Research on the Influencing Factors of the Void Volume of Insoluble Sediment in Salt Cavern Gas Storage

Abstract

:1. Introduction

2. Basic Overview of IS in X SCGS

2.1. Characterization of IS in X SCGS

2.2. Experimental Analysis of Particle Size of IS

2.3. IS Accumulation in Different Cavity Wells

3. Experiments on VVISs Measurement

3.1. Experimental Setup and Methods

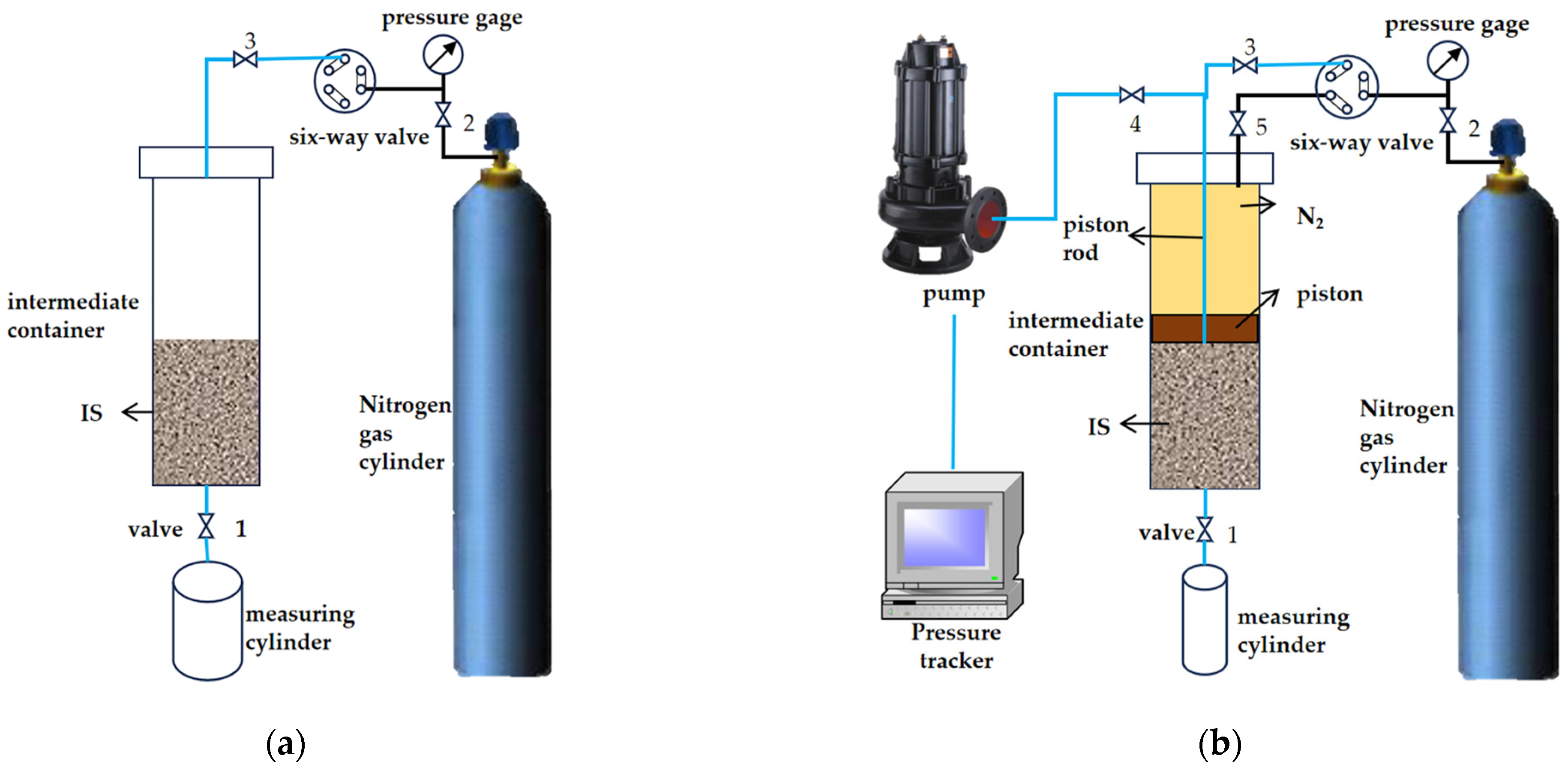

3.1.1. Experiments on VVISs Measurement under the Influence of Particle Size and Mineral Composition

3.1.2. Experiments on Void Volume Measurement under the Influence of Particle Size and Mineral Composition

3.2. Experimental Results

- 1.

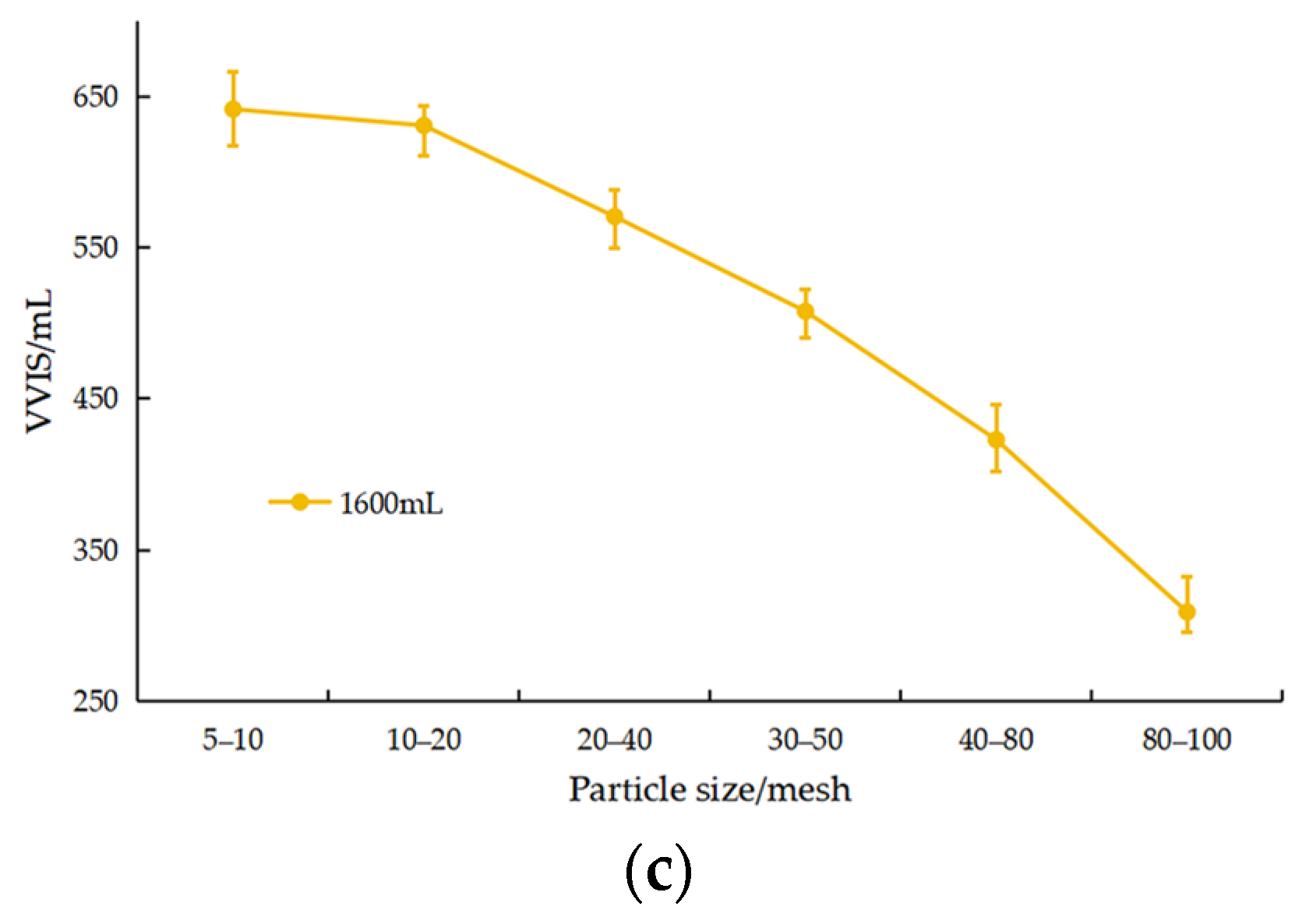

- The influence of particle size on the VVISs is significant. With the change in particle size, the range of the VVISs will change from 5% to 30%, as illustrated in Figure 6. As particle size decreases, the mutual accumulation between rock particles becomes tighter, leading to a continuous decrease in the VVISs [33]. When comparing the reduction in the VVISs between 30 and 50 mesh and 40 and 80 mesh, as well as between 40 and 80 mesh and 80 and 100 mesh, it is evident that a more mixed particle size distribution results in a slower rate of the VVISs reduction. Moreover, with an increase in accumulation volume, the VVISs also tends to increase for rock particles of different sizes, although this effect is less pronounced for small particles. Overall, it is assumed that the experiment involved uniformly distributed rock particles of varying sizes. For every 10-mesh increase in particle size, the VVISs in 1 m3 is estimated to decrease by approximately 1000–2500 mL.

- 2.

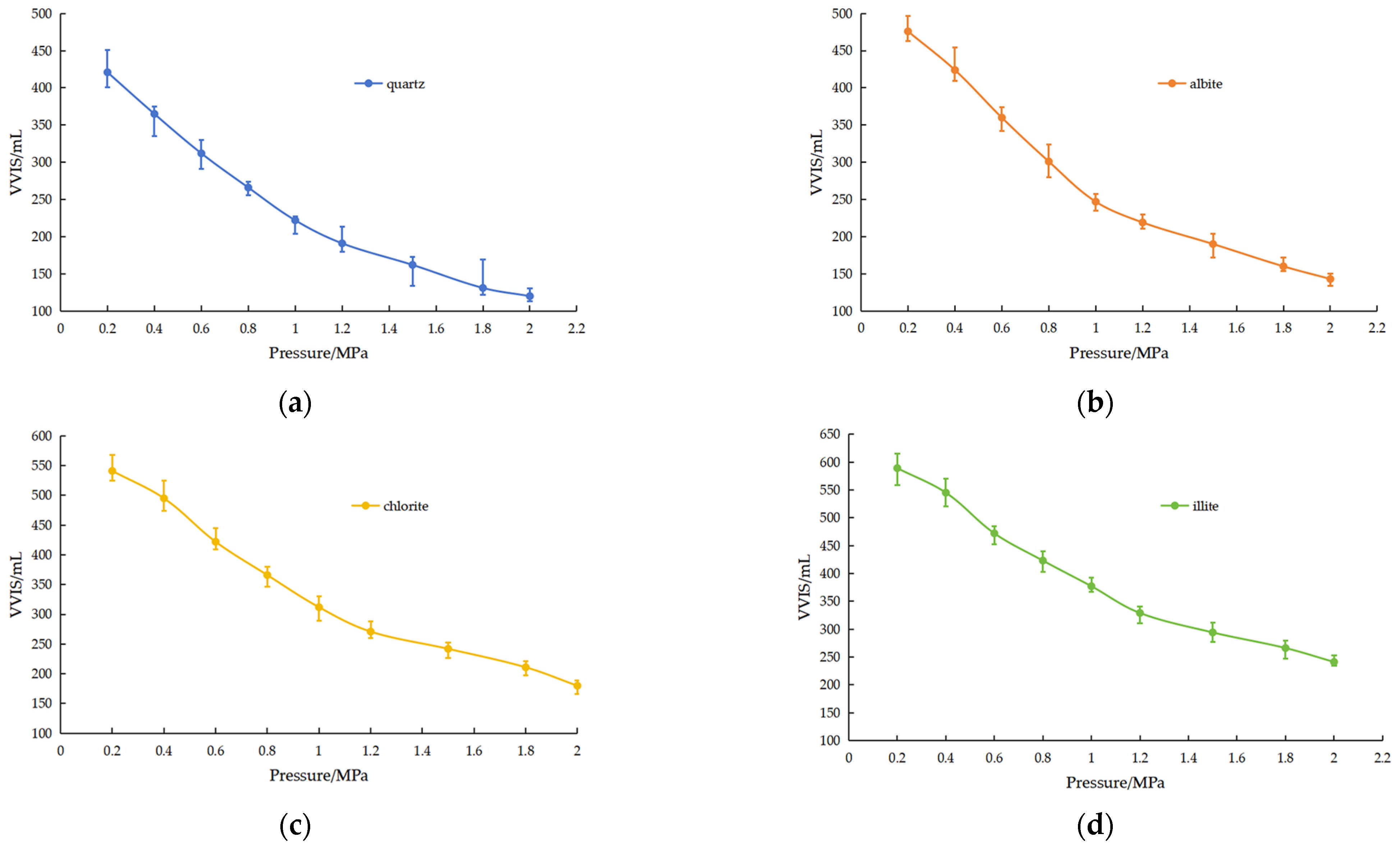

- Different mineral compositions can result in a difference of 6–23% in the VVISs, as illustrated in Figure 7. Under the same particle size, the internal void volume of minerals such as quartz, albite, and illite is relatively large; mineral components such as anhydrite are prone to water absorption and expansion [34,35]. They decompose into small particles or mix with water to form mud-like deposits at the bottom or adhere to the surface of rock particles, which is not conducive to the expulsion of void water; therefore, the VVISs is also low. Considering mineral compositions with different particle sizes, the trend of a variation in void volume is relatively consistent. Similarly, when the particle size decreases to a certain extent, the difference in the VVISs also becomes inapparent. Overall, when other factors are consistent, the more mineral components such as quartz, albite, and illite are present in IS, and the larger the VVISs will be.

- 3.

- It is observed that the VVISs is inversely proportional to compaction pressure, with VVISs decreasing by 5% to 80% as the compaction pressure increases, as illustrated in Figure 8. Larger IS particles exhibit a more rapid decrease in the VVISs compared to smaller particles under increasing pressure due to the initial VVISs between the particles. However, as the compaction pressure continues to rise, the rate of the VVISs’ reduction gradually slows down [36,37]. The mutual support force between rock particles can explain why the VVISs does not decrease initially during mechanical compression. Additionally, mineral components like chlorite and illite are more susceptible to compression [38,39,40], leading to a more pronounced reduction in the VVISs as the compaction pressure increases. Ultimately, when the compaction pressure reaches 2 MPa, the void volume is approximately 100 mL. Considering the principle of similarity analysis, in practical scenarios, IS of the deepest can provide a little space for gas storage.

- 4.

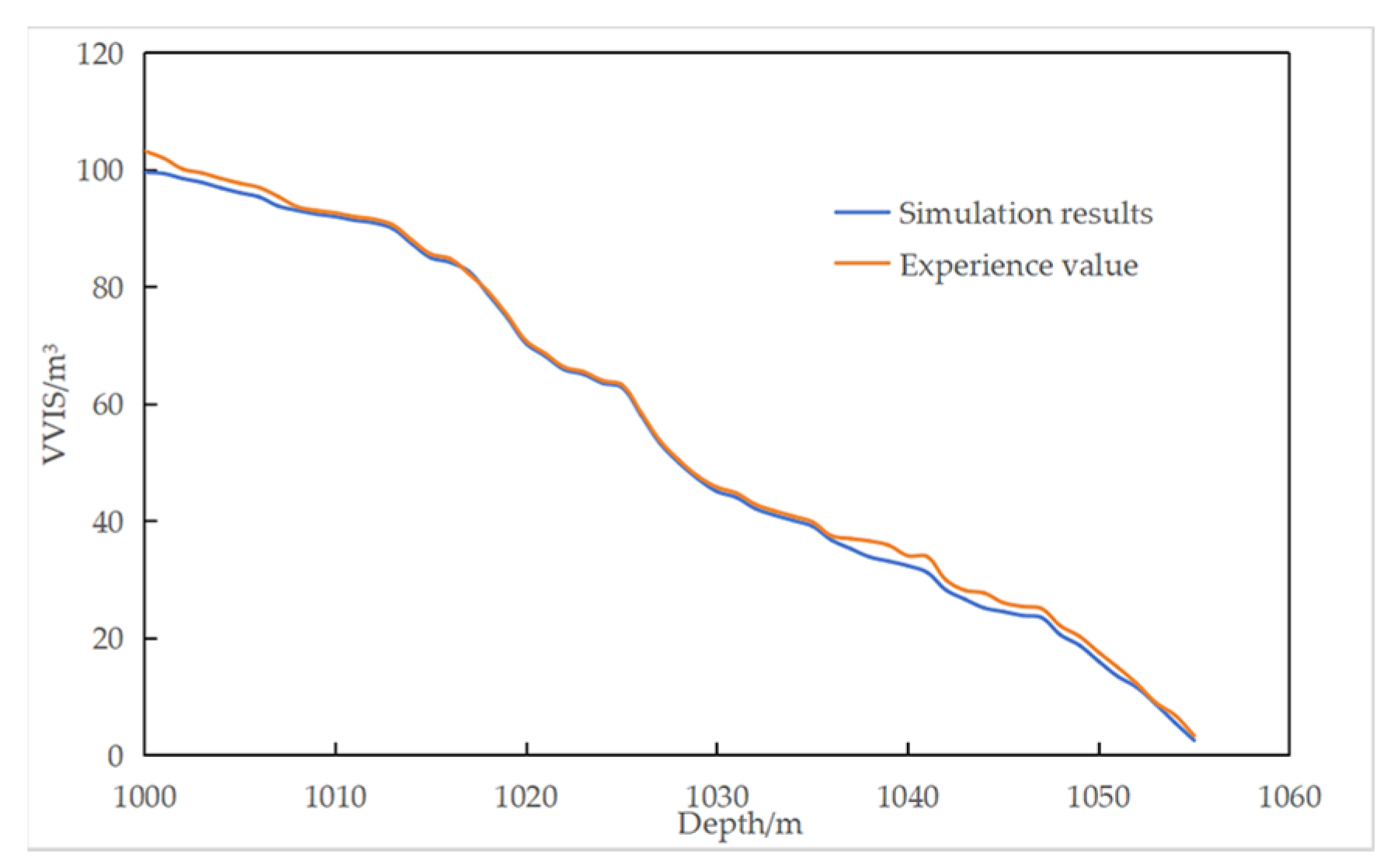

- Here, a method for predicting the VVISs is proposed. The basic model of this method is a cylinder with a height of 60 m and a radius of 40 m in the middle, and a broach with a height of 20 m above and below, as shown in Figure 9a. The prediction involves the following steps, as shown in Figure 9b: Firstly, based on the logging results and the analysis of the core physical properties of each cavity well, the IS content and mineral components of unit formation (in units of 2 m) are determined. Secondly, based on the above results, the compaction pressure on IS at different depths is calculated. Finally, by combining the fitting formula obtained in this study and assigning weights to various factors, the VVISs is predicted. Furthermore, a large amount of relevant data from multiple cavity wells are used for data training to derive patterns that are more closely aligned with field conditions. The results of the empirical value algorithm are derived by field personnel. They combine the geological conditions of cavity creation and the inversion results of sonar cavity measurement to obtain a fragmentation coefficient of IS. Through conversion relationships, the VVISs is then calculated. These values are compared with the predictive results of this study. There is a high degree of fit between the two results, as shown in Figure 10.

4. Conclusions and Discussion

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yang, C.; Liang, W.; Wei, D.; Yang, H. Investigation on possibility of energy storage in salt rock in China. Chin. J. Rock Mech. Eng. 2005, 24, 4409–4417. [Google Scholar]

- Yang, C.; Wang, T.; Li, Y.; Yang, H.; Li, J.; Qu, D. Feasibility analysis of using abandoned salt caverns for large-scale underground energy storage in China. Appl. Energy 2014, 137, 467–481. [Google Scholar] [CrossRef]

- Wu, B.; Zhang, M.; Deng, W.; Que, J.; Liu, W.; Zhou, F.; Wang, Q.; Li, Y.; Liang, T. Study and Mechanism Analysis on Dynamic Shrinkage of Bottom Sediments in Salt Cavern Gas Storage. Processes 2022, 10, 1511. [Google Scholar] [CrossRef]

- Li, J.; Shi, X.; Yang, C.; Li, Y.; Wang, T.; Ma, H.; Shi, J.; Li, J. Repair of irregularly shaped salt cavern gas storage by re-leaching under gas blanket. J. Nat. Gas Sci. Eng. 2017, 45, 848–859. [Google Scholar] [CrossRef]

- Yuan, G.; Shen, R.; Tian, Z.; Yuan, J.; Wang, Q.; Yang, M. Review of Underground Gas Storage in the Bedded Salt Deposit in China. In Proceedings of the SPE Gas Technology Symposium, Calgary, Alberta, AB, Canada, 15–17 May 2006. [Google Scholar]

- Wang, T.; Yang, C.; Li, J. Failure analysis of overhanging blocks in the walls of a gas storage salt cavern: A case study. Rock Mech. Rock Eng. 2017, 50, 125–137. [Google Scholar] [CrossRef]

- Shi, X.; Ma, H.; Zhang, Y. Advances of large-scale gas storage technology in existing salt caverns in high-insoluble salt formations. J. Shandong Univ. Sci. Technol. (Nat. Sci.) 2020, 39, 55–65. [Google Scholar] [CrossRef]

- Shi, X.; Yang, C.; Li, Y.; Li, J.; Ma, H.; Wang, T.; Guo, Y.; Chen, T.; Chen, J.; Liu, W.; et al. Development Prospect of Salt Cavern Gas Storage and New Research Progress of Salt Cavern Leaching in China. In Proceedings of the U.S. Rock Mechanics/Geomechanics Symposium (ARMA), San Francisco, CA, USA, 25 June 2017. [Google Scholar]

- Zheng, Y.; Zhao, Y.; Ding, G.; Wu, Z.; Lu, S.; Lai, X.; Qiu, X.; Yang, D.; Han, B.; Wang, L. Solution mining technology of enlarging space for thick-sandwich salt cavern storage. Pet. Explor. Dev. 2017, 44, 137–143. [Google Scholar] [CrossRef]

- Liang, X.; Ma, H.; Cai, R.; Zhao, K.; Zeng, Z.; Li, H.; Yang, C. Feasibility analysis of natural gas storage in the voids of sediment within salt cavern—A case study in China. Energy 2023, 285, 129340. [Google Scholar] [CrossRef]

- Wei, X.; Shi, X.; Li, Y.; Liu, H.; Li, P.; Ban, S.; Liang, X.; Zhu, S.; Zhao, K.; Yang, K.; et al. Advances in research on gas storage in sediment void of salt cavern in China. Energy 2023, 284, 129243. [Google Scholar] [CrossRef]

- Li, P.; Li, Y.; Shi, X.; Zhao, K.; Liang, X.; Ma, H.; Yang, C.; Liu, K. Compaction and restraining effects of insoluble sediments in underground energy storage salt caverns. Energy 2022, 249, 123752. [Google Scholar] [CrossRef]

- Liu, W.; Jiang, D.; Chen, J. Comprehensive feasibility study of two-well-horizontal caverns for natural gas storage in thinly-bedded salt rocks in China. Energy 2018, 143, 1006–1019. [Google Scholar] [CrossRef]

- Zheng, Y.; Qiu, X.; Ding, G. Experimental research on using sediment void space in salt cavern gas storage. J. Salt Sci. Chem. Ind. 2019, 48, 14–19+23. [Google Scholar] [CrossRef]

- Li, Y.; Shi, X.; Liu, W.; Wang, B.; Ma, X.; Yang, C. Motion of insoluble subsidence during leaching sump for salt cavern storage. Chin. J. Rock Mech. Eng. 2016, 35, 23–31. [Google Scholar] [CrossRef]

- Li, J.; Shi, X.; Wang, T.; Yang, C.; Li, Y.; Ma, H.; Ma, X.; Shi, H. A prediction model of the accumulation shape of insoluble sediments during the leaching of salt cavern for gas storage. J. Nat. Gas Sci. Eng. 2016, 33, 792–802. [Google Scholar] [CrossRef]

- Li, J.; Shi, X.; Yang, C.; Li, Y.; Wang, T.; Ma, H. Mathematical model of salt cavern leaching for gas storage in high-insoluble salt formations. Sci. Rep. 2018, 8, 372. [Google Scholar] [CrossRef] [PubMed]

- Yvan, C.; Nicolas, L. Insoluble deposit in salt cavern–test case. In Proceedings of the Solution Mining Research Institute Fall Meeting, Bad Ischl, Austria, 6–9 October 2002. [Google Scholar]

- Zhang, Y.; Lu, J.; Li, J.; Liu, Y.; Yao, E. The Flow Law of Brine and Sediment Particles in Gas-Driven Brine Drainage in the Sediments of Salt Cavern Gas Storage. Sustainability 2023, 15, 12613. [Google Scholar] [CrossRef]

- Ren, Z.; Yang, H.; Li, J. Testing and calculation of the pore volume of bottom deposits in the saltrock reservoir. J. Southwest Pet. Univ. (Sci. Technol.) 2018, 40, 142–150. [Google Scholar] [CrossRef]

- Ren, Z.; Li, J.; Wang, H. Granularity distribution characteristics of deposits at the bottom of salt rock gas storage based on fractal theory. Oil Gas Storage Transp. 2017, 3, 279–283. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, L.; Li, Y.; Ma, H.; Ji, G. Experimental investigation on bulking expansion coefficient of sediment of storage in bedded salt. Min. Res. Dev. 2013, 33, 34–37+42. [Google Scholar] [CrossRef]

- Liang, X.; Ma, H.; Li, P. A prediction method of the effective volume in sediment-filled salt cavern. J. Energy Storage 2022, 56, 10602. [Google Scholar] [CrossRef]

- Li, P.; Li, Y.; Shi, X.; Ma, H.; Liang, X.; Wei, X.; Yang, C. Pore characteristics and volume capacity evaluation of insoluble sediments for gas storage in multi-interbedded salt formations. Rock Soil Mech. 2022, 43, 76–82. [Google Scholar] [CrossRef]

- Li, P.; Li, Y.; Shi, X.; Zhao, K.; Liu, X.; Ma, H.; Yang, C. Prediction method for calculating the porosity of insoluble sediments for salt cavern gas storage applications. Energy 2021, 221, 119815. [Google Scholar] [CrossRef]

- He, Q.; Feng, Y.; Yuan, G.; Ban, F.; Guan, Y.; Xu, N. Experimental study of dual-well gas injection and brine discharge in salt cavern sediment space. Gas Sci. Eng. 2023, 117, 205084. [Google Scholar] [CrossRef]

- Li, P.; Li, Y.; Shi, X.; Ma, H.; Zhao, K.; Liang, X.; Wei, X.; Yang, C. Pore Structure and Brine Flow Simulation of Salt Cavern Sediments Based on X-ray Computed Tomography. Rock Mech. Rock Eng. 2023, 57, 115–130. [Google Scholar] [CrossRef]

- Liu, J.; Qiao, X.; Li, J. A technology for the reconstruction of existing convection connected salt caverns into underground gas storage. Oil Gas Storage Transp. 2019, 38, 349–355. [Google Scholar] [CrossRef]

- GB/T 6003.1-2022; Test Sieves—Technical Requirements and Testing—Part 1: Test Sieves of Metal Wire Cloth. Xinxiang Bashan Aviation Materials Co., Ltd.: Xinxiang, China, 2022.

- Park, J.; Son, Y.; Noh, S. An Evaluation of the Environmental Safety and Geochemical Characteristics of Coal Combustion Products. KSCE J. Civ. Eng. 2018, 22, 1700–1708. [Google Scholar] [CrossRef]

- Wang, L.; Liu, J.; Wang, X.; Teng, Y.; Luo, L.; Jin, Y. Study on Sound Attenuation Characteristic of Salt Cavity Based on In-Situ Acoustic Testing. Energies 2019, 12, 3154. [Google Scholar] [CrossRef]

- Wei, X.; Shi, X.; Wei, H.; Ban, S.; Li, Y.; Ma, H.; Li, P.; Yang, C. Dynamic tightness evaluation of salt cavern energy storage. J. Energy Storage 2023, 57, 106313. [Google Scholar] [CrossRef]

- Liu, S.; Yao, E.; Luo, Y.; Li, Y.; Zhou, F.; Ran, L.; Chang, Y. Study on Factors Influencing the Shrinkage of Swelled Deposits at the Bottom of Salt Cavern Gas Storage. In Proceedings of the 55th U.S. Rock Mechanics/Geomechanics Symposium, Virtual, 18–25 June 2021. [Google Scholar]

- Yuan, G.; Ban, F.; Zhao, Z. Study on collapsing mechanism of interlayer in salt caverns gas storage. Chin. J. Undergr. SpaceEng. 2016, 12, 675–679. [Google Scholar]

- Yao, E.; Xu, H.; Zhang, K.; Liu, S.; Sheng, L.; Li, B.; Bai, H.; Zhou, F. Experimental and mechanistic study of mudstone volumetric swelling at the bottom of salt cavern gas storage. Arab. J. Chem. 2022, 15, 104082. [Google Scholar] [CrossRef]

- Kuila, U.; Prasad, M. Pore Size Distribution and Ultrasonic Velocities of Compacted Na-montmorillonite Clays. In Proceedings of the 2010 SEG Annual Meeting, Denver, CO, USA, 17–22 October 2010. [Google Scholar]

- Zhang, J.; Li, M.; Liu, Z.; Zhou, N. Fractal characteristics of crushed particles of coal gangue under compaction. Powder Technol. 2017, 305, 12–18. [Google Scholar] [CrossRef]

- Mondol, N.H.; Bjørlykke, K.; Jahren, J.; Høeg, K. Experimental mechanical compaction of clay mineral aggregates-Changes in physical properties of mudstones during burial. Mar. Pet. Geol. 2007, 24, 289–311. [Google Scholar] [CrossRef]

- Prempeh, K.; Chequer, L.; Badalyan, A.; Bedrikovetsky, P. Effects of Kaolinite on Fines Migration and Formation Damage. In Proceedings of the SPE International Conference and Exhibition on Formation Damage Control, Lafayette, LA, USA, 19–21 February 2020. [Google Scholar]

- Wanniarachchi, W.A.M.; Ranjith, P.G.; Perera, M.S.A.; Nguyen, J.T.; Rathnaweera, T.D. An Experimental Study to Investigate the Effect of Mineral Composition on Mechanical Properties of Shale Gas Formations. In Proceedings of the 51st U.S. Rock Mechanics/Geomechanics Symposium, San Francisco, CA, USA, 25–28 June 2017. [Google Scholar]

| Well No. | Lithology | Top Depth (m) | Whole Rock Analysis (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Quartz | K-Feldspar | Albite | Apatite | Calite | Pyrite | Anhydrite | Halite | Clays | |||

| H | Dark gray mudstone | 1110.24 | 13.8 | 1 | 1.9 | 17.7 | 1.3 | 0.9 | 3 | 60.3 | |

| 1119.75 | 9.4 | 2.3 | 3 | 5.4 | 0.9 | 54.6 | 3.5 | 21 | |||

| Z | Gray argillaceous gypsum rock | 1166 | 0.7 | 3.4 | 4.2 | 83.1 | 8.6 | ||||

| 1173.5 | 6.1 | 1.1 | 1.2 | 2.3 | 0.4 | 82.4 | 1.5 | 4.9 | |||

| Grey saline mudstone | 1179.1 | 20.5 | 6.8 | 12.3 | 1.4 | 12.7 | 3.3 | 10.8 | 32.2 | ||

| Well Name | Cavity Formation Rate (%) | IS Height (m) | IS Proportion (%) |

|---|---|---|---|

| N1 | 68 | 35.5 | 32 |

| Z2 | 60 | 46.8 | 40 |

| Y3 | 52 | 56.7 | 48 |

| X4 | 50 | 59.1 | 50 |

| PY5 | 42 | 67.3 | 58 |

| P6 | 39 | 79.8 | 61 |

| H7 | 36 | 98.1 | 64 |

| Cumulative Volume | Fitting Formula | R2 |

|---|---|---|

| 1200 mL | Vvoid = −10.889N2 + 35.916N + 449.58 | 0.9811 |

| 1400 mL | Vvoid = −10.646N2 + 5.8007N + 602.24 | 0.9913 |

| 1600 mL | Vvoid = −10.979N2 + 9.6871N + 646.52 | 0.9983 |

| Mineral Composition | Fitting Formula | R2 |

|---|---|---|

| Quartz | Vvoid = 79.206P2 − 369.42P + 667.28 | 0.9969 |

| Albite | Vvoid = 85.749P2 − 388.84P + 623.12 | 0.995 |

| Chlorite | Vvoid = 108.52P2 − 423.55P + 563.21 | 0.9954 |

| Illite | Vvoid = 77.375P2 − 336.36P + 485.5 | 0.9991 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, X.; Ding, G.; Li, K.; Xin, C.; Wu, Z.; Gou, Y.; Ran, L.; Li, H.; Bai, S.; Wu, J. Research on the Influencing Factors of the Void Volume of Insoluble Sediment in Salt Cavern Gas Storage. Processes 2024, 12, 636. https://doi.org/10.3390/pr12040636

Sun X, Ding G, Li K, Xin C, Wu Z, Gou Y, Ran L, Li H, Bai S, Wu J. Research on the Influencing Factors of the Void Volume of Insoluble Sediment in Salt Cavern Gas Storage. Processes. 2024; 12(4):636. https://doi.org/10.3390/pr12040636

Chicago/Turabian StyleSun, Xiangrui, Guosheng Ding, Kang Li, Chuanqi Xin, Zhide Wu, Yanxia Gou, Li’na Ran, Haitao Li, Song Bai, and Jia’nan Wu. 2024. "Research on the Influencing Factors of the Void Volume of Insoluble Sediment in Salt Cavern Gas Storage" Processes 12, no. 4: 636. https://doi.org/10.3390/pr12040636

APA StyleSun, X., Ding, G., Li, K., Xin, C., Wu, Z., Gou, Y., Ran, L., Li, H., Bai, S., & Wu, J. (2024). Research on the Influencing Factors of the Void Volume of Insoluble Sediment in Salt Cavern Gas Storage. Processes, 12(4), 636. https://doi.org/10.3390/pr12040636