Calculation Method of the Phase Recovery of Gas Cap Reservoir with Bottom Water

Abstract

:1. Introduction

2. Methods

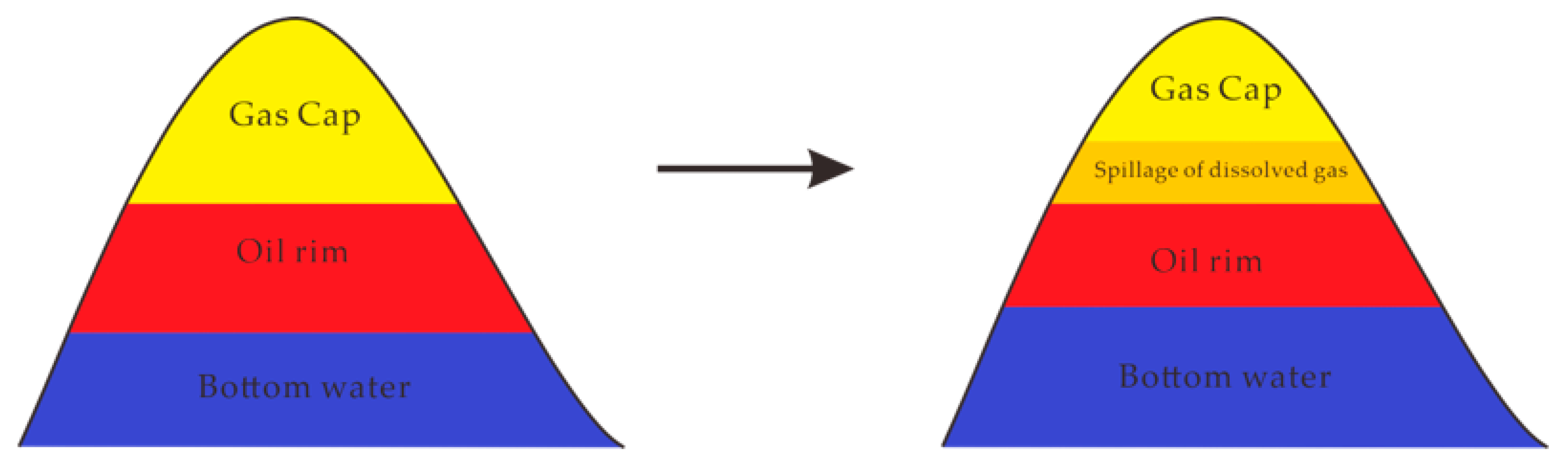

2.1. Analysis of the Oil and Gas Reservoirs

2.2. Average Formation Pressure

2.3. Calculation of Phase Recovery

2.4. Method Flowchart

3. Results

3.1. Model Establishment

3.2. Calculation Steps and Results

4. Discussion

4.1. Average Formation Pressure

4.2. Phase Recovery

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclatures

| Np | Cumulative oil production (m3) |

| Bo | Oil-volume factor (m3/m3) |

| Rp | Production gas–oil ratio (m3/m3) |

| Rs | Dissolved gas–oil ratio(m3/m3) |

| Bg | Gas-volume factor (m3/m3) |

| Wp | Cumulative water production (m3) |

| Bw | Water-volume factor (m3/m3) |

| We | Volume of cumulative intrusion of reservoir water (m3) |

| N | Petroleum resources (m3) |

| Boi | Original oil volume factor (m3/m3) |

| Rsi | Original dissolved gas–oil ratio (m3/m3) |

| m | Ratio of the volume of gas-bearing zone to the volume of oil-bearing zone |

| Bgi | Original gas-volume factor (m3/m3) |

| Swc | Irreducible water saturation (f) |

| cw | Compression factor of formation water (MPa−1) |

| cp | Compression factor of rock-pore volume (MPa−1) |

| pi | Original formation pressure (MPa) |

| p | Formation pressure (MPa) |

| Bt | Crude-oil two-phase volume factor (m3/m3) |

| Bti | Original crude-oil two-phase volume factor (m3/m3) |

| Vw | Volume of water body (104 m3) |

| J | Water-influx index (m3/d/MPa) |

| t | Time (d) |

| ct | Total compressibility (MPa−1) |

| qg | Gas production (m3) |

| qg1 | Dissolved gas production (m3) |

| qg2 | Top gas production (m3) |

| qo | Oil production (m3) |

| qo1 | Oil-rim oil production (m3) |

| Gs | Total dissolved gas reserves (m3) |

| G2 | Total top gas reserves (m3) |

| Z | Compressibility factor (dless) |

| ro1 | Oil recovery from the oil rim |

| rg1 | Dissolved gas recovery |

| rg2 | Gas recovery from the gas cap |

References

- Jamil, M.; Siddiqui, N.A.; Rahman, A.H.B.A.; Ibrahim, N.A.; Ismail, M.S.B.; Ahmed, N.; Usman, M.; Gul, Z.; Imran, Q.S. Facies Heterogeneity and Lobe Facies Multiscale Analysis of Deep-Marine Sand-Shale Complexity in the West Crocker Formation of Sabah Basin, NW Borneo. Appl. Sci. 2021, 11, 5513. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, X.; Yin, C.; Shu, P.; Cao, B.; Zhu, Y. Gas accumulation conditions and key exploration & development technologies in Xushen gas field. Shiyou Xuebao/Acta Pet. Sin. 2019, 40, 866–886. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, Y.; Ni, J.; Qiao, X.; Xin, C.; Zhang, T.; Kang, Y.; Shi, J.; Wu, K. A new method for tracking and calculating average formation pressure of gas reservoirs. Shiyou Xuebao/Acta Pet. Sin. 2021, 42, 492–499+522. [Google Scholar] [CrossRef]

- Wenpeng, B.; Shiqing, C.; Yang, W.; Dingning, C.; Xinyang, G.; Qiao, G. A transient production prediction method for tight condensate gas wells with multiphase flow. Pet. Explor. Dev. 2023, 51, 154–160. [Google Scholar] [CrossRef]

- Miller, C.C.; Dyes, A.B.; Hutchinson, C.A., Jr. The Estimation of Permeability and Reservoir Pressure from Bottom Hole Pressure Build-Up Characteristics. J. Pet. Technol. 1950, 2, 91–104. [Google Scholar] [CrossRef]

- Matthews, C.S.; Brons, F.; Hazebroek, P. A Method for Determination of Average Pressure in a Bounded Reservoir. Trans. AIME 1954, 201, 182–191. [Google Scholar] [CrossRef]

- Brons, F.; Miller, W.C. A Simple Method for Correcting Spot Pressure Readings. J. Pet. Technol. 1961, 13, 803–805. [Google Scholar] [CrossRef]

- Dietz, D.N. Determination of Average Reservoir Pressure from Build-Up Surveys. J. Pet. Technol. 1965, 17, 955–959. [Google Scholar] [CrossRef]

- Bingyu, J. Some understandings on the development trend in research of oil and gas reservoir engineering methods. Acta Pet. Sin. 2020, 41, 1774–1778. [Google Scholar] [CrossRef]

- Muskat, M. Use of Data Oil the Build-Up of Bottom-Hole Pressures. Trans. AIME 1937, 123, 44–48. [Google Scholar] [CrossRef]

- Yongqing, Y. Calculation of average reservoir pressure by using modified flowing material balance. Fault-Block Oil Gas Field 2015, 22, 747–751. [Google Scholar]

- Mattar, L.; McNeil, R. The “Flowing” Gas Material Balance. J. Can. Pet. Technol. 1998, 37, PETSOC-98-02-06. [Google Scholar] [CrossRef]

- Mattar, L.; Anderson, D.; Stotts, G. Dynamic Material Balance-Oil-or Gas-in-Place without Shut-Ins. J. Can. Pet. Technol. 2006, 45, PETSOC-06-11-TN. [Google Scholar] [CrossRef]

- Gonzalez, F.E.; Ilk, D.; Blasingame, T.A. A Quadratic Cumulative Production Model for the Material Balance of an Abnormally Pressured Gas Reservoir. In Proceedings of the SPE Western Regional and Pacific Section AAPG Joint Meeting, Bakersfield, CA, USA, 29 March–2 April 2008. [Google Scholar] [CrossRef]

- Wu, K.-L.; Li, X.-F.; Fan, J.; Li, Y.-J.; Wu, L. An approach to calculate water influx and aquifer region of abnormally high pressure condensate gas reservoir. Zhongguo Kuangye Daxue Xuebao/J. China Univ. Min. Technol. 2013, 42, 105–111. [Google Scholar] [CrossRef]

- Zhang, A.; Fan, Z.; Song, H.; Zhang, H. Reservoir pressure prediction of gas condensate reservoir with oil rim. Zhongguo Shiyou Daxue Xuebao (Ziran Kexue Ban)/J. China Univ. Pet. (Ed. Nat. Sci.) 2014, 38, 124–129. [Google Scholar] [CrossRef]

- Yanfang, J. Feasibility Analysis of Calculating Formation Pressure with the Production Data in Daniudi Gas Field. 2016, 18, 30–33. J. Chongqing Univ. Sci. Technol. 2016, 18, 30–33. [Google Scholar] [CrossRef]

- Yongfu, T.; Rui, X.; Liang, Q.; Jun, Z.; Guohui, F.; Huaqin, Z. Evaluation of formation pressure in M reservoir of Yaerxia Oilfield by material balance method. Oil Gas Well Test. 2019, 28, 72–78. [Google Scholar] [CrossRef]

- Zhang, L.; Guo, C.; Jiang, H.; Cao, G.; Chen, P. Gas in place determination by material balance-quasipressure approximation condition method. Shiyou Xuebao/Acta Pet. Sin. 2019, 40, 337–349. [Google Scholar] [CrossRef]

- Hongjun, Y.; Gang, W.; Cuiqiao, X.; Jing, F.; Fakcharoenphol, P. Average Formation Pressure Calculation for the Composite Oil Reservoir with Multi-Well System. Spec. Oil Gas Reserv. 2019, 26, 76–80. [Google Scholar] [CrossRef]

- Nan, W.; Shi, S.; Shiqi, Z.; Haoyang, Z.; Hongya, W.; Jiangnan, T. Formation pressure calculation of tight sandstone gas reservoir based on material balance inversion method. Coal Geol. Explor. 2022, 50, 115–121. [Google Scholar] [CrossRef]

- Eaton, B.A.; Jacoby, R.H. A New Depletion-Performance Correlation for Gas-Condensate Reservoir Fluids. J. Pet. Technol. 1965, 17, 852–856. [Google Scholar] [CrossRef]

- Kabir, C.S.; Badru, O.; Eme, V.; Carr, B.S. Assessing Producibility of a Region’s Gas/Condensate Reservoirs. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 9–12 October 2005. [Google Scholar] [CrossRef]

- Yu, X. Theory and Application of Dynamic Analysis of Cyclic Gas Injection in Condensate Reservoirs. Ph.D. Thesis, Southwest Petroleum University, Chengdu, China, 2020. [Google Scholar] [CrossRef]

- Chen, W.; Wu, D.; Wu, N.; Zhang, M.; Wang, M.; Wu, Z. The research of performance monitoring technique in yaha condensate gas reservoir of tarim basin. Nat. Gas Geosci. 2004, 15, 553–558. [Google Scholar]

- Jiao, H.; Sun, W.; Sun, Y. Development practices and procedures of gas cap reservoirs in China. Petrochem. Ind. Technol. 2020, 27, 96+99. [Google Scholar] [CrossRef]

- Chen, Y. Application and derivation of material balance equation for abnormally pressured gas reservoirs. Acta Pet. Sin. 1983, 4, 45–53. [Google Scholar] [CrossRef]

- Begland, T.F.; Whitehead, W.R. Depletion Performance of Volumetric High-Pressured Gas Reservoirs. SPE Reserv. Eng. 1989, 4, 279–282. [Google Scholar] [CrossRef]

- Fetkovich, M.J.; Reese, D.E.; Whitson, C.H. Application of a General Material Balance for High-Pressure Gas Reservoirs. SPE J. 1998, 3, 3–13. [Google Scholar] [CrossRef]

- Jing, X.; Xingli, X.; Guang, J.; Kai, L. Derivation and application of material balance equation for over-pressured gas reservoir with aquifer. Acta Pet. Sin. 2007, 28, 96–99. [Google Scholar] [CrossRef]

- Liu, D.; Liu, Z.; Tian, Z. A modified material balance equation for abnormal-pressure gas reservoirs with aquifer. Acta Pet. Sin. 2011, 32, 474–478. [Google Scholar] [CrossRef]

- Chuanliang, L. Principles of Reservoir Engineering, 3rd ed.; Petroleum Industry Press: Beijing, China, 2017; pp. 150–188. [Google Scholar]

- Zhao, L.; Bian, D.; Fan, Z.; Song, H.; Li, J.; Zhao, X. Oil property changes during the waterflooding for reservoirs with condensate gas cap. Pet. Explor. Dev. 2011, 38, 74–78. [Google Scholar] [CrossRef]

- Li, Q.; Wang, N.; Yi, D. Numerical Analysis, 5th ed.; Huazhong University of Science & Technology Press: Wuhan, China, 2018; pp. 149–153. [Google Scholar]

- Mehra, R.K.; Heidemann, R.A.; Aziz, K. Computation of Multiphase Equilibrium for Compositional Simulation. Soc. Pet. Eng. J. 1982, 22, 61–68. [Google Scholar] [CrossRef]

- Wang, N.; Chen, Z.; Zhu, M.; Wang, Y.; Zhang, Y. Dynamic reserve calculation of single well in condensate gas reservoirs based on a principle of mass conservation. Nat. Gas Geosci. 2018, 29, 424–428. [Google Scholar] [CrossRef]

- Pereira, V.J.; Regueira, V.B.; Costa, G.M.N.; Vieira de Melo, S.A.B. Modeling the Saturation Pressure of Systems Containing Crude Oils and CO2 Using the SRK Equation of State. J. Chem. Eng. Data 2019, 64, 2134–2142. [Google Scholar] [CrossRef]

- Gorgonio, F.-C.; Mario, A.V.-C. Reservoir performance analysis through the material balance equation: An integrated review based on field examples. J. Pet. Sci. Eng. 2022, 208, 109377. [Google Scholar] [CrossRef]

- Jianqin, C.; Tao, L.; Xiaojian, W.; Jinling, Z.; Yong, T.; Jiazheng, Q.; Jiehong, T. A New Method to Predict Average Reservoir Pressure for Oil Reservoir Subject to Edge or Bottom Water Drive Considering Time-Varying Water Influx. Drill. Prod. Technol. 2023, 46, 89–93. [Google Scholar] [CrossRef]

| Title of the Article | Calculated Average Formation Pressure | Measured Formation Pressure | Error/% |

|---|---|---|---|

| Calculation of average reservoir pressure by using modified flowing material balance | 16.90 | 16.71 | 1.14 |

| Feasibility analysis of calculating formation pressure with the production data in Daniudi gas field | 15.80 | 15.20 | 3.8 |

| Evaluation of formation pressure in M reservoir of Yaerxia oilfield by material balance method | 30.6 | 31.1 | 1.6 |

| Gas in place determination by material balance-quasipressure approximation condition method | 44.28 | 40.74 | 8.6 |

| Average formation-pressure calculation for the composite oil reservoir with multi-well system | 11.250 | 11.565 | 2.7 |

| A new method for tracking and calculating average formation pressure of gas reservoirs | 13.241 | 13.916 | 4.85 |

| Formation pressure calculation of tight sandstone gas reservoir based on material balance-inversion method | 4.54 | 4.46 | 1.76 |

| P (MPa) | Rs (m3/m3) | Bo | Z |

|---|---|---|---|

| 18.00 | 111.1 | 1.4494 | 0.9367 |

| 17.00 | 105.2 | 1.4399 | 0.9332 |

| 15.00 | 93.0 | 1.4064 | 0.9341 |

| 10.00 | 60.8 | 1.3526 | 0.9450 |

| 5 | 30.4 | 1.2525 | 0.9688 |

| P | Rs | Bo | Bg | Bt | Z | qo | qg (104) | qo | Gp (105) |

|---|---|---|---|---|---|---|---|---|---|

| 19.150 | 117.884 | 1.459 | 0.008 | 1.490 | 0.953 | 19.401 | 17.778 | 734.116 | 42.344 |

| 17.859 | 110.259 | 1.448 | 0.008 | 1.585 | 0.948 | 8.150 | 4.703 | 2021.839 | 160.231 |

| 16.765 | 103.752 | 1.437 | 0.009 | 1.693 | 0.945 | 4.132 | 1.573 | 3591.385 | 231.510 |

| 16.532 | 102.362 | 1.435 | 0.009 | 1.719 | 0.944 | 4.093 | 1.220 | 3952.333 | 243.710 |

| 16.165 | 100.169 | 1.431 | 0.009 | 1.762 | 0.943 | 3.478 | 0.799 | 4602.825 | 261.279 |

| 15.899 | 98.573 | 1.428 | 0.009 | 1.795 | 0.943 | 3.554 | 0.523 | 5236.246 | 272.736 |

| 15.688 | 97.309 | 1.426 | 0.009 | 1.822 | 0.942 | 3.521 | 0.340 | 5884.221 | 281.016 |

| 15.543 | 96.439 | 1.424 | 0.009 | 1.841 | 0.942 | 3.496 | 0.223 | 6495.854 | 285.925 |

| 15.426 | 95.732 | 1.423 | 0.009 | 1.857 | 0.942 | 3.214 | 0.101 | 7117.166 | 289.023 |

| 15.351 | 95.283 | 1.422 | 0.009 | 1.868 | 0.942 | 3.306 | 0.097 | 7625.719 | 290.508 |

| 15.286 | 94.888 | 1.421 | 0.010 | 1.877 | 0.942 | 3.627 | 0.044 | 8248.482 | 291.765 |

| 15.232 | 94.563 | 1.420 | 0.010 | 1.884 | 0.941 | 3.026 | 0.033 | 8825.444 | 292.426 |

| 15.183 | 94.271 | 1.420 | 0.010 | 1.891 | 0.941 | 2.742 | 0.028 | 9363.980 | 293.012 |

| 15.147 | 94.057 | 1.419 | 0.010 | 1.896 | 0.941 | 2.423 | 0.024 | 9810.439 | 293.474 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, M.; Zhang, Y.; Zhang, M.; Ju, B.; Yang, L.; Guo, X. Calculation Method of the Phase Recovery of Gas Cap Reservoir with Bottom Water. Processes 2024, 12, 551. https://doi.org/10.3390/pr12030551

Li M, Zhang Y, Zhang M, Ju B, Yang L, Guo X. Calculation Method of the Phase Recovery of Gas Cap Reservoir with Bottom Water. Processes. 2024; 12(3):551. https://doi.org/10.3390/pr12030551

Chicago/Turabian StyleLi, Mingzhe, Yizhong Zhang, Maolin Zhang, Bin Ju, Long Yang, and Xu Guo. 2024. "Calculation Method of the Phase Recovery of Gas Cap Reservoir with Bottom Water" Processes 12, no. 3: 551. https://doi.org/10.3390/pr12030551

APA StyleLi, M., Zhang, Y., Zhang, M., Ju, B., Yang, L., & Guo, X. (2024). Calculation Method of the Phase Recovery of Gas Cap Reservoir with Bottom Water. Processes, 12(3), 551. https://doi.org/10.3390/pr12030551