Fault Diagnosis of Mechanical Rolling Bearings Using a Convolutional Neural Network–Gated Recurrent Unit Method with Envelope Analysis and Adaptive Mean Filtering

Abstract

:1. Introduction

2. Methodology Theory

2.1. Adaptive Mean Filter

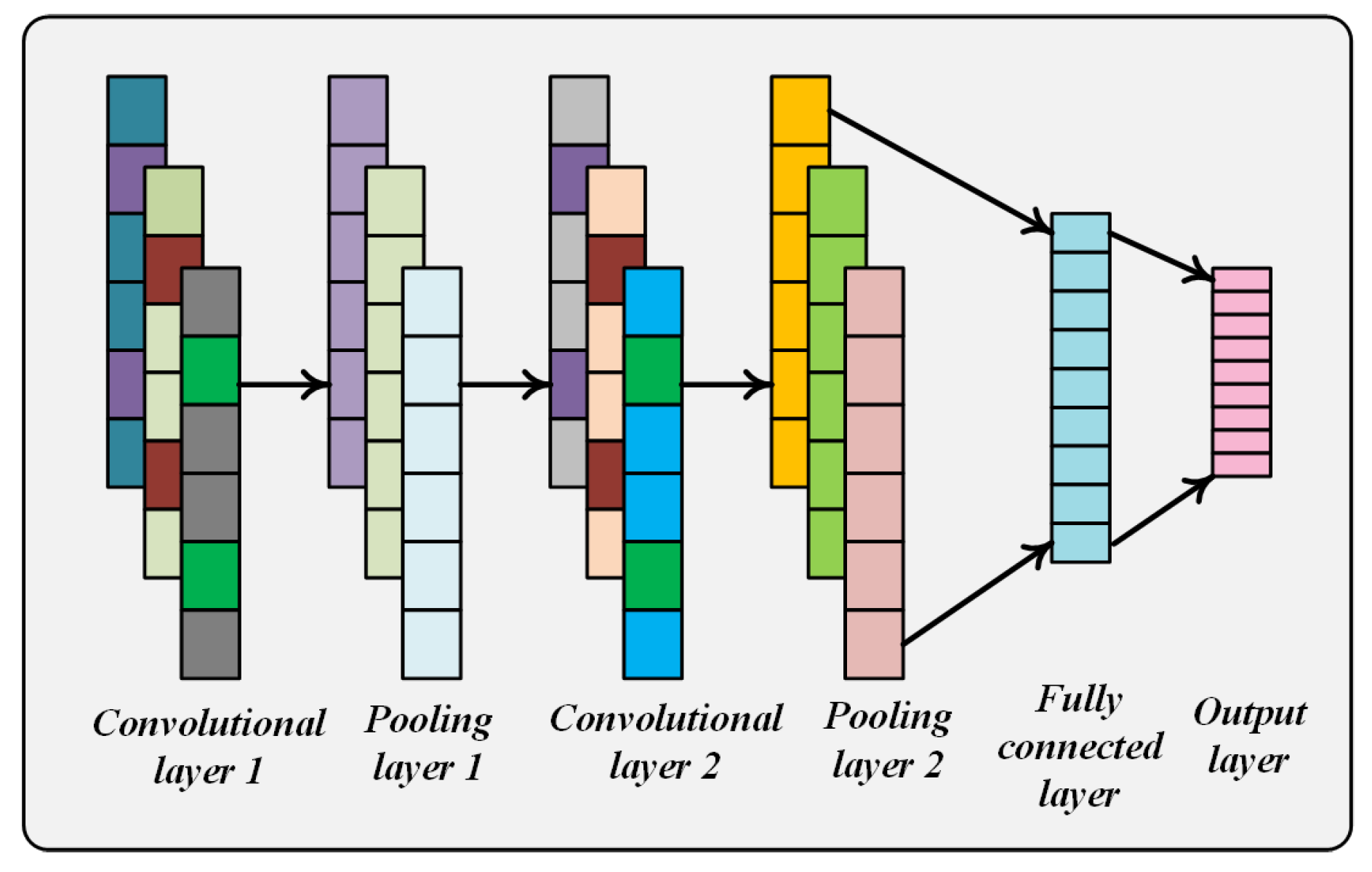

2.2. Convolutional Neural Network

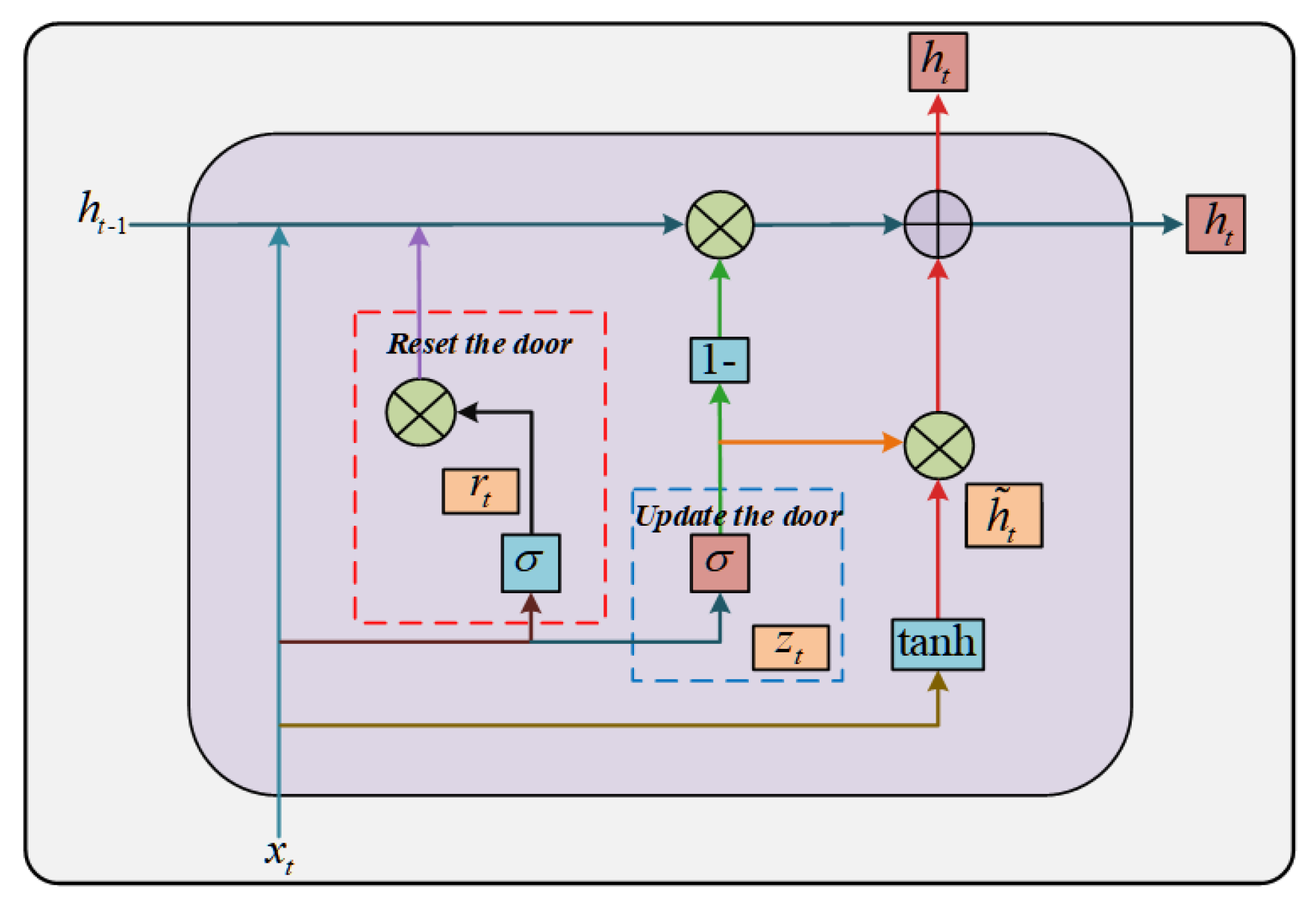

2.3. Gated Recurrent Unit

3. Analysis of Experimental Process

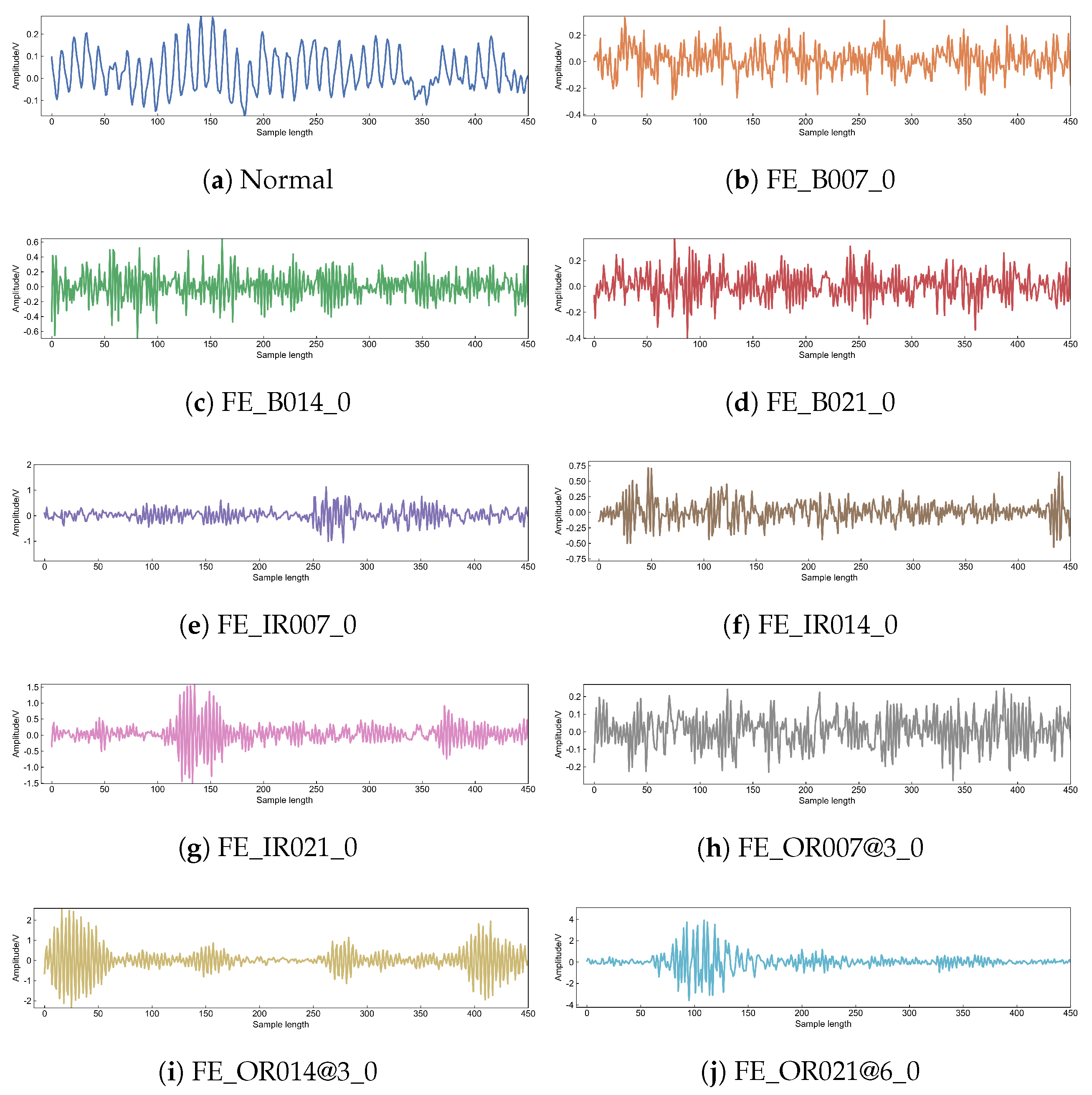

3.1. CWRU Bearing Data Analysis

3.2. Filtering Process

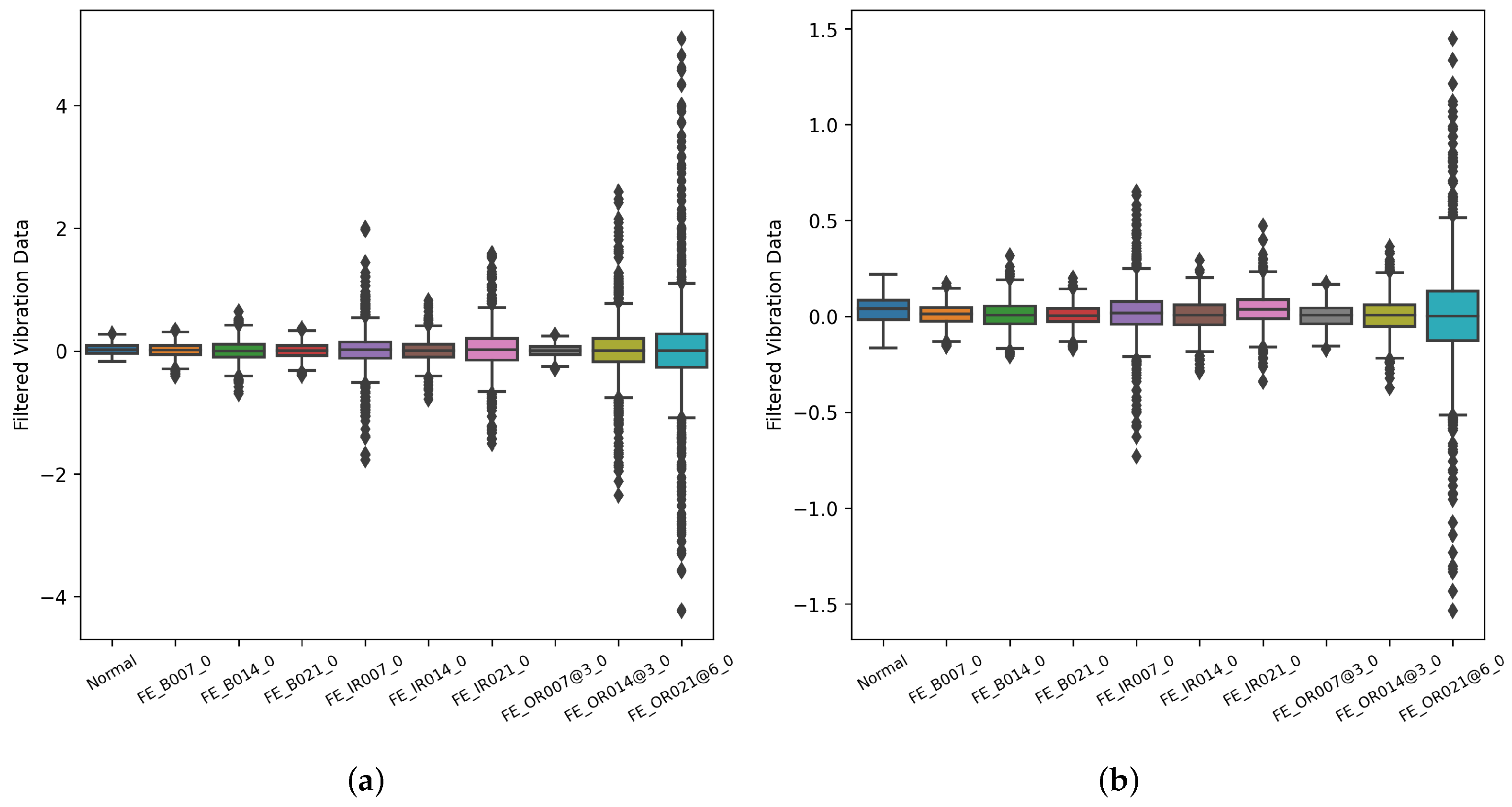

3.3. Z-Score Standardization of Bearing Data

3.4. Box Plot Analysis of Raw and Filtered Bearing Data

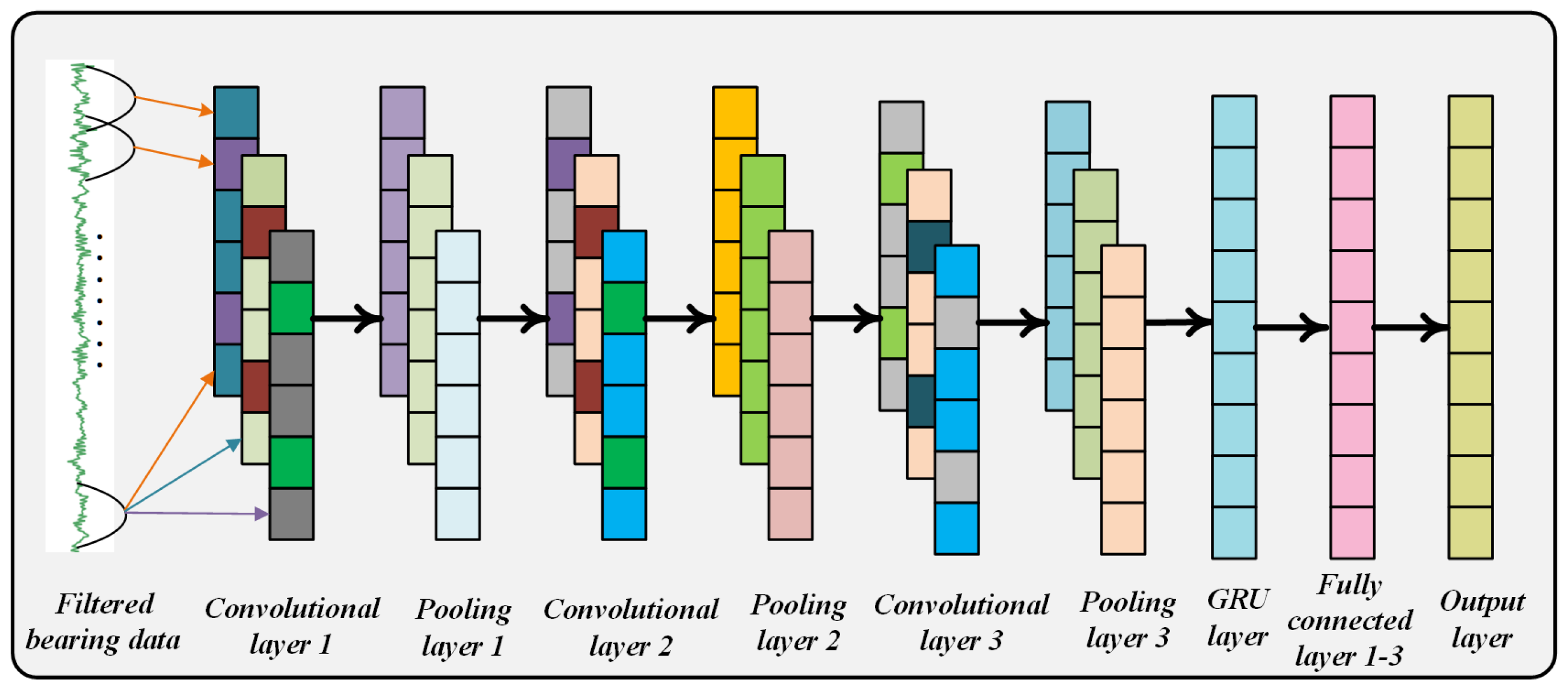

3.5. Establishment of CNN GRU Fault Diagnosis Model

3.6. Introduction to Experimental Equipment and Training Parameters

3.7. Model Training and Test Result Analysis

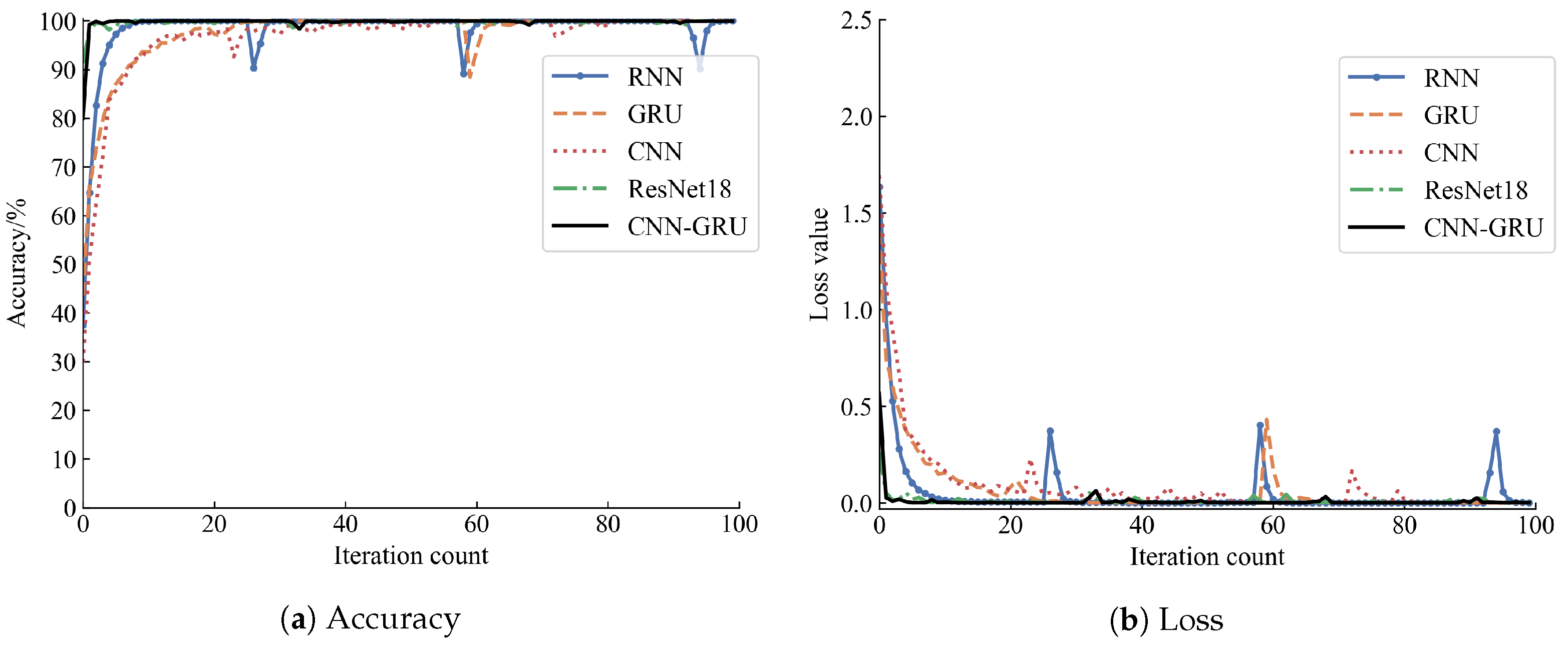

3.7.1. Model Training Analysis and Visualization Display

3.7.2. Model Testing Analysis and Visualization Display

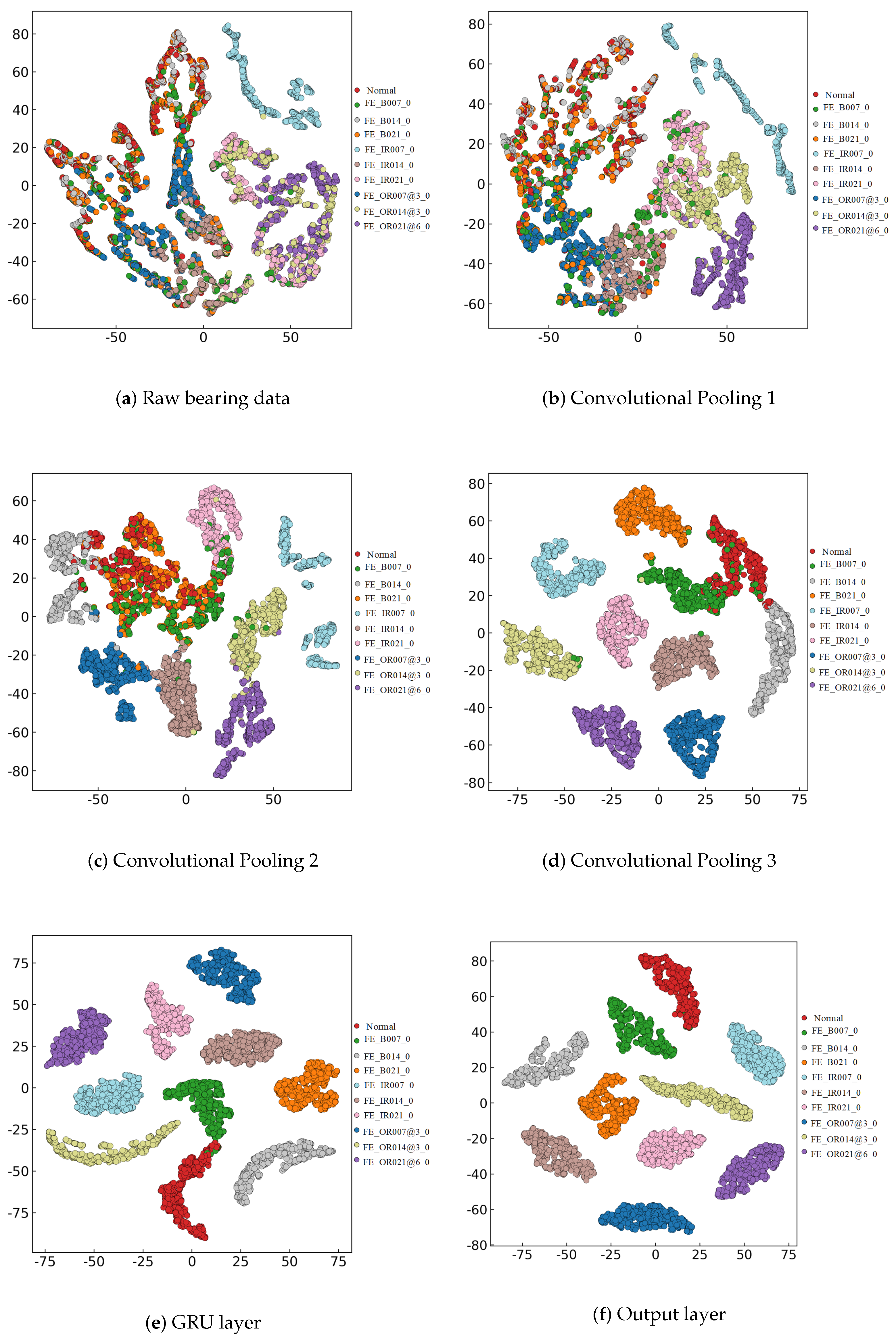

3.7.3. T-SNE Visualization Analysis

4. Summary

- (1)

- To address the issue of noise interference in bearing data, this paper applies envelope analysis and the adaptive mean filtering algorithm for denoising. The experimental results show that this method effectively highlights the main fault features, providing robust data preprocessing for fault diagnosis.

- (2)

- The combination of the CNN for spatial feature extraction and the GRU for temporal dependency modeling enables the proposed method to achieve high-precision fault diagnosis. Visualization techniques, such as confusion matrices and t-SNE, further demonstrate the diagnostic capabilities and generalization performance of the model.

- (3)

- Moving forward, we plan to explore the applicability of the proposed CNN-GRU model to other types of machinery and operational conditions to ensure robustness and scalability. Additionally, the integration of the model with real-time fault diagnosis systems and edge computing frameworks will be investigated to enhance its practical application value.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- AlShorman, O.; Irfan, M.; Saad, N.; Zhen, D.; Haider, N.; Glowacz, A.; AlShorman, A. A review of artificial intelligence methods for condition monitoring and fault diagnosis of rolling element bearings for induction motor. Shock Vib. 2020, 2020, 8843759. [Google Scholar] [CrossRef]

- Salunkhe, V.G.; Khot, S.M.; Jadhav, P.S.; Yelve, N.P.; Kumbhar, M.B. Experimental investigation using robust deep VMD-ICA and 1D-CNN for condition monitoring of roller element bearing. J. Comput. Inf. Sci. Eng. 2024, 24, 124501. [Google Scholar] [CrossRef]

- Pan, Z.; Meng, Z.; Chen, Z.; Gao, W.; Shi, Y. A two-stage method based on extreme learning machine for predicting the remaining useful life of rolling-element bearings. Mech. Syst. Signal Process. 2020, 144, 106899. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, L. A review of failure modes, condition monitoring and fault diagnosis methods for large-scale wind turbine bearings. Measurement 2020, 149, 107002. [Google Scholar] [CrossRef]

- Wu, Z.H.; Xu, Y.Q.; Deng, S.E. Analysis of Dynamic Characteristics of Grease-Lubricated Tapered Roller Bearings. Shock Vib. 2018, 2018, 7183042. [Google Scholar] [CrossRef]

- Dhanola, A.; Garg, H.C. Tribological challenges and advancements in wind turbine bearings: A review. Eng. Fail. Anal. 2020, 118, 104885. [Google Scholar] [CrossRef]

- Su, Y.; Shi, L.; Zhou, K.; Bai, G.; Wang, Z. Knowledge-informed deep networks for robust fault diagnosis of rolling bearings. Reliab. Eng. Syst. Saf. 2024, 244, 109863. [Google Scholar] [CrossRef]

- Liu, Y.; Ma, G.; Qin, H.; Han, C.; Shi, J. Research on damage and failure behaviour of coated self-lubricating spherical plain bearings based on detection of friction torque and temperature rise. Proc. Inst. Mech. Eng. Part J Eng. Tribol. 2022, 236, 514–526. [Google Scholar] [CrossRef]

- Salunkhe, V.G.; Khot, S.M.; Desavale, R.; Yelve, N. Unbalance Bearing Fault Identification Using Highly Accurate Hilbert-Huang Transform Approach. J. Nondestruct. Eval. Diagn. Progn. Eng. Syst. 2023, 6, 031005. [Google Scholar] [CrossRef]

- Brkovic, A.; Gajic, D.; Gligorijevic, J.; Savic-Gajic, I.; Georgieva, O.; Di Gennaro, S. Early fault detection and diagnosis in bearings for more efficient operation of rotating machinery. Energy 2017, 136, 63–71. [Google Scholar] [CrossRef]

- Salunkhe, V.G.; Desavale, R.G.; Khot, S.M.; Yelve, N.P. A Novel Incipient Fault Detection Technique for Roller Bearing Using Deep Independent Component Analysis and Variational Modal Decomposition. J. Tribol. 2023, 145, 074301. [Google Scholar] [CrossRef]

- Hamadache, M.; Jung, J.H.; Park, J.; Youn, B.D. A comprehensive review of artificial intelligence-based approaches for rolling element bearing PHM: Shallow and deep learning. JMST Adv. 2019, 1, 125–151. [Google Scholar] [CrossRef]

- Zio, E. Some challenges and opportunities in reliability engineering. IEEE Trans. Reliab. 2016, 65, 1769–1782. [Google Scholar] [CrossRef]

- Zhen, D.; Guo, J.; Xu, Y.; Zhang, H.; Gu, F. A novel fault detection method for rolling bearings based on non-stationary vibration signature analysis. Sensors 2019, 19, 3994. [Google Scholar] [CrossRef] [PubMed]

- Berrouche, Y. A Non-Parametric Empirical Method for Nonlinear and Non-Stationary Signal Analysis. Eng. Technol. Appl. Sci. Res. 2022, 12, 8058–8062. [Google Scholar] [CrossRef]

- Islam, M.M.; Kim, J.M. Automated bearing fault diagnosis scheme using 2D representation of wavelet packet transform and deep convolutional neural network. Comput. Ind. 2019, 106, 142–153. [Google Scholar] [CrossRef]

- He, M.; He, D. Deep learning based approach for bearing fault diagnosis. IEEE Trans. Ind. Appl. 2017, 53, 3057–3065. [Google Scholar] [CrossRef]

- Yu, X.; Dong, F.; Ding, E.; Wu, S.; Fan, C. Rolling bearing fault diagnosis using modified LFDA and EMD with sensitive feature selection. IEEE Access 2017, 6, 3715–3730. [Google Scholar] [CrossRef]

- Yuan, L.; Lian, D.; Kang, X.; Chen, Y.; Zhai, K. Rolling bearing fault diagnosis based on convolutional neural network and support vector machine. IEEE Access 2020, 8, 137395–137406. [Google Scholar] [CrossRef]

- Li, H.; Liu, T.; Wu, X.; Chen, Q. An optimized VMD method and its applications in bearing fault diagnosis. Measurement 2020, 166, 108185. [Google Scholar] [CrossRef]

- Shi, Z.; Zhang, G.; Liu, J.; Li, X.; Xu, Y.; Yan, C. Influences of inclined crack defects on vibration characteristics of cylindrical roller bearings. Mech. Syst. Signal Process. 2024, 207, 110945. [Google Scholar] [CrossRef]

- Zhou, F.; Gao, Y.; Wen, C. A novel multimode fault classification method based on deep learning. J. Control. Sci. Eng. 2017, 2017, 3583610. [Google Scholar] [CrossRef]

- Yang, S.; Tang, B.; Wang, W.; Yang, Q.; Hu, C. Physics-informed multi-state temporal frequency network for RUL prediction of rolling bearings. Reliab. Eng. Syst. Saf. 2024, 242, 109716. [Google Scholar] [CrossRef]

- Sohaib, M.; Kim, J.M. Reliable fault diagnosis of rotary machine bearings using a stacked sparse autoencoder-based deep neural network. Shock Vib. 2018, 2018, 2919637. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, B.; Gao, D. Bearing fault diagnosis base on multi-scale CNN and LSTM model. J. Intell. Manuf. 2021, 32, 971–987. [Google Scholar] [CrossRef]

- Chen, J.; Jiang, J.; Guo, X.; Tan, L. A self-Adaptive CNN with PSO for bearing fault diagnosis. Syst. Sci. Control. Eng. 2021, 9, 11–22. [Google Scholar] [CrossRef]

- Han, T.; Zhang, L.; Yin, Z.; Tan, A.C. Rolling bearing fault diagnosis with combined convolutional neural networks and support vector machine. Measurement 2021, 177, 109022. [Google Scholar] [CrossRef]

- Tao, H.; Qiu, J.; Chen, Y.; Stojanovic, V.; Cheng, L. Unsupervised cross-domain rolling bearing fault diagnosis based on time-frequency information fusion. J. Frankl. Inst. 2023, 360, 1454–1477. [Google Scholar] [CrossRef]

- Huang, Y.J.; Liao, A.H.; Hu, D.Y.; Shi, W.; Zheng, S.B. Multi-scale convolutional network with channel attention mechanism for rolling bearing fault diagnosis. Measurement 2022, 203, 111935. [Google Scholar] [CrossRef]

- Salunkhe, V.G.; Khot, S.M.; Desavale, R.G.; Yelve, N.P.; Jadhav, P.S. An Integrated Dimension Theory and Modulation Signal Bispectrum Technique for Analyzing Bearing Fault in Industrial Fibrizer. J. Nondestruct. Eval. Diagn. Progn. Eng. Syst. 2024, 7, 031006. [Google Scholar] [CrossRef]

- Xu, T.; You, J.; Li, H.; Shao, L. Energy efficiency evaluation based on data envelopment analysis: A literature review. Energies 2020, 13, 3548. [Google Scholar] [CrossRef]

- Eren, L.; Ince, T.; Kiranyaz, S. A generic intelligent bearing fault diagnosis system using compact adaptive 1D CNN classifier. J. Signal Process. Syst. 2019, 91, 179–189. [Google Scholar] [CrossRef]

- Xu, J.; Sui, Z.; Wang, W.; Xu, F. An Adaptive Discrete Integral Terminal Sliding Mode Control Method for a Two-Joint Manipulator. Processes 2024, 12, 1106. [Google Scholar] [CrossRef]

- Xu, F.; Sui, Z.; Ye, J.; Xu, J. Ternary Precursor Centrifuge Rolling Bearing Fault Diagnosis Based on Adaptive Sample Length Adjustment of 1DCNN-SeNet. Processes 2024, 12, 702. [Google Scholar] [CrossRef]

- Yuan, J.; Tian, Y. An intelligent fault diagnosis method using GRU neural network towards sequential data in dynamic processes. Processes 2019, 7, 152. [Google Scholar] [CrossRef]

- Zhu, J.; Jiang, Q.; Shen, Y.; Qian, C.; Xu, F.; Zhu, Q. Application of recurrent neural network to mechanical fault diagnosis: A review. J. Mech. Sci. Technol. 2022, 36, 527–542. [Google Scholar] [CrossRef]

- Wei, D.; Liu, K.; Wang, J.; Zhou, S.; Li, K. ResNet-18 based Inter-turn Short Circuit Fault Diagnosis of PMSMs with Consideration of Speed and Current Loop Bandwidths. IEEE Trans. Transp. Electrif. 2023, 10, 5805–5818. [Google Scholar] [CrossRef]

- Salunkhe, V.G.; Desavale, R.; Khot, S.M.; Yelve, N. Identification of Bearing Clearance in Sugar Centrifuge Using Dimension Theory and Support Vector Machine on Vibration Measurement. J. Nondestruct. Eval. Diagn. Progn. Eng. Syst. 2024, 7, 021003. [Google Scholar] [CrossRef]

- Lee, C.Y.; Lin, W.C. Induction motor fault classification based on ROC curve and t-SNE. IEEE Access 2021, 9, 56330–56343. [Google Scholar] [CrossRef]

| Acronym | Meaning |

|---|---|

| CNN | Convolutional Neural Network |

| GRU | Gated Recurrent Unit |

| LSTM | Long short-term memory |

| VMD | Variational mode decomposition |

| RNN | Recurrent Neural Network |

| CWRU | Case Western Reserve University |

| FE | Fan end |

| B | Rolling element |

| IR | Inner race |

| OR | Outer race |

| HP | Horsepower |

| Data Name | Fault Size | Applied Load | Speed | Sample Shape | Fault Label |

|---|---|---|---|---|---|

| Normal bearings | – | 0HP | 1797rpm | 1000 × 1024 | Normal |

| Ball damage fault | 0.007 inch | 0 HP | 1797 rpm | 1000 × 1024 | FE_B007_0 |

| Ball damage fault | 0.014 inch | 0 HP | 1797 rpm | 1000 × 1024 | FE_B014_0 |

| Ball damage fault | 0.021 inch | 0 HP | 1797 rpm | 1000 × 1024 | FE_B021_0 |

| Inner damage fault | 0.007 inch | 0 HP | 1797 rpm | 1000 × 1024 | FE_IR007_0 |

| Inner damage fault | 0.014 inch | 0 HP | 1797 rpm | 1000 × 1024 | FE_IR014_0 |

| Inner damage fault | 0.021 inch | 0 HP | 1797 rpm | 1000 × 1024 | FE_IR021_0 |

| Outer damage fault | 0.007 inch | 0 HP | 1797 rpm | 1000 × 1024 | FE_OR007@3_0 |

| Outer damage fault | 0.014 inch | 0 HP | 1797 rpm | 1000 × 1024 | FE_OR014@3_0 |

| Outer damage fault | 0.021 inch | 0 HP | 1797 rpm | 1000 × 1024 | FE_OR021@6_0 |

| Network Layer Name | Number of Output Channels | Convolutional Kernel Size w | Fill Size | Stride | Activation Function | Output Size |

|---|---|---|---|---|---|---|

| Conv 1 | 64 | (16,1) | (1,1) | (1,1) | ReLU | 64@1 × 259 |

| Pooling 1 | 64 | (2,1) | – | (2,1) | – | 64@1 × 129 |

| Conv 2 | 32 | (3,1) | (1,1) | (1,1) | ReLU | 32@1 × 127 |

| Pooling 2 | 32 | (2,1) | – | (2,1) | – | 32@1 × 63 |

| Conv 3 | 32 | (3,1) | (1,1) | (1,1) | ReLU | 32@1 × 62 |

| Pooling 3 | 32 | (2,1) | – | (2,1) | – | 32@1 × 30 |

| GRU 1 | 128 | – | – | – | tanh | 1 × 128 |

| GRU 2 | 256 | – | – | – | tanh | 1 × 256 |

| FC 1 | 1000 | – | – | – | ReLU | 1000 |

| FC 2 | 100 | – | – | – | ReLU | 100 |

| FC 3 | 10 | – | – | – | Softmax | 10 |

| Output | 10 | – | – | – | – | 10 |

| Diagnostic Model | Average Accuracy % | Average Error Rate % |

|---|---|---|

| RNN | 98.85 | 1.15 |

| GRU | 99.05 | 0.95 |

| CNN | 99.15 | 0.85 |

| ResNet18 | 99.30 | 0.70 |

| CNN-GRU | 99.35 | 0.65 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, H.; Sui, Z.; Xu, J.; Lan, Y. Fault Diagnosis of Mechanical Rolling Bearings Using a Convolutional Neural Network–Gated Recurrent Unit Method with Envelope Analysis and Adaptive Mean Filtering. Processes 2024, 12, 2845. https://doi.org/10.3390/pr12122845

Zhu H, Sui Z, Xu J, Lan Y. Fault Diagnosis of Mechanical Rolling Bearings Using a Convolutional Neural Network–Gated Recurrent Unit Method with Envelope Analysis and Adaptive Mean Filtering. Processes. 2024; 12(12):2845. https://doi.org/10.3390/pr12122845

Chicago/Turabian StyleZhu, Huiyi, Zhen Sui, Jianliang Xu, and Yeshen Lan. 2024. "Fault Diagnosis of Mechanical Rolling Bearings Using a Convolutional Neural Network–Gated Recurrent Unit Method with Envelope Analysis and Adaptive Mean Filtering" Processes 12, no. 12: 2845. https://doi.org/10.3390/pr12122845

APA StyleZhu, H., Sui, Z., Xu, J., & Lan, Y. (2024). Fault Diagnosis of Mechanical Rolling Bearings Using a Convolutional Neural Network–Gated Recurrent Unit Method with Envelope Analysis and Adaptive Mean Filtering. Processes, 12(12), 2845. https://doi.org/10.3390/pr12122845