Quantitative Characterization of Pore–Fracture Structures in Coal Reservoirs by Using Mercury Injection–Removal Curves and Permeability Variation under Their Constraints

Abstract

1. Introduction

2. Experimental Tests and Fractal Theory

2.1. Sample Preparation and Experimental Testing

Experimental Methods

2.2. Fractal Theory

3. Results and Discussion

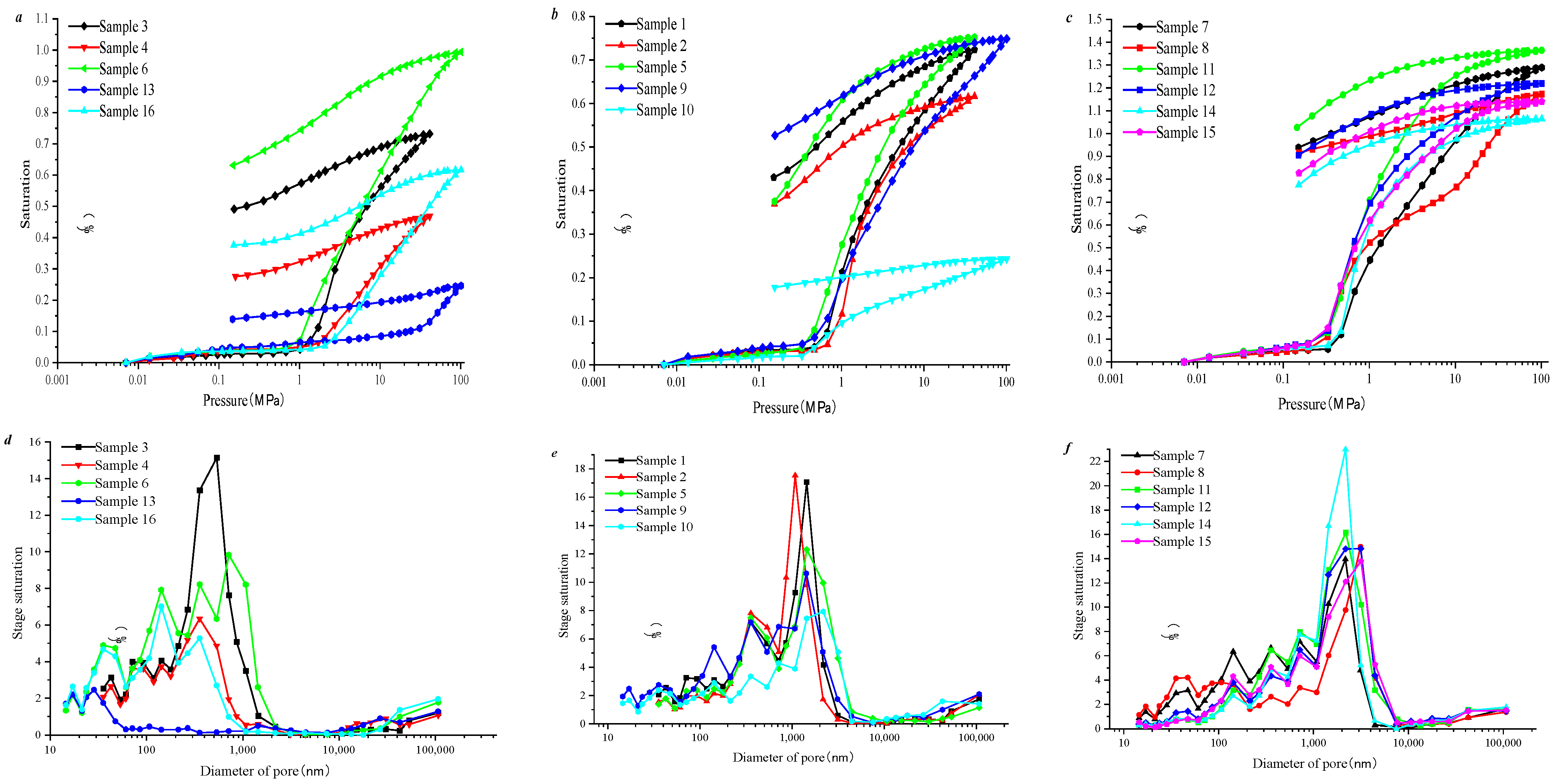

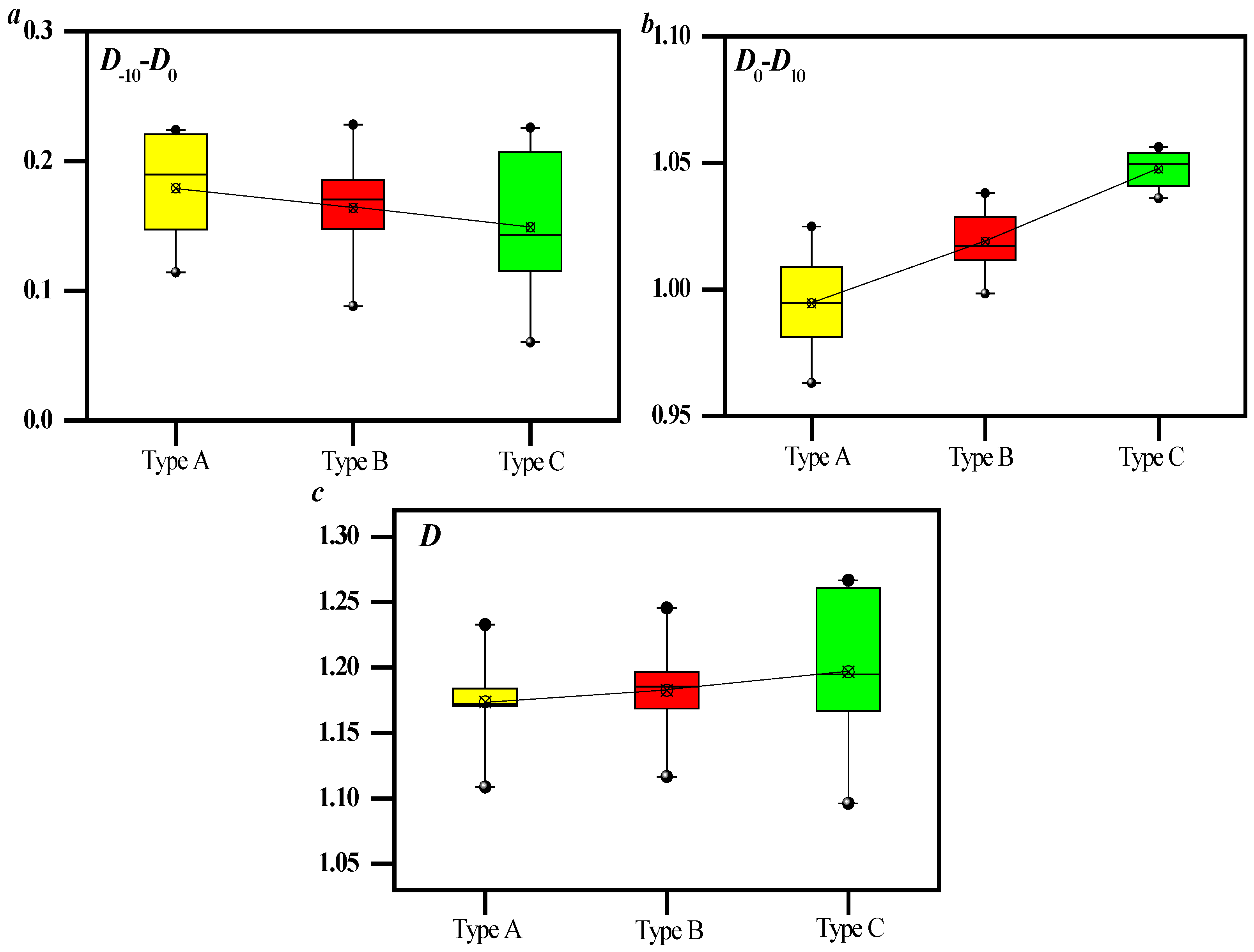

3.1. Pore and Fracture Distribution Based on High-Pressure Mercury Test

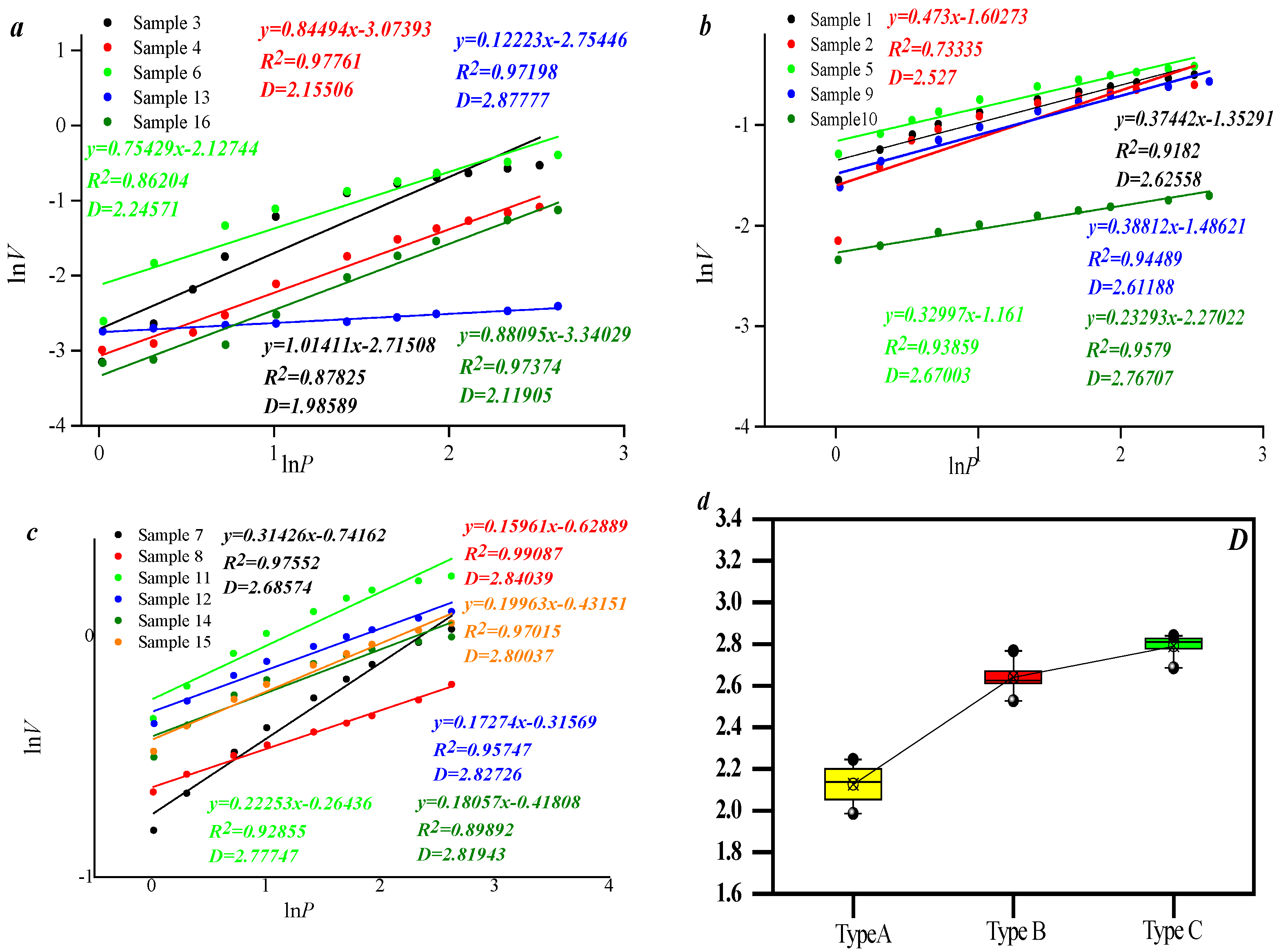

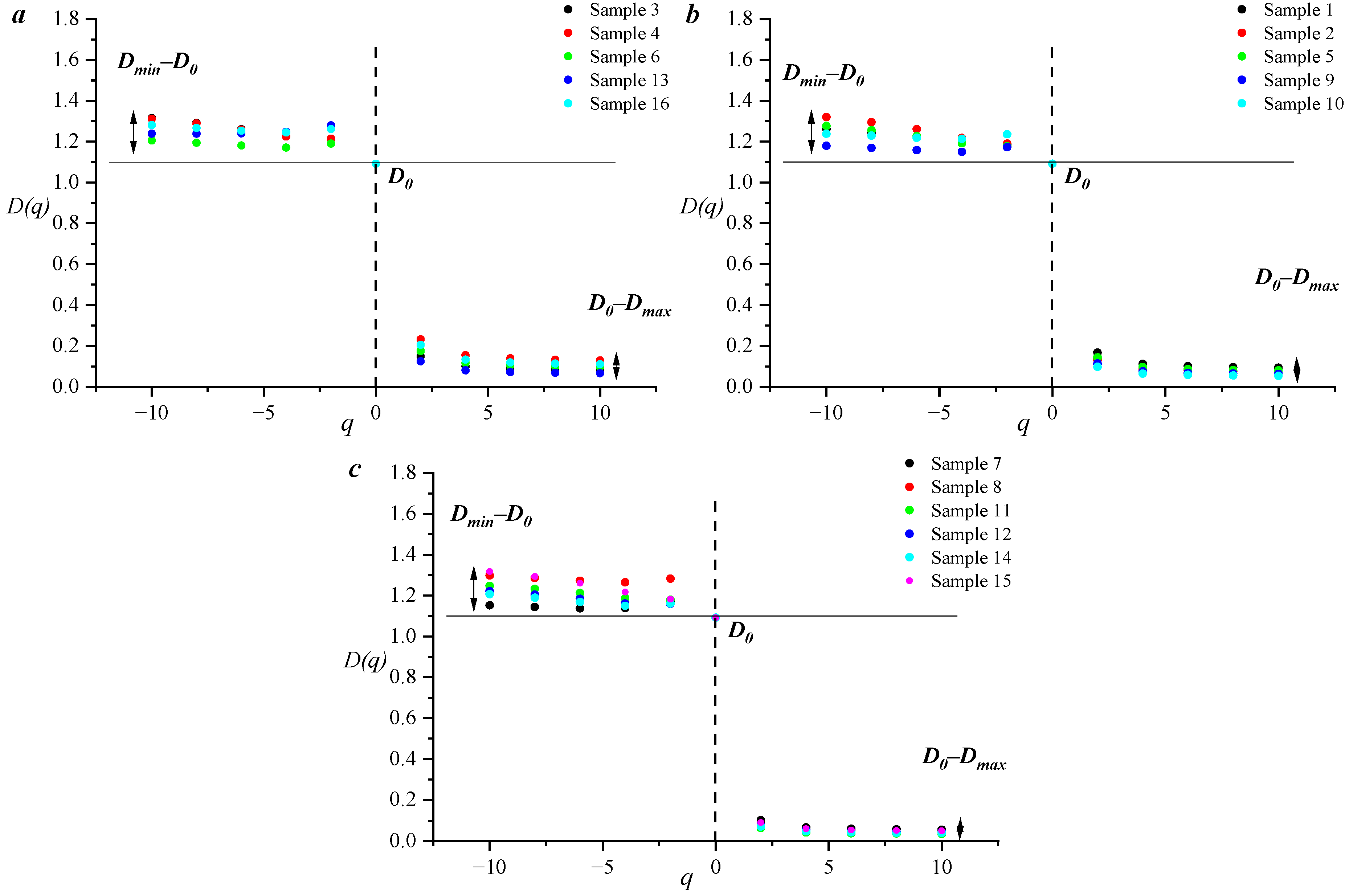

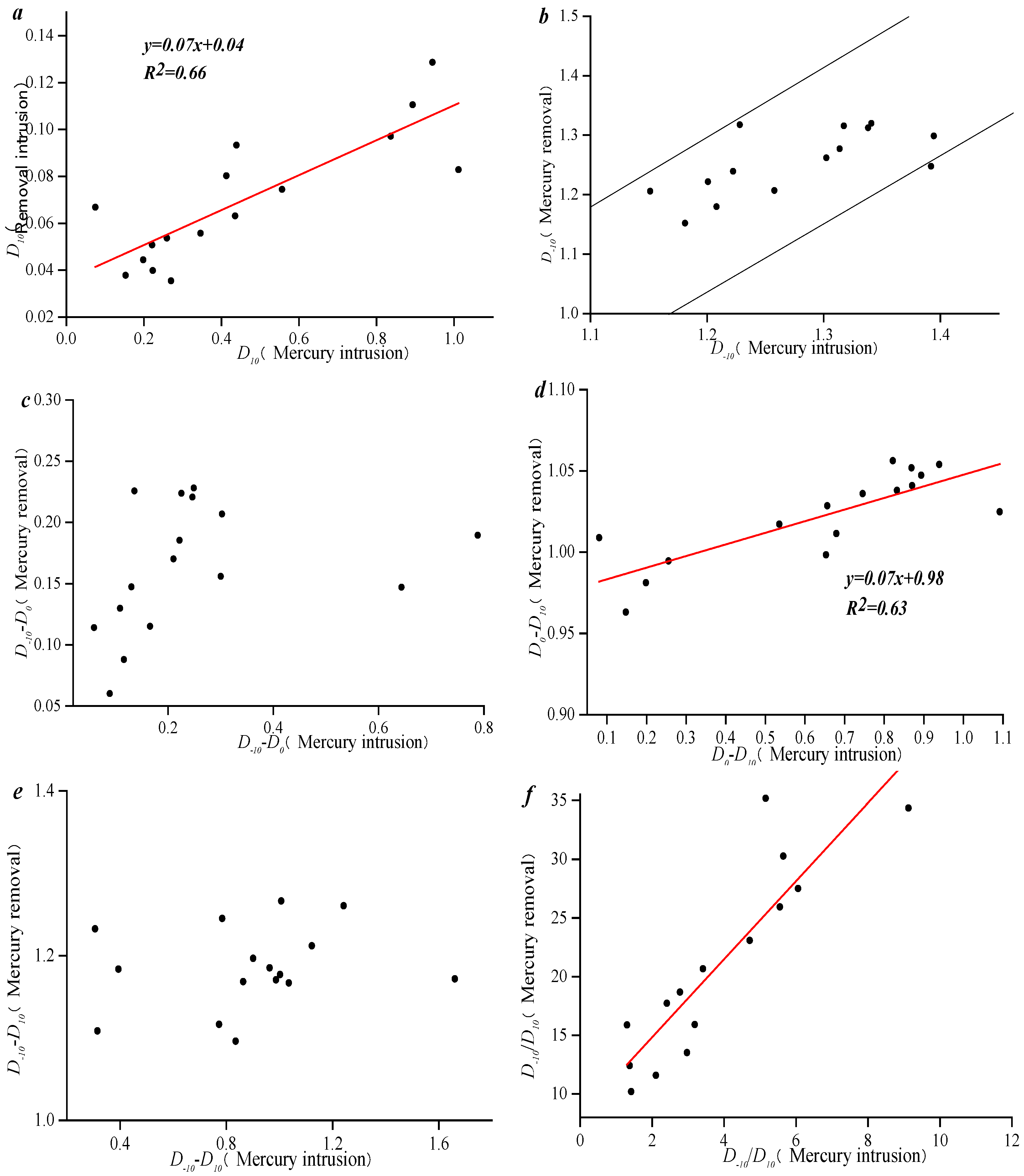

3.2. Pore–Fracture Distribution Heterogeneity by Using Mercury Intrusion Curves

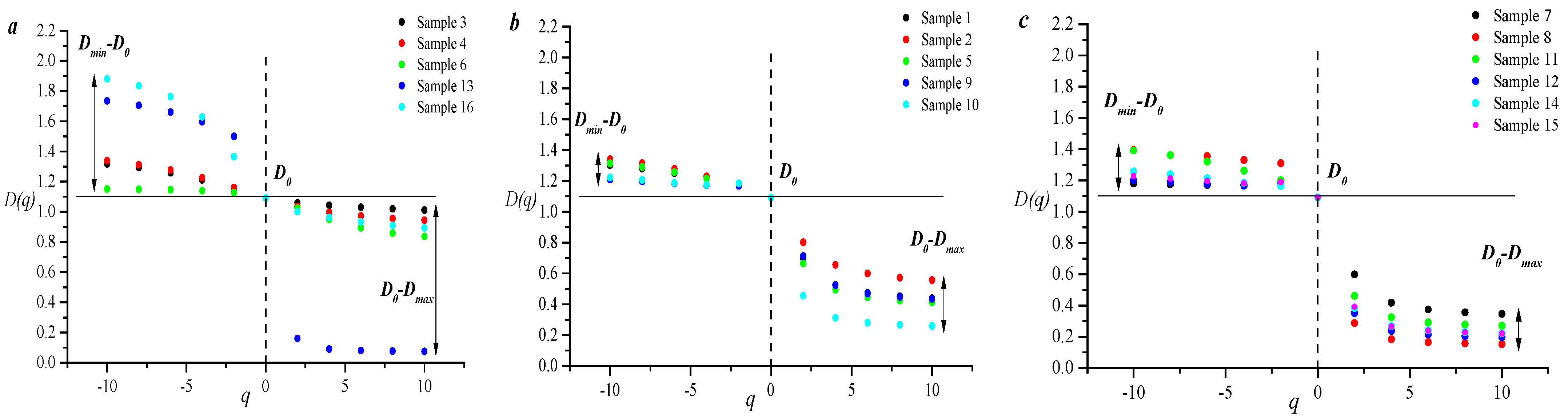

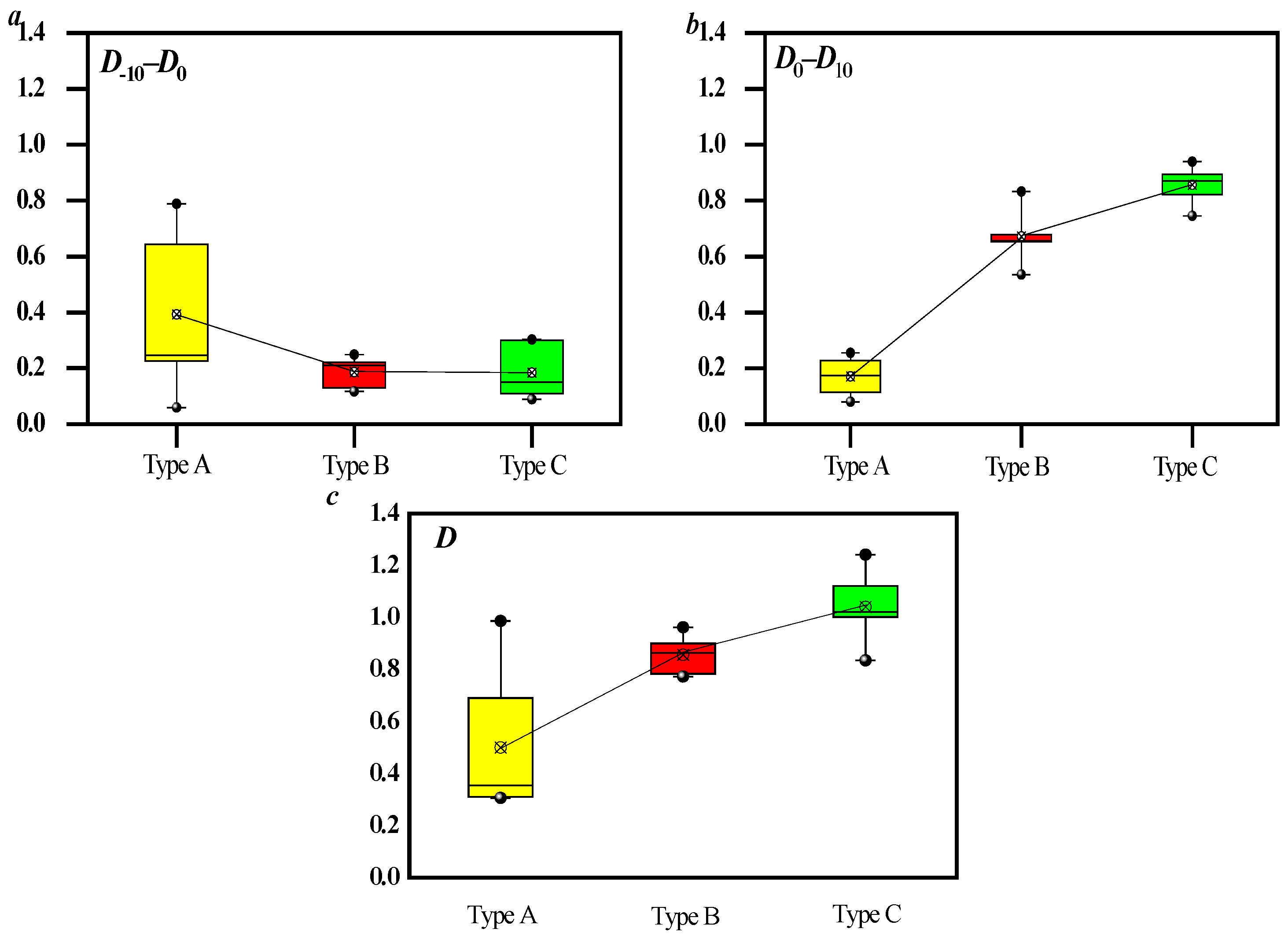

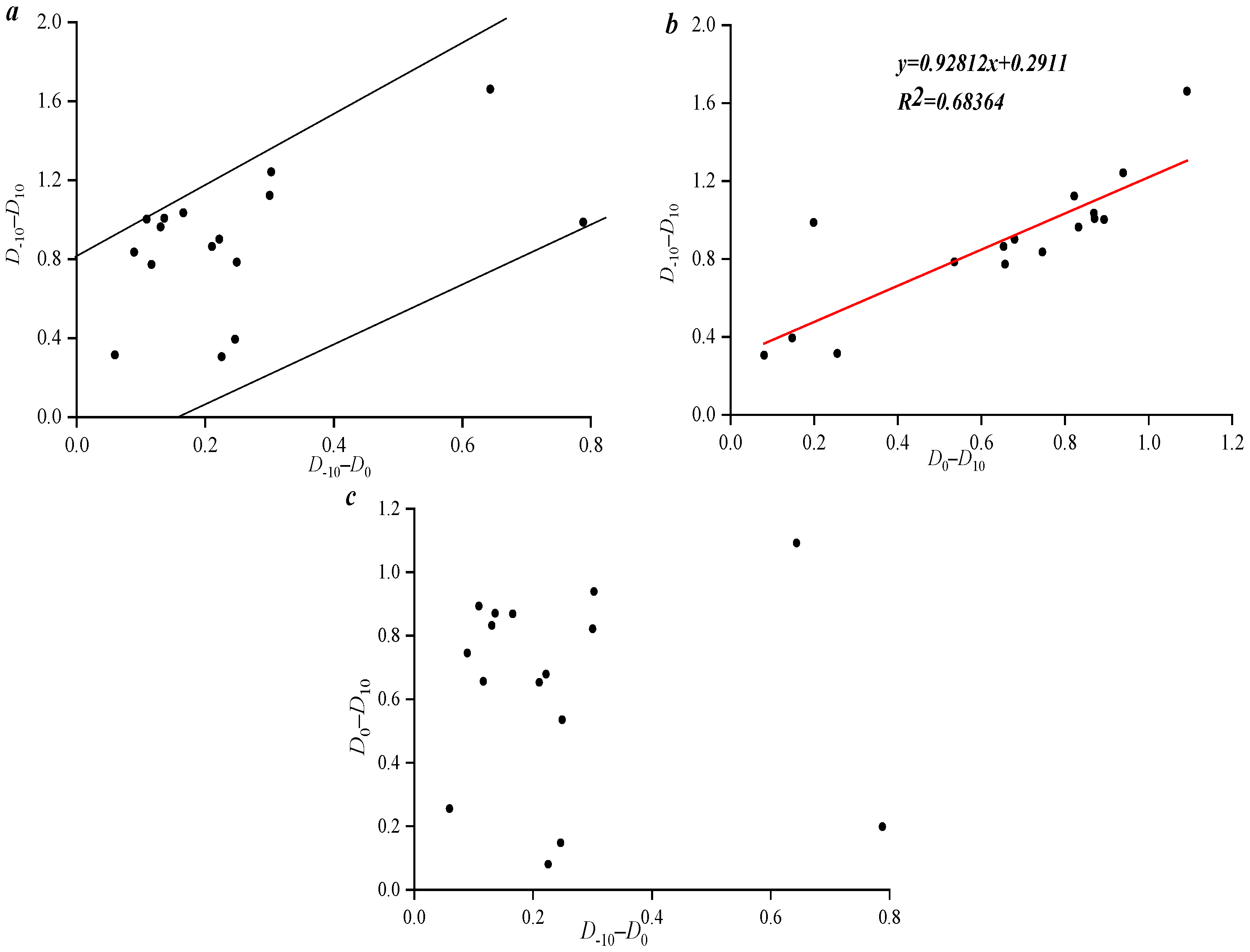

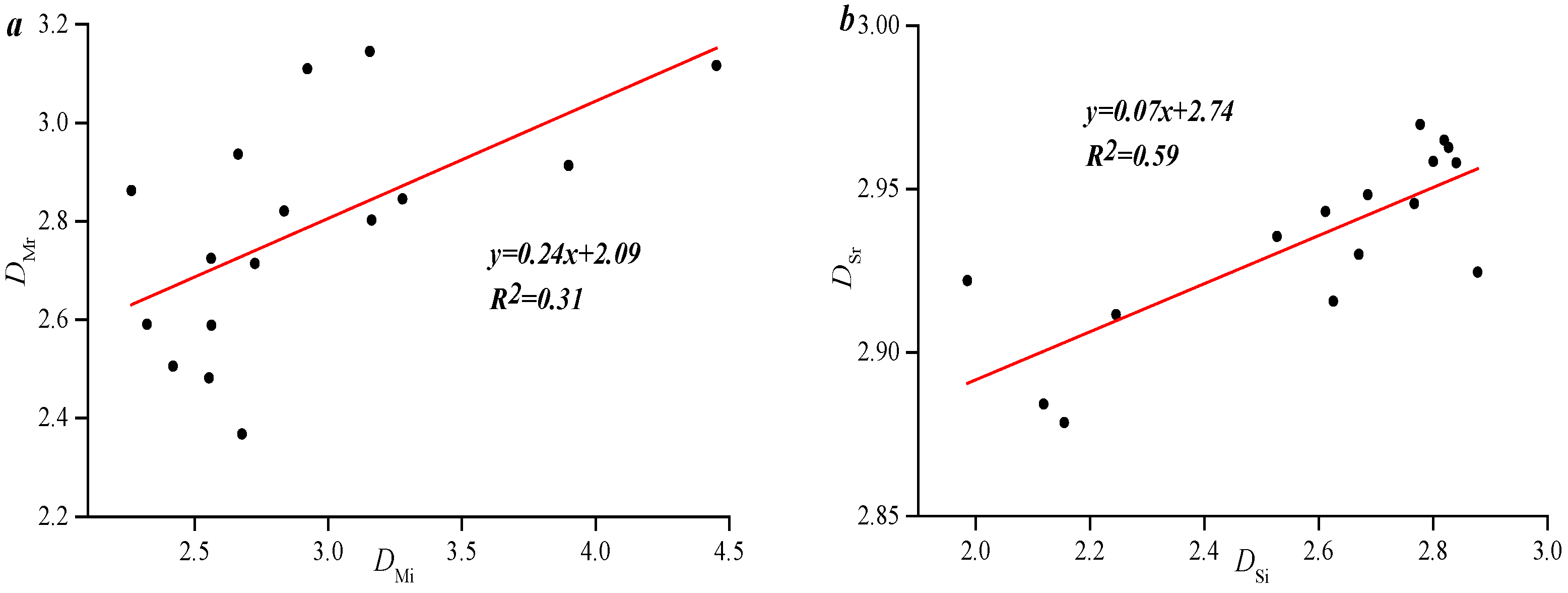

3.3. Pore and Fracture Structure Heterogeneity by Using Mercury Removal Curves

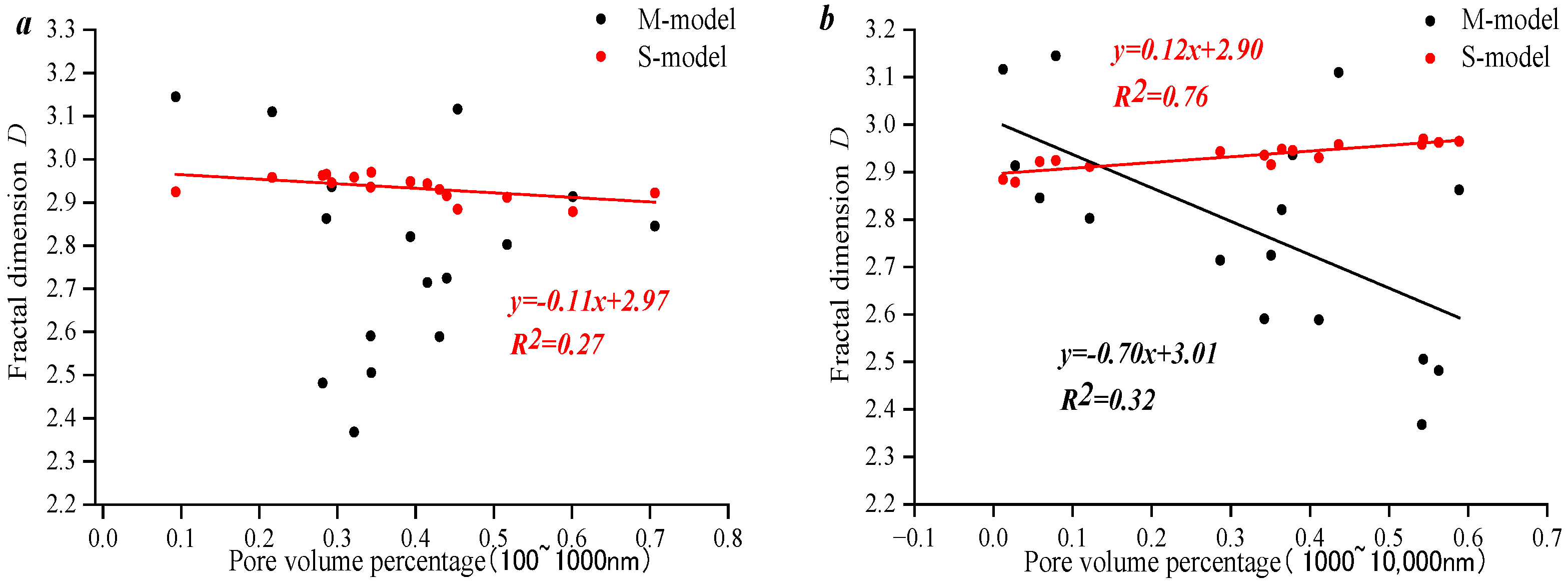

3.4. Influencing Factors of Fractal Dimension and Pore Permeability Variation

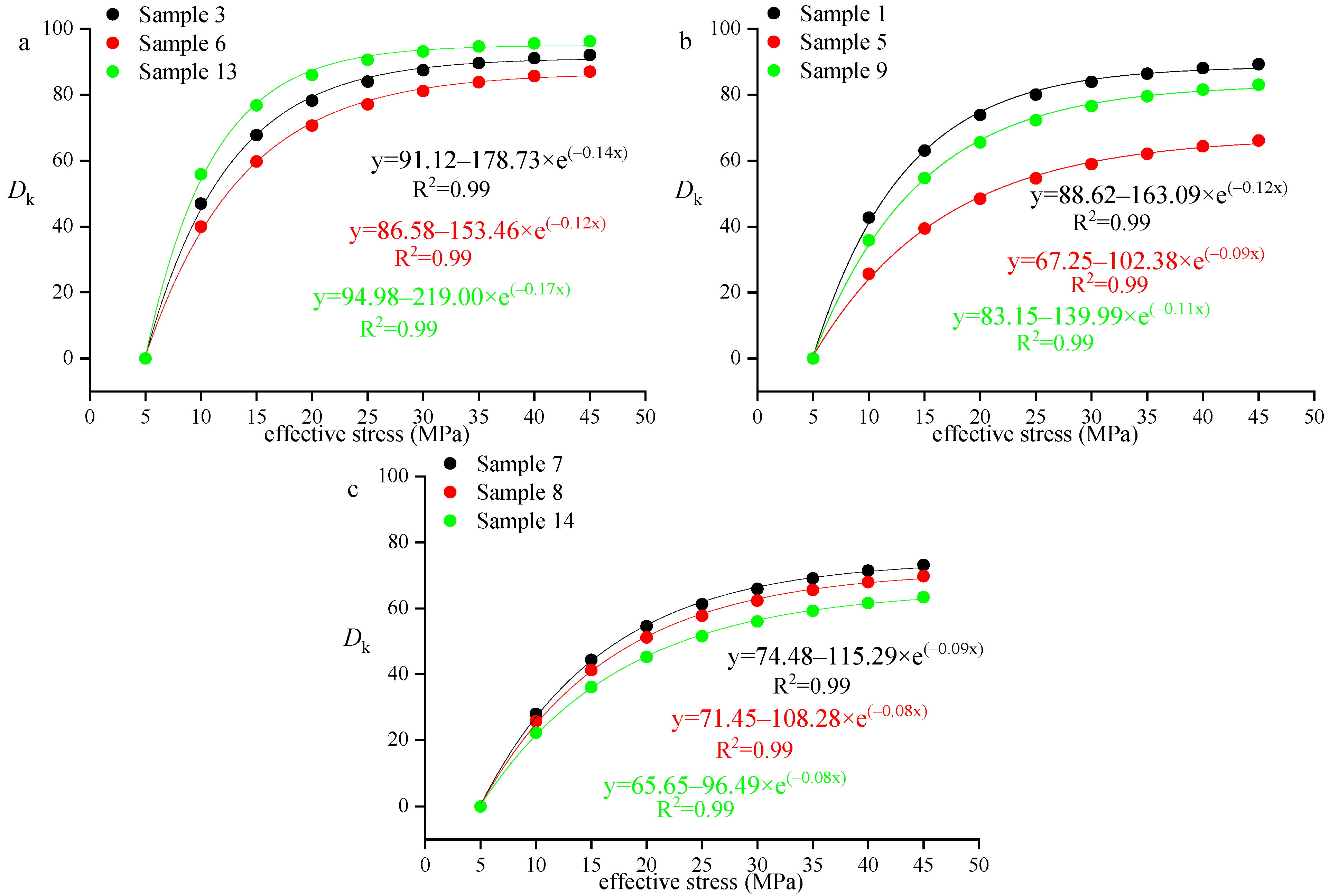

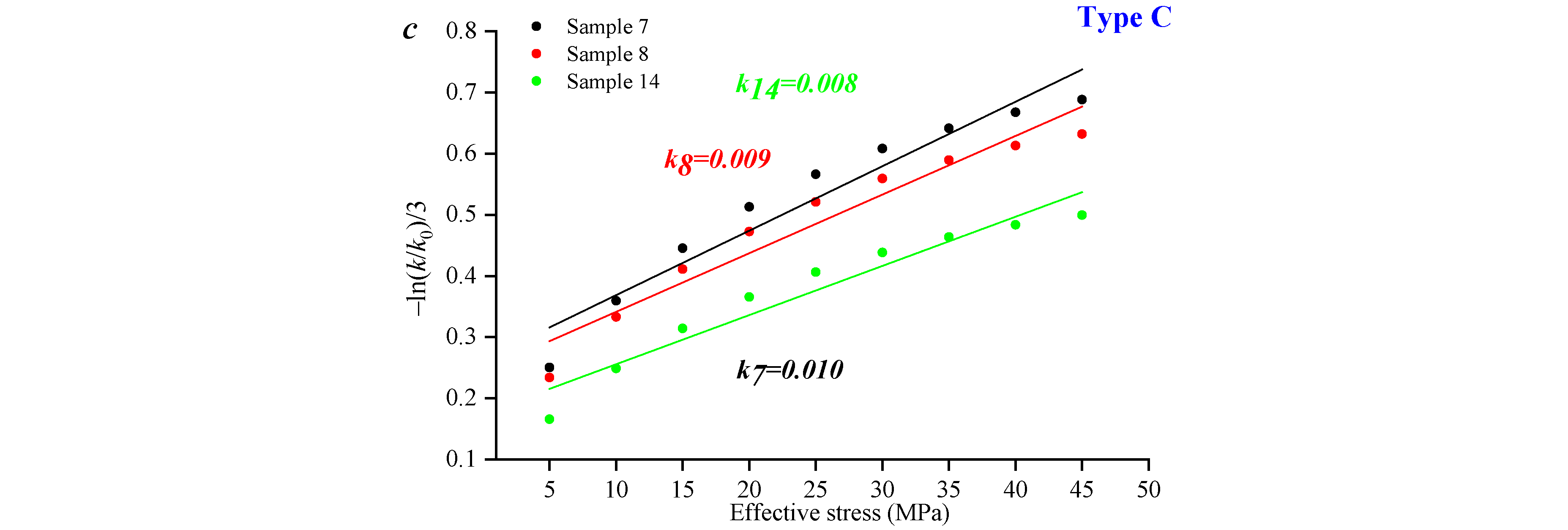

3.5. Permeability Sensitivity by Using Overburden Pore Permeability Test

4. Conclusions

- (1)

- Based on porosity and mercury removal efficiency, all coal samples can be divided into three types, that is, types A, B, and C. Among them, Type A samples are characterized by a lower total pore volume, with pore volume percentages ranging from 1000 to 10,000 nm not exceeding 15%.

- (2)

- During the mercury injection stage, both the M-model and S-model can reflect heterogeneity of seepage pore distribution. In the mercury removal stage, the S-model can characterize the distribution heterogeneity of seepage pores and macropores.

- (3)

- Among them, the Type A samples have the strongest sensitivity of permeability to pressure, with a permeability loss rate of up to 96%. The well-developed original pore and fracture structure of the coal sample is the reason for the initial permeability being relatively high.

- (4)

- The compressibility is only linearly negatively correlated with the pore volume between 1000 and 10,000 nm. There is no relationship between fractal dimension of mercury intrusion and fractal dimension of mercury retreat.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| DSi | The fractal dimension is calculated based on the mercury intrusion curve and S single model. |

| DSr | The fractal dimension is calculated based on the mercury removal curve and S single model. |

| Dk | Permeability loss rate |

| DMi | The fractal dimension is calculated based on the mercury intrusion curve and M single model. |

| DMr | The fractal dimension is calculated based on the mercury removal curve and M single model. |

| Cf | Pore compressibility coefficient under horizontal effective stress variation |

References

- Tao, S.; Chen, S.; Pan, Z. Current status, challenges, and policy suggestions for coalbed methane industry development in China: A review. Energy Sci. Eng. 2019, 7, 1059–1074. [Google Scholar] [CrossRef]

- Zou, Q.; Chen, Z.; Cheng, Z.; Liang, Y.; Xu, W.; Wen, P.; Zhang, B.; Liu, H.; Kong, F. Evaluation and intelligent deployment of coal and coalbed methane coupling coordinated exploitation based on Bayesian network and cuckoo search. Int. J. Min. Sci. Technol. 2022, 32, 1315–1328. [Google Scholar] [CrossRef]

- Li, Z.; Ren, T.; Li, X.; Cheng, Y.; He, X.; Lin, J.; Qiao, M.; Yang, X. Full-scale pore structure characterization of different rank coals and its impact on gas adsorption capacity: A theoretical model and experimental study. Energy 2023, 277, 127621. [Google Scholar] [CrossRef]

- Li, Z.; Ren, T.; Li, X.; Qiao, M.; Yang, X.; Tan, L.; Nie, B. Multi-scale pore fractal characteristics of differently ranked coal and its impact on gas adsorption. Int. J. Min. Sci. Technol. 2023, 33, 389–401. [Google Scholar] [CrossRef]

- Hui, G.; Chen, Z.; Schultz, R.; Chen, S.; Song, Z.; Zhang, Z.; Song, Y.; Wang, H.; Wang, M.; Gu, F. Intricate unconventional fracture networks provide fluid diffusion pathways to reactivate pre-existing faults in unconventional reservoirs. Energy 2023, 282, 128803. [Google Scholar] [CrossRef]

- Qin, Y.; Moore, T.A.; Shen, J.; Yang, Z.; Shen, Y.; Wang, G. Resources and geology of coalbed methane in China: A review. Int. Geol. Rev. 2018, 60, 777–812. [Google Scholar] [CrossRef]

- Liu, Q.; Wu, X.; Wang, X.; Jin, Z.; Zhu, D.; Meng, Q.; Huang, S.; Liu, J.; Fu, Q. Carbon and hydrogen isotopes of methane, ethane, and propane: A review of genetic identification of natural gas. Earth-Sci. Rev. 2019, 190, 247–272. [Google Scholar] [CrossRef]

- Xue, Y.; Liu, J.; Ranjith, P.; Liang, X.; Wang, S. Investigation of the influence of gas fracturing on fracturing characteristics of coal mass and gas extraction efficiency based on a multi-physical field model. J. Pet. Sci. Eng. 2021, 206, 109018. [Google Scholar] [CrossRef]

- Malozyomov, B.V.; Golik, V.I.; Brigida, V.; Kukartsev, V.V.; Tynchenko, Y.A.; Boyko, A.A.; Tynchenko, S.V. Substantiation of drilling parameters for undermined drainage boreholes for increasing methane production from unconventional coal-gas collectors. Energies 2023, 16, 4276. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, C.; Tang, D.; Gan, Q.; Niu, X.; Wang, K.; Shen, R. Coal pore size distributions controlled by the coalification process: An experimental study of coals from the Junggar, Ordos and Qinshui basins in China. Fuel 2017, 206, 352–363. [Google Scholar] [CrossRef]

- Zheng, S.; Yao, Y.; Liu, D.; Cai, Y.; Liu, Y. Characterizations of full-scale pore size distribution, porosity and permeability of coals: A novel methodology by nuclear magnetic resonance and fractal analysis theory. Int. J. Coal Geol. 2018, 196, 148–158. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, D.; Cai, Y.; Yao, Y.; Pan, Z.; Zhou, Y. Application of nuclear magnetic resonance (NMR) in coalbed methane and shale reservoirs: A review. Int. J. Coal Geol. 2020, 218, 103261. [Google Scholar] [CrossRef]

- Tao, S.; Chen, S.; Tang, D.; Zhao, X.; Xu, H.; Li, S. Material composition, pore structure and adsorption capacity of low-rank coals around the first coalification jump: A case of eastern Junggar Basin, China. Fuel 2018, 211, 804–815. [Google Scholar] [CrossRef]

- Li, H.; Shi, S.; Lin, B.; Lu, J.; Ye, Q.; Lu, Y.; Wang, Z.; Hong, Y.; Zhu, X. Effects of microwave-assisted pyrolysis on the microstructure of bituminous coals. Energy 2019, 187, 115986. [Google Scholar] [CrossRef]

- Li, X.; Fu, X.; Tian, J.; Guan, W.; Liu, X.; Ge, Y.; Ranjith, P.; Wang, W.; Wang, M.; Liang, S. Heterogeneities of seepage pore and fracture of high volatile bituminous coal core: Implications on water invasion degree. J. Pet. Sci. Eng. 2019, 183, 106409. [Google Scholar] [CrossRef]

- Wang, G.; Qin, X.; Shen, J.; Zhang, Z.; Han, D.; Jiang, C. Quantitative analysis of microscopic structure and gas seepage characteristics of low-rank coal based on CT three-dimensional reconstruction of CT images and fractal theory. Fuel 2019, 256, 115900. [Google Scholar] [CrossRef]

- Li, S.; Qin, Y.; Tang, D.; Shen, J.; Wang, J.; Chen, S. A comprehensive review of deep coalbed methane and recent developments in China. Int. J. Coal Geol. 2023, 279, 104369. [Google Scholar] [CrossRef]

- Liu, S.; Sun, H.; Zhang, D.; Yang, K.; Wang, D.; Li, X.; Long, K.; Li, Y. Nuclear magnetic resonance study on the influence of liquid nitrogen cold soaking on the pore structure of different coals. Phys. Fluids 2023, 35, 012009. [Google Scholar] [CrossRef]

- Su, P.; Xia, Z.; Wang, P.; Ding, W.; Hu, Y.; Zhang, W.; Peng, Y. Fractal and multifractal analysis of pore size distribution in low permeability reservoirs based on mercury intrusion porosimetry. Energies 2019, 12, 1337. [Google Scholar] [CrossRef]

- Hu, Y.; Guo, Y.; Shangguan, J.; Zhang, J.; Song, Y. Fractal characteristics and model applicability for pores in tight gas sandstone reservoirs: A case study of the upper paleozoic in ordos basin. Energy Fuels 2020, 34, 16059–16072. [Google Scholar] [CrossRef]

- Zheng, S.; Sang, S.; Yao, Y.; Liu, D.; Liu, S.; Wang, M.; Feng, G. A multifractal-based method for determination NMR dual T2 cutoffs in coals. J. Pet. Sci. Eng. 2022, 214, 110488. [Google Scholar] [CrossRef]

- Feng, S.; Li, M.; Zhang, J.; Xu, G.; Vandeginste, V.; Zhang, P.; Ju, W. Single and multi-fractal dimension variation of tight sandstone by using centrifuge T2 spectral curve. Greenh. Gases-Sci. Technol. 2024, 14, 111–137. [Google Scholar] [CrossRef]

- Fu, H.; Tang, D.; Xu, T.; Xu, H.; Tao, S.; Li, S.; Yin, Z.; Chen, B.; Zhang, C.; Wang, L. Characteristics of pore structure and fractal dimension of low-rank coal: A case study of Lower Jurassic Xishanyao coal in the southern Junggar Basin, NW China. Fuel 2017, 193, 254–264. [Google Scholar] [CrossRef]

- Xu, X.; Meng, Z.; Wang, Y. Experimental comparisons of multiscale pore structures between primary and disturbed coals and their effects on adsorption and seepage of coalbed methane. J. Pet. Sci. Eng. 2019, 174, 704–715. [Google Scholar] [CrossRef]

- Wang, G.; Han, D.; Jiang, C.; Zhang, Z. Seepage characteristics of fracture and dead-end pore structure in coal at micro- and meso-scales. Fuel 2020, 266, 117058. [Google Scholar] [CrossRef]

- Jing, D.; Meng, X.; Ge, S.; Zhang, T.; Ma, M.; Tong, L. Reconstruction and seepage simulation of a coal pore-fracture network based on CT technology. PLoS ONE 2021, 16, e0252277. [Google Scholar] [CrossRef] [PubMed]

- Ju, Y.; Chen, J.; Wang, Y.; Gao, F.; Xie, H. Numerical analysis of hydrofracturing behaviors and mechanisms of heterogeneous reservoir glutenite, using the continuum-based discrete element method while considering hydromechanical coupling and leak-off effects. J. Geophys. Res.-Solid Earth 2018, 123, 3621–3644. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, D.; Yang, J.; Wang, B.; Liu, T. Fractal analysis of CT images of tight sandstone with anisotropy and permeability prediction. J. Pet. Sci. Eng. 2021, 205, 108919. [Google Scholar] [CrossRef]

- Zhang, J.; Qin, Z.; Han, Y.; Wang, H.; Hou, M.; Yan, G.; Feng, G.; Zhang, X.; Yin, T.; Zhang, H.; et al. Pore-fracture distribution heterogeneity of shale reservoirs determined by using HPMI and LPN2 GA tests. Acta Geol. Sin. Engl. Ed. 2022, 96, 1659–1672. [Google Scholar] [CrossRef]

- Zhang, P.; Yin, Y.; Lu, S.; Li, J.; Chang, X.; Zhang, J.; Pang, Y.; Chen, G.; Liu, Y.; Li, Z. Insights into pore structures and multifractal characteristics of shale oil reservoirs: A case study from Dongying Sag, Bohai Bay Basin, China. Energy Fuels 2022, 36, 8224–8237. [Google Scholar] [CrossRef]

- Yao, P.; Zhang, J.; Qin, Z.; Fan, A.; Feng, G.; Vandeginste, V.; Zhang, P.; Zhang, X. Effect of pore structure heterogeneity of sandstone reservoirs on porosity–permeability variation by using single–multi-fractal models. ACS Omega 2024, 9, 23339–23354. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Ge, Z.; Li, R.; Zhou, Z.; Hou, Y.; Zhang, H. Coupling effect of temperature, gas, and viscoelastic surfactant fracturing fluid on the microstructure and its fractal characteristics of deep coal. Energy Fuels 2021, 35, 19423–19436. [Google Scholar] [CrossRef]

- Chu, P.; Xie, H.; Li, C.; Liu, Q.; Lu, Z.; Lu, J. Mechanism of desorption hysteresis in coalbed methane: Insights from microscopic pore properties and adsorption theory. Phys. Fluids 2024, 36, 012004. [Google Scholar] [CrossRef]

- Wang, H.; Wang, L.; Zheng, S.; Sun, Y.; Shen, S.; Zhang, X. Research on coal matrix pore structure evolution and adsorption behavior characteristics under different thermal stimulation. Energy 2024, 287, 129677. [Google Scholar] [CrossRef]

- Zhang, J.; Hu, Y. Comparative evaluation of pore structure heterogeneity in low-permeability tight sandstones using different fractal models based on NMR technology: A case study of benxi formation in the central Ordos Basin. Energy Fuels 2020, 34, 13924–13942. [Google Scholar] [CrossRef]

- Zhang, M.; Duan, C.; Li, G.; Fu, X.; Zhong, Q.; Liu, H.; Dong, Z. Determinations of the multifractal characteristics of the pore structures of low-, middle-, and high-rank coal using high-pressure mercury injection. J. Pet. Sci. Eng. 2021, 203, 108656. [Google Scholar] [CrossRef]

- Zhang, J.; Wei, C.; Zhao, J.; Ju, W.; Chen, Y.; Tamehe, L.S. Comparative evaluation of the compressibility of middle and high rank coals by different experimental methods. Fuel 2019, 245, 39–51. [Google Scholar] [CrossRef]

| Sample No. | Pore Volume Percentage | Total Pore Volume (cm3.g−1) | ||

|---|---|---|---|---|

| 1000~10,000 nm | 100~1000 nm | <100 nm | ||

| Sample 1 | 0.350940 | 0.439858 | 0.162607 | 0.62 |

| Sample 2 | 0.342581 | 0.342581 | 0.109484 | 0.72 |

| Sample 3 | 0.058558 | 0.706110 | 0.196726 | 0.45 |

| Sample 4 | 0.027623 | 0.601304 | 0.281899 | 0.61 |

| Sample 5 | 0.411441 | 0.430599 | 0.121557 | 0.72 |

| Sample 6 | 0.121634 | 0.517105 | 0.322312 | 1.01 |

| Sample 7 | 0.364601 | 0.393557 | 0.202819 | 1.25 |

| Sample 8 | 0.436466 | 0.216497 | 0.303412 | 1.07 |

| Sample 9 | 0.286781 | 0.414983 | 0.242208 | 0.78 |

| Sample 10 | 0.378117 | 0.292714 | 0.251814 | 0.25 |

| Sample 11 | 0.543533 | 0.343387 | 0.061794 | 1.23 |

| Sample 12 | 0.562847 | 0.281068 | 0.093983 | 1.27 |

| Sample 13 | 0.078906 | 0.093010 | 0.634251 | 0.61 |

| Sample 14 | 0.588606 | 0.285951 | 0.065170 | 1.34 |

| Sample 15 | 0.541624 | 0.321347 | 0.075186 | 1.09 |

| Sample 16 | 0.012191 | 0.453752 | 0.474507 | 0.56 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, X.; Miao, B.; Zhang, J.; Xi, D.; Qin, Z.; Vandeginste, V. Quantitative Characterization of Pore–Fracture Structures in Coal Reservoirs by Using Mercury Injection–Removal Curves and Permeability Variation under Their Constraints. Processes 2024, 12, 1434. https://doi.org/10.3390/pr12071434

Jiang X, Miao B, Zhang J, Xi D, Qin Z, Vandeginste V. Quantitative Characterization of Pore–Fracture Structures in Coal Reservoirs by Using Mercury Injection–Removal Curves and Permeability Variation under Their Constraints. Processes. 2024; 12(7):1434. https://doi.org/10.3390/pr12071434

Chicago/Turabian StyleJiang, Xuchao, Bin Miao, Junjian Zhang, Danyang Xi, Zhenyuan Qin, and Veerle Vandeginste. 2024. "Quantitative Characterization of Pore–Fracture Structures in Coal Reservoirs by Using Mercury Injection–Removal Curves and Permeability Variation under Their Constraints" Processes 12, no. 7: 1434. https://doi.org/10.3390/pr12071434

APA StyleJiang, X., Miao, B., Zhang, J., Xi, D., Qin, Z., & Vandeginste, V. (2024). Quantitative Characterization of Pore–Fracture Structures in Coal Reservoirs by Using Mercury Injection–Removal Curves and Permeability Variation under Their Constraints. Processes, 12(7), 1434. https://doi.org/10.3390/pr12071434