Double-Closed-Loop Model Predictive Control Based on a Linear Induction Motor

Abstract

1. Introduction

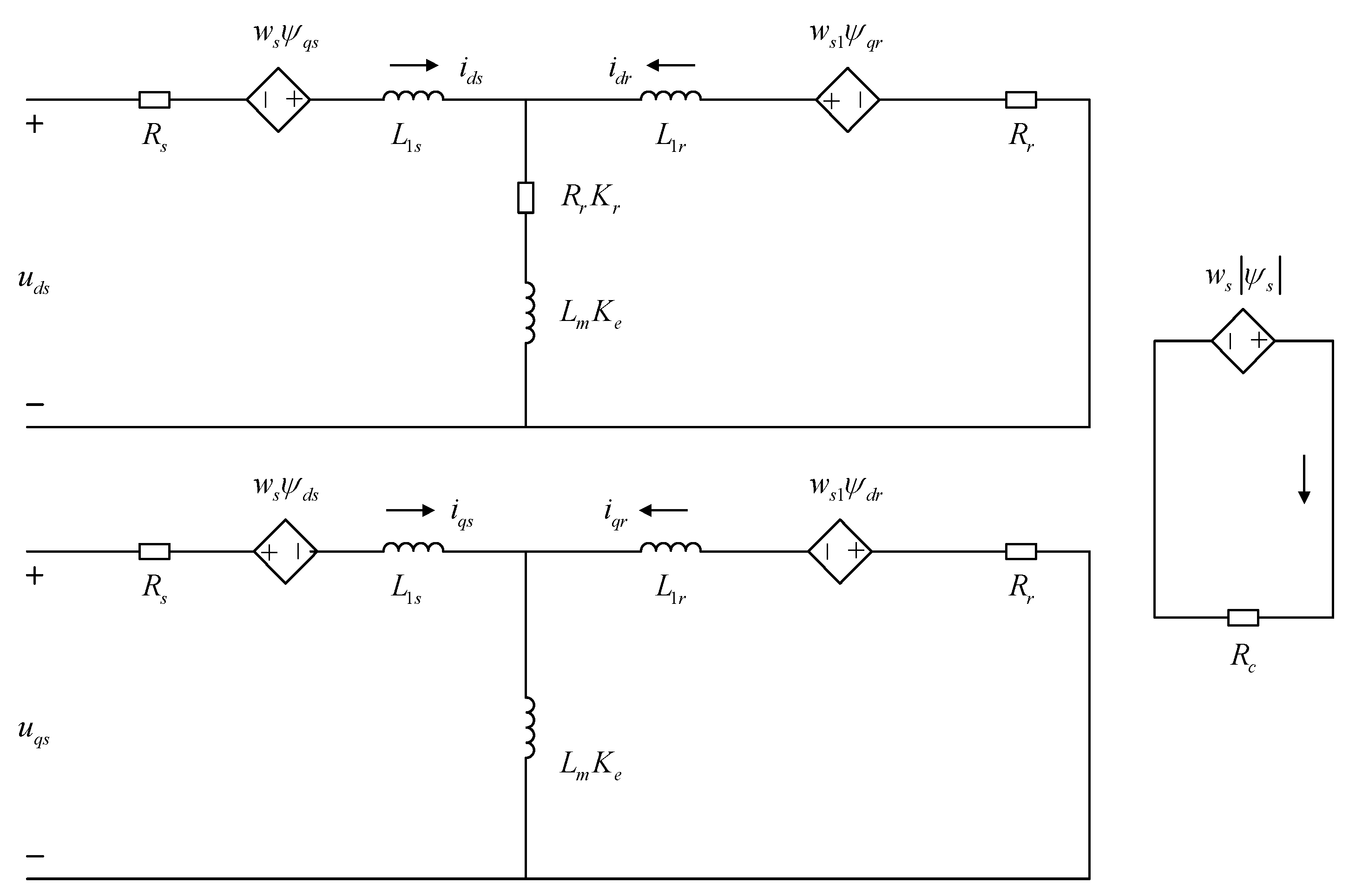

2. Mathematical Modeling of Linear Induction Motors

3. Dual-Closed-Loop Model Predictive Control

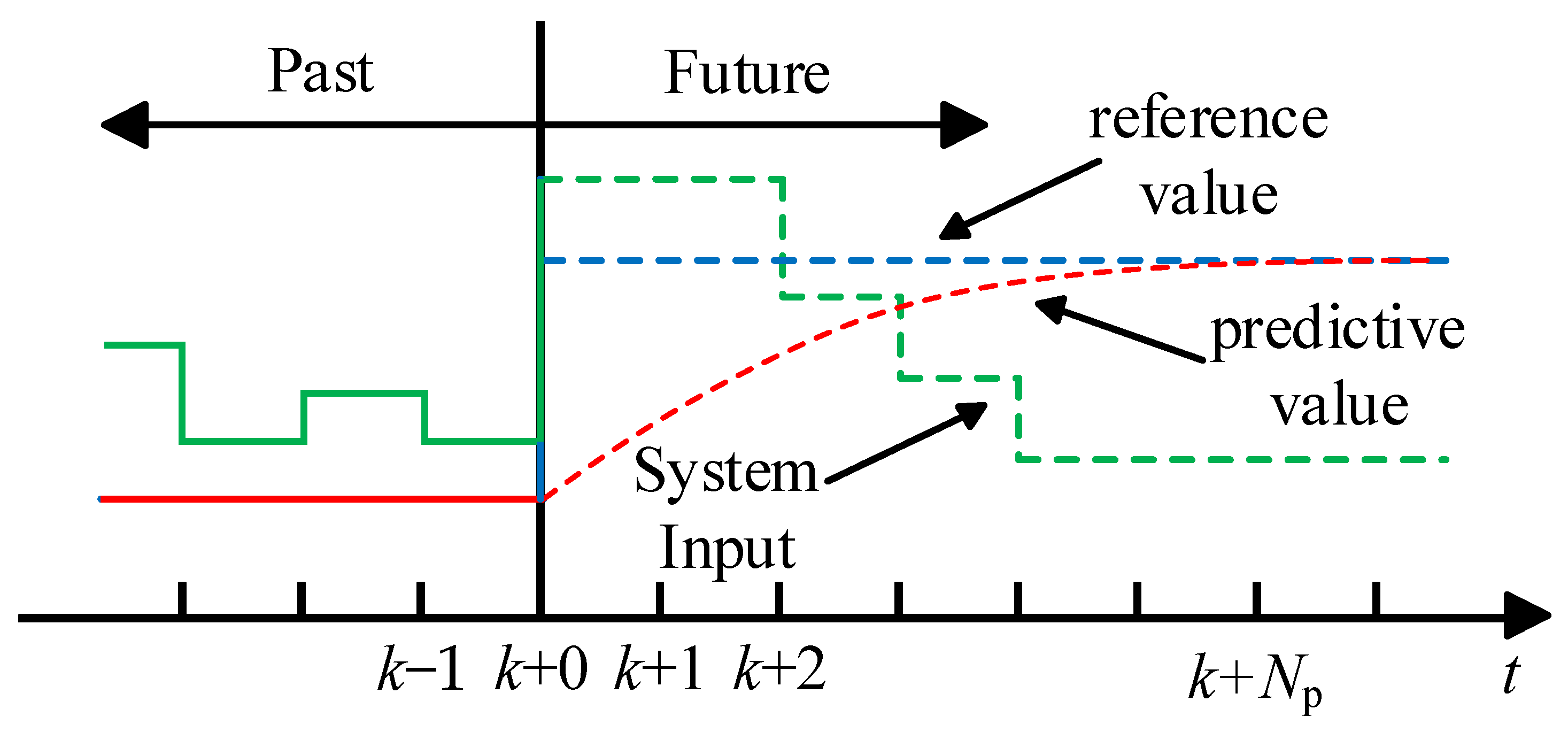

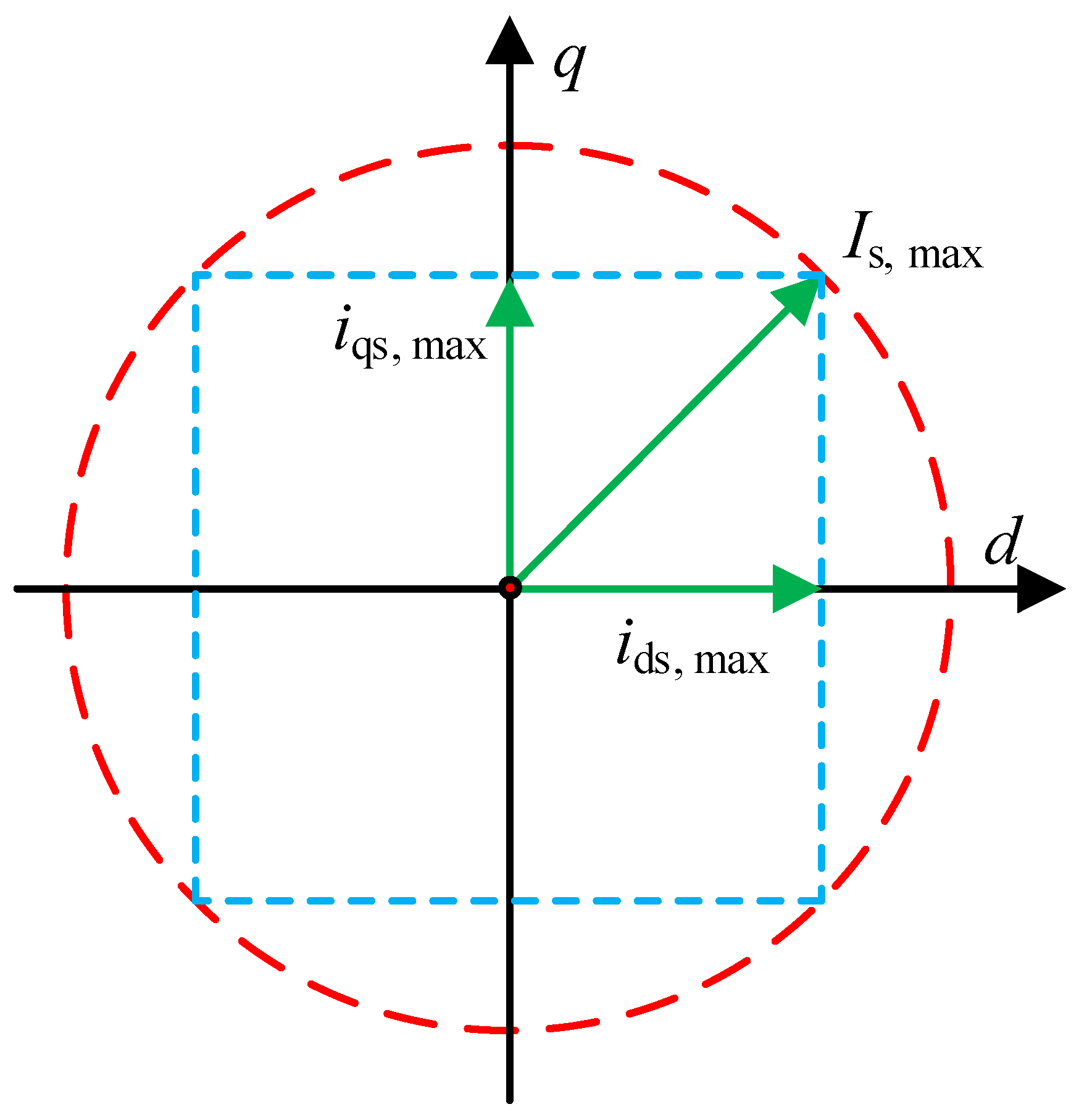

3.1. Model Predictive Current Control

- (1)

- Prediction model

- (2)

- Rolling optimization

- (3)

- Feedback correction

3.2. Model Predictive Speed Control

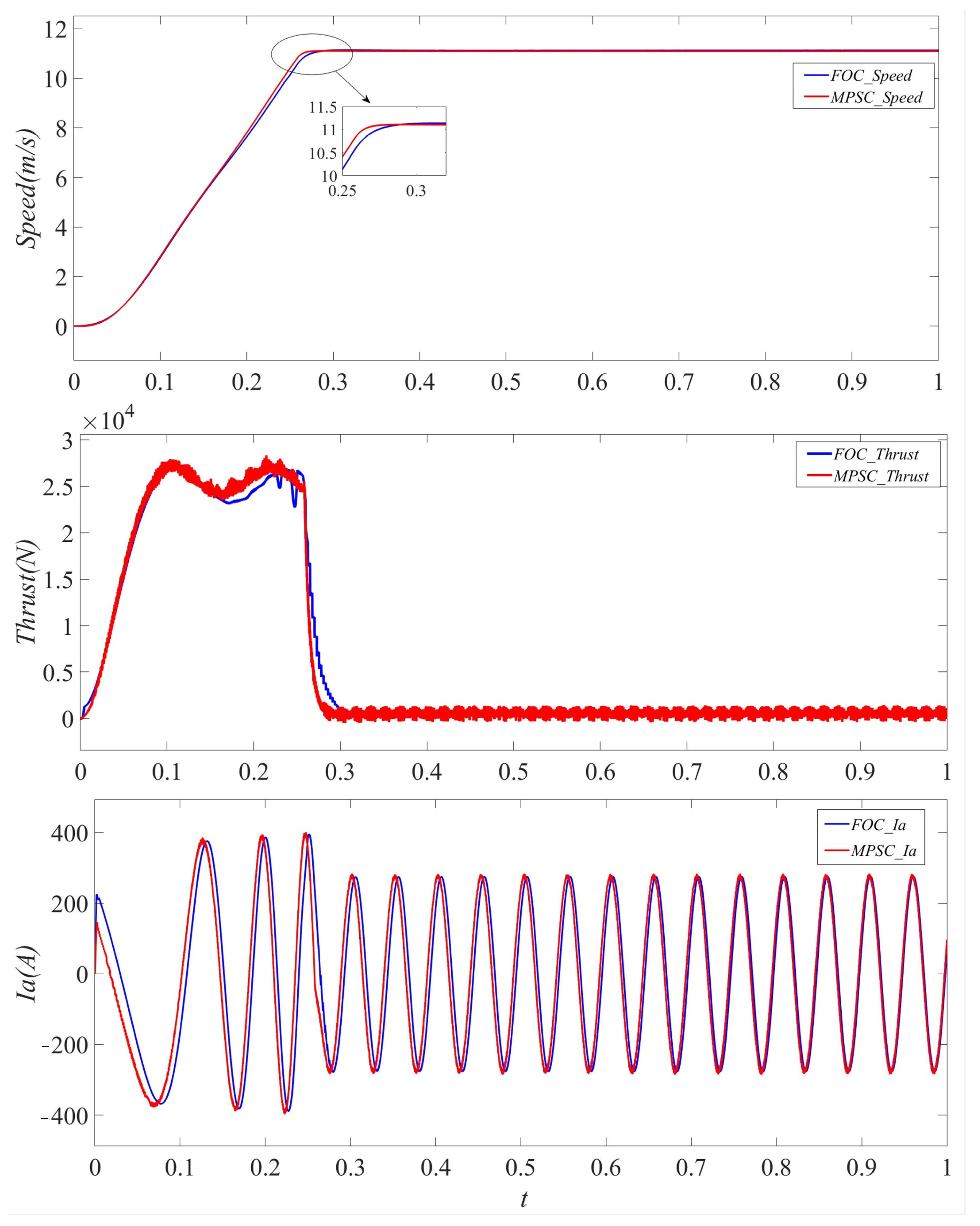

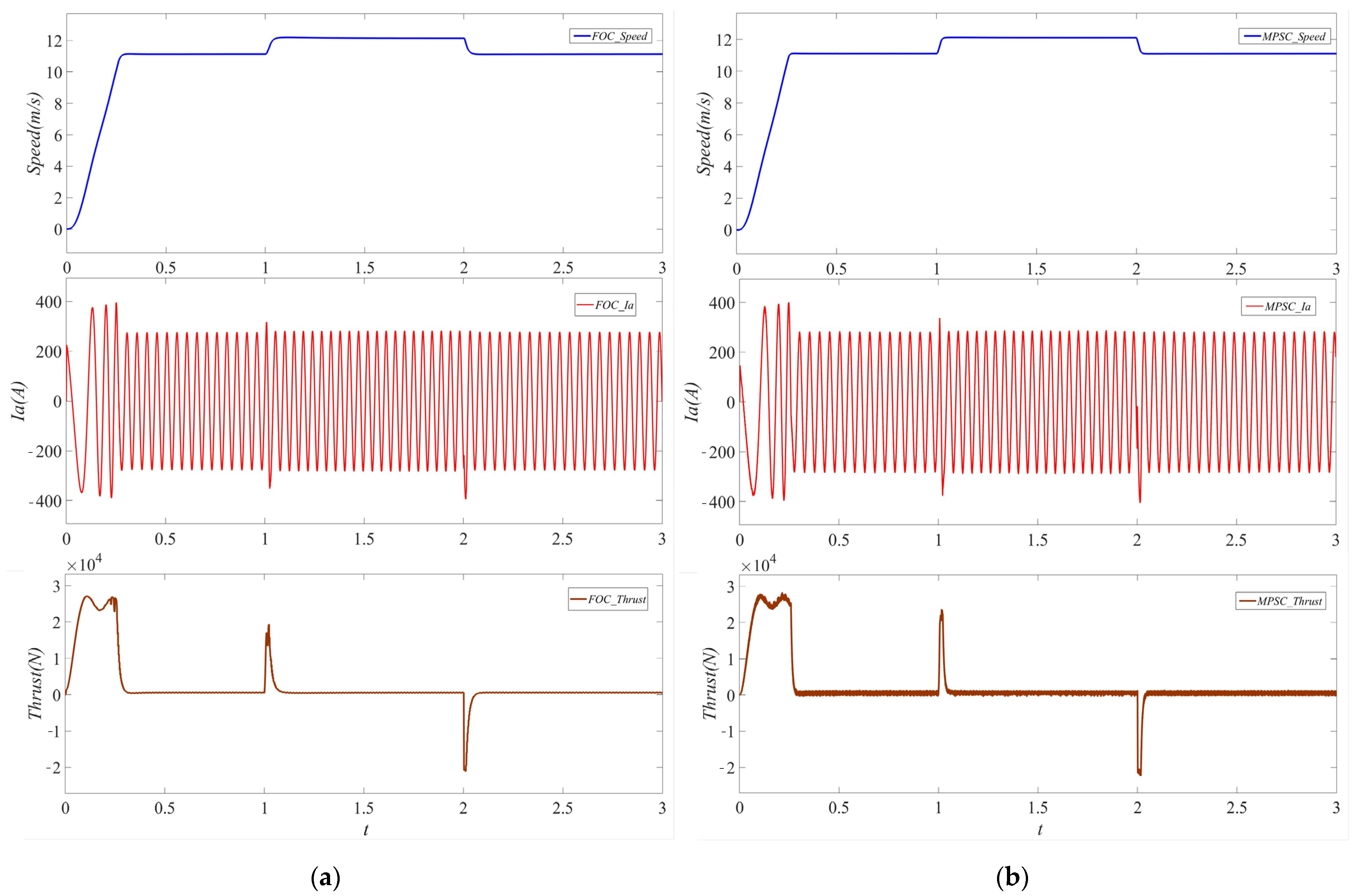

4. Simulation and Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Parameters | Values | Unit |

|---|---|---|

| Pole-pair number | 6 | - |

| Pole pitch | 0.2808 | m |

| Rated flux | 6 | Wb |

| Primary resistance | 0.138 | Ω |

| Secondary resistance | 46.4 | Ω |

| Iron loss resistance | 167 | Ω |

| Magnetizing inductance | 0.026477 | H |

| Primary leakage inductance | 0.006688 | H |

| Secondary leakage inductance | 0.002091 | H |

| Secondary length | 2.476 | m |

References

- Rodriguez, J.; Garcia, C.; Mora, A.; Flores-Bahamonde, F.; Acuna, P.; Novak, M.; Zhang, Y.C.; Tarisciotti, L.; Davari, A.; Zhang, Z.B.; et al. Latest Advances of Model Predictive Control in Electrical Drives—Part I: Basic Concepts and Advanced Strategies. IEEE Trans. Power Electron. 2022, 37, 3927–3942. [Google Scholar] [CrossRef]

- Rodriguez, J.; Garcia, C.; Mora, A.; Davari, S.A.; Rodas, J.; Valencia, D.F.; Elmorshedy, M.; Wang, F.X.; Zuo, K.K.; Tarisciotti, L.; et al. Latest Advances of Model Predictive Control in Electrical Drives—Part II: Applications and Benchmarking With Classical Control Methods. IEEE Trans. Power Electron. 2022, 37, 5047–5061. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, H. Model-Predictive Flux Control of Induction Motor Drives With Switching Instant Optimization. IEEE Trans. Energy Convers. 2015, 30, 1113–1122. [Google Scholar] [CrossRef]

- Vazquez, S.; Rodriguez, J.; Rivera, M.; Franquelo, L.G. Model Predictive Control for Power Converters and Drives: Advances and Trends. IEEE Trans. Ind. Electron. 2017, 64, 935–947. [Google Scholar] [CrossRef]

- Holtz, J. Advanced PWM and Predictive Control—An Overview. IEEE Trans. Ind. Electron. 2016, 63, 3837–3844. [Google Scholar] [CrossRef]

- Xu, B.; Jiang, Q.; Ji, W.; Ding, S.H. An Improved Three-Vector-Based Model Predictive Current Control Method for Surface-Mounted PMSM Drives. IEEE Trans. Transp. Electrif. 2022, 8, 4418–4430. [Google Scholar] [CrossRef]

- Lai, C.K.; Shyu, K.K. A Novel Motor Drive Design for Incremental Motion System via Sliding-Mode Control Method. IEEE Trans. Ind. Electron. 2005, 52, 499–507. [Google Scholar] [CrossRef]

- Sun, Q.; Cheng, M.; Zhou, O.; Hu, M.Q. Variable-parameter PI control of a new biconvex permanent magnet motor speed control system. Proc. CSEE 2003, 6, 117–122. [Google Scholar]

- Garcia, C.; Rodriguez, J.; Silva, C.; Rojas, C.; Zanchetta, P.; Abu-Rub, H. Full Predictive Cascaded Speed and Current Control of an Induction Machine. IEEE Trans. Energy Convers. 2016, 31, 1059–1067. [Google Scholar] [CrossRef]

- Kakosimos, P.; Abu-Rub, H. Predictive Speed Control With Short Prediction Horizon for Permanent Magnet Synchronous Motor Drives. IEEE Trans. Power Electron. 2018, 33, 2740–2750. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, S.; Liu, W.; Geng, Q.; Zhou, Z. Finite control-set model predictive direct speed control of a PMSM drive based on the Taylor series model. IET Electr. Power Appl. 2021, 15, 1452–1465. [Google Scholar] [CrossRef]

- Zhang, X.; He, Y. Direct Voltage-Selection Based Model Predictive Direct Speed Control for PMSM Drives Without Weighting Factor. IEEE Trans. Power Electron. 2019, 34, 7838–7851. [Google Scholar] [CrossRef]

- Dongwen, W.; Chongjian, L.; Yao, W.; Ningze, T. Model Predictive Current Control Scheme for Permanent Magnet Synchronous Motors. Trans. China Electrotech. Soc. 2014, 29, 73–79. [Google Scholar]

- Qiu, Z.C.; Xiao, J.; Guo, J.L. Wang B.; Chen B.Z. Speed prediction current decoupling control for permanent magnet synchronous motors. J. Electron. Meas. Instrum. 2015, 29, 648–654. [Google Scholar]

| ts(s) | |||||

|---|---|---|---|---|---|

| Constant Speed | Acceleration | Deceleration | Adding Loads | Subtracting Loads | |

| PI | 0.259 | 1.0455 | 2.0375 | 1.3195 | 2.3846 |

| MPSC + MPCC | 0.0254 | 1.0393 | 2.0346 | 1.2998 | 2.3144 |

| ts(s) | ||

|---|---|---|

| Adding Loads | Subtracting Loads | |

| PI | 0.1001 | 0.0837 |

| MPSC + MPCC | 0.057 | 0.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, S.; Zhao, J.; Xiong, Y.; Ran, G.; Yao, X. Double-Closed-Loop Model Predictive Control Based on a Linear Induction Motor. Processes 2024, 12, 1492. https://doi.org/10.3390/pr12071492

Ma S, Zhao J, Xiong Y, Ran G, Yao X. Double-Closed-Loop Model Predictive Control Based on a Linear Induction Motor. Processes. 2024; 12(7):1492. https://doi.org/10.3390/pr12071492

Chicago/Turabian StyleMa, Shuhang, Jinghong Zhao, Yiyong Xiong, Guangpu Ran, and Xing Yao. 2024. "Double-Closed-Loop Model Predictive Control Based on a Linear Induction Motor" Processes 12, no. 7: 1492. https://doi.org/10.3390/pr12071492

APA StyleMa, S., Zhao, J., Xiong, Y., Ran, G., & Yao, X. (2024). Double-Closed-Loop Model Predictive Control Based on a Linear Induction Motor. Processes, 12(7), 1492. https://doi.org/10.3390/pr12071492