A Novel Method for the Quantitative Evaluation of Retrograde Condensate Pollution in Condensate Gas Reservoirs

Abstract

1. Introduction

2. Methods

2.1. Construction of the Condensate Gas Phase Simulation Model

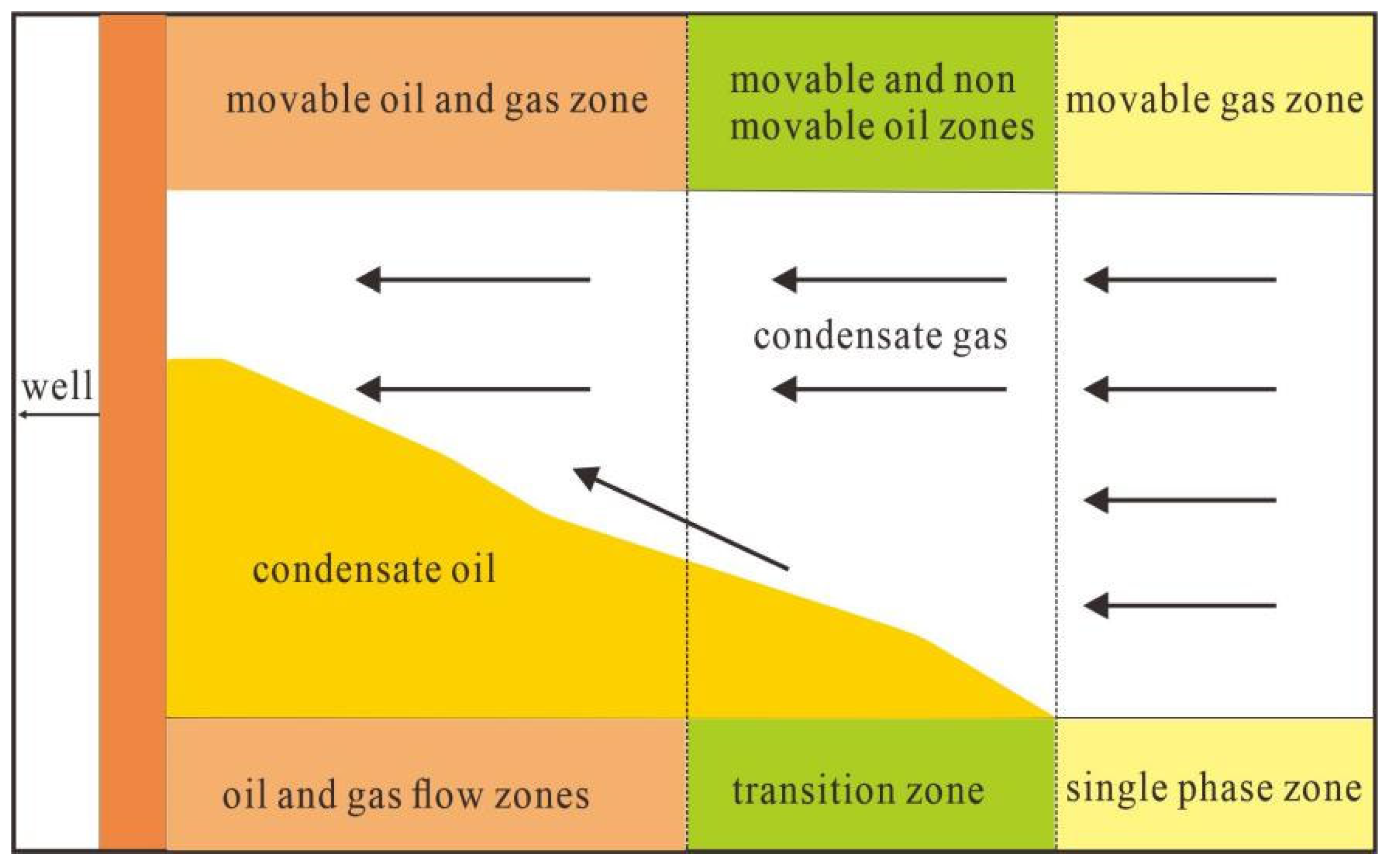

2.2. Construction of the Multiphase Flow Model for Condensate Gas Reservoirs

2.3. Construction of the Retrograde Pollution Skin Coefficient Model

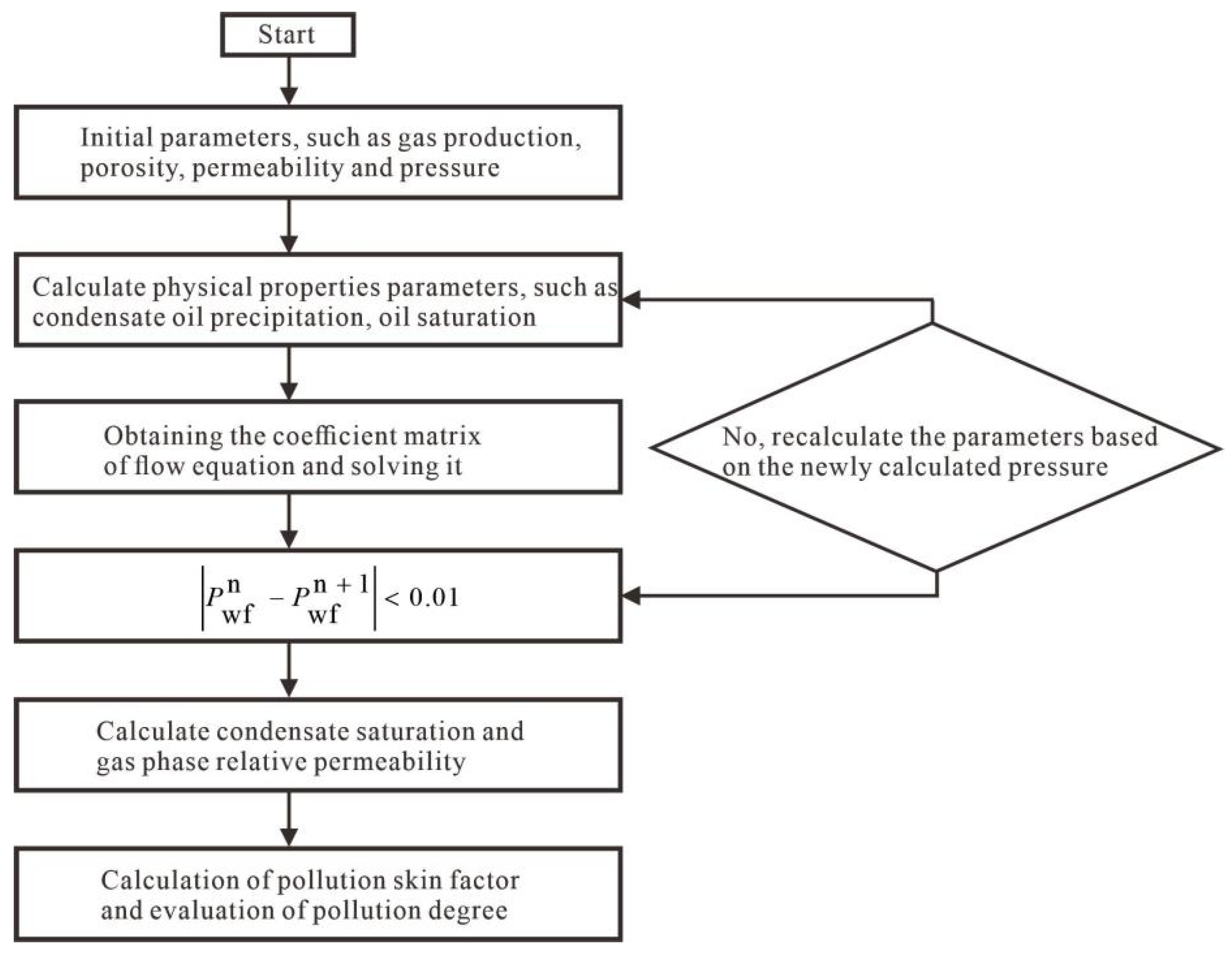

2.4. Model Solution

3. Results and Discussion

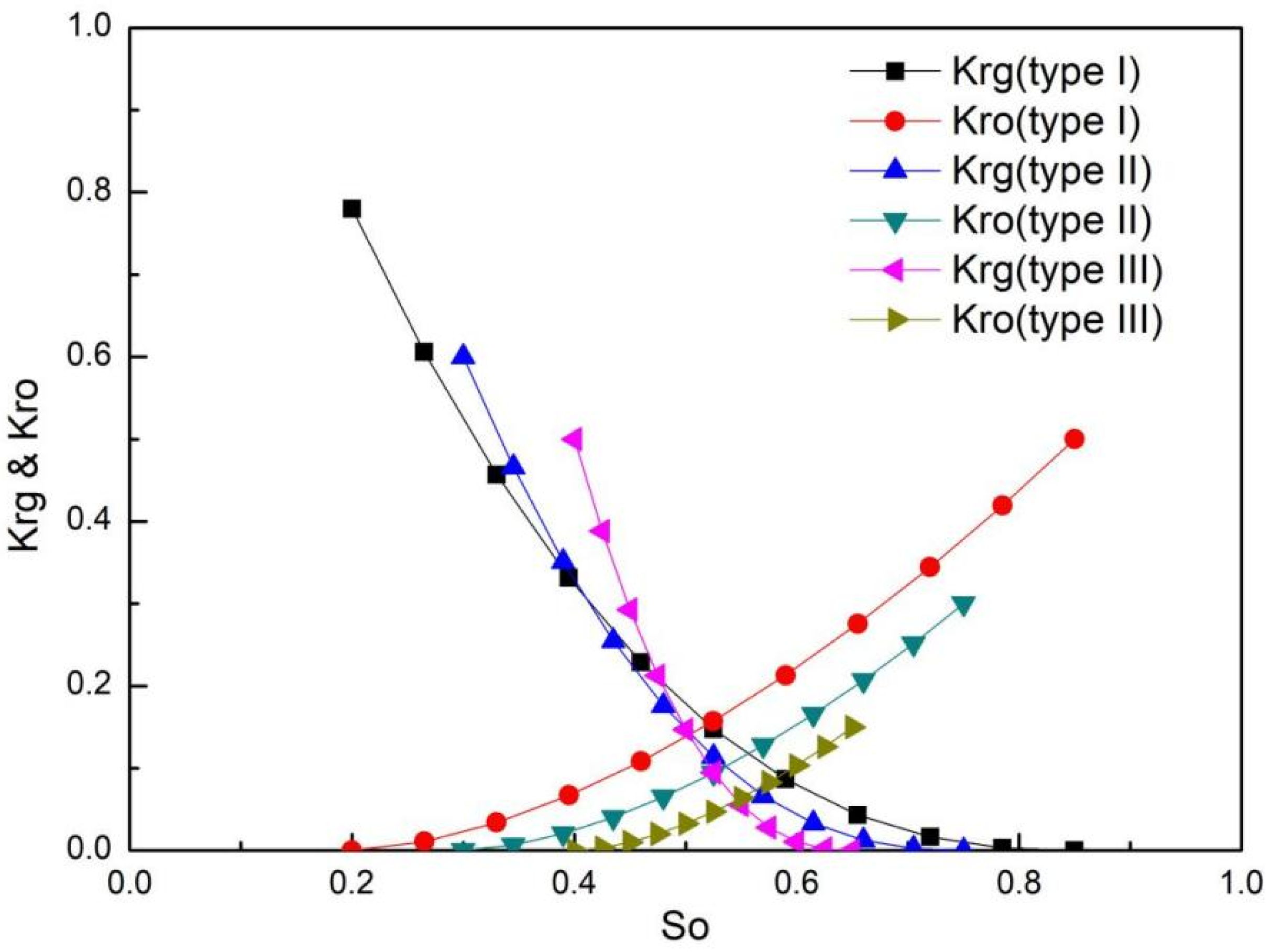

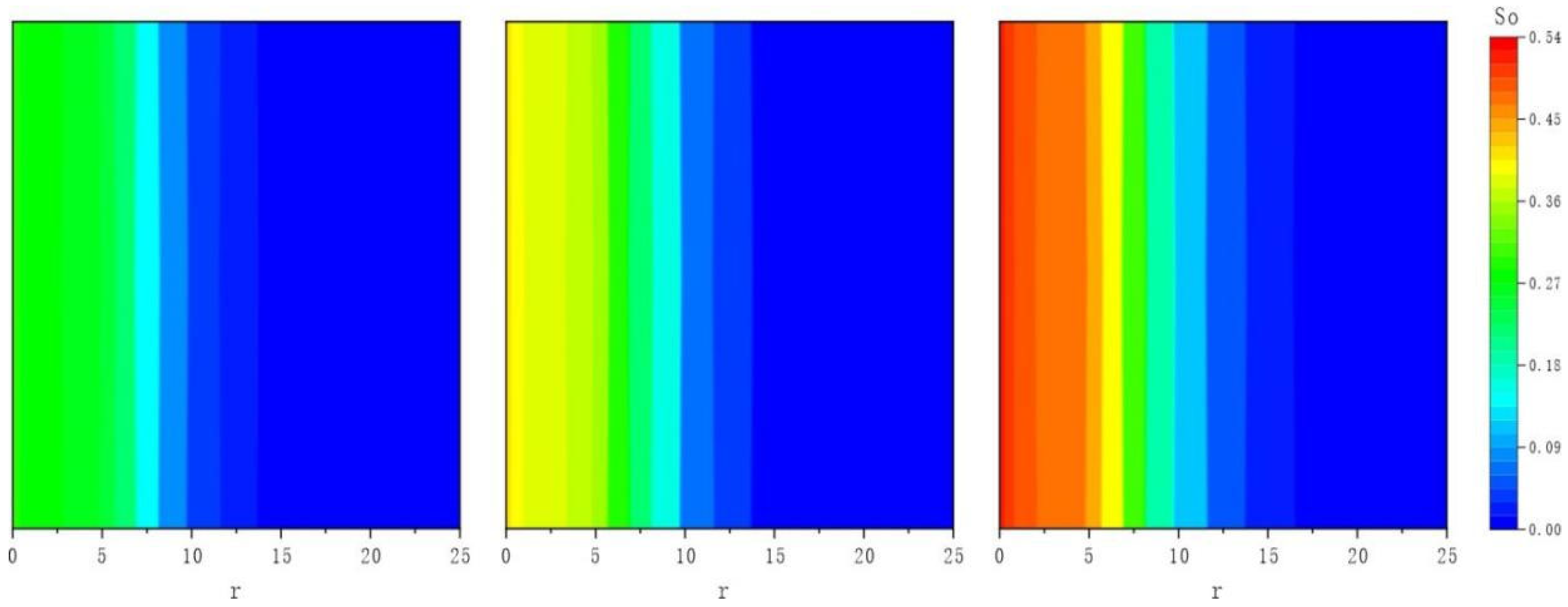

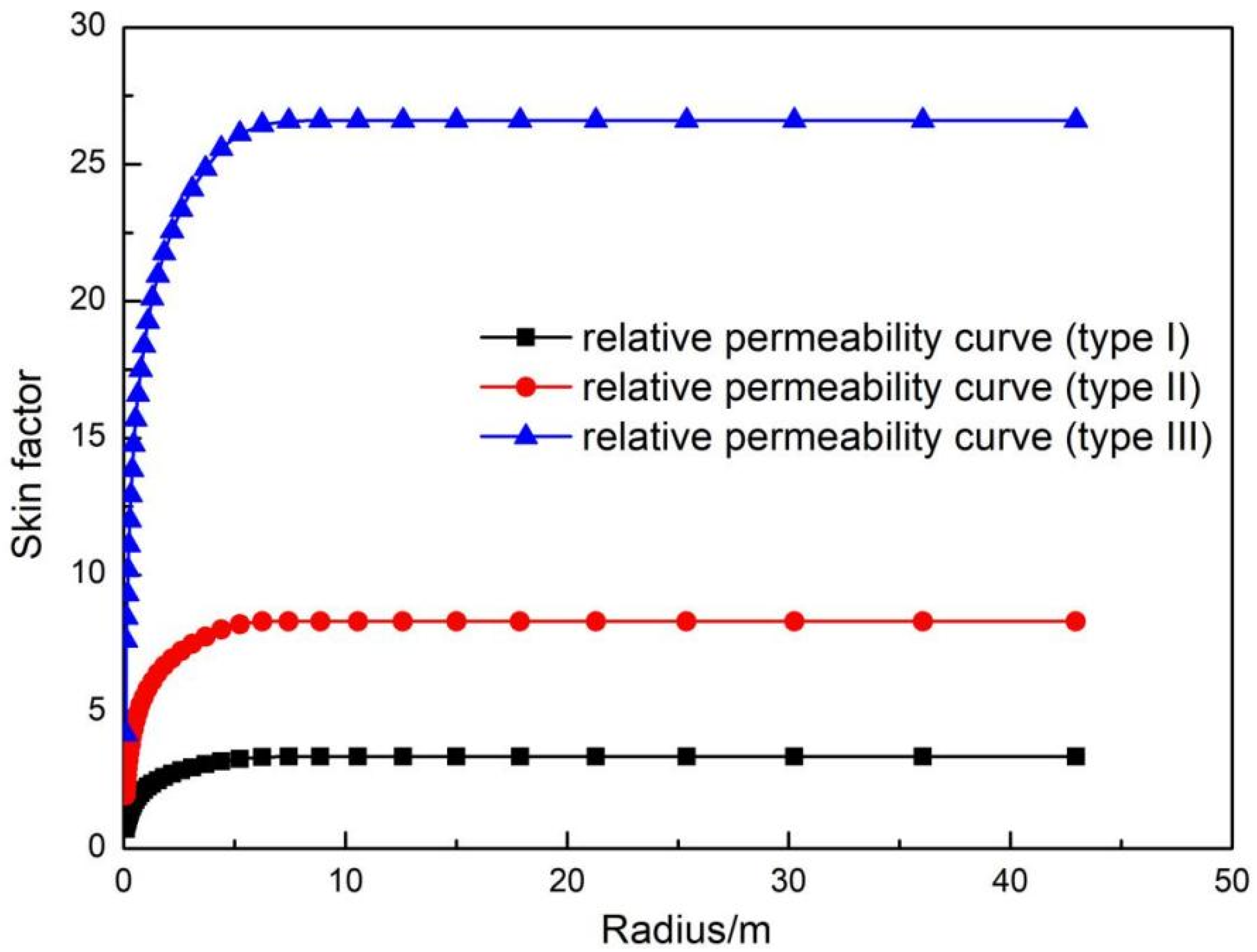

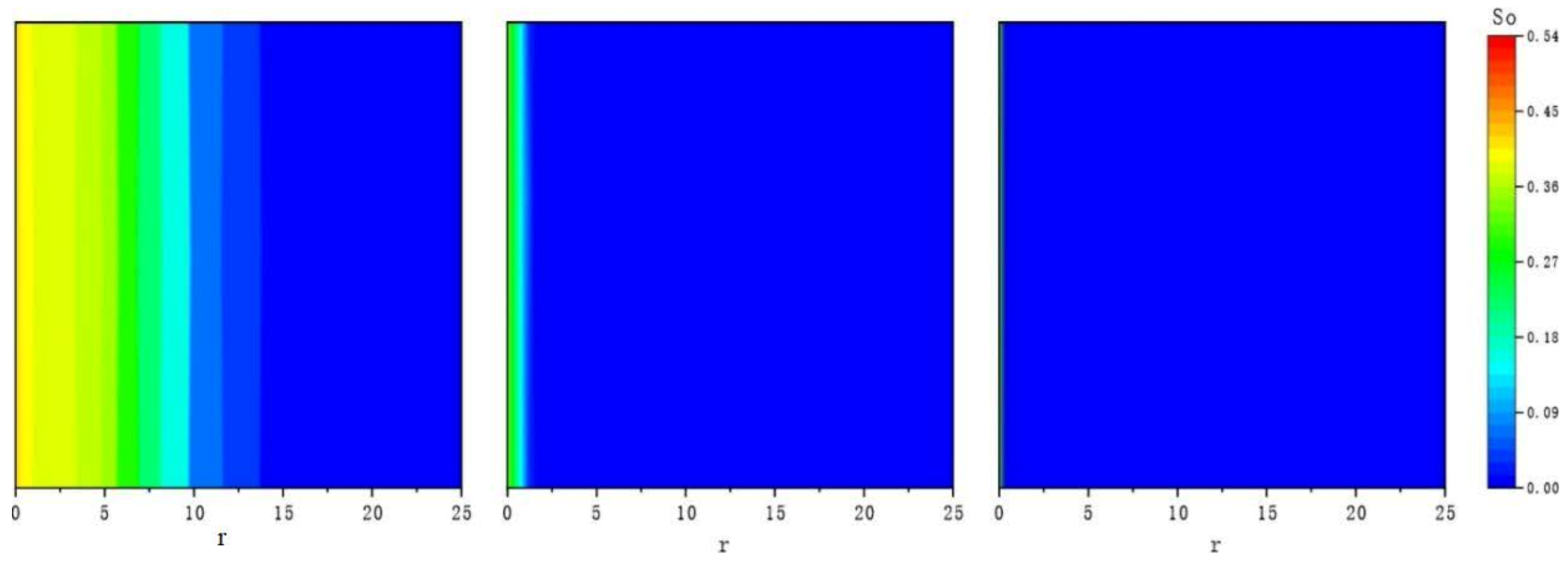

3.1. Influence of the Relative Permeability Curve

3.2. Influence of the Difference between Formation Pressure and Dew Point Pressure

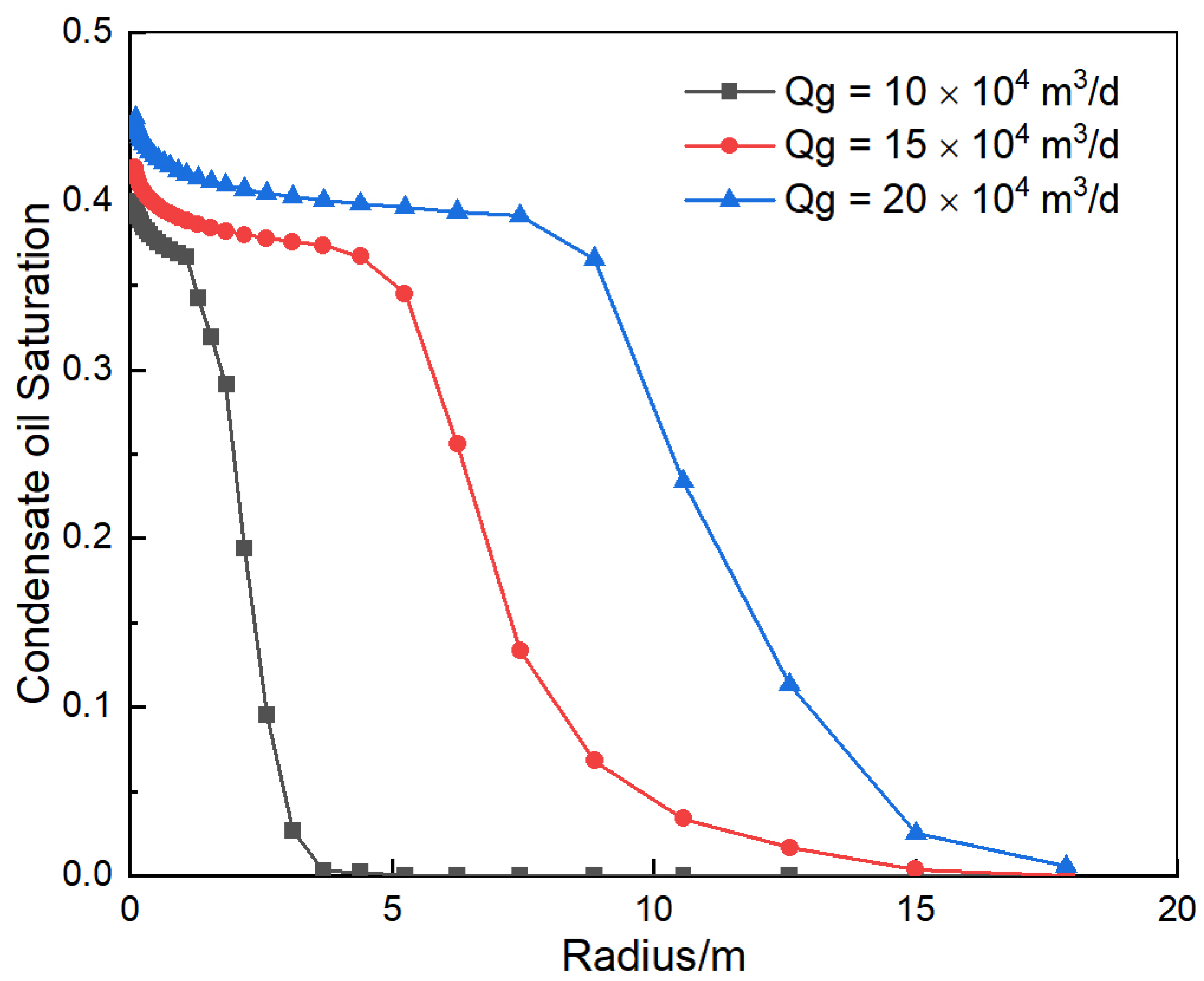

3.3. Influence of Well Production

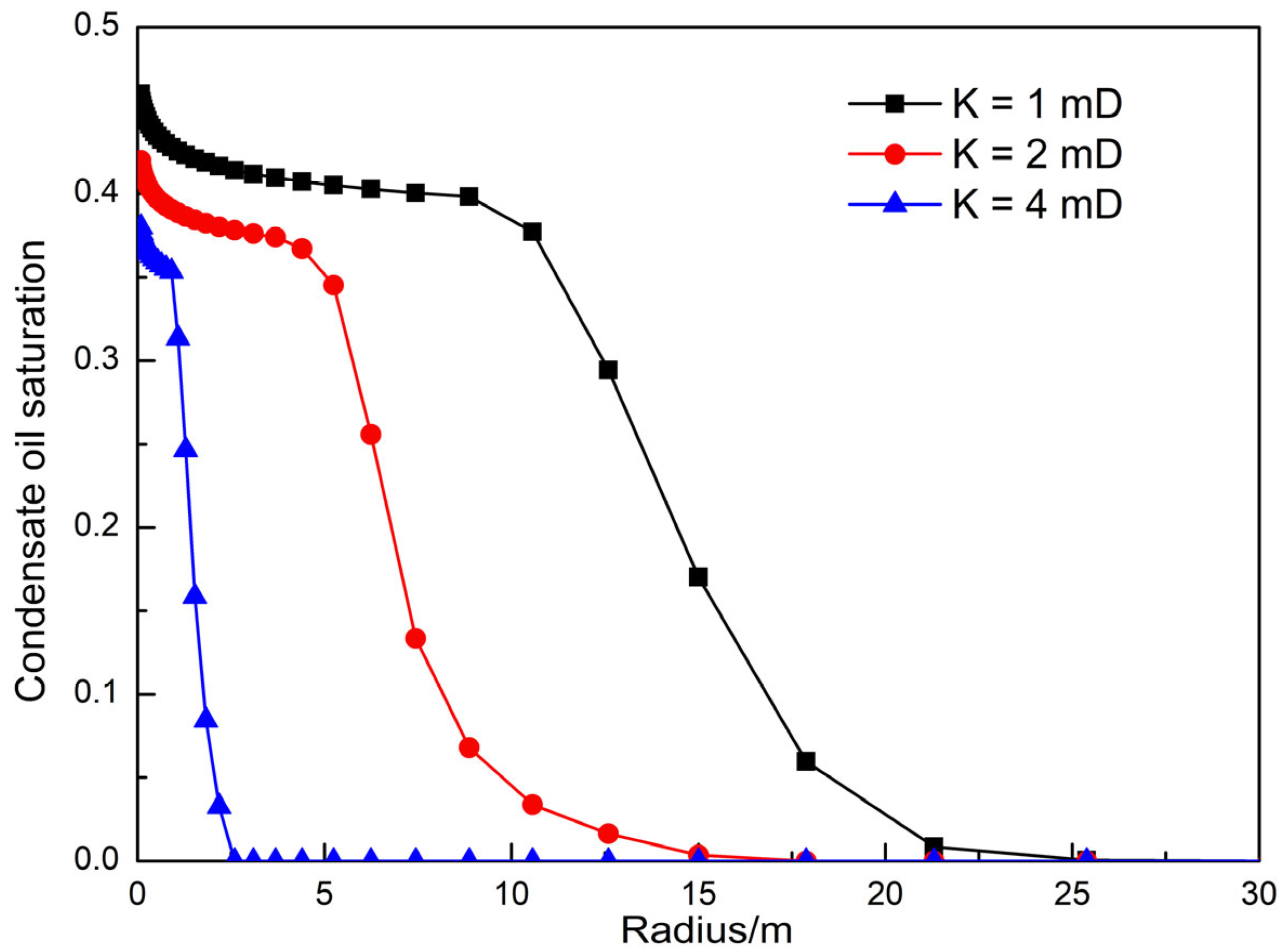

3.4. Influence of Formation Permeability

4. Practical Applications

5. Conclusions

- (1)

- The gas phase simulation model, the multiphase flow model, and the skin coefficient pollution model were constructed to simulate the impact of retrograde condensation on gas flow in allowing the quantitative characterization of retrograde condensation pollution.

- (2)

- In the development of condensate gas reservoirs, the difference between the formation pressure and dew point pressure in addition to gas well production and formation permeability all have a significant impact on retrograde condensation pollution. In the development of gas reservoirs, production systems should be rationally set up according to the characteristics of the gas reservoir.

- (3)

- The model was used to calculate the pollution skin factor of two actual test wells under three different testing systems. The values for the maximum error between the calculated skin factor and the actual test skin factor of these wells are 6.15% and 6.06%, and the average errors are 3.87% and 5.26%, which meet the requirements for engineering calculations.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, Z.M.; Wen, Z.X.; He, Z.J.; Song, C.; Liu, X.; Chen, R.; Liu, Z.; Bian, H.; Shi, H. Global condensate oil resource potential and exploration fields. Acta Pet. Sin. 2021, 42, 1556–1565. [Google Scholar]

- Alafnan, S.; Aljawad, M.; Alismail, F.; Almajed, A. Enhanced recovery from gas condensate reservoirs through renewable energy sources. Energy Fuels 2019, 33, 10115–10122. [Google Scholar] [CrossRef]

- Hosseinzadegan, A.; Raoof, A.; Mahdiyar, H.; Nikooee, E.; Ghaedi, M.; Qajar, J. Review on pore-network modeling studies of gas-condensate flow: Pore structure, mechanisms, and implementations. Geoenergy Sci. Eng. 2023, 226, 211693. [Google Scholar] [CrossRef]

- Maleki, M.R.; Rashidi, F.; Mahani, H.; Khamehchi, E. A simulation study of the enhancement of condensate recovery from one of the Iranian naturally fractured condensate reservoirs. J. Pet. Sci. Eng. 2012, 92–93, 158–166. [Google Scholar] [CrossRef]

- Ghorbani, H.; Moghadasi, J.; Wood, D.A. Prediction of gas flow rates from gas condensate reservoirs through wellhead chokes using a firefly optimization algorithm. J. Nat. Gas Sci. Eng. 2017, 45, 256–271. [Google Scholar] [CrossRef]

- Igwe, U.; Khishvand, M.; Piri, M. Retrograde condensation in natural porous media: An in situ experimental investigation. Phys. Fluids 2022, 34, 13102. [Google Scholar] [CrossRef]

- Liu, N.X.; Huang, X.L.; Luo, H.; Yang, C.; Wang, Z.H.; Min, C.R. Study on eliminating retrograde condensate pollution in low-permeability condensate gas reservoir. J. Porous Media 2023, 26, 1–19. [Google Scholar] [CrossRef]

- Jing, W.; Zhang, L.; Zhang, Y.; Memon, B.S.; Li, A.; Zhong, J.; Sun, H.; Yang, Y.; Cheng, Y.; Yao, J. Phase behavior of gas condensate in fractured-vuggy porous media based on microfluidic technology and real-time computed tomography scanning. Phys. Fluids 2023, 35, 122002. [Google Scholar] [CrossRef]

- Kamari, E.; Shadizadeh, S.R. An experimental phase diagram of a gas condensate reservoir. Pet. Sci. Technol. 2012, 30, 2114–2121. [Google Scholar] [CrossRef]

- Davani, K.; Kord, S.; Mohammadzadeh, O.; Moghadasi, J. Numerical simulation and three-phase pressure transient analysis considering capillary number effect—Case study of a gas condensate reservoir. Int. J. Oil Gas Coal Technol. 2020, 25, 258–291. [Google Scholar] [CrossRef]

- Rahimzadeh, A.; Bazargan, M.; Darvishi, R.; Mohammadi, A.H. Condensate blockage study in gas condensate reservoir. J. Nat. Gas Sci. Eng. 2016, 33, 634–643. [Google Scholar] [CrossRef]

- Onoabhagbe, B.B.; Russell, P.; Ugwu, J.; Gomari, S.R. Application of phase change tracking approach in predicting condensate blockage in tight, low, and high permeability reservoirs. Energies 2020, 13, 6551. [Google Scholar] [CrossRef]

- Wang, A.; Li, J.H.; Zhang, B. Study on the phase behaviors of the condensate gas in porous media. Pet. Geol. Oilfield Dev. Daqing 2021, 40, 61–67. [Google Scholar]

- Abbasov, Z.Y.; Fataliyev, V.M.; Hamidov, N.N. The solubility of gas components and its importance in gas-condensate reservoir development. Pet. Sci. Technol. 2017, 35, 249–256. [Google Scholar] [CrossRef]

- Dinariev, O.Y.; Evseev, N.V. Non-equilibrium transport of a gas-condensate mixture in a porous medium. J. Appl. Mech. Tech. Phys. 2023, 64, 667–674. [Google Scholar] [CrossRef]

- Xiao, L.X.; Du, J.F.; Guo, P.; Yang, S.Y.; Zeng, S. Pollution caused by retrograde condensate gas reservoir. Fault-Block Oil Gas Field 2009, 16, 102–104. [Google Scholar]

- Wang, W.C.; Wu, K.L.; Chen, Z.X.; Li, Z.; Chen, S.; He, Y.; Yuan, J.; Liu, H. Non-equilibrium pressure drop method for alleviating retrograde condensate effect on gas condensate well deliverability. Acta Pet. Sin. 2022, 43, 719–726. [Google Scholar]

- Azin, R.; Sedaghati, H.; Fatehi, R.; Osfouri, S.; Sakhaei, Z. Production assessment of low production rate of well in a supergiant gas condensate reservoir: Application of an integrated strategy. J. Pet. Explor. Prod. Technol. 2019, 9, 543–560. [Google Scholar] [CrossRef]

- Jiang, Y.W.; Bi, J.X.; Li, M.; Luo, Y.; Zou, J.B. Study of the effect of retrograde condensation pollution on the productivity of condensate gas well. J. Southwest Pet. Univ. 2005, 27, 46. [Google Scholar]

- Hosein, R.; Dawe, R. A parametric methodology in tuning the Peng-Robinson (PR) equation of state for gas condensate systems. Pet. Sci. Technol. 2014, 32, 662–672. [Google Scholar] [CrossRef]

- Alarouj, M.; Alomair, O.; Elsharkawy, A. Gas condensate reservoirs: Characterization and calculation of dew-point pressure. Pet. Explor. Dev. 2020, 47, 1091–1102. [Google Scholar] [CrossRef]

- Zou, C.M.; Tang, Y.; Yan, J.; Sun, J.W.; Li, Y.H.; Cui, T.N. The evaluation methods and application of retrograde condensation damage in condensate gas reservoir. Reserv. Eval. Dev. 2019, 9, 30–34. [Google Scholar]

- Chang, A.; Sun, H.; Zhang, Y.; Zheng, C.; Min, F. Spatial fractional Darcy’s law to quantify fluid flow in natural reservoirs. Phys. A Stat. Mech. Its Appl. 2019, 519, 119–126. [Google Scholar] [CrossRef]

- Xu, P.; Yu, B.; Qiao, X.; Qiu, S.; Jiang, Z. Radial permeability of fractured porous media by Monte Carlo simulations. Int. J. Heat Mass Transf. 2013, 57, 369–374. [Google Scholar] [CrossRef]

- Canelas, R.B.; Domínguez, J.M.; Crespo, A.J.; Gómez-Gesteira, M.; Ferreira, R.M. A Smooth Particle Hydrodynamics discretization for the modelling of free surface flows and rigid body dynamics. Fluids 2015, 78, 581–593. [Google Scholar] [CrossRef]

- Li, S.; Zhang, N.; Li, Q.; Vadim, S. Stability study of fluid-solid coupled dynamic system of seepage in accumulative broken rock. Arab. J. Geosci. 2020, 13, 647. [Google Scholar] [CrossRef]

- Santos, M.P.P.C.; Carvalho, M.S. Pore network model for retrograde gas flow in porous media. J. Pet. Sci. Eng. 2020, 185, 106635. [Google Scholar] [CrossRef]

- Liu, Y.; Pan, Y.; Sun, Y.; Liang, B. Experimental Study on the Control Mechanism of Non-Equilibrium Retrograde Condensation in Buried Hill Fractured Condensate Gas Reservoirs. Processes 2023, 11, 3242. [Google Scholar] [CrossRef]

- Tang, Y.; Long, K.; Wang, J.; Xu, H.; Wang, Y.; He, Y.; Shi, L.; Zhu, H. Change of phase state during multi-cycle injection and production process of condensate gas reservoir based underground gas storage. Pet. Explor. Dev. 2021, 48, 395–406. [Google Scholar] [CrossRef]

- Mohammad, I.R.A.; Behnam, S.S. Investigating the effect of fracture–matrix interaction in underground gas storage process at condensate naturally fractured reservoirs. J. Nat. Gas Sci. Eng. 2014, 19, 161–174. [Google Scholar]

| Component | Mole Fraction/% | Component | Mole Fraction/% | Component | Mole Fraction/% |

|---|---|---|---|---|---|

| Carbon dioxide | 14.49 | Nitrogen | 0 | Methane | 61.19 |

| Ethane | 9.84 | Propane | 3.5 | Isobutane | 0.59 |

| Butane | 1.13 | Isopentane | 0.37 | n-Pentane | 0.43 |

| Hexane | 0.5 | Heptane | 0.46 | Octane | 0.49 |

| Nonane | 1 | Decane | 0.66 | C11+ | 5.35 |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Formation depth/m | 3897 | Formation compression coefficient/MPa−1 | 0.0004 |

| Wellbore radius/m | 0.078 | Porosity/% | 3.5 |

| Formation pressure/MPa | 46.93 | Temperature/°C | 152 |

| Formation thickness/m | 118 | Permeability/mD | 2 |

| Relative Permeability Curve | Sd | ΔPd (MPa) | Sd | Qg (×104 m3/d) | Sd | K (mD) | Sd |

|---|---|---|---|---|---|---|---|

| Type I | 3.36 | 1.32 | 8.32 | 10 | 5.14 | 1 | 13.79 |

| Type II | 8.3 | 2.64 | 1.75 | 15 | 8.25 | 2 | 8.25 |

| Type III | 26.6 | 5.28 | 0.69 | 20 | 12.09 | 4 | 3.88 |

| Testing System | Nozzle (mm) | Production (×104 m3/d) | Calculating Skin Coefficient | Testing Skin Coefficient | Relative Error (%) |

|---|---|---|---|---|---|

| Test 1 | 6.35 | 10.73 | 9.76 | 10.4 | 6.15 |

| Test 2 | 7.94 | 14.11 | 14.05 | 14.3 | 1.75 |

| Test 3 | 9.53 | 18.41 | 19.5 | 18.8 | 3.72 |

| Testing System | Nozzle (mm) | Production (×104 m3/d) | Calculating Skin Coefficient | Testing Skin Coefficient | Relative Error (%) |

|---|---|---|---|---|---|

| Test 1 | 9.53 | 22.76 | 6.38 | 6.7 | 5.02 |

| Test 2 | 12.7 | 31.53 | 9.24 | 9.8 | 6.06 |

| Test 3 | 15.88 | 37.85 | 13.85 | 13.2 | 4.69 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, H.; Zhang, X.; Gao, X.; Chen, P.; Guo, K. A Novel Method for the Quantitative Evaluation of Retrograde Condensate Pollution in Condensate Gas Reservoirs. Processes 2024, 12, 522. https://doi.org/10.3390/pr12030522

Zhao H, Zhang X, Gao X, Chen P, Guo K. A Novel Method for the Quantitative Evaluation of Retrograde Condensate Pollution in Condensate Gas Reservoirs. Processes. 2024; 12(3):522. https://doi.org/10.3390/pr12030522

Chicago/Turabian StyleZhao, Hongxu, Xinghua Zhang, Xinchen Gao, Peng Chen, and Kangliang Guo. 2024. "A Novel Method for the Quantitative Evaluation of Retrograde Condensate Pollution in Condensate Gas Reservoirs" Processes 12, no. 3: 522. https://doi.org/10.3390/pr12030522

APA StyleZhao, H., Zhang, X., Gao, X., Chen, P., & Guo, K. (2024). A Novel Method for the Quantitative Evaluation of Retrograde Condensate Pollution in Condensate Gas Reservoirs. Processes, 12(3), 522. https://doi.org/10.3390/pr12030522