Status of Research on the Use of Nanomodified Microcapsules in Cement-Based Materials

Abstract

:1. Introduction

2. Scientometrics Visualized Analysis on Nanomodified Microcapsules

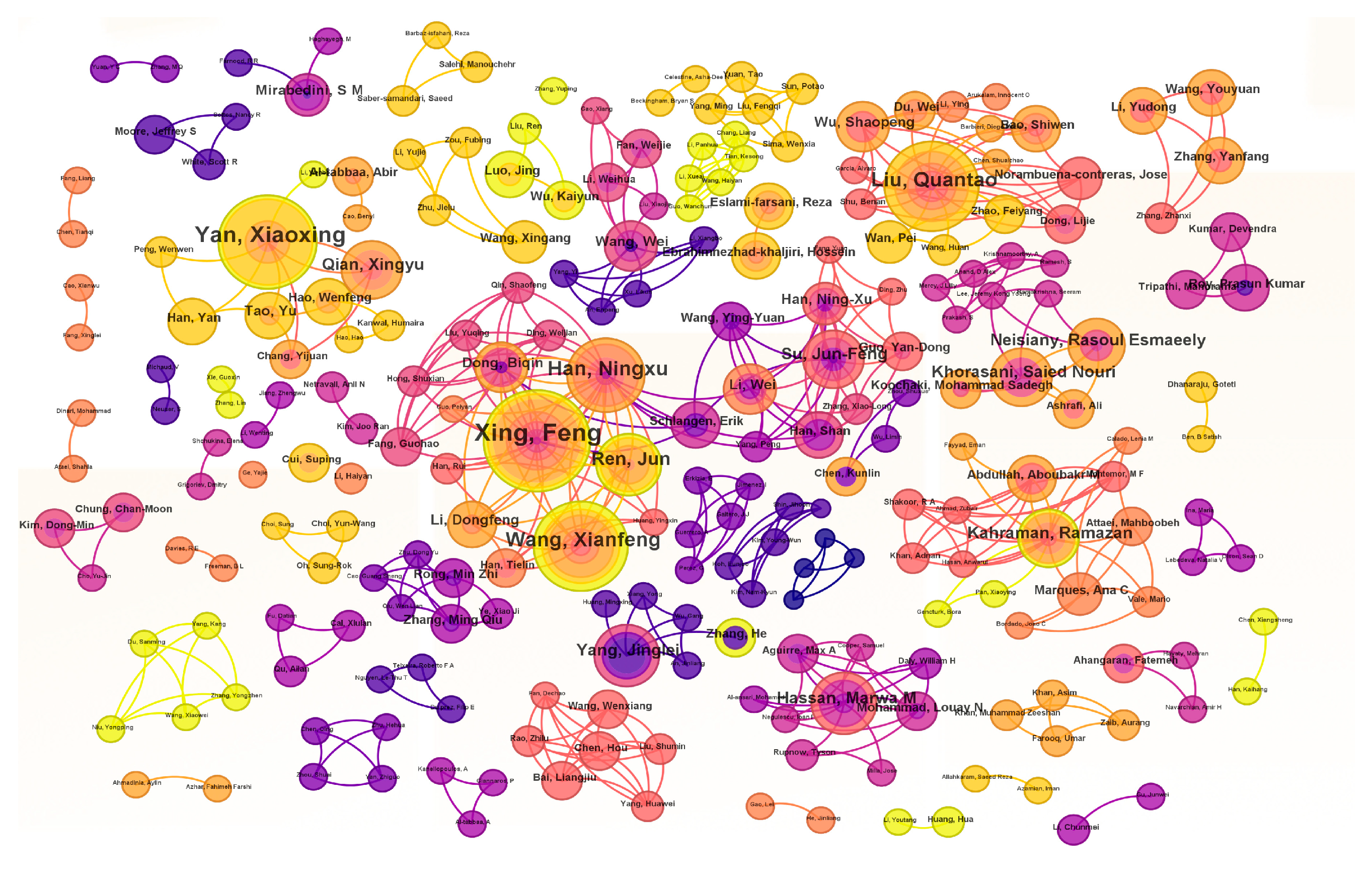

2.1. Analysis of Publication Outputs, Countries and Authors

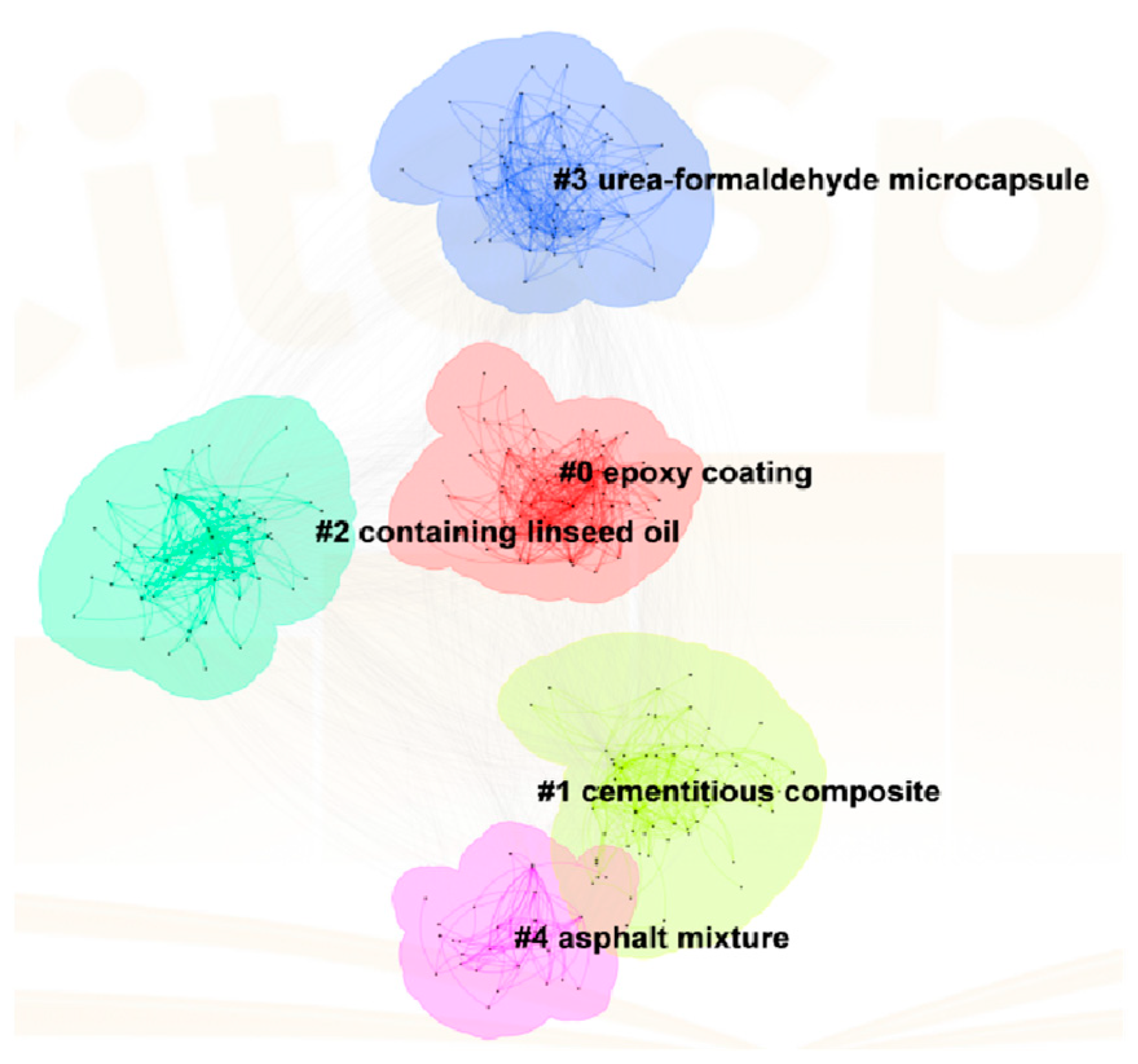

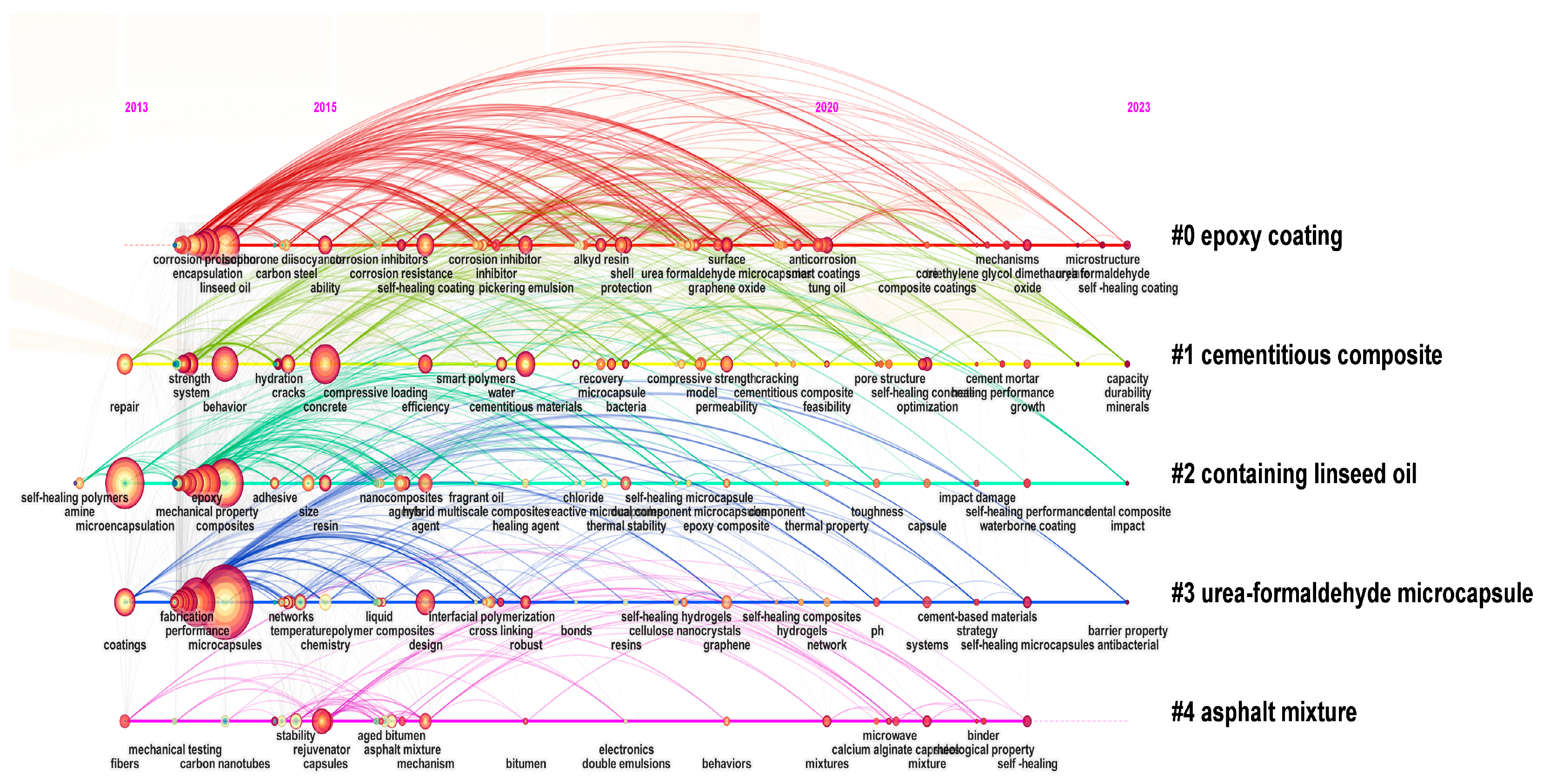

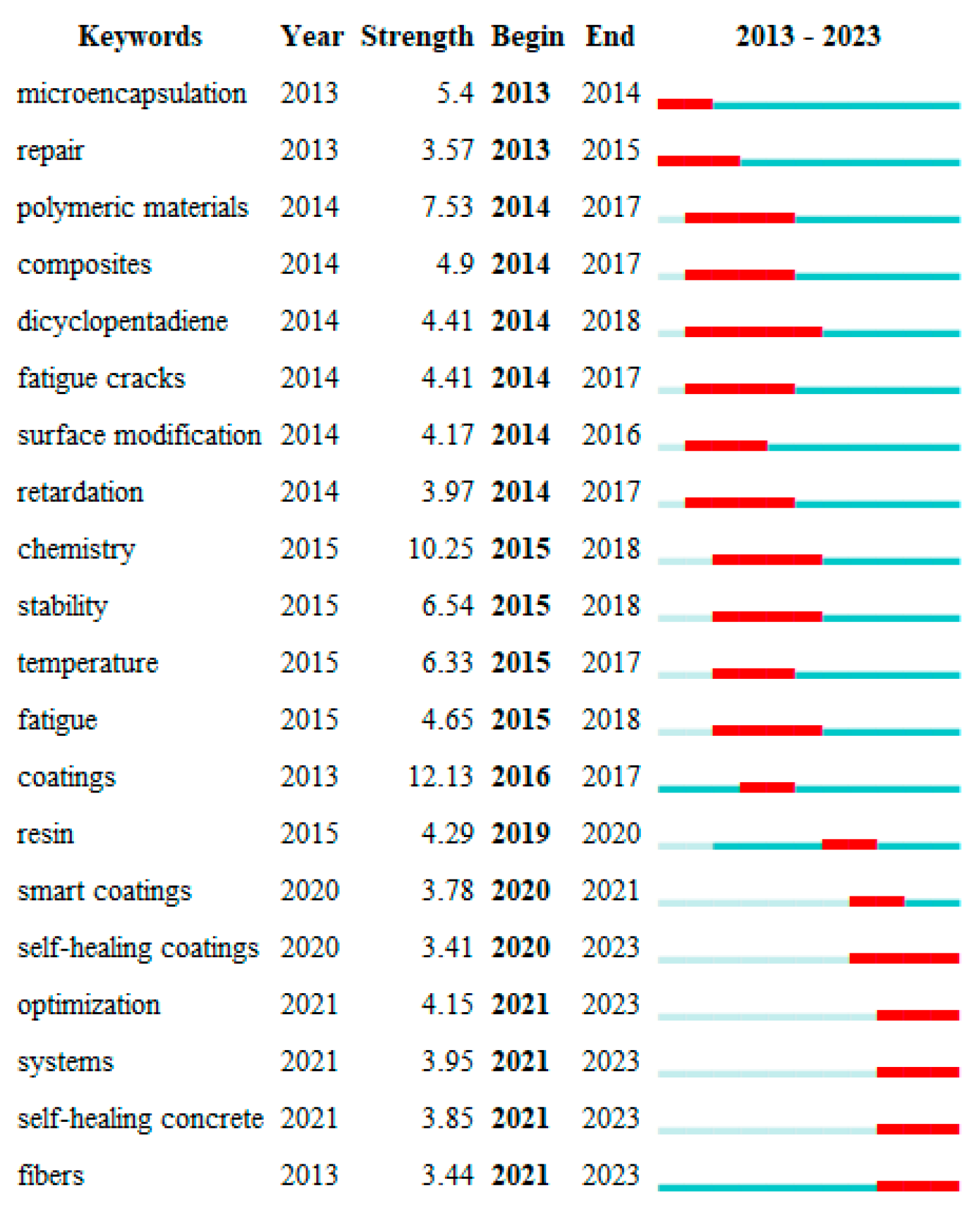

2.2. Analysis of Keywords

3. Nanomaterials and Nanomodification

3.1. Nanomaterials

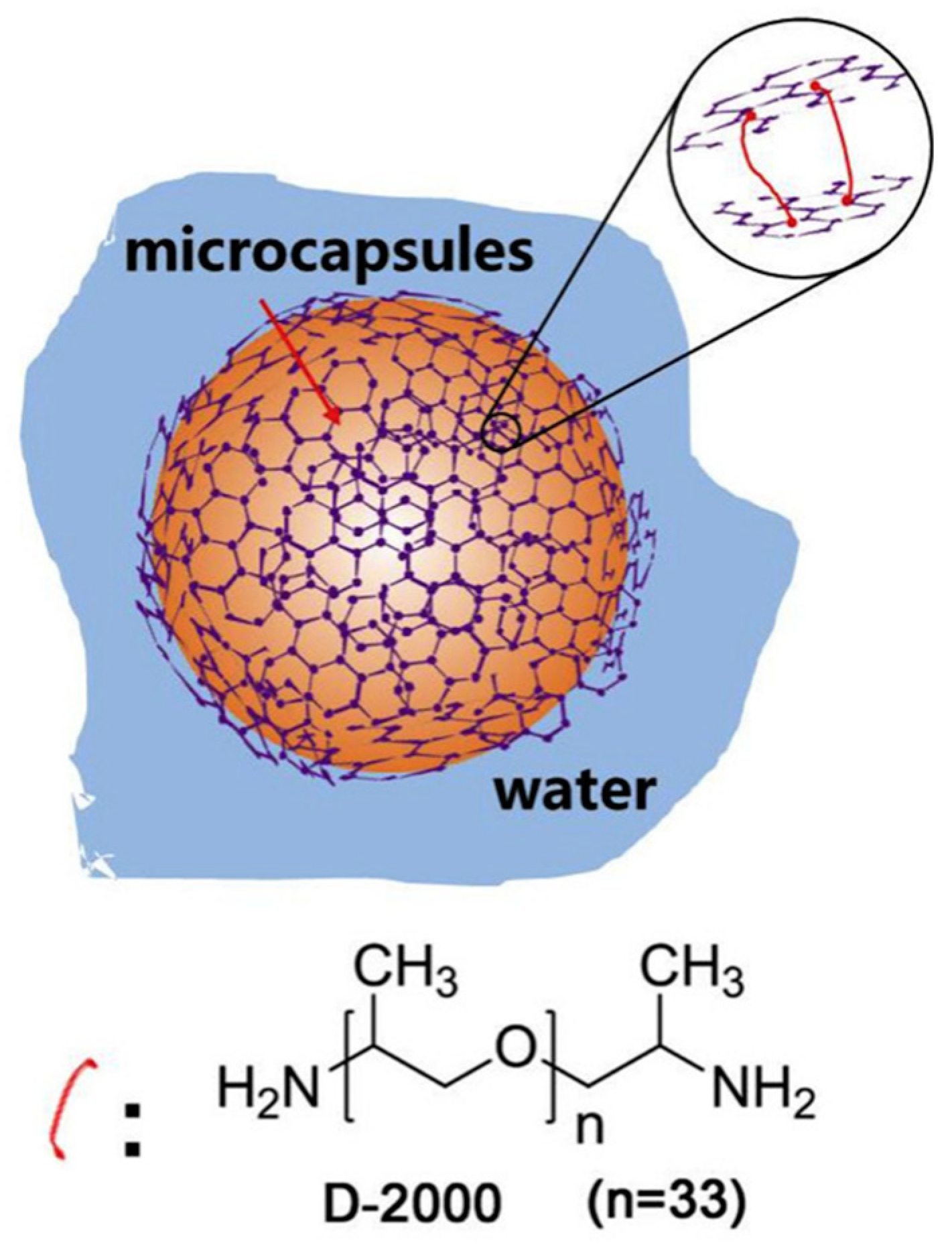

3.2. Walls of Self-Healing Microcapsules

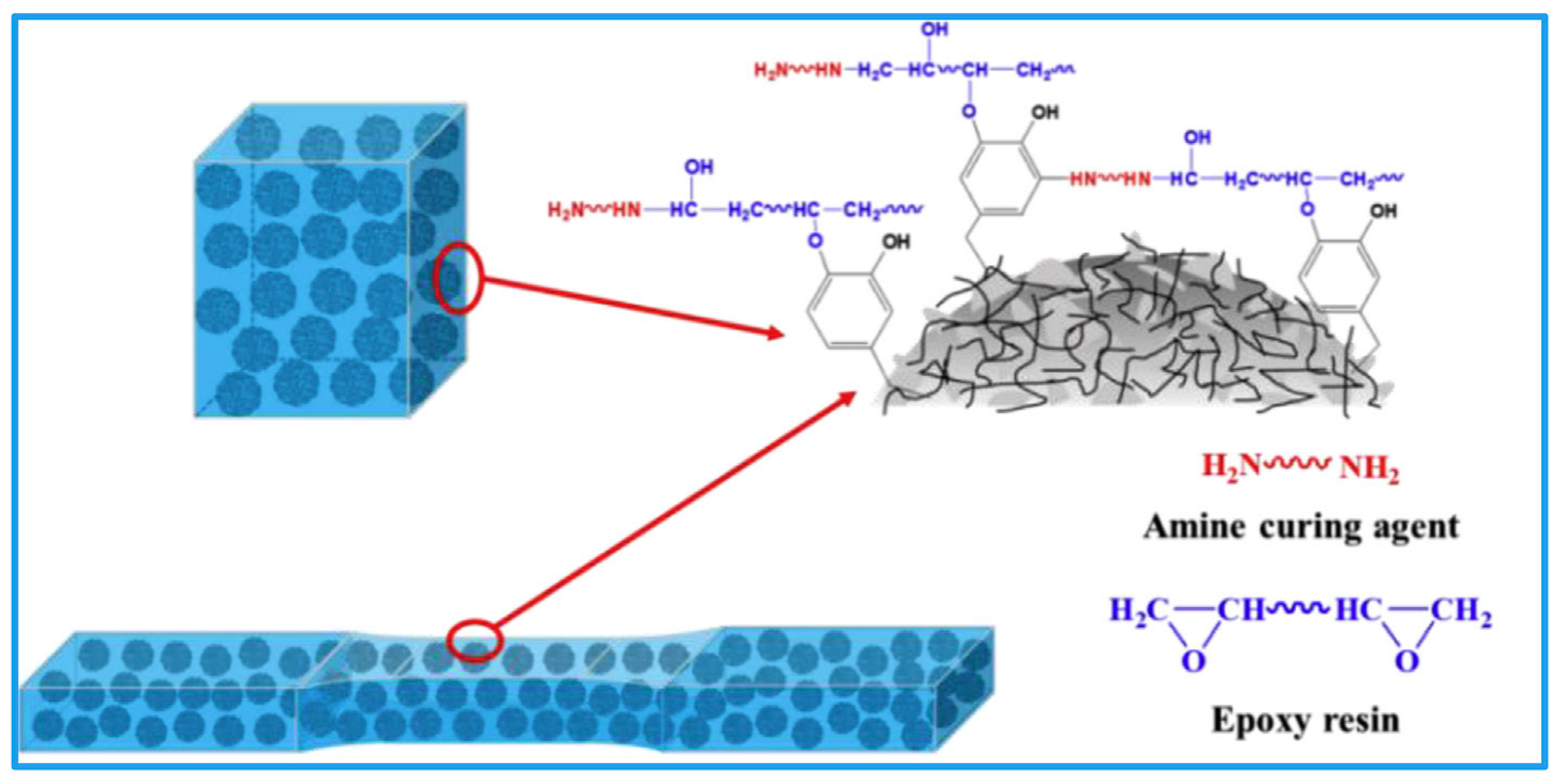

3.3. Cores of Self-Healing Microcapsules

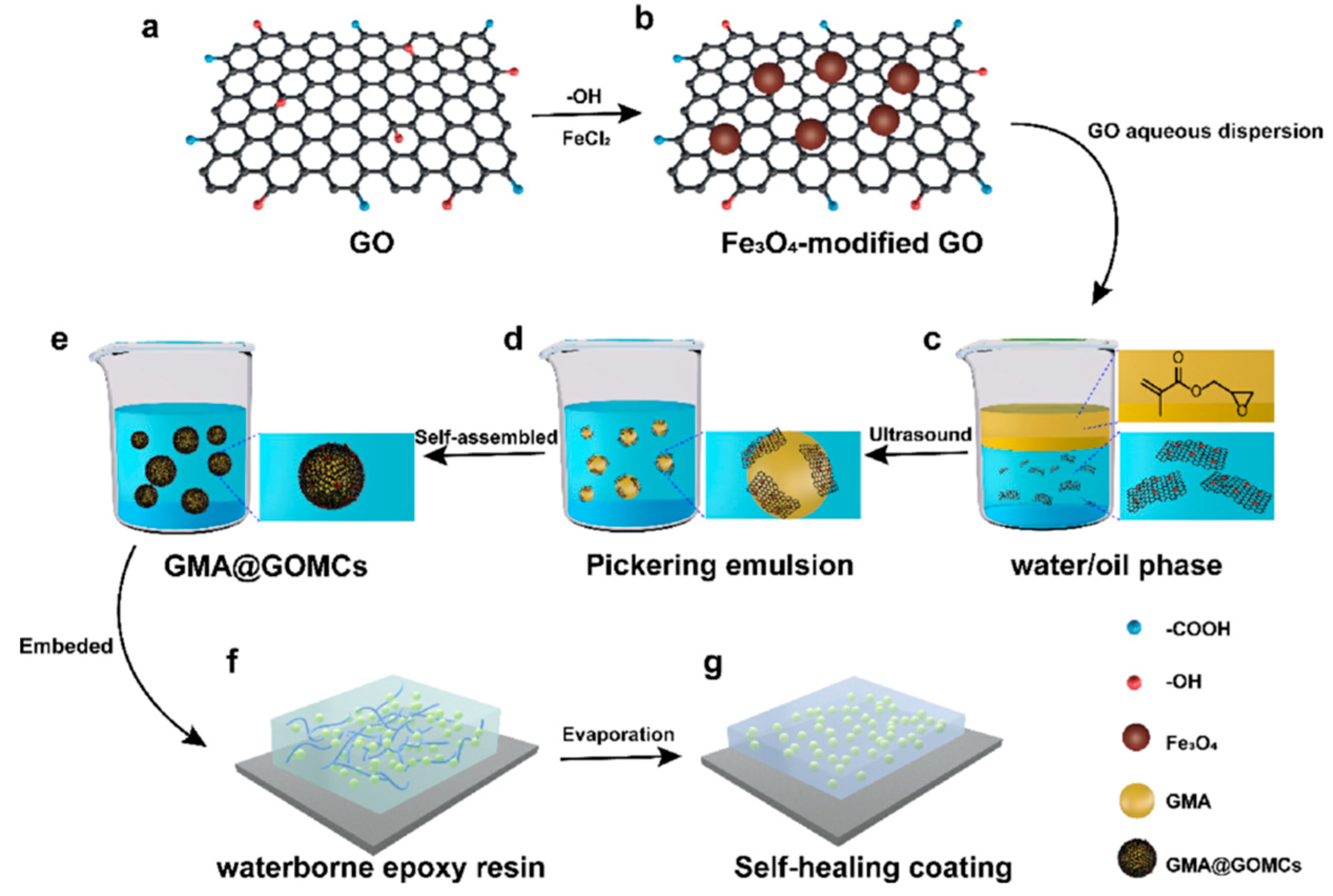

3.4. Syntheses of Nanomodified Microcapsules

4. Applications of Nanomodified Microcapsules in Cement-Based Materials

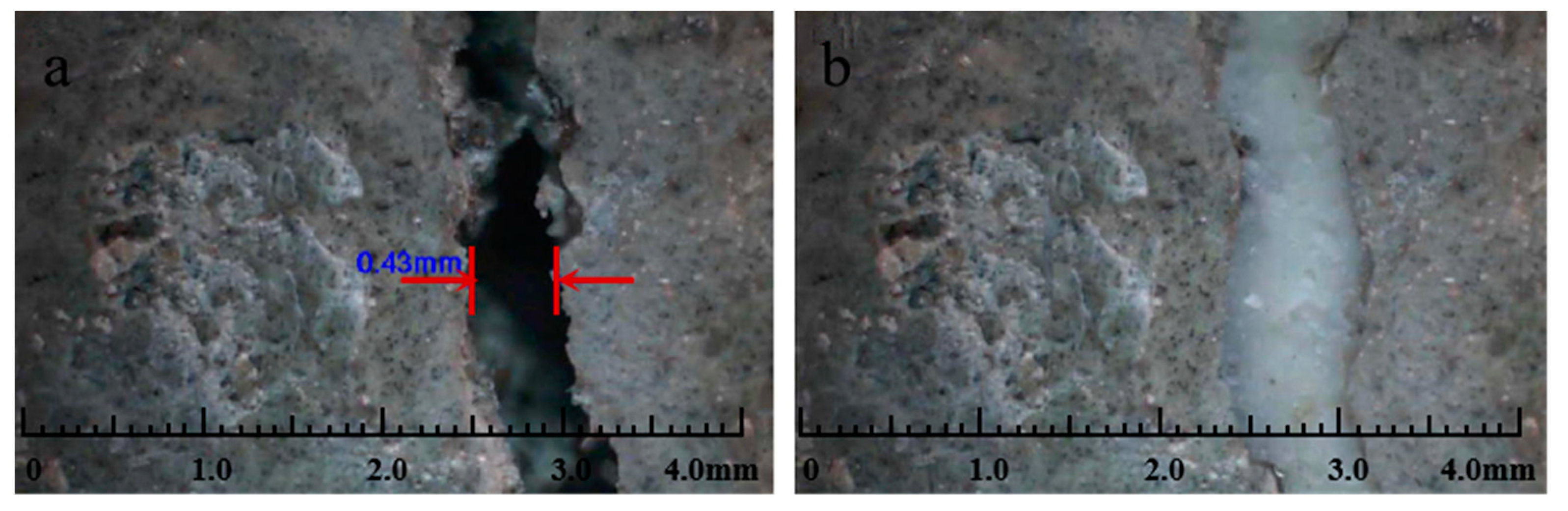

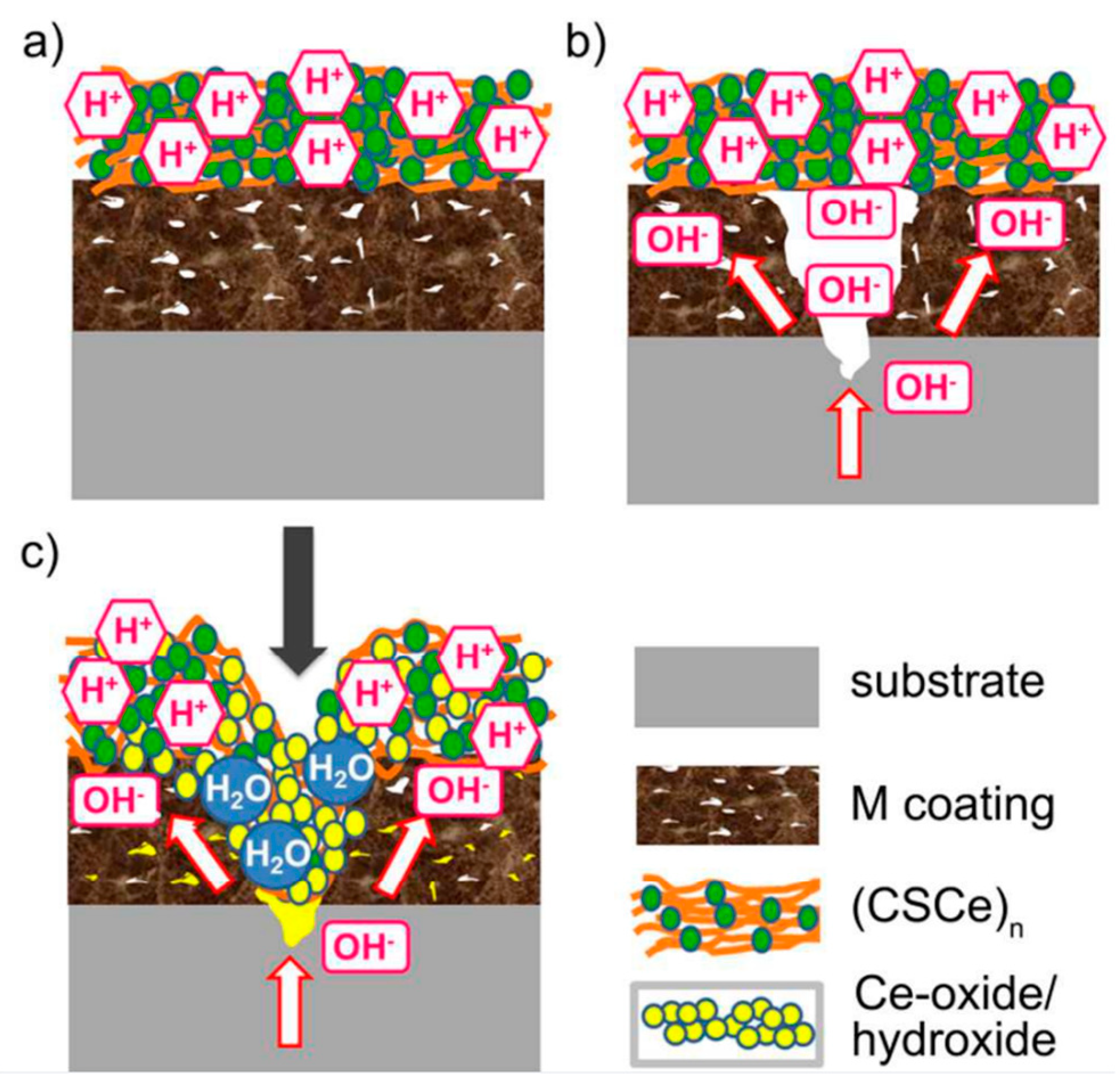

4.1. Performance of Microcapsules Added to Surface Coatings

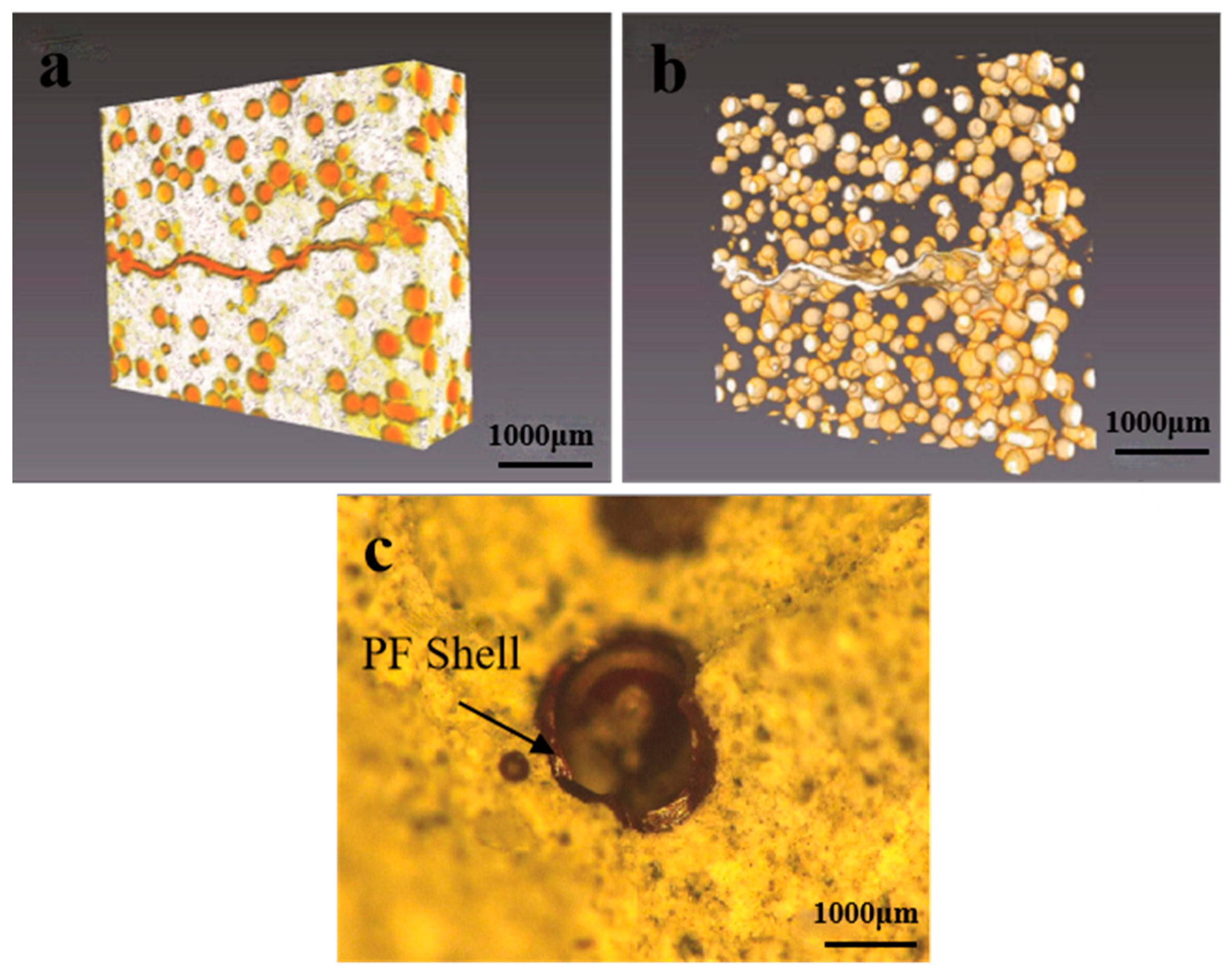

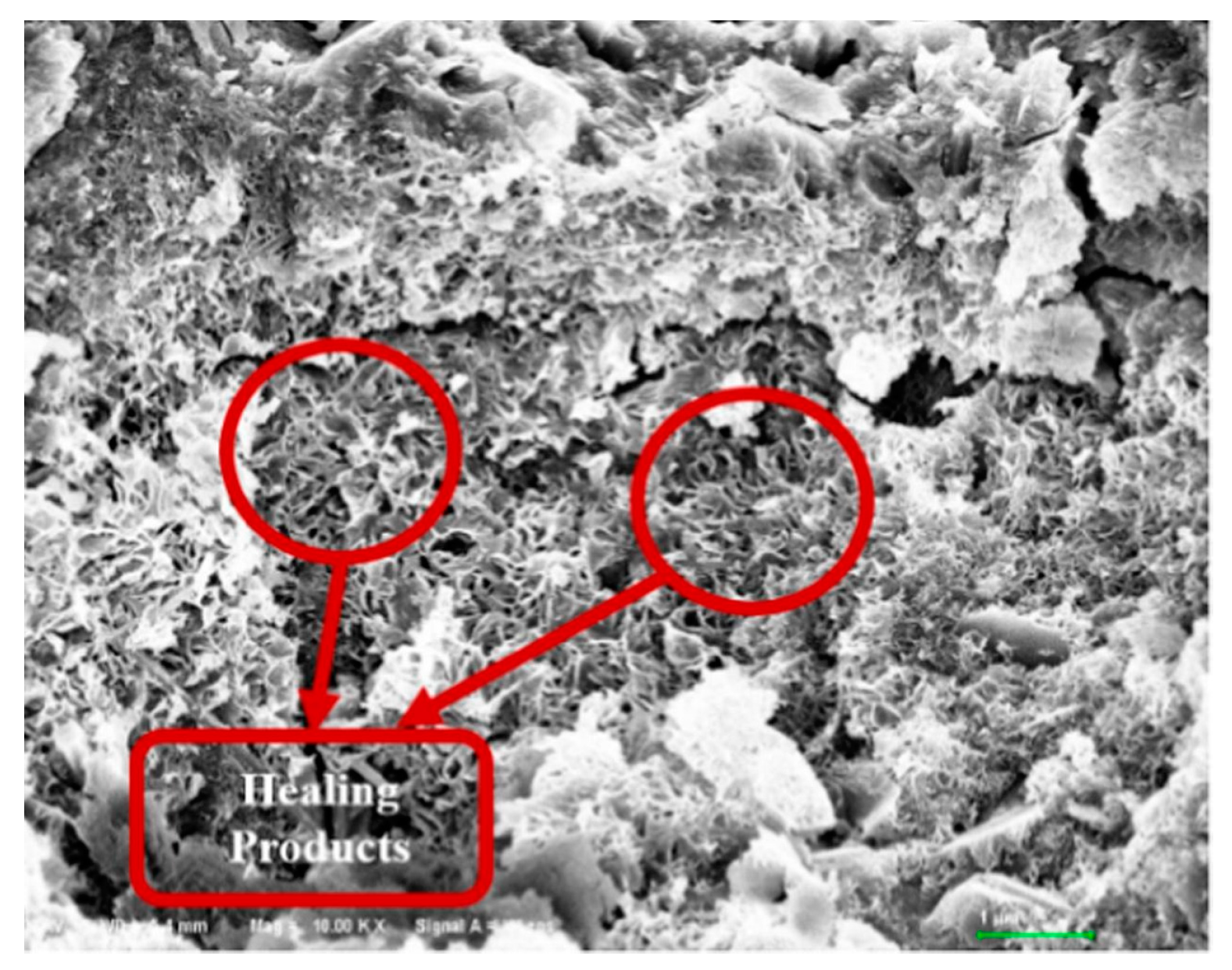

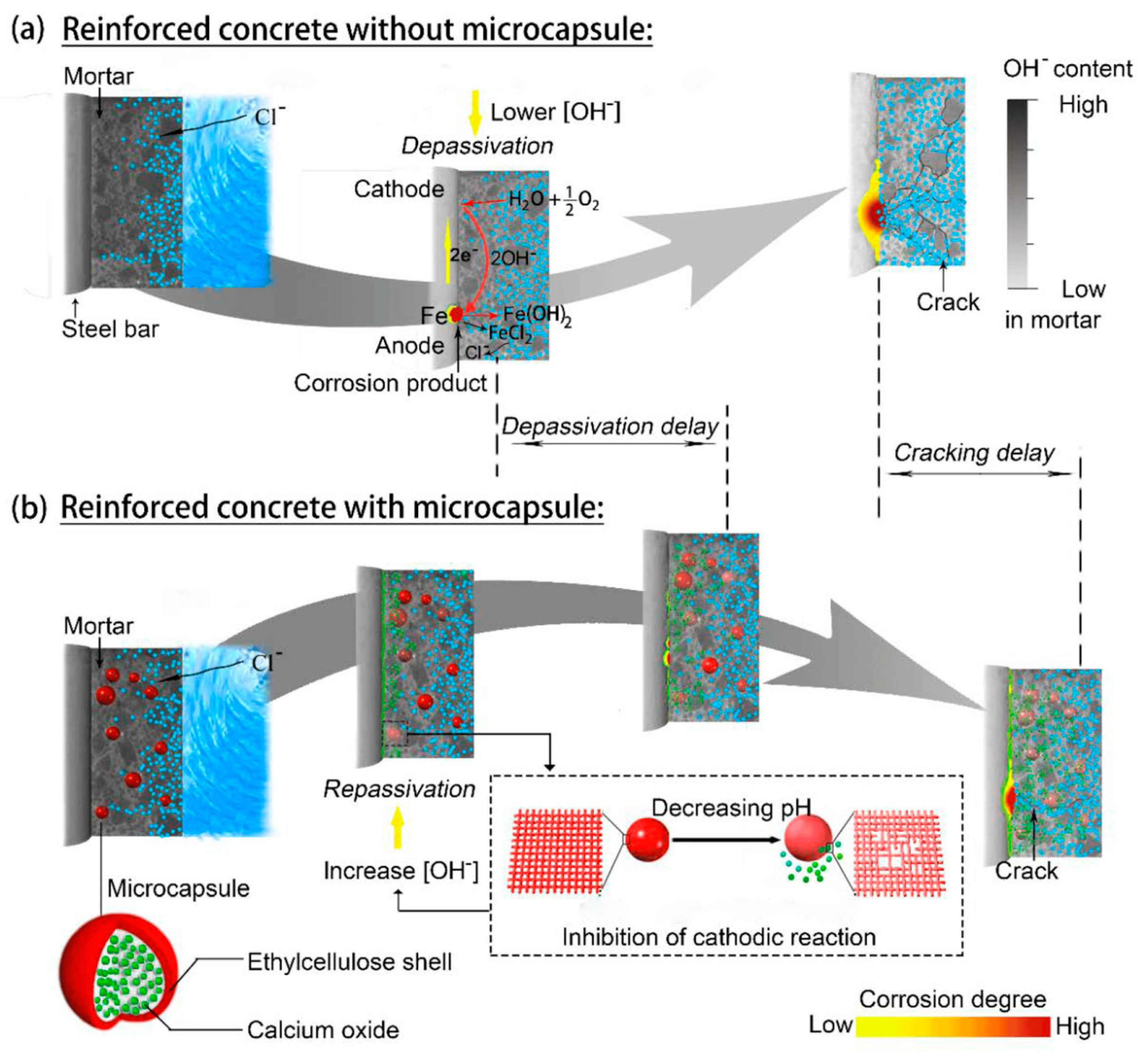

4.2. Performance of Microcapsules Added to Internal Structures

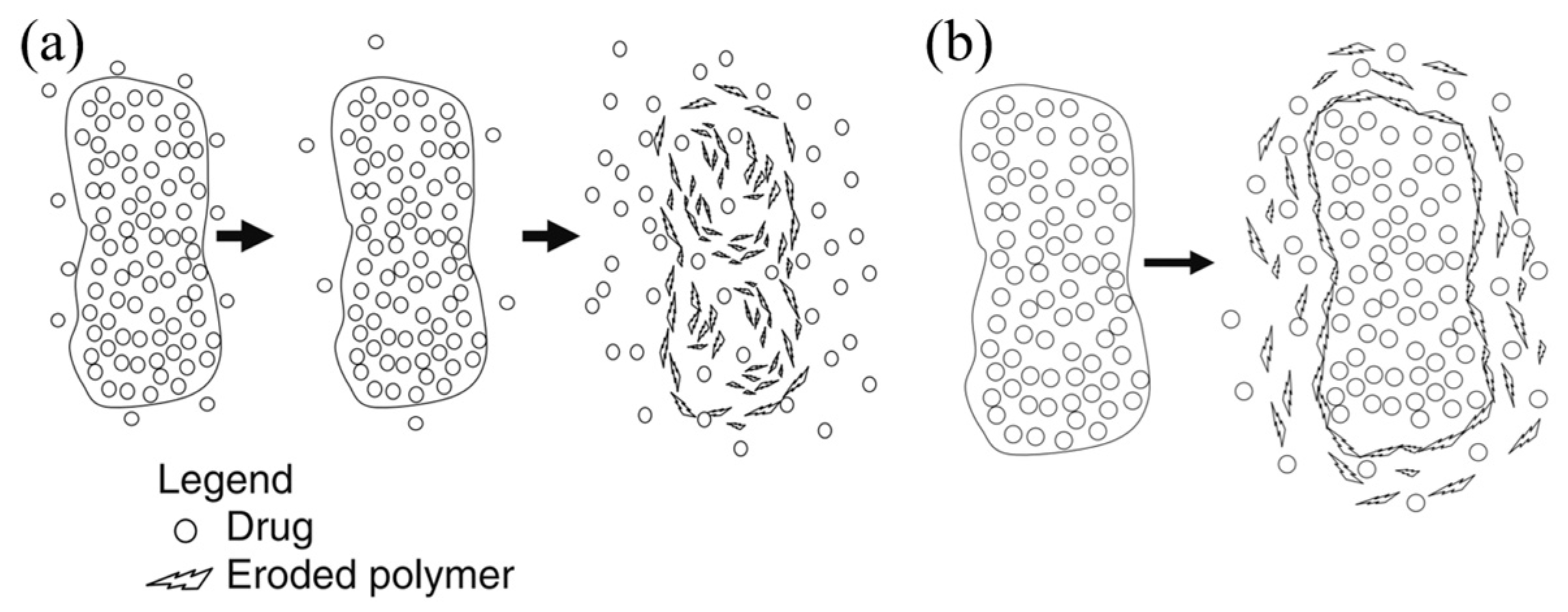

4.3. Release of Core Materials

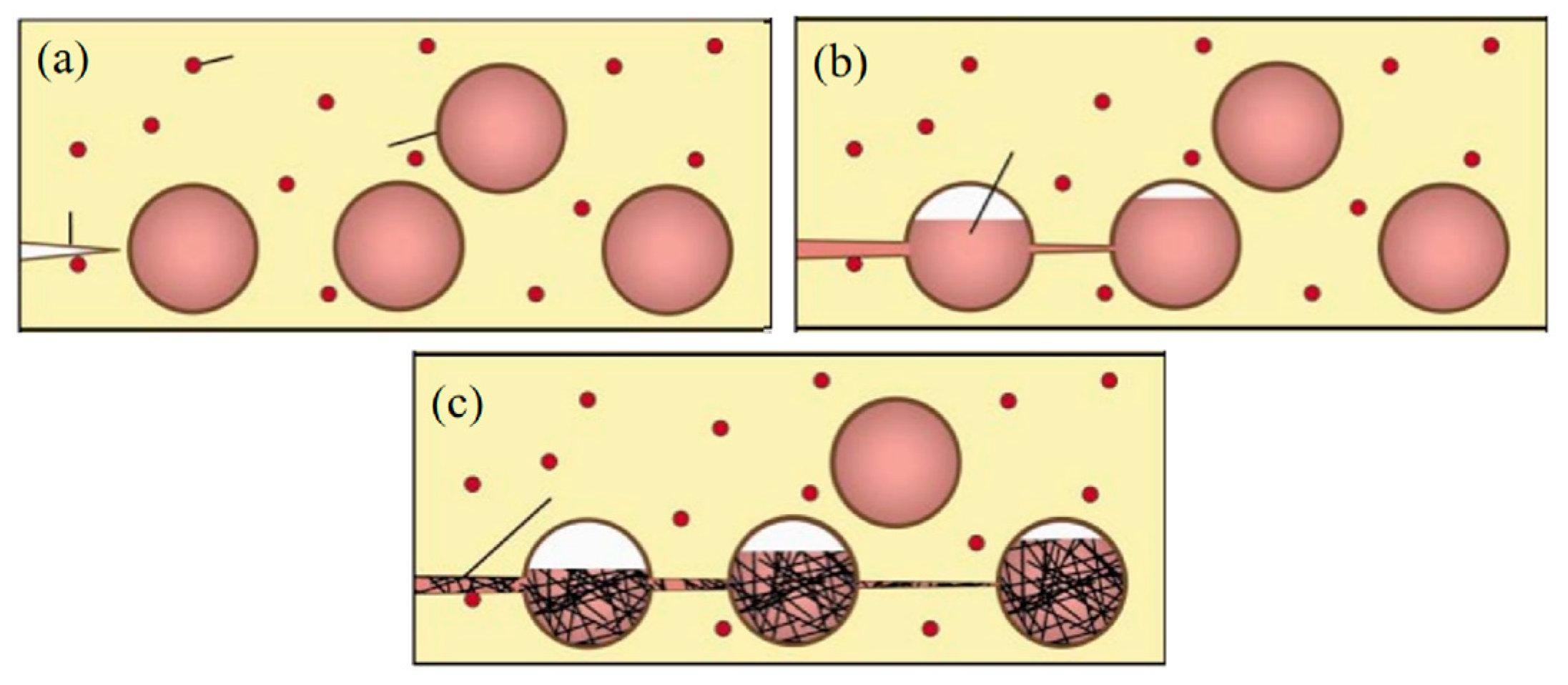

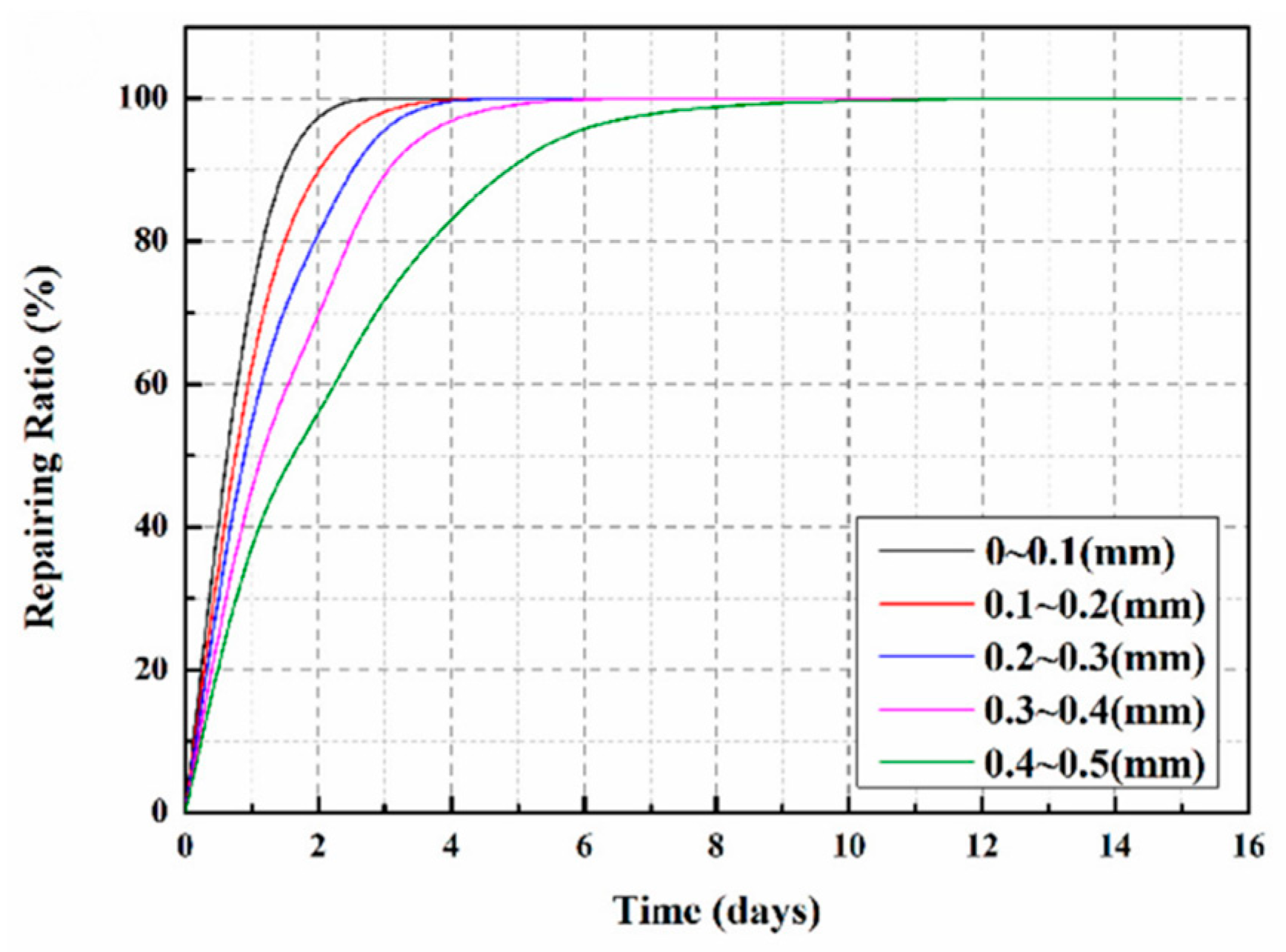

4.3.1. Mechanical Response

4.3.2. pH Response

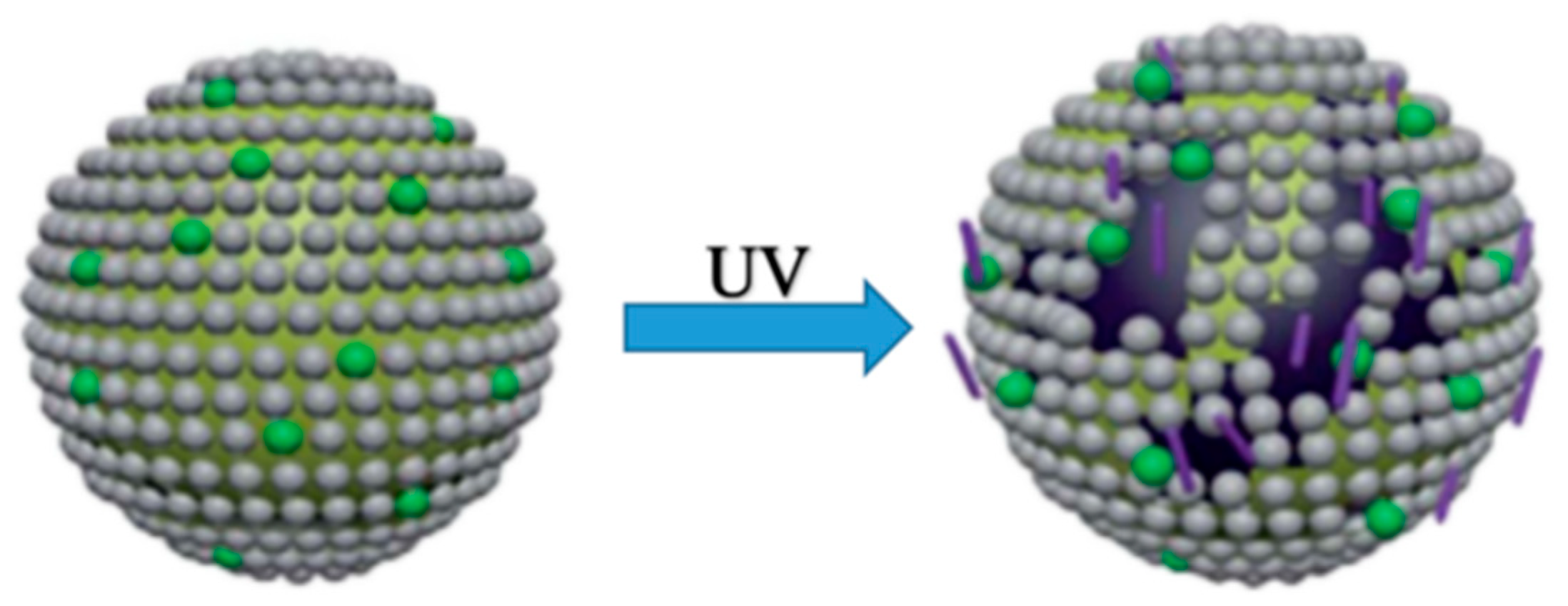

4.3.3. UV Response

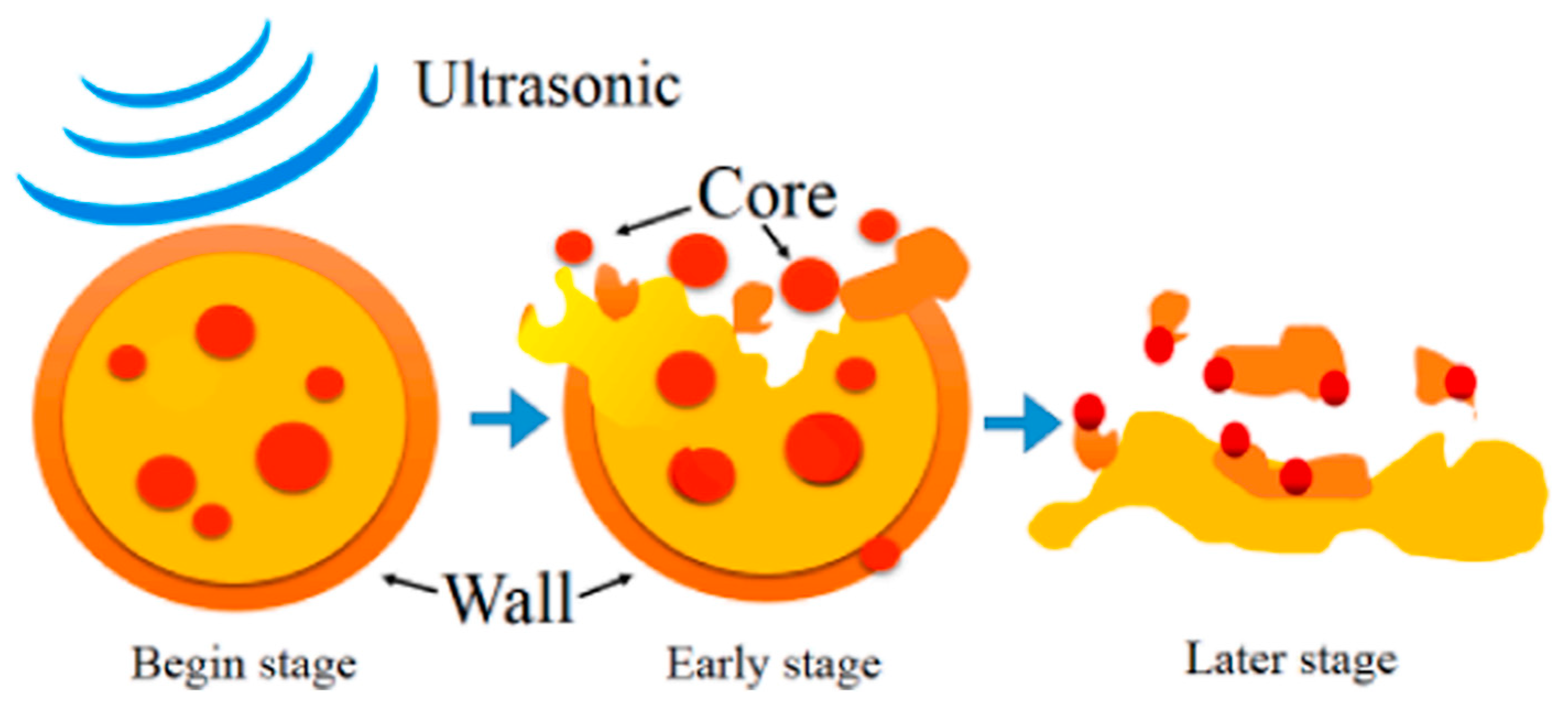

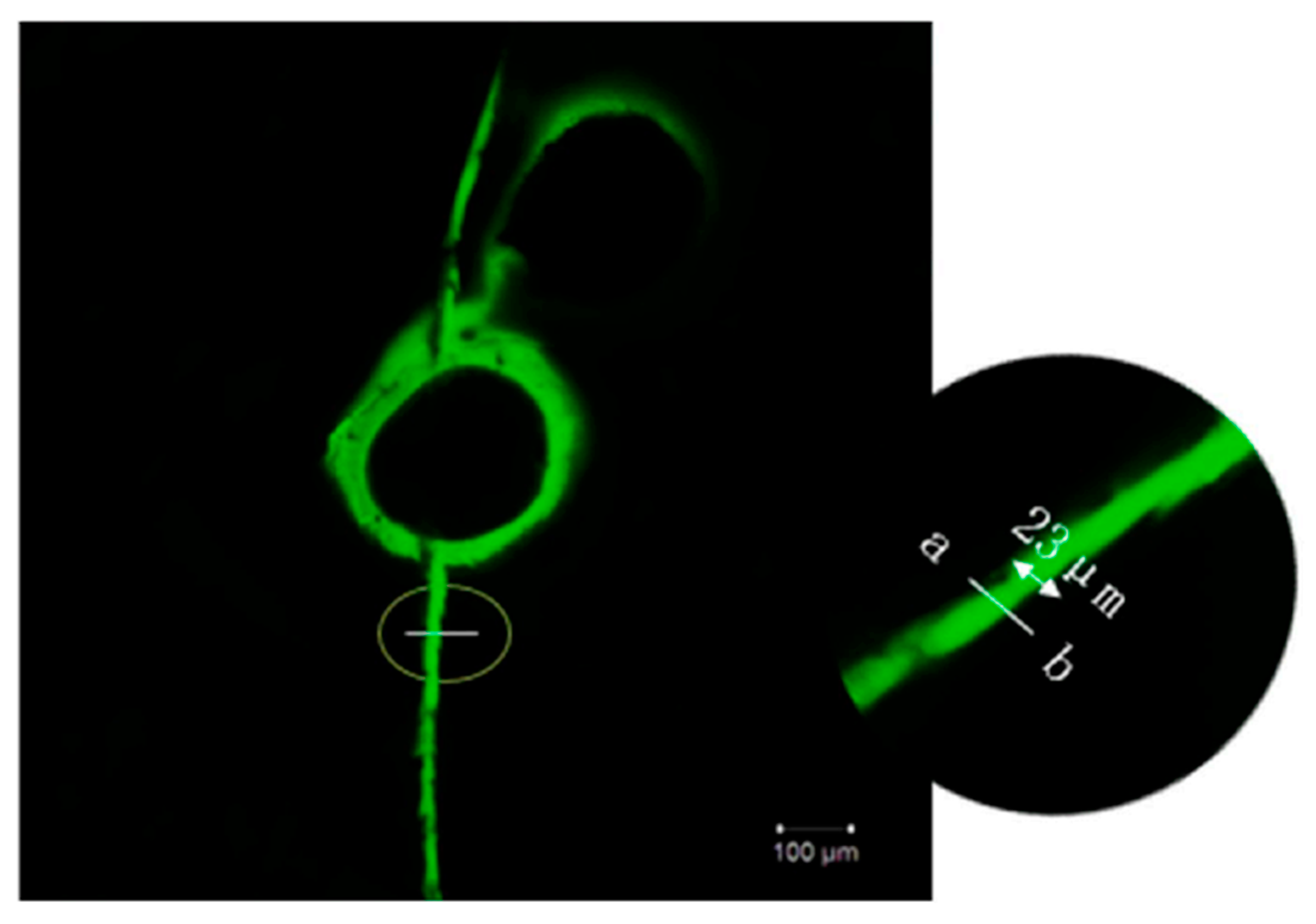

4.3.4. Electromagnetic or Ultrasonic Wave Response

5. Conclusions and Suggestion

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, W.; Dong, B.; Yang, Z.; Xu, J.; Chen, Q.; Li, H.; Xing, F.; Jiang, Z. Recent advances in intrinsic self-healing cementitious materials. Adv. Mater. 2018, 30, 1705679. [Google Scholar] [CrossRef] [PubMed]

- Paul, S.C.; Van Zijl, G.P.A.G. Corrosion deterioration of steel in cracked SHCC. Int. J. Concr. Struct. Mater. 2017, 11, 557–572. [Google Scholar] [CrossRef]

- Zhang, X.; Li, M.; Tang, L.; Memon, S.A.; Ma, G.; Xing, F.; Sun, H. Corrosion induced stress field and cracking time of reinforced concrete with initial defects: Analytical modeling and experimental investigation. Corros. Sci. 2017, 120, 158–170. [Google Scholar] [CrossRef]

- Du, W.; Lin, R.; Liu, Q. Investigation of isophorone diisocyanate microcapsules to improve self-healing properties and sulfate resistance of concrete. Constr. Build. Mater. 2021, 300, 124438. [Google Scholar] [CrossRef]

- Du, W.; Liu, Q.; Lin, R. Effects of toluene-di-isocyanate microcapsules on the frost resistance and self-repairing capability of concrete under freeze-thaw cycles. J. Build. Eng. 2021, 44, 102880. [Google Scholar] [CrossRef]

- Han, W.; Zhou, G.; Gao, D.; Zhang, Z.; Wei, Z.; Wang, H.; Yang, H. Experimental analysis of the pore structure and fractal characteristics of different metamorphic coal based on mercury intrusion-nitrogen adsorption porosimetry. Powder Technol. 2020, 362, 386–398. [Google Scholar] [CrossRef]

- Li, S.; Zhou, G.; Liu, Z.; Wang, N.; Wei, Z.; Liu, W. Synthesis and performance characteristics of a new ecofriendly crust-dust suppressant extracted from waste paper for surface mines. J. Clean. Prod. 2020, 258, 120620. [Google Scholar] [CrossRef]

- Jiang, W.; Zhou, G.; Wang, C.; Xue, Y.; Niu, C. Synthesis and self-healing properties of composite microcapsule based on sodium alginate/melamine-phenol–formaldehyde resin. Constr. Build. Mater. 2021, 271, 121541. [Google Scholar] [CrossRef]

- Dong, B.; Wang, Y.; Fang, G.; Han, N.; Xing, F.; Lu, Y. Smart releasing behavior of a chemical self-healing microcapsule in the stimulated concrete pore solution. Cem. Concr. Compos. 2015, 56, 46–50. [Google Scholar] [CrossRef]

- Yang, Z.; Hollar, J.; He, X.; Shi, X. Laboratory assessment of a self-healing cementitious composite. Transp. Res. Rec. 2010, 2142, 9–17. [Google Scholar] [CrossRef]

- Yang, Z.; Hollar, J.; He, X.; Shi, X. A self-healing cementitious composite using oil core/silica gel shell microcapsules. Cem. Concr. Compos. 2011, 33, 506–512. [Google Scholar] [CrossRef]

- Xue, C.; Li, W.; Li, J.; Tam, V.W.; Ye, G. A review study on encapsulation-based self-healing for cementitious materials. Struct. Concr. 2019, 20, 198–212. [Google Scholar] [CrossRef]

- Dry, C. Matrix cracking repair and filling using active and passive modes for smart timed release of chemicals from fibers into cement matrices. Smart Mater. Struct. 1994, 3, 118. [Google Scholar] [CrossRef]

- Han, N.-X.; Xing, F. A comprehensive review of the study and development of microcapsule based self-resilience systems for concrete structures at Shenzhen University. Materials 2016, 10, 2. [Google Scholar] [CrossRef] [PubMed]

- Shokrian, M.D.; Shelesh-Nezhad, K.; Najjar, R. Toughening effect of nanocomposite-wall microcapsules on the fracture behavior of epoxy. Polymer 2019, 168, 104–115. [Google Scholar] [CrossRef]

- Ilyaei, S.; Sourki, R.; Akbari, Y.H.A. Capsule-based healing systems in composite materials: A review. Crit. Rev. Solid State Mater. Sci. 2021, 46, 491–531. [Google Scholar] [CrossRef]

- Li, W.; Jiang, Z.; Yu, Q. Multiple damaging and self-healing properties of cement paste incorporating microcapsules. Constr. Build. Mater. 2020, 255, 119302. [Google Scholar] [CrossRef]

- Jiang, X.; Luo, R.; Peng, F.; Fang, Y.; Akiyama, T.; Wang, S. Synthesis, characterization and thermal properties of paraffin microcapsules modified with nano-Al2O3. Appl. Energy 2015, 137, 731–737. [Google Scholar] [CrossRef]

- Li, Y.; Yu, J.; Cao, Z.; Du, W.; Zhang, Y.; Zou, Y. Preparation and characterization of nano-Fe3O4/paraffin encapsulated isocyanate microcapsule by electromagnetic controlled rupture for self-healing cementitious materials. Constr. Build. Mater. 2020, 265, 120703. [Google Scholar] [CrossRef]

- Kim, S.; Tserengombo, B.; Choi, S.-H.; Noh, J.; Huh, S.; Choi, B.; Chung, H.; Kim, J.; Jeong, H. Experimental investigation of dispersion characteristics and thermal conductivity of various surfactants on carbon based nanomaterial. Int. Commun. Heat Mass Transf. 2018, 91, 95–102. [Google Scholar] [CrossRef]

- Krishnamoorti, R. Strategies for dispersing nanoparticles in polymers. MRS Bull. 2007, 32, 341–347. [Google Scholar] [CrossRef]

- Jiang, F.; Zhao, W.; Wu, Y.; Wu, Y.; Liu, G.; Dong, J.; Zhou, K. A polyethyleneimine-grafted graphene oxide hybrid nanomaterial: Synthesis and anti-corrosion applications. Appl. Surf. Sci. 2019, 479, 963–973. [Google Scholar] [CrossRef]

- Li, B.; Liu, T.; Hu, L.; Wang, Y.; Gao, L. Fabrication and properties of microencapsulated paraffin@SiO2 phase change composite for thermal energy storage. ACS Sustain. Chem. Eng. 2013, 1, 374–380. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, K.; Tao, W.; Li, D. Preparation of microencapsulated phase change materials used graphene oxide to improve thermal stability and its incorporation in gypsum materials. Constr. Build. Mater. 2019, 224, 48–56. [Google Scholar] [CrossRef]

- Wang, K.; Jansen, D.C.; Shah, S.P.; Karr, A.F. Permeability study of cracked concrete. Cem. Concr. Res. 1997, 27, 381–393. [Google Scholar] [CrossRef]

- Basheer, L.; Kropp, J.; Cleland, D.J. Assessment of the durability of concrete from its permeation properties: A review. Constr. Build. Mater. 2001, 15, 93–103. [Google Scholar] [CrossRef]

- Dong, B.; Fang, G.; Wang, Y.; Liu, Y.; Hong, S.; Zhang, J.; Lin, S.; Xing, F. Performance recovery concerning the permeability of concrete by means of a microcapsule based self-healing system. Cem. Concr. Compos. 2017, 78, 84–96. [Google Scholar] [CrossRef]

- Irico, S.; Bovio, A.; Paul, G.; Boccaleri, E.; Gastaldi, D.; Marchese, L.; Buzzi, L.; Canonico, F. A solid-state NMR and X-ray powder diffraction investigation of the binding mechanism for self-healing cementitious materials design: The assessment of the reactivity of sodium silicate based systems. Cem. Concr. Compos. 2017, 76, 57–63. [Google Scholar] [CrossRef]

- Huang, H.; Ye, G.; Qian, C.; Schlangen, E. Self-healing in cementitious materials: Materials, methods and service conditions. Mater. Des. 2016, 92, 499–511. [Google Scholar] [CrossRef]

- Yu, X.; Qi, H.; Huang, Z.; Zhang, B.; Liu, S. Preparation and characterization of spherical β-cyclodextrin/urea–formaldehyde microcapsules modified by nano-titanium oxide. RSC Adv. 2017, 7, 7857–7863. [Google Scholar] [CrossRef]

- Dahesh, A.Z.; Othman, F.M.; Abdul-Hamead, A.A. Improve Mass Concrete by Controlling the Crack Sealing Mechanism Using Microcapsules of Zinc Oxide. Mater. Sci. Forum 2020, 1002, 541–550. [Google Scholar] [CrossRef]

- Antoniou, M.; Tsounidi, D.; Petrou, P.S.; Beltsios, K.G.; Kakabakos, S.E. Functionalization of silicon dioxide and silicon nitride surfaces with aminosilanes for optical biosensing applications. Med. Devices Sens. 2020, 3, e10072. [Google Scholar] [CrossRef]

- Li, G.; Cui, H.; Zhou, J.; Hu, W. Improvements of nano-TiO2 on the long-term chloride resistance of concrete with polymer coatings. Coatings 2019, 9, 323. [Google Scholar] [CrossRef]

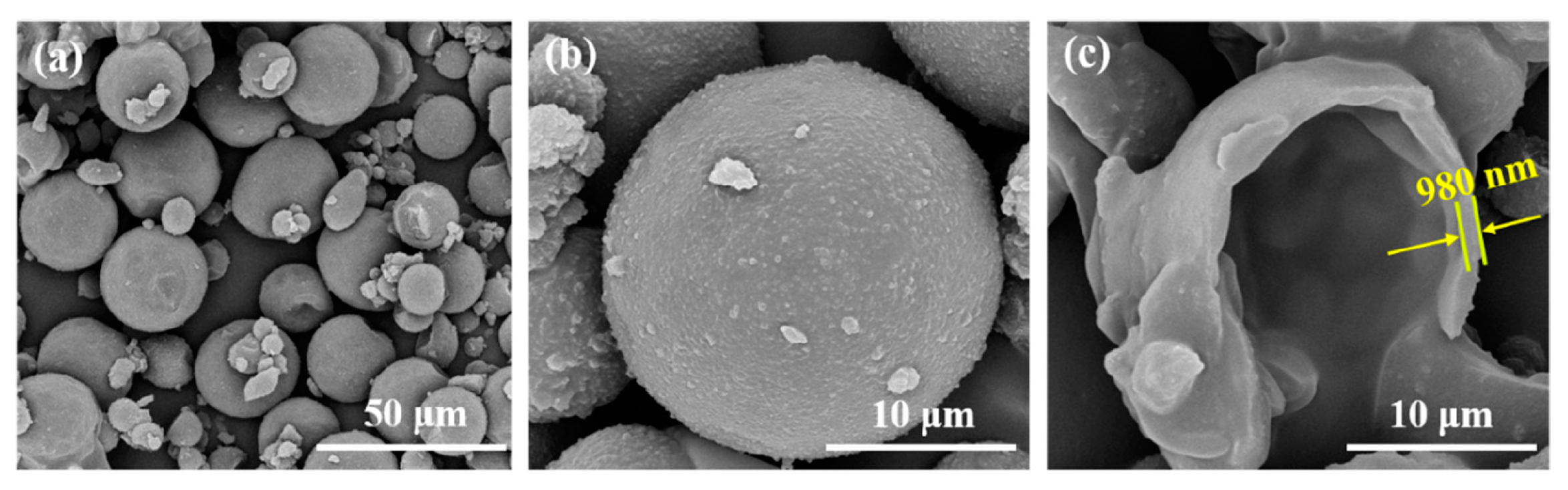

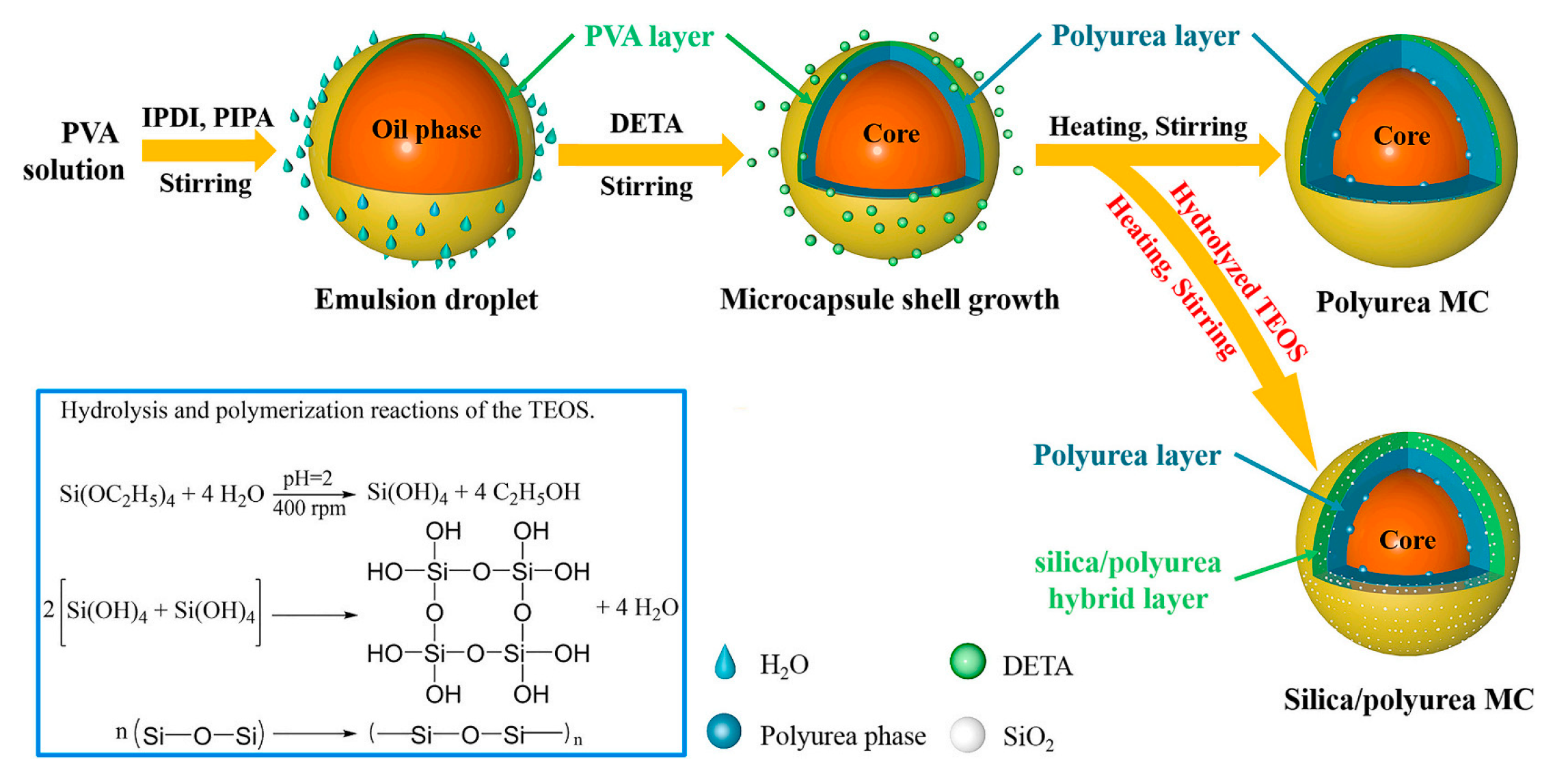

- Li, X.; Li, X.; Zhao, Y.; Li, Q.; Wang, J.; Kang, M. Controllable preparation of isophorone diisocyanate microcapsules with silica/polyurea hybrid shells and application in self-healing epoxy coatings. Prog. Org. Coat. 2022, 163, 106638. [Google Scholar] [CrossRef]

- Yan, J.; Gao, Z.; Tan, Q.; Yang, X.; Hu, W. Study on Wettability and Corrosion Behavior of Al2O3 Doped Polyurea Coatings. Prot. Met. Phys. Chem. Surf. 2020, 56, 965–972. [Google Scholar]

- Du, W.; Li, E.; Lin, R. Preparation and characterization of nano-CaCO3/ceresine wax composite shell microcapsules containing E-44 epoxy resin for self-healing of cement-based materials. Nanomaterials 2022, 12, 197. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Ma, Y.; Li, Z.; Cui, Y.; Wang, H. Synthesis of novel multilayer composite microcapsules and their application in self-lubricating polymer composites. Compos. Sci. Technol. 2018, 164, 120–128. [Google Scholar] [CrossRef]

- Li, J.; Li, Z.; Feng, Q.; Qiu, H.; Yang, G.; Zheng, S.; Yang, J. Encapsulation of linseed oil in graphene oxide shells for preparation of self-healing composite coatings. Prog. Org. Coat. 2019, 129, 285–291. [Google Scholar] [CrossRef]

- Paredes, J.; Villar-Rodil, S.; Martínez-Alonso, A.; Tascon, J.M. Graphene oxide dispersions in organic solvents. Langmuir 2008, 24, 10560–10564. [Google Scholar] [CrossRef]

- Goustouridis, D.; Raptis, I.; Mpatzaka, T.; Fournari, S.; Zisis, G.; Petrou, P.; Beltsios, K.G. Non-Destructive Characterization of Selected Types of Films and Other Layers via White Light Reflectance Spectroscopy (WLRS). Micro 2022, 2, 495–507. [Google Scholar] [CrossRef]

- Kollia, E.; Mastrotheodoros, G.; Kosma, V.; Beltsios, K.G. Single step fabrication of polymer/silicate porous composite membranes via water-glass induced phase inversion. Polym.-Plast. Technol. Mater. 2019, 58, 957–966. [Google Scholar] [CrossRef]

- White, S.R.; Sottos, N.R.; Geubelle, P.H.; Moore, J.S.; Kessler, M.R.; Sriram, S.; Brown, E.N.; Viswanathan, S. Autonomic healing of polymer composites. Nature 2001, 409, 794–797. [Google Scholar] [CrossRef] [PubMed]

- Li, K.; Li, H.; Cui, Y.; Li, Z.; Ji, J.; Feng, Y.; Chen, S.; Zhang, M.; Wang, H. Dual-functional coatings with self-lubricating and self-healing properties by combining poly (urea–formaldehyde)/SiO2 hybrid microcapsules containing linseed oil. Ind. Eng. Chem. Res. 2019, 58, 22032–22039. [Google Scholar] [CrossRef]

- Du, G.; Hu, J.; Zhou, J.; Wang, G.; Guan, S.; Liu, H.; Geng, M.; Lü, C.; Ming, Y.; Qu, J. The study on the mechanical properties of PU/MF double shell self-healing microcapsules. Chin. J. Chem. Eng. 2020, 28, 1459–1473. [Google Scholar] [CrossRef]

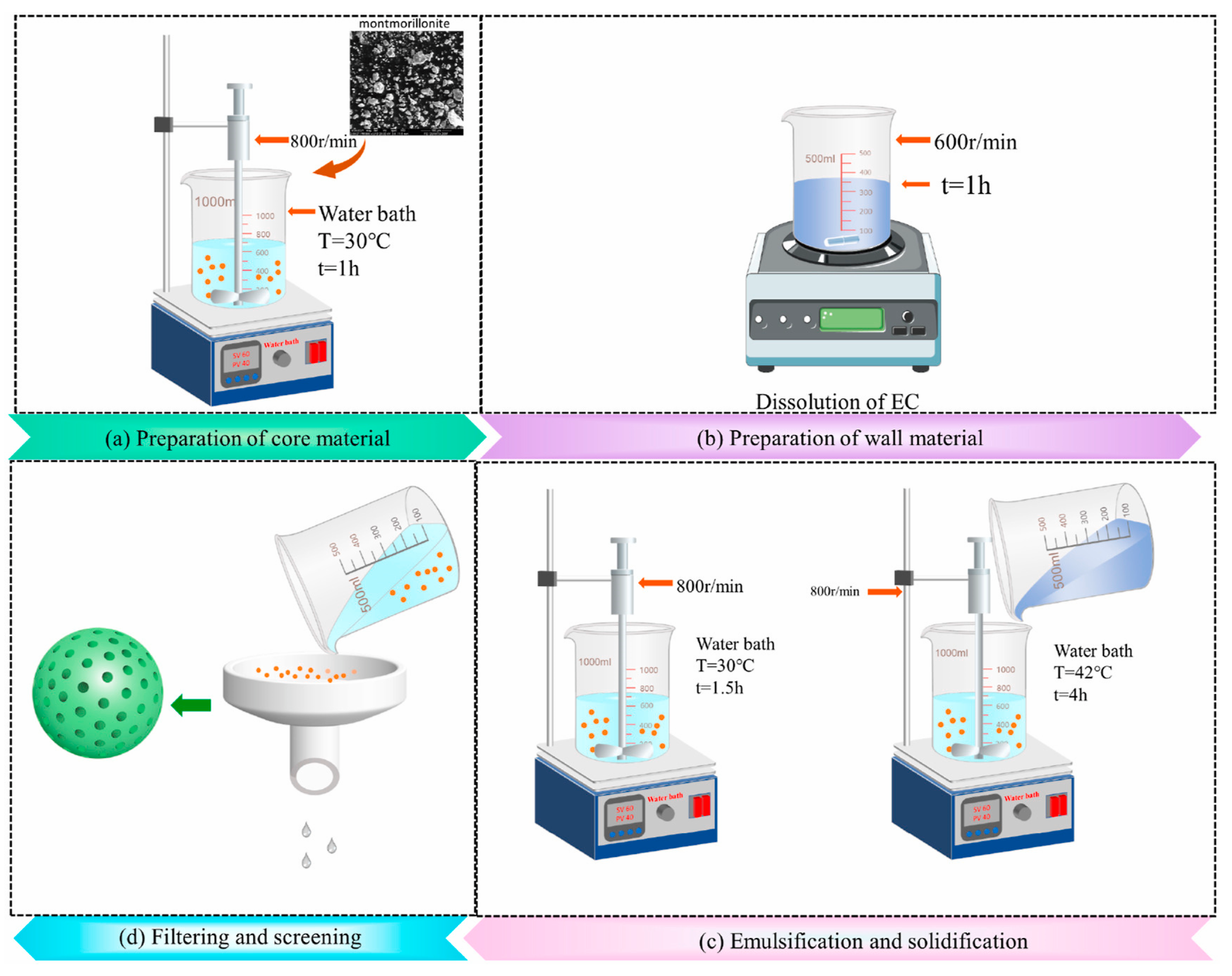

- Wang, X.; Zhang, X.; Zou, F.; Zhu, J. Self-healing microcapsules modified by montmorillonite for modulating slow-release properties. Mater. Chem. Phys. 2022, 291, 126688. [Google Scholar] [CrossRef]

- Kosarli, M.; Foteinidis, G.; Tsirka, K.; Bekas, D.G.; Paipetis, A.S. Concurrent recovery of mechanical and electrical properties in nanomodified capsule-based self-healing epoxies. Polymer 2021, 227, 123843. [Google Scholar] [CrossRef]

- Crall, M.D.; Keller, M.W. Targeted self-healing by magnetically guiding microcapsules. ACS Appl. Mater. Interfaces 2017, 9, 6504–6511. [Google Scholar] [CrossRef]

- Jia, R.; Liu, X.; Huang, Z.; Wang, D.; Zhao, C.; Hui, Z.; He, X.; Wu, D. Novel polyurethane elastomer modified by hybrid shell nano-/microcapsules for unique self-lubricating behavior. Ind. Eng. Chem. Res. 2020, 59, 22123–22131. [Google Scholar] [CrossRef]

- Mytara, A.D.; Chronaki, K.; Nikitakos, V.; Papaspyrides, C.D.; Beltsios, K.; Vouyiouka, S. Synthesis of polyamide-based microcapsules via interfacial polymerization: Effect of key process parameters. Materials 2021, 14, 5895. [Google Scholar] [CrossRef]

- Xu, H.; Tan, Z.; Abe, H.; NAITO, M. Microcapsule assembly of single-walled carbon nanotubes from spray-dried hollow microspheres. J. Ceram. Soc. Jpn. 2011, 119, 180–184. [Google Scholar] [CrossRef]

- Ghorbani, M.; Ebrahimnezhad-Khaljiri, H.; Eslami-Farsani, R.; Vafaeenezhad, H. The synergic effect of microcapsules and titanium nanoparticles on the self-healing and self-lubricating epoxy coatings: A dual smart application. Surf. Interfaces 2021, 23, 100998. [Google Scholar] [CrossRef]

- Zhou, G.; Jiang, W.; Li, S.; Liu, R.; Zhang, Q.; Qi, G.; He, Z. Preparation and performance analysis of dopamine hydrochloride functionalized E-51@ MPF/SiO2 double-wall microcapsules for microcracks self-healing in cement-based materials. Constr. Build. Mater. 2022, 325, 126622. [Google Scholar] [CrossRef]

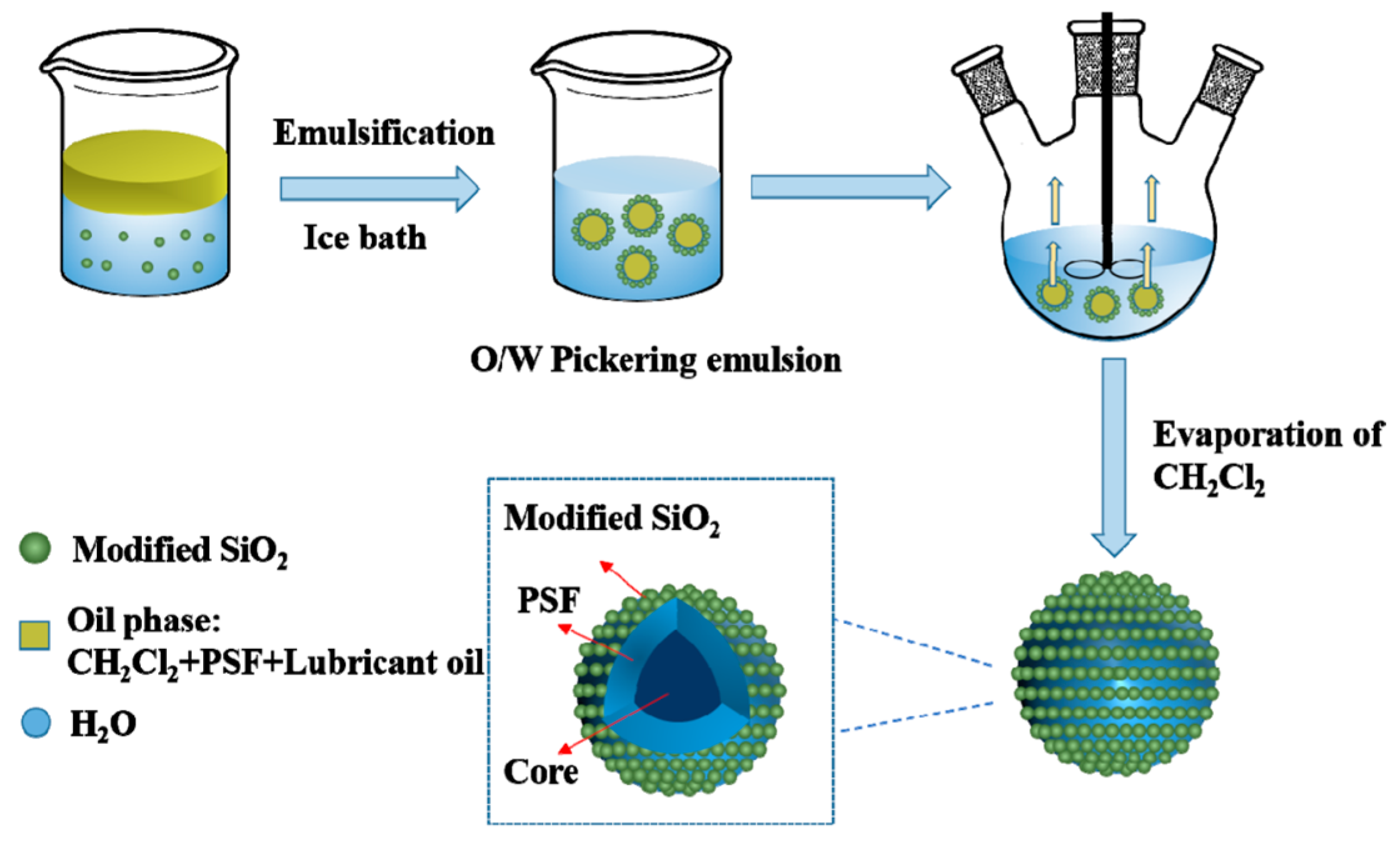

- Li, H.; Li, S.; Li, F.; Li, Z.; Wang, H. Fabrication of SiO2 wrapped polystyrene microcapsules by Pickering polymerization for self-lubricating coatings. J. Colloid Interface Sci. 2018, 528, 92–99. [Google Scholar] [CrossRef] [PubMed]

- Wu, F.; Li, J.; Quan, H.; Han, J.; Liu, X.; Zhang, X.; Yang, J.; Xiang, Y. Robust polyurea/poly (urea–formaldehyde) hybrid microcapsules decorated with Al2O3 nano-shell for improved self-healing performance. Appl. Surf. Sci. 2021, 542, 148561. [Google Scholar] [CrossRef]

- Shahabudin, N.; Yahya, R.; Gan, S.N. Microcapsules of Poly (urea-formaldehyde)(PUF) Containing alkyd from Palm Oil. Mater. Today Proc. 2016, 3, S88–S95. [Google Scholar] [CrossRef]

- Wang, H.P.; Yuan, Y.C.; Rong, M.Z.; Zhang, M.Q. Melamine resin-walled microcapsules containing styrene: Preparation and characterization. Adv. Mater. Res. 2008, 47, 286–289. [Google Scholar] [CrossRef]

- Liu, X.; Sheng, X.; Lee, J.K.; Kessler, M.R. Synthesis and characterization of melamine-urea-formaldehyde microcapsules containing ENB-based self-healing agents. Macromol. Mater. Eng. 2009, 294, 389–395. [Google Scholar] [CrossRef]

- Jia, Y.; Wang, H.; Tian, K.; Li, R.; Xu, Z.; Jiao, J.; Cao, L.; Wu, Y. A combined interfacial and in-situ polymerization strategy to construct well-defined core-shell epoxy-containing SiO2-based microcapsules with high encapsulation loading, super thermal stability and nonpolar solvent tolerance. Int. J. Smart Nano Mater. 2016, 7, 221–235. [Google Scholar] [CrossRef]

- Li, H.; Li, S.; Li, Z.; Zhu, Y.; Wang, H. Polysulfone/SiO2 hybrid shell microcapsules synthesized by the combination of pickering emulsification and the solvent evaporation technique and their application in self-lubricating composites. Langmuir 2017, 33, 14149–14155. [Google Scholar] [CrossRef]

- Bandeira, P.; Monteiro, J.; Baptista, A.M.; Magalhães, F.D. Tribological performance of PTFE-based coating modified with microencapsulated [HMIM][NTf 2] ionic liquid. Tribol. Lett. 2015, 59, 13. [Google Scholar] [CrossRef]

- Xiao, C.-D.; Shen, X.-C.; Tao, L. Modified emulsion solvent evaporation method for fabricating core–shell microspheres. Int. J. Pharm. 2013, 452, 227–232. [Google Scholar] [CrossRef] [PubMed]

- Chen, D.; OuYang, X.; Wang, Y.; Yang, L.; Wu, K.; He, C. Adsorption of caprolactam from aqueous solution by novel polysulfone microcapsules containing [Bmim][PF6]. Colloids Surf. A Physicochem. Eng. Asp. 2014, 441, 72–76. [Google Scholar] [CrossRef]

- Fan, J.; Zheng, Y.; Xie, Y.; Sun, Y.; Luan, Y.; Jiang, W.; Wang, C.; Liu, S.; Liu, X. Effect of solvent evaporation technique on the characteristics of curing agent microcapsules and the curing process. Compos. Sci. Technol. 2017, 138, 80–90. [Google Scholar] [CrossRef]

- Li, H.; Wang, Q.; Li, M.; Cui, Y.; Zhu, Y.; Wang, B.; Wang, H. Preparation of high thermal stability polysulfone microcapsules containing lubricant oil and its tribological properties of epoxy composites. J. Microencapsul. 2016, 33, 286–291. [Google Scholar] [CrossRef]

- Bae, J. Fabrication of carbon microcapsules containing silicon nanoparticles-carbon nanotubes nanocomposite by sol-gel method for anode in lithium ion battery. J. Solid State Chem. 2011, 184, 1749–1755. [Google Scholar] [CrossRef]

- Pi, Z.; Xiao, H.; Liu, R.; Liu, M.; Li, H. Effects of brass coating and nano-SiO2 coating on steel fiber–matrix interfacial properties of cement-based composite. Compos. Part B Eng. 2020, 189, 107904. [Google Scholar] [CrossRef]

- Geng, Y.; Li, S.; Hou, D.; Zhang, W.; Jin, Z.; Li, Q.; Luo, J. Fabrication of superhydrophobicity on foamed concrete surface by GO/silane coating. Mater. Lett. 2020, 265, 127423. [Google Scholar] [CrossRef]

- Fereidoon, A.; Ghorbanzadeh Ahangari, M.; Jahanshahi, M. Effect of nanoparticles on the morphology and thermal properties of self-healing poly (urea-formaldehyde) microcapsules. J. Polym. Res. 2013, 20, 151. [Google Scholar] [CrossRef]

- Li, J.; Cui, J.; Yang, J.; Li, Y.; Qiu, H.; Yang, J. Reinforcement of graphene and its derivatives on the anticorrosive properties of waterborne polyurethane coatings. Compos. Sci. Technol. 2016, 129, 30–37. [Google Scholar] [CrossRef]

- Su, Y.; Kravets, V.; Wong, S.; Waters, J.; Geim, A.K.; Nair, R.R. Impermeable barrier films and protective coatings based on reduced graphene oxide. Nat. Commun. 2014, 5, 4843. [Google Scholar] [CrossRef]

- Yu, F.; Feng, H.; Xiao, L.; Liu, Y. Fabrication of graphene oxide microcapsules based on Pickering emulsions for self-healing water-borne epoxy resin coatings. Prog. Org. Coat. 2021, 155, 106221. [Google Scholar] [CrossRef]

- Meng, L.M.; Yuan, Y.C.; Rong, M.Z.; Zhang, M.Q. A dual mechanism single-component self-healing strategy for polymers. J. Mater. Chem. 2010, 20, 6030–6038. [Google Scholar] [CrossRef]

- Indhumathi, S.; Dinesh, A.; Pichumani, M. Diverse perspectives on self healing ability of Engineered Cement Composite–All-inclusive insight. Constr. Build. Mater. 2022, 323, 126473. [Google Scholar]

- Shang, X.; Zhan, B.; Li, J.; Zhong, R. Novel microcapsules for internal curing of high-performance cementitious system. Sci. Rep. 2020, 10, 8318. [Google Scholar] [CrossRef] [PubMed]

- Ma, W.; Sun, D.; Ma, X.; Cui, S. Preparation and investigation of self-healing cementitious composite based on DMTDA-epoxy binary microcapsules system. J. Build. Eng. 2022, 56, 104779. [Google Scholar] [CrossRef]

- Lv, L.; Yang, Z.; Chen, G.; Zhu, G.; Han, N.; Schlangen, E.; Xing, F. Synthesis and characterization of a new polymeric microcapsule and feasibility investigation in self-healing cementitious materials. Constr. Build. Mater. 2016, 105, 487–495. [Google Scholar] [CrossRef]

- Lv, L.; Tang, J.; Xiao, F.; Schlangen, E.; Zhu, G.; Han, N.; Xing, F. Applying nano-indentation to measure micromechanical properties of phenol–formaldehyde microcapsules for self-healing cement based materials. In Proceedings of the Fifth International Conference on Self-Healing Materials, Durham, NC, USA, 22–24 June 2015; pp. 22–24. [Google Scholar]

- Calvo, J.G.; Pérez, G.; Carballosa, P.; Erkizia, E.; Gaitero, J.; Guerrero, A. Development of ultra-high performance concretes with self-healing micro/nano-additions. Constr. Build. Mater. 2017, 138, 306–315. [Google Scholar] [CrossRef]

- Du, W.; Yu, J.; He, B.; He, Y.; He, P.; Li, Y.; Liu, Q. Preparation and characterization of nano-SiO2/paraffin/PE wax composite shell microcapsules containing TDI for self-healing of cementitious materials. Constr. Build. Mater. 2020, 231, 117060. [Google Scholar] [CrossRef]

- Dong, K.; Ni, G.; Nie, B.; Xu, Y.; Wang, G.; Sun, L.; Liu, Y. Effect of polyvinyl alcohol/aluminum microcapsule expansion agent on porosity and strength of cement-based drilling sealing material. Energy 2021, 224, 119966. [Google Scholar] [CrossRef]

- Salmana, R.T.; Abdul-Hamead, A.A.; Othman, F.M. Investigation of the Effect of Microcapsule Additive on Mechanical and Physical Properties of Concrete. Eng. Technol. J. 2021, 39, 1639–1645. [Google Scholar] [CrossRef]

- Du, W.; Liu, Q.; Lin, R.; Yu, J. Influence of external environment on self-repairing ability of the cement-based materials containing paraffin/toluene-di-isocyanate microcapsules. Constr. Build. Mater. 2021, 281, 122584. [Google Scholar] [CrossRef]

- Du, W.; Yu, J.; Gu, S.; Wang, R.; Li, J.; Han, X.; Liu, Q. Effect of temperatures on self-healing capabilities of concrete with different shell composition microcapsules containing toluene-di-isocyanate. Constr. Build. Mater. 2020, 247, 118575. [Google Scholar] [CrossRef]

- Jiang, W.; Zhou, G.; Duan, J.; Liu, D.; Zhang, Q.; Tian, F. Synthesis and characterization of a multifunctional sustained-release organic–inorganic hybrid microcapsule with self-healing and flame-retardancy properties. ACS Appl. Mater. Interfaces 2021, 13, 15668–15679. [Google Scholar] [CrossRef]

- Qiao, Y.; Wan, J.; Zhou, L.; Ma, W.; Yang, Y.; Luo, W.; Yu, Z.; Wang, H. Stimuli-responsive nanotherapeutics for precision drug delivery and cancer therapy. Wiley Interdiscip. Rev. Nanomed. Nanobiotechnol. 2019, 11, e1527. [Google Scholar] [CrossRef] [PubMed]

- Siegel, R.A.; Rathbone, M.J. Overview of controlled release mechanisms. In Fundamentals and Applications of Controlled Release Drug Delivery; Springer: Boston, MA, USA, 2011; pp. 19–43. [Google Scholar]

- Wiktor, V.; Jonkers, H. Bacteria-based concrete: From concept to market. Smart Mater. Struct. 2016, 25, 084006. [Google Scholar] [CrossRef]

- Feng, J.; Chen, B.; Sun, W.; Wang, Y. Microbial induced calcium carbonate precipitation study using Bacillus subtilis with application to self-healing concrete preparation and characterization. Constr. Build. Mater. 2021, 280, 122460. [Google Scholar] [CrossRef]

- Ren, Y.; Zhu, G.; Tang, J. Synthesis of cement shell microcapsules via W/O Pickering emulsions. Colloids Surf. A Physicochem. Eng. Asp. 2020, 584, 124073. [Google Scholar] [CrossRef]

- Huang, J.; Zhu, Y.; Ma, Y.; Hu, J.; Huang, H.; Wei, J.; Yu, Q. pH-Triggered Release Performance of Microcapsule-Based Inhibitor and Its Inhibition Effect on the Reinforcement Embedded in Mortar. Materials 2021, 14, 5517. [Google Scholar] [CrossRef]

- Stefanoni, M.; Angst, U.; Elsener, B. Corrosion rate of carbon steel in carbonated concrete—A critical review. Cem. Concr. Res. 2018, 103, 35–48. [Google Scholar] [CrossRef]

- Fan, L.; Bao, Y.; Meng, W.; Chen, G. In-situ monitoring of corrosion-induced expansion and mass loss of steel bar in steel fiber reinforced concrete using a distributed fiber optic sensor. Compos. Part B Eng. 2019, 165, 679–689. [Google Scholar] [CrossRef]

- Mennucci, M.; Banczek, E.; Rodrigues, P.; Costa, I. Evaluation of benzotriazole as corrosion inhibitor for carbon steel in simulated pore solution. Cem. Concr. Compos. 2009, 31, 418–424. [Google Scholar] [CrossRef]

- Selvakumar, N.; Jeyasubramanian, K.; Sharmila, R. Smart coating for corrosion protection by adopting nano particles. Prog. Org. Coat. 2012, 74, 461–469. [Google Scholar] [CrossRef]

- Shi, X.; Nguyen, T.A.; Suo, Z.; Liu, Y.; Avci, R. Effect of nanoparticles on the anticorrosion and mechanical properties of epoxy coating. Surf. Coat. Technol. 2009, 204, 237–245. [Google Scholar] [CrossRef]

- Jia, Z.; Xiong, P.; Shi, Y.; Zhou, W.; Cheng, Y.; Zheng, Y.; Xi, T.; Wei, S. Inhibitor encapsulated, self-healable and cytocompatible chitosan multilayer coating on biodegradable Mg alloy: A pH-responsive design. J. Mater. Chem. B 2016, 4, 2498–2511. [Google Scholar] [CrossRef] [PubMed]

- Lv, L.; Guo, P.; Xing, F.; Han, N. Trigger efficiency enhancement of polymeric microcapsules for self-healing cementitious materials. Constr. Build. Mater. 2020, 235, 117443. [Google Scholar] [CrossRef]

- Chen, K.; Zhou, S. Fabrication of ultraviolet-responsive microcapsules via Pickering emulsion polymerization using modified nano-silica/nano-titania as Pickering agents. RSC Adv. 2015, 5, 13850–13856. [Google Scholar] [CrossRef]

- Cong, Y.; Chen, K.; Zhou, S.; Wu, L. Synthesis of pH and UV dual-responsive microcapsules with high loading capacity and their application in self-healing hydrophobic coatings. J. Mater. Chem. A 2015, 3, 19093–19099. [Google Scholar] [CrossRef]

- Li, E.; Du, W.; Zhuang, R.; Ba, M.; Yuan, L.; Zhang, Q.; Zhang, Y. Preparation and characterization of electromagnetic-induced rupture microcapsules for self-repairing mortars. Materials 2022, 15, 3608. [Google Scholar] [CrossRef] [PubMed]

- Song, Z.; Liu, Y.; Jiang, L.; Pei, C.; Xu, N.; Chu, H.; Guo, M. Using ultrasonic wave to trigger microcapsule inhibitor against chloride-induced corrosion of carbon steel in simulated concrete pore solution. Constr. Build. Mater. 2021, 311, 125331. [Google Scholar] [CrossRef]

- Li, Y.; Yu, J.; Cao, Z.; He, P.; Liu, Q.; Han, X.; Wan, Y. Preparation and application of novel microcapsules ruptured by microwave for self-healing concrete. Constr. Build. Mater. 2021, 304, 124616. [Google Scholar] [CrossRef]

- Huang, B.; Chen, F.; Shen, Y.; Qian, K.; Wang, Y.; Sun, C.; Zhao, X.; Cui, B.; Gao, F.; Zeng, Z. Advances in targeted pesticides with environmentally responsive controlled release by nanotechnology. Nanomaterials 2018, 8, 102. [Google Scholar] [CrossRef] [PubMed]

- Hong, S.; Qin, S.; Dong, B.; Xing, F. Corrosion features of the reinforcing bar in concrete with intelligent OH− regulation of microcapsules. Materials 2019, 12, 3966. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Fang, G.; Ding, W.; Han, N.; Xing, F.; Dong, B. Self-immunity microcapsules for corrosion protection of steel bar in reinforced concrete. Sci. Rep. 2015, 5, 18484. [Google Scholar] [CrossRef] [PubMed]

- Parkin, I.P.; Palgrave, R.G. Self-cleaning coatings. J. Mater. Chem. 2005, 15, 1689–1695. [Google Scholar] [CrossRef]

- Yang, Y.; He, J.; Li, Q.; Gao, L.; Hu, J.; Zeng, R.; Qin, J.; Wang, S.X.; Wang, Q. Self-healing of electrical damage in polymers using superparamagnetic nanoparticles. Nat. Nanotechnol. 2019, 14, 151–155. [Google Scholar] [CrossRef]

- Hussain, M.; Sikandar, M.A.; Nasir, A.; Ahmed, W. Effect of SiO2 coated leuco-dye based thermochromic pigment on the properties of Portland cement pastes. J. Build. Eng. 2021, 35, 102019. [Google Scholar] [CrossRef]

- Wang, X.; Li, Y.; Zhang, C.; Zhang, X. Visualization and quantification of self-healing behaviors of microcracks in cement-based materials incorporating fluorescence-labeled self-healing microcapsules. Constr. Build. Mater. 2022, 315, 125668. [Google Scholar] [CrossRef]

| Nanomaterial | Performance and Function | Contents of Nanomaterial | Variation | References |

|---|---|---|---|---|

| Zinc oxide | Improves the sealing of concrete cracks | 1.0 wt% | Increase to 58.9% | [31] |

| Titania | Retards aging and response to ultraviolet light | 2.5 wt% | Increase to 60% | [33] |

| Silica | Improves repair efficiency and emulsion stability | 10.0 wt% | Increase to 1.3 × 106 Ω⋅cm2 | [34] |

| Alumina (Al2O3) | Increases hardness | 5.0 wt% | Increase to 41.3 | [35] |

| Iron(II,III) oxide | Response to electromagnetic waves | 6.0 wt% | Increase to 91.4% | [19] |

| Calcium carbonate | Improves the rate of recovery of compressive strength | 3.0 wt% | Increase to 87.8% | [36] |

| Carbon nanotubes (CNTs) | Reduce specific wear rate | 20.0 wt% | Reduce about 74.27% | [37] |

| Graphene oxide | Increases encapsulation efficiency and emulsion stability | 10.0 wt% | Increase to 106 Ω | [38] |

| Al2O3–CNTs | Increases water resistance | — | Increase to 50° | [39] |

| Response Types | Materials | Literature |

|---|---|---|

| Mechanical response | UF resin, LO, corrosion inhibitors (CeO2 and Cr2O3) | [94] |

| Dopamine, CNTs | [37] | |

| PH response | Porous ceramic precoat, cerium nanoparticles, chitosan multilayers | [95] |

| EC, calcium oxide | [96] | |

| Silane coupling agent [3-(2-aminoethylamino)propyl]trimethoxysilane, polyphenol formaldehyde | [97] | |

| UV response | Fluoroalkylsilane, SiO2, TiO2 | [98] |

| Nano-SiO2, nano-TiO2, 2-(N,N-diethylamino)ethyl methacrylate, n-hexadecane | [99] | |

| Electromagnetic or ultrasonic wave response | Nano-Fe3O4, paraffin, toluene-di-isocyanate | [19] |

| Fe3O4 nanoparticles, polyethylene, wax epoxy resin | [100] | |

| Epoxy resin E-51, emulsifier BGE, sodium dodecyl benzene sulfonate, NaNO2, urea formaldehyde prepolymer | [101] | |

| Paraffin, polyethylene wax (PEW), graphite, toluene-di-isocyanate | [102] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, X.; Zhang, S.; Qi, X.; Guo, S.; Ren, R. Status of Research on the Use of Nanomodified Microcapsules in Cement-Based Materials. Processes 2024, 12, 128. https://doi.org/10.3390/pr12010128

Xie X, Zhang S, Qi X, Guo S, Ren R. Status of Research on the Use of Nanomodified Microcapsules in Cement-Based Materials. Processes. 2024; 12(1):128. https://doi.org/10.3390/pr12010128

Chicago/Turabian StyleXie, Xiaoman, Sulei Zhang, Xiaoqiang Qi, Siyao Guo, and Rui Ren. 2024. "Status of Research on the Use of Nanomodified Microcapsules in Cement-Based Materials" Processes 12, no. 1: 128. https://doi.org/10.3390/pr12010128