Experimental Study on Damage Evaluation of Working Fluid Invasion in Tight Sandstone Gas Reservoirs

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Materials

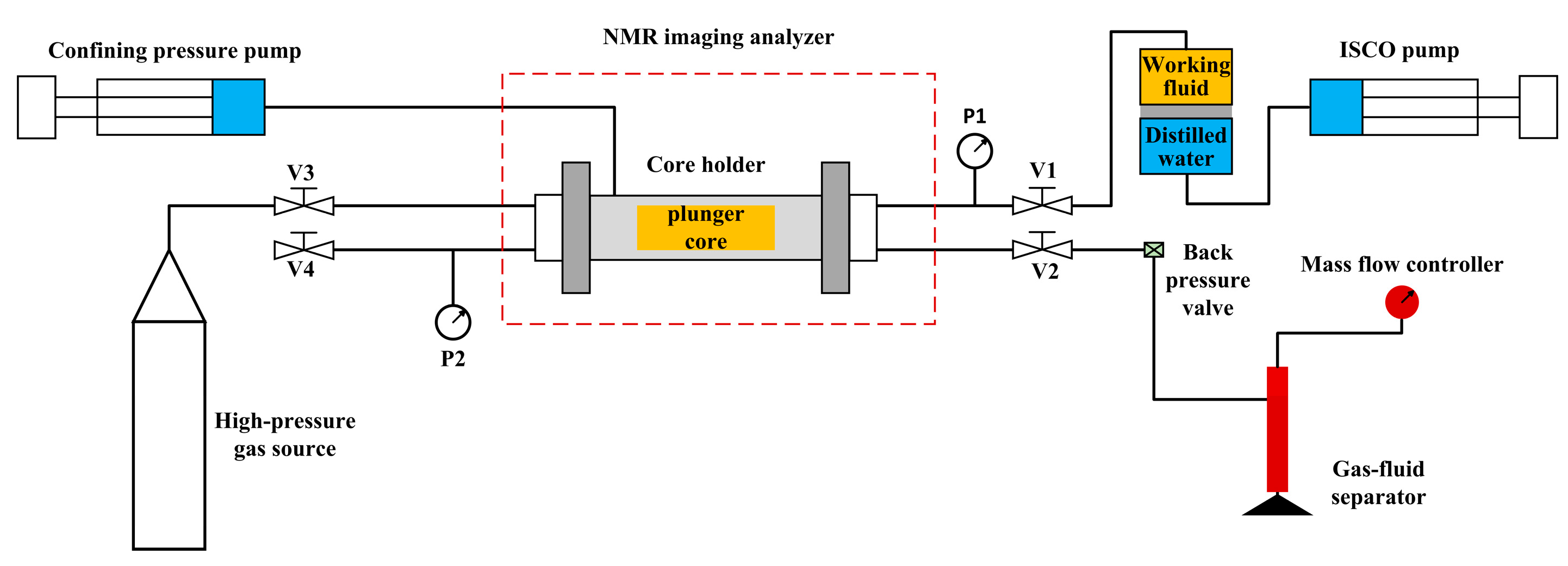

2.2. Experimental Design and Steps

- (1)

- We put the core into the core holder, connected the equipment according to Figure 2, and closed valves V1, V2, V3, and V4;

- (2)

- We opened the confining pressure pump and applied confining pressure to the core to set the confining pressure value;

- (3)

- We opened V3 to fill the core with gas until the two pressure gauges showed the pore pressure and closed V3;

- (4)

- We opened V1, started the ISCO pump, and injected the working fluid into the experimental core according to the pressure set by the experimental design. We then regularly measured the T2 spectrum and NMR imaging of the core;

- (5)

- The V1 and ISCO pumps were closed at 120 min, V4 and V2 were opened to collect the real-time flow, and we measured core permeability.

3. Results

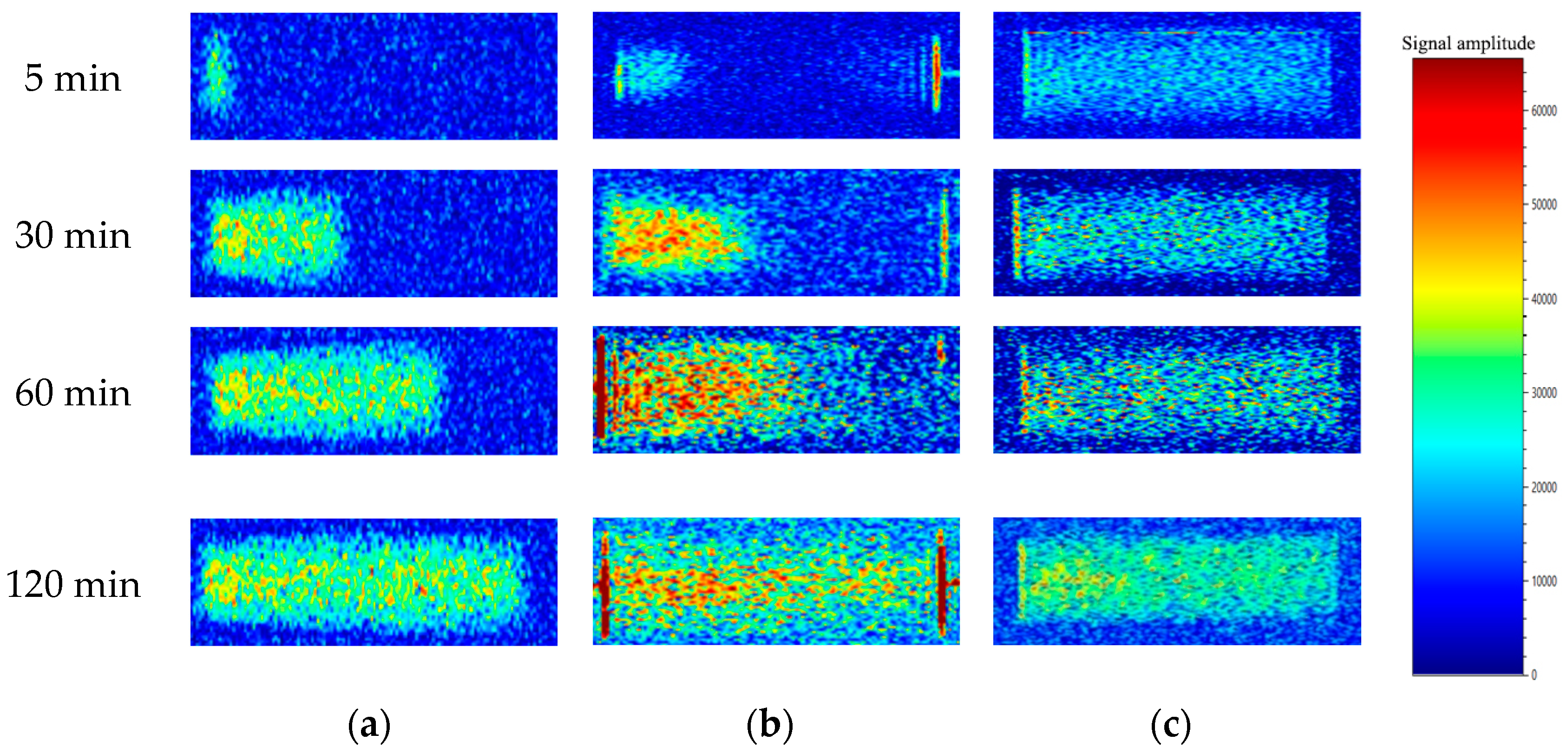

3.1. Visual Monitoring and Dynamic Analysis of Working Fluid Invasion Process

3.1.1. Visual Monitoring of the Invasion Process

3.1.2. The Working Fluid Invasion Rate Variation Law

3.1.3. The Variation Law for the Real-Time Invasion Flow Rate of the Working Fluid

3.1.4. Theoretical Analysis of Working Fluid Invasion Mechanisms

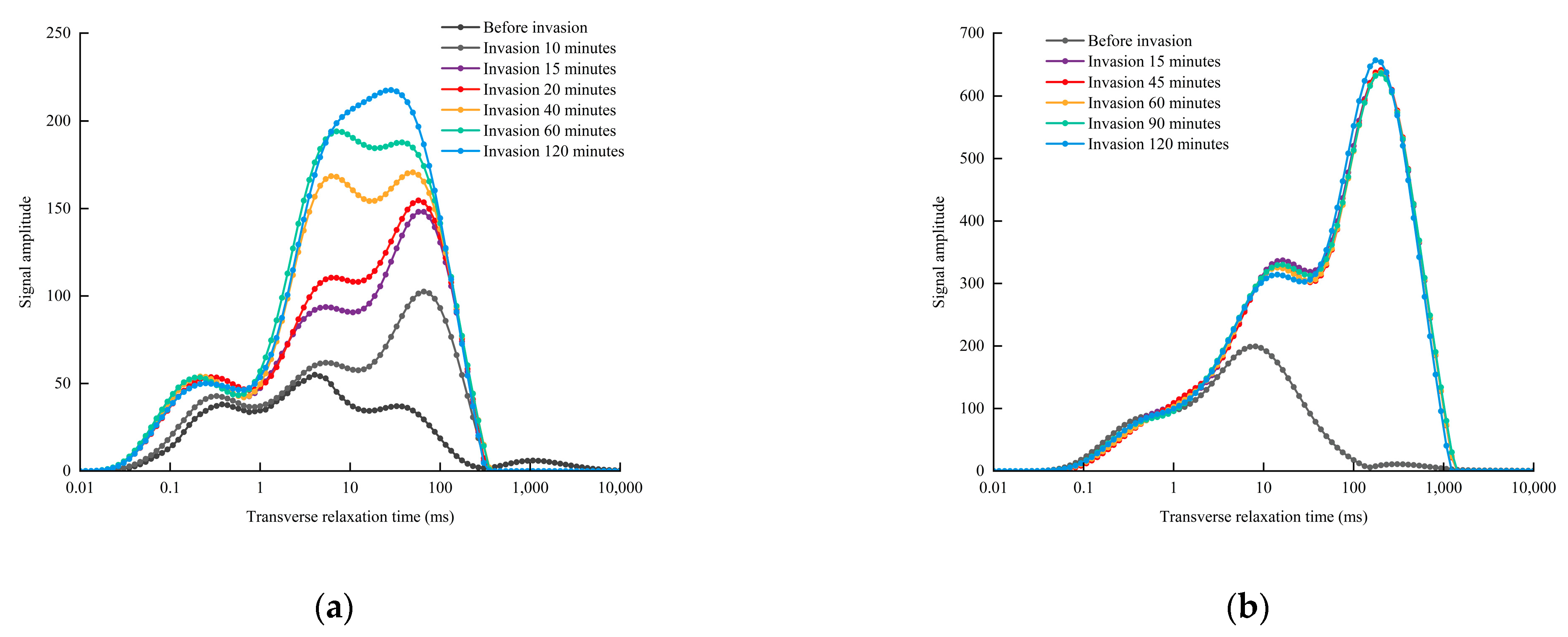

3.2. Working Fluid Damage Evaluation

3.2.1. Real-Time T2 Spectrum of Damage

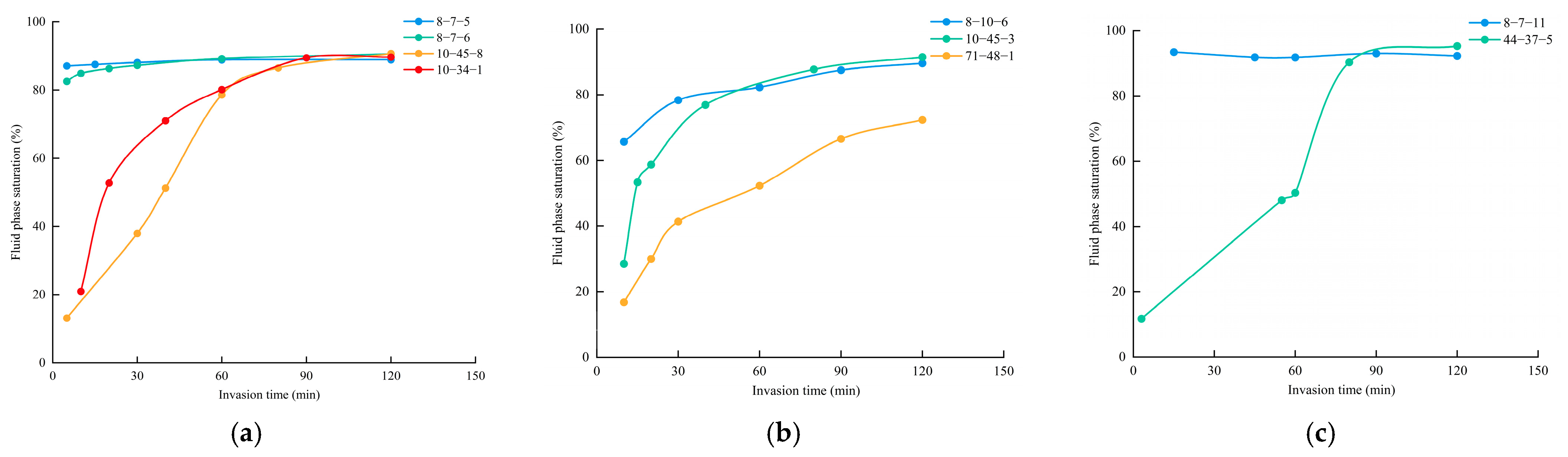

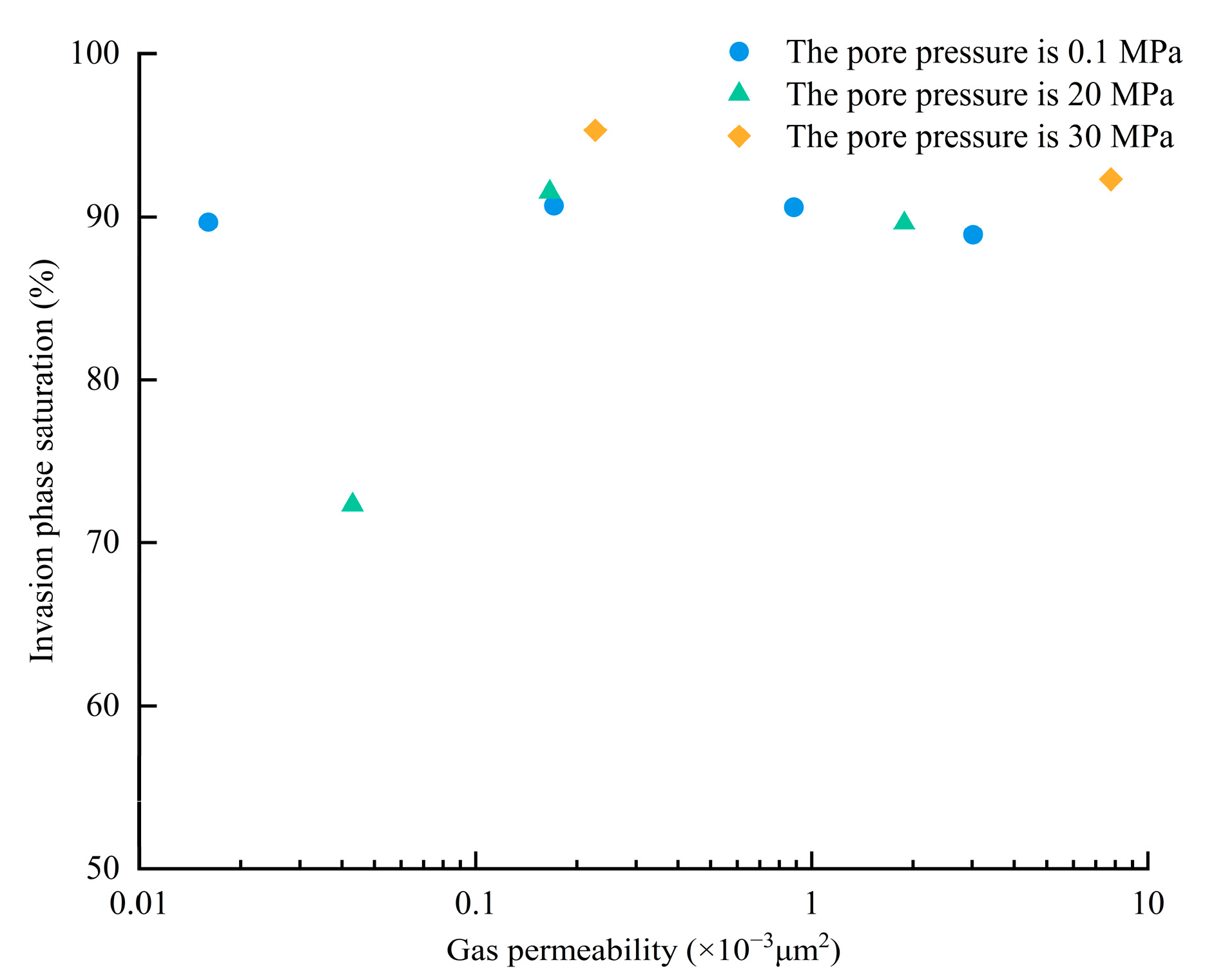

3.2.2. Fluid Saturation Variation Law

3.3. Comprehensive Analysis

4. Conclusions

- (1)

- Permeability is positively correlated with the real-time invasion flow rate and the invasion rate: the higher the permeability, the greater the real-time invasion flow rate and the faster the invasion rate. The pore pressure also significantly impacts the real-time invasion flow rate and invasion rate. As the pore pressure increases, the real-time invasion flow of the working fluid decreases, and the invasion rate slows down.

- (2)

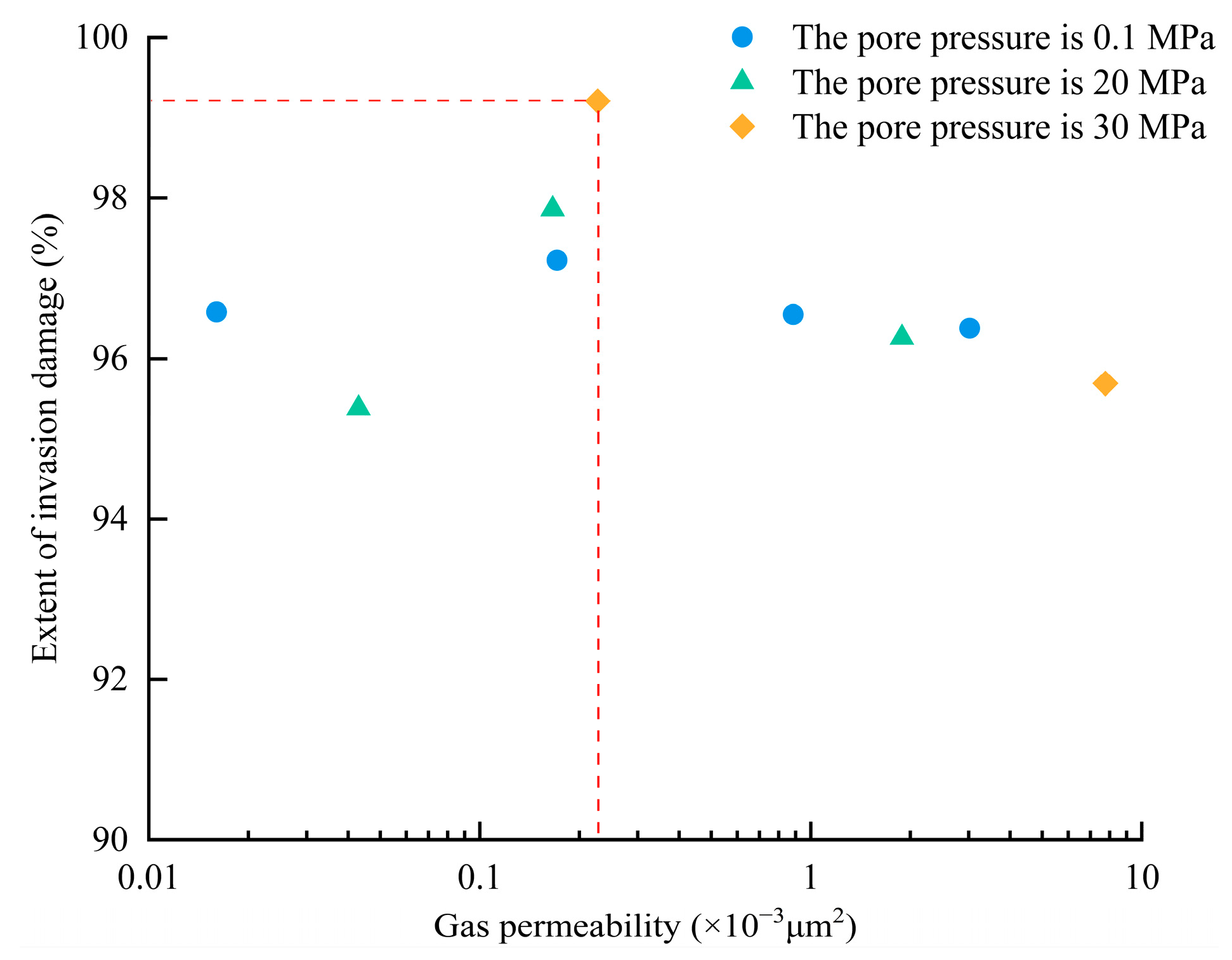

- During construction, working fluid invasion into the reservoir significantly increases fluid saturation. Experimental results indicate that fluid saturation typically reaches or exceeds 70%, with some samples exceeding 90%. The increase in fluid saturation causes severe damage to the gas-phase permeability of the reservoir, with damage extent exceeding 95%, particularly in low-permeability tight cores.

- (3)

- Both permeability and pore pressure influence the invasion-phase saturation and the extent of invasion damage. At the same reservoir pore pressure, cores with permeability ranges between 0.1 × 10−3 μm2 and 1 × 10−3 μm2 exhibit higher fluid-phase saturation and greater invasion damage. This means that, for cores with similar permeability, the higher the pore pressure, the higher the invasion-phase saturation and the greater the extent of invasion damage.

- (4)

- Due to the limited number and size of the samples in this experiment, the conclusions can only be qualitatively analyzed. Effectively removing or reducing the damage in the early stage of development is critical for cost-effective development. Further investigation is needed to explore the influence of the backflow of working fluid and the variation in working fluid with the gas extracted on the degree of reservoir damage during the production process.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ma, X.; Jia, A.; Tan, J.; He, D. Tight sand gas development technologies and practices in China. Petrol. Explor. Develop. 2012, 39, 572–579. [Google Scholar] [CrossRef]

- Li, X.; Wang, L.; Wang, W.; Xiao, Y.; Chen, B.; Zhang, Y.; Zhou, C.; Ma, Z.; Shi, H. Innovation and efficient development practice of key fracturing technologies based on slim-hole completion: A case study of tight gas reservoir in Sulige Gasfield. Nat. Gas Ind. 2022, 42, 76–83. [Google Scholar] [CrossRef]

- Jia, A.; Wei, Y.; Guo, Z.; Wang, G.; Meng, D.; Huang, S. Development status and prospect of tight sandstone gas in China. Nat. Gas Ind. 2022, 42, 83–92. [Google Scholar] [CrossRef]

- Shi, H.; Ding, Y.; Ding, L.; Li, X.; Lyu, X.; Yin, X. Damage mechanism of fracturing fluid in the eastern Sulige Gasfield and countermeasures. J. Oil Gas Technol. 2013, 35, 131–135. [Google Scholar]

- Zhu, J.; You, L.; Li, J.; Kang, Y.; Zhang, J.; Zhang, D.; Huang, C. Damage evaluation on oil-based drill-in fluids for ultra-deep fractured tight sandstone gas reservoirs. Nat. Gas Ind. 2017, 37, 62–68. [Google Scholar] [CrossRef]

- Li, G.; Cai, W.; Meng, Y.; Wang, L.; Wang, L.; Zhang, X. Experimental evaluation on the damages of different drilling modes to tight sandstone reservoirs. Nat. Gas Ind. 2017, 37, 69–76. [Google Scholar] [CrossRef]

- Huang, W.; Lei, M.; Teng, X.; Zhu, J.; Li, N.; Zhang, Z.; Zhou, B. Damaging mechanism of tight sandstone gas reservoirs and optimization of drilling fluids for reservoir protection. Drill. Fluid Complet. Fluid 2018, 35, 33–38. [Google Scholar] [CrossRef]

- Xi, S.; Yan, W.; Liu, X.; Zhang, C.; Yin, L.; Dong, G.; Jing, X.; Wei, L. New fields, new types, and resource potential of natural gas exploration in Ordos Basin. Acta Pet. Sin. 2024, 45, 33–51. [Google Scholar] [CrossRef]

- Zhao, W.; Huang, D.; Wang, K.; Hu, X.; Hui, J.; Chen, Y. Accumulation conditions and key technologies of exploration and development for Qingshimao gas field in Ordos Basin. Acta Pet. Sin. 2023, 44, 1739–1754. [Google Scholar] [CrossRef]

- Xu, B.; Li, L.; He, Q.; Luo, Y.; Zhang, Y.; Li, G. Discussion on damage mechanism of fracturing fluid in tight sandstone reservoir. Fault-Block Oil Gas Field 2013, 20, 639–643. [Google Scholar] [CrossRef]

- Xu, L.; Zhang, S.; Ma, X. Characteristics of Damage of Guar Fracturing Fluid to Reservoir Permeability. Xinjiang Pet. Geol. 2016, 37, 456–459. [Google Scholar] [CrossRef]

- Cao, Y.; Qu, Z.; Guo, T.; Xu, H.; Gong, D. Experimental study on damage mechanism of water-based fracturing fluid to reservoir. J. Xi’an Shiyou Univ. (Nat. Sci. Ed.) 2016, 31, 87–92. [Google Scholar] [CrossRef]

- Guo, J.; Li, Y.; Wang, S. Hydrogen bond inhibition method: Reducing the adsorption damage of guar fracturing fluid to sandstone reservoirs. Nat. Gas Ind. 2019, 39, 57–62. [Google Scholar] [CrossRef]

- Tang, H.; Tang, H.; He, J.; Zhao, F.; Zhang, L.; Liao, J.; Wang, Q.; Yuan, X. Damage mechanism of water-based fracturing fluid to tight sandstone gas reservoirs: Improvement of the evaluation measurement for properties of water-based fracturing fluid: SY/T 5107-2016. Nat. Gas Ind. 2020, 40, 55–63. [Google Scholar] [CrossRef]

- National Energy Administration. Lab Testing Method of Drilling and Completion Fluids Damaging Oil Formation: SY/T 6540-2021; Petroleum Industry Press: Beijing, China, 2021. [Google Scholar]

- Hu, Y.; Li, X.; Wan, Y.; Lu, J.; Zhu, H.; Zhang, Y.; Zhu, Q.; Yang, M.; Niu, L. Physical simulation on gas percolation in tight sandstone. Petrol. Explor. Develop. 2013, 40, 580–584. [Google Scholar] [CrossRef]

- Dong, X.; Meng, X.; Pu, R. Occurrence characteristics of movable fluids based on the division of pore throat system in tight gas reservoir by fractal theory. Nat. Gas Ind. 2023, 43, 78–90. [Google Scholar] [CrossRef]

- Li, X.; Feng, D.; Zhang, T.; Sun, Z.; He, M.; Liu, Q.; Liu, W.; Zhao, W.; Li, J. The role and its application of capillary force in the development of unconventional oil and gas reservoirs. Acta Pet. Sin. 2020, 41, 1719–1733. [Google Scholar] [CrossRef]

- Ren, X.; Li, A.; Wang, Y.; Wu, S.; Wang, G. Pore structure of tight sand reservoir and its influence on percolation—Taking the Chang 8 reservoir in Maling oilfield in Ordos Basin as an example. Oil Gas Geol. 2015, 36, 774–779. [Google Scholar] [CrossRef]

- Li, G.; Ren, W.; Meng, Y.; Wang, C.; Wei, N. Micro-flow kinetics research on water invasion in tight sandstone reservoirs. J. Nat. Gas Sci. Eng. 2014, 20, 184–191. [Google Scholar] [CrossRef]

- Zhang, J.; Gao, S.; Xiong, W.; Ye, L.; Liu, H.; Zhu, W.; Yang, Y.; Niu, W. A new productivity model based on gas-water seepage resistance coefficient for tight sandstone reservoirs. Nat. Gas Ind. 2023, 43, 177–187. [Google Scholar] [CrossRef]

- Li, X.; Hu, Y.; Xu, X.; Jiao, C. Research and Application of Tight Sandstone Gas Development Mechanism; Science Press: Beijing, China, 2020. [Google Scholar]

- Sheng, J.; Sun, W.; Duan, B.; Liu, Y.; Zhang, T.; Cao, L. Water lock effect mechanism of tight sandstone gas reservoir: An example of the He 8 reservoir of the upper Paleozoic in the southeast region of Sulige Gasfield. Nat. Gas Geosci. 2015, 26, 1972–1978. [Google Scholar] [CrossRef]

- Ye, L.; Gao, S.; Yang, H.; Xiong, W.; Hu, Z.; Iiu, H.; Du, S. Water production mechanism and development strategy of tight sandstone gas reservoirs. Nat. Gas Ind. 2015, 35, 41–46. [Google Scholar] [CrossRef]

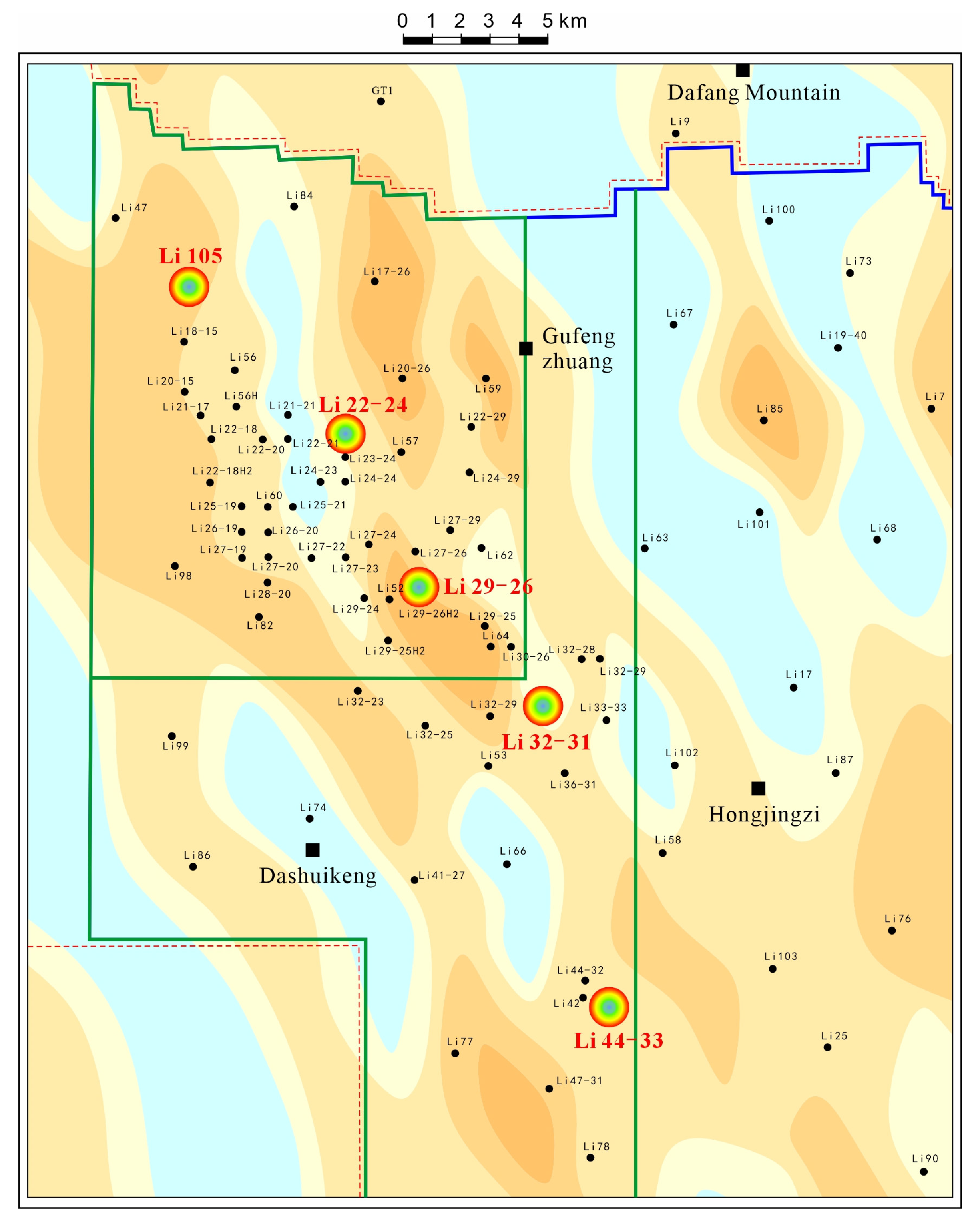

| Well Name | Core Number | Physical Parameters | Experimental Parameters | ||||

|---|---|---|---|---|---|---|---|

| Length (cm) | Diameter (cm) | Porosity (%) | Permeability (×10−3 μm2) | Pore Pressure (MPa) | Working Fluid Pressure (MPa) | ||

| Li 44-33 | 10-34-1 | 6.97 | 2.51 | 8.26 | 0.016 | 0.1 | 5 |

| Li 44-33 | 10-45-8 | 7.09 | 2.50 | 8.90 | 0.171 | ||

| Li 29-26 | 8-7-6 | 7.18 | 2.51 | 9.50 | 0.884 | ||

| Li 29-26 | 8-7-5 | 7.10 | 2.50 | 10.81 | 3.02 | ||

| Li 32-31 | 71-48-1 | 6.94 | 2.50 | 6.29 | 0.043 | 20 | 25 |

| Li 44-33 | 10-45-3 | 6.98 | 2.50 | 8.75 | 0.166 | ||

| Li 22-24 | 8-10-6 | 6.43 | 2.51 | 9.51 | 1.885 | ||

| Li 29-26 | 8-7-11 | 6.6 | 2.5 | 11.33 | 7.76 | 30 | 35 |

| Li 105 | 44-37-5 | 7.10 | 2.5 | 6.68 | 0.227 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, L.; Fang, F.; He, S.; Hu, Y.; Wang, J.; Jiao, C.; Luo, J.; Zhang, Y.; Guo, C. Experimental Study on Damage Evaluation of Working Fluid Invasion in Tight Sandstone Gas Reservoirs. Processes 2024, 12, 2857. https://doi.org/10.3390/pr12122857

Chen L, Fang F, He S, Hu Y, Wang J, Jiao C, Luo J, Zhang Y, Guo C. Experimental Study on Damage Evaluation of Working Fluid Invasion in Tight Sandstone Gas Reservoirs. Processes. 2024; 12(12):2857. https://doi.org/10.3390/pr12122857

Chicago/Turabian StyleChen, Luyao, Feifei Fang, Sijie He, Yong Hu, Jiping Wang, Chunyan Jiao, Jianning Luo, Yuanyuan Zhang, and Changmin Guo. 2024. "Experimental Study on Damage Evaluation of Working Fluid Invasion in Tight Sandstone Gas Reservoirs" Processes 12, no. 12: 2857. https://doi.org/10.3390/pr12122857

APA StyleChen, L., Fang, F., He, S., Hu, Y., Wang, J., Jiao, C., Luo, J., Zhang, Y., & Guo, C. (2024). Experimental Study on Damage Evaluation of Working Fluid Invasion in Tight Sandstone Gas Reservoirs. Processes, 12(12), 2857. https://doi.org/10.3390/pr12122857