Assessment of Solid Waste Management and Decarbonization Strategies

Abstract

:1. Introduction

2. A Brief Overview of Solid Waste Generation Sources and Decarbonization Technologies

2.1. Source of Solid Waste

2.2. Environmental Pollution of Solid Waste

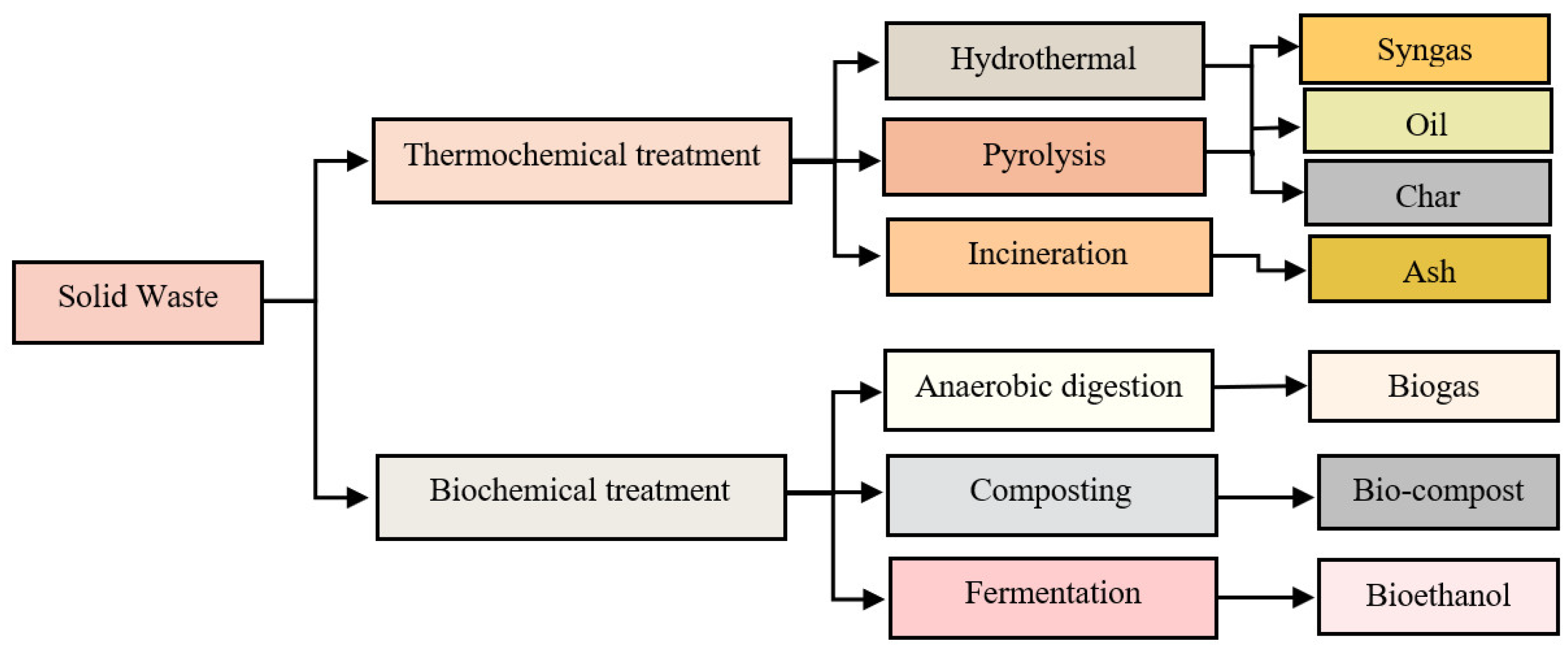

2.3. Treatment Technologies of Solid Waste

3. Waste Management Decarbonization Strategies

4. Decarbonization Challenges

4.1. Technological Challenges

4.2. Legal and Political Constraint

4.3. Economic and Financial Limitation

4.4. Social Limitations

5. Waste Decarbonization Future Perspectives and Outlook

5.1. Waste Reduction and Circular Economy Approaches

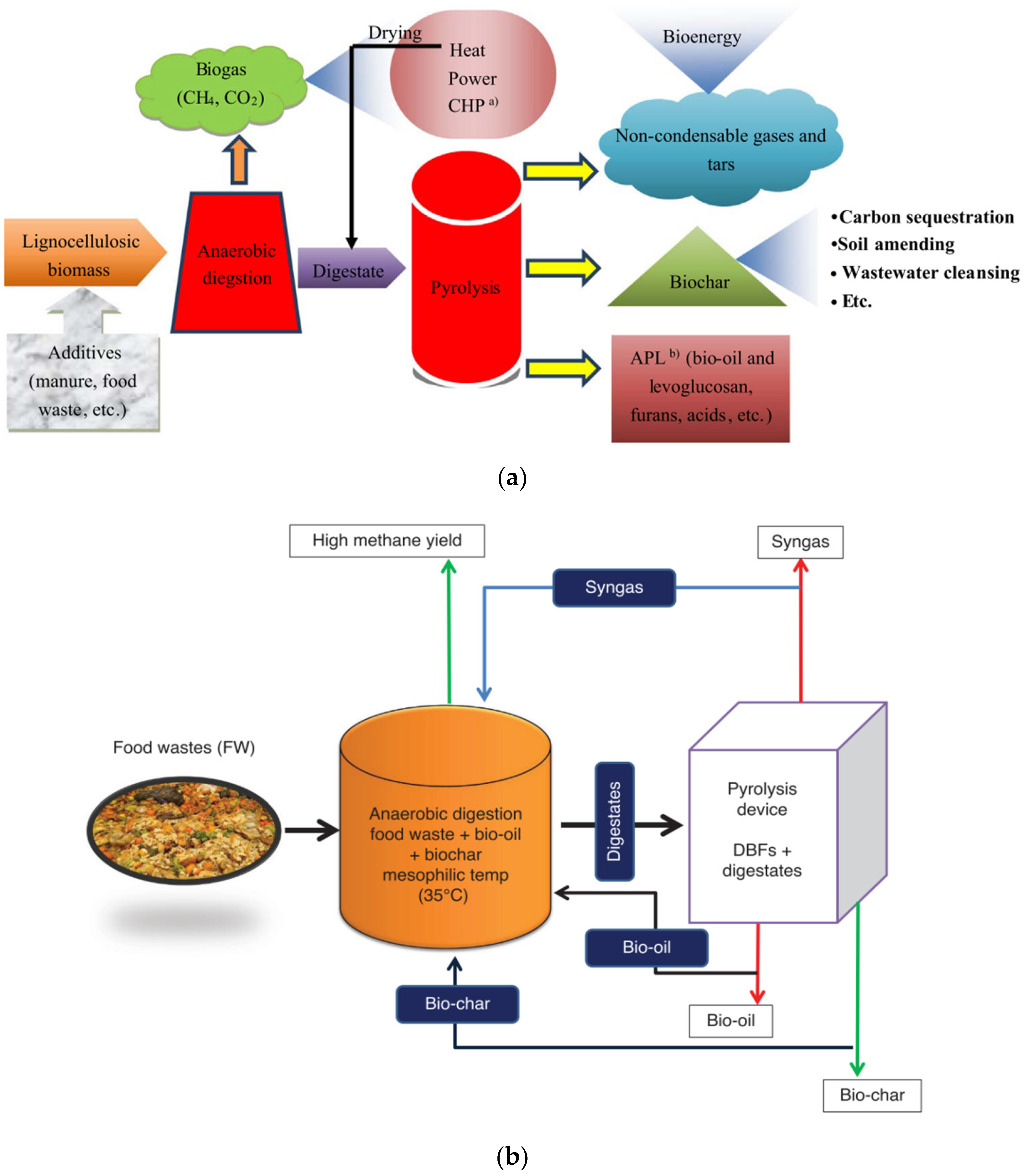

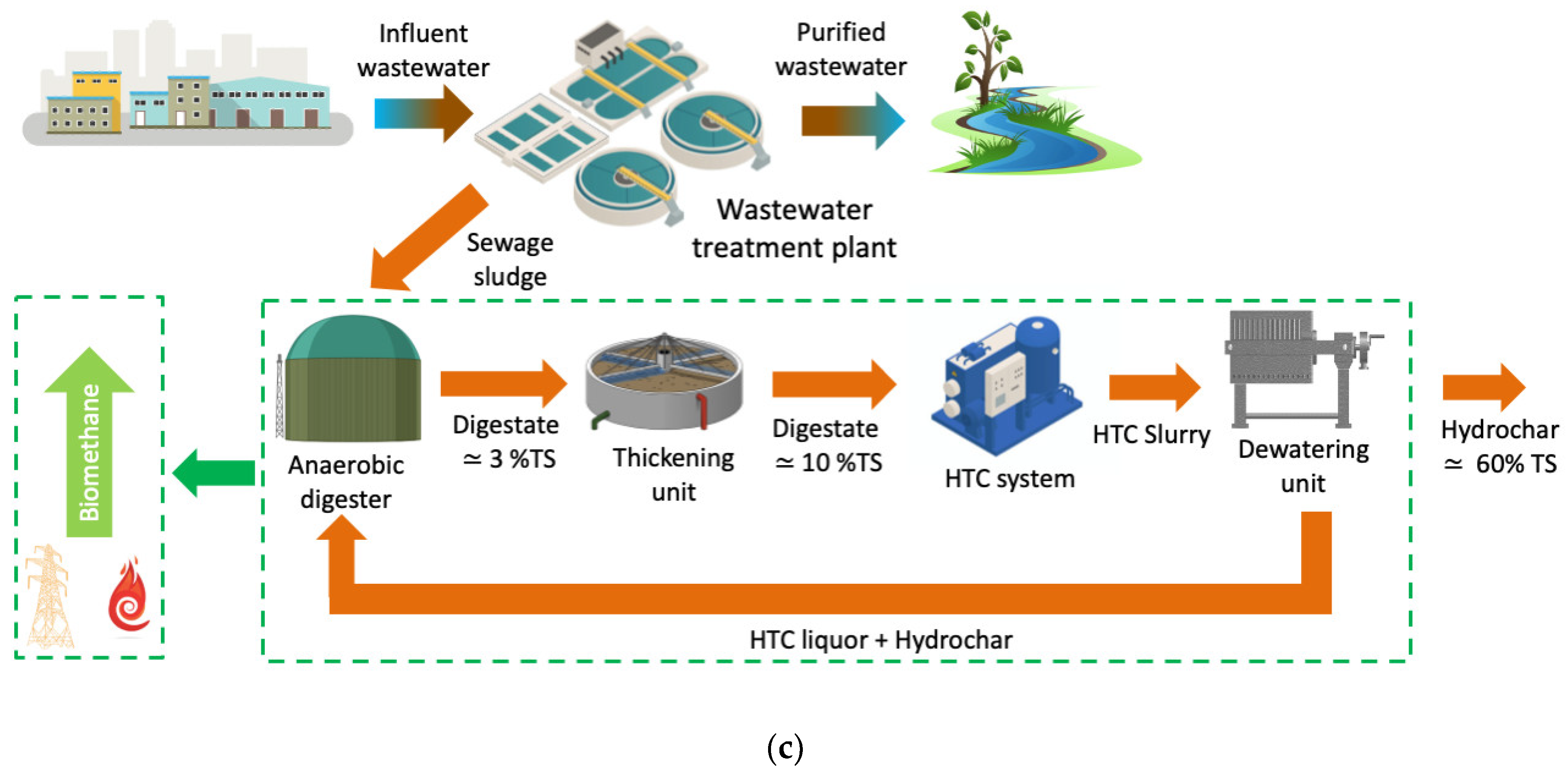

5.2. Waste-to-Energy and Bioenergy Technologies

5.3. Landfill Gas Capture and Utilization

5.4. Public Awareness and Stakeholder Engagement

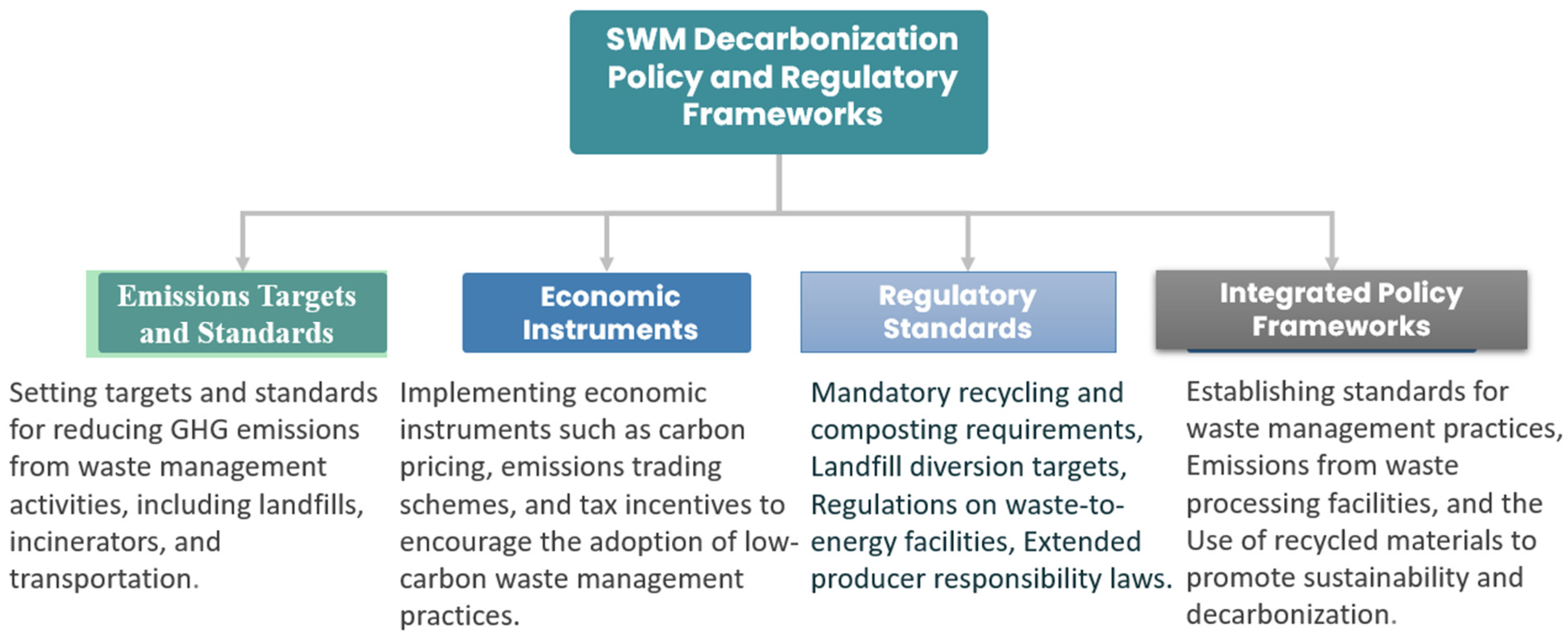

5.5. Policy and Regulatory Frameworks

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Khan, A.H.; López-Maldonado, E.A.; Khan, N.A.; Villarreal-Gómez, L.J.; Munshi, F.M.; Alsabhan, A.H.; Perveen, K. Current Solid Waste Management Strategies and Energy Recovery in Developing Countries—State of Art Review. Chemosphere 2022, 291, 133088. [Google Scholar] [CrossRef] [PubMed]

- Panepinto, D.; Riggio, V.A.; Zanetti, M. Analysis of the Emergent Climate Change Mitigation Technologies. Int. J. Environ. Res. Public Health 2021, 18, 6767. [Google Scholar] [CrossRef] [PubMed]

- Yuan, X.; Wang, J.; Deng, S.; Dissanayake, P.D.; Wang, S.; You, S.; Yip, A.C.K.; Li, S.; Jeong, Y.; Tsang, D.C.W.; et al. Sustainable Food Waste Management: Synthesizing Engineered Biochar for CO2 Capture. ACS Sustain. Chem. Eng. 2022, 10, 13026–13036. [Google Scholar] [CrossRef]

- Blevins, C.; Karanja, E.; Omojah, S.; Chishala, C.; Oniosun, T.I. Wastesites.Io: Mapping Solid Waste to Meet Sustainable Development Goals. In Open Mapping towards Sustainable Development Goals; Springer: Cham, Switzerland, 2023; pp. 231–239. ISBN 9783031051821. [Google Scholar]

- Giwa, A.S.; Memon, A.G.; Vakili, M.; Ge, Y.; Wang, B. The Resource Recovery Potential of Blackwater and Foodwaste: Anaerobic Co-Digestion in Serial Semi-Continuous Stirred Tank Reactors. Int. J. Environ. Sci. Technol. 2022, 19, 5401–5408. [Google Scholar] [CrossRef]

- de la Hoz, J.; Martín, H.; Guerrero, J.M. Editorial: Technologies and Policies for Decarbonisation of the Industrial and Transport Sectors. Front. Energy Res. 2023, 11, 1200837. [Google Scholar] [CrossRef]

- Sonnenschein, J.; Mundaca, L. Decarbonization under Green Growth Strategies? The Case of South Korea. J. Clean. Prod. 2016, 123, 180–193. [Google Scholar] [CrossRef]

- Knobloch, F.; Pollitt, H.; Chewpreecha, U.; Daioglou, V.; Mercure, J.F. Simulating the Deep Decarbonisation of Residential Heating for Limiting Global Warming to 1.5 °C. Energy Effic. 2019, 12, 521–550. [Google Scholar] [CrossRef]

- Saunders, P.J.; Turekian, V. A Climate Policy for the Real World. Policy Rev. 2011, 15. [Google Scholar]

- Sotiriou, C.; Zachariadis, T. A Multi-Objective Optimisation Approach to Explore Decarbonisation Pathways in a Dynamic Policy Context. J. Clean. Prod. 2021, 319, 128623. [Google Scholar] [CrossRef]

- Pan, X.; Ma, X.; Zhang, Y.; Shao, T.; Peng, T.; Li, X.; Wang, L.; Chen, W. Implications of Carbon Neutrality for Power Sector Investments and Stranded Coal Assets in China. Energy Econ. 2023, 121, 106682. [Google Scholar] [CrossRef]

- Cheema-Fox, A.; LaPerla, B.R.; Serafeim, G.; Turkington, D.; Wang, H. (Stacie) Practical Applications of Decarbonization Factors. Pract. Appl. 2022, 2, pa.2022.pa523. [Google Scholar] [CrossRef]

- Karimi, I.A.; Farooq, S. Experience and Perspectives on Our Journey towards Deep Decarbonization. Comput. Aided Chem. Eng. 2022, 49, 25–30. [Google Scholar] [CrossRef]

- Organschi, A.; Kuittinen, M.; Ruff, A. Chapter Threecase Studies in Decarbonization. In Carbon: A Field Manual for Building Designers; Wiley: Hoboken, NJ, USA, 2022; pp. 86–179. [Google Scholar] [CrossRef]

- Lewis, D.D.; Patrick, A.; Jones, E.S.; Alden, R.E.; Al Hadi, A.; McCulloch, M.D.; Ionel, D.M. Decarbonization Analysis for Thermal Generation and Regionally Integrated Large-Scale Renewables Based on Minutely Optimal Dispatch with a Kentucky Case Study. Energies 2023, 16, 1999. [Google Scholar] [CrossRef]

- Giwa, A.S.; Sheng, M.; Maurice, N.J.; Liu, X.; Wang, Z.; Chang, F.; Huang, B.; Wang, K. Biofuel Recovery from Plantain and Banana Plant Wastes: Integration of Biochemical and Thermochemical Approach. J. Renew. Mater. 2023, 11, 2593–2629. [Google Scholar] [CrossRef]

- Shukla, J.B.; Verma, M.; Misra, A.K. Effect of Global Warming on Sea Level Rise: A Modeling Study. Ecol. Complex. 2017, 32, 99–110. [Google Scholar] [CrossRef]

- Jones, M.W.; Peters, G.P.; Gasser, T.; Andrew, R.M.; Schwingshackl, C.; Gütschow, J.; Houghton, R.A.; Friedlingstein, P.; Pongratz, J.; Le Quéré, C. National Contributions to Climate Change Due to Historical Emissions of Carbon Dioxide, Methane, and Nitrous Oxide since 1850. Sci. Data 2023, 10, 155. [Google Scholar] [CrossRef]

- Mar, K.A.; Unger, C.; Walderdorff, L.; Butler, T. Beyond CO2 Equivalence: The Impacts of Methane on Climate, Ecosystems, and Health. Environ. Sci. Policy 2022, 134, 127–136. [Google Scholar] [CrossRef]

- Giwa, A.S.; Ndungutse, J.M.; Li, Y.; Liu, X.; Vakili, M.; Memon, A.G.; Ai, L. Modification of Biochar with Fe3O4 and Humic Acid-Salt for Removal of Mercury from Aqueous Solutions: A Review. Environ. Pollut. Bioavailab. 2022, 34, 352–364. [Google Scholar] [CrossRef]

- Wei, J.; Li, H.; Liu, J. Heavy Metal Pollution in the Soil around Municipal Solid Waste Incinerators and Its Health Risks in China. Environ. Res. 2022, 203, 111871. [Google Scholar] [CrossRef]

- Mangoro, N.; Kubanza, N.S. Community Perceptions on the Impacts of Solid Waste Management on Human Health and the Environment in Sub-Saharan African Cities: A Study of Diepsloot, Johannesburg, South Africa. Dev. S. Afr. 2023, 40, 1214–1233. [Google Scholar] [CrossRef]

- Chabuk, A.; Jahad, U.A.; Majdi, A.; Majdi, H.S.H.; Isam, M.; Al-Ansari, N.; Laue, J. Estimating of Gases Emission from Waste Sites to Generate Electrical Energy as a Case Study at Al-Hillah City in Iraq. Sci. Rep. 2023, 13, 15193. [Google Scholar] [CrossRef] [PubMed]

- Giwa, A.S.; Zhang, X.; Wang, K. Trends of Food Waste Treatment/Resources Recovery with the Integration of Biochemical and Thermochemical Processes. In FOOD WASTE VALORISATION: Food, Feed, Fertiliser, Fuel and Value-Added Products; World Scientific: Singapore, 2023; pp. 55–80. [Google Scholar] [CrossRef]

- Pantcheva, R.; Mengov, G. Recycling Rate in Europe: Econometric Modeling and DART Clustering Analysis. In Proceedings of the International Conference Automatics and Informatics, ICAI 2022—Proceedings, Varna, Bulgaria, 6–8 October 2022; pp. 179–182. [Google Scholar]

- Roy, D.; Tarafdar, A. Solid Waste Management and Landfill in High-Income Countries. In Circular Economy in Municipal Solid Waste Landfilling: Biomining & Leachate Treatment. Radionuclides and Heavy Metals in the Environment; Springer: Cham, Switzerland, 2022; pp. 1–23. [Google Scholar]

- Mor, S.; Ravindra, K. Municipal Solid Waste Landfills in Lower- and Middle-Income Countries: Environmental Impacts, Challenges and Sustainable Management Practices. Process Saf. Environ. Prot. 2023, 174, 510–530. [Google Scholar] [CrossRef]

- Vinti, G.; Vaccari, M. Solid Waste Management in Rural Communities of Developing Countries: An Overview of Challenges and Opportunities. Clean Technol. 2022, 4, 1138–1151. [Google Scholar] [CrossRef]

- Adhikari, R.C. Investigation on Solid Waste Management in Developing Countries. J. Res. Dev. 2022, 5, 42–52. [Google Scholar] [CrossRef]

- Ahmed, A.; Pieter van Dijk, M. Waste Separation and 3R’s Principles for Sustainable SWM: Practice of Households, Private Companies and Municipalities in Five Ethiopian Cities. In Solid Waste and Landfills Management-Recent Advances; IntechOpen: London, UK, 2023. [Google Scholar] [CrossRef]

- Shovon, S.M.; Akash, F.A.; Rahman, W.; Rahman, M.A.; Chakraborty, P.; Hossain, H.M.Z.; Monir, M.U. Strategies of Managing Solid Waste and Energy Recovery for a Developing Country—A Review. Heliyon 2024, 10, e24736. [Google Scholar] [CrossRef] [PubMed]

- Pecchi, M.; Baratieri, M. Coupling Anaerobic Digestion with Gasification, Pyrolysis or Hydrothermal Carbonization: A Review. Renew. Sustain. Energy Rev. 2019, 105, 462–475. [Google Scholar] [CrossRef]

- Giwa, A.S.; Chang, F.; Xu, H.; Zhang, X.; Huang, B.; Li, Y.; Wu, J.; Wang, B.; Vakili, M.; Wang, K. Pyrolysis of Difficult Biodegradable Fractions and the Real Syngas Bio-Methanation Performance. J. Clean. Prod. 2019, 233, 711–719. [Google Scholar] [CrossRef]

- Chiang, P.F.; Han, S.; Claire, M.J.; Maurice, N.J.; Vakili, M.; Giwa, A.S. Sustainable Treatment of Spent Photovoltaic Solar Panels Using Plasma Pyrolysis Technology and Its Economic Significance. Clean Technol. 2024, 6, 432–452. [Google Scholar] [CrossRef]

- Nanda, S.; Berruti, F. A Technical Review of Bioenergy and Resource Recovery from Municipal Solid Waste. J. Hazard. Mater. 2021, 403, 123970. [Google Scholar] [CrossRef]

- Fan, X.; Yuan, R.; Gan, M.; Ji, Z.; Sun, Z. Subcritical Hydrothermal Treatment of Municipal Solid Waste Incineration Fly Ash: A Review. Sci. Total Environ. 2023, 865, 160745. [Google Scholar] [CrossRef]

- Zhang, B.; Biswal, B.K.; Zhang, J.; Balasubramanian, R. Hydrothermal Treatment of Biomass Feedstocks for Sustainable Production of Chemicals, Fuels, and Materials: Progress and Perspectives. Chem. Rev. 2023, 123, 7193–7294. [Google Scholar] [CrossRef] [PubMed]

- Giwa, A.S.; Ali, N.; Vakili, M.; Guo, X.; Liu, D.; Wang, K. Opportunities for Holistic Waste Stream Valorization from Food Waste Treatment Facilities: A Review. Rev. Chem. Eng. 2022, 38, 35–53. [Google Scholar] [CrossRef]

- Stanescu, L.A.; Robescu, L.D.; Futselaar, H. Biogas Production Modeling and Simulation in Low End Conditions. In Proceedings of the 8th International Conference on Energy and Environment: Energy Saved Today is Asset for Future, CIEM 2017, Bucharest, Romania, 19–20 October 2017; pp. 381–384. [Google Scholar]

- Chen, T.; Zhang, S.; Yuan, Z. Adoption of Solid Organic Waste Composting Products: A Critical Review. J. Clean. Prod. 2020, 272, 122712. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, X.; Zhu, W.; Zhao, Y.; Wang, N.; Gao, M.; Wang, Q. Anaerobic Fermentation of Organic Solid Waste: Recent Updates in Substrates, Products, and the Process with Multiple Products Co-Production. Environ. Res. 2023, 233, 116444. [Google Scholar] [CrossRef] [PubMed]

- Beyene, H.D.; Werkneh, A.A.; Ambaye, T.G. Current Updates on Waste to Energy (WtE) Technologies: A Review. Renew. Energy Focus 2018, 24, 1–11. [Google Scholar] [CrossRef]

- Themelis, N.J. Energy and Materials Recovery from Post— Recycling Wastes: WTE. Waste Dispos. Sustain. Energy 2023, 5, 249–257. [Google Scholar] [CrossRef]

- Babalola, M.A. A Benefit-Cost Analysis of Food and Biodegradable Waste Treatment Alternatives: The Case of Oita City, Japan. Sustainability 2020, 12, 1916. [Google Scholar] [CrossRef]

- Giwa, A.S.; Xu, H.; Wu, J.; Li, Y.; Chang, F.; Zhang, X.; Jin, Z.; Huang, B.; Wang, K. Sustainable Recycling of Residues from the Food Waste (FW) Composting Plant via Pyrolysis: Thermal Characterization and Kinetic Studies. J. Clean. Prod. 2018, 180, 43–49. [Google Scholar] [CrossRef]

- Tucker, T.N.; Meyer, T. Reshaping Global Trade and Investment Law for a Green New Deal. In Routledge Handbook on the Green New Deal; Routledge: New York, NY, USA, 2022; pp. 120–138. ISBN 9781000640076. [Google Scholar]

- Anua, S.M.; Anwar, N.N.K.; Mohd Zain, N.; Abd Rahman, W.N.W.; Hamzah, N.A.; Abdul Rahman, H. Reduce, Reuse and Recycle (3r) Awareness Programme to Increase the Knowledge, Attitude and Practice on 3r among Primary School Students. Int. J. Acad. Res. Bus. Soc. Sci. 2022, 12, 62–74. [Google Scholar] [CrossRef]

- Velghe, I.; Carleer, R.; Yperman, J.; Schreurs, S. Study of the Pyrolysis of Municipal Solid Waste for the Production of Valuable Products. J. Anal. Appl. Pyrolysis 2011, 92, 366–375. [Google Scholar] [CrossRef]

- Giwa, A.S.; Sheng, M.; Zhang, X.; Bo, H.; Memon, A.G.; Bai, S.; Ali, N.; Maurice, J.; Kaijun, W.; Bo, H.; et al. Approaches for Treating Domestic Wastewater with Food Waste and Recovery of Potential Resources. Environ. Pollut. Bioavailab. 2022, 34, 501–517. [Google Scholar] [CrossRef]

- Galaly, A.R. Sustainable Development Solutions for the Medical Waste Problem Using Thermal Plasmas. Sustainability 2022, 14, 11045. [Google Scholar] [CrossRef]

- U.S. Environmental Protection Agency. National Overview: Facts and Figures on Materials, Wastes and Recycling; U.S. Environmental Protection Agency: Washington, DC, USA, 2022; Volume 2022, pp. 1–27.

- Evans, K. The History, Challenges, and New Developments in the Management and Use of Bauxite Residue. J. Sustain. Metall. 2016, 2, 316–331. [Google Scholar] [CrossRef]

- Srivastava, R.R.; Rajak, D.K.; Ilyas, S.; Kim, H.; Pathak, P. Challenges, Regulations, and Case Studies on Sustainable Management of Industrial Waste. Minerals 2023, 13, 51. [Google Scholar] [CrossRef]

- Suryavanshi, A.V.; Ahammed, M.M.; Shaikh, I.N. Energy, Economic, and Environmental Analysis of Waste-to-Energy Technologies for Municipal Solid Waste Treatment: A Case Study of Surat, India. J. Hazard. Toxic Radioact. Waste 2023, 27, 04023005. [Google Scholar] [CrossRef]

- Ahmad Fuad, F.H.; Shahdan, M.S. Overview of Recyclable Waste Materials for Building Constructions and Demolitions (C&D). Int. J. Acad. Res. Bus. Soc. Sci. 2023, 13, 2288–2296. [Google Scholar] [CrossRef]

- Varshney, R.; Singh, P.; Yadav, D. Hazardous Wastes Treatment, Storage, and Disposal Facilities. In Hazardous Waste Management—An Overview of Advanced and Cost-Effective Solutions; Elsevier: Amsterdam, The Netherlands, 2021; pp. 33–64. [Google Scholar] [CrossRef]

- Deshpande, K.; Deshmukh, V.; Kharde, A.; Nagmode, P. Production and Application of Bioculture for Farm Waste Recycling. Int. J. Curr. Microbiol. Appl. Sci. 2023, 12, 135–141. [Google Scholar] [CrossRef]

- Attrah, M.; Elmanadely, A.; Akter, D.; Rene, E.R. A Review on Medical Waste Management: Treatment, Recycling, and Disposal Options. Environments 2022, 9, 146. [Google Scholar] [CrossRef]

- DeCotis, P.A.; Cartwright, E.D. The Role of Small Modular Reactors in Decarbonization. Clim. Energy 2022, 38, 12–17. [Google Scholar] [CrossRef]

- Pharande, D.V.A.; Bagwan, S.S. A Review Conversation of Waste Plastics into Fuel. Int. J. Sci. Res. Eng. Manag. 2023, 07. [Google Scholar] [CrossRef]

- Giwa, A.S. Effectiveness of Torrefaction By-Products as Additive in Vacuum Blackwater under Anaerobic Digestion and Economic Significance. Processes 2023, 11, 3330. [Google Scholar] [CrossRef]

- Reiter, W.; Rieger, J.; Raupenstrauch, H.; Cattini, L.; Maystrenko, N.; Kovalev, D.; Alexey, A.; Mitrofanov, A. Recovery of Valuable Materials with the RecoDust Process. Metals 2023, 13, 1191. [Google Scholar] [CrossRef]

- Liang, X.; Miao, J.; Lu, Q. Harmless Disposal Technology of Hazardous Waste from Thermal Power Plants Harmless Disposal Technology of Hazardous Waste from Thermal Power Plants. IOP Conf. Ser. Earth Environ. Sci. 2019, 300, 032013. [Google Scholar] [CrossRef]

- Necibi, M.C.; Brouziyne, Y.; Chehbouni, A. Decarbonization: Regulation and Policies. In Emerging Carbon Capture Technologies: Towards a Sustainable Future; Elsevier: Amsterdam, The Netherlands, 2022; pp. 401–426. ISBN 9780323897822. [Google Scholar]

- Gills, B.; Morgan, J. Economics and Climate Emergency. Globalizations 2021, 18, 1071–1086. [Google Scholar] [CrossRef]

- Lewis, E.; Edwards, R.; Howe, J. Delivering the Industrial Decarbonisation Challenge: Geographical Considerations for Decarbonisation. Geography 2023, 108, 86–94. [Google Scholar] [CrossRef]

- Zhang, C.; Zhai, H.; Cao, L.; Li, X.; Cheng, F.; Peng, L.; Tong, K.; Meng, J.; Yang, L.; Wang, X. Understanding the Complexity of Existing Fossil Fuel Power Plant Decarbonization. iScience 2022, 25, 104758. [Google Scholar] [CrossRef] [PubMed]

- Doucet, F.; Jürgens, L.; Barkow, H.; Schütte, C.; Neubauer, N.; Von Düsterlho, E.; Schäfers, H. Decarbonization of the Industry—Demand and Cost Comparison of Green Hydrogen in Germany. In Proceedings of the 2023 19th International Conference on the European Energy Market (EEM), Lappeenranta, Finland, 6–8 June 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Wang, H.; Chen, W. Modelling Deep Decarbonization of Industrial Energy Consumption under 2-Degree Target: Comparing China, India and Western Europe. Appl. Energy 2019, 238, 1563–1572. [Google Scholar] [CrossRef]

- Gardarsdottir, S.O.; Normann, F.; Andersson, K.; Johnsson, F. Process Evaluation of CO2 Capture in Three Industrial Case Studies. Energy Procedia 2014, 63, 6565–6575. [Google Scholar] [CrossRef]

- Yaïci, W.; Entchev, E.; Longo, M. Recent Advances in Small-Scale Carbon Capture Systems for Micro-Combined Heat and Power Applications. Energies 2022, 15, 2938. [Google Scholar] [CrossRef]

- Dernbach, J.C. Legal Pathways to Deep Decarbonization in the United States; Environmental Law Institute: Washington, DC, USA, 2021; ISBN 9781585761951. [Google Scholar]

- The Government of British Columbia Community Energy Efficiency & Emissions Reduction. 2007. Available online: https://www2.gov.bc.ca/gov/content/governments/local-governments/climate-action/climate-change-mitigation/community-energy-efficiency-emissions-reduction (accessed on 3 December 2023).

- Carlin, D.; Gourri, C.; Fischer, R. Decarbonisation and Disruption. Oliver Wyman 2021, 50. [Google Scholar]

- Hu, Y.; Xu, G.; Xu, C.; Yang, Y. Thermodynamic Analysis and Techno-Economic Evaluation of an Integrated Natural Gas Combined Cycle (NGCC) Power Plant with Post-Combustion CO2 Capture. Appl. Therm. Eng. 2017, 111, 308–316. [Google Scholar] [CrossRef]

- Supekar, S.D.; Skerlos, S.J. Reassessing the Efficiency Penalty from Carbon Capture in Coal-Fired Power Plants. Environ. Sci. Technol. 2015, 49, 12576–12584. [Google Scholar] [CrossRef] [PubMed]

- Jacobsson, S.; Bergek, A. Transforming the Energy Sector: The Evolution of Technological Systems in Renewable Energy Technology. Ind. Corp. Chang. 2004, 13, 815–849. [Google Scholar] [CrossRef]

- Loftus, P.J.; Cohen, A.M.; Long, J.C.S.; Jenkins, J.D. A Critical Review of Global Decarbonization Scenarios: What Do They Tell Us about Feasibility? Wiley Interdiscip. Rev. Clim. Chang. 2015, 6, 93–112. [Google Scholar] [CrossRef]

- Cotterman, T.; Small, M.J.; Wilson, S.; Abdulla, A.; Wong-Parodi, G. Applying Risk Tolerance and Socio-Technical Dynamics for More Realistic Energy Transition Pathways. Appl. Energy 2021, 291, 116751. [Google Scholar] [CrossRef]

- Welton, S. Electricity Markets and the Social Project of Decarbonization. Columbia Law Rev. 2018, 118, 1067–1138. [Google Scholar]

- Costello, C. The Concept of Zero Waste. In Saving Food Production, Supply Chain, Food Waste and Food Consumption; Academic Press: Cambridge, MA, USA, 2019; pp. 369–391. [Google Scholar] [CrossRef]

- Frohmann, F. Business Models. Manag. Prof. 2023, F288, 49–82. [Google Scholar]

- Biswas, W.K.; John, M. Engineering for Sustainable Development: Theory and Practice. In Engineering for Sustainable Development: Theory and Practice; John Wiley & Sons: Hoboken, NJ, USA, 2023; ISBN 9781119720980. [Google Scholar]

- Illinois Environmental Protection Agency. Priority Climate Action Plan; EPA: Springfield, IL, USA, 2024; pp. 1–98.

- Haq, U.N.; Alam, S.M.R. Implementing Circular Economy Principles in the Apparel Production Process: Reusing Pre-Consumer Waste for Sustainability of Environment and Economy. Clean. Waste Syst. 2023, 6, 100108. [Google Scholar] [CrossRef]

- Giwa, A.S.; Xu, H.; Fengmin, C.; Wang, B.; Guo, X.; Wang, K. Recalcitrant Organic Residue Compositions and the Resource Recovery from a Food Waste Treatment Facility. J. Mater. Cycles Waste Manag. 2021, 23, 1479–1489. [Google Scholar] [CrossRef]

- Al Yahya, S.; Iqbal, T.; Omar, M.M.; Ahmad, M. Techno-Economic Analysis of Fast Pyrolysis of Date Palm Waste for Adoption in Saudi Arabia. Energies 2021, 14, 6048. [Google Scholar] [CrossRef]

- Feng, Q.; Lin, Y. Integrated Processes of Anaerobic Digestion and Pyrolysis for Higher Bioenergy Recovery from Lignocellulosic Biomass: A Brief Review. Renew. Sustain. Energy Rev. 2017, 77, 1272–1287. [Google Scholar] [CrossRef]

- Nakatsuka, N.; Kishita, Y.; Kurafuchi, T.; Akamatsu, F. Integrating Wastewater Treatment and Incineration Plants for Energy-Efficient Urban Biomass Utilization: A Life Cycle Analysis. J. Clean. Prod. 2020, 243, 118448. [Google Scholar] [CrossRef]

- Giwa, A.S.; Xu, H.; Chang, F.; Zhang, X.; Ali, N.; Yuan, J.; Wang, K. Pyrolysis Coupled Anaerobic Digestion Process for Food Waste and Recalcitrant Residues: Fundamentals, Challenges, and Considerations. Energy Sci. Eng. 2019, 7, 2250–2264. [Google Scholar] [CrossRef]

- Ferrentino, R.; Merzari, F.; Fiori, L.; Andreottola, G. Coupling Hydrothermal Carbonization with Anaerobic Digestion for Sewage Sludge Treatment: Influence of HTC Liquor and Hydrochar on Biomethane Production. Energies 2020, 13, 6262. [Google Scholar] [CrossRef]

- Xie, W.; Li, H.; Yang, M.; He, L.; Li, H. Green Chemical Engineering CO2 Capture and Utilization with Solid Waste. Green Chem. Eng. 2022, 3, 199–209. [Google Scholar] [CrossRef]

- Pheakdey, D.V.; Noudeng, V.; Xuan, T.D. Landfill Biogas Recovery and Its Contribution to Greenhouse Gas Mitigation. Energies 2023, 16, 4689. [Google Scholar] [CrossRef]

- Parameswaran, T.G.; Sivakumar Babu, G.L. Design of Gas Collection Systems: Issues and Challenges. Waste Manag. Res. 2022, 40, 1608–1617. [Google Scholar] [CrossRef] [PubMed]

- Borge-Diez, D.; Rosales-Asensio, E.; Açıkkalp, E.; Alonso-Martínez, D. Analysis of Power to Gas Technologies for Energy Intensive Industries in European Union. Energies 2023, 16, 538. [Google Scholar] [CrossRef]

- Zhou, Y.; İnce, F.; Teng, H.; Kaabar, M.K.A.; Xu, J.; Yue, X.G. Waste Management within the Scope of Environmental Public Awareness Based on Cross-Sectional Survey and Social Interviews. Front. Environ. Sci. 2022, 10, 1–10. [Google Scholar] [CrossRef]

- Gallagher, C.L.; Holloway, T. U.S. Decarbonization Impacts on Air Quality and Environmental Justice. Environ. Res. Lett. 2022, 17, 114018. [Google Scholar] [CrossRef]

- Fesenfeld, L.; Rudolph, L.; Bernauer, T. Policy Framing, Design and Feedback Can Increase Public Support for Costly Food Waste Regulation. Nat. Food 2022, 3, 227–235. [Google Scholar] [CrossRef] [PubMed]

- Hiraoka, T.; Muraki, M. A Study on Urban Developments Through the Cooperation Between Residential and Transport Sectors for Decarbonization in the Existing Residential Areas. AIJ J. Technol. Des. 2023, 29, 1017–1022. [Google Scholar] [CrossRef]

- Htun, N. Holistic and Integrated Systemic Policies and Practices for Decarbonization. Environ. Prog. Sustain. Energy 2023, 42, e14102. [Google Scholar] [CrossRef]

- Tangri, N. Waste Incinerators Undermine Clean Energy Goals. PLoS Clim. 2023, 2, e0000100. [Google Scholar] [CrossRef]

- Chew, Z.T.; Hoy, Z.X.; Woon, K.S.; Liew, P.Y. Integrating Greenhouse Gas Reduction and Waste Policy Targets to Identify Optimal Waste Treatment Configurations via Carbon Emission Pinch Analysis. Process Saf. Environ. Prot. 2022, 160, 661–675. [Google Scholar] [CrossRef]

- Leelah, S.; Mudhoo, A. Greenhouse Gas Emission Reductions from Solid Waste Management: Prognosis of Related Issues. In Green Energy and Technology; Springer: Cham, Switzerland, 2018; pp. 347–366. ISBN 978-3-319-63612-2. [Google Scholar]

- Alhanaqtah, V. Economic Instruments to Fund Solid Waste Management Services: Analysis and Recommendations for Jordan. J. Econ. Sustain. Dev. 2020, 10, 144–153. [Google Scholar] [CrossRef]

- Xu, J.; Huang, Y.; Shi, Y.; Li, R. Reverse Supply Chain Management Approach for Municipal Solid Waste with Waste Sorting Subsidy Policy. Socioecon. Plann. Sci. 2022, 81, 101180. [Google Scholar] [CrossRef]

- Awino, F.B.; Apitz, S.E. Solid Waste Management in the Context of the Waste Hierarchy and Circular Economy Frameworks: An International Critical Review. Integr. Environ. Assess. Manag. 2024, 20, 9–35. [Google Scholar] [CrossRef]

- Kuldeep; Saini, S.; Singh, P.; Singh, R. Integrated Online Framework for Waste Management. In Proceedings of the 2019 International Conference on Innovative Sustainable Computational Technologies, CISCT 2019, Dehradun, India, 11–12 October 2019. [Google Scholar]

| Strategy | Description | Benefits | Shortcomings | References |

|---|---|---|---|---|

| Waste-to-Energy (WtE) | Conversion of waste materials into energy. | Reduces landfill use, generates energy. | High initial costs, technological needs. | [42,43] |

| Recycling and Composting | Processing waste to recover materials or decompose organics. | Reduces demand for raw materials, lowers emissions. | Requires segregation, public participation. | [44] |

| Anaerobic Digestion | Breakdown of organic waste in the absence of oxygen. | Produces biogas, can be used for energy. | Needs controlled conditions, infrastructure. | [24] |

| Landfill Gas Capture | Collection of methane from landfills. | Reduces GHG emissions, can be used as fuel. | Requires advanced systems, monitoring. | [45] |

| Regulatory Reforms | Updating laws and policies to support SWM and decarbonization. | Aligns SWM with climate goals, promotes compliance. | Implementation can be complex and slow. | [46] |

| Public Awareness Campaigns | Education and outreach to promote recycling and reduction. | Increases participation, reduces waste. | Continuous effort needed, cultural barriers. | [47] |

| Item | Type of Solid Waste | Sources | Decarbonization Techniques | References |

|---|---|---|---|---|

| 1 | Municipal Solid Waste (MSW) | Households, offices, restaurants | Recycling, Waste-to-Energy Incineration, Composting | [51] |

| 2 | Industrial Waste | Industrial processes, manufacturing activities | Material Recovery, Waste-to-Energy Processes, Recycling | [52,53] |

| 3 | Commercial Waste | Commercial establishments like offices, shops, and restaurants | Recycling, Composting, Waste-to-Energy Incineration | [54] |

| 4 | Construction and Demolition Debris (C&D) | Construction, renovation, demolition activities | Recycling, Reuse in Construction, Landfilling | [55] |

| 5 | Hazardous Waste | Industries, hospitals, households (e.g., batteries, chemicals, etc.) | Secure Landfills, Chemical Treatment, Incineration | [56] |

| 6 | Electronic Waste (E-waste) | Discarded electronic devices and equipment | Recycling, Material Recovery | [34] |

| 7 | Agricultural Waste | Farming activities | Bioenergy Production, Composting | [57] |

| 8 | Biomedical Waste | Hospitals, healthcare facilities | Incineration, Autoclaving, Chemical Treatment | [58] |

| 9 | Radioactive Waste | Nuclear reactors, medical applications | Secure Storage, Containment | [59] |

| 10 | Chemical Waste | Chemical manufacturing, industrial processes | Chemical Treatment, Secure Disposal | [56] |

| 11 | Plastic Waste | Households, commercial, industrial sources | Recycling, Conversion to Fuel | [60] |

| 12 | Organic Waste | Households, food processing industries | Composting, Anaerobic Digestion | [61] |

| 13 | Inorganic Waste | Various industrial and commercial processes | Recycling, Material Recovery Facilities | [62] |

| 14 | Municipal Services Waste | Street cleaning, parks, beaches | Recycling, Composting, Landfilling | [49] |

| 15 | Treatment Plants and Sites Waste | Refineries, power plants, processing plants | Treatment and reuse of by-products, Secure disposal | [63] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chiang, P.F.; Zhang, T.; Claire, M.J.; Maurice, N.J.; Ahmed, J.; Giwa, A.S. Assessment of Solid Waste Management and Decarbonization Strategies. Processes 2024, 12, 1473. https://doi.org/10.3390/pr12071473

Chiang PF, Zhang T, Claire MJ, Maurice NJ, Ahmed J, Giwa AS. Assessment of Solid Waste Management and Decarbonization Strategies. Processes. 2024; 12(7):1473. https://doi.org/10.3390/pr12071473

Chicago/Turabian StyleChiang, Ping Fa, Tengling Zhang, Mugabekazi Joie Claire, Ndungutse Jean Maurice, Jabran Ahmed, and Abdulmoseen Segun Giwa. 2024. "Assessment of Solid Waste Management and Decarbonization Strategies" Processes 12, no. 7: 1473. https://doi.org/10.3390/pr12071473