Carbon Dioxide Prevents Oxygen Adsorption at Low-Temperature Oxidation Stage of Low-Rank Coal: Laboratory Study and Molecular Simulation

Abstract

:1. Introduction

2. Coal Samples and Methods

2.1. Experimental

2.1.1. Low-Rank Coal Sample Preparation

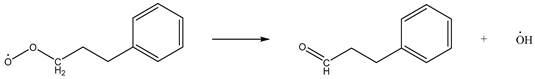

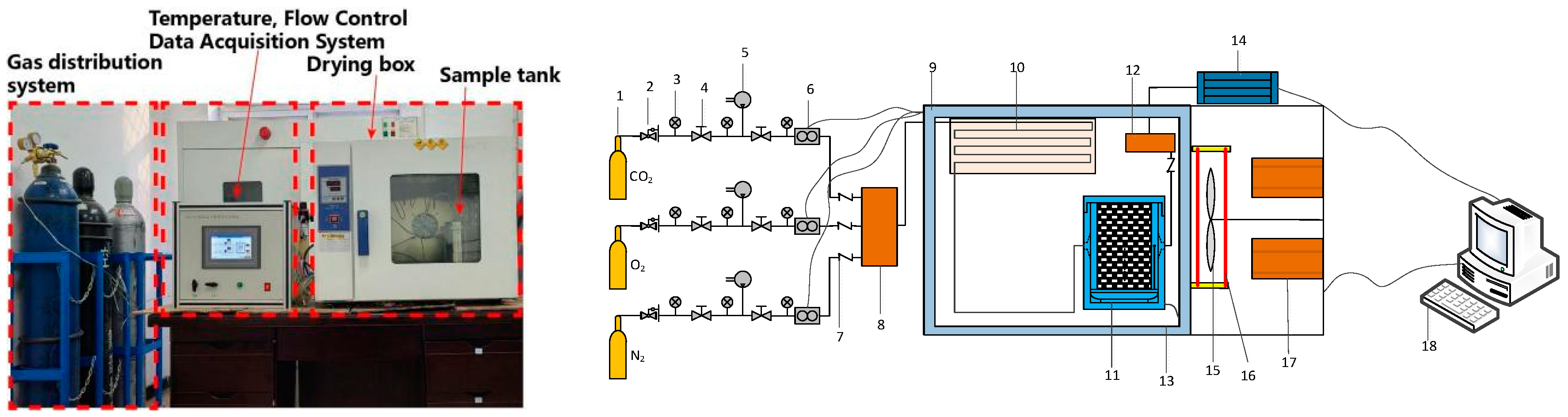

2.1.2. Device and Process of Temperature-Programmed Adiabatic Oxidation Experiment

2.1.3. Device and Process of In Situ Infrared Cooling Experiment

2.2. Simulation Method

2.2.1. Method of Physisorption Simulation

- (1)

- GCMC physisorption method

- (2)

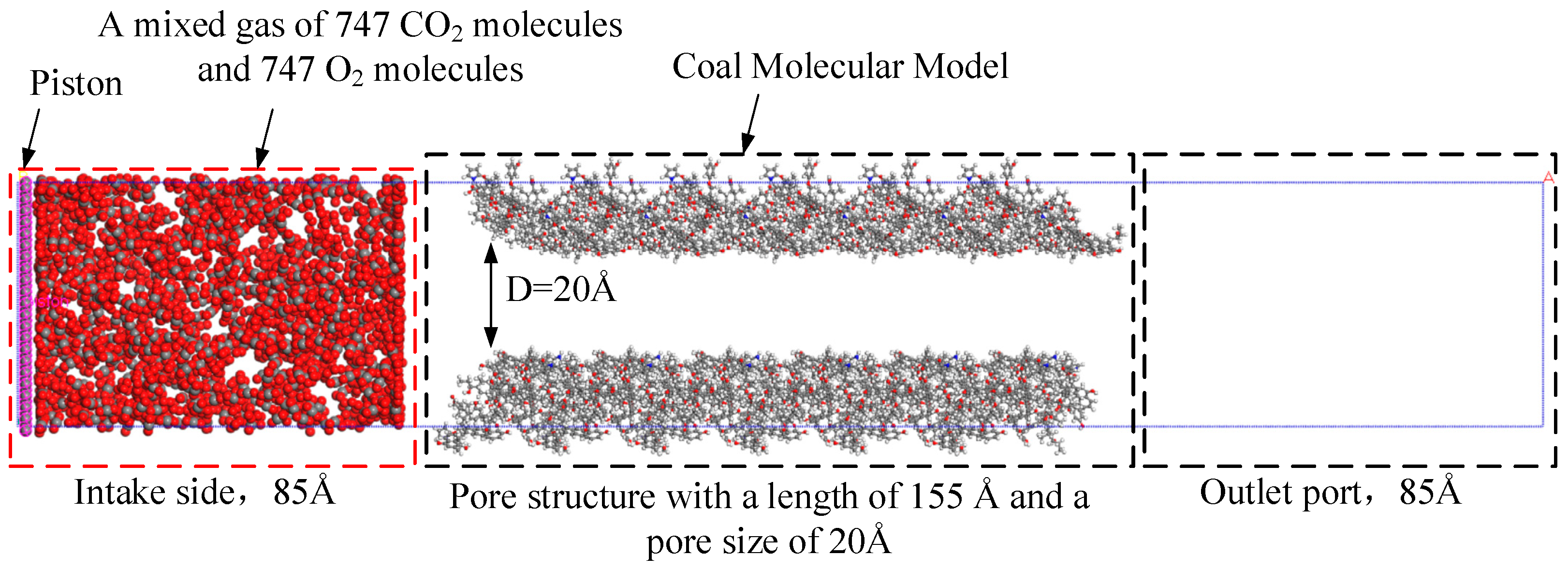

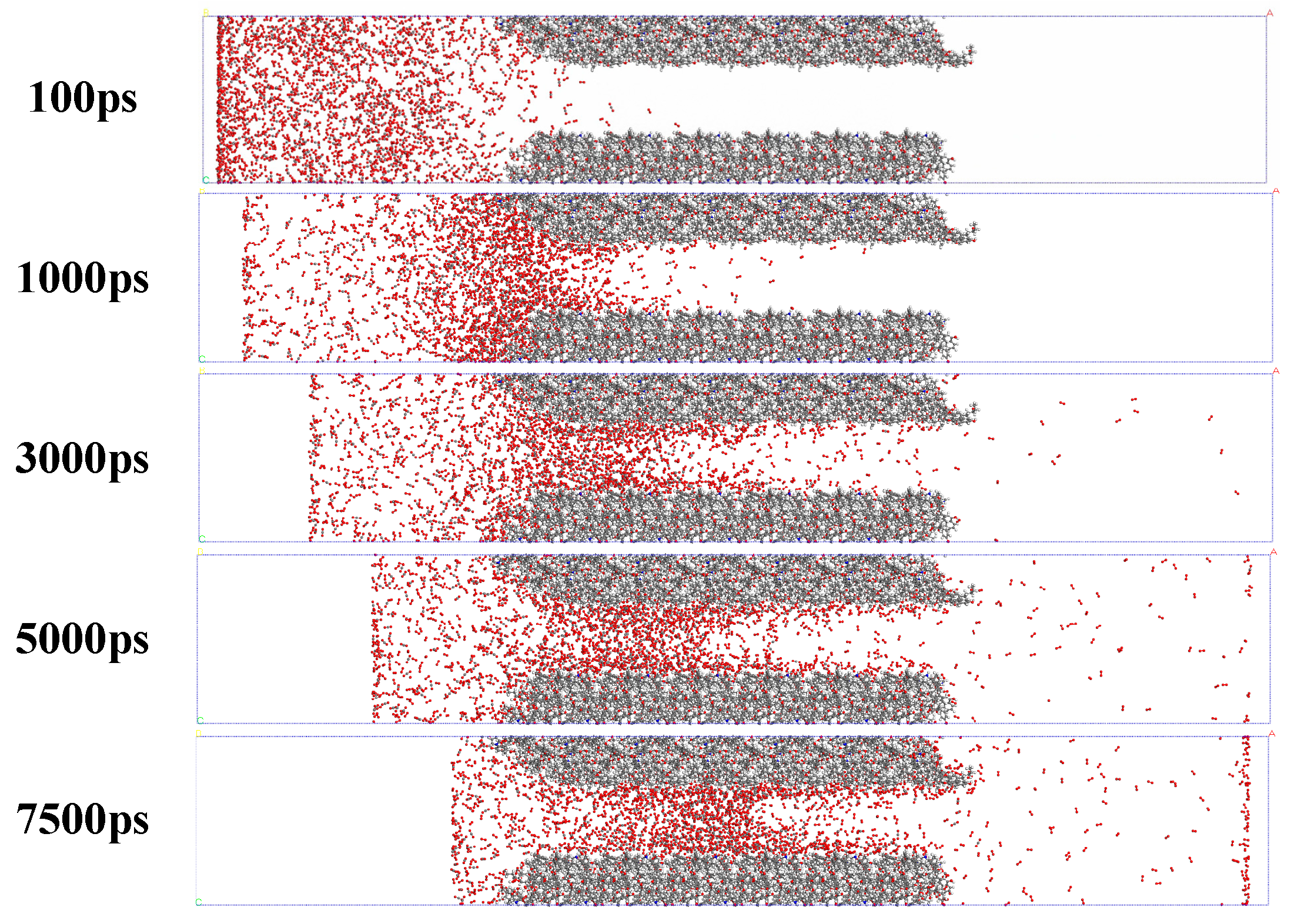

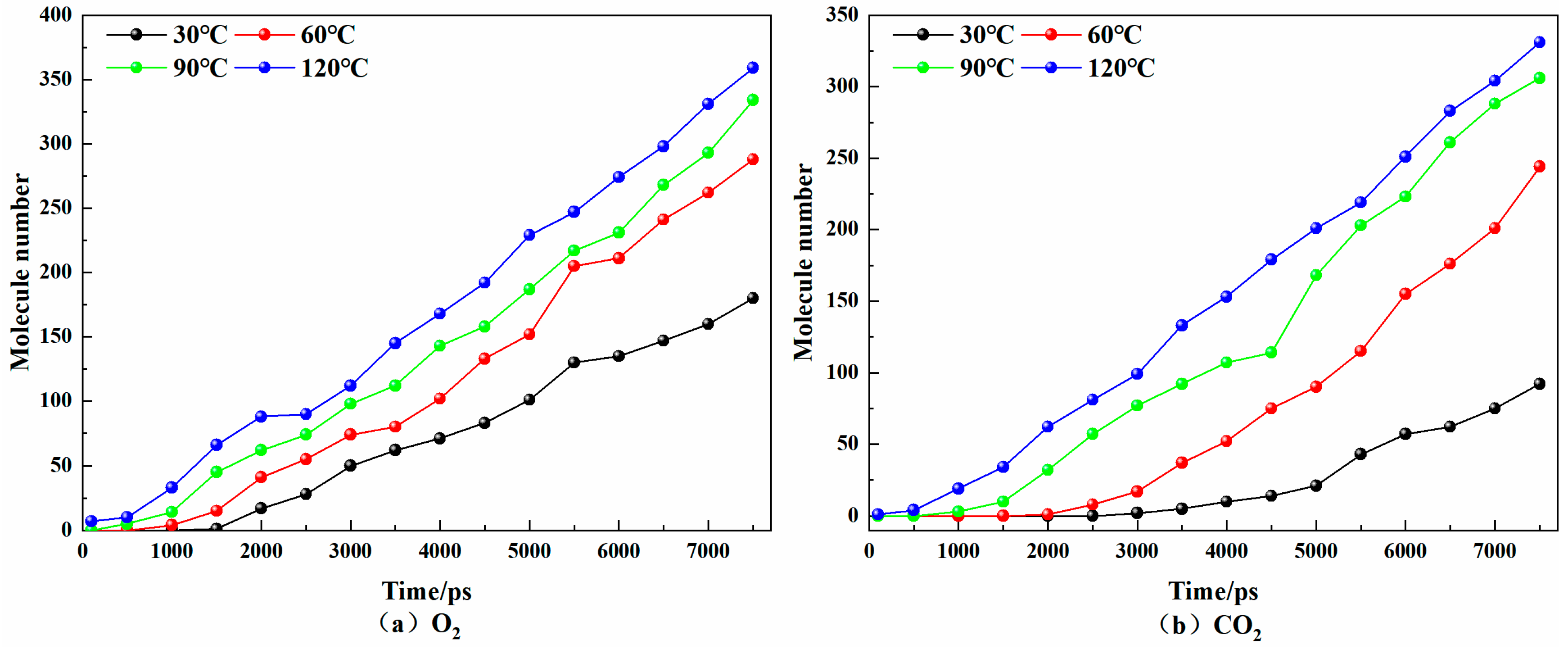

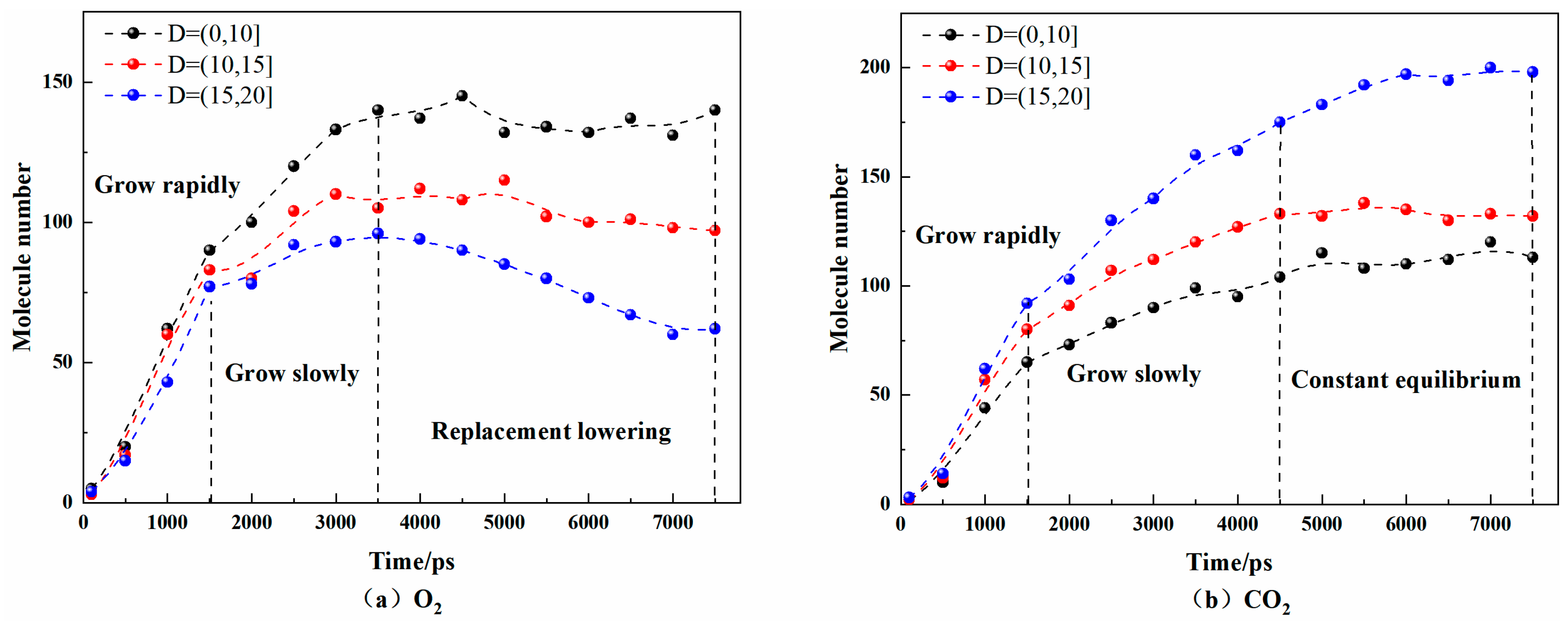

- Simulation of Competitive Adsorption of CO2 and O2 in Coal Surface Pores

2.2.2. Method for Chemisorption Simulation

3. Results and Analysis

3.1. Analysis on the Physical Mechanism of CO2 Preventing O2 Adsorption

3.2. Analysis on the Chemical Mechanism of CO2 Preventing O2 Adsorption

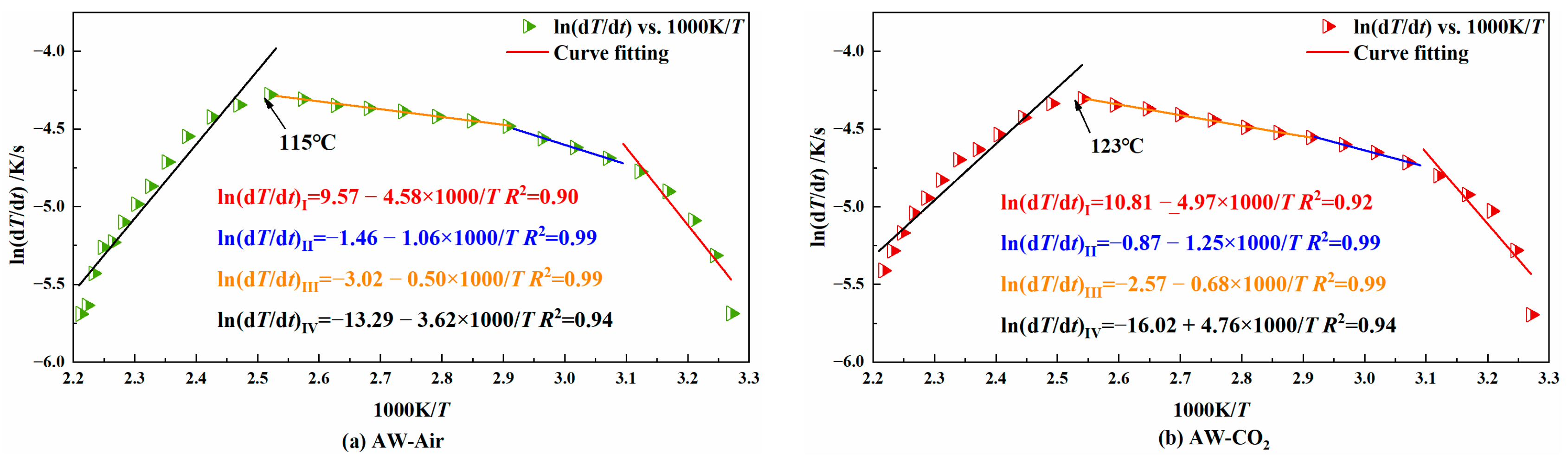

3.2.1. Influence of Pre-Injection of CO2 into Coal on Its Heating Process

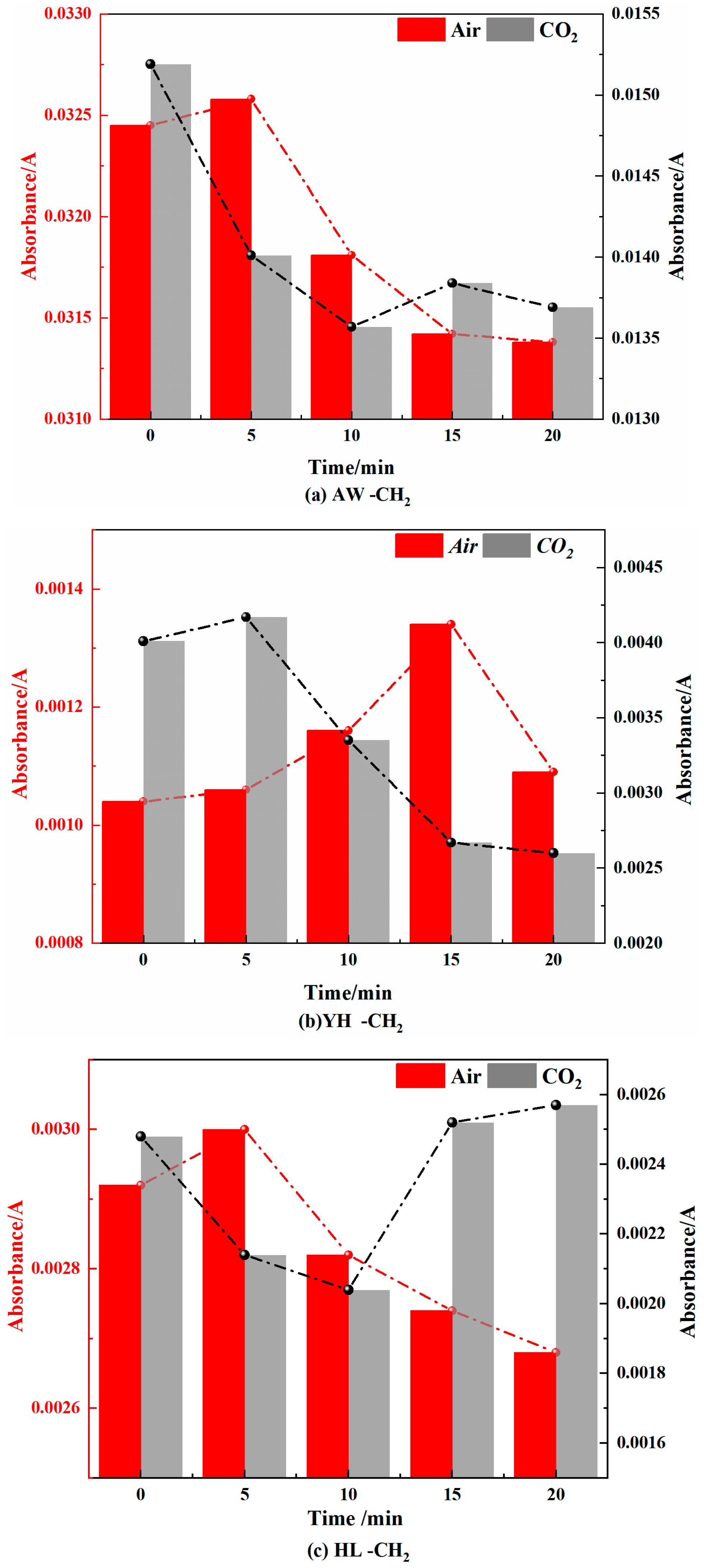

3.2.2. Analysis of Functional Group Changes in CO2 Injection during Coal Cooling

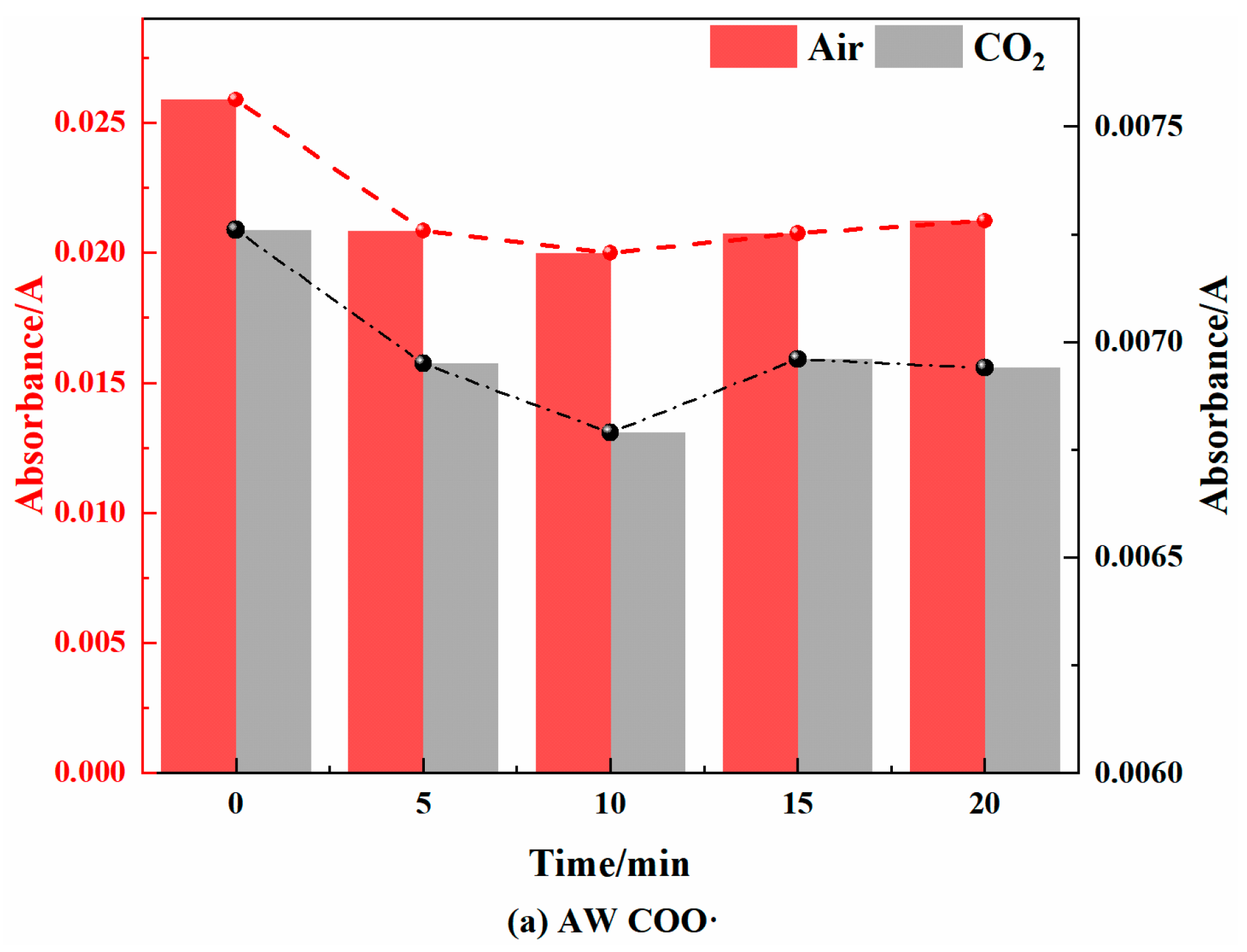

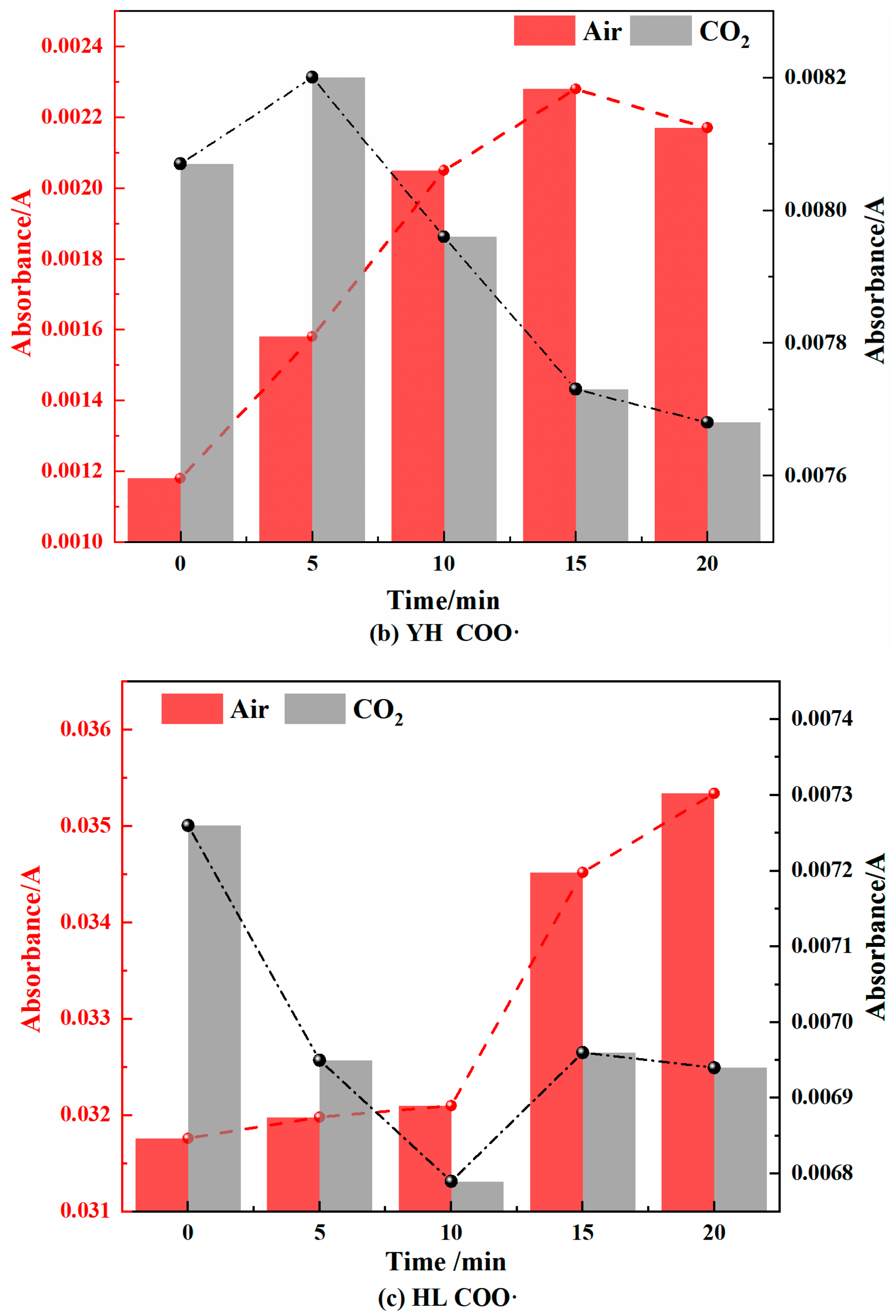

- (1)

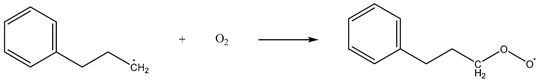

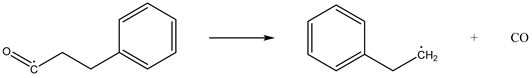

- Peroxide (C–O–O·)

- (2)

- Free hydroxyl (HO·)

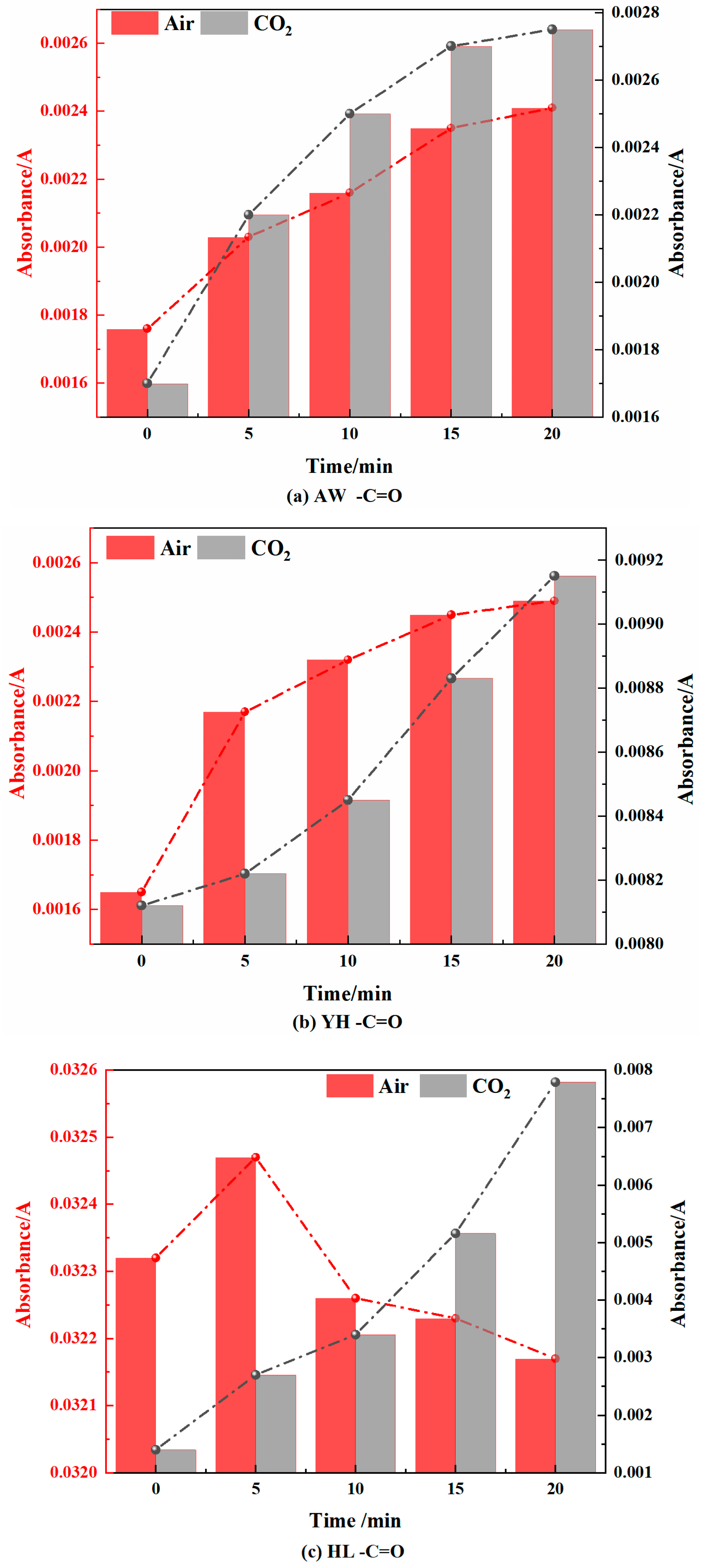

- (3)

- Aldehyde group (-CH=O)

- (4)

- Carboxyl (-COOH)

- (5)

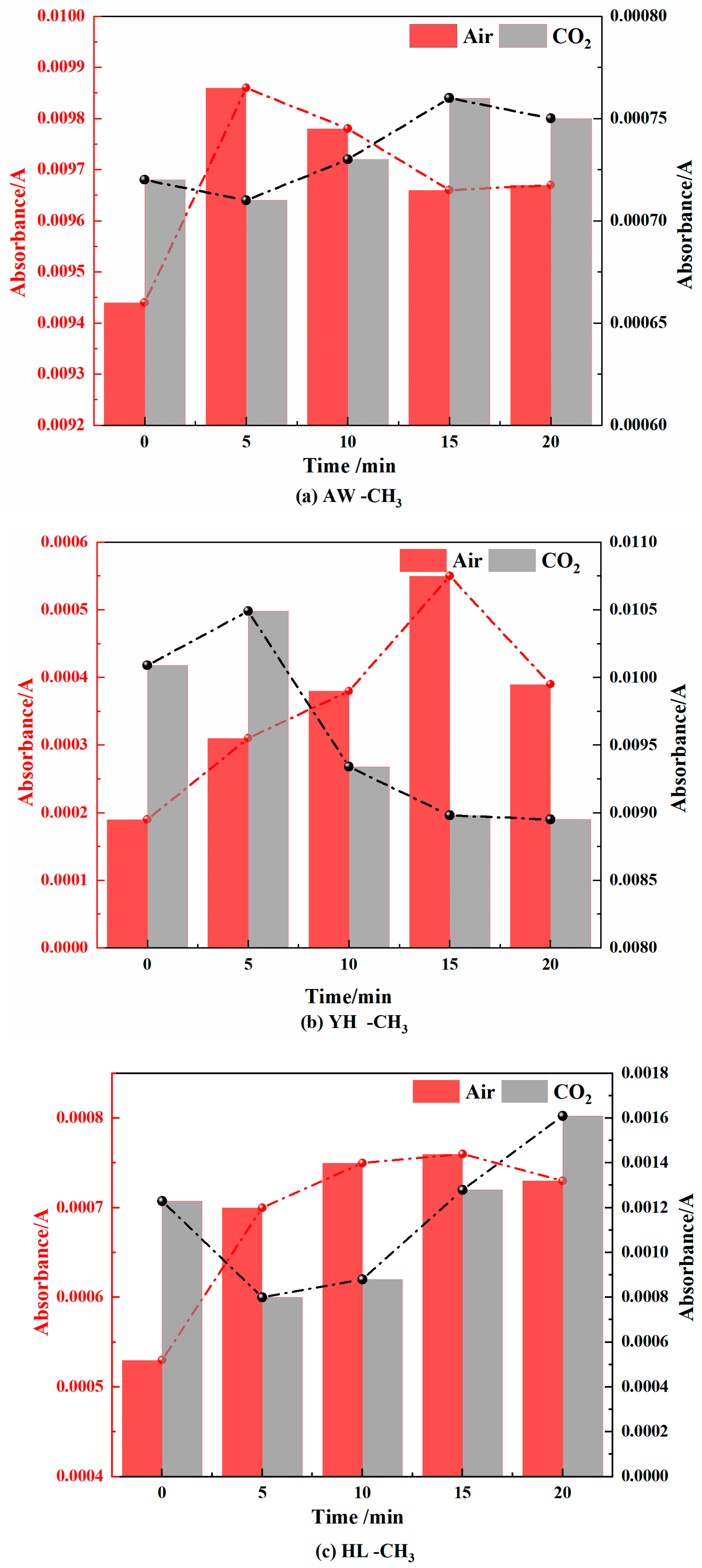

- Methyl (-CH3) and methylene (-CH2-)

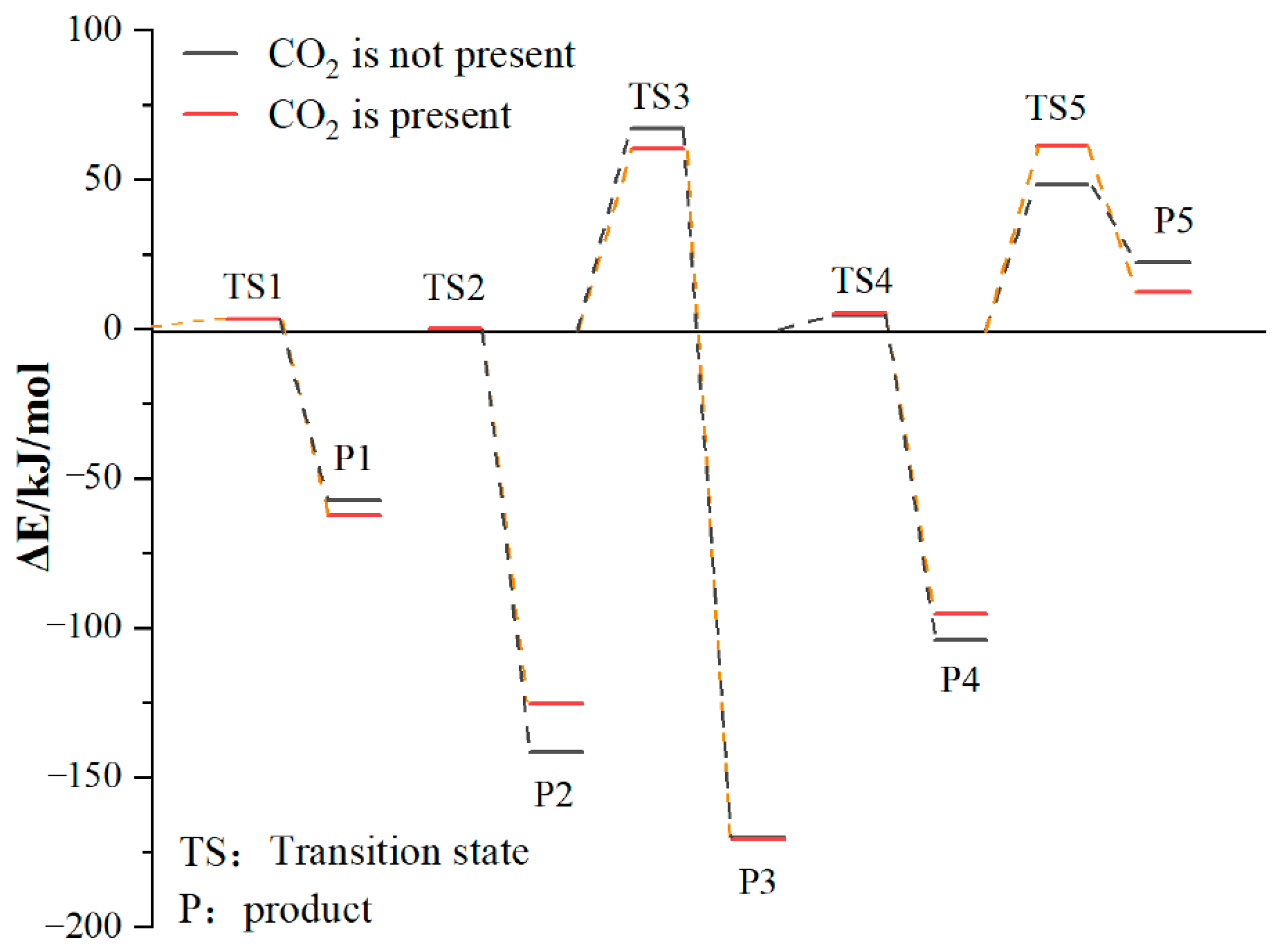

3.2.3. Effect of CO2 on the Reaction Process of Coal Chemical Adsorption of O2

| Reaction 1 |  |

| Reaction 2 |  |

| Reaction 3 |  |

| Reaction 4 |  |

| Reaction 5 |  |

3.3. Construction of the Model of CO2 Prevents O2 Adsorption

4. Conclusions

- (1)

- The adsorption capacity of coal pores for CO2 is stronger than that of O2. CO2 tends to be adsorbed near the pore wall and O2 tends to be adsorbed in the center of the pores. Moreover, CO2 can replace O2 adsorbed in coal, and the replacement mostly occurs in the area near the pore wall.

- (2)

- The injection of CO2 can block the adsorption of O2 in the low-temperature oxidation process of coal, its hindering effect is mainly exerted in the slow heating stage, and at about 120 °C, the coal loses the protective effect of CO2.

- (3)

- When coal is cooled in a CO2 atmosphere, the coal will mainly undergo pyrolysis and condensation reactions, which eventually leads to the increase in -CH=O and -COOH in the coal, and the changes in other structures are small.

- (4)

- In the chemisorption chain reaction of coal oxide, the effect of CO2 on each step of the reaction chain is not the same, but in general, it increases the activation energy and reduces the heat release, which has the effect of inhibiting the chemical reaction.

- (5)

- In this paper, the model of carbon dioxide physical–chemical oxygen barrier adsorption is constructed based on experiments and simulations, which lacks field practice verification. However, the research in this paper can guide the work and improve the efficiency of underground fire prevention in coal mines and save labor, time, and material resources.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Song, Z.; Kuenzer, C.; Zhu, H.; Zhang, Z.; Jia, Y.; Sun, Y.; Zhang, J. Analysis of coal fire dynamics in the Wuda syncline impacted by fire-fighting activities based on in-situ observations and Landsat-8 remote sensing data. Int. J. Coal. Geol. 2015, 141–142, 91–102. [Google Scholar] [CrossRef]

- Liu, J.; Wang, Y.; Yan, S.; Zhao, F.; Li, Y.; Dang, L.; Liu, X.; Shao, Y.; Peng, B. Underground Coal Fire Detection and Monitoring Based on Landsat-8 and Sentinel-1 Data Sets in Miquan Fire Area, XinJiang. Remote Sens. 2021, 13, 1141. [Google Scholar] [CrossRef]

- Tan, B.; Zhang, F.; Zhang, Q.; Wei, H.; Shao, Z. Firefighting of subsurface coal fires with comprehensive techniques for detection and control: A case study of the Fukang coal fire in the Xinjiang region of China. Environ. Sci. Pollut. Res. 2019, 26, 29570–29584. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Wang, Y.; Zhao, F.; Feng, H.; Liu, J.; Zhang, L.; Zhang, N.; Yuan, G.; Wang, D. A spatio-temporal temperature-based thresholding algorithm for underground coal fire detection with satellite thermal infrared and radar remote sensing. Int. J. Appl. Earth Obs. Geoinf. 2022, 110, 102805. [Google Scholar] [CrossRef]

- Song, Z.; Kuenzer, C. Coal fires in China over the last decade: A comprehensive review. Int. J. Coal. Geol. 2014, 133, 72–99. [Google Scholar] [CrossRef]

- Shao, Z.; Jia, X.; Zhong, X.; Wang, D.; Wei, J.; Wang, Y.; Chen, L. Detection, extinguishing, and monitoring of a coal fire in Xinjiang, China. Environ. Sci. Pollut. Res. 2018, 25, 26603–26616. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Ge, S.; Guo, G. (Eds.) Mining Science and Technology: Proceedings of the 5th International Symposium on Mining Science and Technology, Xuzhou, China, 20–22 October 2004; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Wang, H.; Dlugogorski, B.; Kennedy, E. Kinetic modeling of low-temperature oxidation of coal. Combust. Flame 2002, 131, 452–464. [Google Scholar] [CrossRef]

- Tan, B.; Cheng, G.; Zhu, X.; Yang, X. Experimental Study on the Physisorption Characteristics of O2 in Coal Powder are Effected by Coal Nanopore Structure. Sci. Rep. 2020, 10, 6946. [Google Scholar] [CrossRef]

- Karsner, G.G.; Perlmutter, D.D. Model for coal oxidation kinetics. 1. Reaction under chemical control. Fuel 1982, 61, 29–34. [Google Scholar] [CrossRef]

- Wang, H.; Dlugogorski, B.Z.; Kennedy, E.M. Coal oxidation at low temperatures: Oxygen consumption, oxidation products, reaction mechanism and kinetic modelling. Prog. Energy Combust. Sci. 2003, 29, 487–513. [Google Scholar] [CrossRef]

- Xue, D.; Hu, X.; Cheng, W.; Wu, M.; Shao, Z.; Li, Y.; Zhao, Y.; Zhang, K. Carbon dioxide sealing-based inhibition of coal spontaneous combustion: A temperature-sensitive micro-encapsulated fire-retardant foamed gel. Fuel 2020, 266, 117036. [Google Scholar] [CrossRef]

- Liu, Y.; Wen, H.; Guo, J.; Jin, Y.; Wei, G.; Yang, Z. Coal spontaneous combustion and N2 suppression in triple goafs: A numerical simulation and experimental study. Fuel 2020, 271, 117625. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, J.; Wang, D. Experimental Study on the Inhibition Effects of Nitrogen and Carbon Dioxide on Coal Spontaneous Combustion. Energies 2020, 13, 5256. [Google Scholar] [CrossRef]

- Deng, J.; Ren, L.F.; Ma, L.; Qin, X.Y.; Wang, W.F.; Liu, C.C. Low-temperature oxidation and reactivity of coal in O2/N2 and O2/CO2 atmospheres, a case of carboniferous–permian coal in Shaanxi, China. Environ. Earth Sci. 2019, 78, 234. [Google Scholar] [CrossRef]

- Khatami, R.; Stivers, C.; Levendis, Y.A. Ignition characteristics of single coal particles from three different ranks in O2/N2 and O2/CO2 atmospheres. Combust. Flame 2012, 159, 3554–3568. [Google Scholar] [CrossRef]

- Wang, F.; Liu, H.W. Comparative experiment study on fire prevention and extinguishing in goaf by N-2-water mist and CO2-water mist. Arab. J. Geosci. 2020, 13, 856. [Google Scholar] [CrossRef]

- Liu, W.; Chu, X.; Xu, H.; Chen, W.; Ma, L.; Qin, Y.; Wei, J. Oxidation reaction constants for coal spontaneous combustion under inert gas environments: An experimental investigation. Energy 2022, 247, 123457. [Google Scholar] [CrossRef]

- Su, H.; Kang, N.; Shi, B.; Ji, H.; Li, Y.; Shi, J. Simultaneous thermal analysis on the dynamical oxygen-lean combustion behaviors of coal in a O-2/N-2/CO2 atmosphere. J. Energy Inst. 2021, 96, 128–139. [Google Scholar] [CrossRef]

- Liu, H.W.; Wang, F. Thermal characteristics and kinetic analysis of coal-oxygen reaction under the condition of inert gas. Int. J. Coal Prep. Util. 2022, 42, 846–862. [Google Scholar] [CrossRef]

- Wu, L.; Qiao, Y.; Yao, H. Experimental and numerical study of pulverized bituminous coal ignition characteristics in O2/N2 and O2/CO2 atmospheres. Asia-Pac. J. Chem. Eng. 2012, 7, S195–S200. [Google Scholar] [CrossRef]

- Li, Q.; Zhao, C.; Chen, X.; Wu, W.; Lin, B. Properties of char particles obtained under O2/N2 and O2/CO2 combustion environments. Chem. Eng. Process. Process Intensif. 2010, 49, 449–459. [Google Scholar] [CrossRef]

- Ma, L.; Yu, W.; Ren, L.; Qin, X.; Wang, Q. Micro-characteristics of low-temperature coal oxidation in CO2/O2 and N2/O2 atmospheres. Fuel 2019, 246, 259–267. [Google Scholar] [CrossRef]

- Zhou, B.; Yang, S.; Yang, W.; Jiang, X.; Song, W.; Cai, J.; Xu, Q.; Tang, Z. Variation characteristics of active groups and macroscopic gas products during low-temperature oxidation of coal under the action of inert gases N-2 and CO2. Fuel 2022, 307, 121893. [Google Scholar] [CrossRef]

- Wu, S.; Jin, Z.; Deng, C. Molecular simulation of coal-fired plant flue gas competitive adsorption and diffusion on coal. Fuel 2019, 239, 87–96. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, J.; Zhang, C.; Li, Z.; Zhu, J.; Lu, B. Molecular simulation of gases competitive adsorption in lignite and analysis of original CO desorption. Sci. Rep. 2021, 11, 11706. [Google Scholar] [CrossRef] [PubMed]

- Long, H.; Lin, H.F.; Yan, M.; Bai, Y.; Tong, X.; Kong, X.G.; Li, S.G. Adsorption and diffusion characteristics of CH4, CO2, and N2 in micropores and mesopores of bituminous coal: Molecular dynamics. Fuel 2021, 292, 120268. [Google Scholar] [CrossRef]

- Dong, X.; Wang, F.; Guo, L.; Zhang, Y.; Dong, X. Investigation of Competitive Adsorption Properties of CO/CO2/O2 onto the Kailuan Coals by Molecular Simulation. ACS Omega 2022, 7, 19305–19318. [Google Scholar] [CrossRef]

- Liu, Y.; Fu, P.; Bie, K.; Gong, Y.; Xu, T. The intrinsic reactivity of coal char conversion compared under different conditions of O2/CO2, O2/H2O and air atmospheres. J. Energy Inst. 2020, 93, 1883–1891. [Google Scholar] [CrossRef]

- Liu, M.-X.; Shi, G.-Q.; Guo, Z.; Wang, Y.-M.; Ma, L.-Y. 3-D simulation of gases transport under condition of inert gas injection into goaf. Heat Mass Transf. 2016, 52, 2723–2734. [Google Scholar] [CrossRef]

- Yan, F.; Xu, J.; Peng, S.; Zou, Q.; Zhou, B.; Long, K.; Zhao, Z. Breakdown process and fragmentation characteristics of anthracite subjected to high-voltage electrical pulses treatment. Fuel 2020, 275, 117926. [Google Scholar] [CrossRef]

- Yan, F.; Xu, J.; Lin, B.; Peng, S.; Zou, Q.; Zhang, X. Changes in pore structure and permeability of anthracite coal before and after high-voltage electrical pulses treatment. Powder Technol. 2019, 343, 560–567. [Google Scholar] [CrossRef]

- Ren, J.; Song, Z.; Li, B.; Liu, J.; Lv, R.; Liu, G. Structure feature and evolution mechanism of pores in different metamorphism and deformation coals. Fuel 2021, 283, 119292. [Google Scholar] [CrossRef]

- Kamran, U.; Rhee, K.Y.; Park, S.-J. Effect of Triblock Copolymer on Carbon-Based Boron Nitride Whiskers for Efficient CO2 Adsorption. Polymers 2019, 11, 913. [Google Scholar] [CrossRef] [PubMed]

- Kamran, U.; Rhee, K.Y.; Lee, S.Y.; Park, S.J. Solvent-free conversion of cucumber peels to N-doped microporous carbons for efficient CO2 capture performance. J. Clean. Prod. 2022, 369, 133367. [Google Scholar] [CrossRef]

- Kamran, U.; Park, S.J. Acetic acid-mediated cellulose-based carbons: Influence of activation conditions on textural features and carbon dioxide uptakes. J. Colloid Interface Sci. 2021, 594, 745–758. [Google Scholar] [CrossRef]

- Fu, S.; Tan, B.; Cheng, G.; Wang, H.; Fang, X.; Shao, Z.; Li, Z. Study of Adsorption Characteristics of CO2, O2, and N2 in Coal Micropores and Mesopores at Normal Pressure. Ind. Eng. Chem. Res. 2022, 61, 12845–12856. [Google Scholar] [CrossRef]

- Bai, Y.; Lin, H.-F.; Li, S.-G.; Yan, M.; Long, H. Molecular simulation of N2 and CO2 injection into a coal model containing adsorbed methane at different temperatures. Energy 2021, 219, 119686. [Google Scholar] [CrossRef]

- Cheng, G.; Tan, B.; Zhang, Z.; Fu, S.; Haiyan, W.; Wang, F. Characteristics of coal-oxygen chemisorption at the low-temperature oxidation stage: DFT and experimental study. Fuel 2022, 315, 123120. [Google Scholar] [CrossRef]

- Zhu, H.; Huo, Y.; Wang, W.; He, X.; Fang, S.; Zhang, Y. Quantum chemical calculation of reaction characteristics of hydroxyl at different positions during coal spontaneous combustion. Process Saf. Environ. Prot. 2021, 148, 624–635. [Google Scholar] [CrossRef]

- Chen, Q.; Zheng, J.; Xu, J.; Dang, Z.; Zhang, L. Insights into sulfamethazine adsorption interfacial interaction mechanism on mesoporous cellulose biochar: Coupling DFT/FOT simulations with experiments. Chem. Eng. J. 2019, 356, 341–349. [Google Scholar] [CrossRef]

| Coal Sample | Mad | Ad | Vdaf | FCad | Cdaf | Hdaf | Ndaf | Odaf | St,ad /% | Ro,ran /% |

|---|---|---|---|---|---|---|---|---|---|---|

| HL | 14.35 | 6.92 | 42.46 | 36.27 | 73.29 | 5.16 | 1.06 | 19.22 | 1.27 | 0.35 |

| YH | 4.67 | 6.18 | 38.09 | 51.06 | 81.92 | 5.24 | 0.93 | 9.32 | 2.68 | 0.58 |

| AW | 0.82 | 8.73 | 35.82 | 54.63 | 86.25 | 5.91 | 1.13 | 6.37 | 0.34 | 0.78 |

| Coal Sample | Oxidation Stage | Inject Air | Inject CO2 | ||

|---|---|---|---|---|---|

| Activation Energy Ea/kJ/mol | Critical Temperature of Spontaneous Combustion T/°C | Activation Energy Ea/kJ/mol | Critical Temperature of Spontaneous Combustion T/°C | ||

| AW | I | 38.08 | 115 | 41.32 | 123 |

| II | 8.81 | 10.39 | |||

| III | 4.16 | 5.65 | |||

| IV | −30.10 | −39.58 | |||

| YH | I | 20.87 | 107 | 26.36 | 112 |

| II | 7.90 | 8.32 | |||

| III | 3.41 | 2.00 | |||

| IV | −28.77 | −40.57 | |||

| HL | I | 33.67 | 110 | 47.72 | 119 |

| II | 6.90 | 7.40 | |||

| III | 1.08 | 2.25 | |||

| IV | −34.67 | −43.90 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, G.; Wang, H.; Tan, B.; Fu, S. Carbon Dioxide Prevents Oxygen Adsorption at Low-Temperature Oxidation Stage of Low-Rank Coal: Laboratory Study and Molecular Simulation. Processes 2023, 11, 2504. https://doi.org/10.3390/pr11082504

Cheng G, Wang H, Tan B, Fu S. Carbon Dioxide Prevents Oxygen Adsorption at Low-Temperature Oxidation Stage of Low-Rank Coal: Laboratory Study and Molecular Simulation. Processes. 2023; 11(8):2504. https://doi.org/10.3390/pr11082504

Chicago/Turabian StyleCheng, Gang, Haiyan Wang, Bo Tan, and Shuhui Fu. 2023. "Carbon Dioxide Prevents Oxygen Adsorption at Low-Temperature Oxidation Stage of Low-Rank Coal: Laboratory Study and Molecular Simulation" Processes 11, no. 8: 2504. https://doi.org/10.3390/pr11082504

APA StyleCheng, G., Wang, H., Tan, B., & Fu, S. (2023). Carbon Dioxide Prevents Oxygen Adsorption at Low-Temperature Oxidation Stage of Low-Rank Coal: Laboratory Study and Molecular Simulation. Processes, 11(8), 2504. https://doi.org/10.3390/pr11082504