Research on the Temperature Field Distribution Characteristics of Bottomhole PDC Bits during the Efficient Development of Unconventional Oil and Gas in Long Horizontal Wells

Abstract

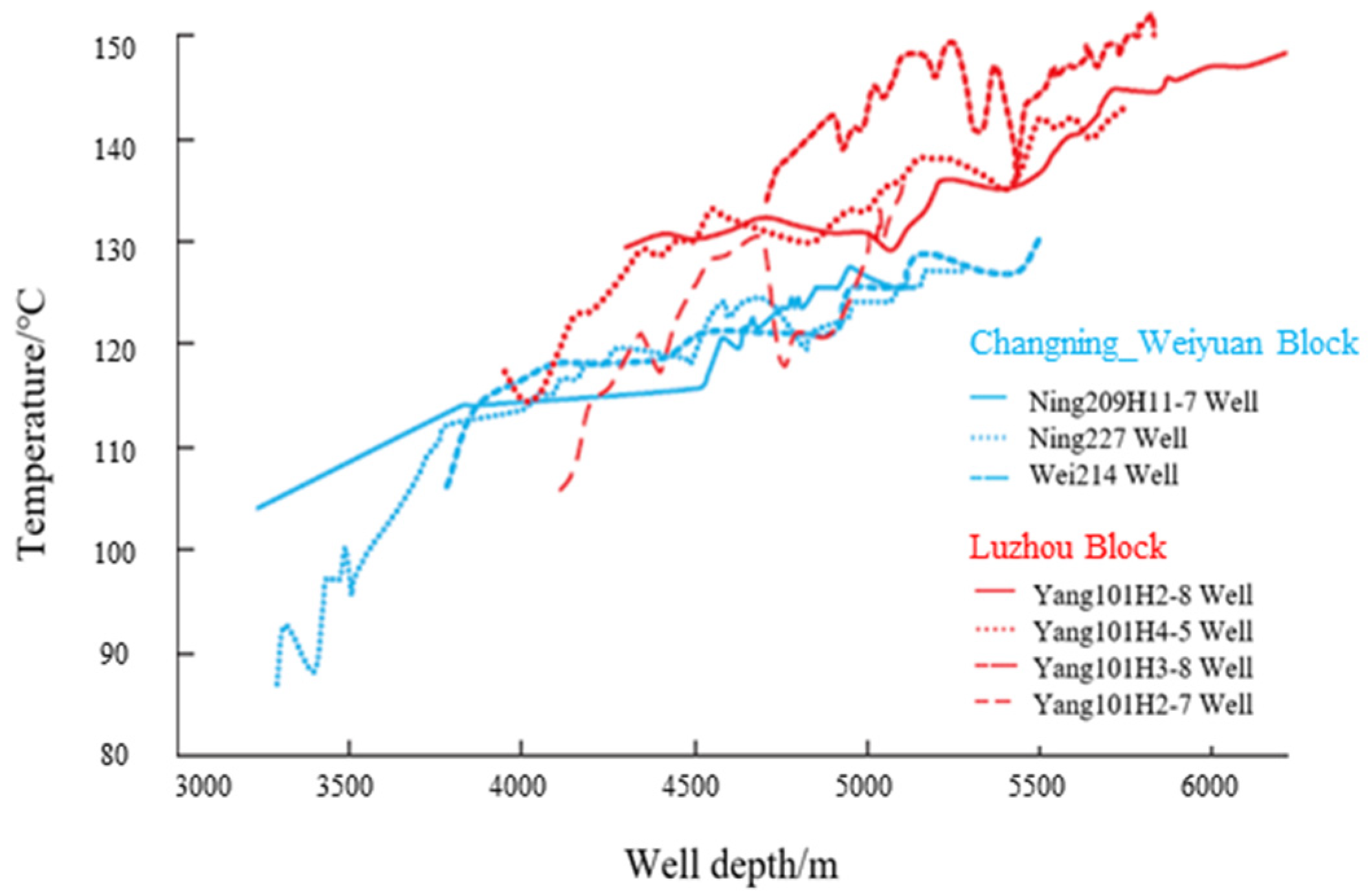

1. Introduction

2. Current Research Status on Temperature Rise Characteristics of PDC Cutting Teeth

3. Experimental Preparation

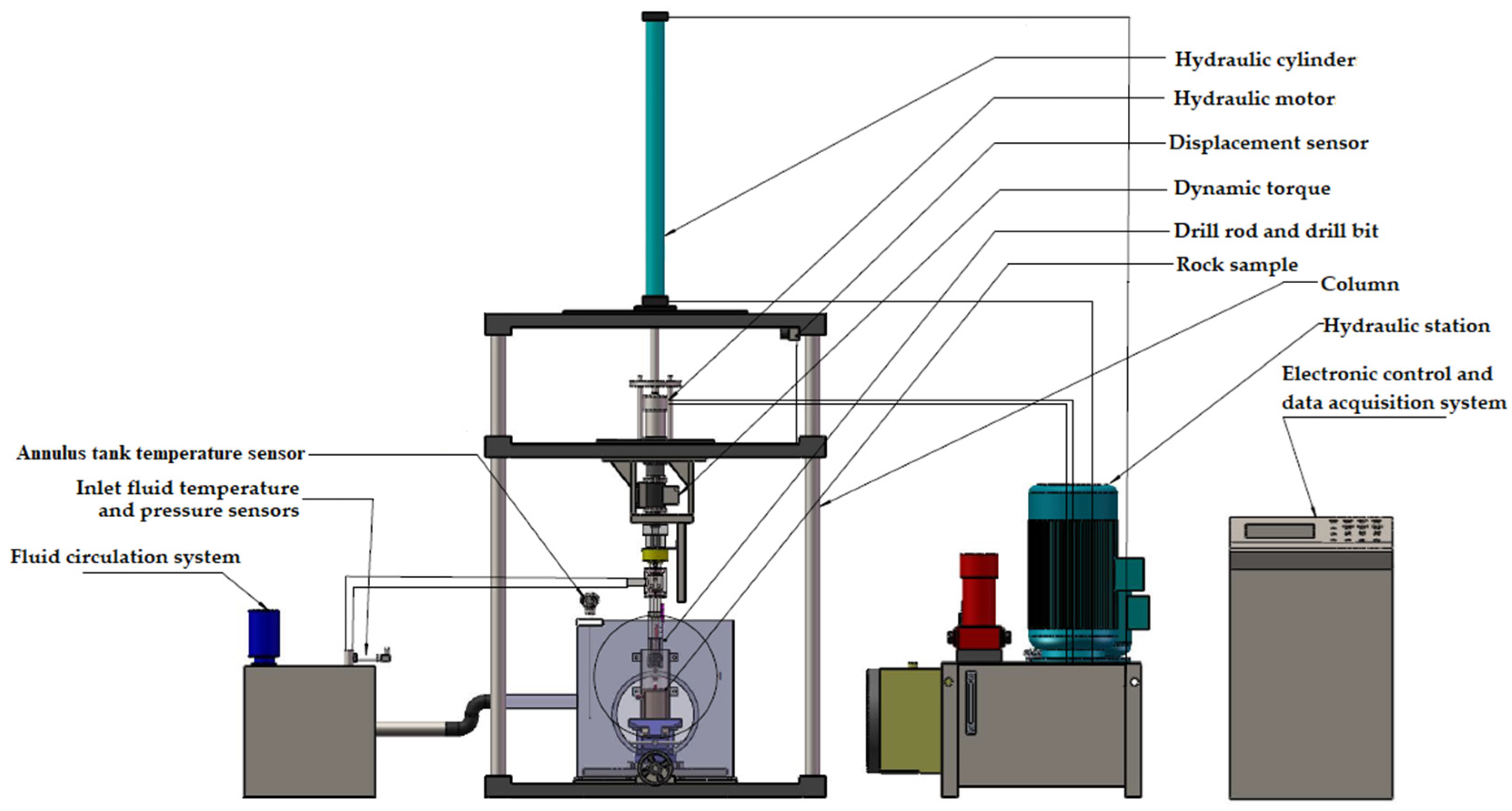

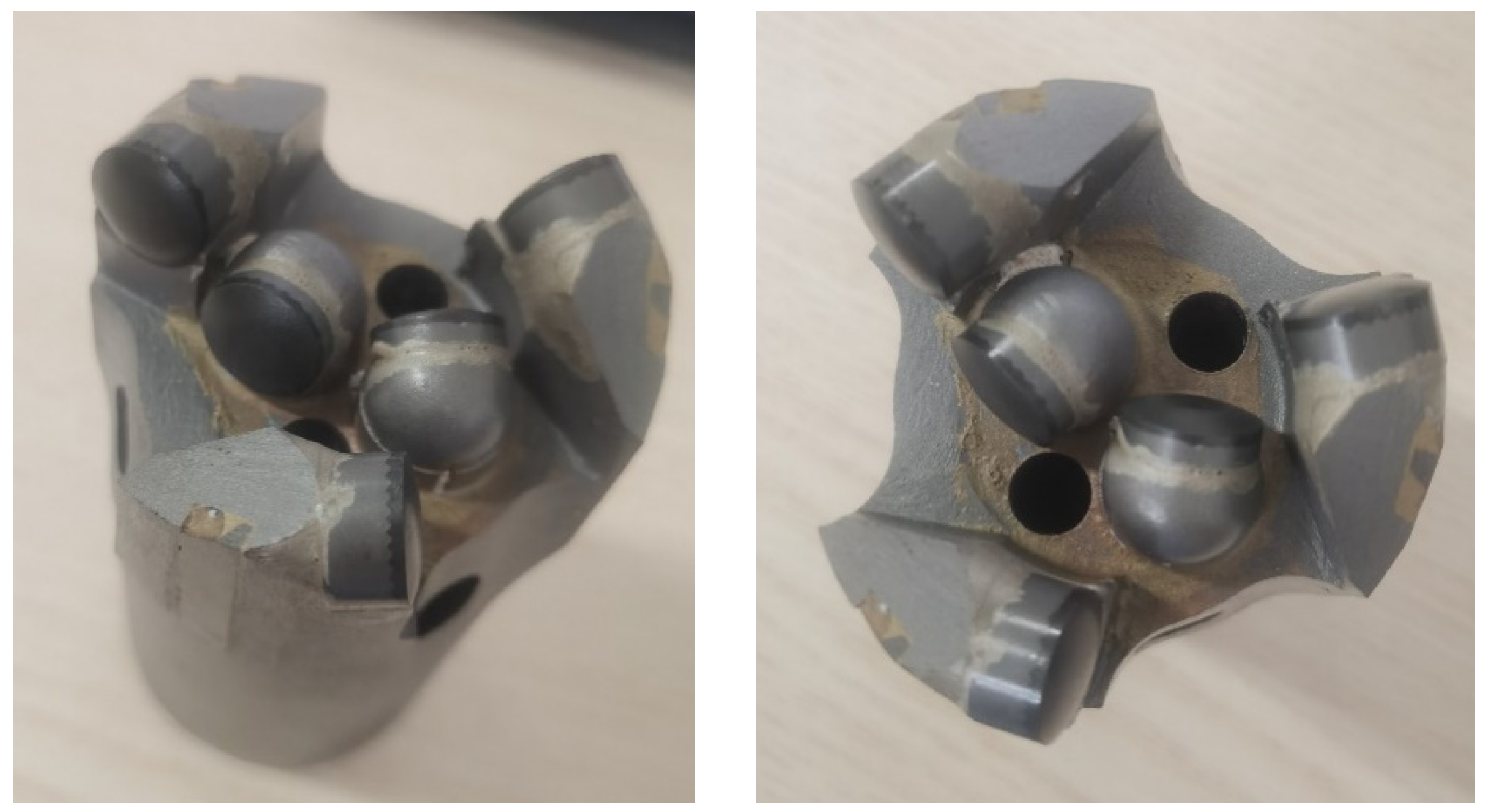

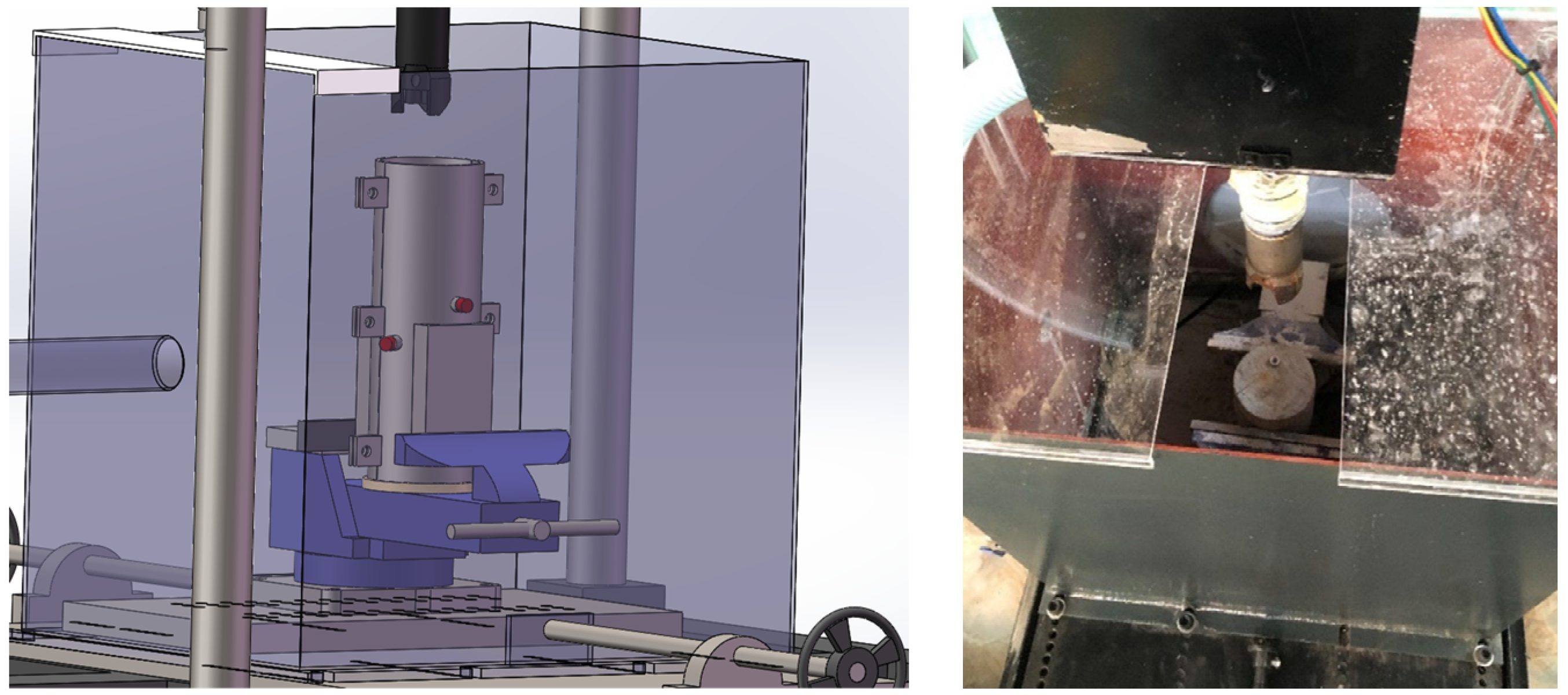

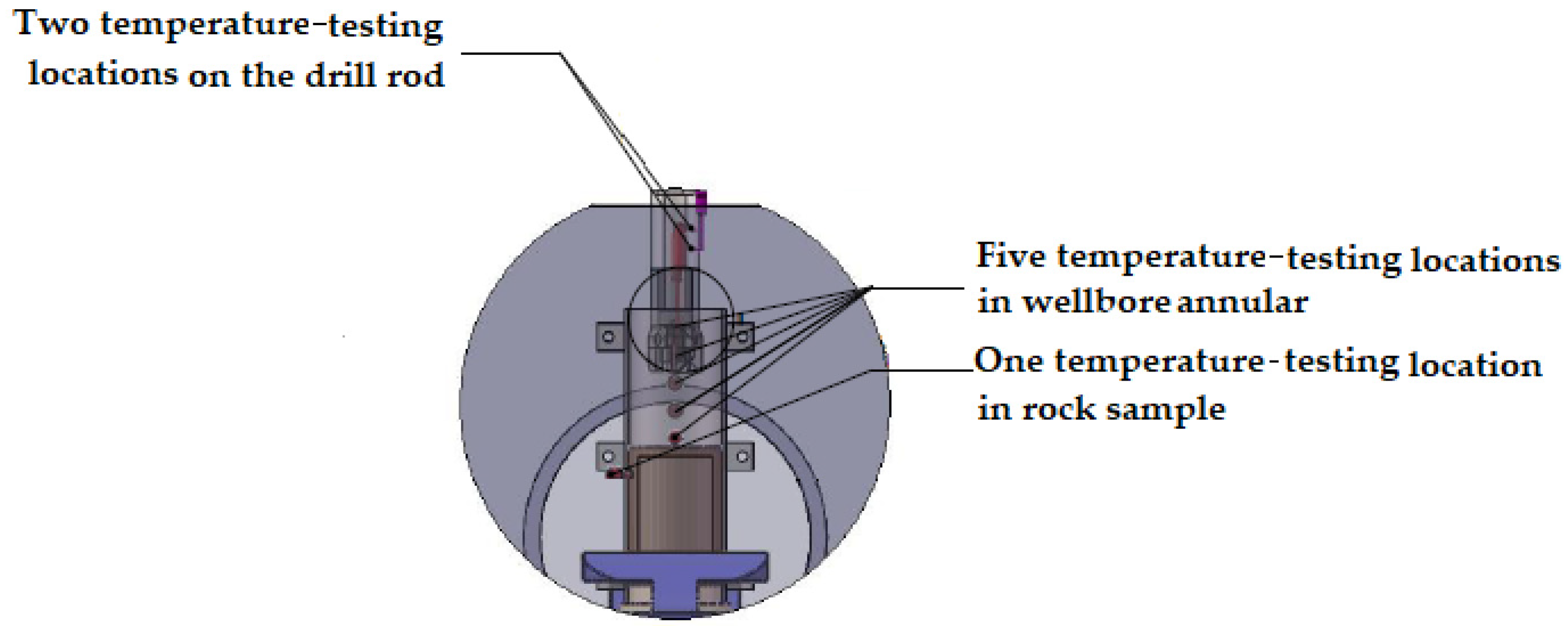

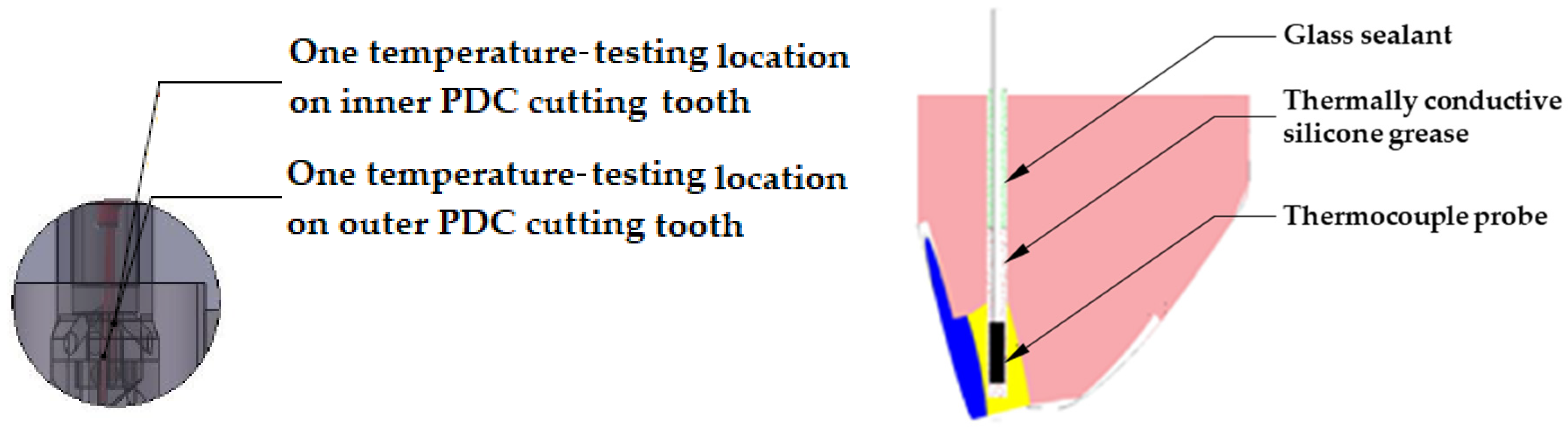

3.1. Experimental Equipment

3.2. Experimental Equipment Operation Process

- a.

- Firstly, power on the electronic control and data acquisition system and input parameters such as WOB (4.5 kN was used for general experiments; 1, 3, 4.5, 6, and 7.5 kN were used for WOB comparative experiments), rotation speed (50 r/min was used for general experiments; 50, 100, and 150 r/min were used for rotation speed comparative experiments), and lifting and lowering speed into the data acquisition control system.

- b.

- Secondly, insert the experimental core sample (several typical core samples were prepared, including cement stone, sandstone, marble, and granite) and fix it in place.

- c.

- Thirdly, start the circulation pump and adjust the fluid flow rate (50 L/min was used for general experiments; 0, 25, 50, 75, and 100 L/min were used for flow rate comparative experiments).

- d.

- Fourthly, start the hydraulic system, rotate the drill rod and drill bit, and begin collecting data such as WOB, rotation speed, torque, ROP, drill bit temperature, bottomhole temperature, annulus temperature, inlet fluid temperature, and inlet fluid pressure.

- e.

- Then, lower the drill rod and drill bit and start breaking and drilling after touching the rock core. After drilling to the predetermined depth or time, stop drilling, and lift up the drill rod and drill bit.

- f.

- Finally, turn off the hydraulic system, stop the circulation pump, and output and analyze the experimental data.

4. Experimental Results and Discussion

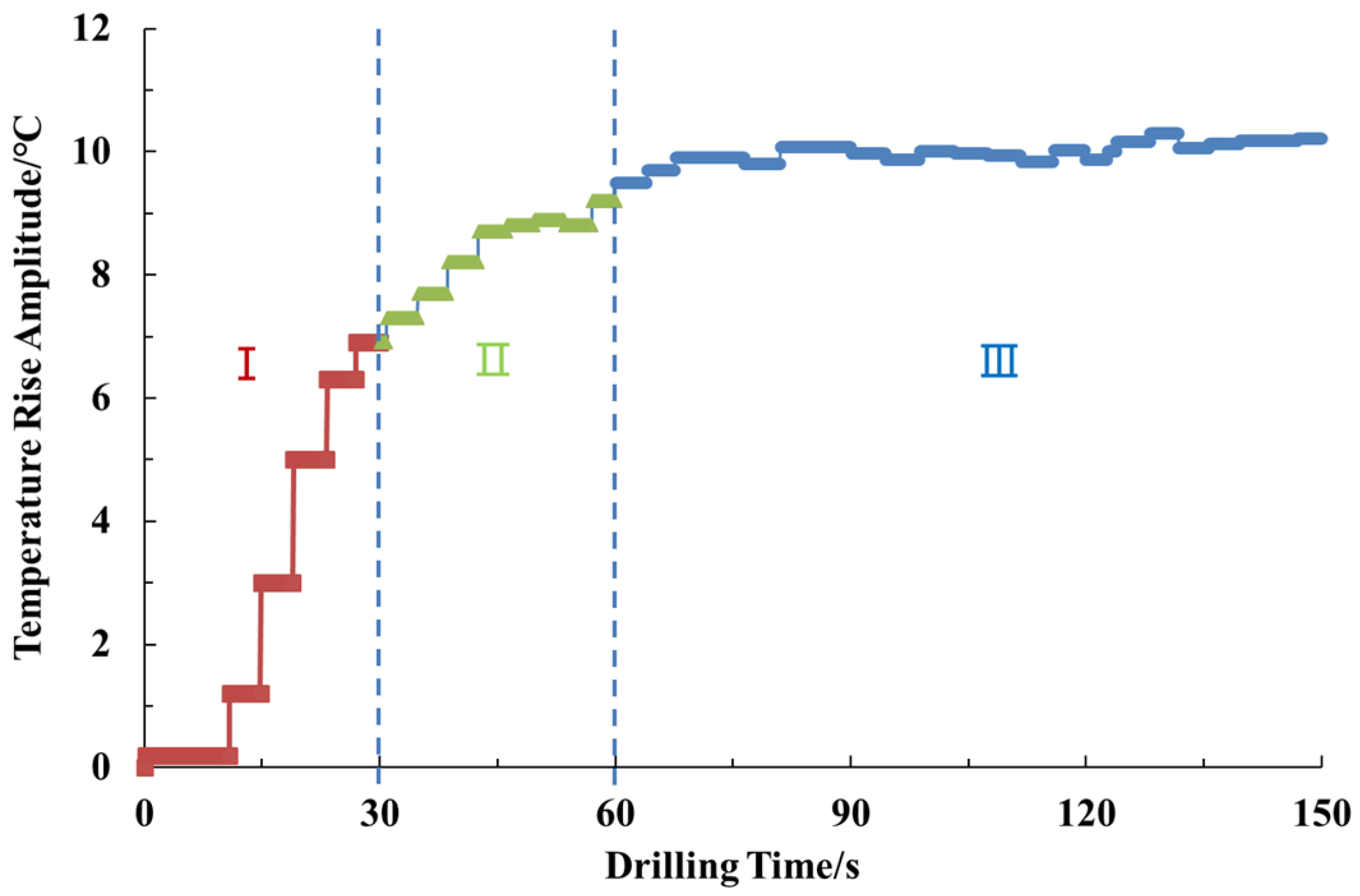

4.1. Analysis of Temperature Rise Law during PDC Bit Drilling

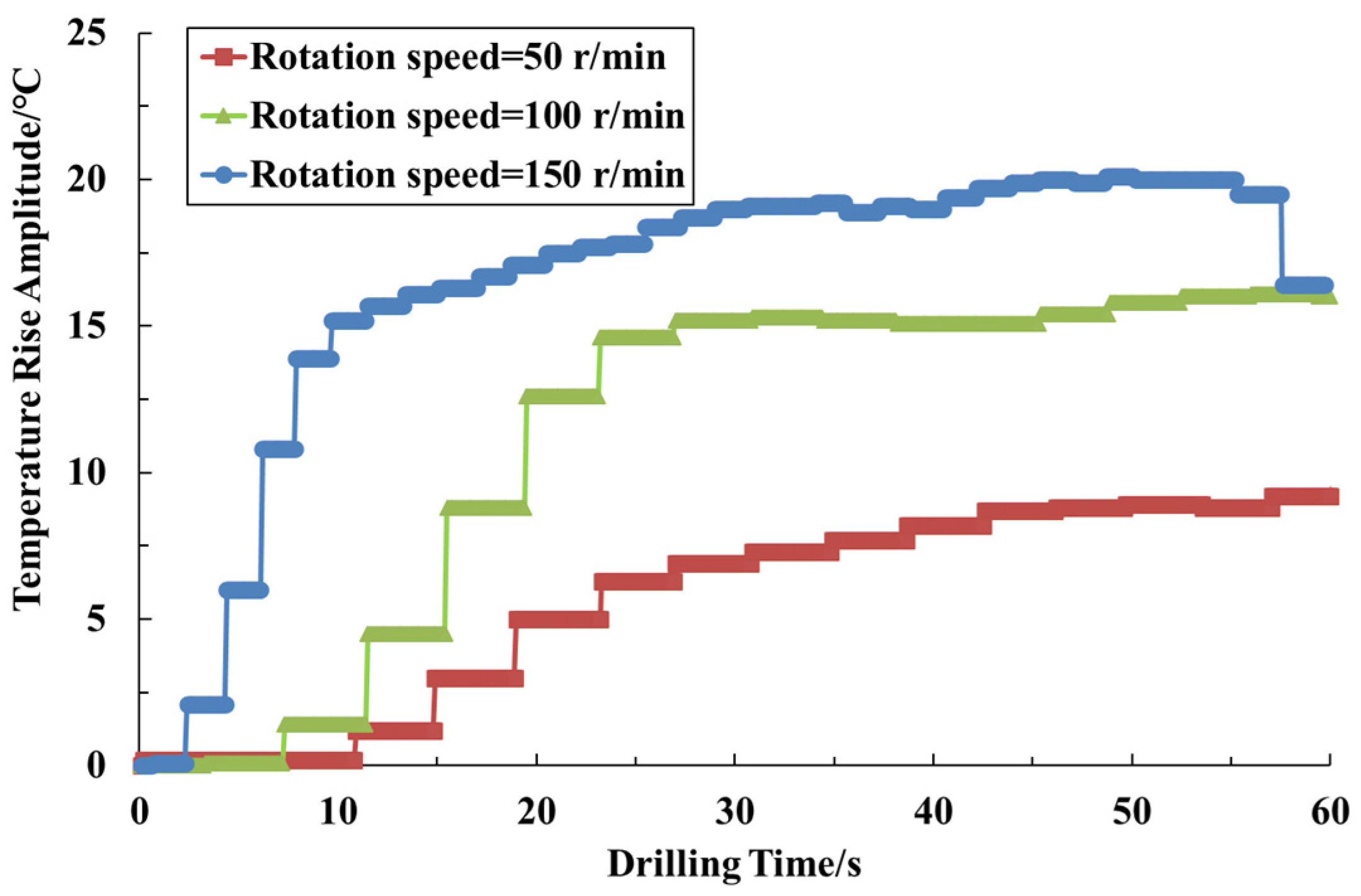

4.2. Drilling Experiment under Different Rotation Speed Conditions

4.3. Drilling Experiment under Different WOB Conditions

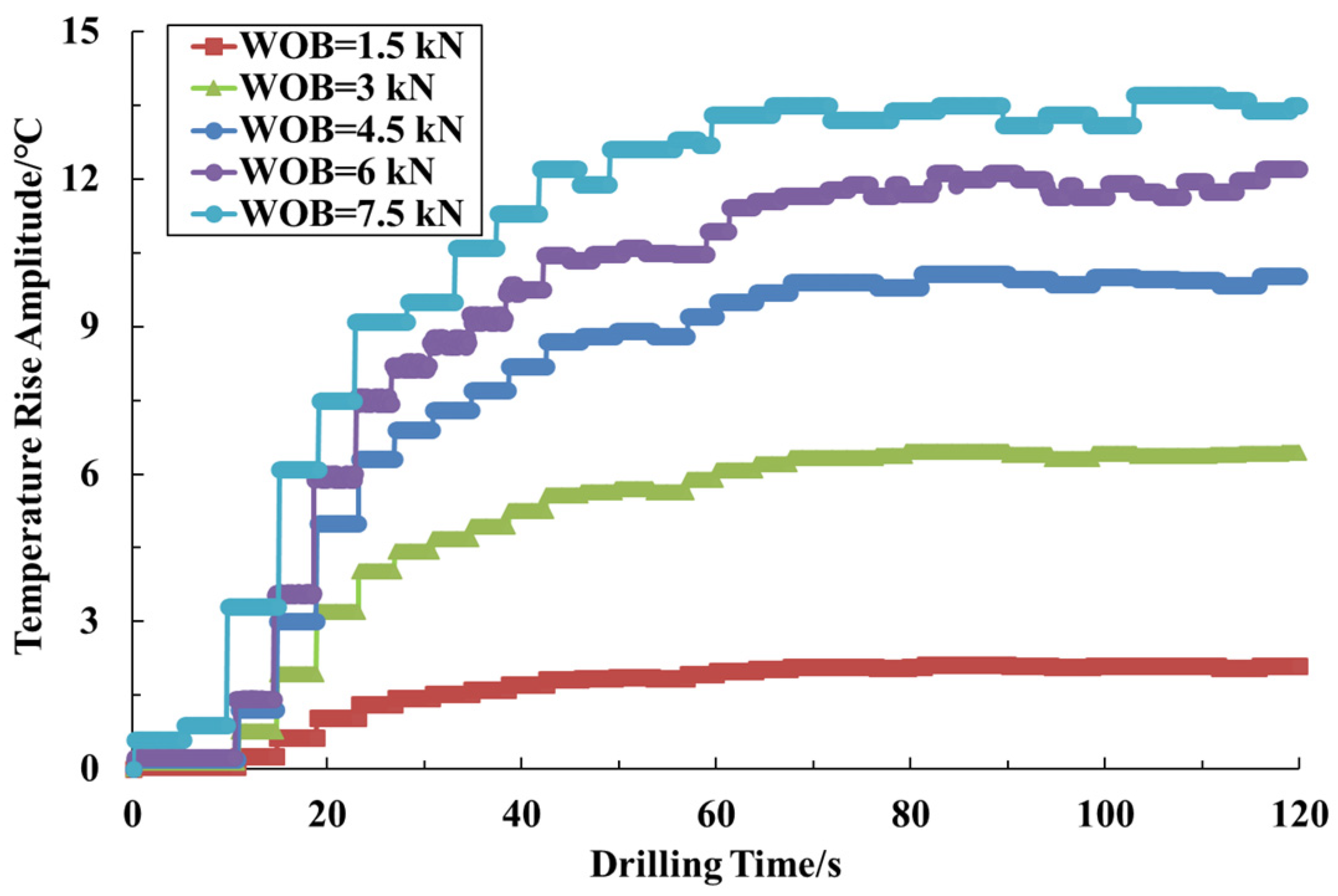

4.4. Drilling Experiment under Different Drilling Fluid Flow Rate Conditions

4.5. Drilling Experiment under Different Rock Type Conditions

5. Conclusions

- (a)

- The temperature rise curve during the PDC drill bit drilling process exhibits three stages: a rapid increase stage, a slow increase stage, and a relatively stable stage, with the temperature ultimately reaching dynamic equilibrium.

- (b)

- The higher the rotation speed and the greater the WOB, the higher the temperature rise of the cutting tooth of the PDC drill bit.

- (c)

- There is a negative correlation between flow rate and cutting tooth temperature. In this experiment, under conditions without circulating water, the highest temperature rise amplitude of the cutting tooth reached 75.2 °C.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zou, C.N.; Zhao, Q.; Wang, H.Y.; Xiong, W.; Dong, D.Z.; Yu, R.Z. The main characteristics of marine shale gas and the theory & technology of exploration and development in China. Nat. Gas Ind. 2022, 42, 1–13. [Google Scholar]

- Li, Q.; Liu, J.; Wang, S.; Guo, Y.; Han, X.; Li, Q.; Cheng, Y.; Dong, Z.; Li, X.; Zhang, X. Numerical insights into factors affecting collapse behavior of horizontal wellbore in clayey silt hydrate-bearing sediments and the accompanying control strategy. Ocean Eng. 2024, 297, 117029. [Google Scholar] [CrossRef]

- Li, Q.; Wang, Y.; Wang, F.; Ning, X.; Chuanbao, Z.; Zhang, J.; Zhang, C. Factor analysis and mechanism disclosure of supercritical CO2 filtration behavior in tight shale reservoirs. Environ. Sci. Pollut. Res. 2022, 29, 17682–17694. [Google Scholar] [CrossRef]

- Wu, P.; Zhao, P.; Chen, Y.; Yang, H.; Yang, Y.; Dong, Q.; Chang, Y.; Wen, L.; Yuan, K.; Du, Y.; et al. Tight Reservoir Characteristics and Controlling Factors of Permian Lucaogou Formation in Yongfeng Sub-Sag, Chaiwopu Sag. Processes 2023, 11, 3068. [Google Scholar] [CrossRef]

- Ma, X.; Wang, H.; Zhou, S.; Shi, Z.; Zhang, L. Deep shale gas in China: Geological characteristics and development strategies. Energy Rep. 2021, 7, 1903–1914. [Google Scholar] [CrossRef]

- Zou, C.; Zhao, Q.; Cong, L.; Wang, H.; Shi, Z.; Wu, J.; Pan, S. Development progress, potential and prospect of shale gas in China. Nat. Gas Ind. 2021, 41, 1–14. [Google Scholar]

- She, C.Y. New progress and development prospect of key technologies for drilling of deep shale gas wells in the Sichuan Basin. Nat. Gas Ind. 2024, 44, 1–9. [Google Scholar]

- Yuan, G.J.; Fu, L.; Wang, Y.; Guo, K.; Chen, G. The up-to-date drilling and completion technologies for economic and effective development of unconventional oil & gas and suggestions for further improvements. Pet. Drill. Tech. 2022, 50, 1–12. [Google Scholar]

- Li, R.; Shih, A.J. Spiral point drill temperature and stress in high-throughput drilling of titanium. Int. J. Mach. Tools Manuf. 2007, 47, 2005–2017. [Google Scholar] [CrossRef]

- Glowka, D.A.; Stone, C.M. Thermal response of polycrystalline diamond compact cutters under simulated downhole conditions. Soc. Pet. Eng. J. 1985, 25, 143–156. [Google Scholar] [CrossRef]

- Zhao, J.K.; Sun, Y.H.; Zhang, Z.P. Study on drilling technology of thermo-mechanical rock fragmentation. Drill. Eng. 2004, 12, 36–39. [Google Scholar]

- Wu, J.G.; Tan, Z.S.; Wu, J.H. Research on the temperature field in thermo-mechanical drilling. Chin. J. Undergr. Space Eng. 2005, 1, 885–888. [Google Scholar]

- Wu, J.H.; Zhang, Z.P. Study Distribution of drill of rock’s damage and padding’s TEM perature place by friction heat and mechanical energy. Geol. Prospect. 2007, 43, 91–94. [Google Scholar]

- Wang, H.B.; Duan, L.C.; Yang, D.H. Analysis of characteristics of PDC rock bits applied to the hard rock. Min. Process. Equip. 2009, 37, 20–22. [Google Scholar]

- Liu, B.C.; Cao, X.; Ji, S.L.; Han, Z.; Zhao, X.Z.; Li, S.Q. Simulation and experimental research on flow field and temperature field of diamond impregnated drill bit. Diam. Abras. Eng. 2018, 38, 33–38. [Google Scholar]

- Li, X.H.; Yang, X.F.; Lu, Y.Y.; Lu, Z.H.; Yang, B.K. Temperature analysis of cemented carbide drill cutting rock associated with water jet. J. China Coal Soc. 2010, 35, 844–849. [Google Scholar]

- Yang, X.F.; Lu, Y.Y.; Kang, Y. Flash temperature in the process of tool-rock friction. J. Sichuan Univ. (Eng. Sci. Ed.) 2011, 43, 225–231. [Google Scholar]

- Yang, X.F.; Li, X.H.; Lu, Y.Y.; Kang, Y. Experimental of infrared thermal image in limestone drilling. J. Jilin Univ. (Earth Sci. Ed.) 2011, 41, 1504–1511. [Google Scholar]

- Shao, W.; Li, X.; Sun, Y.; Huang, H.; Tang, J. An experimental study of temperature at the tip of point-attack pick during rock cutting proces. Int. J. Rock Mech. Min. Sci. 2018, 107, 39–47. [Google Scholar] [CrossRef]

- Kim, E. Effect of skew angle on main precursor of frictional ignition in bench-scale simulation of excavation processes. Int. J. Rock Mech. Min. Sci. 2015, 80, 101–106. [Google Scholar] [CrossRef]

- Kim, E.; Hirro, K.; Oliveira, D.; Kim, A. Effects of the skew angle of conical bits on bit temperature, bit wear, and rock cutting performance. Int. J. Rock Mech. Min. Sci. 2017, 100, 263–268. [Google Scholar] [CrossRef]

- Shao, C.; Zhang, Y.; Pan, B.S.; Yan, T.N. Study on heat exchange of hole-bottom rock in diamond drilling based on ANSYS. Diam. Abras. Eng. 2011, 31, 11–14. [Google Scholar]

- Wu, K.S.; Ke, X.; Long, J.G. Research on the Temperature Rise Law for Single Tooth Rock-breaking of Thermal Structure Coupling PDC Bit. China Pet. Mach. 2013, 41, 24–26. [Google Scholar]

- Li, Y.; Deng, R.; Liu, Y.S. Temperature Field Analysis and Simulation of the PDC Bit Cutting Teeth Based on ABAQUS Software. Mod. Manuf. Technol. Equip. 2012, 2, 1–3. [Google Scholar]

- Deng, R.; Li, Y. Simulation Analysis of Temperature Field for PDC Bit Cutter Rock Breaking. China Pet. Mach. 2012, 40, 37–42. [Google Scholar]

- Zhang, H.Y.; Gao, D.L.; Guo, B.Y.; Qiao, W.X. Numerical Simulation Research of ’Temperature Field for PDC Bit Cutter and Rock Interaction. New Technol. New Process 2015, 7, 103–105. [Google Scholar]

- Tan, Q.; Yi, L.; Tian, Z.Y.; Chen, L.; Yao, P.P.; Xia, Y.M. The analysis of the cutting temperature field by pre-cutting machine cutter. J. Railw. Sci. Eng. 2016, 13, 1199–1205. [Google Scholar]

- Zhang, L.X.; Shen, Q.; Zhang, K.; Wei, C.Y. Broken rock simulation and thermal analysis of PDC drill cutting edge based on ABAQUS. J. Shenyang Jianzhu Univ. 2018, 34, 912–920. [Google Scholar]

- Zhang, Z.X.; Zhou, Q.; Zhang, K.; Li, L.; Li, Y. Influence of cutting angle on temperature distribution of cutter. China Pet. Mach. 2021, 49, 17–26. [Google Scholar]

- Qian, L.; Wang, X.C.; Kang, Y.; Ma, Z.W.; Xiang, M.J. Temperature analysis and experimental study of core drill cutting and drilling process. J. Cent. South Univ. 2020, 51, 1402–1409. [Google Scholar]

- Zhou, Q.; Zhang, Z.X.; Zhang, K.; Zheng, G.J.; He, L.Z. Temperature variation tests and mechanism analysis of rock breaking by bit cutters. Nat. Gas Ind. 2020, 40, 102–110. [Google Scholar]

- Zheng, G.J.; Zhou, Q.; Zhang, K.; Zhang, Z.X. Numerical Analysis of the Influence of PDC Cutting Edge Radius on Temperature Distribution. China Pet. Mach. 2020, 48, 18–24. [Google Scholar]

| Rock Type | Drilling Time (s) | Temperature Rise Amplitude (°C) | Temperature Rise Rate (°C/s) | Drilling Depth (mm) | ROP (mm/s) |

|---|---|---|---|---|---|

| Granite | 120 | 18.9 | 0.158 | 12.5 | 0.104 |

| Marble | 120 | 10.3 | 0.086 | 23.5 | 0.196 |

| Sandstone | 120 | 6.7 | 0.056 | 51.4 | 0.428 |

| Cement stone | 120 | 5.3 | 0.044 | 66.5 | 0.554 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, L.; Yang, H.; He, C.; Wang, Y.; Zhang, H.; Chen, G.; Du, Y. Research on the Temperature Field Distribution Characteristics of Bottomhole PDC Bits during the Efficient Development of Unconventional Oil and Gas in Long Horizontal Wells. Processes 2024, 12, 1268. https://doi.org/10.3390/pr12061268

Fu L, Yang H, He C, Wang Y, Zhang H, Chen G, Du Y. Research on the Temperature Field Distribution Characteristics of Bottomhole PDC Bits during the Efficient Development of Unconventional Oil and Gas in Long Horizontal Wells. Processes. 2024; 12(6):1268. https://doi.org/10.3390/pr12061268

Chicago/Turabian StyleFu, Li, Henglin Yang, Chunlong He, Yuan Wang, Heng Zhang, Gang Chen, and Yukun Du. 2024. "Research on the Temperature Field Distribution Characteristics of Bottomhole PDC Bits during the Efficient Development of Unconventional Oil and Gas in Long Horizontal Wells" Processes 12, no. 6: 1268. https://doi.org/10.3390/pr12061268

APA StyleFu, L., Yang, H., He, C., Wang, Y., Zhang, H., Chen, G., & Du, Y. (2024). Research on the Temperature Field Distribution Characteristics of Bottomhole PDC Bits during the Efficient Development of Unconventional Oil and Gas in Long Horizontal Wells. Processes, 12(6), 1268. https://doi.org/10.3390/pr12061268