | 177.3 ± 7.1 | 59.7 ± 3.4 | 106.4 ± 4.5 |

| 30 | 1 | 181.6 ± 7.3 | 61.8 ± 4.2 | 112.6 ± 5.0 |

| 40 | 1 | 187.3 ± 8.6 | 63.3 ± 4.6 | 118.9 ± 5.4 |

| 60 | 1 | 200.5 ± 9.4 | 64.9 ± 5.3 | 130.4 ± 6.1 |

| 80 | 1 | 213.2 ± 11.3 | 65.6 ± 5.6 | 140.6 ± 6.5 |

| 60 | 1 | 200.5 ± 8.42 | 64.9 ± 5.3 | 130.3 ± 6.1 |

| 60 | 2 | 207.8 ± 10.2 | 65.8 ± 4.9 | 136.6 ± 6.2 |

| 60 | 3 | 213.9 ± 10.8 | 66.3 ± 5.3 | 141.3 ± 6.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, H.; Liang, J.; Zhang, Y.; Chang, J.; Zhang, R.; Zhang, P. Conversion of Materials and Energy in Anaerobic Digestion of Sewage Sludge with High-Pressure Homogenization Pretreatment. Processes 2023, 11, 2467. https://doi.org/10.3390/pr11082467

Xiao H, Liang J, Zhang Y, Chang J, Zhang R, Zhang P. Conversion of Materials and Energy in Anaerobic Digestion of Sewage Sludge with High-Pressure Homogenization Pretreatment. Processes. 2023; 11(8):2467. https://doi.org/10.3390/pr11082467

Chicago/Turabian StyleXiao, Huihuang, Jinsong Liang, Yuxuan Zhang, Jianning Chang, Ru Zhang, and Panyue Zhang. 2023. "Conversion of Materials and Energy in Anaerobic Digestion of Sewage Sludge with High-Pressure Homogenization Pretreatment" Processes 11, no. 8: 2467. https://doi.org/10.3390/pr11082467

APA StyleXiao, H., Liang, J., Zhang, Y., Chang, J., Zhang, R., & Zhang, P. (2023). Conversion of Materials and Energy in Anaerobic Digestion of Sewage Sludge with High-Pressure Homogenization Pretreatment. Processes, 11(8), 2467. https://doi.org/10.3390/pr11082467