Transportation Machinery and Feeding Systems for Pigs in Multi-Storey Buildings: A Review

Abstract

:1. Introduction

2. Feed Transportation Machinery

2.1. Pneumatic Conveying

2.2. Scraper Pipeline Conveying

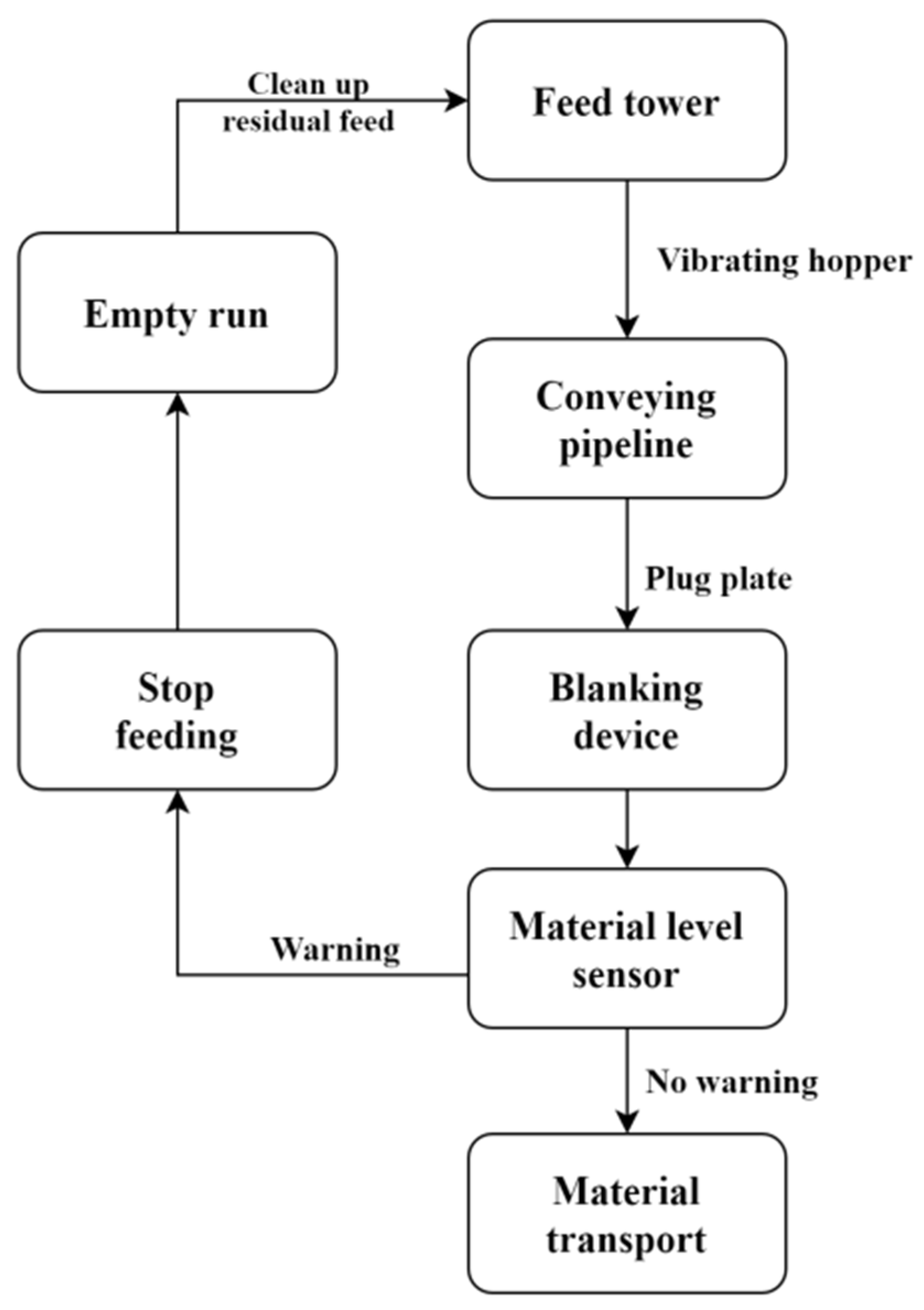

2.3. Screw Conveying

2.4. Rail Conveying

3. Automated Feeding Systems

3.1. “Gestalt” Feeding System

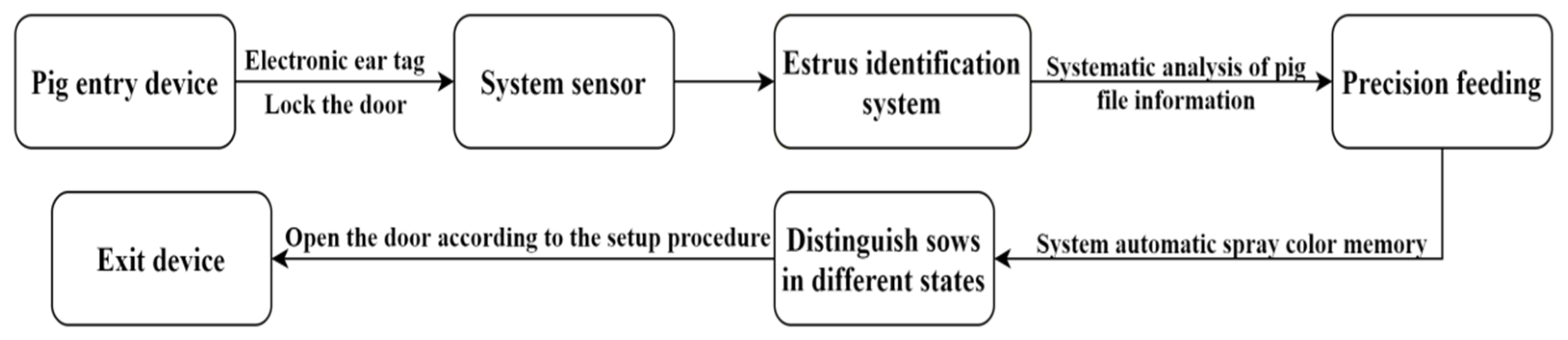

3.2. Velos Feeding System

3.3. Fattening Pig Partitioned Feeding System

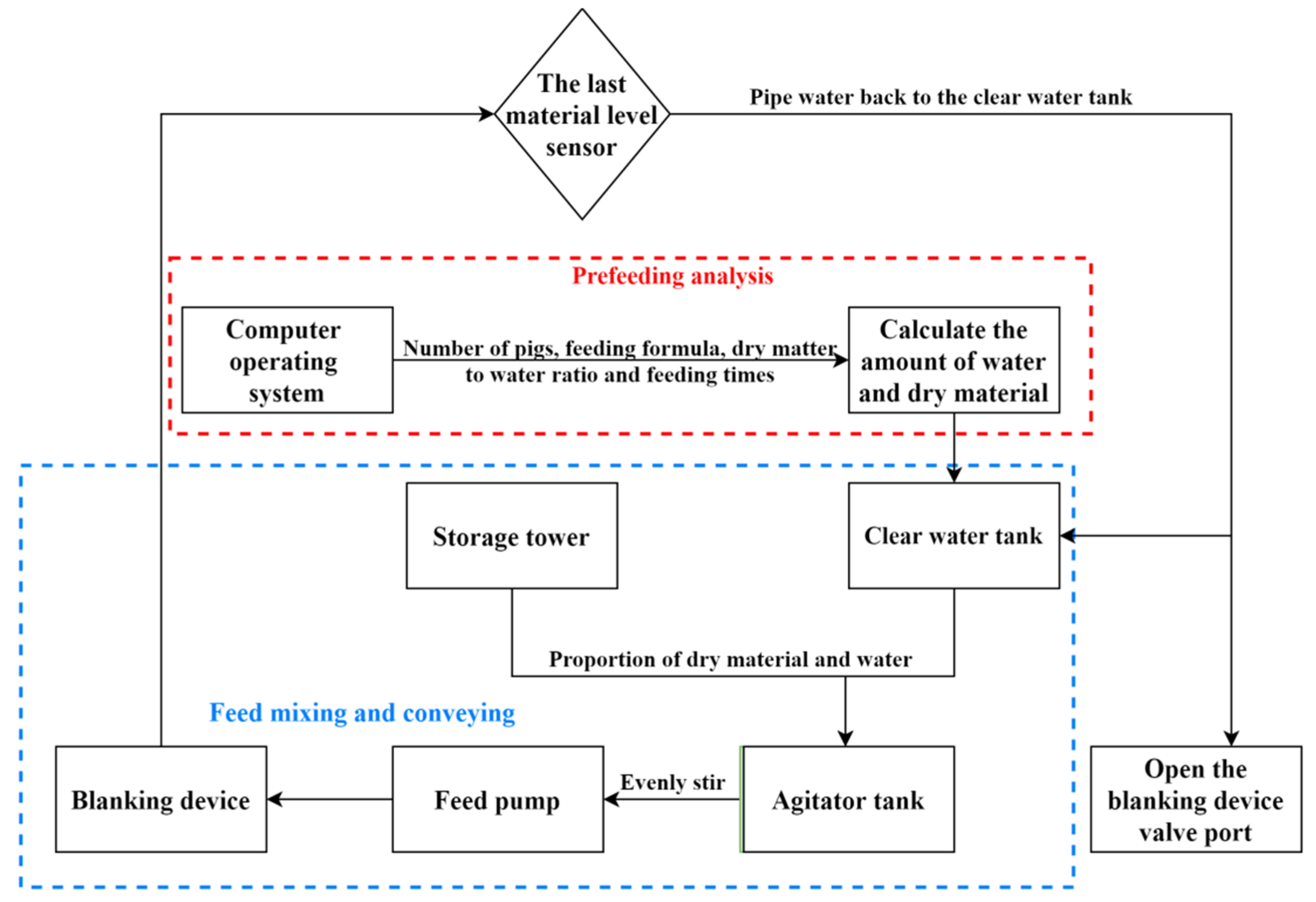

3.4. Liquid Feed Intelligent Feeding System

- Although the accuracy of fattening pig partitioned feeding systems has been relatively high, it incorporates 3D point cloud modeling to predict the size of the pig to determine whether it is normal or not. However, no special studies have been conducted on abnormal pigs, such as estrus, illness, and loss of ear tags, and on the use of ultrasound technology and infrared thermography to classify fattening pigs. Future research should incorporate infrared thermography to achieve a fast and efficient penning system capable of automatically identifying and marking abnormal pigs and separating them automatically into specific areas. This will enable the tracking and handling of abnormal pigs to ensure that they receive appropriate attention and management.

- Despite the relatively low downstream error of liquid feed intelligent feeding systems, pipeline conveying systems are more costly. In contrast, the cost of the liquid feeder trolley is lower, but its transportation efficiency is not as high. Additionally, although the emerging fermented liquid feed combines the advantages of beneficial bacterial strains and liquid feed, which can significantly increase the daily feed intake and improve the body condition of pigs, there is relatively little screening and research on beneficial bacterial strains and the exploration of fermentation technology. Future research should focus on optimizing and simplifying the screening process for beneficial strains while ensuring the accuracy of the liquid feed ratios and reducing the effects of different seasonal temperatures on fermented liquid feeds. This can improve the efficiency and consistency of feed fermentation, further optimizing the quality and stability of liquid feed.

4. Challenges and Developments

- Feed conveying machinery has problems such as frequent maintenance and poor layout flexibility, making it challenging to meet the feed transportation needs of building pig raising. Conveying machinery for feed is mainly divided into four types: pneumatic conveying, scraper pipeline conveying, screw conveying, and rail conveying. Among them, pneumatic conveying, scraper pipeline conveying, and screw conveying all belong to pipeline transportation and are favored for their efficient feed delivery. However, they all have drawbacks, such as feed residue and pipe wear problems. To overcome these problems, rail conveying was introduced and effectively improved upon the shortcomings of pipeline conveying. However, in general, rail conveying is only applicable to feed delivery at the same level, and its low transportation efficiency makes it difficult to meet the needs of large-scale feed delivery at the industrial level.

- Automated feeding systems mainly include the “Gestalt” feeding system, the Velos feeding system, the fattening pig partitioned feeding system, and the liquid feed intelligent feeding system, which, despite the high feeding accuracy, still have some problems. The “Gestalt” feeding system and the Velos feeding system have use limitations, are highly costly, and do not allow for good monitoring of the body condition of the sows while they are being fed. Although the fattening pig partitioned feeding system performs better in pen accuracy and is suitable for large barns, the system is currently unable to achieve automatic color spray marking and the special treatment of abnormal pigs, which limits the ability to track and deal with abnormal pigs. Although the liquid feed intelligent feeding system helps to improve the daily feed intake and weight gain of pigs compared with the solid feed feeding system, it has high equipment costs, inaccurate feed ratios, difficulties in screening beneficial bacterial strains, and the liquid fermented feed is susceptible to the effects of temperature in different seasons. These factors can cause instabilities in the quality of liquid feed.

- Explore new feed conveying machinery with many applications, good stability, and high erosion resistance. Study the working principles of pipeline transportation and rail transportation, combine the advantages of both, exploit the strengths and avoid the weaknesses, and develop new transportation machinery with a wide range, good stability, and high corrosion resistance to realize the least amount of pipeline residue in the transportation of feed as well as the least impact on the erosion of pipeline bends. For pipeline transportation, explore new structures for bending pipes to reduce feed residue. For rail transportation, try to explore the large-capacity loading silo to improve transportation efficiency. In addition, the use of current signals and vibration signals for equipment fault diagnosis is also an important exploration direction.

- Explore high-precision, low-cost, and widely adaptable solid feed feeding systems. High accuracy means higher feeding accuracy and less feed residue than existing discharge systems. Low cost means relative cost reduction while maintaining or improving the performance of existing automatic feeding systems. Existing automated feeding systems have limitations on what they can use for cost reasons, resulting in pigs needing to adapt to different feeding equipment at different stages, which can easily trigger stress reactions. Therefore, studying the solid feed feeding system with a wide range of adaptations and low cost is essential for liquid feed intelligent feeding systems for process simplicity, low cost, and accurate dosing. In addition, exploring a feed prediction system with multi-parameter correlation is likewise a key research direction to achieve personalized and precise feeding regimens. Currently, the liquid feed intelligent feeding system is not perfect and is high-cost, making it difficult to popularize in real life. However, liquid feed helps increase the daily intake of pigs and improve their gastrointestinal system, so future research on intelligent liquid feed feeding systems will be more likely to reduce costs and improve the process of liquid feeding systems.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

References

- Gao, S.; Li, Y. Construction and application of building type pig house. Mod. Anim. Husb. Vet. Sci. 2015, 323, 23–24. (In Chinese) [Google Scholar]

- Da, J. Analysis on the key points of biosafety in modern building pig breeding. Today’s Pig Breed. Ind. 2021, 5, 34–36. (In Chinese) [Google Scholar]

- Zhao, J.; Chen, Y.; Yu, L.; Yin, C. Spatial-temporal characteristics and affecting factors of swine breeding industry in China. Econ. Geogr. 2019, 39, 180–189. [Google Scholar]

- Cai, Q. Application and problems of mechanization in Guangdong pig breeding. Agric. Mach. Qual. Superv. 2021, 1, 7–8. [Google Scholar]

- Gao, Y. Structural innovation of building pig farms is a feasible model for preventing and securing supply. Swine Sci. 2020, 37, 67–69. (In Chinese) [Google Scholar]

- Gu, H.; Luo, Q.; Wang, P.; Cai, Y.; Wang, Z.; Wei, Y. Current situation and prospect analysis of intelligent pig raising in cluster buildings in China. Tianjin Agric. Sci. 2023, 29, 34–37. (In Chinese) [Google Scholar]

- Zeng, S.; Zhang, Y. Comparative analysis of two modes of pig raising in buildings and cottages--Taking Guizhou Fuziyuan pig farm as an example. Swine Sci. 2022, 39, 58–61. (In Chinese) [Google Scholar]

- Yuan, Y.; He, P.; Zeng, Z.; Pei, X. Study on the influence of Internet popularization and mechanization level on pig production capacity: Comprehensive FGLS and threshold model estimation based on the Yangtze River Economic Belt. J. Chin. Agric. Mech. 2022, 43, 131. [Google Scholar]

- Qian, H.; Wu, B.; Ji, B.; Yang, J. Overview of research on feed conveying and feeding equipment for hog farming. Agric. Eng. Equip. 2022, 49, 9–14. (In Chinese) [Google Scholar]

- Guan, X. Application of wet feed or porridge in farming. Anim. Husb. Vet. Sci. Technol. Inf. 2020, 6, 180–181. (In Chinese) [Google Scholar]

- Hong, J.S.; Jin, S.S.; Jung, S.W.; Fang, L.H.; Kim, Y.Y. Evaluation of dry feeding and liquid feeding to lactating sows under high temperature environment. J. Anim. Sci. Technol. 2016, 58, 36. [Google Scholar] [CrossRef]

- Kuang, S.; Zhou, M.; Yu, A. CFD-DEM modelling and simulation of pneumatic conveying: A review. Powder Technol. 2020, 365, 186–207. [Google Scholar] [CrossRef]

- Shijo, J.S.; Behera, N. Statistical analysis of fuidized dense phase conveying of fine particles. Powder Technol. 2022, 404, 117441. [Google Scholar]

- Baker, J.D.; Klinzing, G.E. Optimal performance of pneumatic transport systems. Powder Technol. 1999, 104, 240–247. [Google Scholar] [CrossRef]

- Suetina, T.A.; Koroteev, D.D. Systems of pneumatic transportation of cement and other fine materials with the minimum energy consumption. J. Fundam. Appl. Sci. 2017, 9, 425–436. [Google Scholar]

- Song, J.; Wang, T.; Hu, G.; Zhang, Z.; Zhao, W.; Wang, Z.; Zhang, Y. Conveying Characteristics of Shrimp Feed Pellets in Pneumatic Conveying System and Minimum Power Consumption Dissipation Factor. Aquac. Eng. 2023, 102, 102347. [Google Scholar] [CrossRef]

- Freitas, A.G.; Santos, R.B.; Riascos, L.A.M. Experimental design and optimization of a novel solids feeder device in energy efficient pneumatic conveying systems. Energy Rep. 2023, 9, 387–400. [Google Scholar] [CrossRef]

- Zenz, F.A. Two-phase fluid-solid flow. Ind. Eng. Chem. 1949, 41, 2801–2806. [Google Scholar] [CrossRef]

- Kong, X.; Liu, J.; Yang, T.; Su, Y.; Geng, J.; Niu, Z. Numerical simulation of feed pellet breakage in pneumatic conveying. Biosyst. Eng. 2022, 218, 31–42. [Google Scholar] [CrossRef]

- Ghafori, H.; Sharifi, M. Numerical and experimental study of an innovative design of elbow in the pipe line of a pneumatic conveying system. Powder Technol. 2018, 331, 171–178. [Google Scholar] [CrossRef]

- Mills, D.; Mason, J.S. Particle size effects in bend erosion. Wear 1977, 44, 311–328. [Google Scholar] [CrossRef]

- Levy, A.V.; Chik, P. The effects of erodent composition and shape on the erosion of steel. Wear 1983, 89, 151–162. [Google Scholar] [CrossRef]

- Duarte, C.; de Souza, F.; Venturi, D.; Sommerfeld, M. A numerical assessment of two geometries for reducing elbow erosion. Particuology 2020, 49, 117–133. [Google Scholar] [CrossRef]

- Alkassar, Y.; Agarwal, V.K.; Pandey, R.K.; Behera, N. Influence of particle attrition on erosive wear of bends in dilute phase pneumatic conveying. Wear 2021, 476, 203594. [Google Scholar] [CrossRef]

- Zhou, F.; Feng, L.; Zhang, Q.; Gao, K. Collision characteristics of coal particles in arc-shaped plug elbow for pneumatic conveying. Adv. Powder Technol. 2024, 35, 104480. [Google Scholar] [CrossRef]

- Guo, Z.; Zhang, J.; Li, H. Optimal Design for Erosion Resistance of Pneumatic Conveying pipe with Rib Structure. Chin. J. Corros. Prot. 2023, 43, 525–534. (In Chinese) [Google Scholar]

- Guo, Z.; Zhang, J.; Li, H.; He, H. A comprehensive evaluation of the anti-erosion characteristics of several new structural elbows in the pneumatic conveying system. Powder Technol. 2022, 412, 117976. [Google Scholar] [CrossRef]

- Saluja, G.; Mallick, S.S.; Karmakar, S. Modeling minimum transport boundary for pneumatic conveying of powders. Part. Sci. Technol. 2024, 42, 418–426. [Google Scholar] [CrossRef]

- Zhao, M.; Wu, D.; Li, H.; Qian, T.; Song, X. Design of SP60 chain tray feed conveyor. Feed Ind. 2014, 35, 6–9. [Google Scholar] [CrossRef]

- Yao, Y. Research on Discrete Element Simulation and Multi-Attribute Evaluation of Disc Pipe Scraper Conveyor. Ph.D. Thesis, Taiyuan University of Technology, Taiyuan, China, 2015. [Google Scholar]

- Zou, P. Design of scraper type all-mechanical automatic conveying (feed) equipment in pig farm. Pig Ind. Obs. 2014, 6, 84–88. (In Chinese) [Google Scholar]

- Dou, J.; Wang, K.; Chen, J.; Cheng, D. Application and development of plug tray feeding system in feed conveying link of large-scale pig farm. Feed Res. 2022, 45, 134–138. (In Chinese) [Google Scholar] [CrossRef]

- Gan, L.; Huang, R.; Luo, Q. Structure Optimization and Performance Analysis of chain tray feed conveyor. Mod. Agric. Equip. 2019, 40, 38–41. (In Chinese) [Google Scholar]

- Qiu, Z.; Qiu, X.; Sun, T.; Ren, Y.; Wang, F. Influence and Study of Resistance between Sealing Layer and Plug Disc of Pneumatic Actuator on Action Effect. Hydraul. Pneum. Seals 2020, 40, 73–77. (In Chinese) [Google Scholar]

- He, R.; Wang, H.; Wu, Z. Analysis of plug plate feed line and its structure improvement by ANSYS simulation. Feed Anim. Husb. 2018, 11, 61–62. (In Chinese) [Google Scholar]

- Lu, Z. Intelligent control of chain tension of mining scraper conveyor based on fuzzy adaptive algorithm. In Proceedings of the 2023 4th International Conference on Mechatronics Technology and Intelligent Manufacturing (ICMTIM), Nanjing, China, 26–28 May 2023; IEEE: Piscataway, NJ, USA, 2023; Volume 5, pp. 26–28. [Google Scholar]

- Shprekher, D.M.; Ovsyannikov, D.S.; Zelenkov, A.V. Dynamic Analysis of the Reaction of a Scraper Conveyor When a Chain is Jammed. In Proceedings of the 2024 International Conference on Industrial Engineering, Applications and Manufacturing (ICIEAM), Sochi, Russia, 22–23 August 2024; IEEE: Piscataway, NJ, USA, 2024; Volume 5, pp. 20–24. [Google Scholar]

- Zhao, S.; Wang, P.; Li, S. Study on the fault diagnosis method of scraper conveyor gear under time-varying load condition. Appl. Sci. 2020, 10, 5053. [Google Scholar] [CrossRef]

- Jiang, S.; Ren, W.; Mao, Q.; Zeng, Q.; Yu, Q.; Gao, K. Dynamic analysis of the scraper conveyor under abnormal operating conditions based on the vibration and speed characteristics. Shock Vib. 2021, 2021, 8887744. [Google Scholar] [CrossRef]

- Bianchi, M. Metrological Characterization of a Measuring System for Scraper Chains Wear. Master’s Thesis, Politecnico, POLITesi, Turin, Italy, 2020. [Google Scholar]

- Mao, J.; Yang, Z.; Lu, J. Research on signal analysis and diagnosis of chain drive system of the scraper conveyor guided by artificial intelligence algorithm. Optik 2022, 271, 170149. [Google Scholar] [CrossRef]

- Roberts, A.W. The influence of granular vortex motion on the volumetric performance of enclosed screw conveyors. Powder Technol. 1999, 104, 56–67. [Google Scholar] [CrossRef]

- Liu, M.; Wang, N.; Chen, X.; Shan, Y.; Li, J. Design of feed screw conveyor. In Journal of Physics Conference Series; IOP Publishing: Bristol, UK, 2020; Volume 1601, p. 062005. [Google Scholar]

- Hevko, R.; Rozum, R.; Klendiy, O. Development of design and investigation of operation processes of loading pipes of screw conveyors. INMATEH–Agric. Eng. 2016, 50, 89–96. [Google Scholar]

- Chakarborthy, S.; Mehta, A. Product design of semi flexible screw conveyor. IOSR J. Mech. Civ. Eng. (IOSR-JMCE) E-ISSN 2014, 11, 01–13. [Google Scholar] [CrossRef]

- Bulgakov, V.; Trokhaniak, O.; Adamchuk, V.; Chernovol, M.; Korenko, M.; Dukulis, I.; Ivanovs, S. A Study of Dynamic Loads of a Flexible Sectional Screw Conveyor. Acta Technol. Agric. 2022, 25, 131–136. [Google Scholar] [CrossRef]

- Zhu, H.; Tan, H. Research on Performance of Screw Conveyor Based on EDEM. Mech. Electr. Eng. Technol. 2018, 47, 27–29. (In Chinese) [Google Scholar]

- Wang, S.; Li, H.; Tian, R.; Wang, R.; Wang, X.; Sun, Q.; Fan, J. Numerical simulation of particle flow behavior in a screw conveyor using the discrete element method. Particuology 2019, 43, 137–148. [Google Scholar] [CrossRef]

- Sun, L.; Zhang, X.; Zeng, Q.; Gao, K.; Jiang, K.; Zhou, J. Application of a screw conveyor with axial tilt blades on a shearer drum and investigation of conveying performance based on DEM. Particuology 2022, 61, 91–102. [Google Scholar] [CrossRef]

- Wu, L. Optimization of anti-wear of inclined screw conveyor based on discrete element method. J. Taiyuan Coll. (Nat. Sci. Ed.) 2023, 41, 58–63. (In Chinese) [Google Scholar] [CrossRef]

- Kalay, E.; Boğoçlu, M.E.; Bolat, B. Mass flow rate prediction of screw conveyor using artificial neural network method. Powder Technol. 2022, 408, 117757. [Google Scholar] [CrossRef]

- Li, Y. Deep Learning Based Prediction of Clogging Occurrences during Lignocellulosic Biomass Feeding in Screw Conveyors. Master’s Thesis, University of Tennessee, Knoxville, TN, USA, 2021. [Google Scholar]

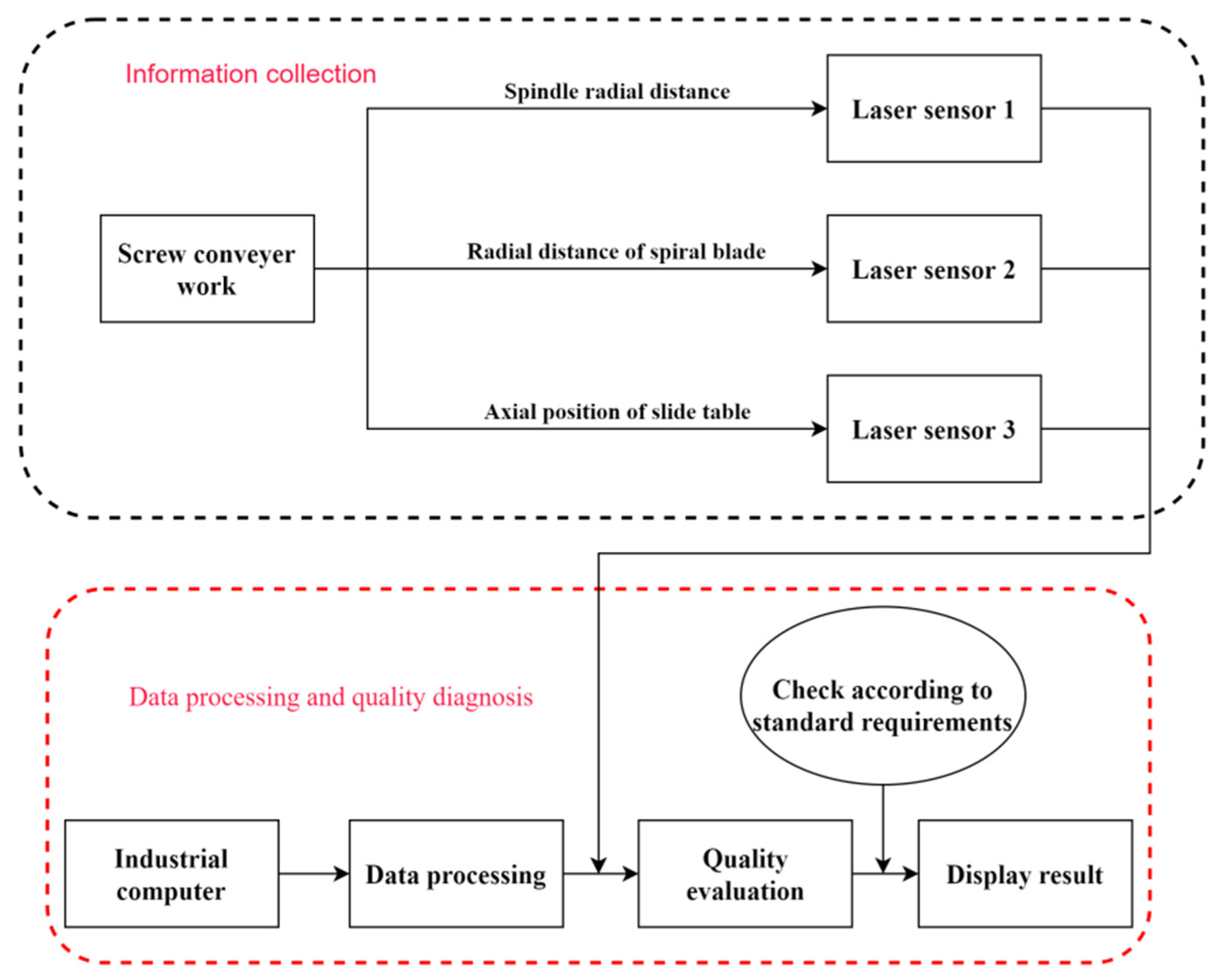

- Gao, R.; Wang, L.; Niu, K.; Zhou, L.; Zhao, B.; Yuan, Y. Online Welding Quality Detection of Spiral Conveyor based on Laser Scanning. Trans. Chin. Soc. Agric. Mach. 2020, 51, 292–297. (In Chinese) [Google Scholar]

- Wu, T. Problems encountered in using sow automatic feeding system and improvement measures. Pig Ind. Sci. 2016, 33, 94–95. [Google Scholar]

- Ye, H.; Xiao, S.; Meng, X.; Lan, Z.; Jiang, Q. Design and implementation of automatic feeding car in large pig Farm. Agric. Mech. Res. 2010, 32, 146–148. (In Chinese) [Google Scholar] [CrossRef]

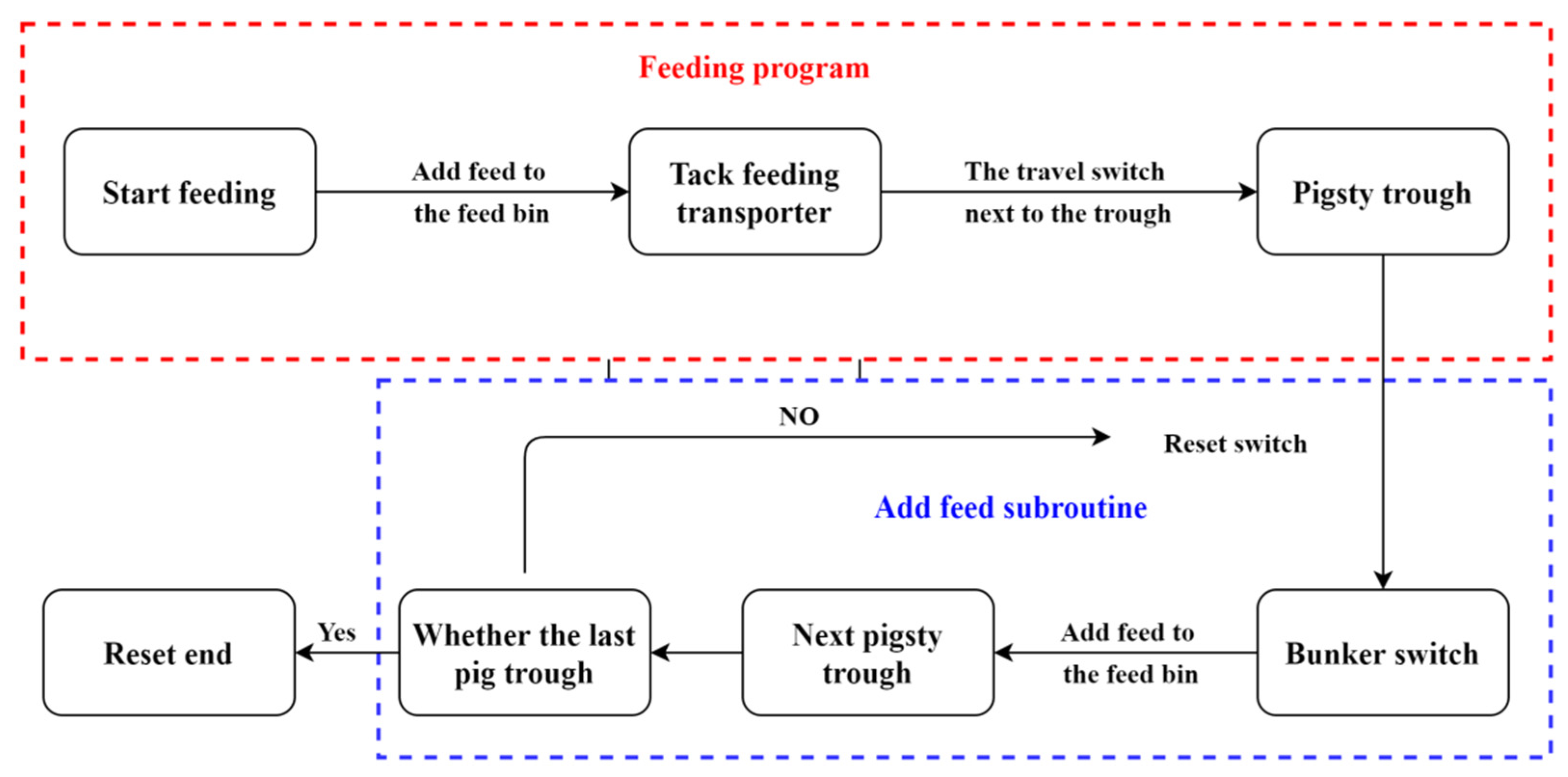

- Pang, C.; Cheng, J.; Zhang, D.; Chen, G. Design and Experiment of Rail Type Automatic Feed System for Pig House. Trans. Chin. Soc. Agric. Mach. 2018, 49, 122–129. (In Chinese) [Google Scholar]

- Zhao, D.; Guan, Y.; Qi, Z.; Wu, L.; Liang, L.; Yao, Y. Design and test of an intelligent feeding wagon for hogs with liquid feed. Chin. J. Agric. Mech. Chem. 2022, 43, 91. (In Chinese) [Google Scholar] [CrossRef]

- Li, H.; Hu, J.; Zhan, Y.; Li, D. Design of PLC-based crawler-type remote-controlled pigsty feed transporter. Chin. J. Agric. Mech. Chem. 2020, 41, 132. (In Chinese) [Google Scholar] [CrossRef]

- Wang, J.; Chen, X.; Chu, S.; Yang, Y.; Lu, X.; Xue, S.; Yu, Y. Current situation, problems and trend of intelligent pig breeding in China. Pig Ind. 2018, 13, 17–23. (In Chinese) [Google Scholar] [CrossRef]

- Yu, W.; Jensen, J.D. Sustainability implications of rising global pork demand. Anim. Front. 2022, 12, 56–60. [Google Scholar] [CrossRef] [PubMed]

- Garcia, R.; Aguilar, J.; Toro, M.; Pinto, A.; Rodriguez, P. A systematic literature review on the use of machine learning in precision livestock farming. Comput. Electron. Agric. 2020, 179, 105826. [Google Scholar] [CrossRef]

- Xu, D.; Cao, J.; Yang, N.; Xu, C.; Lu, X.; Li, H.; Zhao, L.; Fu, L. Research on the application of intelligent feeding technology for lactating sows in pig farm. Pig Breed. 2016, 2, 87–88. (In Chinese) [Google Scholar] [CrossRef]

- Wang, D. Inventory of Modern pig farm production equipment technology. Pig Sci. 2012, 29, 59–61. (In Chinese) [Google Scholar]

- Chen, H.; Feng, L.; Zhang, C.; Wang, N.; Wang, K.; Lin, H.; Huang, Z.; He, D.; Zhu, Y.; Ling, G. Application status and analysis of intelligent pig breeding and intelligent pig farm. Swine Sci. 2021, 38, 30–33. (In Chinese) [Google Scholar]

- Tao, Z. British pig farms: “Gestalt” system: A new tool for feeding management of lactating sows. Swine Sci. 2012, 29, 92–93. (In Chinese) [Google Scholar]

- Wang, D.; Zhu, L.; Wang, X. Study on the effect of “Gestalt” intelligent sow breeding management system on reproductive performance. Swine Sci. 2013, 30, 80–81. (In Chinese) [Google Scholar]

- Xiong, B.; Yang, L.; Cao, P.; Pan, X.; Wang, M. Optimized design and test of electromechanical control system for automatic feeding of lactating sows. Trans. Chin. Soc. Agric. Eng. 2014, 30, 28–33. (In Chinese) [Google Scholar]

- Xiong, B.; Yang, L.; Zheng, S.; Cao, P.; Pan, X.; Wu, G. Design and experiment of precise feeding and feeding control system for lactating sows. Trans. Chin. Soc. Agric. Eng. 2017, 33, 177–182. (In Chinese) [Google Scholar]

- Gauthier, R.; Largouët, C.; Rozé, L.; Dourmad, J. Online forecasting of daily feed intake in lactating sows supported by offline time-series clustering, for precision livestock farming. Comput. Electron. Agric. 2021, 188, 106329. [Google Scholar] [CrossRef]

- Gaillard, C.; Quiniou, N.; Gauthier, R.; Cloutier, L.; Dourmad, J. Evaluation of a decision support system for precision feeding of gestating sows. J. Anim. Sci. 2020, 98, skaa255. [Google Scholar] [CrossRef] [PubMed]

- Gaillard, C.; Dourmad, J.Y. Application of a precision feeding strategy for gestating sows. Anim. Feed Sci. Technol. 2022, 287, 115280. [Google Scholar] [CrossRef]

- Gaillard, C.; Durand, M.; Largouët, C.; Dourmad, J. Effects of the environment and animal behavior on nutrient requirements for gestating sows: Future improvements in precision feeding. Anim. Feed Sci. Technol. 2021, 279, 115034. [Google Scholar] [CrossRef]

- Jiang, Q.; Wang, S. The “Three major factors” affecting the labor process of sows. China Anim. Husb. 2013, 23, 78–79. (In Chinese) [Google Scholar]

- Linag, L.; Bai, X.; Tan, X.; Li, L.; Liu, Q.; Lu, Y.; Xiong, Y. Comparative study on the effects of static sow feeding management system (Velos) and traditional confinement pen feeding on gestating sows. Feed Res. 2016, 2, 28–30+41. (In Chinese) [Google Scholar] [CrossRef]

- Tan, G.; Wen, B. Advantages and problems of Velos intelligent sow management system in breeding process. Guangxi Anim. Husb. Vet. Sci. 2014, 30, 141–142. (In Chinese) [Google Scholar]

- Yang, Q.; Geng, M. Application of digital pig raising technology. Xinjiang Anim. Husb. 2011, 11, 13–15. (In Chinese) [Google Scholar] [CrossRef]

- Luo, Y. Selection of pig individual recognition technology in intelligent pig breeding. Pig Ind. Sci. 2021, 38, 52–54. (In Chinese) [Google Scholar]

- Rossing, W. Animal identification: Introduction and history. In Electronic Animal Identification. Computers and Electronics in Agriculture; Rossing, W., Ed.; Elsevier Science: Amsterdam, The Netherlands, 1999; Volume 24, pp. 1–4. [Google Scholar]

- Trevarthen, A.; Michael, K. The RFID-enabled dairy farm: Towards total farm management. In Proceedings of the 2008 7th International Conference on Mobile Business, Barcelona, Spain, 7–8 July 2008; IEEE: Piscataway, NJ, USA, 2008; Volume 7, pp. 7–8. [Google Scholar]

- Burose, F.; Anliker, T.; Herd, D.; Jungbluth, T.; Zahner, M. Readability of electronic ear tags in stationary antenna systems. Landtechnik 2010, 65, 446–449. [Google Scholar]

- Ruiz-Garcia, L.; Lunadei, L. The role of RFID in agriculture: Applications, limitations and challenges. Comput. Electron. Agric. 2011, 79, 42–50. [Google Scholar] [CrossRef]

- Suriyasomboon, A.; Chavananikul, V. Electronic identification of pigs in Thailand. In Proceedings of the IAALD AFTA WCCA, Tokyo, Japan, 24–27 August 2008; pp. 1059–1062. [Google Scholar]

- Jiang, F.; Mao, C.; Bai, N. Design of electronic ear tags under information aquaculture. J. Anqing Norm. Univ. (Nat. Sci. Ed.) 2023, 29, 56–60. (In Chinese) [Google Scholar] [CrossRef]

- Wang, M. Application of RFID-based Internet of Things technology in Animal husbandry. Anim. Husb. Vet. Sci. Technol. Inf. 2018, 6, 6. (In Chinese) [Google Scholar]

- Zhang, X.; Zhang, J.; Dong, M.; Jing, W.; Yang, J.; Yu, Z.; Feng, Z.; Li, B. Research on UHF RFID light-emitting electronic ear tag test method. Chin. J. Vet. Med. 2022, 56, 75–80. (In Chinese) [Google Scholar]

- de Bruijn, B.G.C.; de Mol, R.M.; Hogewerf, P.H.; van der Fels, J.B. A correlated-variables model for monitoring individual growing-finishing pig’s behavior by RFID registrations. Smart Agric. Technol. 2023, 4, 100189. [Google Scholar]

- Vargovic, L.; Hermesch, S.; Athorn, R.Z.; Bunter, K. Feed intake and feeding behavior traits for gestating sows recorded using electronic sow feeders. J. Anim. Sci. 2021, 99, skaa395. [Google Scholar] [CrossRef]

- Borell, E.; Morris, J.R.; Hurnik, J.F.; Mallard, B.A.; Buhr, M.M. The performance of gilts in a new group housing system: Endocrinological and immunological functions. J. Anim. Sci. 1992, 70, 2714–2721. [Google Scholar] [CrossRef]

- McGlone, J.; Salak-Johnson, J.; Nicholson, R.; Hicks, T. Evaluation of crates and girth tethers for sows: Reproductive performance, immunity, behavior and ergonomic measures. Appl. Anim. Behav. Sci. 1994, 39, 297–311. [Google Scholar] [CrossRef]

- Broom, D.; Mendl, M.; Zanella, A. A comparison of the welfare of sows in different housing conditions. Anim. Sci. 1995, 61, 369–385. [Google Scholar] [CrossRef]

- Zhang, F. Analysis of advantages of multi-column feeding system in pig fattening. Sichuan Anim. Husb. Vet. Sci. 2022, 49, 39–40. (In Chinese) [Google Scholar]

- Li, B. Japan’s fast pig breeding technology. Jiangxi Feed 2006, 1, 44. (In Chinese) [Google Scholar]

- Yin, H.; Yao, M.; Huang, D. Development status and cost-effectiveness of intelligent feeding equipment for large-scale pig farms. Heilongjiang Anim. Husb. Vet. Sci. 2016, 498, 69–71. (In Chinese) [Google Scholar] [CrossRef]

- Huang, R.; Zhong, W.; Zhong, R.; Zou, P.; Chen, Y.; Mai, Y.; Bian, F. Segregation Device for Individual Pigs for Group Pig Rearing, China. Guangdong Patent CN201499510U, 9 June 2010. [Google Scholar]

- Liu, Z.; Cao, P.; Wei, H.; Zhang, G.; Song, C. Fattening Pig Group Feeding Automatic Portioning System and Its Portioning Feeding Device, China. Henan Patent CN201976564U, 21 September 2011. [Google Scholar]

- Liu, Z.; Cao, P.; Wei, H.; Zhang, G.; Yang, Y. Livestock Feeding Column Feeding Device and Its Double Door Electric Lock Mechanism, China. Henan Patent CN103098717A, 15 May 2013. [Google Scholar]

- Reckels, B.; Hölscher, R.; Schwennen, C.; Lengling, A.; Stegemann, U.; Waldmann, K. Resource-efficient classification and early predictions of carcass composition in fattening pigs by means of ultrasound examinations. Agriculture 2020, 10, 222. [Google Scholar] [CrossRef]

- Lengling, A.; Alfert, A.; Reckels, B.; Buscher, W. Feasibility study on the use of infrared thermography to classify fattening pigs into feeding groups according their body composition. Sensors 2020, 20, 5221. [Google Scholar] [CrossRef] [PubMed]

- Brand, N.; Jørgensen, E. Determination of live weight of pigs from dimensions measured using image analysis. Comput. Electron. Agric. 1996, 15, 57–72. [Google Scholar] [CrossRef]

- Kashiha, M.; Bahr, C.; Ott, S.; Moons, C.; Niewold, T.; Odberg, F.; Berckmans, D. Weight estimation of pigs using top-view image processing. In Proceedings of the Image Analysis and Recognition: 11th International Conference, ICIAR 2014, Vilamoura, Portugal, 22–24 October 2014; Springer International Publishing: Berlin/Heidelberg, Germany, 2014; Volume 8814, Part I 11. pp. 496–503. [Google Scholar]

- Li, D. Design and Implementation of Dynamic Weighing System Based on Lab VIEW. Ph.D. Thesis, North University of China, Taiyuan, China, 2022. [Google Scholar] [CrossRef]

- Kwon, K.; Mun, D. Iterative offset-based method for reconstructing a mesh model from the point cloud of a pig. Comput. Electron. Agric. 2022, 198, 106996. [Google Scholar] [CrossRef]

- Li, Y.; Xu, Z.; Li, F.; Tao, X.; Lv, J. Effects of Fermented grain liquid Feed on Growth Performance and intestinal microflora diversity of super early weaned piglets. Chin. J. Anim. Nutr. 2010, 22, 1650–1657. (In Chinese) [Google Scholar]

- Brooks, P.H. Liquid feeding as a means to promote pig health. In Proceedings of the London Swine Conference-Maintaining Your Competitive Edge, London, UK, 9–10 April 2003; Volume 4, pp. 9–10. [Google Scholar]

- Li, F. Liquid Fermentation Treatment of Feedstuffs and Its Effects on Growth Performance and Digestive Microecology of Piglets. Ph.D. Thesis, Zhejiang Normal University, Jinhua, China, 2010. [Google Scholar]

- Huang, L.; Yu, Y.; Wang, J.; Gao, J.; Wang, L.; Wei, C. Application technology of intelligent feeding equipment and technology of liquid feed in pig farm. Today’s Pig Ind. 2017, 4, 44–48. (In Chinese) [Google Scholar]

- Dong, G.Z.; Pluske, J.R. The low feed intake in newly-weaned pigs: Problems and possible solutions. Asian-Australas. J. Anim. Sci. 2007, 20, 440–452. [Google Scholar] [CrossRef]

- Hampson, D.J.; Kidder, D.E. Influence of creep feeding and weaning on brush border enzyme activities in the piglet small intestine. Res. Vet. Sci. 1986, 40, 24–31. [Google Scholar] [CrossRef]

- Ni, M. Application of liquid feeding system in pig production. China, China Anim. Health 2023, 25, 89–90. (In Chinese) [Google Scholar]

- Olaniyi, O.M.; Folorunso, T.A.; Dogo, E.M.; Bima, M.E.; Adejumo, A. Performance evaluation of mobile intelligent poultry liquid feed dispensing system using two-way controller technique. AIMS Res. J. 2015, 1, 113–124. [Google Scholar]

- Yılmaz, M.; Can, K.; Başçi, A. PI+ Feed Forward Controller Tuning Based on Genetic Algorithm for Liquid Level Control of Coupled-Tank System. J. Inst. Sci. Technol. 2021, 11, 1014–1026. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, Y.; Lv, M.; Wang, J.; Xu, Z.; Chen, X. Design and experiment of automatic fine feeding system for piglets. Trans. Chin. Soc. Agric. Mach. 2018, 49, 39–45. (In Chinese) [Google Scholar]

- Li, X. Development of Automatic Liquid Feeding System Based on STM32. Ph.D. Thesis, Chongqing University, Chongqing, China, 2020. [Google Scholar]

- Deng, K.; Liu, R.; Zhang, K.; Xu, Y. Design and validation of intelligent feeding system for liquid feed. Heilongjiang Anim. Husb. Vet. Med. 2020, 16, 50–53. [Google Scholar] [CrossRef]

- Geary, T.M.; Brooks, P.H.; Beal, J.D.; Campbell, A. Effect on weaner pig performance and diet microbiology of feeding a liquid diet acidified to pH 4 with either lactic acid or through fermentation with Pediococcus acidilactici. J. Sci. Food Agric. 1999, 79, 633–640. [Google Scholar] [CrossRef]

- Nout, M.J.R.; Rombouts, F.M.; Havelaar, A. Effect of accelerated natural lactic fermentation of infant good ingredients on some pathogenic microorganisms. Int. J. Food Microbiol. 1989, 8, 351–361. [Google Scholar] [CrossRef] [PubMed]

- Canibe, N.; Jensen, B.B. Fermented liquid feed—Microbial and nutritional aspects and impact on enteric diseases in pigs. Anim. Feed Sci. Technol. 2012, 173, 17–40. [Google Scholar] [CrossRef]

- Brooks, P.H. Fermented liquid feed for pigs. CABI Rev. 2009, 2008, 1–18. [Google Scholar] [CrossRef]

- Wang, Y. Research and Demonstration on Integrated Technology of Automatic Liquid Feed Fermentation and Feeding in Pig Farm; Hebei Province, Shijiazhuang Huayao Dairy Co.: Shijiazhuang, China, 2020; Volume 8, p. 12. [Google Scholar]

- Luo, Z.; Yin, B.; Wang, L.; Nie, T.; Mi, S.; Liu, Y. Design and research and development of liquid fermentation device. South China Agric. Mach. 2023, 54, 39–41+45. (In Chinese) [Google Scholar]

- Fu, Y.; Li, G.; Jia, Q.; Wen, H.; Zhou, W.; Pang, L. Application of liquid fermentation material in pig production. North. Anim. Husb. 2022, 8, 14–15. (In Chinese) [Google Scholar]

- Meng, R.; Cui, X.; Yu, L.; Ding, L.; Gao, R.; Zhu, J.; Du, T.; Li, Q. Current status and prospect of the development of precision feeding management technology for livestock and poultry. J. Livest. Ecol. 2021, 32, 1–7. (In Chinese) [Google Scholar]

| Conveying Methods | Advantages | Drawbacks | References | |

|---|---|---|---|---|

| pipeline conveying | Pneumatic conveying |

|

| [14,15,16,17,18,19,20,21,22,23,24,25,26,27,28] |

| scraper pipeline conveying |

|

| [33,34,35,36,37,38,39,40,41] | |

| screw conveying |

|

| [45,46,47,48,49,50,51,52,53] | |

| Rail conveying |

|

| [55,58] | |

| Feeding Systems | System Design | Effect | References |

|---|---|---|---|

| “Gestalt” feeding system | An Intelligent feeding system for lactating sows combining feed Intake modeling with precise rotation of wiper motor technology | 20.5% higher than manual daily feeding | [67] |

| A new embedded precision feeding control system for lactating sows | 22.4% higher than manual daily feeding | [68] | |

| A time series forecasting program based on big data, K-Shape clustering approach | Predicting the next feed intake based on the current day’s feed intake | [69] | |

| A multi-parameters correlated precision feeding system | Predicting next feed intake based on environmental and behavioral factors | [70] | |

| Velos feeding system | Comparison of the performance of low and high frequency electronic ear tags using chi-square analysis | High-frequency electronic ear tag with better performance | [82] |

| An electronic ear tag comprising UHF RFID chip, pedometer and ZigBee communication module | Reduced equipment costs and dependence on foreign technology | [83] | |

| An online monitoring method combining electronic ear tags and GPS technology | Easy to keep track of the general location of the pig | [84] | |

| A luminous electronic ear tag test platform | Easy targeting of pigs using luminescent commands | [85] | |

| An early warning model for correlated variables based on RFID enrollment and kalman filtering | Compare predicted and actual FDB values of pigs to determine if pigs are abnormal | [86] | |

| An electronic feeding system suitable for monitoring group-housed sows | Simulating feeding curves to monitor potential health problems in pigs | [87] |

| Feeding Systems | System Design | Effect | References |

|---|---|---|---|

| Fattening pig partitioned feeding system | A kind of group rearing fattening pig partitioned device | Realization of rapid separation of large-scale group pigs | [94] |

| An automatic portioning system and portioning feeding device for fattening pigs | Personalized group feeding when partitioning is not possible | [95] | |

| A livestock feeding partitioned feeding device | Avoiding pig entrapment in case of power failure | [96] | |

| A method for classifying fattening pigs based on ultrasonic detection | Classification is achieved by the ratio of backfat to the diameter of the longissimus dorsi muscle. | [97] | |

| A classification method based on infrared thermal imaging technology | Non-invasive, non-contact classification, fitting fattening pig temperature profiles for monitoring | [98] | |

| An image analysis system using a hybrid model | Accuracy of weight estimation is about 95% | [99] | |

| A pig weight method using top view image processing | Accuracy of weight estimation is about 97.5% | [100] | |

| A dynamic weighing and partitioned system based on LabVIEW and particle swarm algorithms | Weight estimation within 1 kg | [101] | |

| An iterative offset-based reconstruction method for pig-related point cloud mesh models | Accuracy of weight estimation is about 97.57% | [102] | |

| Liquid feed intelligent feeding system | A bi-directional controller method using genetic algorithm to tune PI controller and internal mode controller | Positive impact on system transient response and AE controller evaluation aspects | [110] |

| A genetic algorithm based Pl+ feedforward controller | Improved system responsiveness and stability | [111] | |

| An automatic fine feeding system for piglets | The accuracy of the feed is about 95% | [112] | |

| An accuracy control algorithm combining arithmetic mean filtering and least squares method | The accuracy of the feed is over 99% | [113] | |

| A liquid feed intelligent feeding system based on programmable logic controller | The accuracy of the feed is over 98.4% | [114] | |

| An intelligent pig liquid feeder trolley | The accuracy of the feed is about 97.5% | [57] | |

| Designing experiments to compare the effects of liquid and dry feed on piglet growth | Average pigs daily gained weight in the fermented grain liquid group was increased by 13.5% | [103] | |

| A set of automated feeding equipment for liquid fermentation by cyclic discharging method | Average daily weight gain reached 0.907 kg and morbidity was reduced to 1.5 percent | [119] | |

| A kind of double-tank liquid feed fermentation device | Effectively alleviates problems with feed rationing and temperature detection | [120] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, Y.; Zheng, Z.; Zeng, J.; Chen, Y.; Abdeen, M.A.; Qiu, W.; Wu, W.; Luo, Y. Transportation Machinery and Feeding Systems for Pigs in Multi-Storey Buildings: A Review. Processes 2024, 12, 1427. https://doi.org/10.3390/pr12071427

Lv Y, Zheng Z, Zeng J, Chen Y, Abdeen MA, Qiu W, Wu W, Luo Y. Transportation Machinery and Feeding Systems for Pigs in Multi-Storey Buildings: A Review. Processes. 2024; 12(7):1427. https://doi.org/10.3390/pr12071427

Chicago/Turabian StyleLv, Youjie, Zeyong Zheng, Jinbin Zeng, Yingmei Chen, Mohamed Anwer Abdeen, Wenlong Qiu, Weibin Wu, and Yuanqiang Luo. 2024. "Transportation Machinery and Feeding Systems for Pigs in Multi-Storey Buildings: A Review" Processes 12, no. 7: 1427. https://doi.org/10.3390/pr12071427

APA StyleLv, Y., Zheng, Z., Zeng, J., Chen, Y., Abdeen, M. A., Qiu, W., Wu, W., & Luo, Y. (2024). Transportation Machinery and Feeding Systems for Pigs in Multi-Storey Buildings: A Review. Processes, 12(7), 1427. https://doi.org/10.3390/pr12071427