Mechanical Characterization of Main Minerals in Carbonate Rock at the Micro Scale Based on Nanoindentation

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Information

2.2. Experimental Principle

2.3. Experimental Scheme

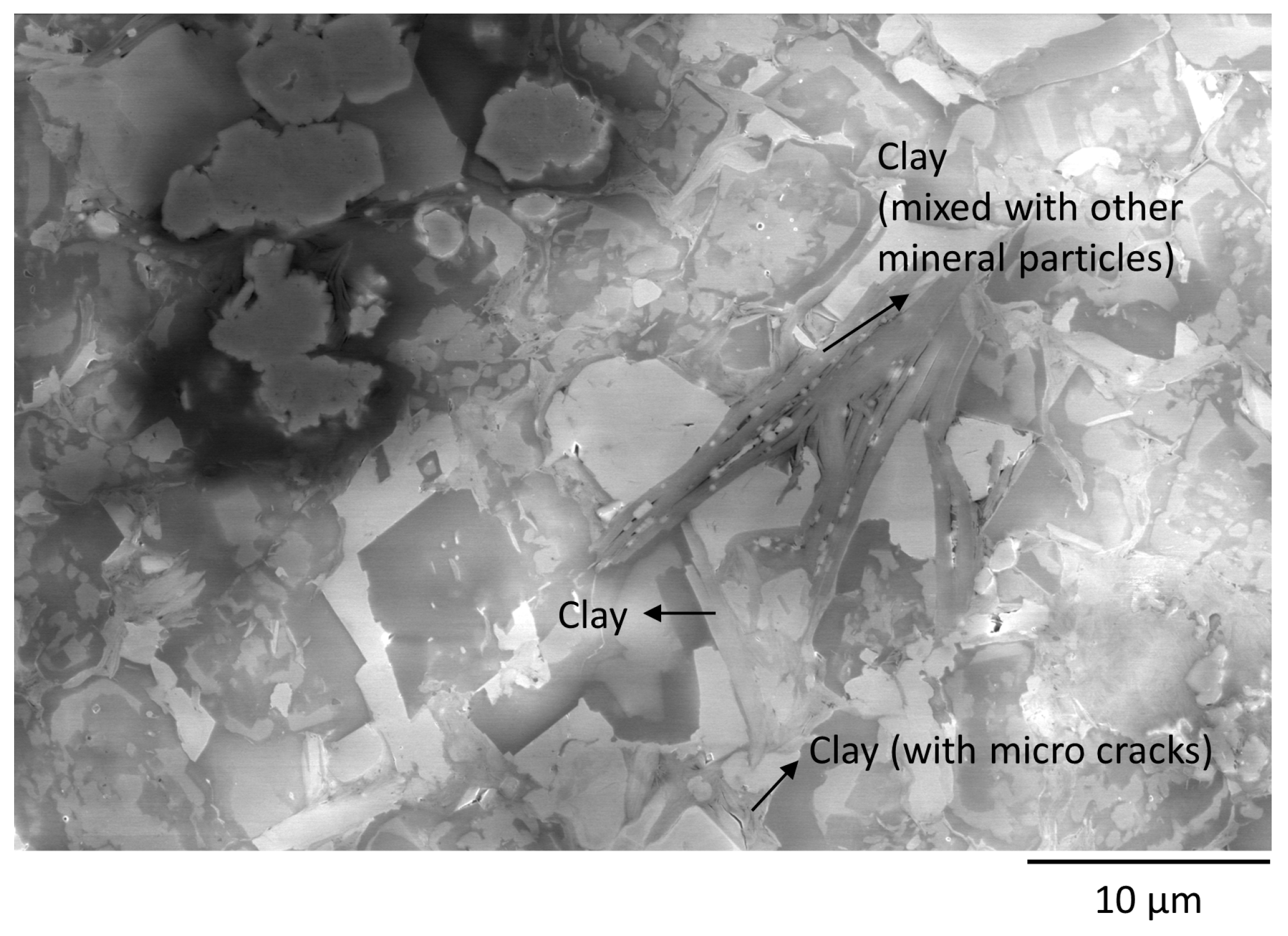

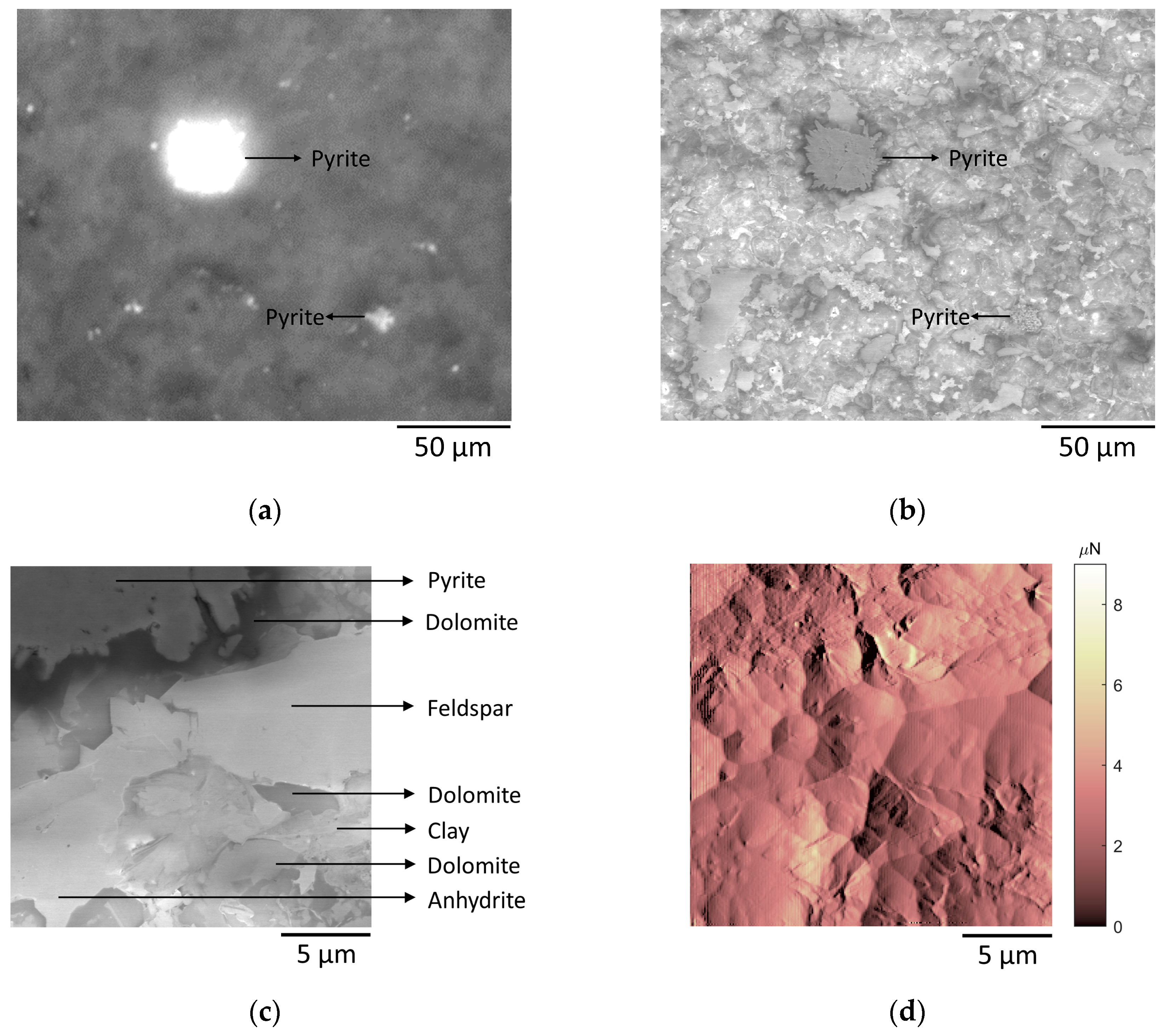

2.3.1. Test Area Observation and Selection

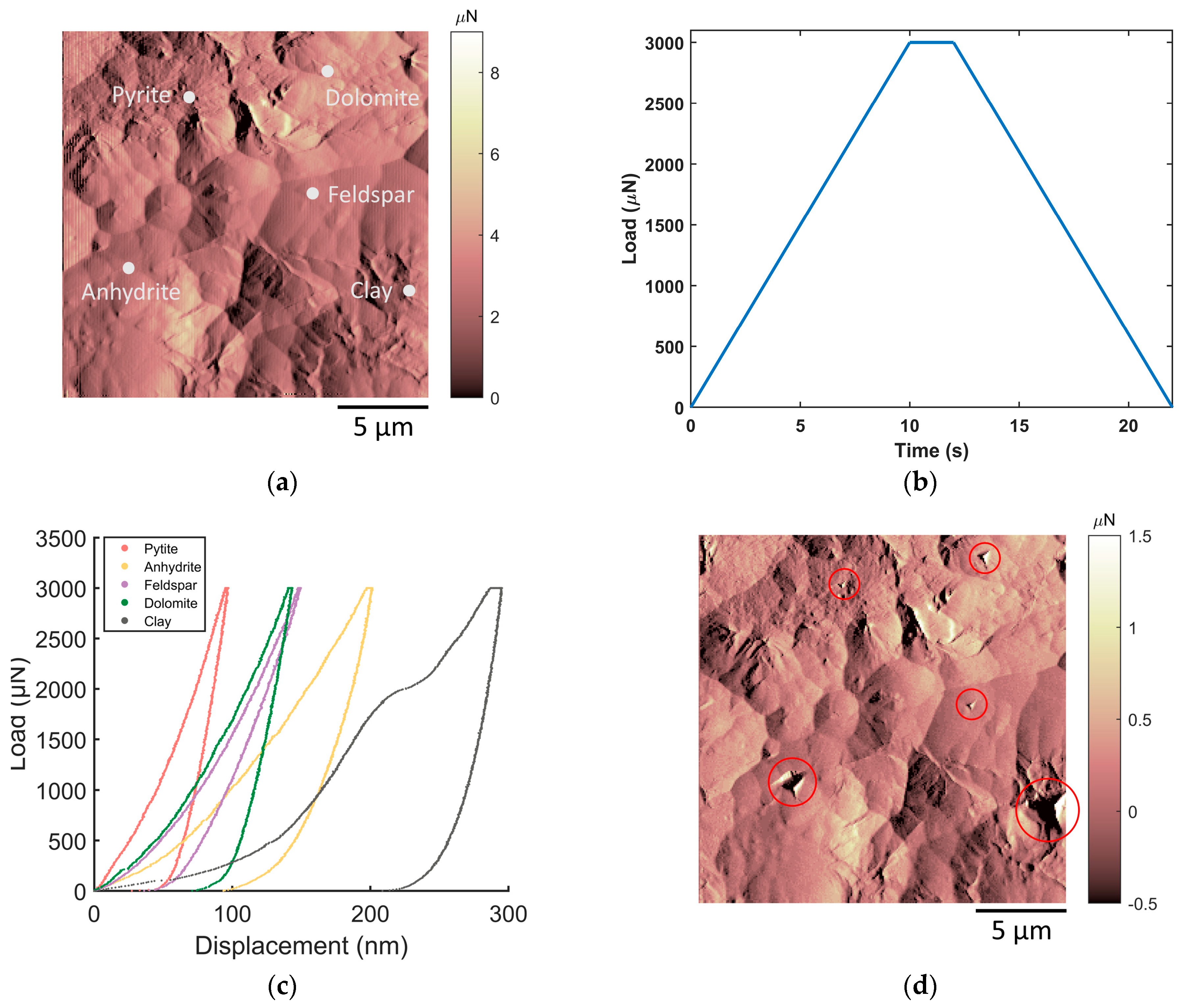

2.3.2. Test Area Positioning

2.3.3. Nanoindentation Test

3. Results and Discussion

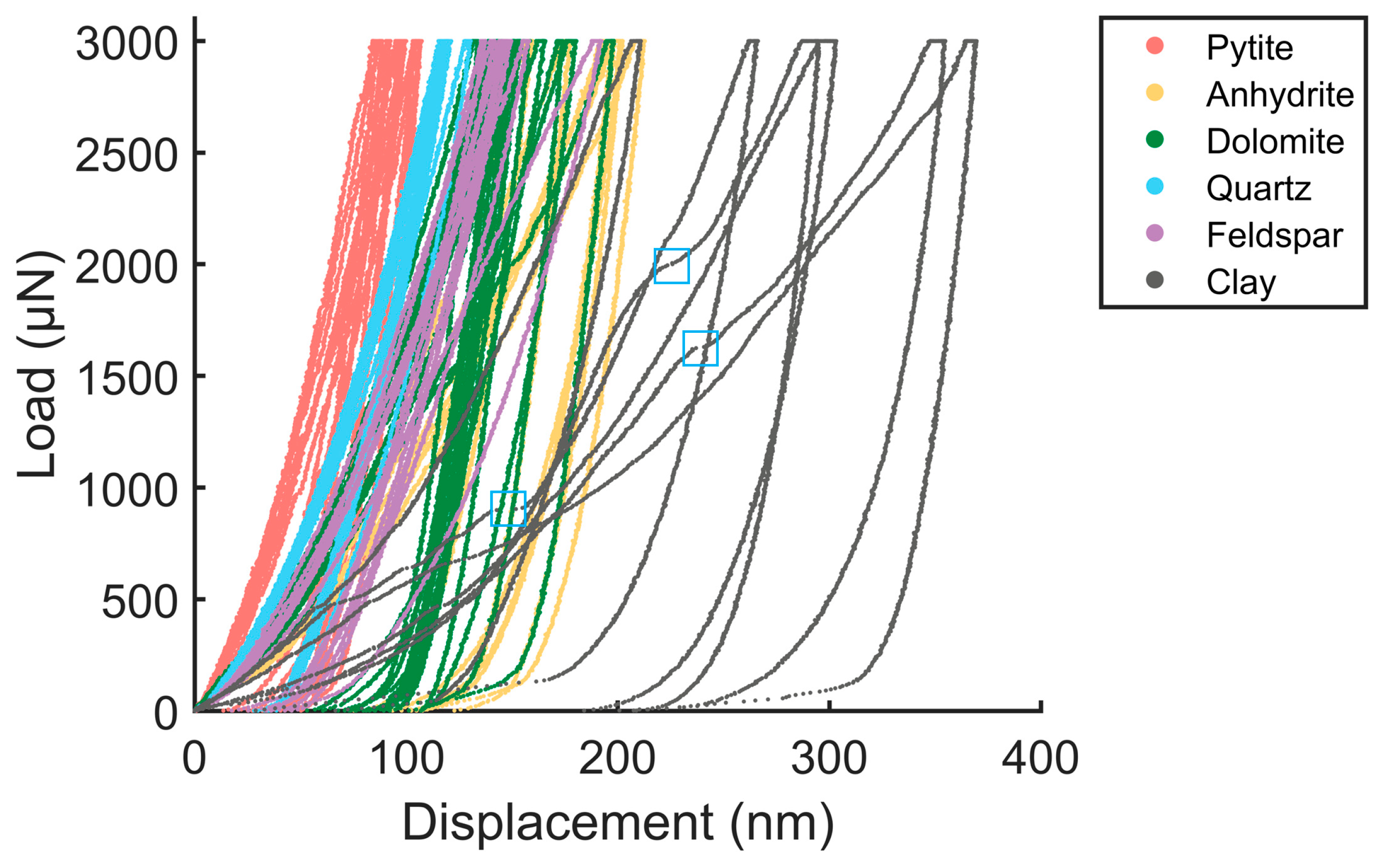

3.1. Micromechanical Features of Minerals in Carbonate Rock

3.2. Influence of Poisson’s Ratio Values and Comparison with Reported Mineral Data

3.3. Characterization Ability Analysis

4. Conclusions

- (1)

- This study focuses on a typical carbonate rock sample from the Huangcaoxia gas storage and explores the application of quasi-static nanoindentation to the study of the mechanical properties of carbonate rock. A complete workflow, including sample preparation, test area selection and positioning, mechanical testing, and data processing and analysis for the micromechanical characterization of a carbonate rock sample, is developed and presented.

- (2)

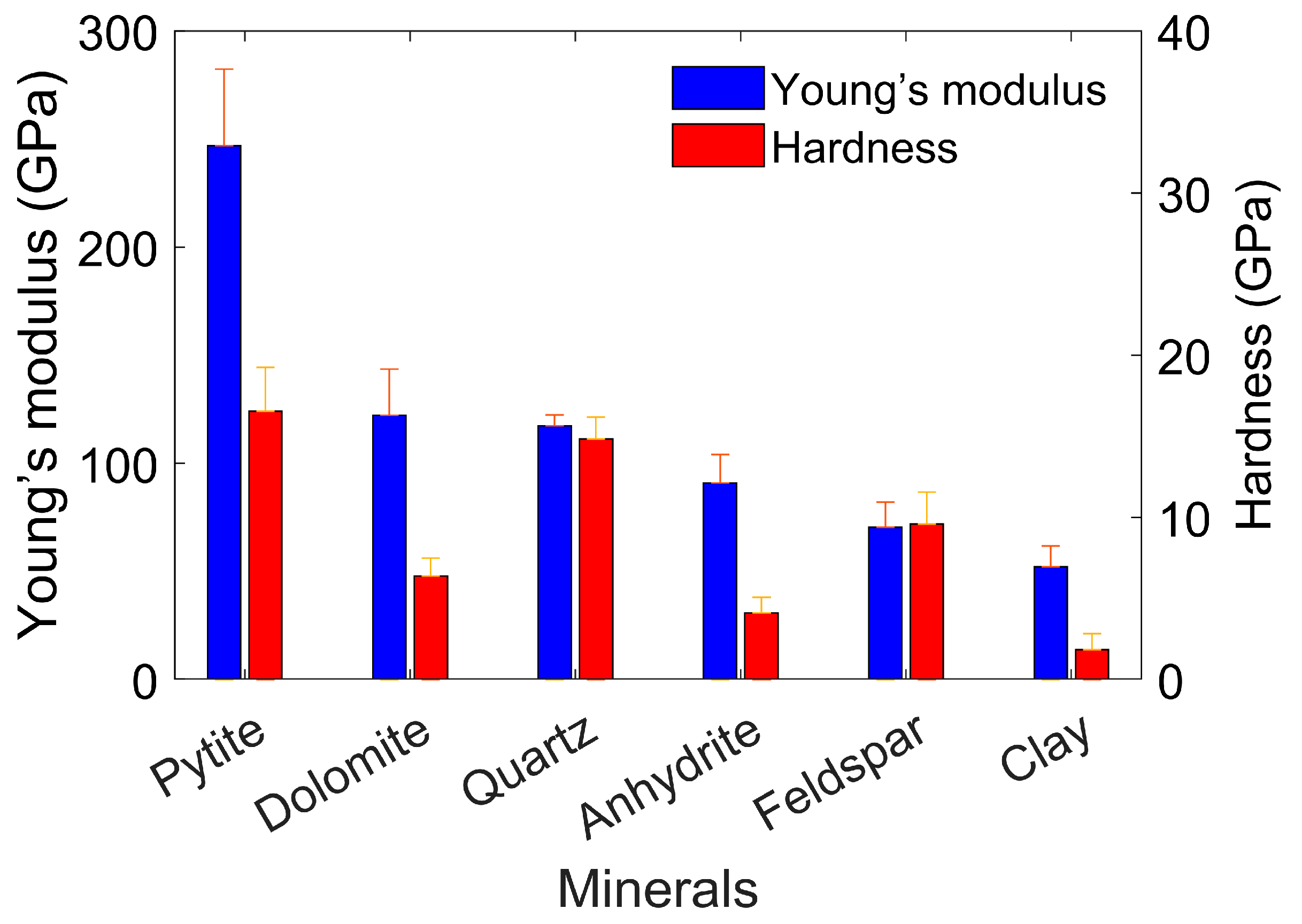

- The mechanical properties of the main minerals in the carbonate rock sample are characterized. The experimental results indicate strong micromechanical heterogeneity. The Young’s modulus of pyrite is over 200 GPa, and that of dolomite is between 100 GPa and 150 GPa. However, the Young’s modulus of clay is only approximately 50 GPa. In addition, the minerals with higher Young’s moduli do not uniformly possess higher nanoindentation hardness. These quantitative data at the micro scale can be used for the interpretation of the macroscopic mechanical features of carbonate rock, for the parameter input and validation of mineral related simulation, and for the construction of a mechanical upscaling model.

- (3)

- The Young’s moduli of different minerals obtained from nanoindentation measurements can be influenced by the corresponding Poisson’s ratio values. For the minerals with unknown Poisson’s ratio values, the value is assumed to be 0.25. Sensitivity analysis results suggest that the maximum possible error introduced by this assumption is below 15%.

- (4)

- To discuss the effectiveness of the micromechanical characterization in this study, the characterization ability, which is constituted by lateral spatial resolution and elastic response depth in the vertical direction, is quantitatively analyzed based on the experimental results. For most of the minerals in the carbonate rock sample, the lateral spatial resolution is better than 1.5 μm, and the elastic response depth is lower than 1 μm, which guarantees a relatively stable and accurate mechanical measurement of a single mineral particle. However, the mechanical characterization of clay minerals can be more easily influenced by the surroundings as compared to other kinds of minerals, and the mechanical properties of clay may be slightly overestimated with the current experimental setup. In the future, the experimental scheme can be further refined to achieve a more accurate characterization of clay minerals in carbonate rock.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Palharini Schwalbert, M.; Aljawad, M.S.; Hill, A.D.; Zhu, D. Decision criterion for acid-stimulation method in carbonate reservoirs: Matrix acidizing or acid fracturing? SPE J. 2020, 25, 2296–2318. [Google Scholar] [CrossRef]

- Li, N.; Dai, J.; Liu, C.; Liu, P.; Zhang, Y.; Luo, Z.; Zhao, L. Feasibility study on application of volume acid fracturing technology to tight gas carbonate reservoir development. Petroleum 2015, 1, 206–216. [Google Scholar] [CrossRef]

- Al-Ameri, W.A.; Abdulraheem, A.; Mahmoud, M. Long-term effects of CO2 sequestration on rock mechanical properties. J. Energy Resour. 2016, 138, 012201. [Google Scholar] [CrossRef]

- Raza, A.; Gholami, R.; Sarmadivaleh, M. Feasibility of limestone reservoirs as a carbon dioxide storage site: An experimental study. AAPG Bull. 2020, 104, 83–96. [Google Scholar] [CrossRef]

- Tang, H.; Zheng, X.; Wang, X.; Zhao, Z.; Chen, Y.; Zhao, Y.; Zhang, L. Mechanical stability analysis of fracture-cavity carbonate gas storage. In Proceedings of the ARMA US Rock Mechanics/Geomechanics Symposium, Golden, CO, USA, 23–26 June 2024; ARMA: Arma, KS, USA, 2024. [Google Scholar] [CrossRef]

- Shao, J.; You, L.; Kang, Y.; Gao, X.; Chen, M.; Meng, S.; Zhang, N. Experimental study on stress sensitivity of underground gas storage. J. Pet. Sci. Eng. 2020, 195, 107577. [Google Scholar] [CrossRef]

- Skrzypkowski, K.; Zagórski, K.; Zagórska, A. Determination of the extent of the rock destruction zones around a gasification channel on the basis of strength tests of sandstone and claystone samples heated at high temperatures up to 1200 C and exposed to water. Energies 2021, 14, 6464. [Google Scholar] [CrossRef]

- Sheshde, E.A.; Cheshomi, A.; Gharechelou, S. Estimation of mode I static fracture toughness of carbonate rock using small rock fragments. J. Pet. Sci. Eng. 2022, 218, 110980. [Google Scholar] [CrossRef]

- Palchik, V. On the ratios between elastic modulus and uniaxial compressive strength of heterogeneous carbonate rocks. Rock Mech. Rock Eng. 2011, 44, 121–128. [Google Scholar] [CrossRef]

- Yasar, E.; Erdogan, Y. Correlating sound velocity with the density, compressive strength and Young’s modulus of carbonate rocks. Int. J. Rock Mech. Min. Sci. 2004, 41, 871–875. [Google Scholar] [CrossRef]

- Baud, P.; Exner, U.; Lommatzsch, M.; Reuschlé, T.; Wong, T.f. Mechanical behavior, failure mode, and transport properties in a porous carbonate. J. Geophys. Res. Solid Earth 2017, 122, 7363–7387. [Google Scholar] [CrossRef]

- Vajdova, V.; Baud, P.; Wong, T.F. Compaction, dilatancy, and failure in porous carbonate rocks. J. Geophys. Res. Solid Earth 2004, 109, B05204. [Google Scholar] [CrossRef]

- Nardini, L.; Rybacki, E.; Krause, M.; Morales, L.F.; Dresen, G. Control of the geometric arrangement of material heterogeneities on strain localization at the brittle-to-ductile transition in experimentally deformed carbonate rocks. J. Struct. Geol. 2020, 135, 104038. [Google Scholar] [CrossRef]

- Tsikrikis, A.; Papaliangas, T.; Marinos, V. Brittle-ductile transition and Hoek–Brown mi constant of low-porosity carbonate rocks. Geotech. Geol. Eng. 2022, 40, 1833–1849. [Google Scholar] [CrossRef]

- Rohmer, J.; Pluymakers, A.; Renard, F. Mechano-chemical interactions in sedimentary rocks in the context of CO2 storage: Weak acid, weak effects? Earth-Sci. Rev. 2016, 157, 86–110. [Google Scholar] [CrossRef]

- Hugman Iii, R.; Friedman, M. Effects of texture and composition on mechanical behavior of experimentally deformed carbonate rocks. AAPG Bull. 1979, 63, 1478–1489. [Google Scholar] [CrossRef]

- Abdullah, G.M.; El Aal, A.A.; Radwan, A.E.; Qadri, T.; Aly, N. The influence of carbonate textures and rock composition on durability cycles and geomechanical aspects of carbonate rocks. Acta Geotech. 2023, 18, 105–125. [Google Scholar] [CrossRef]

- Verwer, K.; Braaksma, H.; Kenter, J.A. Acoustic properties of carbonates: Effects of rock texture and implications for fluid substitution. Geophysics 2008, 73, B51–B65. [Google Scholar] [CrossRef]

- Zhao, J.; Zhang, W.; Zhang, D. Elastic characterization of shale at microscale: A comparison between modulus mapping, PeakForce quantitative nanomechanical mapping, and contact resonance method. SPE J. 2022, 27, 3136–3157. [Google Scholar] [CrossRef]

- Hoffler, C.E.; Guo, X.E.; Zysset, P.K.; Goldstein, S.A. An application of nanoindentation technique to measure bone tissue lamellae properties. J. Biomech. Eng. 2005, 127, 1046–1053. [Google Scholar] [CrossRef]

- Gindl, W.; Gupta, H.; Schöberl, T.; Lichtenegger, H.; Fratzl, P. Mechanical properties of spruce wood cell walls by nanoindentation. Appl. Phys. A 2004, 79, 2069–2073. [Google Scholar] [CrossRef]

- Killgore, J.P.; DelRio, F.W. Contact resonance force microscopy for viscoelastic property measurements: From fundamentals to state-of-the-art applications. Macromolecules 2018, 51, 6977–6996. [Google Scholar] [CrossRef]

- Fischer, H.; Stadler, H.; Erina, N. Quantitative temperature-depending mapping of mechanical properties of bitumen at the nanoscale using the AFM operated with PeakForce TappingTM mode. J. Microsc. 2013, 250, 210–217. [Google Scholar] [CrossRef]

- Rabe, U. Applied Scanning Probe Methods II; Springer: Berlin/Heidelberg, Germany, 2006. [Google Scholar]

- Bennett, K.C.; Berla, L.A.; Nix, W.D.; Borja, R.I. Instrumented nanoindentation and 3D mechanistic modeling of a shale at multiple scales. Acta Geotech. 2015, 10, 1–14. [Google Scholar] [CrossRef]

- Yang, C.; Xiong, Y.; Wang, J.; Li, Y.; Jiang, W. Mechanical characterization of shale matrix minerals using phase-positioned nanoindentation and nano-dynamic mechanical analysis. Int. J. Coal. Geol. 2020, 229, 103571. [Google Scholar] [CrossRef]

- Zhao, J.; Zhang, W.; Zhang, D.; Wei, R.; Wang, Y. Influence of geochemical features on the mechanical properties of organic matter in shale. J. Geophys. Res. Solid Earth 2020, 125, e2020JB019809. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, S.; Kang, Y. Probing nanomechanical properties of a shale with nanoindentation: Heterogeneity and the effect of water–shale interactions. Energy Fuels 2021, 35, 11930–11946. [Google Scholar] [CrossRef]

- Mo, C.; Zhao, J.; Zhang, D. Real-time measurement of mechanical behavior of granite during heating–cooling cycle: A mineralogical perspective. Rock Mech. Rock Eng. 2022, 55, 4403–4422. [Google Scholar] [CrossRef]

- Li, M.; Sun, H.; Peng, L.; Zuo, J.; Wang, Z. Laboratory investigation on physical and mechanical behaviors of granite after heating and different cooling rates. Energy 2024, 302, 131718. [Google Scholar] [CrossRef]

- Liu, X.-Y.; Xu, D.-P.; Li, S.-J.; Qiu, S.-L.; Jiang, Q. An insight into the mechanical and fracture characterization of minerals and mineral interfaces in granite using nanoindentation and micro X-ray computed tomography. Rock Mech. Rock Eng. 2023, 56, 3359–3375. [Google Scholar] [CrossRef]

- Li, Y.; Luo, S.; Lu, M.; Wu, Y.; Zhou, N.; Wang, D.; Lu, Y.; Zhang, G. Cross-scale characterization of sandstones via statistical nanoindentation: Evaluation of data analytics and upscaling models. Int. J. Rock Mech. Min. Sci. 2021, 142, 104738. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, D.; Zhao, J. Control of fracture toughness of kerogen on artificially-matured shale samples: An energy-based nanoindentation analysis. Gas Sci. Eng. 2024, 124, 205266. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Pharr, G.; Oliver, W.; Brotzen, F. On the generality of the relationship among contact stiffness, contact area, and elastic modulus during indentation. J. Mater. Res. 1992, 7, 613–617. [Google Scholar] [CrossRef]

- Johnson, K.L. Contact Mechanics; Cambridge University Press: Cambridge, UK, 1987. [Google Scholar]

- Riester, L.; Bridge, R.; Breder, K. Characterization of vickers, berkovich, spherical and cube cornered diamond indenters by nanoindentation and SFM. MRS Online Proc. Libr. 1998, 522, 45. [Google Scholar] [CrossRef]

- Shikimaka, O.; Grabco, D. Deformation created by Berkovich and Vickers indenters and its influence on surface morphology of indentations for LiF and CaF2 single crystals. J. Phys. D Appl. Phys. 2008, 41, 074012. [Google Scholar] [CrossRef]

- Zong, W.; Wu, D.; He, C. Radius and angle determination of diamond Berkovich indenter. Measurement 2017, 104, 243–252. [Google Scholar] [CrossRef]

- Čech, J.; Haušild, P.; Kovářík, O.; Materna, A. Examination of Berkovich indenter tip bluntness. Mater. Des. 2016, 109, 347–353. [Google Scholar] [CrossRef]

- Nohava, J.; Čech, J.; Havlíček, M.; Consiglio, R. Indenter wear study and proposal of a simple method for evaluation of indenter blunting. J. Mater. Res. 2021, 36, 4449–4459. [Google Scholar] [CrossRef]

- Zhao, J.; Zhang, D.; Wu, T.; Tang, H.; Xuan, Q.; Jiang, Z.; Dai, C. Multiscale approach for mechanical characterization of organic-rich shale and its application. Int. J. Geomech. 2019, 19, 04018180. [Google Scholar] [CrossRef]

- Page, T.F.; Oliver, W.C.; McHargue, C.J. The deformation behavior of ceramic crystals subjected to very low load (nano) indentations. J. Mater. Res. 1992, 7, 450–473. [Google Scholar] [CrossRef]

- Sato, Y.; Shinzato, S.; Ohmura, T.; Hatano, T.; Ogata, S. Unique universal scaling in nanoindentation pop-ins. Nat. Commun. 2020, 11, 4177. [Google Scholar] [CrossRef]

- Bradby, J.; Williams, J.; Swain, M.V. Pop-in events induced by spherical indentation in compound semiconductors. J. Mater. Res. 2004, 19, 380–386. [Google Scholar] [CrossRef]

- Abdallah, Y.; Vandamme, M.; Chateau, C.; Garnier, D.; Jolivet, I.; Onaisi, A.; Richard, D.; Zandi, S. Linking elastic properties of various carbonate rocks to their microstructure by coupling nanoindentation and SEM-EDS. Int. J. Rock Mech. Min. Sci. 2023, 170, 105456. [Google Scholar] [CrossRef]

- Faisal, T.F.; Islam, A.; Jouini, M.S.; Devarapalli, R.S.; Jouiad, M.; Sassi, M. Numerical prediction of carbonate elastic properties based on multi-scale imaging. Geomech. Energy Environ. 2019, 20, 100125. [Google Scholar] [CrossRef]

- Tandon, R.S.; Gupta, V. The control of mineral constituents and textural characteristics on the petrophysical & mechanical (PM) properties of different rocks of the Himalaya. Eng. Geol. 2013, 153, 125–143. [Google Scholar] [CrossRef]

- Ahrens, T.J. Mineral Physics and Crystallography: A Handbook of Physical Constants; American Geophysical Union: Washington, DC, USA, 1995. [Google Scholar]

- Eliyahu, M.; Emmanuel, S.; Day-Stirrat, R.J.; Macaulay, C.I. Mechanical properties of organic matter in shales mapped at the nanometer scale. Mar. Pet. Geol. 2015, 59, 294–304. [Google Scholar] [CrossRef]

- Jiang, K.; Zhou, W.; Deng, N.; Song, W. Statistical analysis and significance of pyrite in the Wufeng-Lower Longmaxi Shale Formation in South China. Arab. J. Geosci. 2020, 13, 1181. [Google Scholar] [CrossRef]

- Zhou, Q.; Liu, J.; Ma, B.; Li, C.; Xiao, Y.; Chen, G.; Lyu, C. Pyrite Characteristics in Lacustrine Shale and Implications for Organic Matter Enrichment and Shale Oil: A Case Study from the Triassic Yanchang Formation in the Ordos Basin, NW China. ACS Omega 2024, 9, 16519–16535. [Google Scholar] [CrossRef]

- Deirieh, A.; Ortega, J.; Ulm, F.-J.; Abousleiman, Y. Nanochemomechanical assessment of shale: A coupled WDS-indentation analysis. Acta Geotech. 2012, 7, 271–295. [Google Scholar] [CrossRef]

- Wilkinson, T.M.; Zargari, S.; Prasad, M.; Packard, C.E. Optimizing nano-dynamic mechanical analysis for high-resolution, elastic modulus mapping in organic-rich shales. J. Mater. Sci. 2015, 50, 1041–1049. [Google Scholar] [CrossRef]

- Wei, Y.; Liang, S.; Gao, X. Phase quantification in cementitious materials by dynamic modulus mapping. Mater. Charact. 2017, 127, 348–356. [Google Scholar] [CrossRef]

- Wang, C.Y.; Mao, N.H.; Wu, F.T. Mechanical properties of clays at high pressure. J. Geophys. Res. Solid Earth 1980, 85, 1462–1468. [Google Scholar] [CrossRef]

- Goodarzi, M.; Rouainia, M.; Aplin, A.; Cubillas, P.; de Block, M. Predicting the elastic response of organic-rich shale using nanoscale measurements and homogenisation methods. Geophys. Prospect. 2017, 65, 1597–1614. [Google Scholar] [CrossRef]

| Mineral Type | Maximum Displacement (nm) |

|---|---|

| Pyrite | 97.61 ± 7.38 |

| Dolomite | 155.19 ± 16.13 |

| Quartz | 120.25 ± 4.09 |

| Anhydrite | 192.89 ± 18.04 |

| Feldspar | 153.22 ± 18.43 |

| Clay | 300.01 ± 58.22 |

| Mineral Type | Poisson’s Ratio [50] | Reported Young’s Modulus (GPa) |

|---|---|---|

| Pyrite | 0.16 | 129 [43] |

| Dolomite | 0.292 | 115~120 [26] |

| Quartz | 0.079 | 105~110 [26] |

| Anhydrite | 0.25 | 91.3~108.5 [47] |

| Feldspar | 0.285 | 75~85 [26] |

| Clay | 0.25 | 30 [26] |

| Mineral Type | Lateral Spatial Resolution (μm) | Elastic Response Depth (μm) |

|---|---|---|

| Pyrite | 0.65 ± 0.05 | 0.39 ± 0.03 |

| Dolomite | 1.06 ± 0.11 | 0.62 ± 0.06 |

| Quartz | 0.69 ± 0.04 | 0.48 ± 0.02 |

| Anhydrite | 1.32 ± 0.14 | 0.77 ± 0.07 |

| Feldspar | 0.87 ± 0.13 | 0.62 ± 0.08 |

| Clay | 2.08 ± 0.46 | 1.20 ± 0.23 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, T.; Zhao, J.; Yin, H.; Xie, Q.; Gou, L. Mechanical Characterization of Main Minerals in Carbonate Rock at the Micro Scale Based on Nanoindentation. Processes 2024, 12, 2727. https://doi.org/10.3390/pr12122727

Deng T, Zhao J, Yin H, Xie Q, Gou L. Mechanical Characterization of Main Minerals in Carbonate Rock at the Micro Scale Based on Nanoindentation. Processes. 2024; 12(12):2727. https://doi.org/10.3390/pr12122727

Chicago/Turabian StyleDeng, Ting, Junliang Zhao, Hongchuan Yin, Qiang Xie, and Ling Gou. 2024. "Mechanical Characterization of Main Minerals in Carbonate Rock at the Micro Scale Based on Nanoindentation" Processes 12, no. 12: 2727. https://doi.org/10.3390/pr12122727

APA StyleDeng, T., Zhao, J., Yin, H., Xie, Q., & Gou, L. (2024). Mechanical Characterization of Main Minerals in Carbonate Rock at the Micro Scale Based on Nanoindentation. Processes, 12(12), 2727. https://doi.org/10.3390/pr12122727