An Analysis of Hybrid Renewable Energy-Based Hydrogen Production and Power Supply for Off-Grid Systems

Abstract

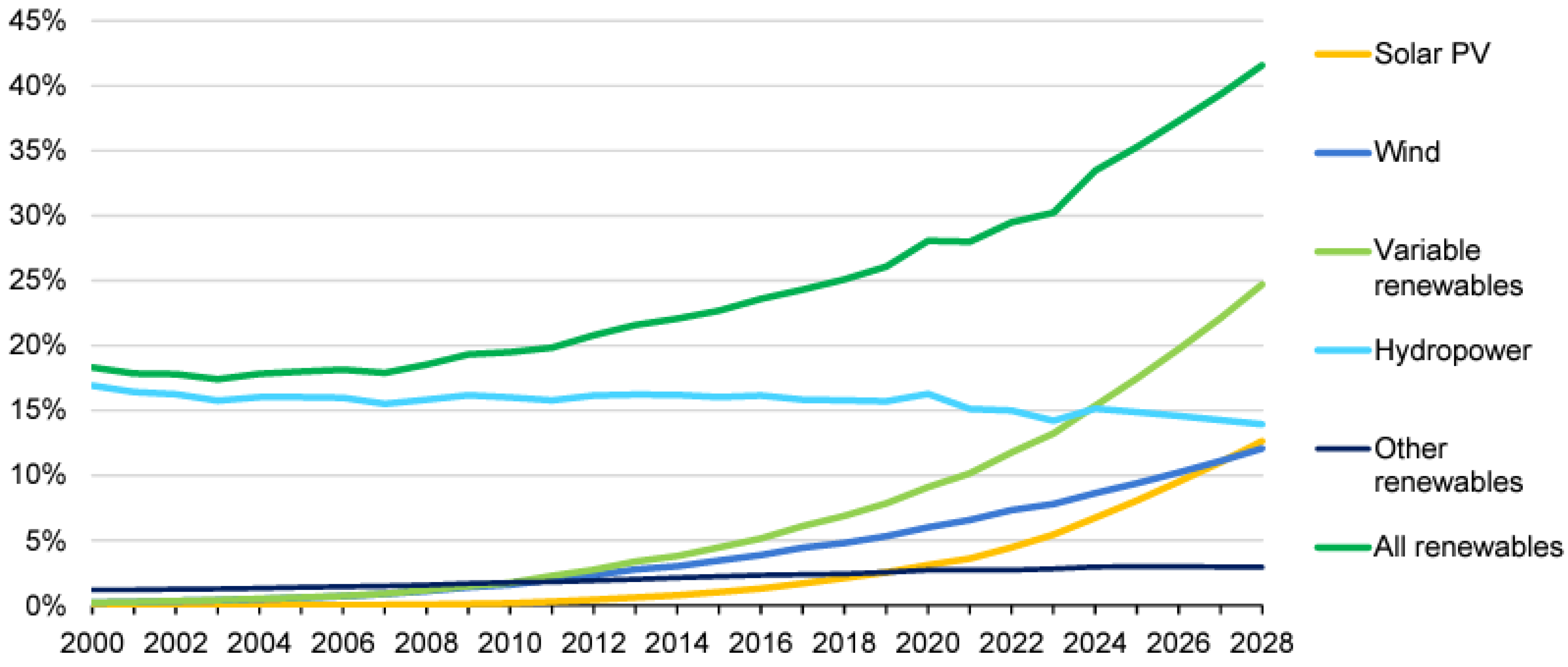

:1. Introduction

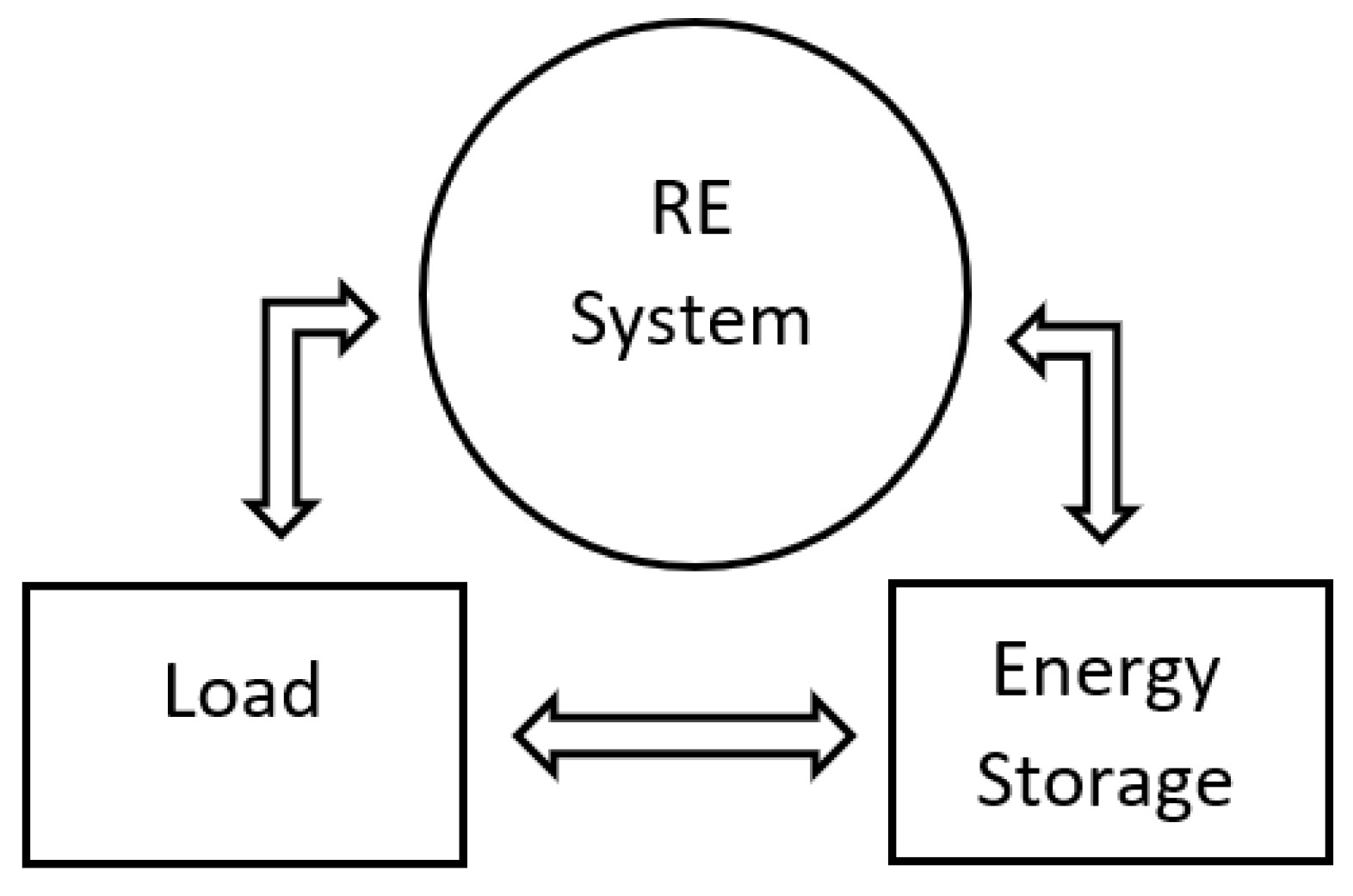

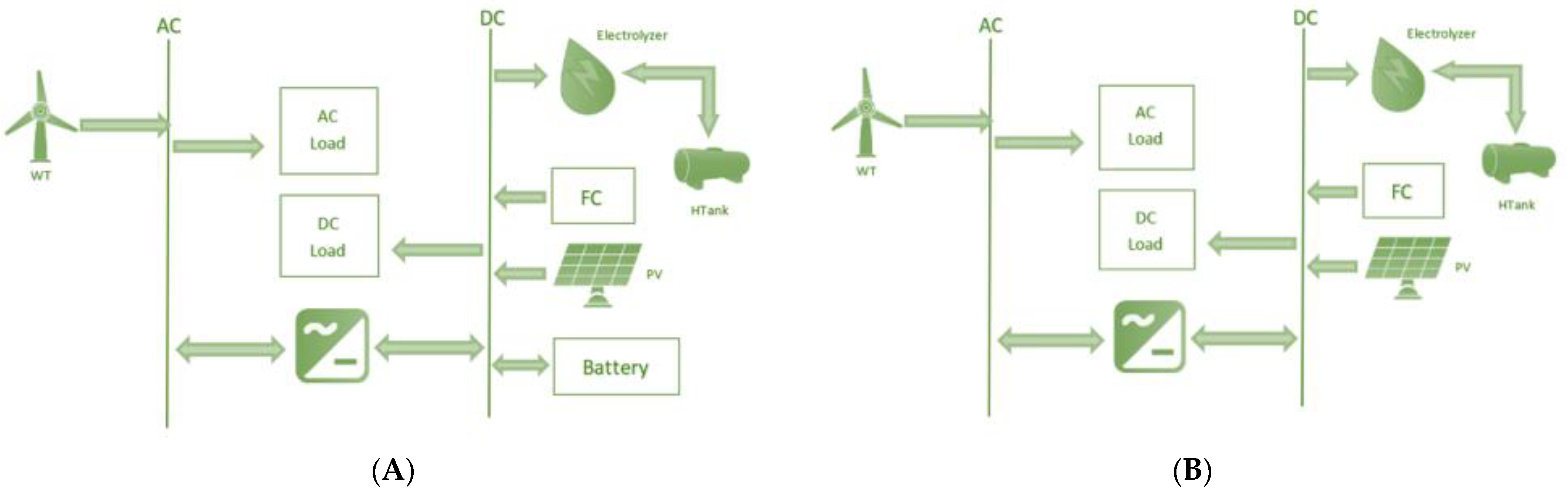

2. The Hybrid Energy System

2.1. Components of System

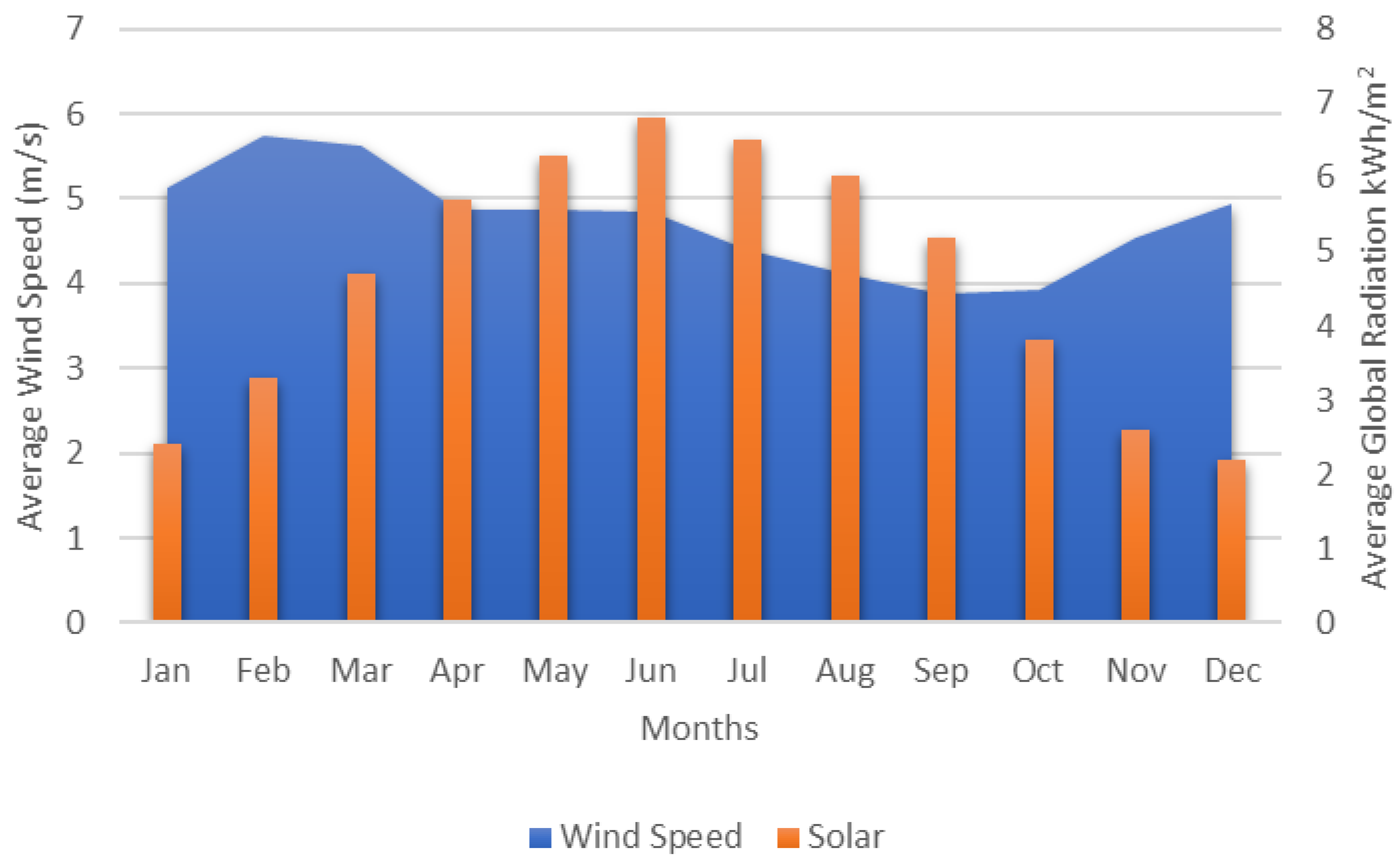

2.1.1. Captured Energy

2.1.2. Energy Storage

3. Sizing the System Component

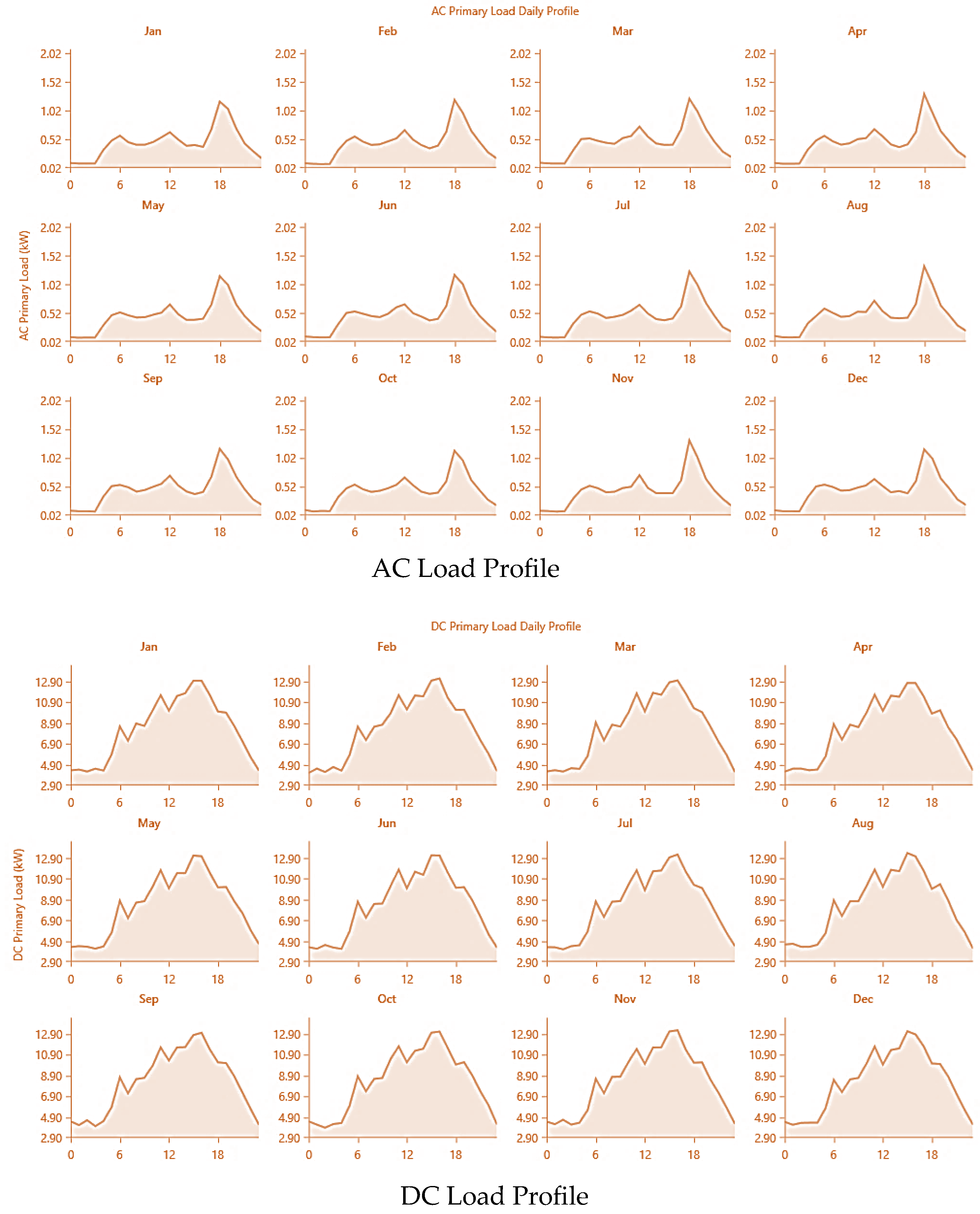

3.1. Load Demand Estimation

3.2. The System Cost Estimation

4. Results and Discussion

4.1. Optimization Process

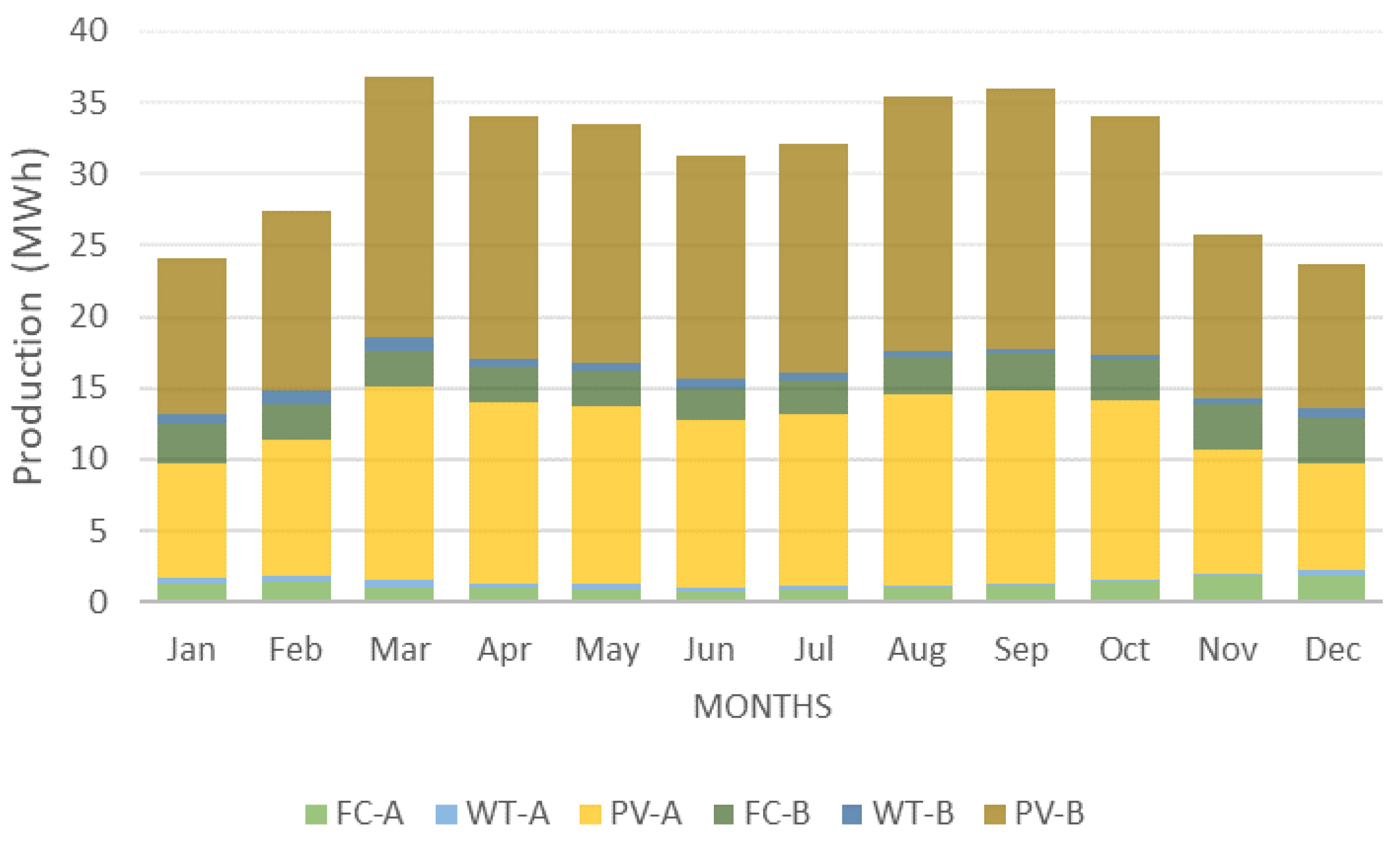

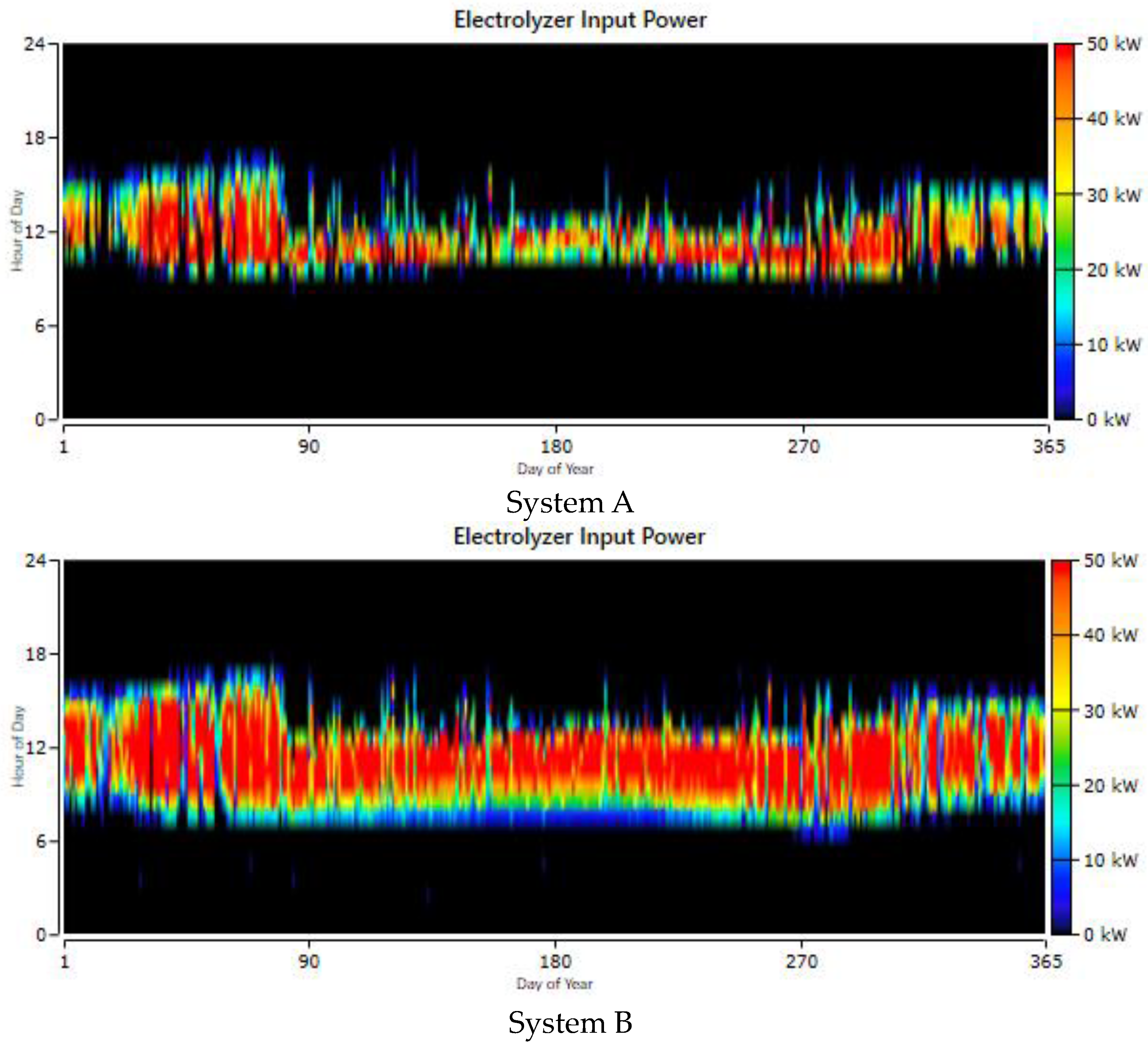

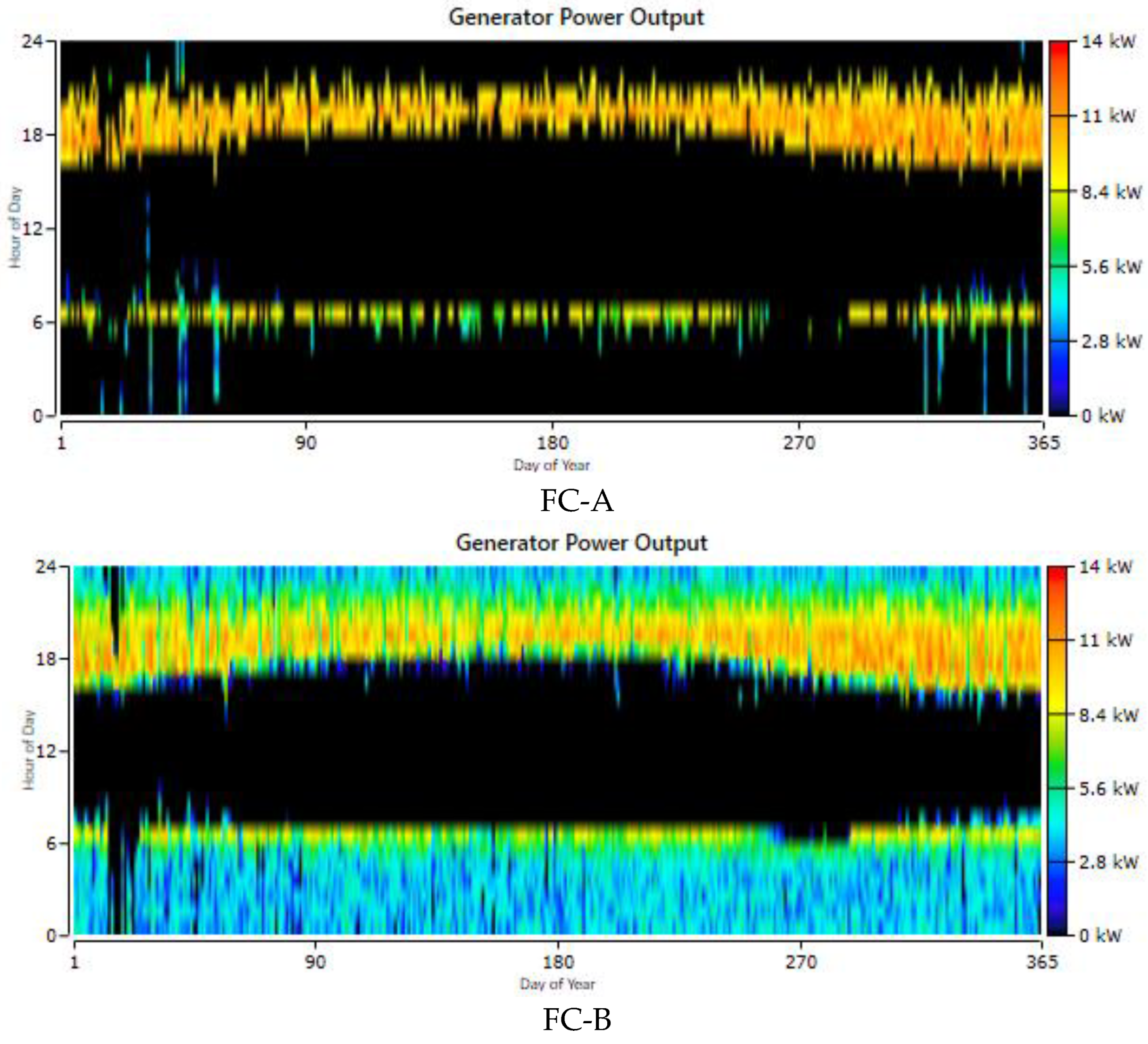

4.2. Power and Hydrogen Production

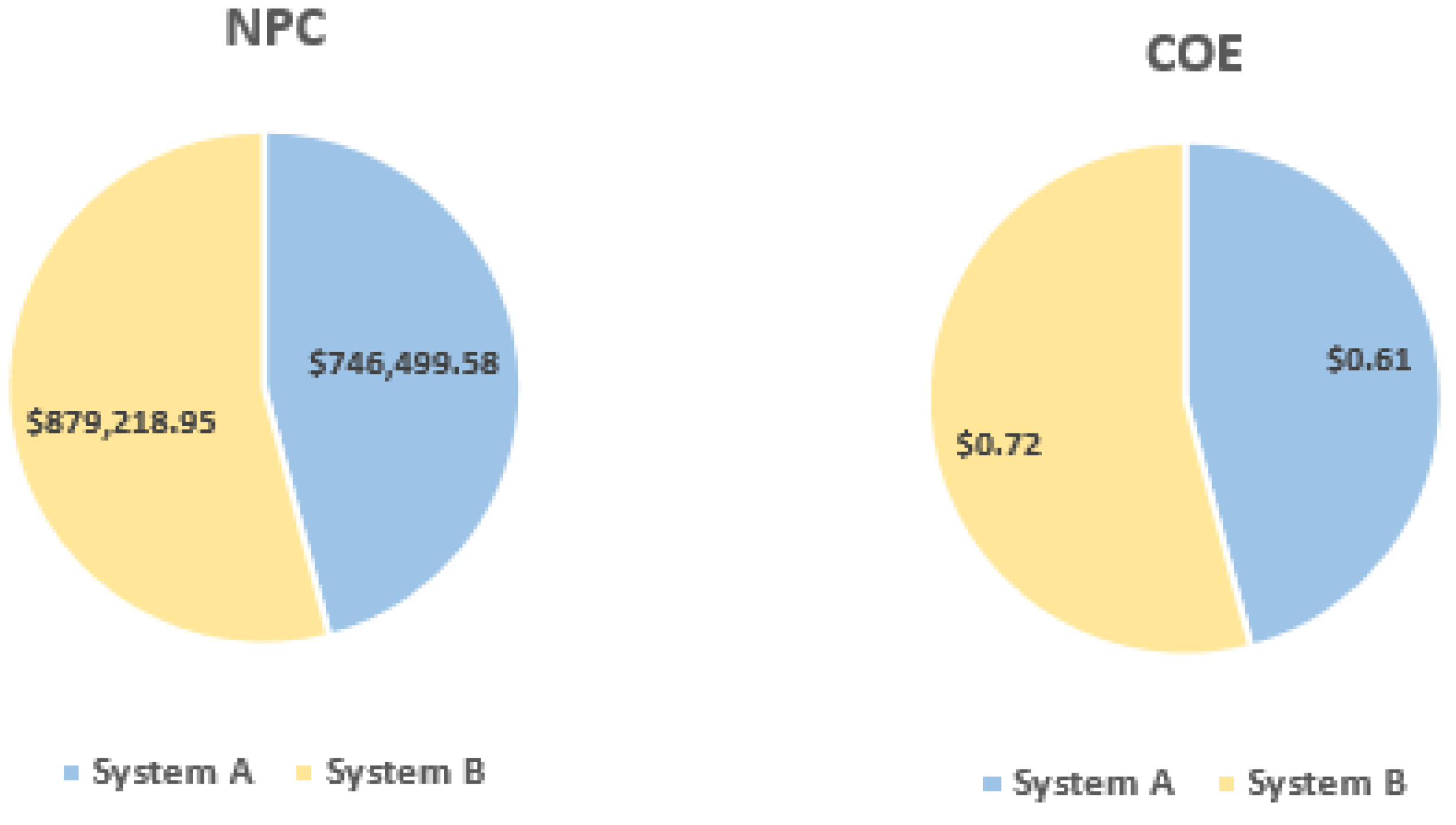

4.3. Economic Analysis

5. Conclusions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| AC | Alternating Current |

| DC | Direct Current |

| LPSP | Loss of Power Supply Probability |

| SOH | State of Hydrogen |

| Vcn | Cut-Out Speed |

| Vci | Cut-In Speed |

| BSS | Battery Storage System |

| PEM | Proton-Exchange Membrane (PEM) |

| CDF | Cumulative Distribution Function |

| DOD | Depth of Discharge |

| SOC | State of Charge |

| COE | Cost of Energy |

| DCF | Discounted Cash Flow |

| DEG | Diesel Engine Generator |

| DG | Diesel Generator |

| FC | Fuel Cell |

| HOMER | Hybrid Optimization of Multiple Electric Renewables |

| HRES | Hybrid Renewable Energy System |

| KSA | Kingdom of Saudi Arabia |

| kWh | Kilowatts per Hour |

| LCOE | Levelized Cost of Energy |

| NPC | Net Present Cost |

| NREL | National Renewable Energy Laboratory |

| PV | Photovoltaic |

| RE | Renewable Energy |

| RES | Renewable Energy Source |

| HST | Hydrogen Storage Tank |

| LCH | Levelized Cost of Hydrogen |

References

- Adeosun, T.A.; Amosu, C.O.; Omitogun, O.A.; Amusa, O.M.; Morenikeji, B.A. Renewable Energy for Sustainable Development in Developing Countries: Benefits to the Environment. J. Energy Res. Rev. 2023, 13, 1–25. [Google Scholar] [CrossRef]

- Vallero, D.A. Introduction to Environmental Aspects of Renewable Energy. In Comprehensive Renewable Energy; Elsevier: Amsterdam, The Netherlands, 2022; pp. 9–13. [Google Scholar] [CrossRef]

- Sankarananth, S.; Sutar, A.S. An Environmental Impact Review of Renewable Energy Use and Mitigation Strategies through Implementing Most Suited Engineering and Material Science Insights. Technoarete Trans. Renew. Energy Green Energy Sustain. 2022, 2, 17–22. [Google Scholar] [CrossRef]

- Alharthi, Y.Z.; Siddiki, M.K.; Chaudhry, G.M. Techno-Economic Analysis of Hybrid PV/Wind System Connected to Utility Grid. In Proceedings of the 2019 IEEE Texas Power Energy Conference, College Station, TX, USA, 7–8 February 2019; pp. 1–6. [Google Scholar]

- Alharthi, Y.Z.; Siddiki, M.K.; Chaudhry, G.M. The New Vision and the Contribution of Solar Power in the Kingdom of Saudi Arabia Electricity Production. In Proceedings of the 2017 Ninth Annual IEEE Green Technologies Conference (GreenTech), Denver, CO, USA, 29–31 March 2017; pp. 83–88. [Google Scholar]

- Baykara, S.Z.; Figen, H.E.; Karaismailoglu, M. Environmental Issues and Social Issues With Renewable Energy. In Comprehensive Renewable Energy; Elsevier: Amsterdam, The Netherlands, 2022; pp. 152–164. [Google Scholar] [CrossRef]

- Halabi, L.M.; Mekhilef, S.; Olatomiwa, L.; Hazelton, J. Performance analysis of hybrid PV/diesel/battery system using HOMER: A case study Sabah, Malaysia. Energy Convers. Manag. 2017, 144, 322–339. [Google Scholar] [CrossRef]

- Farahmand-Zahed, A.; Nojavan, S.; Zare, K.; Mohammadi-Ivatloo, B. Economic and Environmental Benefits of Renewable Energy Sources in Multi-generation Systems. In Integration of Clean and Sustainable Energy Resources and Storage in Multi-Generation Systems; Springer International Publishing: Cham, Switzerland, 2020; pp. 1–14. [Google Scholar] [CrossRef]

- Javed, M.S.; Jurasz, J.; Guezgouz, M.; Canales, F.A.; Ruggles, T.H.; Ma, T. Impact of multi-annual renewable energy variability on the optimal sizing of off-grid systems. Renew. Sustain. Energy Rev. 2023, 183, 113514. [Google Scholar] [CrossRef]

- Suwi, O.; Justo, J. Optimal Energy Management for off-Grid Hybrid Renewable Energy Systems. Tanzan. J. Eng. Technol. 2023, 42, 72–78. [Google Scholar] [CrossRef]

- Pop, T.; Ungureanu, C.; Pentiuc, R.D.; Afanasov, C.; Ifrim, V.C.; Atănăsoae, P.; Milici, L.D. Off-Grid Hybrid Renewable Energy System Operation in Different Scenarios for Household Consumers. Energies 2023, 16, 2992. [Google Scholar] [CrossRef]

- Annapandi, P.; Ramya, R.; Kotaiah, N.C.; Rajesh, P.; Subramanian, A. Optimal energy management system for the design of off grid hybrid renewable energy systems: A hybrid technique. J. Intell. Fuzzy Syst. 2023, 44, 2593–2614. [Google Scholar] [CrossRef]

- Jurasz, J.; Guezgouz, M. Off-grid hybrid systems reliability and transmission line utilization from the perspective of renewables complementarity. In Complementarity of Variable Renewable Energy Sources; Elsevier: Amsterdam, The Netherlands, 2022; pp. 359–377. [Google Scholar] [CrossRef]

- International Energy Agency. Available online: https://www.iea.org/energy-system/renewables (accessed on 2 April 2024).

- Tlili, I. Renewable energy in Saudi Arabia: Current status and future potentials. Environ. Dev. Sustain. 2015, 17, 859–886. [Google Scholar] [CrossRef]

- de Cataldo, A.; Astolfi, M.; Chiesa, P.; Campanari, S.; Martelli, E.; Silva, P.; Bedogni, S.; Ottolina, L.; Tappani, M.; Romano, M.C. Power and Hydrogen Co-Production in Flexible “Powdrogen” Plants. J. Eng. Gas Turbines Power 2023, 145, 061007. [Google Scholar] [CrossRef]

- Nikolaidis, P.; Poullikkas, A. Power-to-hydrogen concepts for 100% renewable and sustainable energy systems. In Hydrogen Economy; Elsevier: Amsterdam, The Netherlands, 2023; pp. 595–627. [Google Scholar] [CrossRef]

- Zhang, M.; Liu, R.; Wang, K.; Sun, K.; Guo, Q.; Li, Y. Research on Low Voltage Ride through and Reactive Power Support of Hydrogen Production Power Supply. In Proceedings of the 2022 4th International Conference on Smart Power & Internet Energy Systems (SPIES), Beijing, China, 27–30 October 2022; pp. 438–442. [Google Scholar] [CrossRef]

- Ni, H.; Qu, X.; Zhao, G.; Zhang, P.; Peng, W. Energy Analysis and Parametric Study of Hydrogen and Electricity Co-Production System Coupled with a Very-High-Temperature Gas-Cooled Reactor. In Proceedings of the International Conference on Nuclear Engineering, Shenzhen, China, 8–12 August 2022; American Society of Mechanical Engineers: New York, NY, USA, 2022. [Google Scholar]

- Tashie-Lewis, B.C.; Nnabuife, S.G. Hydrogen Production, Distribution, Storage and Power Conversion in a Hydrogen Economy-A Technology Review. Chem. Eng. J. Adv. 2021, 8, 100172. [Google Scholar] [CrossRef]

- Rasul, M.G.; Hazrat, M.; Sattar, M.A.; Jahirul, M.I.; Shearer, M.J. The future of hydrogen: Challenges on production, storage and applications. Energy Convers. Manag. 2022, 272, 116326. [Google Scholar] [CrossRef]

- Lee, D.; Quarme Gbadago, D.; Jo, Y.; Hwang, G.; Jo, Y.; Smith, R.; Hwang, S. Integrating hydrogen liquefaction with steam methane reforming and CO2 liquefaction processes using techno-economic perspectives. Energy Convers. Manag. 2021, 245, 114620. [Google Scholar] [CrossRef]

- Liu, T.; Yang, Z.; Duan, Y.; Hu, S. Techno-economic assessment of hydrogen integrated into electrical/thermal energy storage in PV+ Wind system devoting to high reliability. Energy Convers. Manag. 2022, 268, 116067. [Google Scholar] [CrossRef]

- Al-Sharafi, A.; Sahin, A.Z.; Ayar, T.; Yilbas, B.S. Techno-economic analysis and optimization of solar and wind energy systems for power generation and hydrogen production in Saudi Arabia. Renew. Sustain. Energy Rev. 2017, 69, 33–49. [Google Scholar] [CrossRef]

- Qolipour, M.; Mostafaeipour, A.; Tousi, O.M. Techno-economic feasibility of a photovoltaic-wind power plant construction for electric and hydrogen production: A case study. Renew. Sustain. Energy Rev. 2017, 78, 113–123. [Google Scholar] [CrossRef]

- Xia, T.; Rezaei, M.; Dampage, U.; Alharbi, S.A.; Nasif, O.; Borowski, P.F.; Mohamed, M.A. Techno-Economic Assessment of a Grid-Independent Hybrid Power Plant for Co-Supplying a Remote Micro-Community with Electricity and Hydrogen. Processes 2021, 9, 1375. [Google Scholar] [CrossRef]

- Kusakana, K.; Vermaak, H.J. Hydrokinetic power generation for rural electricity supply: Case of South Africa. Renew. Energy 2013, 55, 467–473. [Google Scholar] [CrossRef]

- Mohammadi, A.; Mehrpooya, M. Techno-economic analysis of hydrogen production by solid oxide electrolyzer coupled with dish collector. Energy Convers. Manag. 2018, 173, 167–178. [Google Scholar] [CrossRef]

- Gökçek, M.; Kale, C. Optimal design of a Hydrogen Refuelling Station (HRFS) powered by Hybrid Power System. Energy Convers. Manag. 2018, 161, 215–224. [Google Scholar] [CrossRef]

- Fadaeenejad, M.; Radzi, M.A.M.; AbKadir, M.Z.A.; Hizam, H. Assessment of hybrid renewable power sources for rural electrification in Malaysia. Renew. Sustain. Energy Rev. 2014, 30, 299–305. [Google Scholar] [CrossRef]

- Pode, R.; Diouf, B.; Pode, G. Sustainable rural electrification using rice husk biomass energy: A case study of Cambodia. Renew. Sustain. Energy Rev. 2015, 44, 530–542. [Google Scholar] [CrossRef]

- Baurzhan, S.; Jenkins, G.P. Off-grid solar PV: Is it an affordable or appropriate solution for rural electrification in Sub-Saharan African countries? Renew. Sustain. Energy Rev. 2016, 60, 1405–1418. [Google Scholar] [CrossRef]

- Li, B.; de Queiroz, A.R.; DeCarolis, J.F.; Bane, J.; He, R.; Keeler, A.G.; Neary, V.S. The economics of electricity generation from Gulf Stream currents. Energy 2017, 134, 649–658. [Google Scholar] [CrossRef]

- Murugaperumal, K.; Srinivasn, S.; Satya Prasad, G.R.K.D. Optimum design of hybrid renewable energy system through load forecasting and different operating strategies for rural electrification. Sustain. Energy Technol. Assess. 2020, 37, 100613. [Google Scholar] [CrossRef]

- Sarkar, T.; Bhattacharjee, A.; Samanta, H.; Bhattacharya, K.; Saha, H. Optimal design and implementation of solar PV-wind-biogas-VRFB storage integrated smart hybrid microgrid for ensuring zero loss of power supply probability. Energy Convers. Manag. 2019, 191, 102–118. [Google Scholar] [CrossRef]

- Suresh, V.; Muralidhar, M.; Kiranmayi, R. Modelling and optimization of an off-grid hybrid renewable energy system for electrification in a rural areas. Energy Rep. 2020, 6, 594–604. [Google Scholar] [CrossRef]

- Gómez-Hernández, D.F.; Domenech, B.; Moreira, J.; Farrera, N.; López-González, A.; Ferrer-Martí, L. Comparative evaluation of rural electrification project plans: A case study in Mexico. Energy Policy 2019, 129, 23–33. [Google Scholar] [CrossRef]

- López-González, A.; Ferrer-Martí, L.; Domenech, B. Sustainable rural electrification planning in developing countries: A proposal for electrification of isolated communities of Venezuela. Energy Policy 2019, 129, 327–338. [Google Scholar] [CrossRef]

- Fodhil, F.; Hamidat, A.; Nadjemi, O. Potential, optimization and sensitivity analysis of photovoltaic-diesel-battery hybrid energy system for rural electrification in Algeria. Energy 2019, 169, 613–624. [Google Scholar] [CrossRef]

- Nurunnabi, M.; Roy, N.K.; Hossain, E.; Pota, H.R. Size optimization and sensitivity analysis of hybrid Wind/PV micro-grids-A case study for a tropical country. IEEE Access 2019, 7, 150120–150140. [Google Scholar] [CrossRef]

- Sinha, S.; Chandel, S.S. Review of software tools for hybrid renewable energy systems. Renew. Sustain. Energy Rev. 2014, 32, 192–205. [Google Scholar] [CrossRef]

- Abdin, Z.; Mérida, W. Hybrid energy systems for off-grid power supply and hydrogen production based on renewable energy: A techno-economic analysis. Energy Convers. Manag. 2019, 196, 1068–1079. [Google Scholar] [CrossRef]

- Lambert, T.; Gilman, P.; Lilienthal, P. Micropower System Modeling with HOMER, Cha 15. Available online: https://onlinelibrary.wiley.com/doi/book/10.1002/0471755621 (accessed on 12 March 2024).

- HOMER Energy. Available online: https://www.homerenergy.com (accessed on 10 February 2024).

- Kalinci, Y.; Hepbasli, A.; Dincer, I. Techno-economic analysis of a stand-alone hybrid renewable energy system with hydrogen production and storage options. Int. J. Hydrogen Energy 2015, 40, 7652–7664. [Google Scholar] [CrossRef]

- Merei, G.; Berger, C.; Sauer, D.U. Optimization of an off-grid hybrid PV–Wind–Diesel system with different battery technologies using genetic algorithm. Sol. Energy 2013, 97, 460–473. [Google Scholar] [CrossRef]

- Schmidt, O.; Gambhir, A.; Staffell, I.; Hawkes, A.; Nelson, J.; Few, S. Future cost and performance of water electrolysis: An expert elicitation study. Int. J. Hydrogen Energy 2017, 42, 30470–30492. [Google Scholar] [CrossRef]

- Final Report: Hydrogen Storage System Cost Analysis. Available online: https://www.osti.gov (accessed on 2 February 2024).

| System Production | System A | System B | Unit |

|---|---|---|---|

| PV | 135,630 | 181,278 | kWh/year |

| Fuel Cell | 14,372 | 31,741 | |

| WT | 3613 | 7226 | |

| Total | 153,615 | 220,245 | |

| Electrolyzer | 868 | 1905 | kg/year |

| FC Operation Hours | 1496 | 5454 | h/year |

| FC NO of starts | 617 | 378 | starts/year |

| FC Operational Lifetime | 26.7 | 7.33 | year |

| FC Capacity Factor | 8.20 | 18.1 | % |

| Total Fuel Consumed | 868 | 1905 | kg |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alharthi, Y.Z. An Analysis of Hybrid Renewable Energy-Based Hydrogen Production and Power Supply for Off-Grid Systems. Processes 2024, 12, 1201. https://doi.org/10.3390/pr12061201

Alharthi YZ. An Analysis of Hybrid Renewable Energy-Based Hydrogen Production and Power Supply for Off-Grid Systems. Processes. 2024; 12(6):1201. https://doi.org/10.3390/pr12061201

Chicago/Turabian StyleAlharthi, Yahya Z. 2024. "An Analysis of Hybrid Renewable Energy-Based Hydrogen Production and Power Supply for Off-Grid Systems" Processes 12, no. 6: 1201. https://doi.org/10.3390/pr12061201