System Identification for Robust Control of an Electrode Positioning System of an Industrial Electric Arc Melting Furnace

Abstract

:1. Introduction

2. Materials and Methods

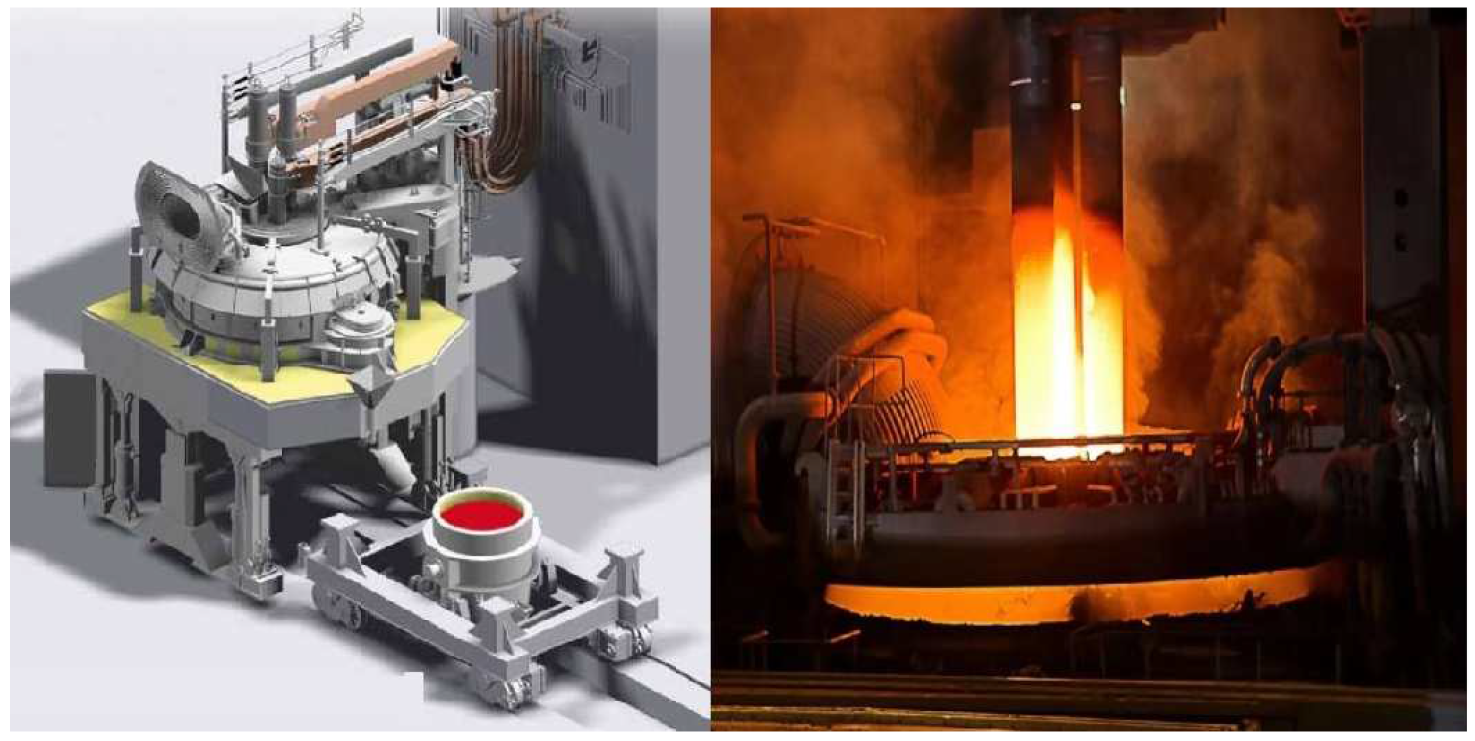

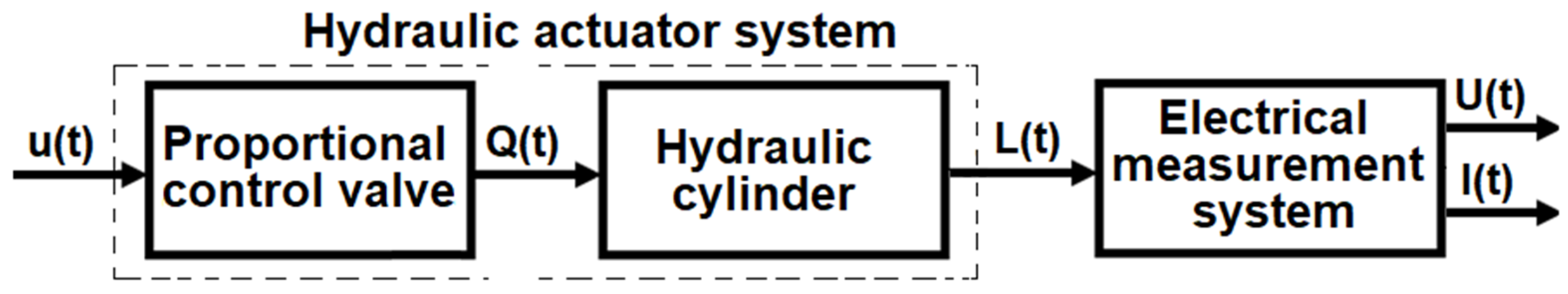

2.1. EAF Description

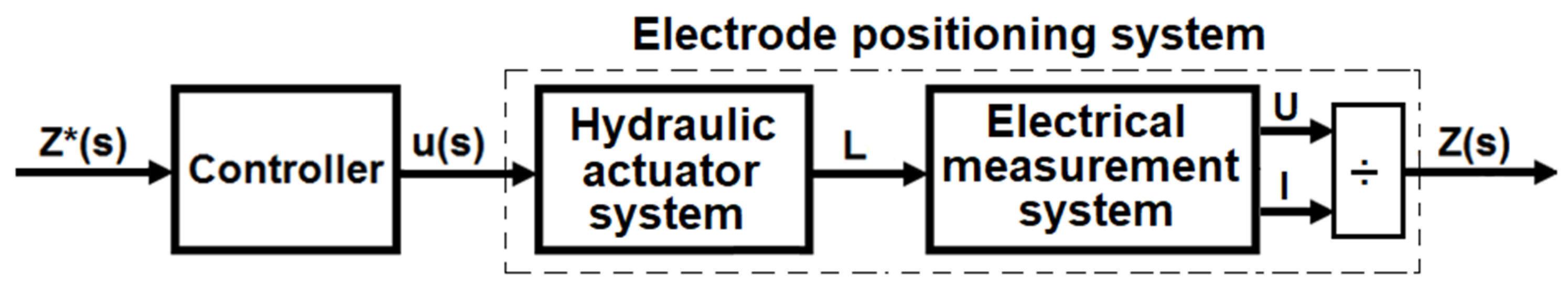

2.2. System Identification for Robust Control of EPS

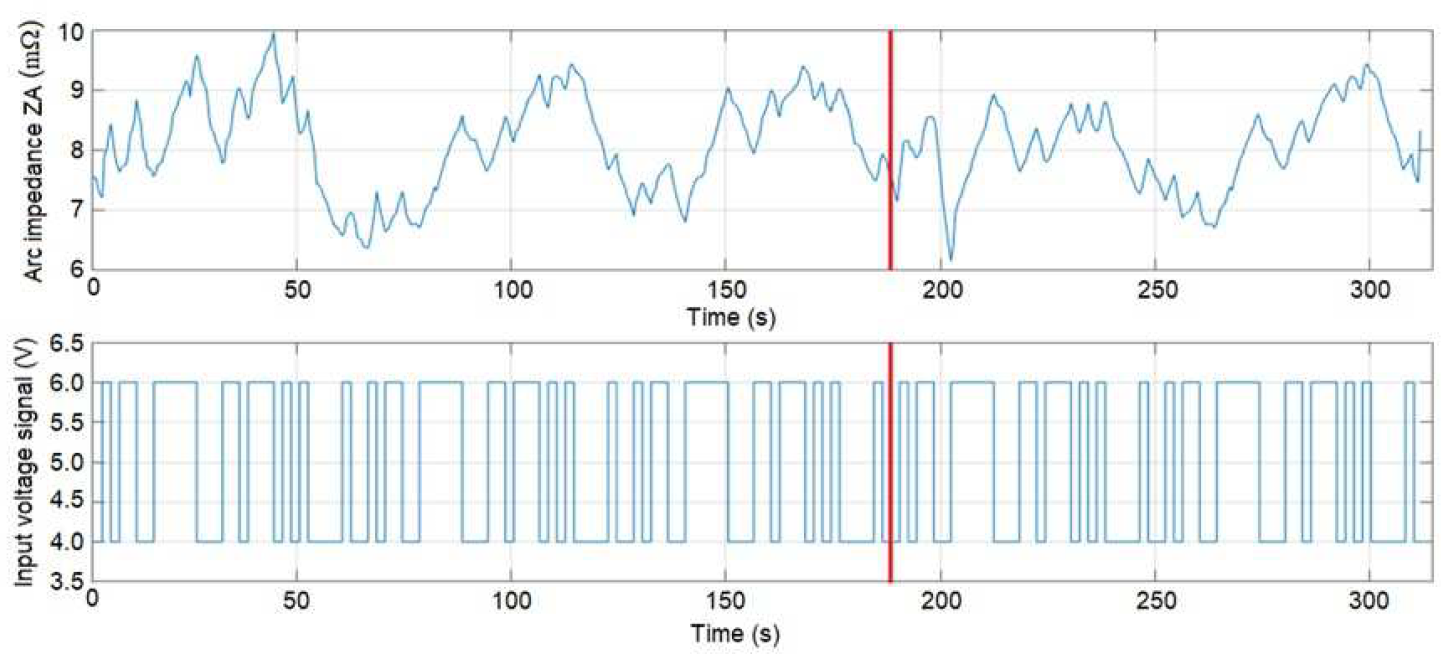

2.3. Experiment Design

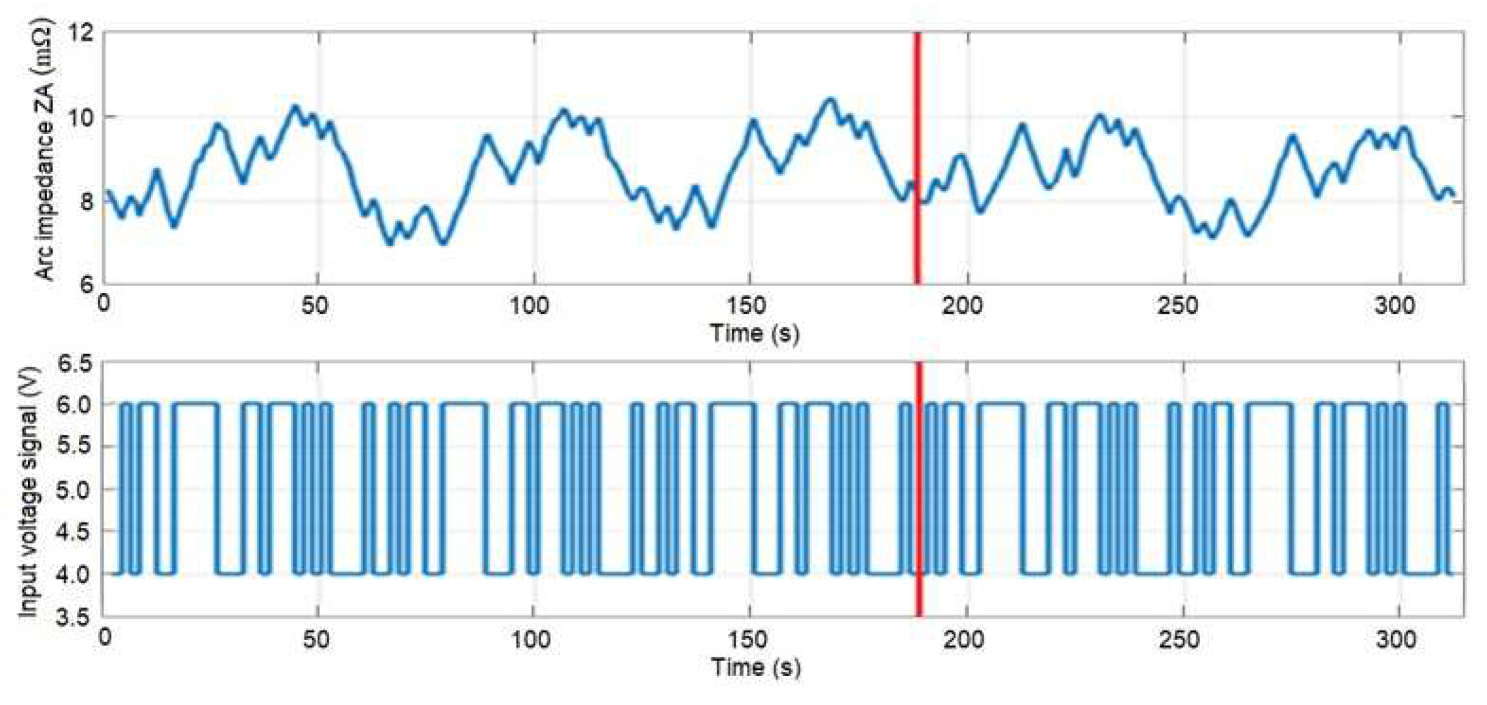

2.4. DPVLS Under the Nominal Electrode Weight Operating Regime

2.4.1. Nonparametric Identification

2.4.2. Parametric Identification

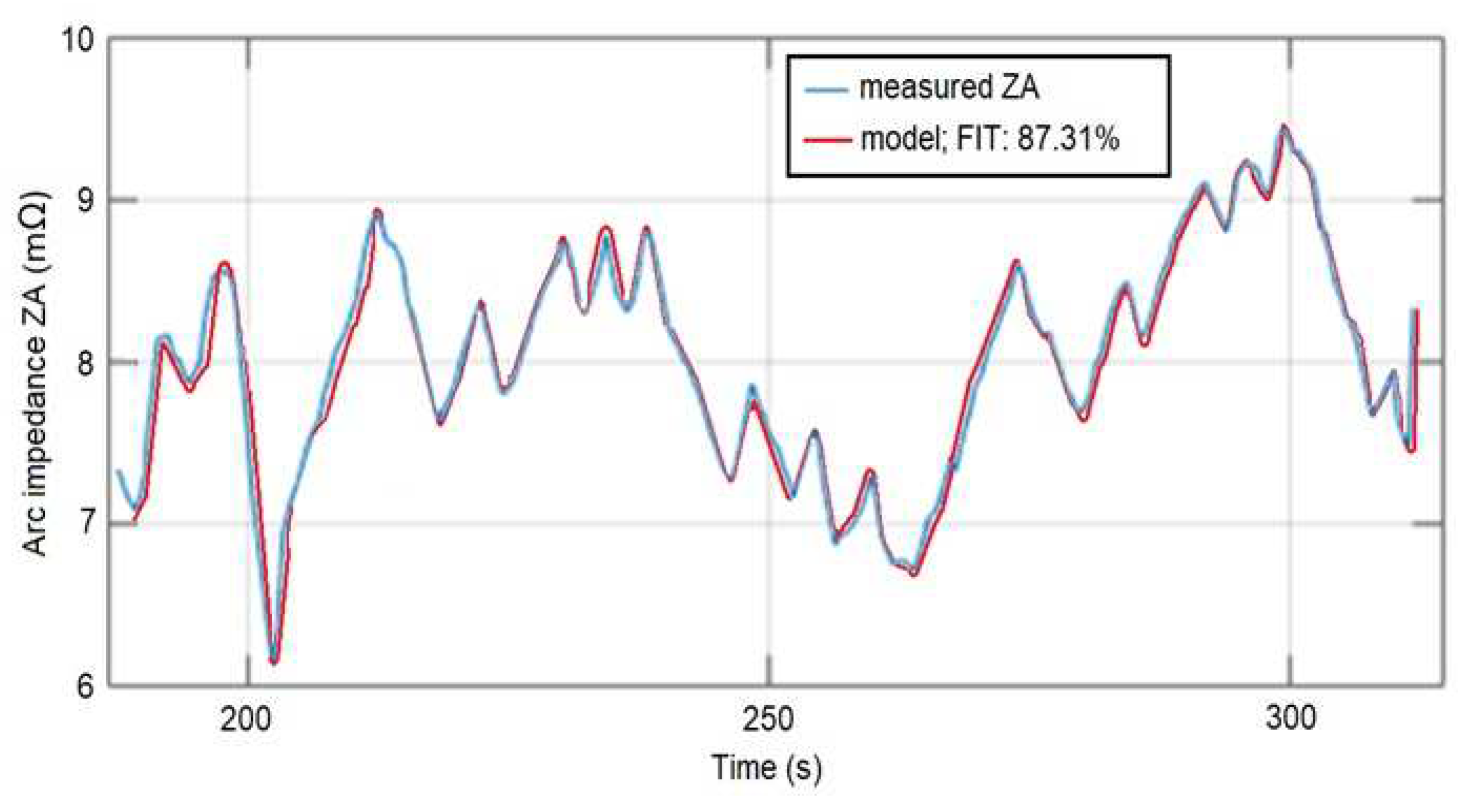

2.4.3. Model Validation

2.5. DPVLS Under Electrode Weight Limit Operating Regimes (Model Uncertainty Region)

2.5.1. Case of the Maximum Electrode Weight

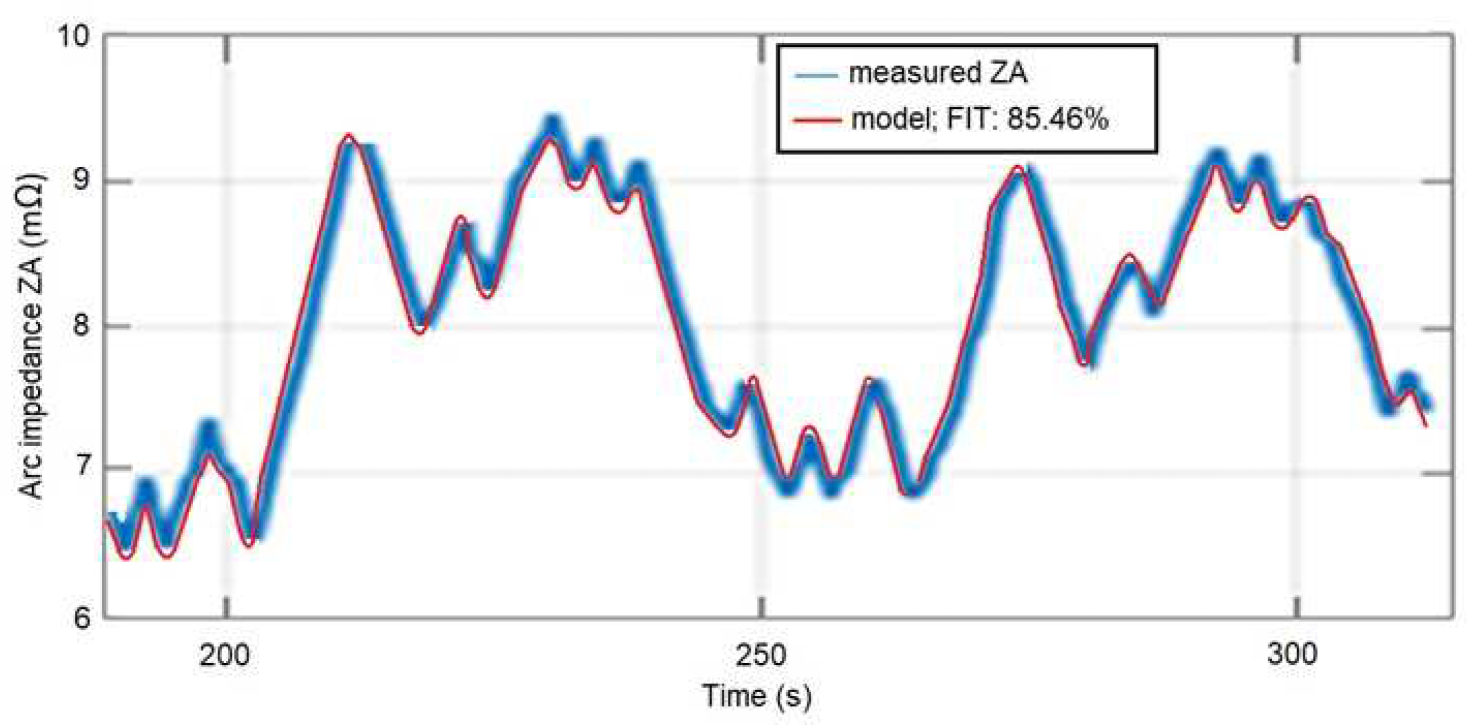

2.5.2. Model Validation

2.5.3. Case of the Minimum Electrode Weight

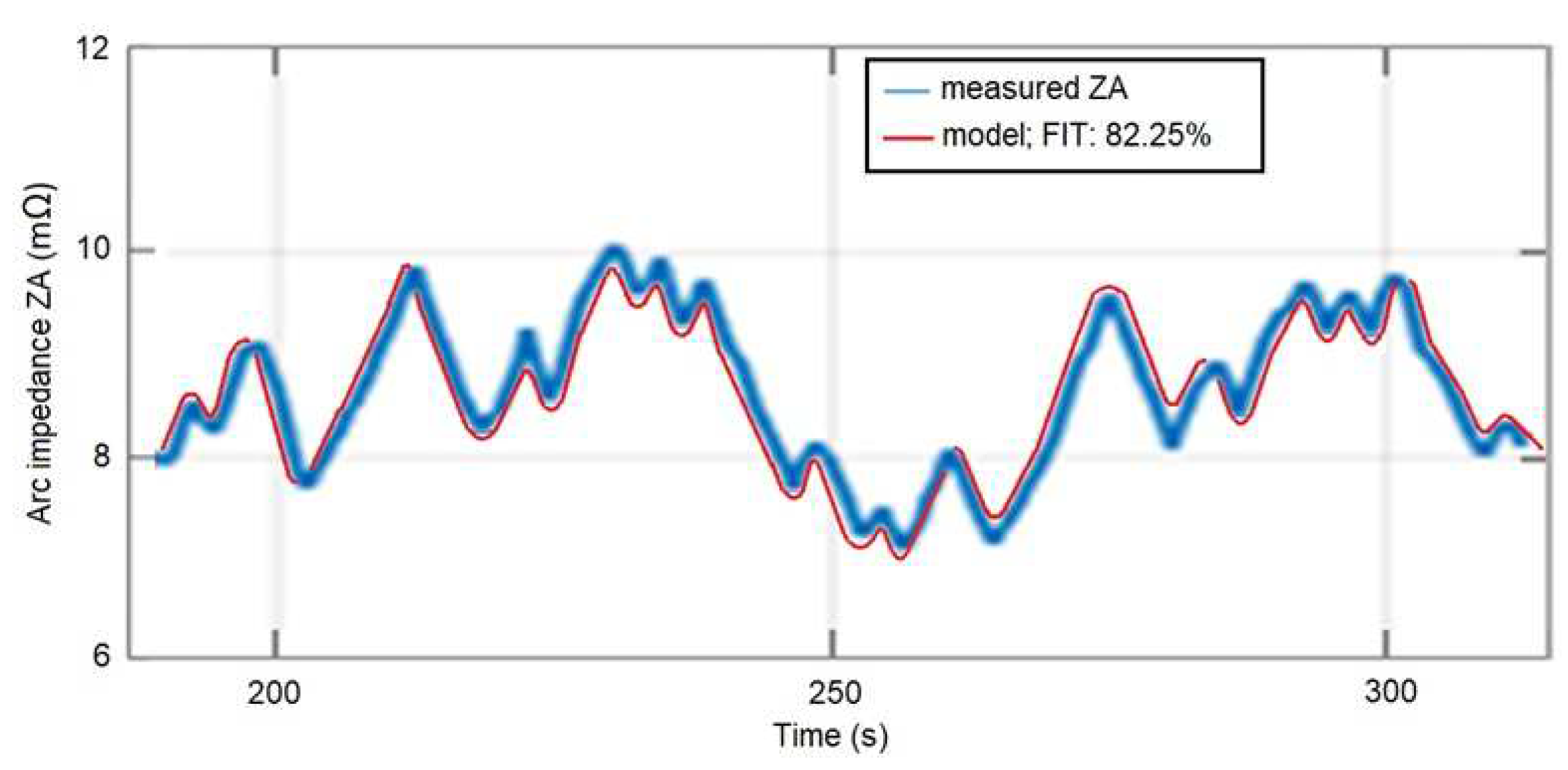

2.5.4. Model Validation

3. Results

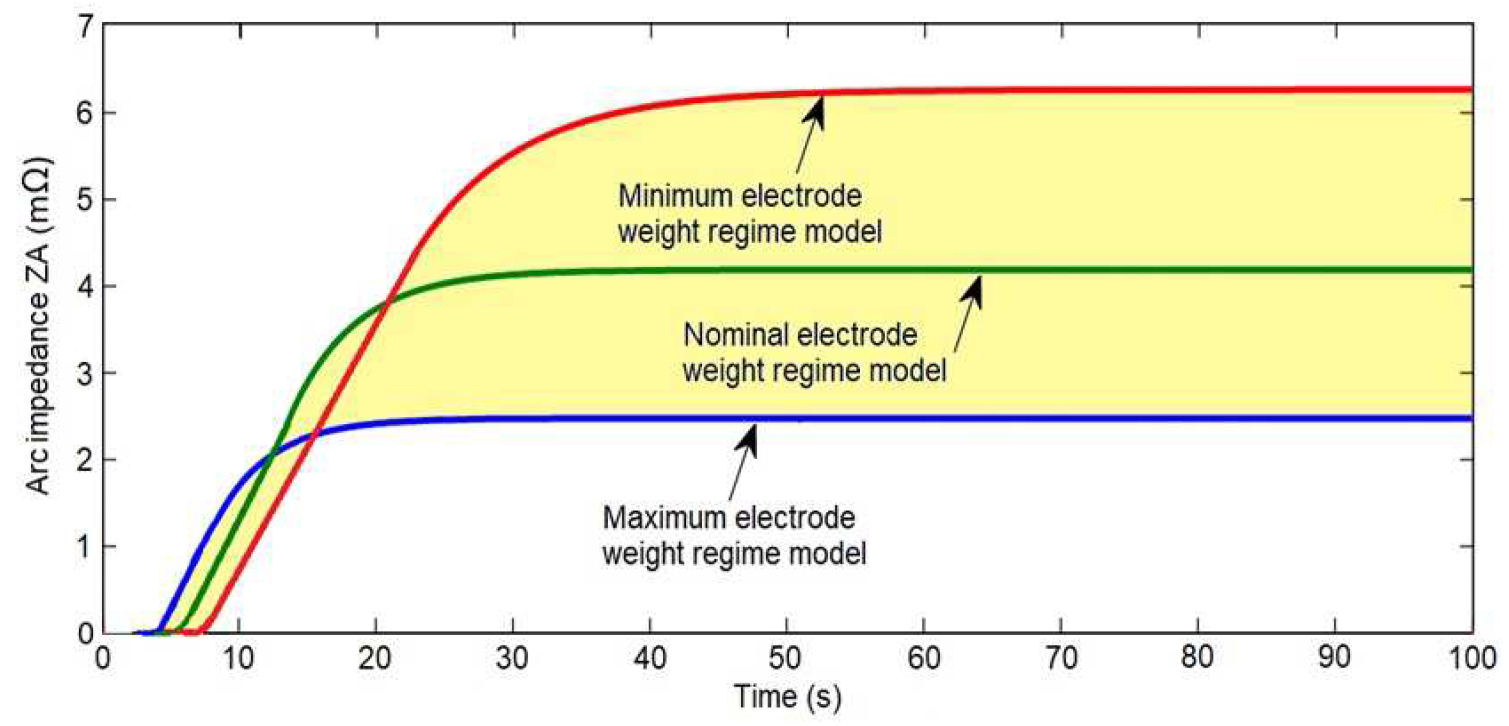

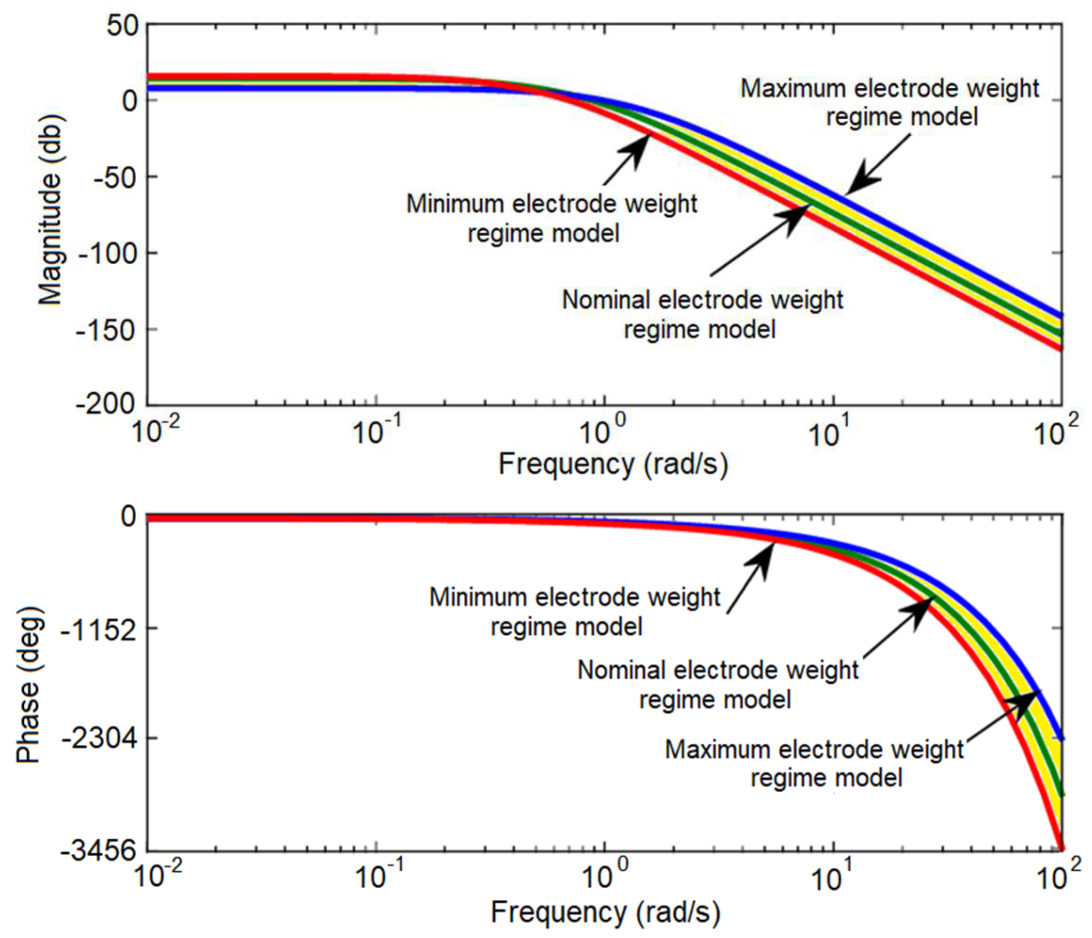

3.1. The Model Uncertainty Region of the True Electrode Positioning System

3.2. Time-Domain Responses of the Set of the Uncertainty of the Models

3.3. Frequency-Domain Responses of the Derived Set of the Uncertainty of the Models

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviation

| Abbreviation | Meaning |

| EAF | Electric Arc Melting Furnace |

| EPS | Electrode Positioning System |

| PID | Proportional Integral Derivative Controller |

| AC-EAF | Alternating Current Electric Arc Melting Furnace |

| PSS | Power Supply System |

| EAS | Electric Arc System |

| HAS | Hydraulic Actuator System |

| EMS | Electrical Measurement System |

| PRBS | Pseudorandom Binary Sequence |

| PC | Personal Computer |

| PLC | Programmable Logic Controller |

| ARX | Auto Regressive with Exogenous Input |

| ARMAX | Auto Regressive Moving Average with Exogenous Inputs |

| OE | Output Error Model |

| PEM | Prediction Error Method |

| FIT | Performance Index |

| SIRC | System Identification for Robust Control |

References

- Verdeja González, L.F.; Fernández González, D.; Verdeja González, J.I. Operations and Basic Processes in Steelmaking; Springer: Cham, Switzerland, 2021. [Google Scholar]

- Karbowniczek, M. Electric Arc Furnace Steelmaking, 1st ed.; CRC Press: Boca Raton, FL, USA, 2021. [Google Scholar]

- Odenthal, H.J.; Kemminger, A.; Krause, F.; Sankowski, L.; Uebber, N.; Vogl, N. Review on modeling and simulation of the electric arc furnace (EAF). Steel Res. Int. 2018, 89, 1700098. [Google Scholar] [CrossRef]

- Dutta, S.K.; Chokshi, Y.B. Basic Concepts of Iron and Steel Making; Springer: Singapore, 2020. [Google Scholar]

- Abadi, M.M.; Tang, H.; Rashidi, M.M. A review of simulation and numerical modeling of electric arc furnace (EAF) and its processes. Heliyon 2024, 10, e32157. [Google Scholar] [CrossRef] [PubMed]

- Shyamal, S.; Swartz, C.L. Real-time energy management for electric arc furnace operation. J. Process Control 2019, 74, 50–62. [Google Scholar] [CrossRef]

- Martynova, E.S.; Bazhin, V.Y.; Kharazov, V.G. Increasing the level of control and management of arc steel smelting furnaces. IOP Conf. Ser. Mater. Sci. Eng. 2019, 537, 032039. [Google Scholar] [CrossRef]

- Saboohi, Y.; Fathi, A.; Skrjanc, I.; Logar, V. Optimization of the electric arc furnace process. IEEE Trans. Ind. Electron. 2019, 66, 8030–8039. [Google Scholar] [CrossRef]

- Hernandez, J.; Onofri, L.; Engell, S. Modeling and energy efficiency analysis of the steelmaking process in an electric arc furnace. Metall. Mater. Trans. B 2022, 53, 3413–3441. [Google Scholar] [CrossRef]

- Hay, T.; Visuri, V.V.; Aula, M.; Echterhof, T. A review of mathematical process models for the electric arc furnace process. Steel Res. Int. 2021, 92, 2000395. [Google Scholar] [CrossRef]

- Tomažic, S.; Andonovski, G.; Škrjanc, I.; Logar, V. Data-driven modelling and optimization of energy consumption in EAF. Metals 2022, 12, 816. [Google Scholar] [CrossRef]

- Nikolaev, A.; Povelitsa, E.; Kornilov, G.; Anufriev, A. Research and development of automatic control system for electric arc furnace electrode positioning. Appl. Mech. Mater. 2015, 785, 707–713. [Google Scholar] [CrossRef]

- Feliu-Batlle, V.; Rivas-Perez, R.; Castillo-Garcia, F.J.; Rodriguez-Martinez, C.A. A robust fractional order controller for an EAF electrode position system. IFAC Proc. Vol. 2014, 47, 10670–10675. [Google Scholar] [CrossRef]

- Kleimt, B.; Krieger, W.; Mier Vasallo, D.; Arteaga Ayarza, A.; Unamuno Iriondo, I. Model-based decision support system for electric arc furnace (EAF) online monitoring and control. Metals 2023, 13, 1332. [Google Scholar] [CrossRef]

- Feliu-Batlle, V.; Rivas-Perez, R. Robust fractional-order controller for an EAF electrode position system. Control Eng. Pract. 2016, 56, 159–173. [Google Scholar] [CrossRef]

- Nikolaev, A.A.; Tulupov, P.G. Electric arc furnace control system with smelting stage diagnostic function and adaptive non-linear impedance controller. In Proceedings of the International Conference on Industrial Engineering, Applications and Manufacturing, Sochi, Russia, 17–21 May 2021; pp. 581–585. [Google Scholar]

- Li, Y.; Mao, Z.Z.; Wang, Y.; Yuan, P.; Jia, M.X. Model predictive control synthesis approach of electrode regulator system for electric arc furnace. J. Iron Steel Res. Int. 2011, 18, 20–25. [Google Scholar] [CrossRef]

- Kozyra, J.; Lozynskyy, A.; Lukasik, Z.; Kusminska-Fijalkowska, A.; Kutsyk, A.; Kasha, L. Increasing the level of autonomy of control of the electric arc furnace by weakening interphase interactions. Energies 2023, 16, 8114. [Google Scholar] [CrossRef]

- Li, L.; Mao, Z. A direct adaptive controller for EAF electrode regulator system using neural networks. Neurocomputing 2012, 82, 91–98. [Google Scholar] [CrossRef]

- Janabi-Sharifi, F.; Jorjani, G. An adaptive system for modelling and simulation of electrical arc furnaces. Control Eng. Pract. 2009, 17, 1202–1219. [Google Scholar] [CrossRef]

- Niu, S.S.; Xiao, D. Process Control, Engineering Analyses and Best Practices; Springer Nature: Cham, Switzerland, 2022. [Google Scholar]

- Benitez, I.O.; Rivas, R.; Feliu, V.; Sanchez, L.P.; Sanchez, L.A. Fuzzy gain scheduled Smith predictor for temperature control in an industrial steel slab reheating furnace. IEEE Lat. Am. Trans. 2016, 14, 4439–4447. [Google Scholar] [CrossRef]

- Rivas-Perez, R.; Feliu-Batlle, V.; Castillo-Garcia, F.J.; Benitez-Gonzalez, I. Temperature control of a crude oil preheating furnace using a modified Smith predictor improved with a disturbance rejection term. IFAC Proc. Vol. 2014, 47, 5760–5765. [Google Scholar] [CrossRef]

- Balan, R.; Hancu, O.; Lupu, E. Modeling and adaptive control of an electric arc furnace. IFAC Proc. Vol. 2007, 40, 163–168. [Google Scholar] [CrossRef]

- Klimas, M.; Grabowsk, D. Application of the deterministic chaos in AC electric arc furnace modeling. IEEE Trans. Ind. Appl. 2024, 60, 4978–4986. [Google Scholar] [CrossRef]

- Lozynskyy, O.; Lozynskyi, A.; Paranchuk, Y.; Biletskyi, Y. Optimal control of the electrical mode of an arc furnace on the basis of the three-dimensional vector of phase currents. Math. Model. Comput. 2019, 6, 69–76. [Google Scholar] [CrossRef]

- Dietz, M.; Grabowski, D.; Klimas, M.; Starkloff, H.-J. Estimation and analysis of the electric arc furnace model coefficients. IEEE Trans. Power Deliv. 2022, 37, 4956–4967. [Google Scholar] [CrossRef]

- Astrom, K.J.; Hagglund, T. Advanced PID Control; ISA—The Instrumentation, Systems, and Automation Society: Pittsburgh, PA, USA, 2006. [Google Scholar]

- Calderon Mendoza, E.M.; Rivas-Perez, R.; Sotomayor-Moriano, J.J. Design of an adaptive neuro-fuzzy controller of an irrigation main canal pool. IEEE Lat. Am. Trans. 2016, 14, 471–476. [Google Scholar] [CrossRef]

- Rivas-Perez, R.; Sotomayor-Moriano, J.; Perez-Zuniga, C.G. Design of a multivariable GPC based on an industrial PC for control of a reverse osmosis unit of a pharmaceutical industry. Rev. Mex. Ing. Quim. 2016, 15, 259–273. [Google Scholar]

- Mercorelli, P. Robust control as a mathematical paradigm for innovative engineering applications. Mathematics 2022, 10, 4399. [Google Scholar] [CrossRef]

- Feliu-Batlle, V.; Rivas-Perez, R. Control of the temperature in a petroleum refinery heating furnace based on a robust modified Smith predictor. ISA Trans. 2021, 112, 251–270. [Google Scholar] [CrossRef]

- Tacx, P.; de Rozario, R.; Oomen, T. Towards model order selection for robust-control-relevant system identification. IFAC-Papers-OnLine 2021, 54, 1–6. [Google Scholar] [CrossRef]

- Jawahery, S.; Visuri, V.V.; Wasbo, S.O.; Hammervold, A.; Hyttinen, N.; Schlautmann, M. Thermophysical model for online optimization and control of the electric arc furnace. Metals 2021, 11, 1587. [Google Scholar] [CrossRef]

- Logar, V.; Dovzan, D.; Skrjanc, I. Modeling and validation of an electric arc furnace: Part 1, heat and mass transfer. ISIJ Int. 2012, 52, 402–412. [Google Scholar] [CrossRef]

- Opitz, F.; Treffinger, P. Physics-based modeling of electric operation, heat transfer, and scrap melting in an AC electric arc furnace. Met. Mater. Trans. 2016, 47, 1489–1503. [Google Scholar] [CrossRef]

- Carlsson, L.S.; Samuelsson, P.B.; Jönsson, P.G. Using statistical modeling to predict the electrical energy consumption of an electric arc furnace producing stainless steel. Metals 2020, 10, 36. [Google Scholar] [CrossRef]

- Gajic, D.; Savic-Gajic, I.; Savic, I.; Georgieva, O.; Gennaro, S.D. Modelling of electrical energy consumption in an electric arc furnace using artificial neural networks. Energy 2016, 108, 132–139. [Google Scholar] [CrossRef]

- Klimas, M.; Grabowsk, D. Application of shallow neural networks in electric arc furnace modeling. IEEE Trans. Ind. Appl. 2022, 58, 6814–6823. [Google Scholar] [CrossRef]

- Garcia-Segura, R.; Vázquez Castillo, J.; Martell-Chavez, F.; Longoria-Gandara, O.; Ortegón Aguilar, J. Electric arc furnace modeling with artificial neural networks and arc length with variable voltage gradient. Energies 2017, 10, 1424. [Google Scholar] [CrossRef]

- Reinicke, A.; Engbrecht, T.N.; Schüttensack, L.; Echterho, T. Application of an artificial neural network for efficient computation of chemical activities within an EAF process model. Metals 2024, 14, 736. [Google Scholar] [CrossRef]

- Moghadasian, M.; Alenasser, E. Modelling and artificial intelligence-based control of electrode system for an EAF. J. Electromagn. Anal. Appl. 2011, 3, 47–55. [Google Scholar]

- Kozyra, J.; Lozynskyy, A.; Lukasik, Z.; Kusminska-Fijalkowska, A.; Kutsyk, A.; Kasha, L. Electric arc furnace electrode movement control system based on a fuzzy arc length identifier. Energies 2023, 16, 7281. [Google Scholar] [CrossRef]

- Paranchuk, Y.; Shabatura, Y.; Kuznyetsov, O. The electrodes positioning control system for the electric arc furnace basing on fuzzy logic. In Proceedings of the IEEE International Conference on Modern Electrical and Energy Systems, Kremenchuk, Ukraine, 21–24 September 2021. [Google Scholar]

- Mohseni, M.; Askari, M. System identification of electric arc furnace suction subsystem. In Proceedings of the 6th National Conference on New Technologies in Electrical and Computer Engineering, Isfaham, Iran, 13–14 December 2023. [Google Scholar]

- Collantes-Bellido, R.; Gomez, T. Identification and modelling of a three-phase arc furnace for voltage disturbances simulation. IEEE Trans. Power Del. 1997, 12, 1812–1817. [Google Scholar] [CrossRef]

- Yu, F.; Mao, Z. Recursive identification for electric arc furnace—Electrode regulator system. In Proceedings of the 36th Chinese Control Conference, Dalian, China, 26–28 July 2017; pp. 1989–1994. [Google Scholar]

- Guého, D.; Singla, P.; Majji, M.; Juang, J.N. Advances in system identification: Theory and applications. In Proceedings of the 60th IEEE Conference on Decision and Control, Austin, TX, USA, 14–17 December 2021. [Google Scholar]

- Rodriguez Vasquez, J.R.; Rivas Perez, R.; Sotomayor Moriano, J.; Peran Gonzalez, J.R. System identification of steam pressure in a fire-tube boiler. Comput. Chem. Eng. 2008, 32, 2839–2848. [Google Scholar] [CrossRef]

- Pauna, H.; Willms, T.; Aula, M.; Echterhof, T.; Huttula, M.; Fabritius, T. Electric arc length-voltage and conductivity characteristics in a pilot-scale ac electric arc furnace. Metall. Mater. Trans. B 2020, 51, 1646–1655. [Google Scholar] [CrossRef]

- Xue, B.; Yang, L.; Guo, Y.; Chen, F.; Wang, S.; Zheng, F.; Yang, Z. Design and construction of a laboratory-scale direct-current electric arc furnace for metallurgical and high-titanium slag smelting studies. Metals 2021, 11, 732. [Google Scholar] [CrossRef]

- Gevers, M. Identification for control: From the early achievements to the revival of experiment design. Eur. J. Control 2005, 11, 335–352. [Google Scholar] [CrossRef]

- Rivas-Perez, R.; Feliu-Batlle, V.; Castillo-Garcia, F.J.; Linares-Saez, A. Mathematical model for robust control of an irrigation main canal pool. Environ. Model. Softw. 2014, 51, 207–220. [Google Scholar] [CrossRef]

- Slavov, T.; Kralev, J.; Petkov, P. Identification, uncertain modelling, and robust control of embedded systems. Eng. Sci. Technol. 2021, 2, 96–115. [Google Scholar]

- Chen, J.; Gu, G. Control Oriented System Identification; Wiley Interscience: New York, NY, USA, 2000. [Google Scholar]

- Rodriguez-Martinez, C.A.; Rivas-Perez, R.; Feliu-Batlle, V.; Castillo-Garcia, F. Fractional order control system of EAF of Antillana de Acero. In Proceedings of the X International Symposium on Automation, XIV Convention and International Fair Informatica’2011, La Habana, Cuba, 7–11 February 2011. [Google Scholar]

- Tian, W.; Wang, L.; Yu, J.; Lv, Y.; Zhang, S.; Xu, Q.; Gao, B. A hybrid impedance matching network for underwater acoustic transducers. IEEE Trans. Power Electron. 2023, 38, 7622–7633. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, Z.; Xu, M.; Li, S.; Zhang, Y.; Zhu, X.F.; Ouyang, X.; Alù, A. Digital non-Foster-inspired electronics for broadband impedance matching. Nat. Commun. 2024, 15, 4346. [Google Scholar] [CrossRef]

- Ljung, L. System Identification. Theory for the User; Prentice Hall: Upper Saddle River, NJ, USA, 1999. [Google Scholar]

- Rivas-Perez, R.; Sotomayor-Moriano, J.; Pérez-Zuñiga, G.; Soto-Angles, M.E. Real-time implementation of an expert model predictive controller in a pilot-scale reverse osmosis plant for brackish and seawater desalination. Appl. Sci. 2019, 9, 2932. [Google Scholar] [CrossRef]

| Model Structure | Model Order (na, nb, nc, nd, nf, nk) | FIT | (mΩ) |

|---|---|---|---|

| ARX | (2, 2, 0, 0, 0, 2) | 69.92% | < 1.36 |

| OE | (0, 2, 0, 0, 2, 3) | 70.86 | < 1.24 |

| ARMAX | (2, 2, 2, 0, 0, 5) | 71.25% | < 0.6 |

| ARX | (4, 4, 0, 0, 0, 3) | 77.52% | < 0.51 |

| OE | (0, 4, 0, 0, 4, 4) | 83.46% | < 0.37 |

| ARMAX | (4, 4, 4, 0, 0, 5) | 87.31% | < 0.2 |

| Electrode Weight Limit Operating Regimes | Model Order (na, nb, nc, nd, nf, nk) | FIT | (mΩ) |

|---|---|---|---|

| Maximum electrode weight operating regime | (4, 4, 4, 0, 0, 4) | 85.46% | < 0.25 |

| Minimum electrode weight operating regime | (4, 4, 4, 0, 0, 6) | 82.25% | < 0.3 |

| Model Uncertainty Set of the True EPS | |||

|---|---|---|---|

| Model Parameters | Nominal Electrode Weight Operating Regime Model | ||

| Maximum Electrode Weight Operating Regime Model | Minimum Electrode Weight Operating Regime Model | ||

| (mΩ/V) | 4.15 | 2.51 | 6.21 |

| (s) | 1.70 | 0.70 | 1.80 |

| (s) | 1.55 | 1.05 | 1.75 |

| (s) | 1.10 | 0.85 | 1.90 |

| (s) | 0.90 | 0.50 | 1.55 |

| (s) | 5.00 | 4.00 | 6.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feliu-Batlle, V.; Rivas-Perez, R.; Borges-Rivero, R.A.; Misa-Llorca, R. System Identification for Robust Control of an Electrode Positioning System of an Industrial Electric Arc Melting Furnace. Processes 2024, 12, 2509. https://doi.org/10.3390/pr12112509

Feliu-Batlle V, Rivas-Perez R, Borges-Rivero RA, Misa-Llorca R. System Identification for Robust Control of an Electrode Positioning System of an Industrial Electric Arc Melting Furnace. Processes. 2024; 12(11):2509. https://doi.org/10.3390/pr12112509

Chicago/Turabian StyleFeliu-Batlle, Vicente, Raul Rivas-Perez, Romar A. Borges-Rivero, and Roger Misa-Llorca. 2024. "System Identification for Robust Control of an Electrode Positioning System of an Industrial Electric Arc Melting Furnace" Processes 12, no. 11: 2509. https://doi.org/10.3390/pr12112509

APA StyleFeliu-Batlle, V., Rivas-Perez, R., Borges-Rivero, R. A., & Misa-Llorca, R. (2024). System Identification for Robust Control of an Electrode Positioning System of an Industrial Electric Arc Melting Furnace. Processes, 12(11), 2509. https://doi.org/10.3390/pr12112509