Research on an Adaptive Active Suspension Leveling Control Method for Special Vehicles

Abstract

1. Introduction

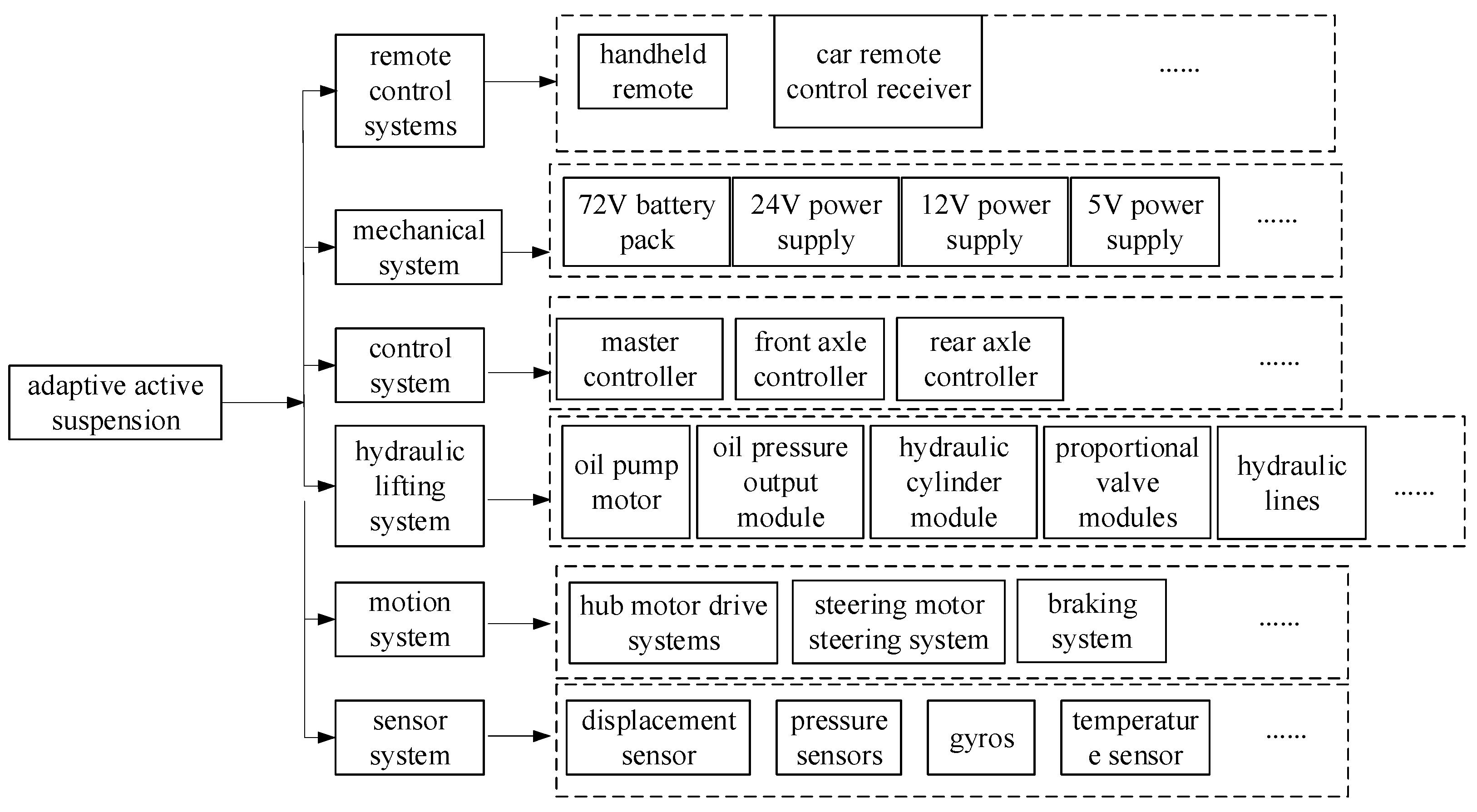

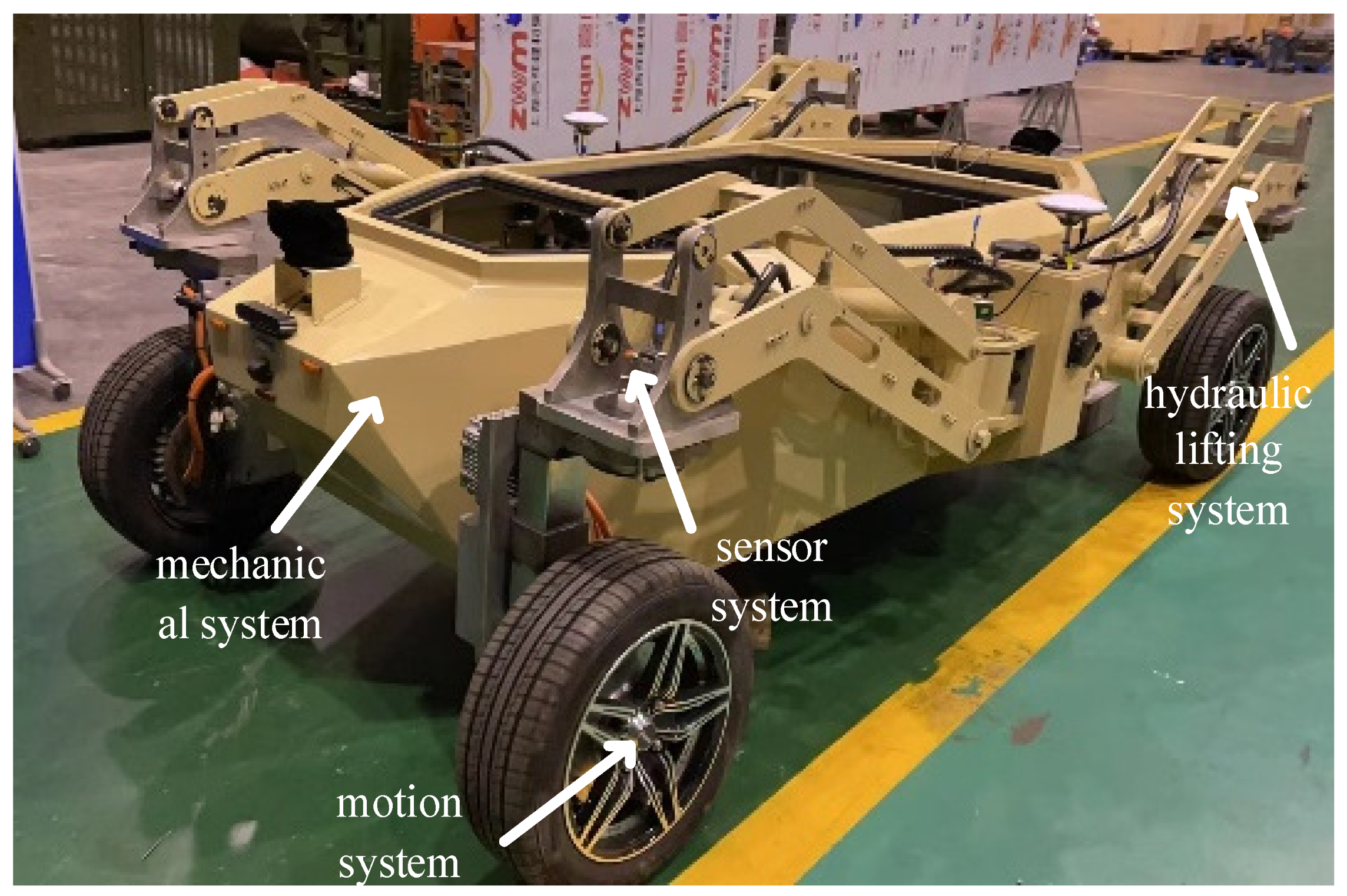

2. Adaptive Active Suspension System Components

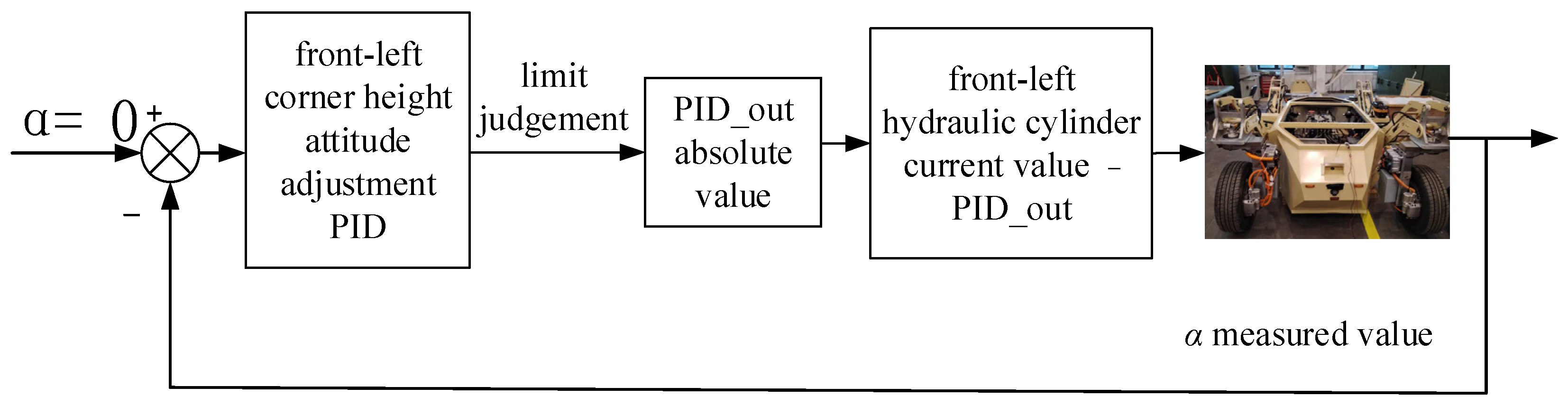

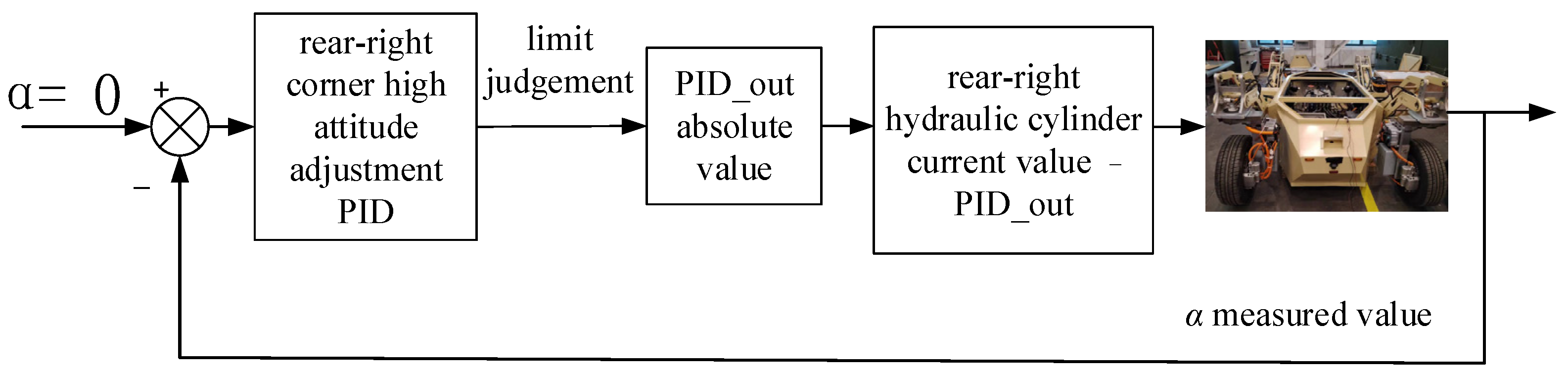

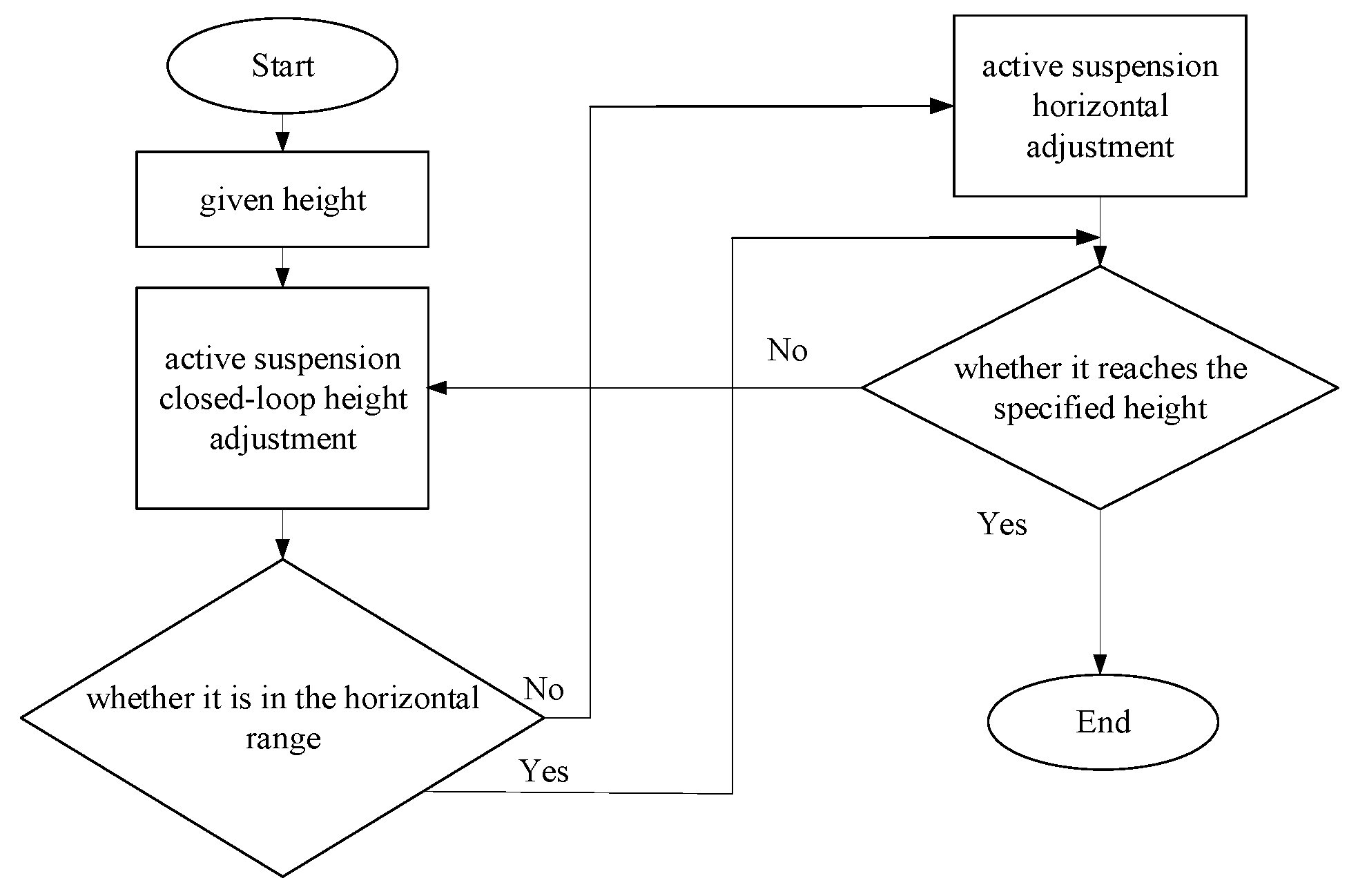

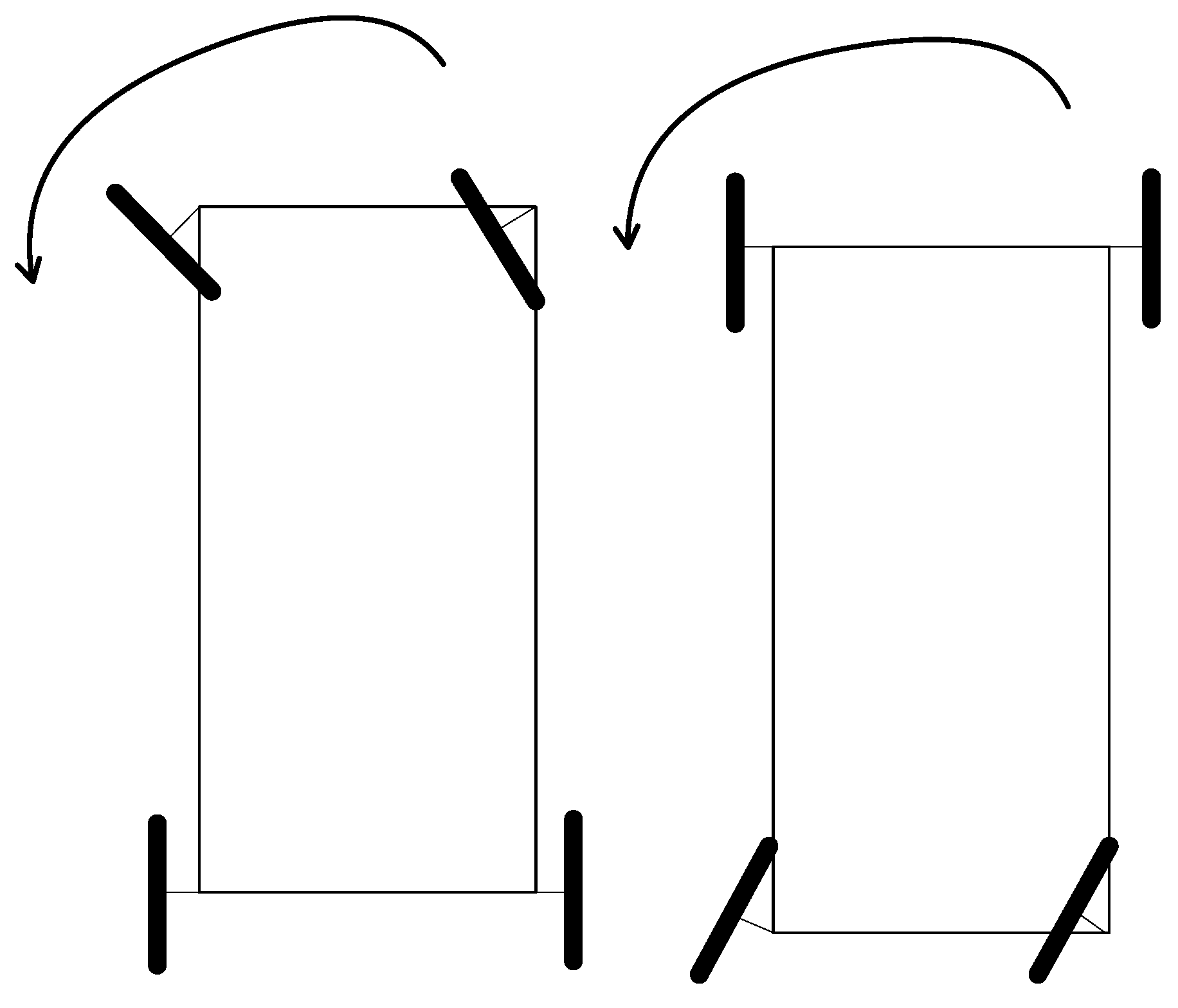

3. Adaptive Active Suspension Leveling

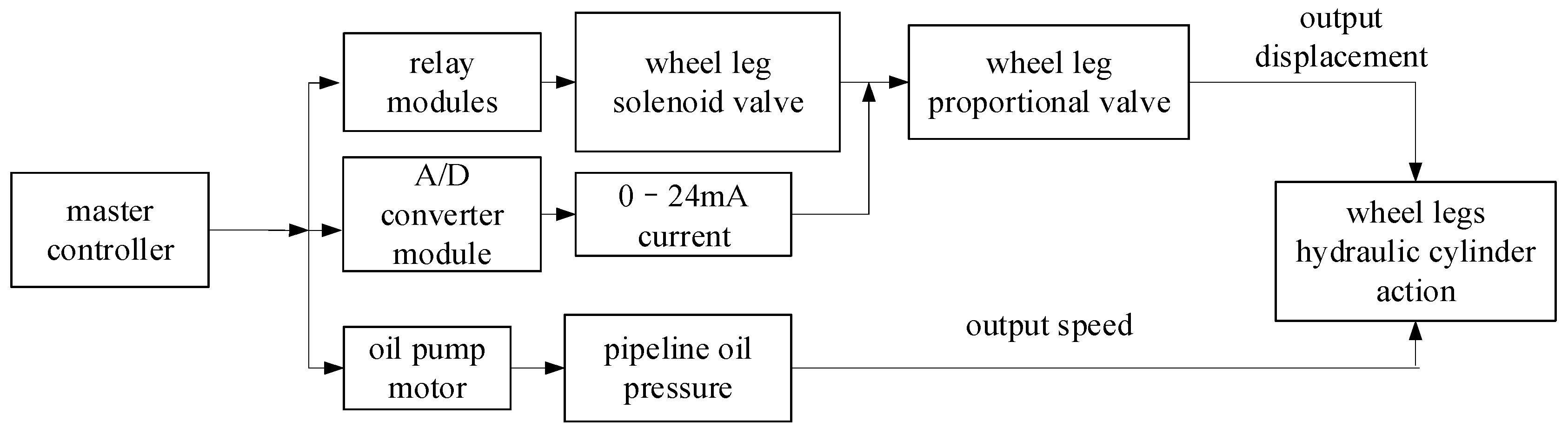

3.1. Wheel-Leg Hydraulic Cylinder Principle of Action

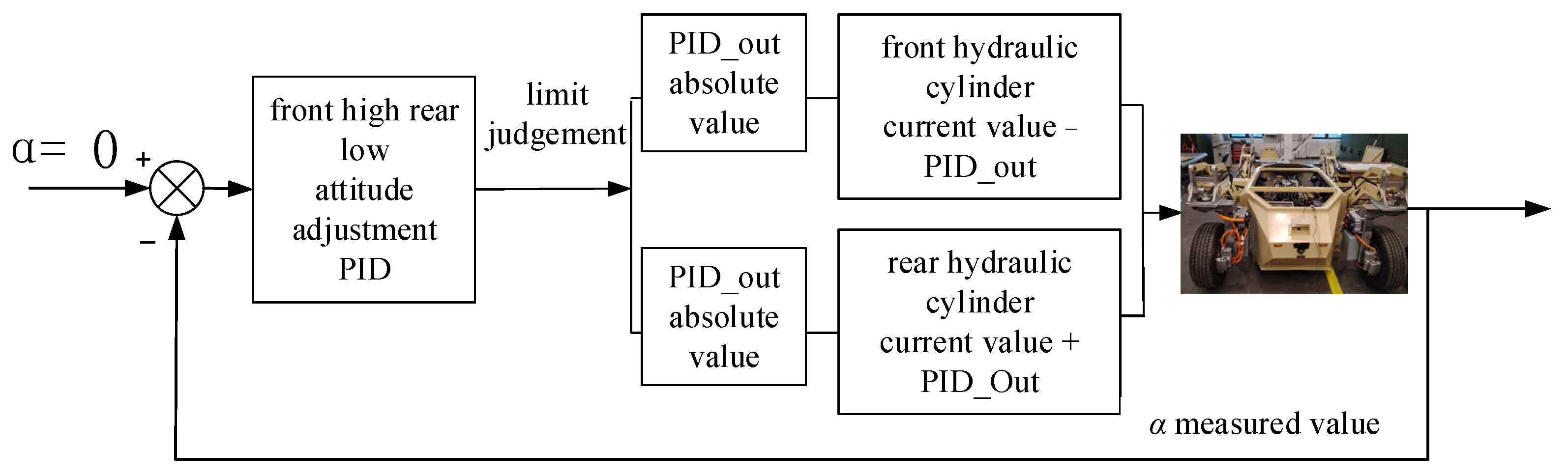

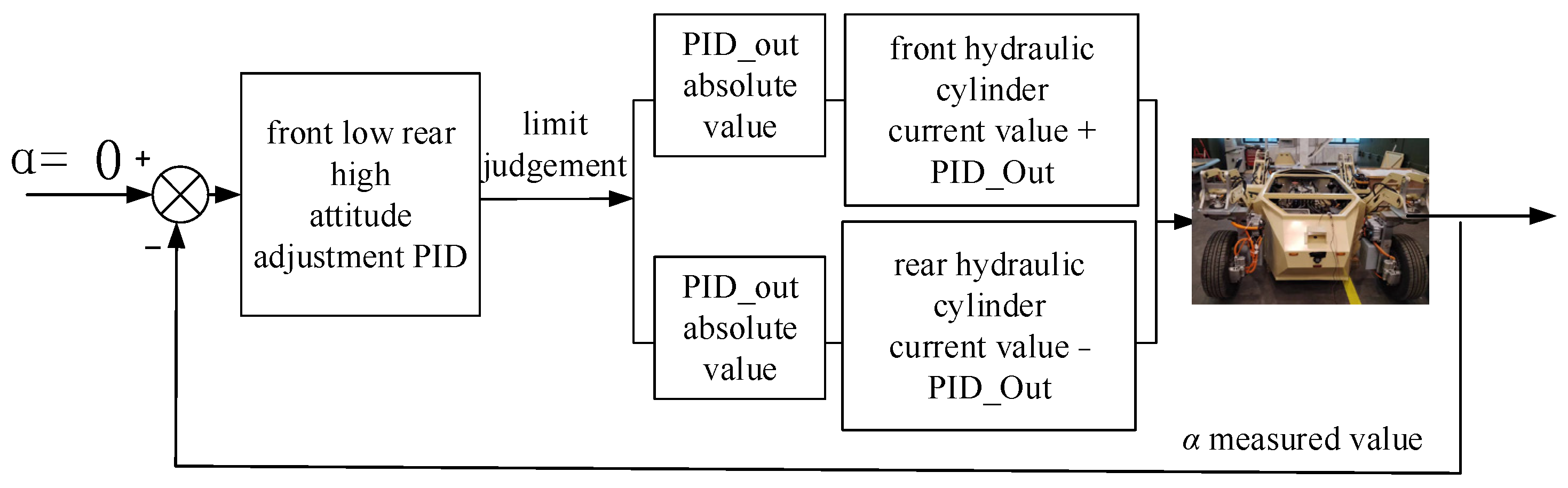

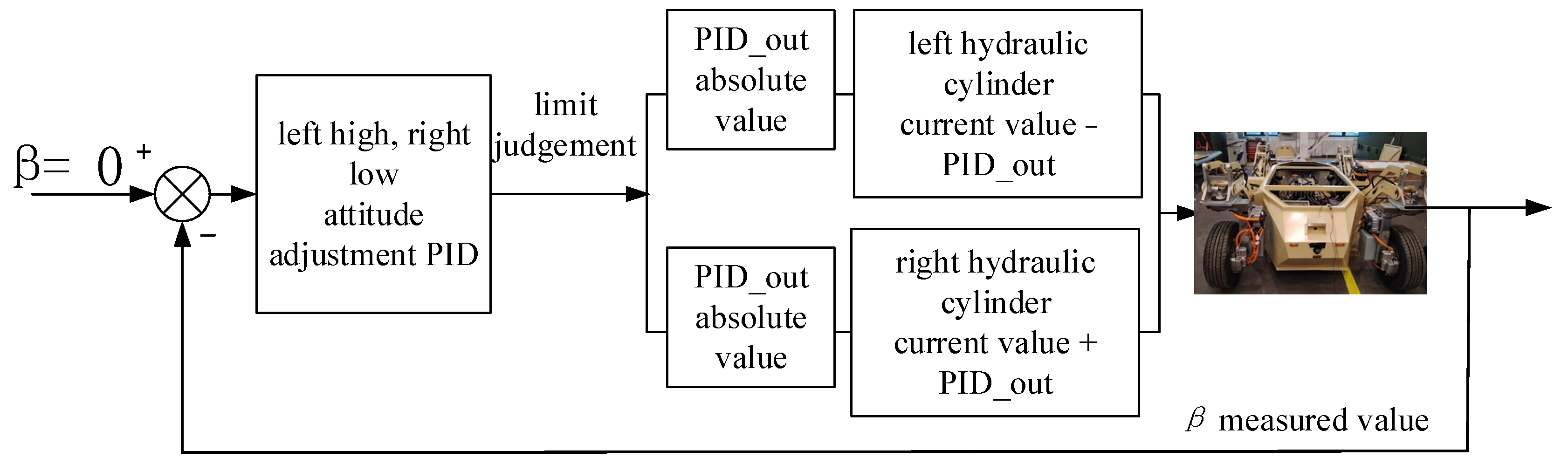

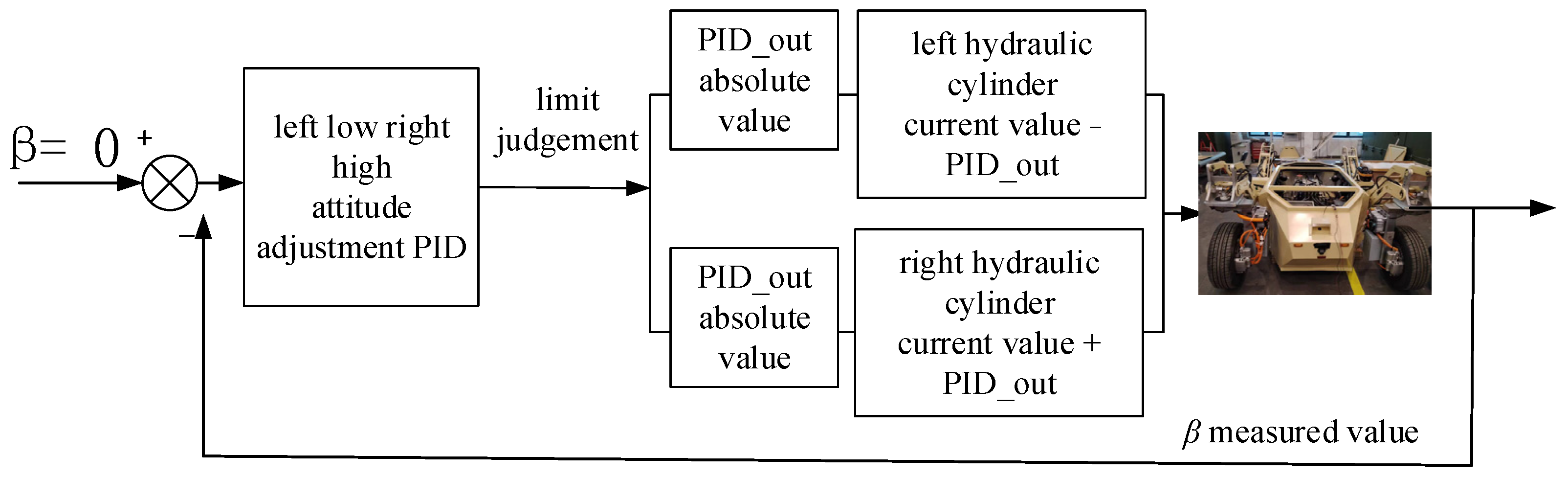

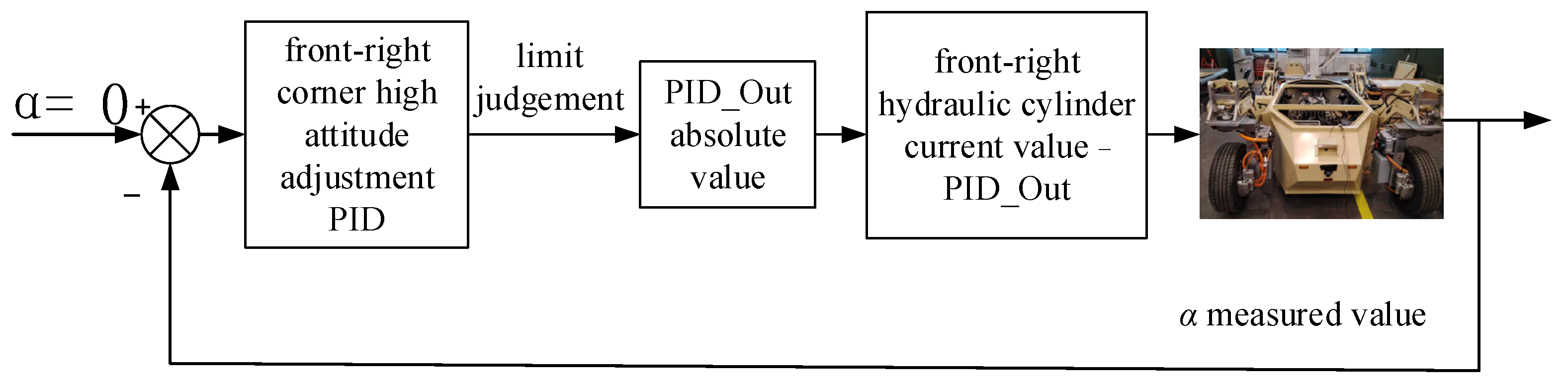

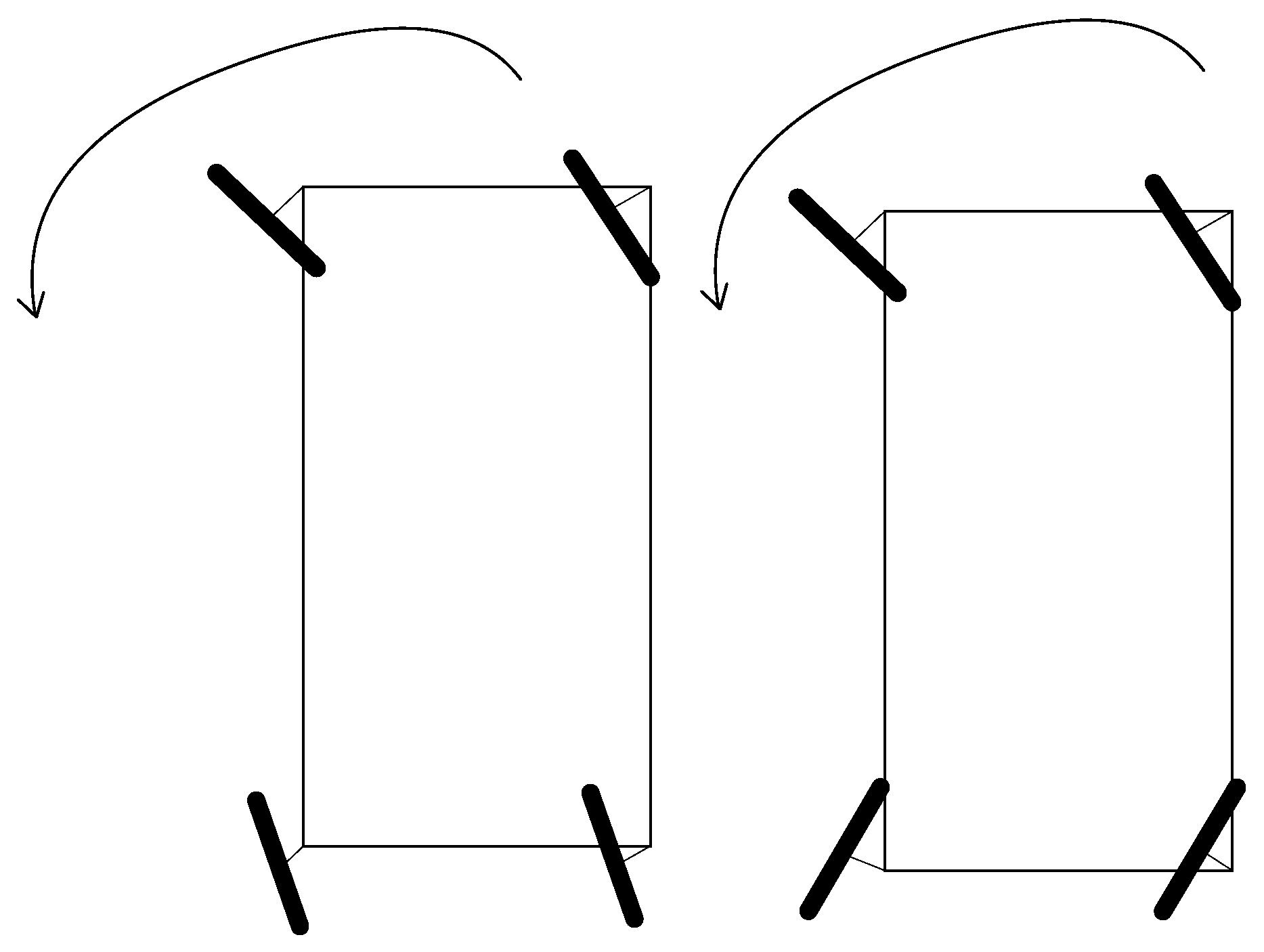

3.2. Adaptive Active Suspension Leveling

4. Adaptive Active Suspension Height Adjustment

5. Kalman Filter

6. Active Suspension Ackermann Steering

6.1. Front-Wheel Ackermann Steering Corner Distribution

6.2. Four-Wheel Reverse-Turn Ackermann Corner Distribution

7. Analysis of the Experimental Results

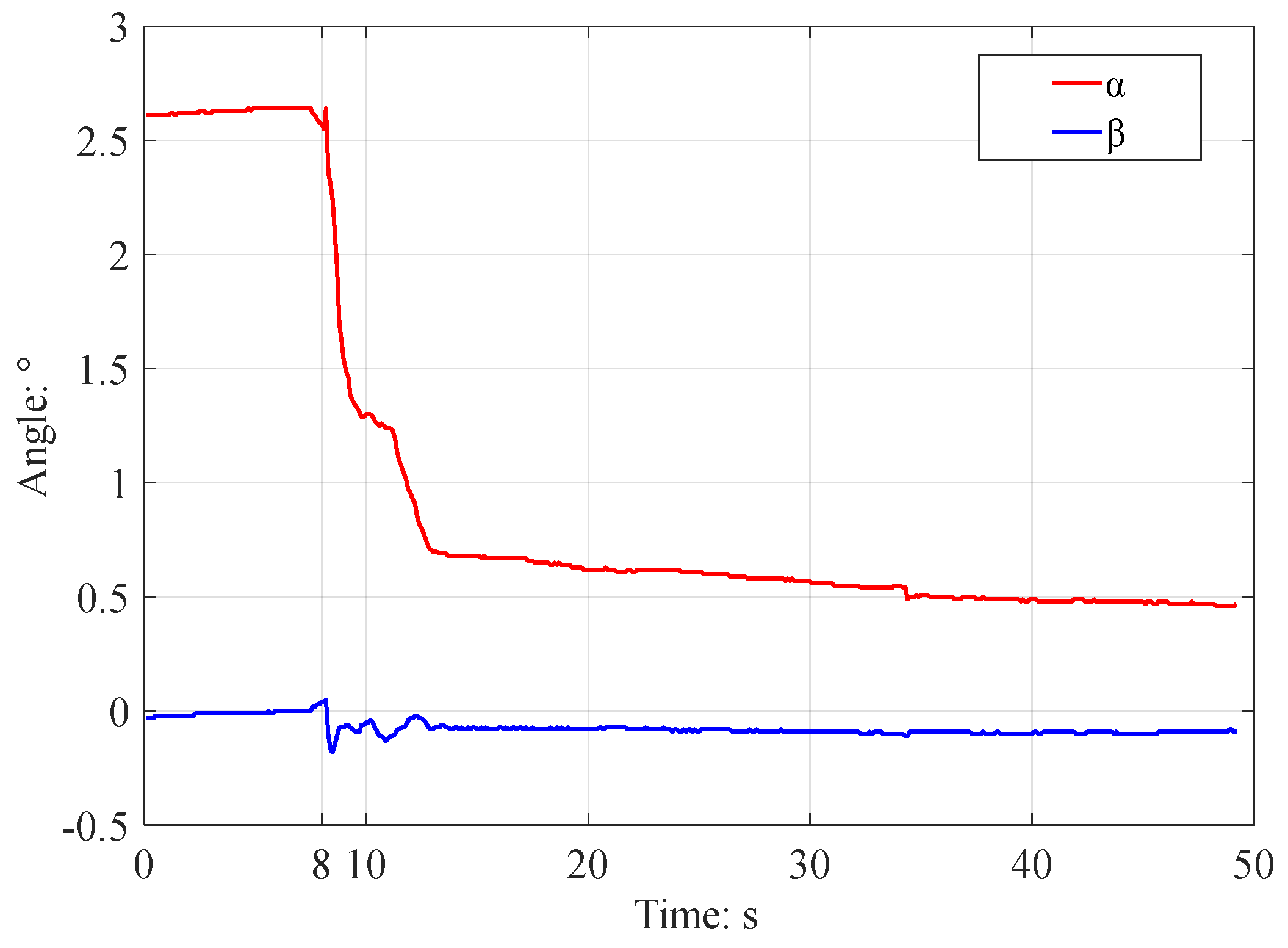

7.1. Analysis of Leveling Results

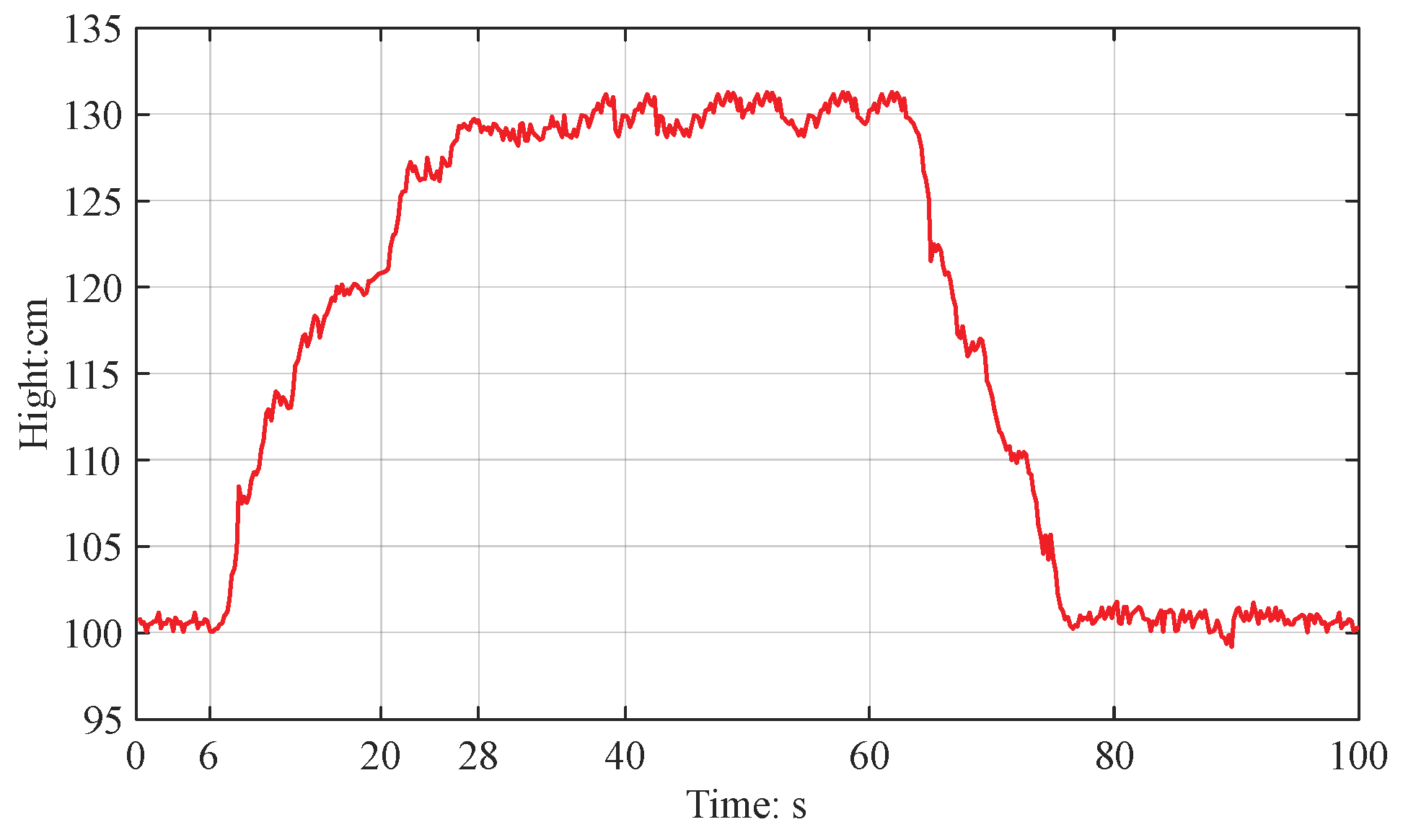

7.2. Analysis of the Upgrading Results

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Fitzsimmons, J.A. A methodology for emergency ambulance deployment. Manag. Sci. 1973, 19, 627–636. [Google Scholar] [CrossRef]

- Kim, D.; Jeong, D.; Seo, Y. Intelligent design for simulation models of weapon systems using a mathematical structure and case-based reasoning. Appl. Sci. 2020, 10, 7642. [Google Scholar] [CrossRef]

- Bélanger, V.; Ruiz, A.; Soriano, P. Recent optimization models and trends in location, relocation, and dispatching of emergency medical vehicles. Eur. J. Oper. Res. 2019, 272, 1–23. [Google Scholar] [CrossRef]

- Li, M.; Imou, K.; Wakabayashi, K.; Yokoyama, S. Review of research on agricultural vehicle autonomous guidance. Int. J. Agric. Biol. Eng. 2009, 2, 1–16. [Google Scholar]

- Liu, Y.; Wu, J.; Tang, J.; Wang, W.; Wang, X. Scheduling optimisation of multi-type special vehicles in an airport. Transp. B Transp. Dyn. 2022, 10, 954–970. [Google Scholar] [CrossRef]

- Wang, Y.; Yu, J.; Yan, B.; Wang, G.; Shan, Z. BSV-PAGS: Blockchain-based special vehicles priority access guarantee scheme. Comput. Commun. 2020, 161, 28–40. [Google Scholar] [CrossRef]

- Liu, H.; Li, S. Speed control for PMSM servo system using predictive functional control and extended state observer. IEEE Trans. Ind. Electron. 2011, 59, 1171–1183. [Google Scholar] [CrossRef]

- Vo, H.H. Sliding mode speed controller design for field oriented controlled PMSM drive of an electric vehicle. J. Adv. Eng. Comput. 2023, 7, 164–173. [Google Scholar] [CrossRef]

- Keshari, R.; Jarariya, S. Performance Analysis of PMSM-Electric Vehicle with Fuzzy Logic Controller. Int. J. Progress. Res. Eng. Manag. Sci. 2023, 3, 562–570. [Google Scholar]

- Jian, L. Research status and development prospect of electric vehicles based on hub motor. In Proceedings of the 2018 China International Conference on Electricity Distribution (CICED), Tianjin, China, 17–19 September 2018. [Google Scholar]

- Shi, Z.; Sun, X.; Cai, Y.; Yang, Z. Robust design optimization of a five-phase PM hub motor for fault-tolerant operation based on Taguchi method. IEEE Trans. Energy Convers. 2020, 35, 2036–2044. [Google Scholar] [CrossRef]

- Msaddek, H.; Mansouri, A.; Brisset, S.; Trabelsi, H. Design and optimization of PMSM with outer rotor for electric vehicle. In Proceedings of the 2015 IEEE 12th International Multi-Conference on Systems, Signals & Devices (SSD15), Mahdia, Tunisia, 16–19 March 2015. [Google Scholar]

- Dai, Y.; Song, L.; Cui, S. Development of PMSM drives for hybrid electric car applications. IEEE Trans. Magn. 2006, 43, 434–437. [Google Scholar] [CrossRef]

- Kim, H.; Son, J.; Lee, J. A high-speed sliding-mode observer for the sensorless speed control of a PMSM. IEEE Trans. Ind. Electron. 2010, 58, 4069–4077. [Google Scholar] [CrossRef]

- Said-Romdhane, M.B.; Skander-Mustapha, S.; Belhassen, R. Adaptive Deadbeat Predic-tive Control for PMSM-based solar-powered electric vehicles with enhanced stator resistance compensation. Sci. Technol. Energy Transit. 2023, 78, 35. [Google Scholar] [CrossRef]

- Khodarahmi, M.; Maihami, V. A review on Kalman filter models. Arch. Comput. Methods Eng. 2023, 30, 727–747. [Google Scholar] [CrossRef]

- Feng, S.; Li, X.; Zhang, S.; Jian, Z.; Duan, H.; Wang, Z. A review: State estimation based on hybrid models of Kalman filter and neural network. Syst. Sci. Control. Eng. 2023, 11, 2173682. [Google Scholar] [CrossRef]

- Bai, G.; Su, Y.; Rahman, M.M.; Wang, Z. Prognostics of Lithium-Ion batteries using knowledge-constrained machine learning and Kalman filtering. Reliab. Eng. Syst. Saf. 2023, 231, 108944. [Google Scholar] [CrossRef]

- Naya, M.Á.; Sanjurjo, E.; Rodríguez, A.J.; Cuadrado, J. Kalman filters based on multibody models: Linking simulation and real world. A comprehensive review. Multibody Syst. Dyn. 2023, 58, 479–521. [Google Scholar] [CrossRef]

- Feng, Z.; Wang, G.; Peng, B.; He, J.; Zhang, K. Distributed minimum error entropy Kalman filter. Inf. Fusion 2023, 91, 556–565. [Google Scholar] [CrossRef]

- Valade, A.; Acco, P.; Grabolosa, P.; Fourniols, J.-Y. A study about Kalman filters applied to embedded sensors. Sensors 2017, 17, 2810. [Google Scholar] [CrossRef] [PubMed]

- Budak, S.; Tekïn, M.H.; Durdu, A.; Sungur, C. Kalman Filter and PID Application on Underwater Vehicles. Turk. J. Forecast. 2022, 6, 27–33. [Google Scholar] [CrossRef]

| Stance | Gyro Feedback Angle |

|---|---|

| High in front and low at the back (attitude 1) | α > 0, β = 0 |

| Front low/back high (attitude 2) | α < 0, β = 0 |

| Left high/right low (attitude 3) | α = 0, β > 0 |

| Left low/right high (attitude 4) | α = 0, β < 0 |

| Front right angle high (attitude 5) | α > 0, β < 0 |

| Front left angle high (attitude 6) | α > 0, β > 0 |

| Back right angle high (attitude 7) | α < 0, β < 0 |

| Back left angle high (attitude 8) | α < 0, β > 0 |

| Horizontal (attitude 9) | α = 0, β = 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, P.; Yue, H.; Zhang, P.; Gu, J.; Yu, H. Research on an Adaptive Active Suspension Leveling Control Method for Special Vehicles. Processes 2024, 12, 1483. https://doi.org/10.3390/pr12071483

Zhang P, Yue H, Zhang P, Gu J, Yu H. Research on an Adaptive Active Suspension Leveling Control Method for Special Vehicles. Processes. 2024; 12(7):1483. https://doi.org/10.3390/pr12071483

Chicago/Turabian StyleZhang, Pan, Huijun Yue, Pengchao Zhang, Jie Gu, and Hongjun Yu. 2024. "Research on an Adaptive Active Suspension Leveling Control Method for Special Vehicles" Processes 12, no. 7: 1483. https://doi.org/10.3390/pr12071483

APA StyleZhang, P., Yue, H., Zhang, P., Gu, J., & Yu, H. (2024). Research on an Adaptive Active Suspension Leveling Control Method for Special Vehicles. Processes, 12(7), 1483. https://doi.org/10.3390/pr12071483