Low-Carbon Economic Dispatch of Virtual Power Plant Considering Hydrogen Energy Storage and Tiered Carbon Trading in Multiple Scenarios

Abstract

:1. Introduction

- (1)

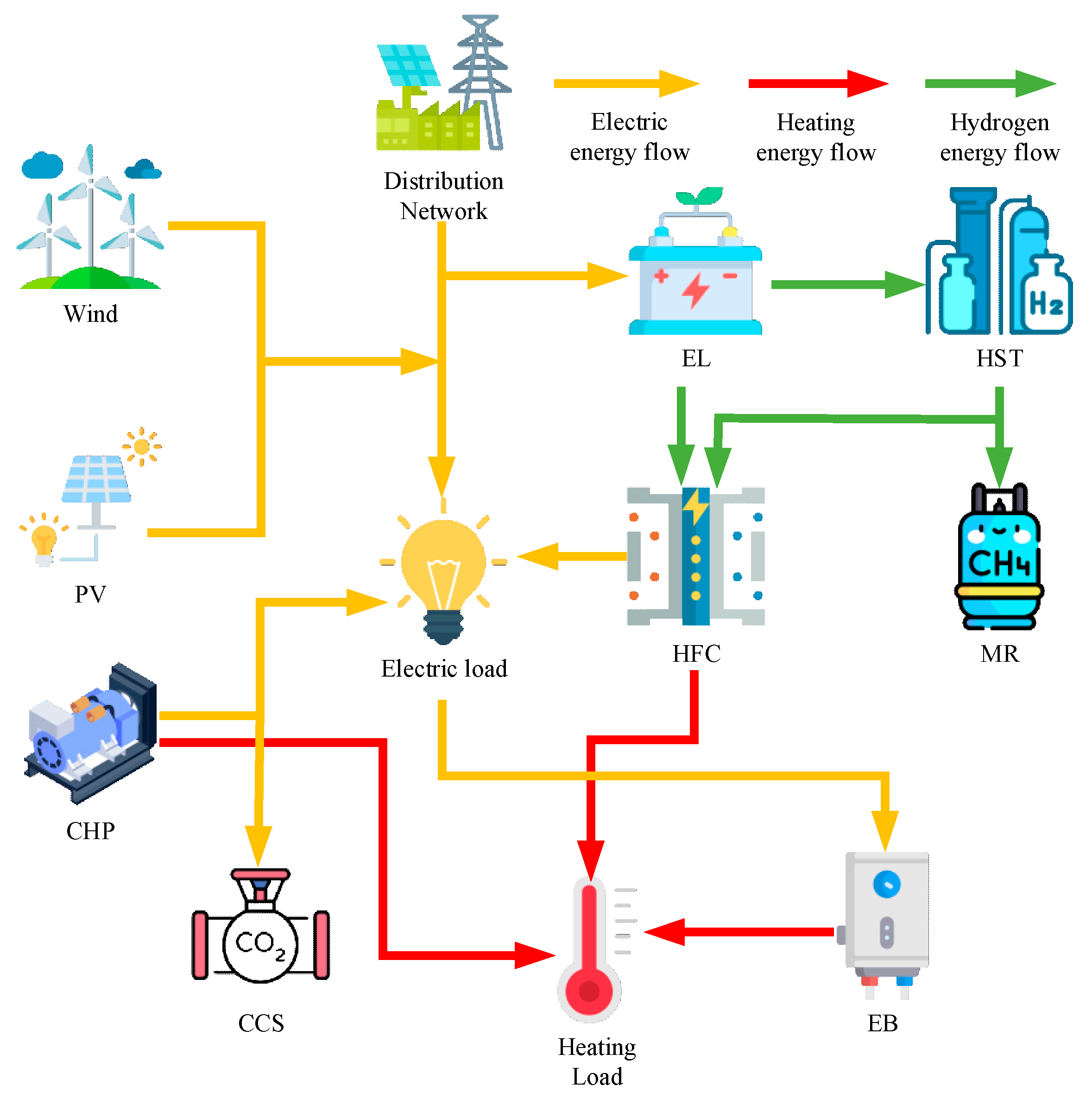

- A new VPP structure is designed by integrating hydrogen energy storage and carbon capture into the traditional VPP. The surplus wind and solar resources are converted into hydrogen energy through hydrogen storage, and the carbon emissions from CHP generation are captured and stored or transported to MR, and CO2 is converted into CH4, achieving the optimization effect of the electric–thermal–carbon–hydrogen cycle.

- (2)

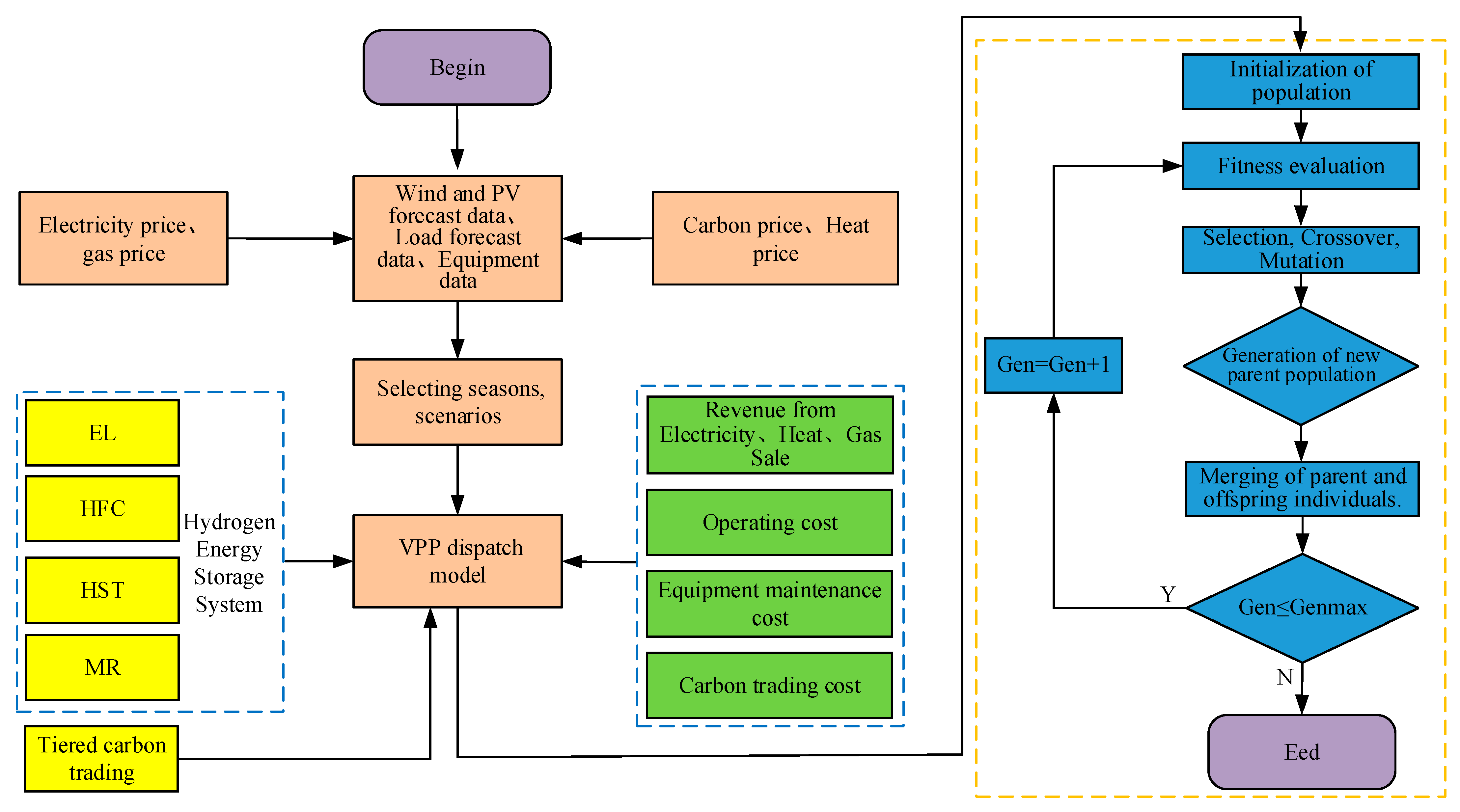

- Based on the new VPP structure, a low-carbon economic scheduling model is established considering the tiered carbon trading, which takes into account factors such as revenue, renewable energy consumption, and carbon emissions. The model is solved using a genetic algorithm.

- (3)

- Different scheduling strategies are proposed for three different scenarios: cooling season, transition season, and heating season. By selecting some parameters for comprehensive comparison, it shows that the proposed scheduling approach has high practicality and economic benefits, effectively improving the VPP’s ability to integrate renewable energy generation, mitigating the problem of mismatch between renewable energy output and load demand, achieving source–load balance, promoting VPP’s low-carbon transformation, strengthening electric–thermal load coupling and complementary use, and has strong academic significance and engineering application value.

2. Framework for VPP Operation with Hydrogen Storage and Carbon Trading

2.1. Composition of Virtual Power Plant (VPP)

2.2. Hydrogen Energy Storage Model and Methanation Process

- (1)

- Electrolysis cell equipment (EL)

- (2)

- Hydrogen fuel cell (HFC)

- (3)

- Hydrogen storage tank (HST)

- (4)

- Methane reactor (MR)

2.3. Tiered Carbon-Trading Model

- (1)

- VPP Carbon-Emission Quota Allocation Model.

- (2)

- Actual Carbon Emissions of VPP

- (3)

- Tiered Carbon-Trading Model.

3. Virtual Power Plant Low-Carbon Economic Dispatch Model

3.1. Objective Function

3.1.1. Revenue from Selling Electricity, Heat, and Gas for a Virtual Power Plant (VPP)

3.1.2. Operating Cost of a Virtual Power Plant (VPP)

- (1)

- The Fuel Cost of Combined Heat and Power (CHP) Units

- (2)

- The Purchased Electricity Cost

- (3)

- The Cost of Curtailment for Wind and Solar Power

- (4)

- Cost of CO2 Capture and Storage (CCS)

- (5)

- Environmental Cost of VPP

3.1.3. Operational and Maintenance Cost of VPP

- (1)

- Operational and Maintenance Cost of Hydrogen Energy Storage System

- (2)

- Operational and Maintenance Cost of Carbon-Capture Power Plants [34].

- (3)

- Operational and Maintenance Cost of Electric Boiler

3.1.4. Carbon-Trading Cost

3.2. Constraint Conditions

3.2.1. The Constraint on Wind and Solar Power Output

3.2.2. The Constraint of Electricity Balance

3.2.3. The Constraint of Thermal Balance

3.2.4. The Constraint of Hydrogen Power Balance

3.2.5. The Constraints of the Hydrogen Energy Storage System

3.2.6. The Constraints on Carbon-Capture Quantity for CCS

3.2.7. Capacity Constraint of Electric Boiler

3.2.8. Constraint on Electric–Thermal Conversion of Electric Boiler

3.2.9. Constraints on Thermal and Electric Output and Ramping of CHP Units

3.2.10. Operational Region Constraints for Combined Heat and Power Generation

3.3. Algorithm Flowchart for Model Solving

4. Case Study Analysis

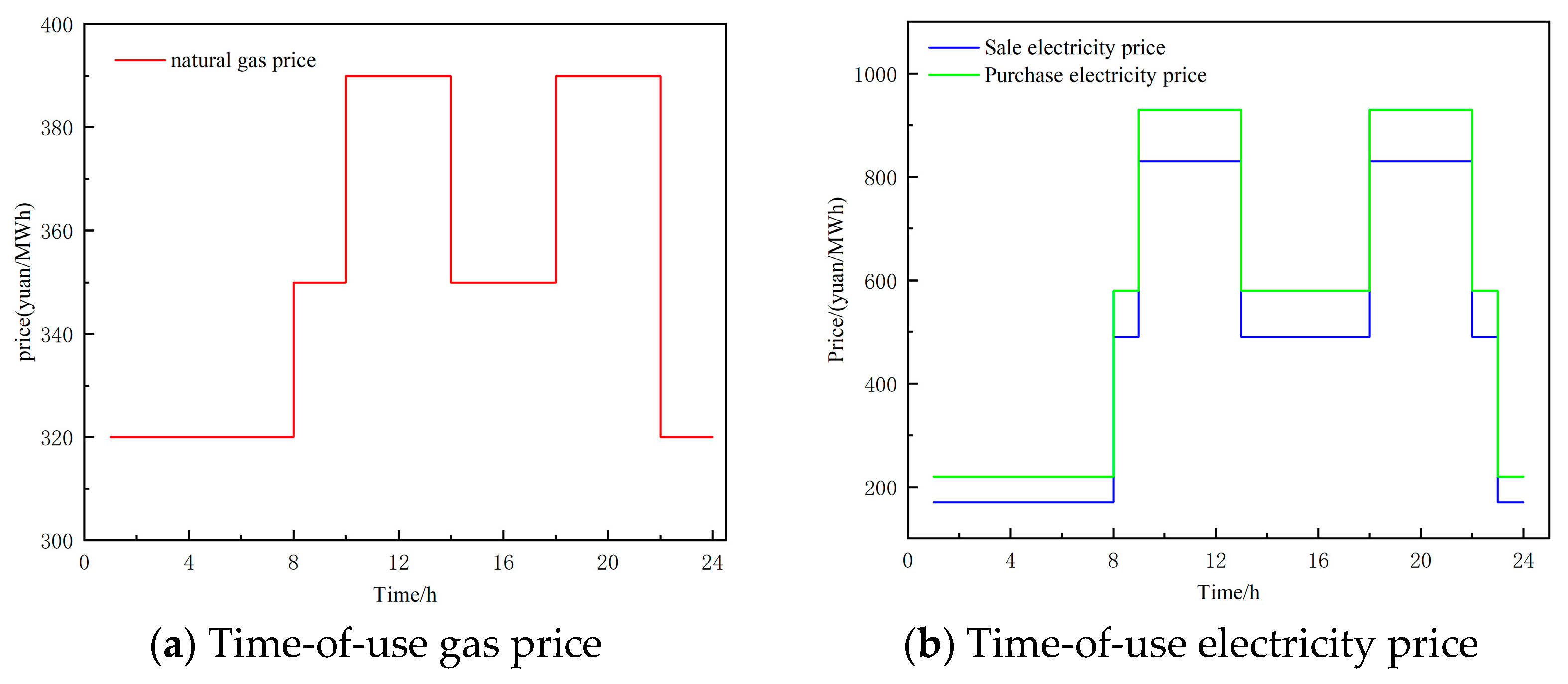

4.1. Case Study Parameters

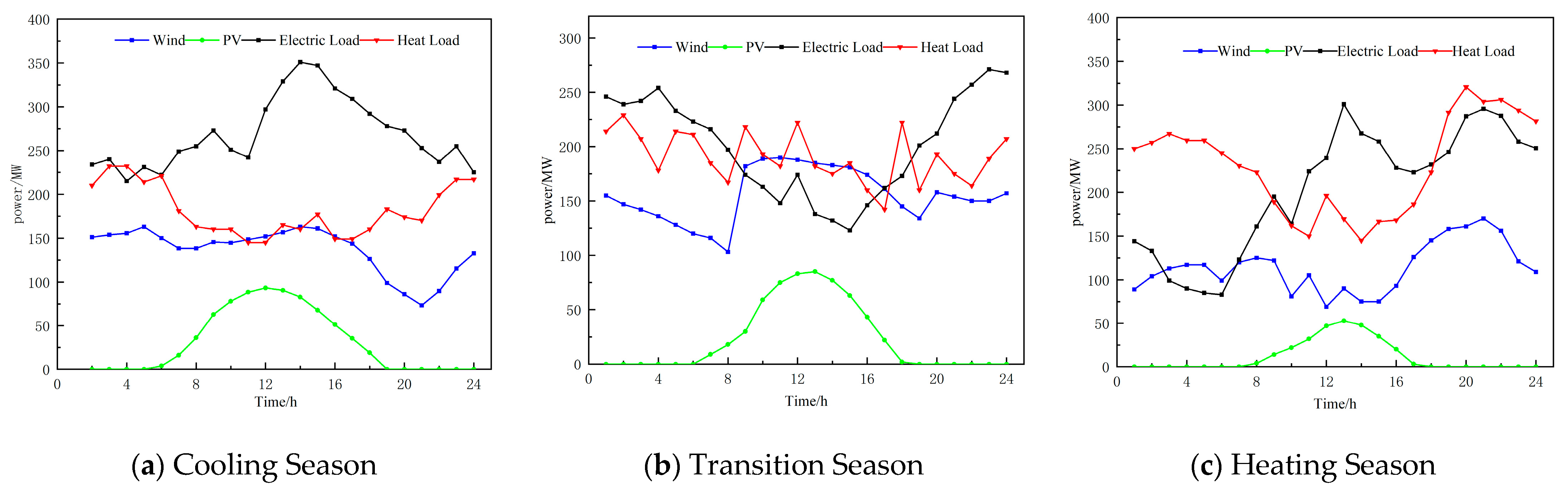

4.2. Scenario Setting

4.3. Analysis of Scheduling Results under Different Scenarios

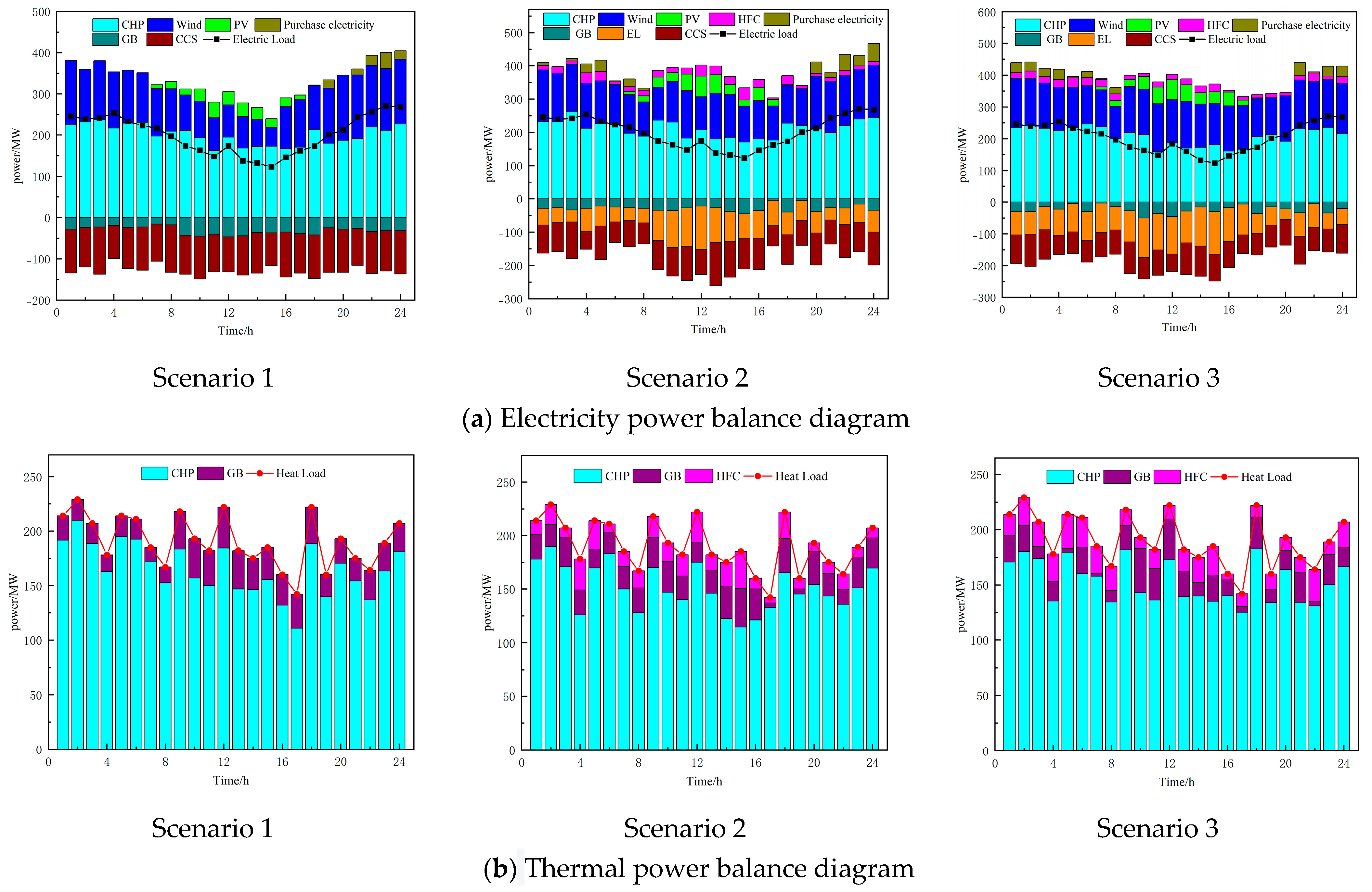

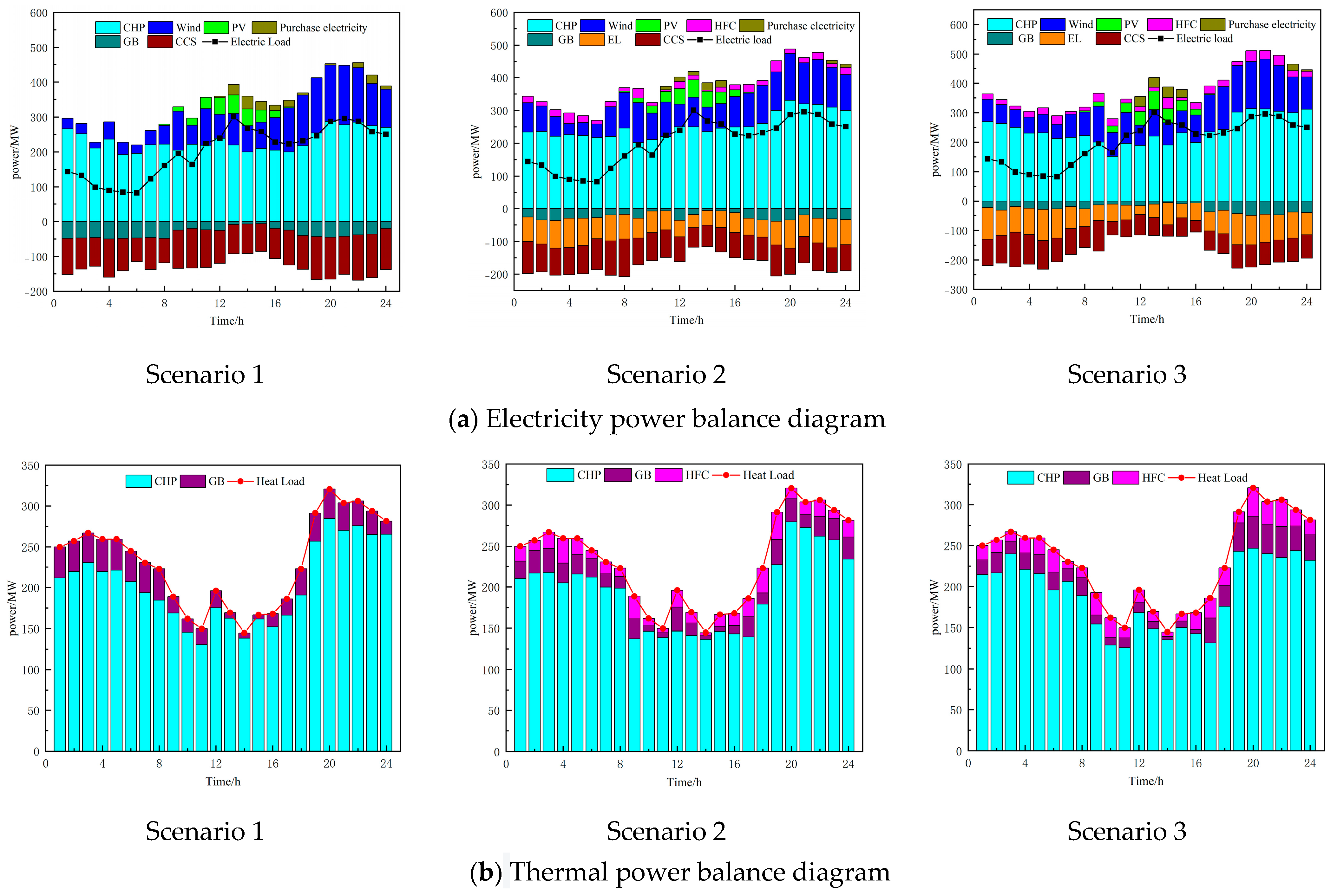

4.3.1. Analysis of Scheduling Results during the Cooling Season

4.3.2. Analysis of Scheduling Results during the Transition Season

4.3.3. Analysis of Scheduling Results during the Heating Season

4.4. Sensitivity Analysis of VPP System Parameters

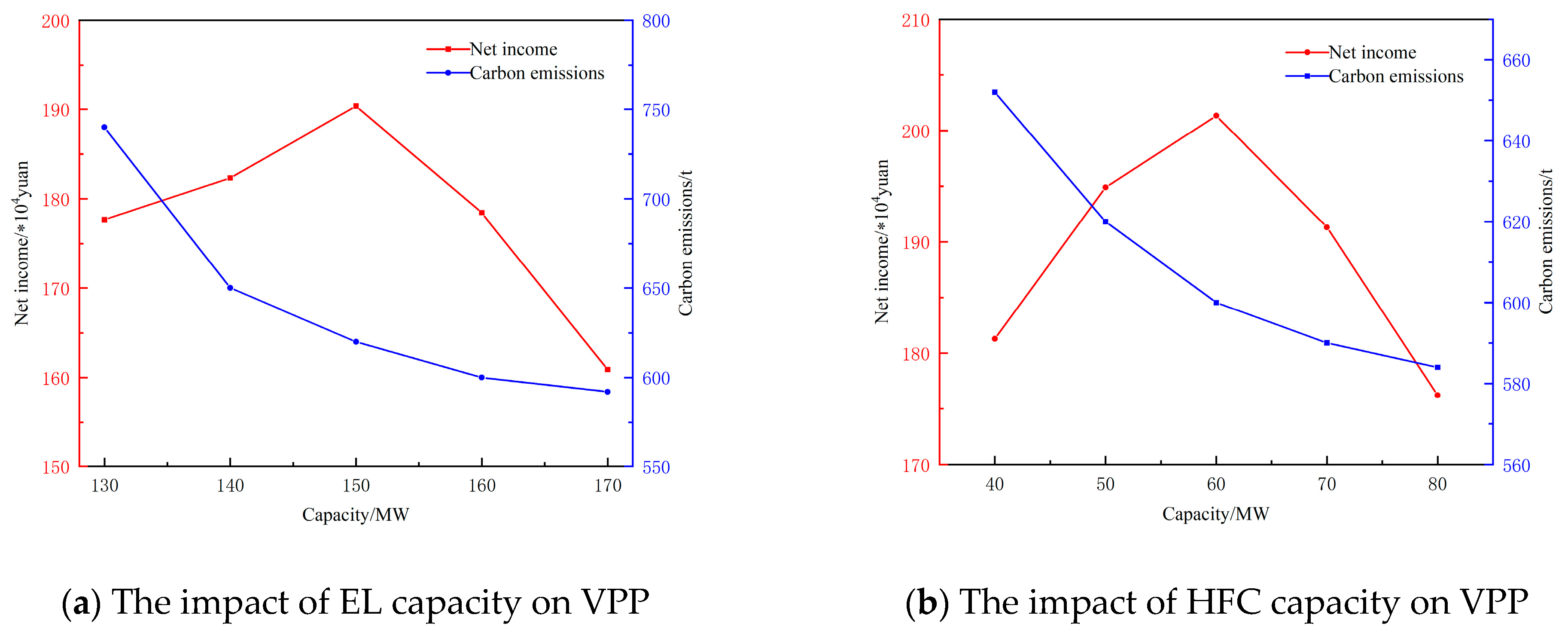

4.4.1. Sensitivity Analysis of Hydrogen Energy Storage System Equipment Capacity

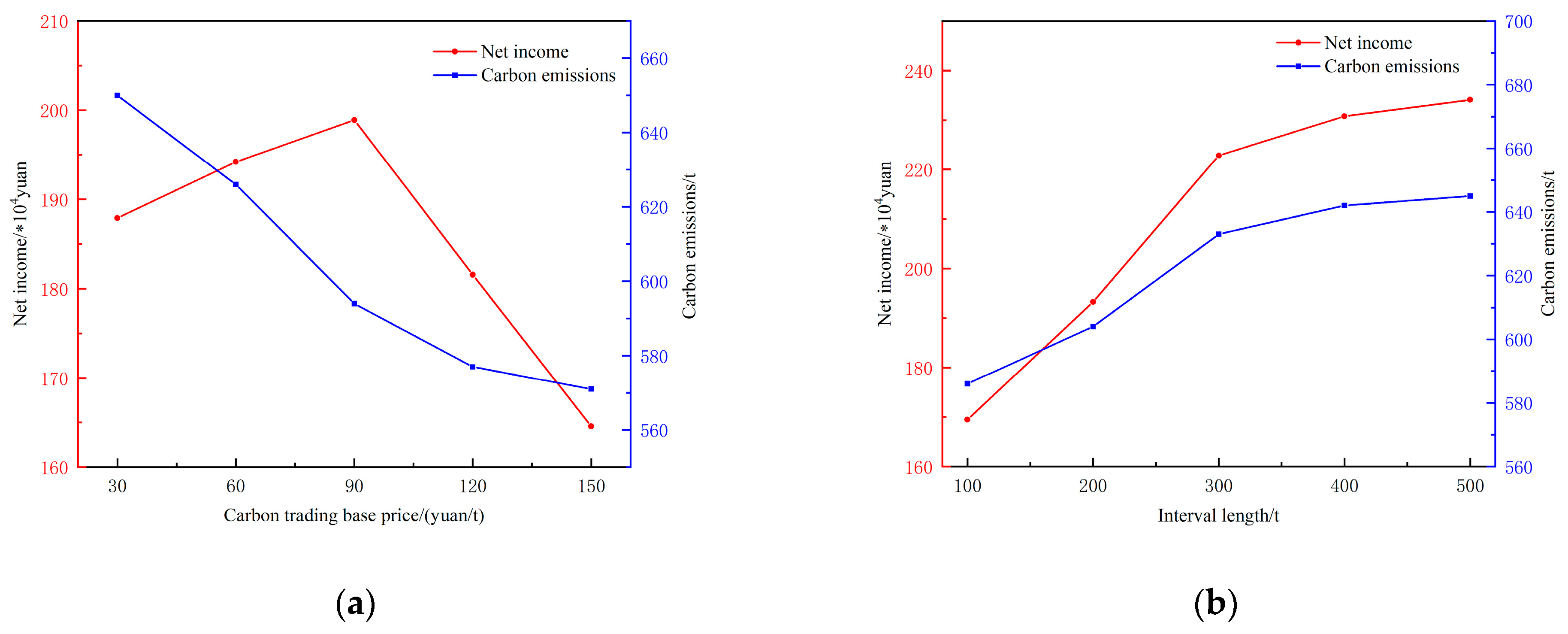

4.4.2. Sensitivity Analysis of Carbon-Trading Parameters

5. Conclusions

- (1)

- Introducing a hydrogen energy storage system and the tiered carbon-trading mechanism based on carbon capture facilitates carbon reuse. On one hand, it reduces carbon emissions from the VPP and increases the integration of renewable energy. On the other hand, the generated methane can be supplied to the natural gas consumption system, further enhancing the economic benefits of the VPP.

- (2)

- Through the collaborative operation of multiple units, the coupling of hydrogen energy storage and an electric boiler enables the decoupling of heat and power in combined heat and power (CHP) units. This effectively optimizes the output of CHP units, improves their operational flexibility and peak-shaving ability, reduces coal consumption cost, lowers carbon emissions, enhances the utilization of renewable energy generation, and mitigates the contradiction between renewable energy generation and electricity demand. It achieves a balance between supply and demand, optimizes the energy structure of the VPP, and improves its economic benefits.

- (3)

- Sensitivity analysis of the VPP’s low-carbon economic conditions is conducted by considering different parameters for the tiered carbon trading and the capacity of hydrogen energy storage devices. The results demonstrate that reasonable parameter settings and capacity configurations are more conducive to reducing carbon emissions and increasing the economic benefits of the VPP.

- (4)

- Lastly, three scenarios are established to comprehensively compare the scheduling results of different scenarios in the same season, considering different load inputs. This validates the practicality of the proposed model and demonstrates that the optimization and scheduling approach has high generality and economic benefits, effectively improving the VPP’s ability to integrate renewable energy generation and reduce carbon emissions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Wind | Wind Power |

| PV | Photovoltaic Power |

| CHP | Combined Heat and Power Units |

| CCS | Carbon Capture and Storage |

| EL | Electrolyzer |

| HFC | Hydrogen Fuel Cell |

| MR | Methane Reactor |

| HST | Hydrogen Storage Tank |

| EB | Electric Boiler |

| VPP | Virtual power plant |

| IES | Integrated Energy System |

| CCPP | Carbon-Capture Power Plant |

| The electrical energy input to EL in time period t | |

| The energy conversion efficiency of EL | |

| The hydrogen energy output from EL in time period t | |

| The upper limit of electrical energy input to EL | |

| The lower limit of electrical energy input to EL | |

| The upper limit of EL’s ramp rate | |

| The lower limit of EL’s ramp rate | |

| The hydrogen energy input to the HFC in time period t | |

| The hydrogen-to-electricity conversion efficiency of the HFC | |

| The hydrogen-to-thermal energy conversion efficiency of the HFC | |

| The upper limit of the hydrogen energy input to the HFC | |

| The lower limit of the hydrogen energy input to the HFC | |

| The upper limit of the ramp rate of the HFC | |

| The lower limit of the ramp rate of the HFC | |

| The hydrogen charging efficiency of the hydrogen storage tank | |

| The hydrogen discharging efficiency of the hydrogen storage tank | |

| The hydrogen storage level of the hydrogen storage tank at time t | |

| The upper limit of the hydrogen storage tank capacity | |

| The lower limit of the hydrogen storage tank capacity | |

| T | The scheduling period, which is 24 h |

| The scheduling step size is 1 h | |

| The hydrogen power input to the methane reactor in time period t | |

| The methane power output | |

| The conversion efficiency of the methane reactor | |

| The upper limit of the hydrogen power input | |

| The lower limit of the hydrogen power input | |

| The upper limit of the ramp rate of the MR | |

| The lower limit of the ramp rate of the MR | |

| The carbon-emission quota for unit heat supply | |

| The conversion factor for converting electricity generation into heat supply | |

| The carbon-emission quota assigned to unit purchased electricity | |

| The electrical power input from the superior power grid to VPP | |

| The carbon-emission calculation parameters for purchased electricity power | |

| The carbon-emission calculation parameters for CHP output | |

| The parameter for CO2 absorption during the hydrogen-to-natural-gas conversion process in the MR equipment | |

| The index of the CHP unit | |

| The total number of CHP units in the VPP | |

| The base carbon-trading price | |

| The length of the carbon-emission range | |

| The rate of price increase | |

| The fitting coefficient for the coal consumption characteristics of the CHP unit | |

| The unit price of standard coal | |

| The control cost of the jth pollutant | |

| The amount of the jth pollutant emitted per unit output of the CHP unit | |

| The penalty cost for emitting the jth pollutant by the CHP unit | |

| The proportion of operational and maintenance costs to the total cost | |

| The line loss rate | |

| The service life | |

| The proportion of annual maintenance costs of the EB to the total construction cost | |

| The installation cost required for a unit capacity of EB | |

| The upper limit of ramping rate for the ith CHP unit | |

| The lower limit of ramping rate for the ith CHP unit | |

| The thermal output corresponding to the minimum electric output of the i-th CHP unit | |

| The decrease in maximum output under constant turbine intake when extracting a unit of heat for the ith unit | |

| The decrease in minimum output under constant turbine intake when extracting a unit of heat for the ith unit | |

| The coefficient of the ratio between electric output and thermal output when the ith CHP unit operates under back pressure conditions |

References

- Kong, X.; Xiao, J.; Wang, C.; Cui, K.; Jin, Q.; Kong, D. Bi-level multi-time scale scheduling method based on bidding formulti-operator virtual power plant. Appl. Energy 2019, 249, 178–189. [Google Scholar] [CrossRef]

- Wei, C.; Xu, J.; Liao, S.; Sun, Y.; Jiang, Y.; Ke, D.; Zhang, Z.; Wang, J. A bi-level scheduling model for virtual power plants with aggregated thermostatically controlled loads and renewable energy. Appl. Energy 2018, 224, 659–670. [Google Scholar] [CrossRef]

- Naval, N.; Yusta, J.M. Virtua l power plant models and electricity markets-A review, Renewable and Sustainable. Energy Rev. 2021, 149, 111393. [Google Scholar]

- Wang, X.; Liu, Q. Development and practice of virtual power plant participating in power grid regulation and market operation. Autom. Electr. Power Syst. 2022, 46, 158–168. [Google Scholar]

- Xue, G.Y.; Wu, C.; Wang, H.R.; Zhang, H.M.; Li, Y.; Cui, M.L. Coordinated development mechanism of carbon market and power market under carbon peak and Neutrality goals. Electr. Power Sci. Eng. 2022, 38, 1–7. [Google Scholar]

- Ning, L.; Yuan, T.M.; Wu, H.T. New power system based on renewable energy in the context of dual carbon. Int. Trans. Electr. Energy Syst. 2022, 2022, 6428791. [Google Scholar] [CrossRef]

- Fang, G.; Chen, G.; Yang, K.; Yin, W.; Tian, L. Can green tax policy promote China’s energy transformation?—A nonlinear analysis from production and consumption perspectives. Energy 2023, 269, 126818. [Google Scholar] [CrossRef]

- Wang, S.Y.; Wu, W.C. Aggregate flexibility of Virtual power plant with temporal coupling constraints. IEEE Trans. Smart Grid 2021, 12, 5043–5051. [Google Scholar] [CrossRef]

- Wang, W.Y.; Liu, H.T.; Ji, Y. Unified modeling of virtual power plant adjustable space and optimal operation strategy for participating in peak shaving market. Autom. Electr. Power Syst. 2022, 46, 74–82. [Google Scholar]

- Falabretti, D.; Gulotta, F.; Siface, D. Scheduling and operation of RES-based virtual power plants with e-mobility: A novel integrated stochastic model. Int. J. Electr. Power Energy Syst. 2023, 144, 108604. [Google Scholar] [CrossRef]

- Gougheri, S.S.; Dehghani, M.; Nikoofard, A.; Jahangir, H.; Golkar, M.A. Economic assessment of multi-operator virtual power plants in electricity market: A game theory-based approach. Sustain. Energy Technol. Assess. 2022, 53, 102733. [Google Scholar] [CrossRef]

- Rotas, R.; Fotopoulou, M.; Drosatos, P.; Rakopoulos, D.; Nikolopoulos, N. Adaptive Dynamic Building Envelopes with Solar Power Components: Annual Performance Assessment for Two Pilot Sites. Energies 2023, 16, 2148. [Google Scholar] [CrossRef]

- Wang, Y.; Hao, L.; Zheng, L.; Chen, L.; Xu, F.; Chen, Q.; Min, Y. Low-Carbon Economic Dispatch of Electricity and Cooling Energy System. Processes 2023, 11, 2787. [Google Scholar] [CrossRef]

- MacDowell, N.; Florin, N.; Buchard, A.; Hallett, J.; Galindo, A.; Jackson, G.; Adjiman, C.S.; Williams, C.K.; Shah, N.; Fennell, P. An overview of CO2 capture technologies. Energy Environ. Sci. 2010, 3, 1645–1669. [Google Scholar] [CrossRef]

- Cui, Y.; Zeng, P.; Hui, X.; Li, H.; Zhao, J. Economic dispatch model of virtual power plant considering electricity consumption under a carbon trading mechanism. Power Syst. Technol. 2021, 45, 1877–1886. [Google Scholar]

- Zhou, R.; Sun, H.; Tang, X.; Zhang, W.; Yu, H. Economic dispatch model of virtual power plant considering electricity consumption under a carbon trading mechanism. Proc. CSEE 2018, 38, 1675–1683. [Google Scholar]

- Chen, D.; Liu, F.; Liu, S. Optimization of virtual power plant scheduling coupling with P2G-CCS and doped with gas hydrogen based on stepped carbon trading. Power Syst. Technol. 2022, 46, 2042–2054. [Google Scholar]

- Zhong, W.; Huang, S.; Cui, Y.; Xu, J.; Zhao, Y. Capture coordination in virtual power plant considering source-load uncertainty. Power Syst. Technol. 2020, 44, 3424–3432. [Google Scholar]

- Zhang, X.; Liu, X.; Zhong, J. Integrated energy system planning considering a reward and punishment ladder-type carbon trading and electric-thermal transfer load uncertainty. Proc. CSEE 2020, 40, 6132–6141. [Google Scholar]

- Zou, Y.; Zeng, A.; Hao, S.; Ning, J.; Ni, L. Multi-time-scale Optimal Scheduling of Integrated Energy Systems Under Stepped Carbon Trading Mechanism. Proc. CSEE 2023, 47, 2185–2198. [Google Scholar]

- Li, Y.; Han, M.; Shahidehpour, M.; Li, J.; Long, C. Data-driven distributionally robust scheduling of community integrated energy systems with uncertain renewable generations considering integrated demand response. Appl. Energy 2023, 335, 120749. [Google Scholar] [CrossRef]

- Cui, Y.; Zeng, P.; Zhong, W.; Cui, W.; Zhao, Y. Low-carbon economic dispatch of electricity-gas-heat integrated energy system based on ladder-type carbon trading. Electr. Power Autom. Equip. 2021, 41, 10–17. [Google Scholar]

- Li, Y.; Wang, B.; Yang, Z.; Li, J.; Chen, C. Hierarchical stochastic scheduling of multi-community integrated energy systems in uncertain environments via Stackelberg game. Appl. Energy 2022, 308, 118392. [Google Scholar] [CrossRef]

- Dou, C.; Zhou, X.; Zhang, T.; Xu, S. Economic Optimization Dispatching Strategy of Microgrid for Promoting Photoelectric Consumption Considering Cogeneration and Demand Response. J. Mod. Power Syst. Clean Energy 2020, 8, 557–563. [Google Scholar] [CrossRef]

- Martínez-Sánchez, R.A.; Rodriguez-Resendiz, J.; Álvarez-Alvarado, J.M.; Macías-Socarrás, I. Solar Energy-Based Future Perspective for Organic Rankine Cycle Applications. Micromachines 2022, 13, 944. [Google Scholar] [CrossRef] [PubMed]

- Marefati, M.; Mehrpooya, M.; Pourfayaz, F. Performance analysis of an integrated pumped-hydro and compressed-air energy storage system and solar organic Rankine cycle. J. Energy Storage 2021, 44, 103488. [Google Scholar] [CrossRef]

- Wu, G.; Li, T.; Xu, W.; Xiang, Y.; Su, Y.; Liu, J.; Liu, F. Chance-constrained energy-reserve co-optimization scheduling ofwind-photovoltaic-hydrogen integrated energy systems. Int. J. Hydrogen Energy 2022, 48, 6892–6905. [Google Scholar] [CrossRef]

- Kiryanova, N.; Matrenin, P.; Mitrofanov, S.; Kokin, S.; Safaraliev, M.K. Hydrogen energy storage systems to improve wind power plant efficiency considering electricity tariff dynamics. Int. J. Hydrogen Energy 2022, 47, 10156–10165. [Google Scholar] [CrossRef]

- Razmi, A.R.; Alirahmi, S.M.; Nabat, M.H.; Assareh, E.; Shahbakhti, M. A green hydrogen energy storage concept based on parabolic trough collector and proton exchange membrane electrolyzer/fuel cell: Thermodynamic and exergoeconomic analyses with multi-objective optimization. Int. J. Hydrogen Energy 2022, 47, 26468–26489. [Google Scholar] [CrossRef]

- Cui, Y.; Yan, S.; Zhong, W.; Wang, Z.; Zhang, P.; Zhao, Y. Optimal thermoelectric dispatching of regional integrated energy system with power-to-gas. Power Syst. Technol. 2020, 44, 4254–4264. [Google Scholar]

- Chen, J.; Hu, Z.J.; Chen, Y.G.; Chen, J.; Chen, W. Thermoelectric optimization of integrated energy system considering ladder-type carbon trading mechanism and electric hydrogen production. Electr. Power Autom. Equip. 2021, 41, 48–55. [Google Scholar]

- Sun, H.; Sun, X.; Kou, L.; Zhang, B.; Zhu, X. Optimal scheduling of park-level integrated energy system considering ladder-type carbon trading mechanism and flexible load. Energy Rep. 2023, 9, 3417–3430. [Google Scholar] [CrossRef]

- Yuan, G.; Chen, S.; Wang, L. Economic optimal dispatch of virtual power plant considering environmental benefits. Adv. New Renew. Energy 2015, 3, 398–404. [Google Scholar]

- Yuan, G.; Zhong, F.; Zhang, R.; Zhou, T. Combined heat and power scheduling optimization for Virtual power plant considering carbon capture and demand response. Power Syst. Technol. 2023, 47, 4458–4467. [Google Scholar] [CrossRef]

- Zhong, J.; Wang, Y.; Zhao, Z. Research on multi-objective robust optimization about low carbon generation expansion planning considering uncertainty. Acta Energiae Solaris Sin. 2020, 41, 114–120. [Google Scholar]

- Yuan, G.; Wang, L.; Wang, B. Optimal Dispatch of Heat-Power Load and Economy Benefit Analysis Based on Decoupling of Heat and Power of Virtual Power Plant. Proc. CSEE 2017, 37, 4974–4985. [Google Scholar]

| Generator Unit | ||||||

|---|---|---|---|---|---|---|

| CHP1 | 12 | 0.03 | 0.02 | 0.0013 | 0.0017 | 0.00012 |

| CHP2 | 25 | 0.012 | 0.016 | 0.0012 | 0.0048 | 0.00013 |

| Contaminant | dej/(kg/(MWh)) | Vej (CNY/kg) | Vj/ CNY |

|---|---|---|---|

| SO2 | 6.48 | 6.4 | 1.0 |

| NOx | 2.88 | 8.0 | 2.0 |

| CO2 | 623 | 0.044 | 0.01 |

| CO | 0.1083 | 1.0 | 0.16 |

| Revenue from Sales of Electricity, Heat and Gas/ ×104 CNY | Fuel Cost/×104 CNY | Purchase Cost of Electricity/×104 CNY | Cost of Wind and Solar Power Curtailment/×104 CNY | Carbon-Trading Cost/×104 CNY | Carbon Emissions/t | Net Income/×104 CNY | |

|---|---|---|---|---|---|---|---|

| Scenario 1 | 279.89 | 98.67 | 10.99 | 19.73 | 16.32 | 1272 | 97.21 |

| Scenario 2 | 266.73 | 74.74 | 13.85 | 17.17 | 11.7 | 1157 | 126.10 |

| Scenario 3 | 264.41 | 66.11 | 8.50 | 9.83 | 6.59 | 733 | 146.25 |

| Revenue from Sales of Electricity, Heat and Gas/×104 CNY | Fuel Cost/×104 CNY | Purchase Cost of Electricity/×104 CNY | Cost of Wind and Solar Power Curtailment/×104 CNY | Carbon-Trading Cost/×104 CNY | Carbon Emissions/t | Net Income/×104 CNY | |

|---|---|---|---|---|---|---|---|

| Scenario 1 | 342.52 | 137.10 | 6.76 | 29.57 | 14.76 | 1070 | 125.63 |

| Scenario 2 | 324.85 | 107.19 | 13.27 | 19.72 | 8.85 | 960 | 155.81 |

| Scenario 3 | 323.84 | 99.21 | 9.01 | 14.12 | 5.31 | 589 | 174.89 |

| Revenue from Sales of Electricity, Heat and Gas/×104 CNY | Fuel Cost/×104 CNY | Purchase Cost of Electricity/×104 CNY | Cost of Wind and Solar Power Curtailment/×104 CNY | Carbon-Trading Cost/×104 CNY | Carbon Emissions/t | Net Income/×104 CNY | |

|---|---|---|---|---|---|---|---|

| Scenario 1 | 312.80 | 116.86 | 13.01 | 15.13 | 19.23 | 1356 | 148.78 |

| Scenario 2 | 301.13 | 94.16 | 7.16 | 12.09 | 12.51 | 1042 | 167.79 |

| Scenario 3 | 297.02 | 80.77 | 11.36 | 7.82 | 6.92 | 767 | 177.67 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, T.; Wang, Q.; Zhang, G.; Zhang, K.; Li, H. Low-Carbon Economic Dispatch of Virtual Power Plant Considering Hydrogen Energy Storage and Tiered Carbon Trading in Multiple Scenarios. Processes 2024, 12, 90. https://doi.org/10.3390/pr12010090

Xie T, Wang Q, Zhang G, Zhang K, Li H. Low-Carbon Economic Dispatch of Virtual Power Plant Considering Hydrogen Energy Storage and Tiered Carbon Trading in Multiple Scenarios. Processes. 2024; 12(1):90. https://doi.org/10.3390/pr12010090

Chicago/Turabian StyleXie, Tuo, Qi Wang, Gang Zhang, Kaoshe Zhang, and Hua Li. 2024. "Low-Carbon Economic Dispatch of Virtual Power Plant Considering Hydrogen Energy Storage and Tiered Carbon Trading in Multiple Scenarios" Processes 12, no. 1: 90. https://doi.org/10.3390/pr12010090

APA StyleXie, T., Wang, Q., Zhang, G., Zhang, K., & Li, H. (2024). Low-Carbon Economic Dispatch of Virtual Power Plant Considering Hydrogen Energy Storage and Tiered Carbon Trading in Multiple Scenarios. Processes, 12(1), 90. https://doi.org/10.3390/pr12010090