Plasma Processing of Rubber Powder from End-of-Life Tires: Numerical Analysis and Experiment

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Numerical Modeling Methods

2.2.1. Thermodynamic Modeling

2.2.2. Kinetic Modeling

- The equation for the conservation of the gaseous components is

- The equation for the conservation of the solid components is

- The equation for the number of particles’ conservation is

- The momentum equation is

- The equation for energy is

- The equation of the particles’ motion is

- The equation for the particles’ temperature is

- The equation of the state of ideal gas is

- The gas residence time is

- The solids’ residence time is

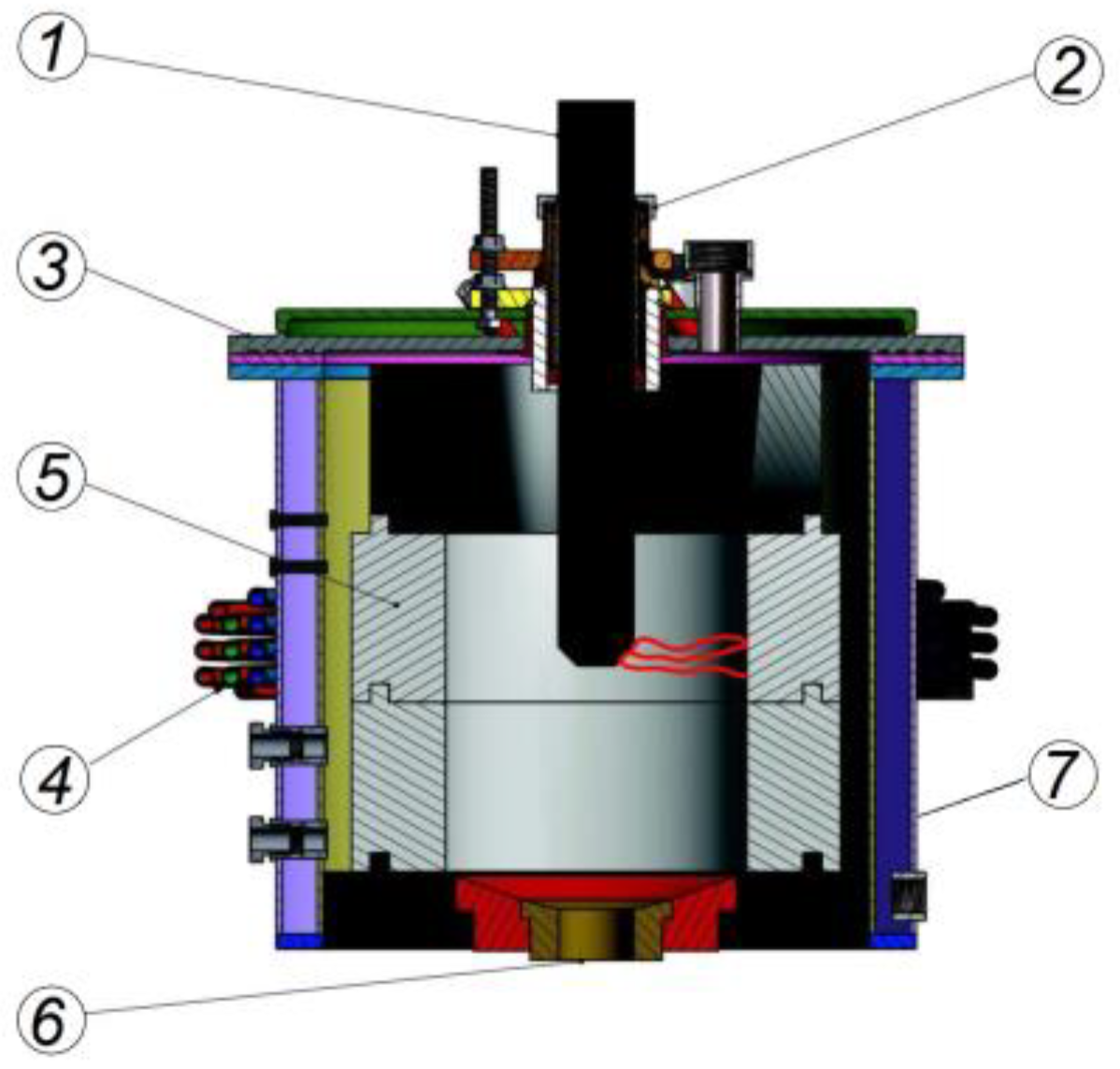

2.3. Experimental Setup

2.4. Measurements

3. Results and Discussion

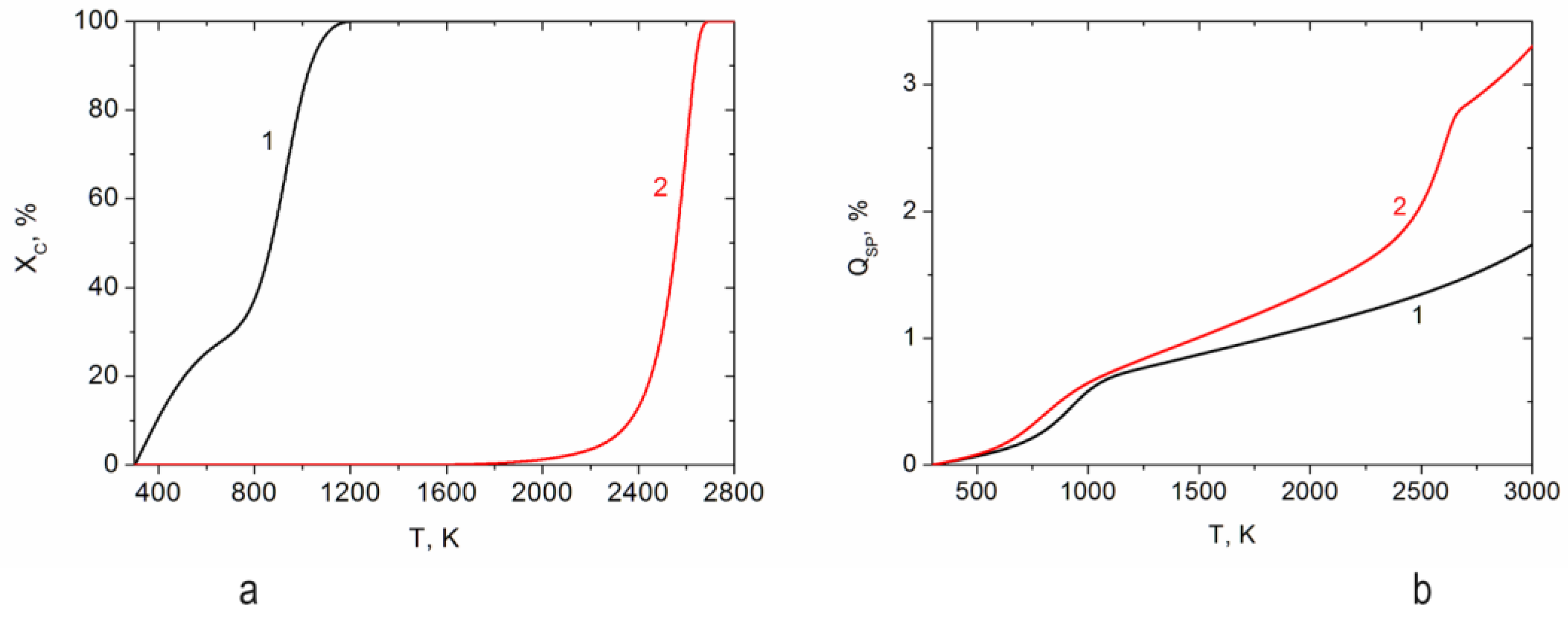

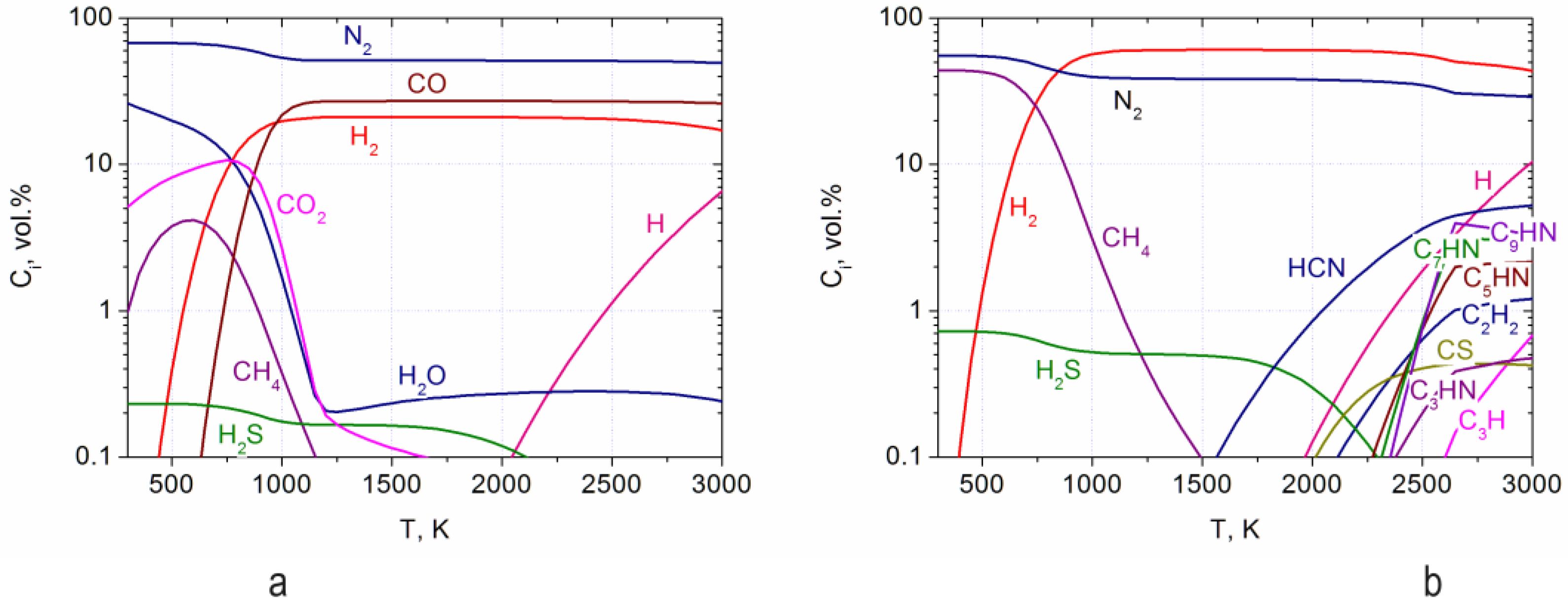

3.1. Thermodynamic Analysis

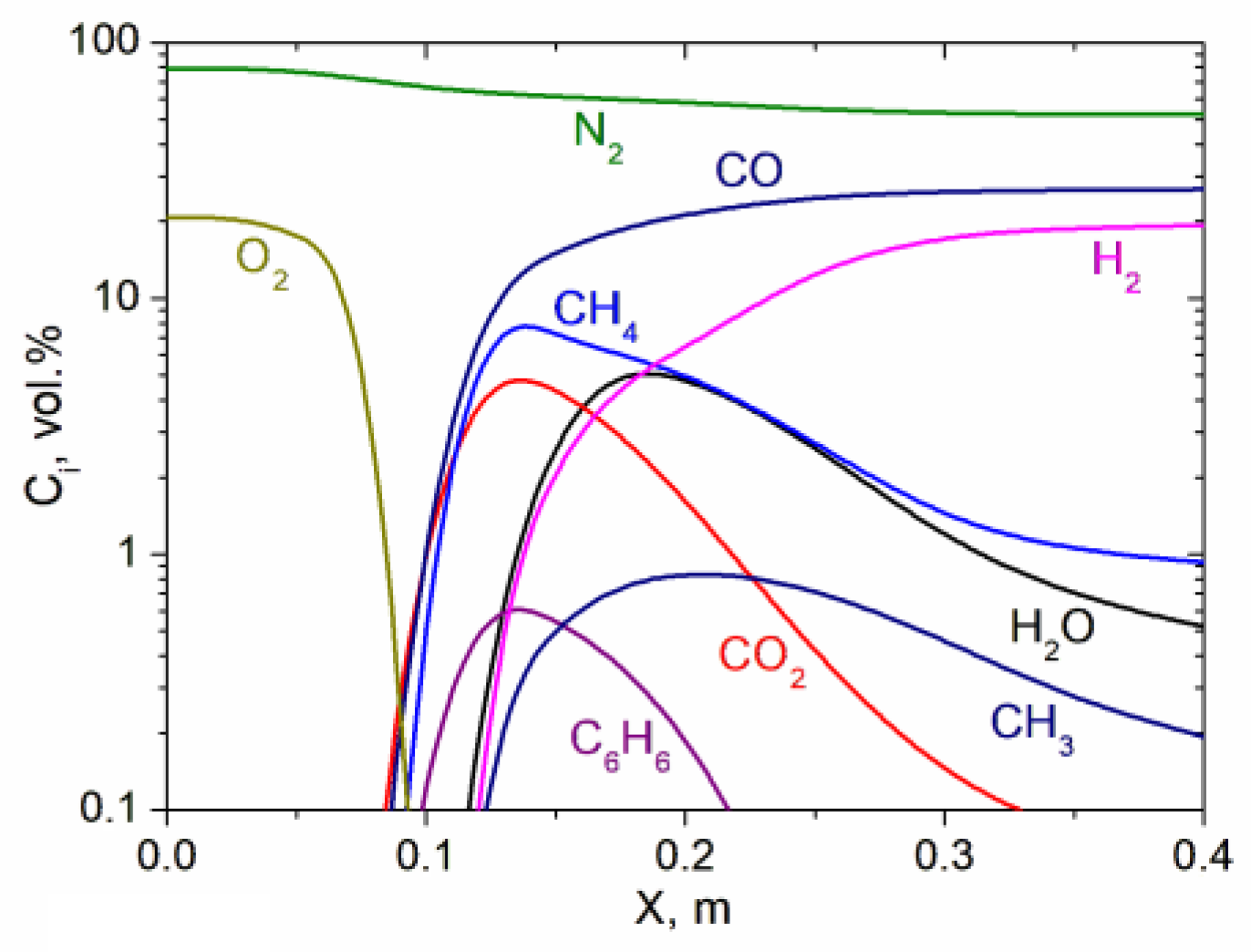

3.2. Kinetic Analysis

3.3. Experiment

3.4. Comparison of Experimental and Calculated Data

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- An’shakov, A.S.; Faleev, V.A.; Danilenko, A.A.; Urbakh, E.K.; Urbakh, A.E. Investigation of plasma gasification of carbonaceous technogeneous wastes. Thermophys. Aeromechanics 2007, 14, 607–616. [Google Scholar] [CrossRef]

- Miller, C. Scrap Tires. Scrap Tire Stockpiles Have Been Reduced by 87 Percent since 1990. Waste 360. 2010. Available online: https://www.waste360.com/Recycling_And_Processing/scrap-tires-201003 (accessed on 26 March 2024).

- Davidson, G. Waste Management Practices: Literature Review. Dalhousie University–Office of Sustainability. 2011, 54p. Available online: https://studylib.net/doc/18527000/waste-management-practices--literature-review (accessed on 26 March 2024).

- Heberlein, J.; Murphy, A.B. Topical review: Thermal plasma waste treatment. J. Phys. D Appl. Phys. 2008, 41, 053001. [Google Scholar] [CrossRef]

- Messerle, V.E.; Mosse, A.L.; Ustimenko, A.B. Processing of biomedical waste in plasma gasifier. Waste Manag. 2018, 79, 791–799. [Google Scholar] [CrossRef]

- Surov, A.V.; Popov, S.D.; Popov, V.E.; Subbotin, D.I.; Serba, E.O.; Spodobin, V.A.; Nakonechny, G.V.; Pavlov, A.V. Multi-gas AC plasma torches for gasification of organic substances. Fuel 2017, 203, 1007–1014. [Google Scholar] [CrossRef]

- Tire Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2023–2028. Report. January 2023. ID: 5732907, 2005, 165p. Available online: https://www.researchandmarkets.com/report/automotive-tires (accessed on 17 April 2024).

- Market Research Report. Tier Market Report by Design (Radial Market, Bias Market), End-Use (OEM Market, Replacement Market), Vehicle Type (Passenger Cars, Light Commercial Vehicles, Medium and Heavy Commercial Vehicles, Two Wheelers, Three Wheelers, Off-The-Road (OTR)), Distribution Channel (Offline, Online), Season (All Season Tires, Winter Tires, Summer Tiers), and Region 2023-2028. Report ID: SR112023A575. 2023. Available online: https://www.imarcgroup.com/tyre-manufacturing-plant (accessed on 26 March 2024).

- Ćetković, J.; Lakić, S.; Žarković, M.; Vujadinović, R.; Knežević, M.; Živković, A.; Cvijović, J. Environmental Benefits of Air Emission Reduction in the Waste Tire Management Practice. Processes 2022, 10, 787. [Google Scholar] [CrossRef]

- Valentini, F.; Pegoretti, A. End-of-life options of tyres. A review. Adv. Ind. Eng. Polym. Res. 2022, 5, 203–213. [Google Scholar] [CrossRef]

- Dabic-Miletic, S.; Simic, V. Smart and Sustainable Waste Tire Management: Decision-Making Challenges and Future Directions. Decis. Mak. Adv. 2023, 1, 10–16. [Google Scholar] [CrossRef]

- Gigli, S.; Landi, D.; Germani, M. Cost-benefit analysis of a circular economy project: A study on a recycling system for end-of-life tyres. J. Clean. Prod. 2019, 229, 680–694. [Google Scholar] [CrossRef]

- Castagnoli, A.; Pasciucco, F.; Iannelli, R.; Meoni, C.; Pecorini, I. Keu Contamination in Tuscany: The Life Cycle Assessment of Remediation Project as a Decision Support Tool for Local Administration. Sustainability 2022, 14, 14828. [Google Scholar] [CrossRef]

- Astrup, T.F.; Tonini, D.; Turconi, R.; Boldrin, A. Life cycle assessment of thermal Waste-to-Energy technologies: Review and recommendations. Waste Manag. 2015, 37, 104–115. [Google Scholar] [CrossRef]

- Khandelwal, H.; Dhar, H.; Thalla, A.K.; Kumar, S. Application of life cycle assessment in municipal solid waste management: A worldwide critical review. J. Clean. Prod. 2019, 209, 630–654. [Google Scholar] [CrossRef]

- Mohan, S.V.; Nikhil, G.N.; Chiranjeevi, P.; Reddy, C.N.; Rohit, M.V.; Kumar, A.N.; Sarkar, O. Waste biorefinery models towards sustainable circular bioeconomy: Critical review and future perspectives. Bioresour. Technol. 2016, 215, 2–12. [Google Scholar] [CrossRef] [PubMed]

- Lönnermark, A.; Blomqvist, P. Emissions from Tyre Fires. SP Swedish National Testing and Research Institute. SP Report 2005, 43. Available online: https://www.academia.edu/84151122/Emissions_from_Tyre_Fires (accessed on 26 March 2024).

- Messerle, V.E.; Ustimenko, A.B.; Lavrichshev, O.A. Plasma coal conversion including mineral mass utilization. Fuel 2017, 203, 877–883. [Google Scholar] [CrossRef]

- Iaquaniello, G.; Centi, G.; Salladini, A.; Palo, E.; Perathoner, S.; Spadaccinid, L. Waste-to-Methanol: Process and Economics Assessmen. Bioresour. Technol. 2017, 243, 611–619. [Google Scholar] [CrossRef]

- Beneroso, D.; Bermúdez, J.M.; Arenillas, A.; Menéndez, J.A. Comparing the composition of the synthesis-gas obtained from the pyrolysis of different organic residues for a potential use in the synthesis of bioplastics. J. Anal. Appl. Pyrolysis 2015, 111, 55–63. [Google Scholar] [CrossRef]

- Borgogna, A.; Salladini, A.; Spadacini, L.; Pitrelli, A.; Annesini, M.C.; Iaquaniello, G. Methanol production from Refuse Derived Fuel: Influence of feedstock composition on process yield through gasification analysis. J. Clean. Prod. 2019, 235, 1080–1089. [Google Scholar] [CrossRef]

- Yasin, M.; Cha, M.; Chang, I.S.; Atiyeh, H.K.; Munasinghe, P.; Khanal, S.K. Chapter 13-Syngas Fermentation Into Biofuels and Biochemicals. In Biomass, Biofuels, Biochemicals, Biofuels: Alternative Feedstocks and Conversion Processes for the Production of Liquid and Gaseous Biofuels, 2nd ed.; Pandey, A., Larroche, C., Dussap, C.-G., Gnansounou, E., Khanal, S.K., Ricke, S., Eds.; Academic Press: Cambridge, MA, USA, 2019; pp. 301–327. [Google Scholar] [CrossRef]

- Galvita, V.; Messerle, V.E.; Ustimenko, A.B. Hydrogen production by coal plasma gasification for fuel cell technology. Int. J. Hydrogen Energy 2007, 32, 3899–3906. [Google Scholar] [CrossRef]

- Kuznetsov, V.A.; Kumkova, I.I.; Lerner, A.S.; Popov, V.E. Equilibrium analysis of hydrogen production using the steam-plasma gasification process of the used car tires. J. Phys. Conf. Ser. 2012, 406, 012023. [Google Scholar] [CrossRef]

- Ma, Y.; Qi, H.; Zhang, J.; Cui, P.; Zhu, Z.; Wang, Y. Thermodynamic analysis of a carbon capture hydrogen production process for end-of-life tires using plasma gasification. J. Clean. Prod. 2023, 384, 135662. [Google Scholar] [CrossRef]

- Popov, V.E.; Subbotin, D.I.; Surov, A.V.; Popov, S.D.; Serba, E.O.; Godina, E.P.; Kiselev, A.A. Co-gasification of lignite and used car tires by H2O/air thermal plasma. J. Phys. Conf. Ser. 2019, 1243, 012010. [Google Scholar] [CrossRef]

- Paskalov, G.; Gafarov, I.; Mong, T.H.; Jarvis, R.; Abdullin, I.; Hubathuzin, A.; Musharatskiy, L. Plasma-thermal processing of rubber crumb from waste tires. In Proceedings of the 22nd International Symposium on Plasma Chemistry, Antwerp, Belgium, 5–10 July 2015; Available online: http://www.ispc-conference.org/ispcproc/ispc22/P-III-9-9.pdf (accessed on 26 March 2024).

- Huang, H.; Tang, L.; Wu, C.Z. Characterization of gaseous and solid product from thermal plasma pyrolysis of waste rubber. Environ. Sci. Technol. 2003, 37, 4463–4467. [Google Scholar] [CrossRef] [PubMed]

- Tendler, M.; Rutberg, P.; Van Oost, G. Plasma based waste treatment and energy production. Plasma Phys. Control. Fusion 2005, 47, A219–A230. [Google Scholar] [CrossRef]

- James, G.S.; Nema, S.K.; Murugan, P.; Deendayal, P. A Comparative Analysis of Pyrolysis and Gasification of WT by Thermal Plasma Technology for Environmentally Sound Waste Disposal. CorpusID:204856961. 2019. Available online: https://api.semanticscholar.org/CorpusID:204856961 (accessed on 26 March 2024).

- Pak, A.Y.; Larionov, K.B.; Kolobova, E.N.; Slyusarskiy, K.V.; Bolatova, J.; Yankovsky, S.A.; Stoyanovskii, V.O.; Vassilyeva, Y.Z.; Gubin, V.E. A novel approach of waste tires rubber utilization via ambient air direct current arc discharge plasma. Fuel Process. Technol. 2022, 227, 107111. [Google Scholar] [CrossRef]

- Markl, E.; Lackner, M. Devulcanization Technologies for Recycling of Tire-Derived Rubber: A Review. Materials 2020, 13, 1246. [Google Scholar] [CrossRef] [PubMed]

- Gorokhovski, M.; Karpenko, E.I.; Lockwood, F.C.; Messerle, V.E.; Trusov, B.G.; Ustimenko, A.B. Plasma Technologies for Solid Fuels: Experiment and Theory. J. Energy Inst. 2005, 78, 157–171. [Google Scholar] [CrossRef]

- Kalinenko, R.A.; Kuznetsov, A.P.; Levitsky, A.A.; Messerle, V.E.; Mirokhin, Y.A.; Polak, L.S.; Sakipov, Z.B.; Ustimenko, A.B. Pulverized Coal Plasma Gasification. Plasma Chem. Plasma Process 1993, 13, 141–167. [Google Scholar] [CrossRef]

- Askarova, A.S.; Karpenko, E.I.; Lavrishcheva, Y.I.; Messerle, V.E.; Ustimenko, A.B. Plasma-Supported Coal Combustion in Boiler Furnace. IEEE Trans. Plasma Sci. 2007, 35, 1607–1616. [Google Scholar] [CrossRef]

- Messerle, V.E.; Ustimenko, A.B.; Lavrichshev, O.A. Comparative study of coal plasma gasification: Simulation and experiment. Fuel 2016, 164, 172–179. [Google Scholar] [CrossRef]

- Messerle, V.E.; Ustimenko, A.B. Hydrogen Production by Thermal Plasma Pyrolysis of Hydrocarbon Gases. IEEE Trans. Plasma Sci. 2023, 1–5. [Google Scholar] [CrossRef]

| j | Reaction (a) | LgA (b) | n | E, kcal∙mol−1 | j | Reaction (a) | LgA (b) | n | E, kcal∙mol−1 |

|---|---|---|---|---|---|---|---|---|---|

| 1 | [H2]S = H2 | 18.2 | 0 | 88.8 | 25 | H2 + O = H + OH | 7.26 | 1.0 | 8.9 |

| 2 | [CH4]S = CH4 | 14.2 | 0 | 51.6 | 26 | H2O + M = H + OH + M | 13.3 | 0 | 105.0 |

| 3 | [C6H6]S = C6H6 | 11.9 | 0 | 37.4 | 27 | H2O + O = OH + OH | 10.53 | 0 | 18.3 |

| 4 | C + H2O = CO + H2 | 11.32 | 0 | 60.8 | 28 | CO + OH = CO2 + H | 4.11 | 1.3 | −0.77 |

| 5 | C + CO2 = CO + CO | 13.2 | 0 | 83.6 | 29 | CO + O2 = CO2 + O | 11.5 | 0 | 37.6 |

| 6 | C + O2 = CO2 | 9.42 | 0 | 38.0 | 30 | CO2 + H = CO + OH | 6.15 | 1.3 | 21.6 |

| 7 | C + C + O2 = CO + CO | 9.72 | 0 | 41.8 | 31 | CO + O + M = CO2 + M | 12.77 | 0 | 4.1 |

| 8 | CH4 + H = CH3 + H2 | 11.1 | 0 | 11.9 | 32 | C2H2 + M = C2H + H + M | 11.0 | 0 | 114.0 |

| 9 | CH4 + OH = CH3 + H2O | 0.54 | 3.1 | 2.0 | 33 | C2H2 = C + C + H2 | 6.0 | 0 | 30.0 |

| 10 | CH4 + M = CH3 + H + M | 14.15 | 0 | 88.4 | 34 | C2H2 + O2 = HCO + HCO | 9.6 | 0 | 28.0 |

| 11 | CH4 + O = CH3 + OH | 10.2 | 0 | 9.2 | 35 | C2H2 + H = C2H + H2 | 11.3 | 0 | 19.0 |

| 12 | CH3 + H2O = CH4 + OH | 9.84 | 0 | 24.8 | 36 | C2H2 + OH = CH3 + CO | 9.1 | 0 | 0.5 |

| 13 | CH3 + H2 = CH4 + H | 9.68 | 0 | 11.4 | 37 | C2H2 + O = CH2 + CO | 10.83 | 0 | 4.0 |

| 14 | CH3 + M = CH2 + H + M | 13.29 | 0 | 91.6 | 38 | CH2 + H2O= CH2O + H2 | 11.0 | 0 | 3.7 |

| 15 | CH3 + O2= CH3O + O | 10.68 | 0 | 29.0 | 39 | CH2 + O2 = HCO + OH | 11.0 | 0 | 3.7 |

| 16 | CH3 + OH = CH2O + H2 | 9.6 | 0 | 0 | 40 | C2H + O2 = HCO + CO | 10.0 | 0 | 7.0 |

| 17 | CH3 + O = CH2O + H | 11.11 | 0 | 2.0 | 41 | C2H + H2O = CH3 + CO | 9.08 | 0 | 0.5 |

| 18 | CH3O + M = CH2O + H + M | 10.7 | 0 | 21.0 | 42 | C6H6 = C2H2 + C2H2 + C2H2 | 12.0 | 0 | 85.0 |

| 19 | CH2O + M = HCO + H + M | 13.52 | 0 | 81.0 | 43 | OH + OH = H2O + O | 9.5 | 0 | 1.1 |

| 20 | HCO + M = H + CO + M | 11.16 | 0 | 19.0 | 44 | H + OH + M = H2O + M | 10.56 | 0 | 0.0 |

| 21 | O2 + M = O + O + M | 12.7 | 0 | 115.0 | 45 | H + H + M = H2 + M | 9.56 | 0 | 0.0 |

| 22 | H2 + M = H + H + M | 11.34 | 0 | 96.0 | 46 | CH2O + OH = HCO + H2O | 10.5 | 0 | 1.5 |

| 23 | H + O2 = O + OH | 11.27 | 0 | 16.8 | 47 | H + OH = H2 + O | 9.84 | 0 | 7.04 |

| 24 | H + H2O= H2 + OH | 10.98 | 0 | 20.3 | 48 | H2 + OH = H2O + H | 11.4 | 0 | 10.0 |

| Test Number | Consumption, kg/h | I, A | U, V | P, kW | QSP, kW h/kg | |

|---|---|---|---|---|---|---|

| RP | Air | |||||

| 1 | 4.6 | 23.0 | 150 | 270 | 40.5 | 1.47 |

| 2 | 4.7 | 24.0 | 151 | 270 | 40.8 | 1.42 |

| Test Number | TAV, K | Synthesis Gas Composition, vol.% | XC, % | |||

|---|---|---|---|---|---|---|

| H2 | CO | N2 | O2 | |||

| 1 | 1750 | 19.1 | 25.5 | 55.2 | 0.2 | 95.6 |

| 2 | 1700 | 17.8 | 26.4 | 55.5 | 0.3 | 93.7 |

| Method | TAV, K | QSP, kW h/kg | Gas Composition, vol.% | XC, % | ||

|---|---|---|---|---|---|---|

| CO | H2 | N2 | ||||

| Test number 1 (Table 2) | 1750 | 1.47 | 25.5 | 19.1 | 55.2 | 95.6 |

| Thermodynamic calculation | 1750 | 1.33 (a) | 27.0 | 21.2 | 51.2 | 100 |

| Kinetic calculation | 1873 | 1.47 | 26.7 | 19.3 | 52.3 | 100 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Messerle, V.; Ustimenko, A. Plasma Processing of Rubber Powder from End-of-Life Tires: Numerical Analysis and Experiment. Processes 2024, 12, 994. https://doi.org/10.3390/pr12050994

Messerle V, Ustimenko A. Plasma Processing of Rubber Powder from End-of-Life Tires: Numerical Analysis and Experiment. Processes. 2024; 12(5):994. https://doi.org/10.3390/pr12050994

Chicago/Turabian StyleMesserle, Vladimir, and Alexandr Ustimenko. 2024. "Plasma Processing of Rubber Powder from End-of-Life Tires: Numerical Analysis and Experiment" Processes 12, no. 5: 994. https://doi.org/10.3390/pr12050994

APA StyleMesserle, V., & Ustimenko, A. (2024). Plasma Processing of Rubber Powder from End-of-Life Tires: Numerical Analysis and Experiment. Processes, 12(5), 994. https://doi.org/10.3390/pr12050994