Fracture Propagation of Multi-Stage Radial Wellbore Fracturing in Tight Sandstone Reservoir

Abstract

:1. Introduction

2. Model Establishment of Multi-Stage Radial Wellbore Fracturing

- (1)

- The reservoir rock is considered an isotropic material.

- (2)

- Fracture propagation is treated as a quasi-static process.

- (3)

- The radial wellbores are substituted with weakened material.

- (4)

- Fracturing fluid is injected at a constant pressure, permitting its permeation from the boreholes into the rock matrix.

2.1. Governing Equations

2.1.1. Solid Phase

2.1.2. Fluid Phase

2.1.3. Criterion of Fracture Propagation

2.2. Model Parameters

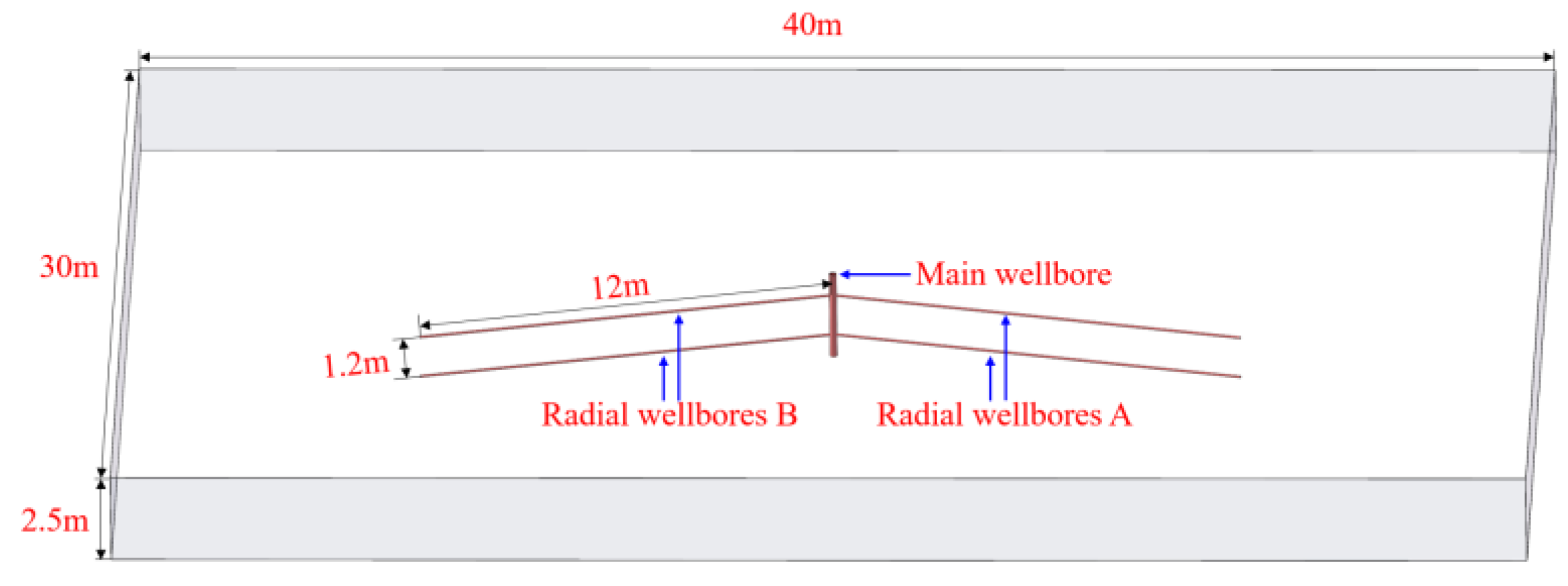

2.2.1. Layout of Radial Wellbores

2.2.2. Geometric Parameters

2.3. Modeling Procedures

- (1)

- Nodes of the preset fracture in radial wellbores B are fixed to prevent further expansion. Stage-1 fracture, initiated from radial wellbores A, propagates driven by fracturing fluid.

- (2)

- Once stage-1 fracture ceases propagating, the coordinates of mesh nodes, pore pressure data, and coordinates of the fracture geometry are extracted.

- (3)

- Nodes of stage-1 fracture are then fixed to prevent further expansion, and nodes of the preset fracture in radial wellbores B are released.

- (4)

- Mesh node coordinates and pore pressure data extracted in step 2 are utilized as the model node coordinates and initial pore pressure for the second stage of MRWF.

- (5)

- Stage-2 fracture propagates driven by fracturing fluid.

2.4. Mesh Sensitivity

2.5. Model Validation

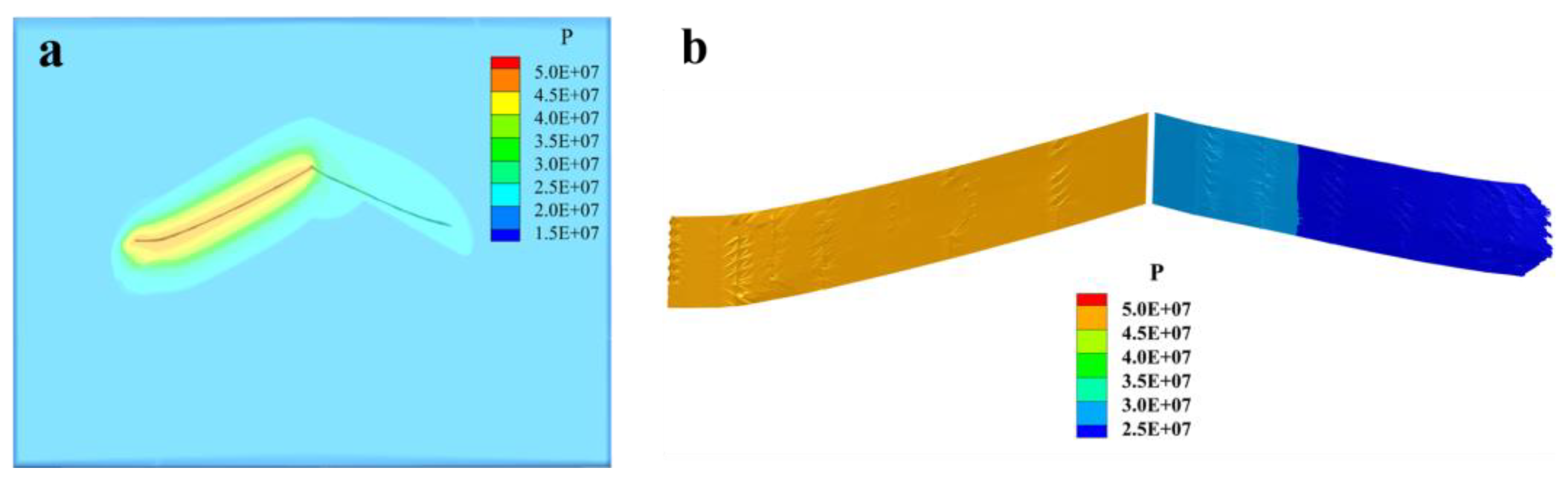

3. Results and Discussion

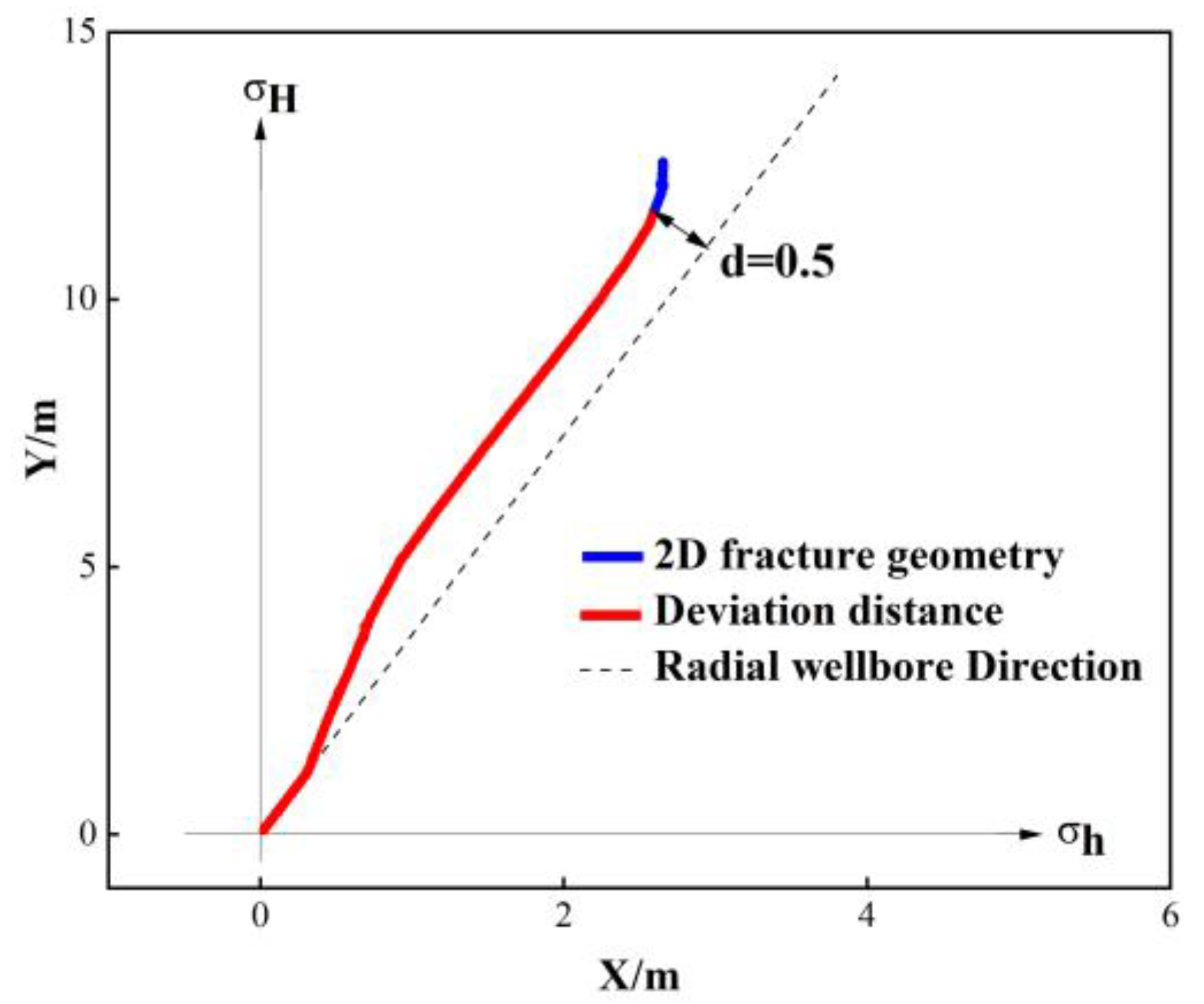

3.1. Deviation Distance

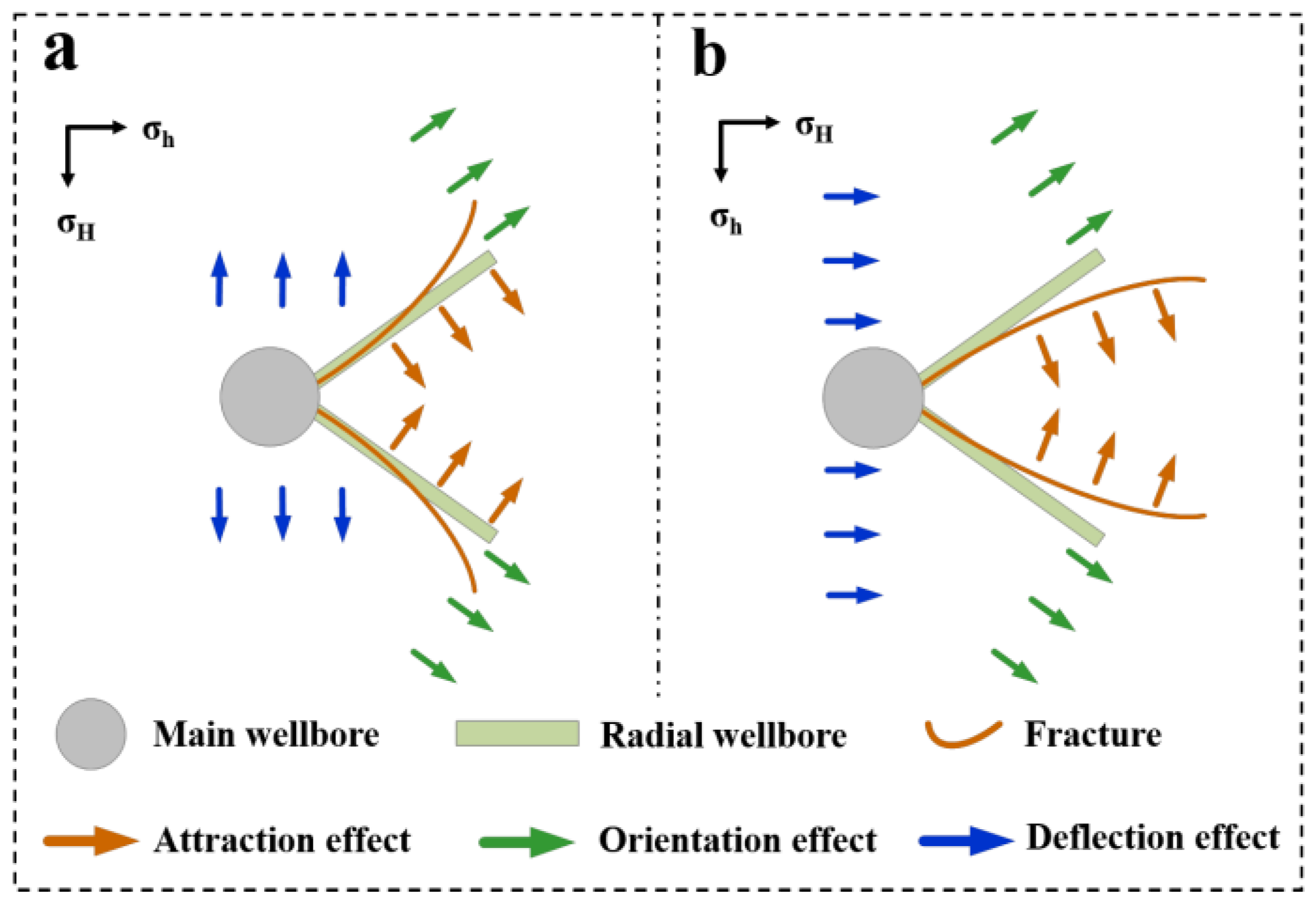

3.2. Attraction Effect and Conceptual Model

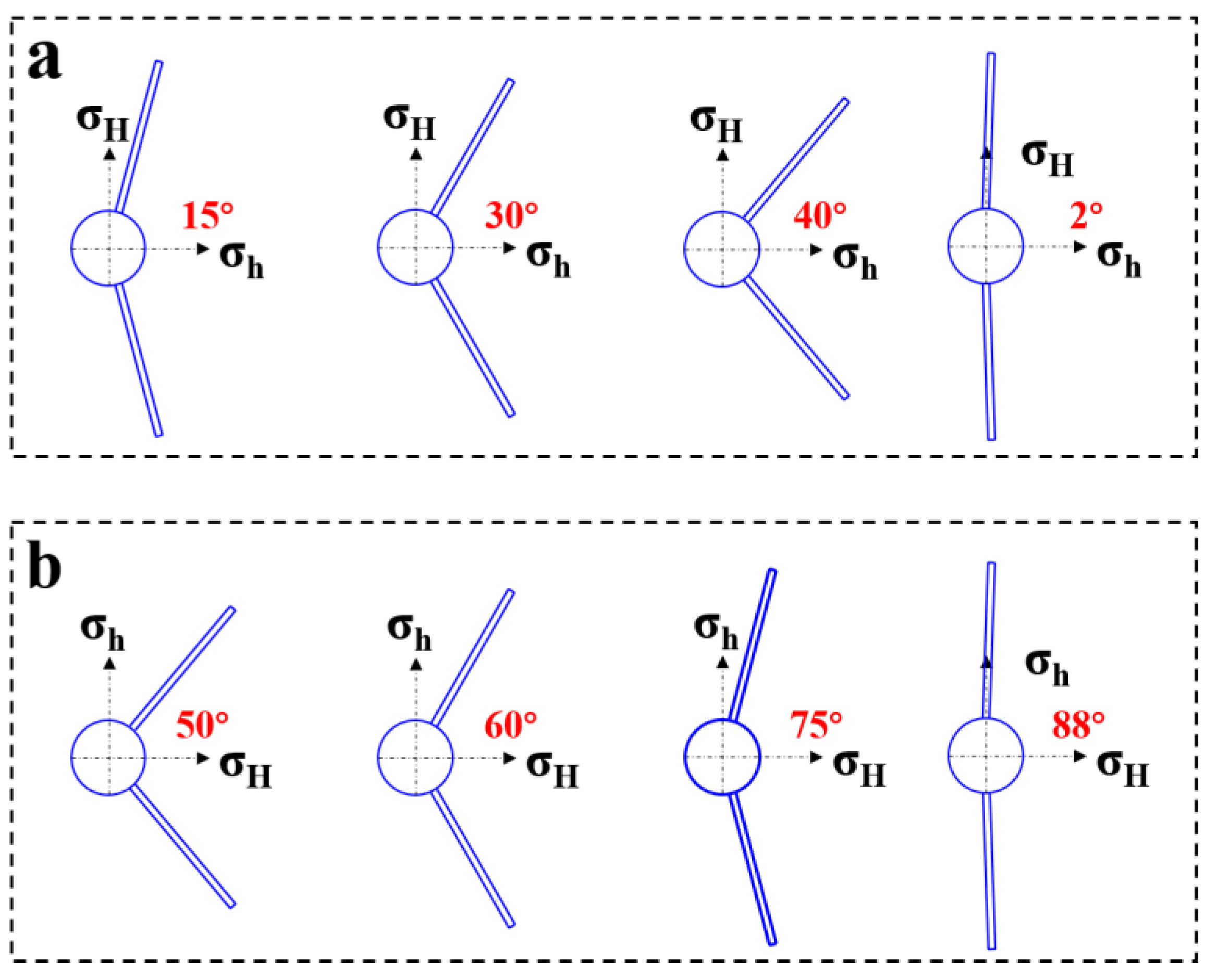

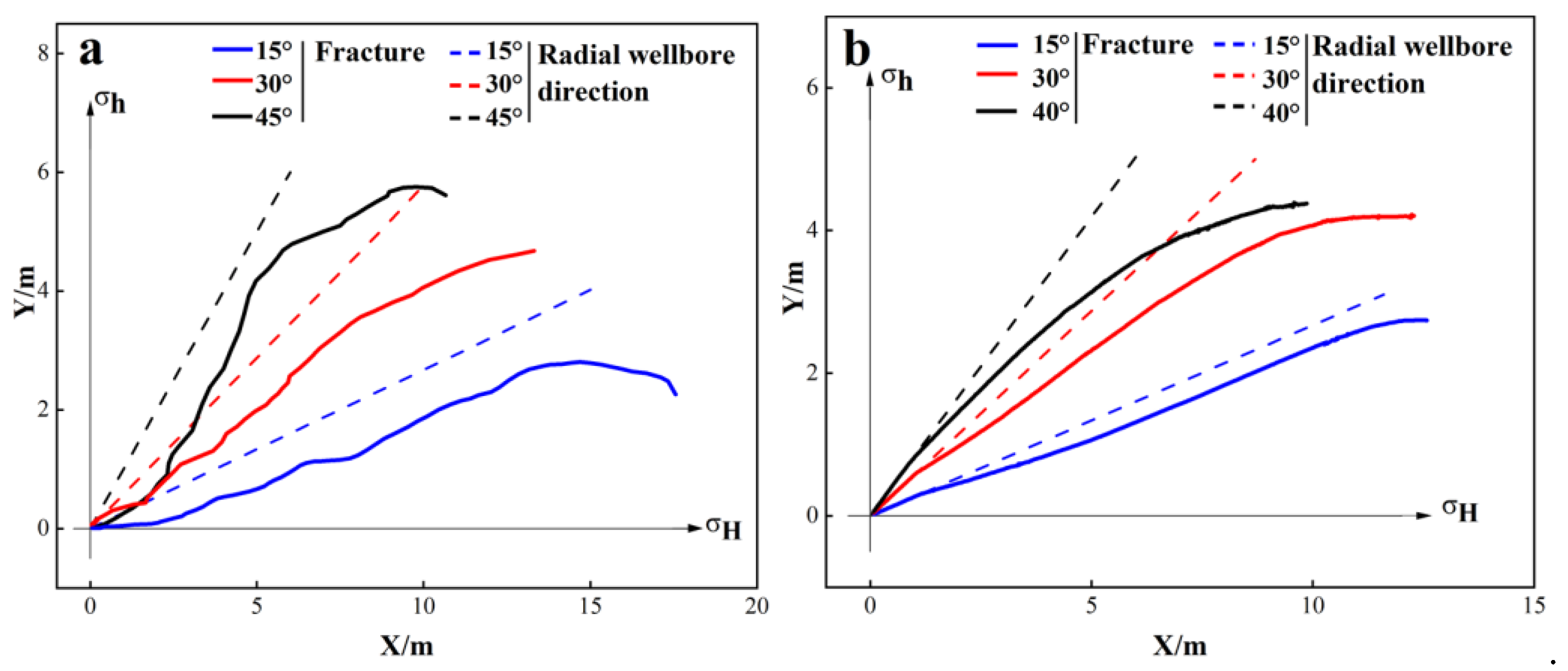

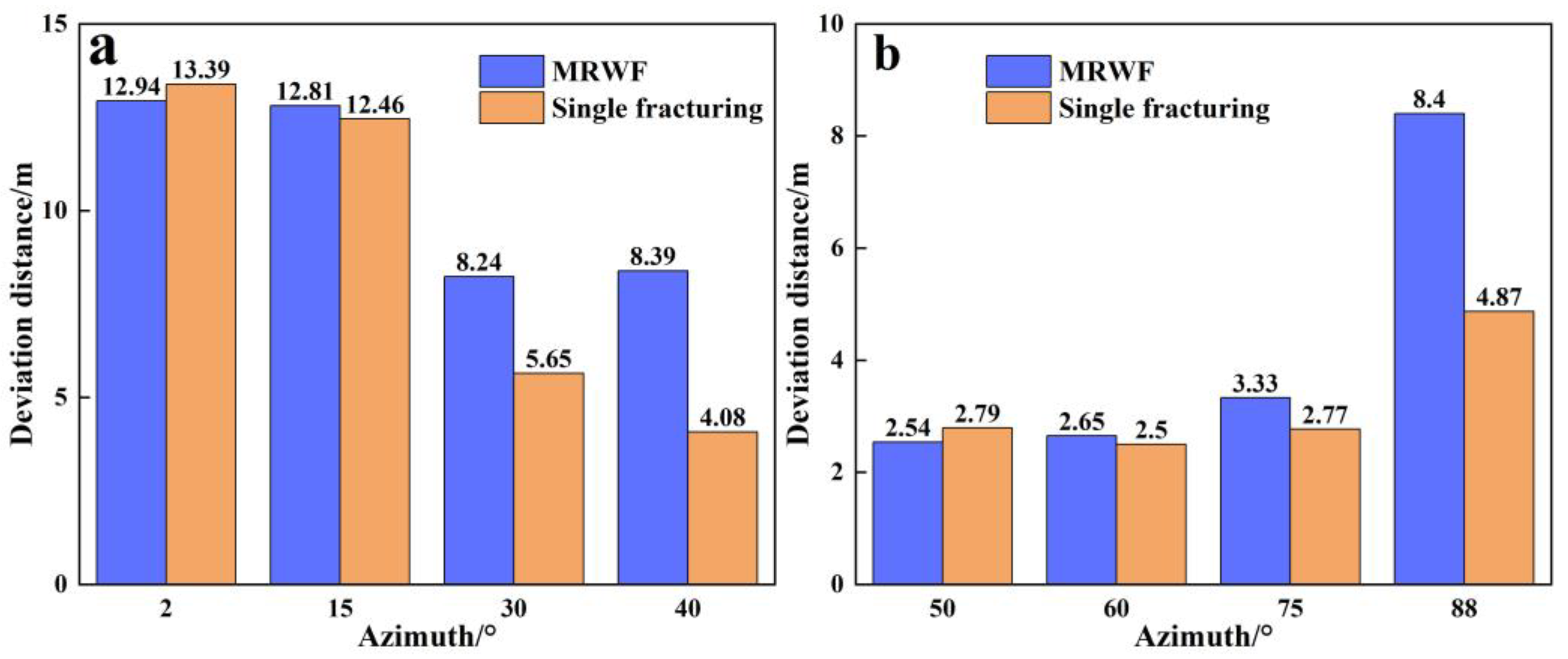

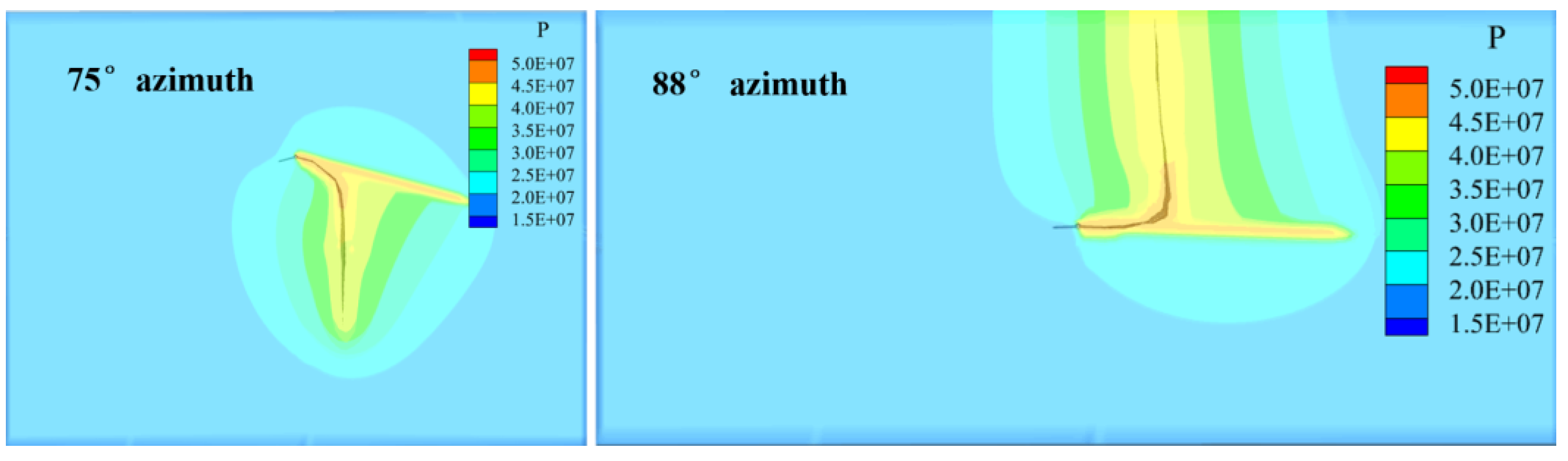

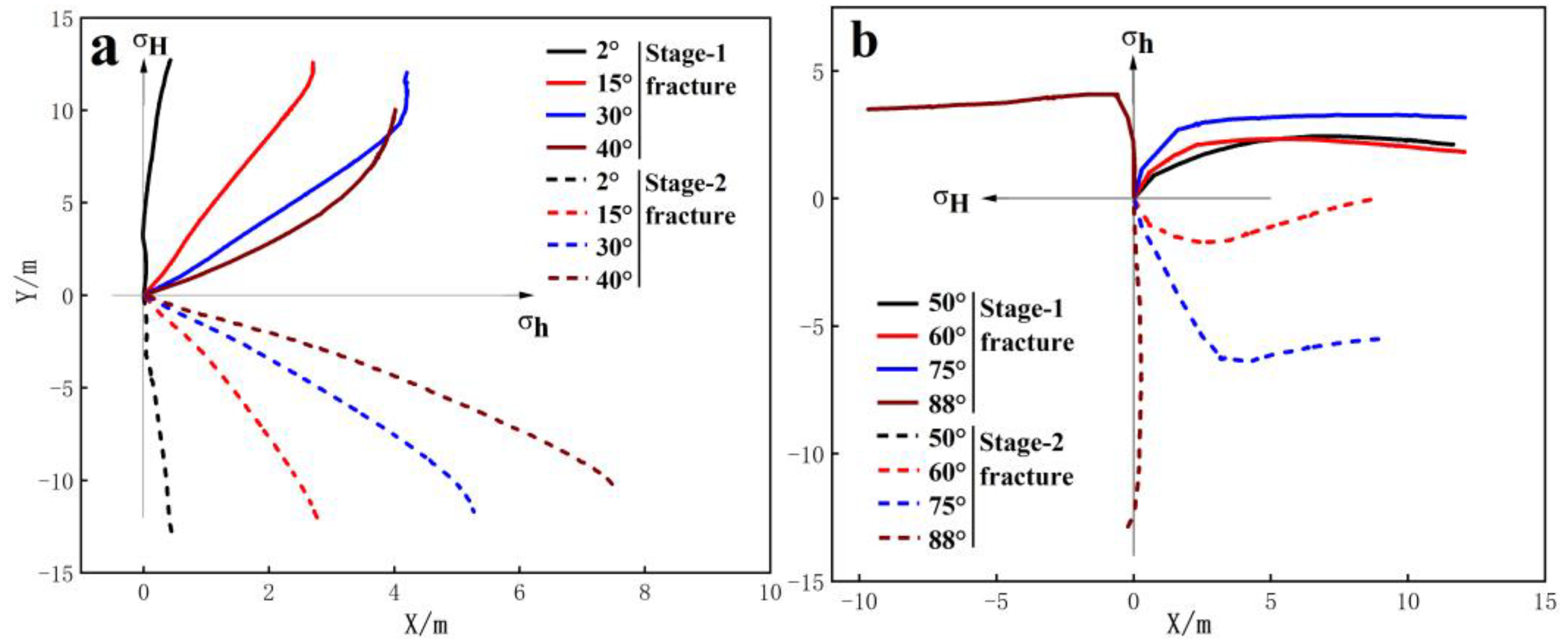

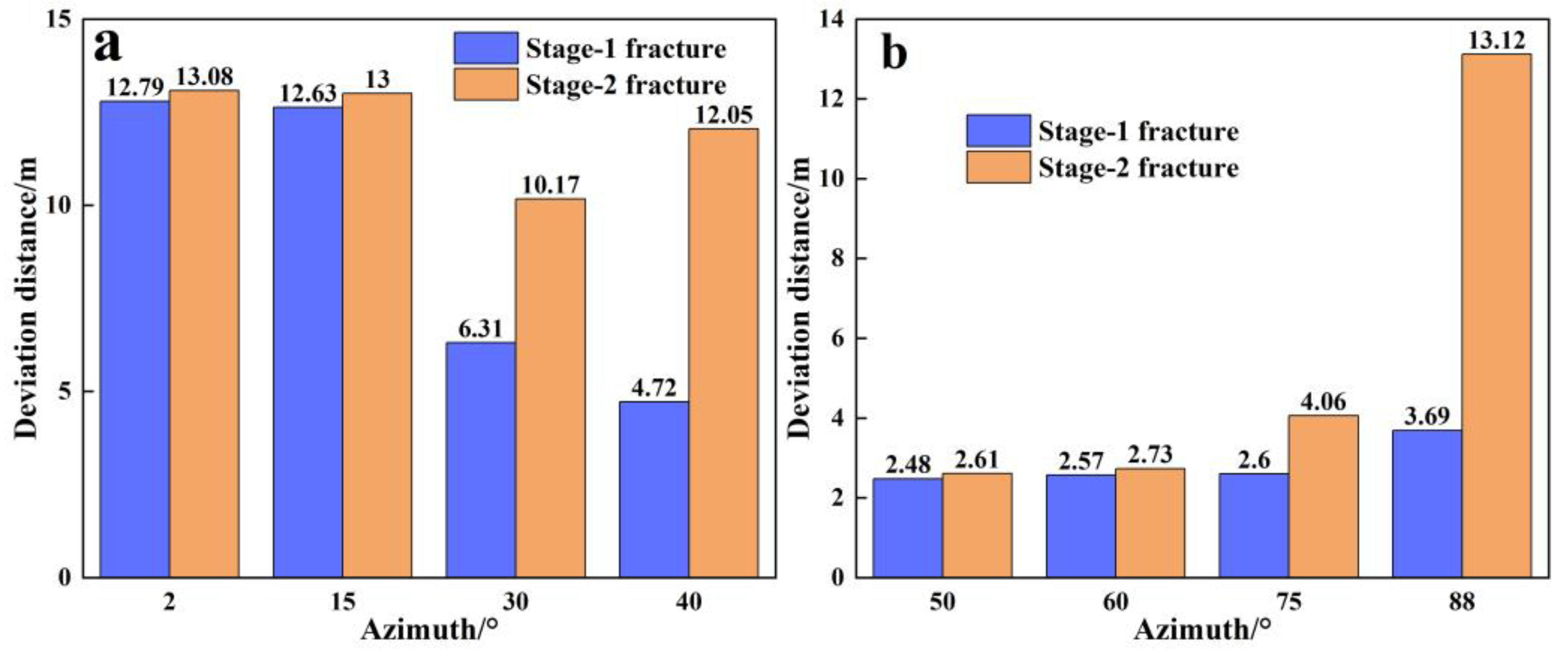

3.3. Effect of the Azimuth

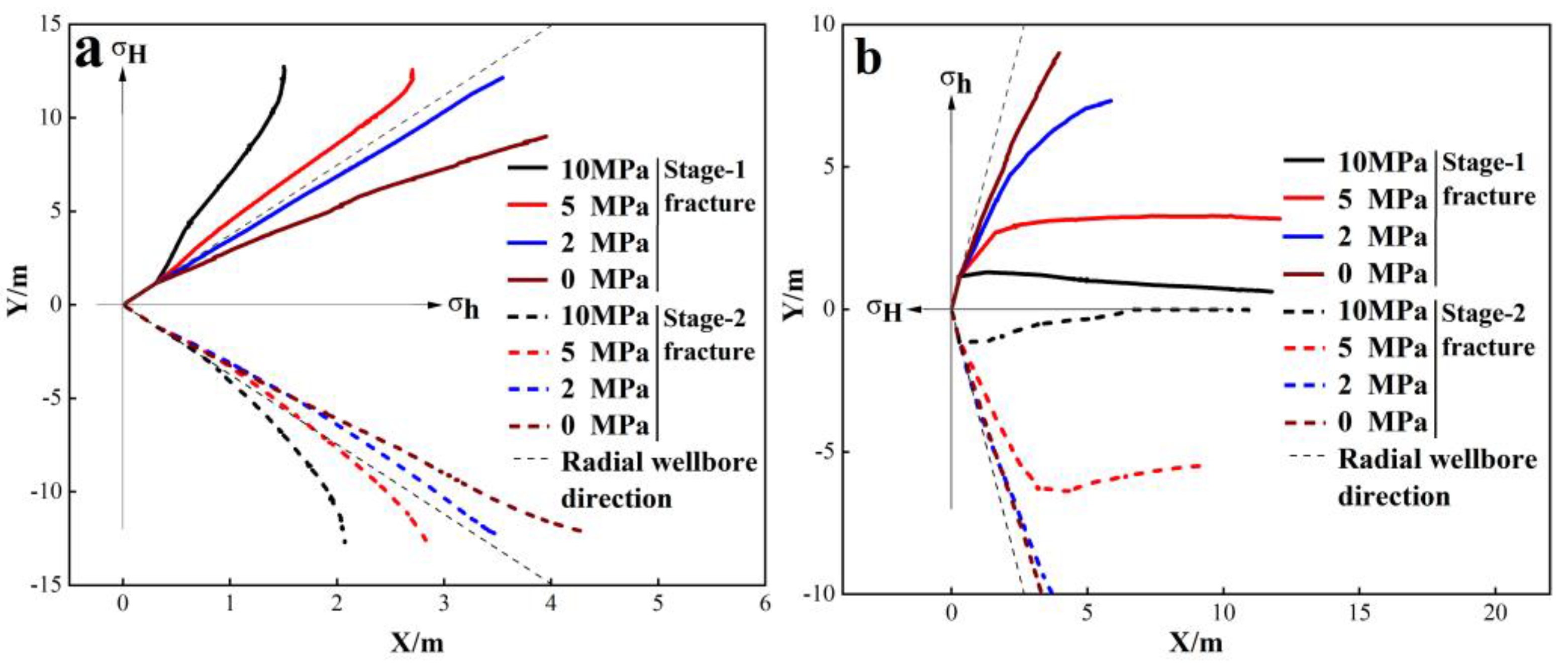

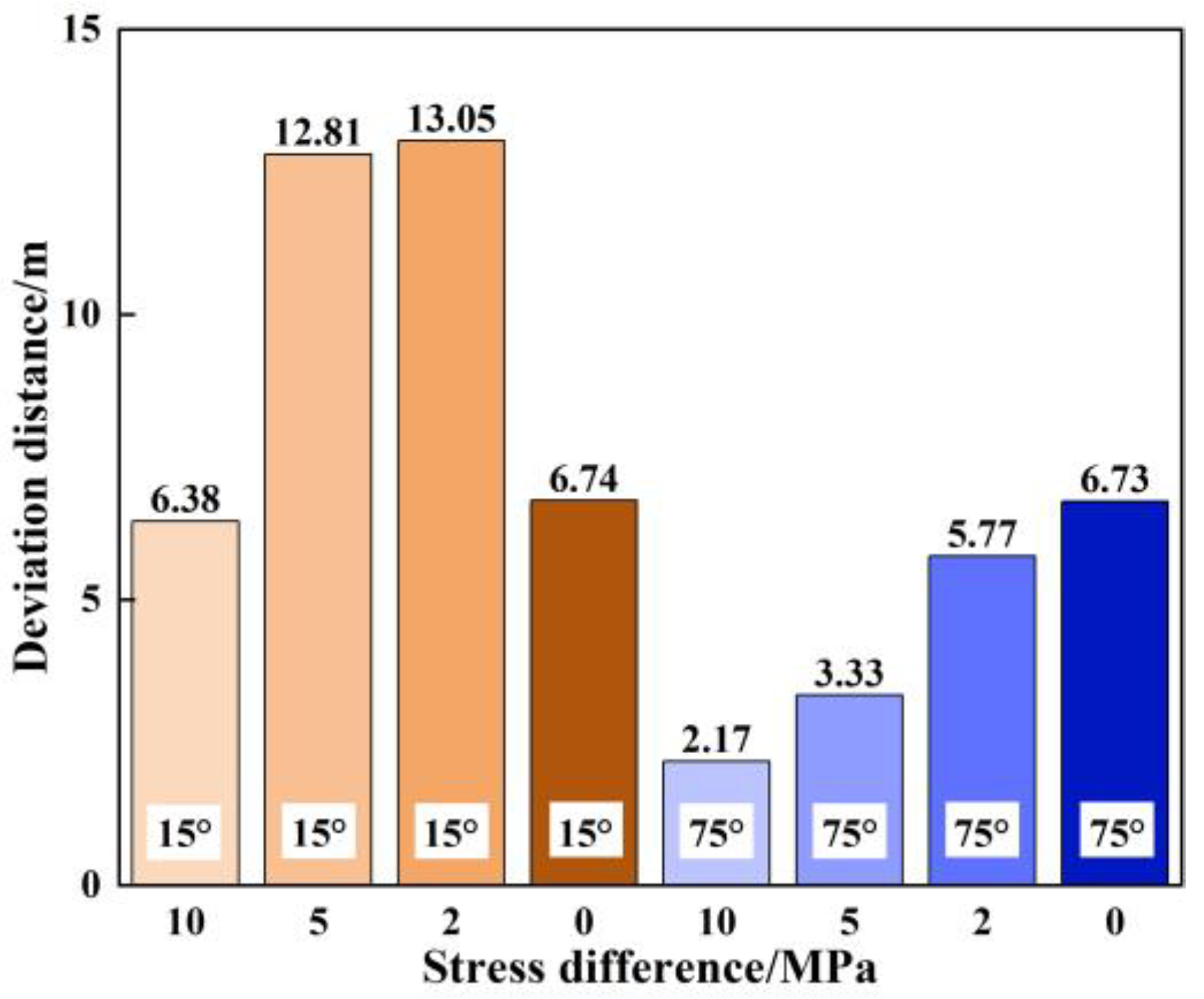

3.4. Effect of the Horizontal Stress Difference

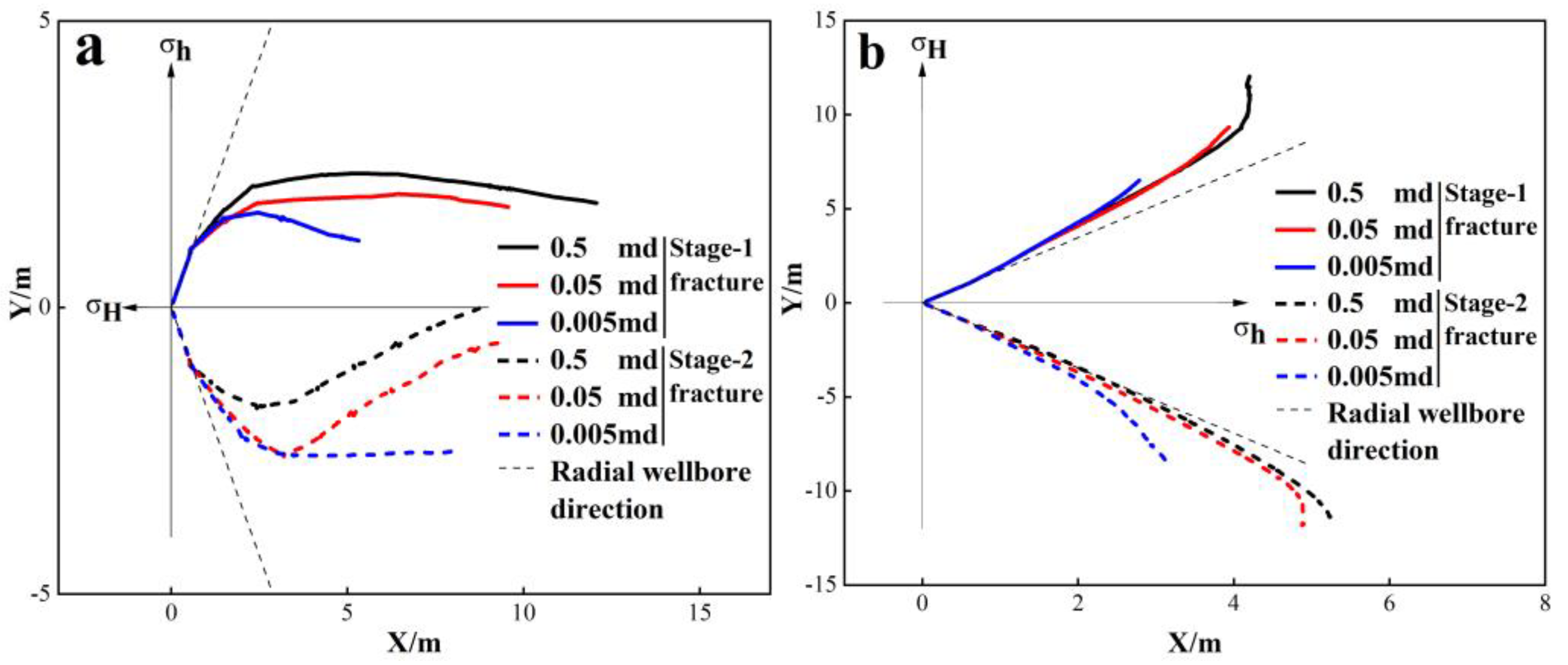

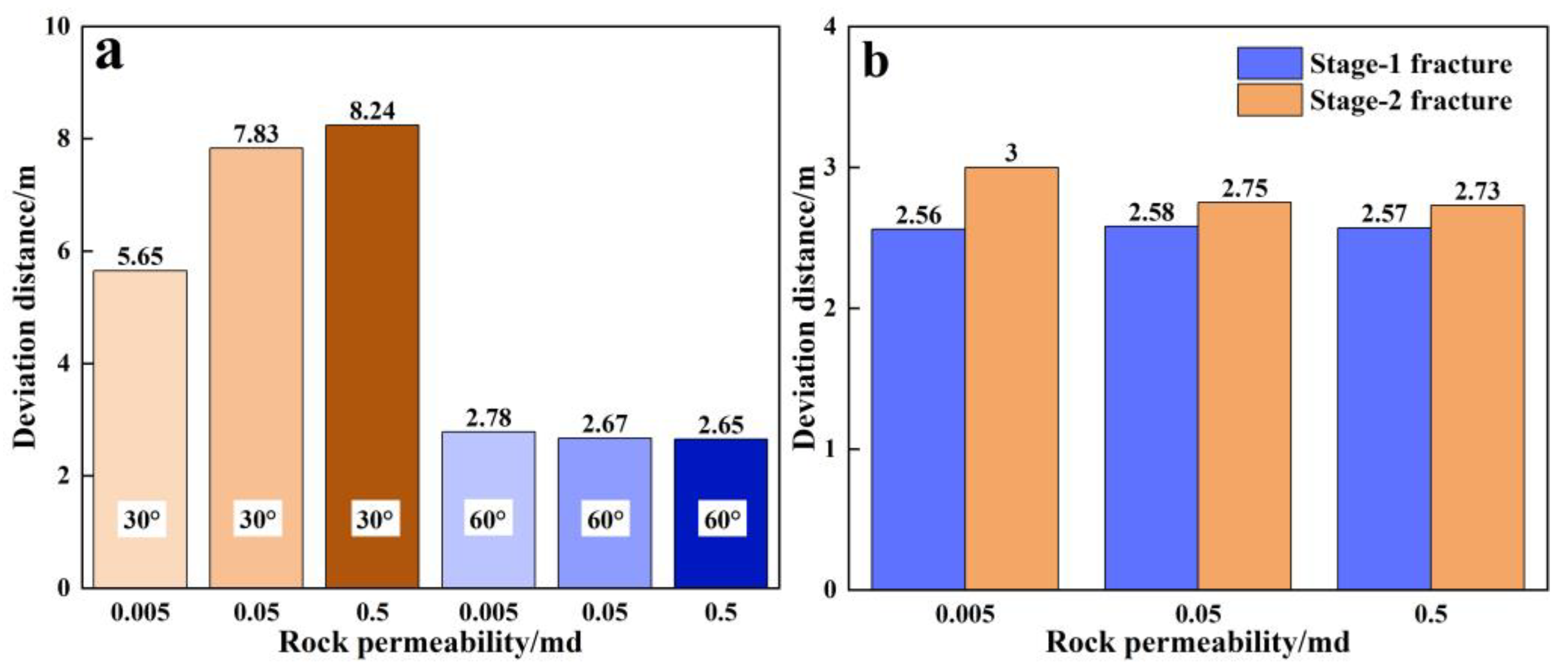

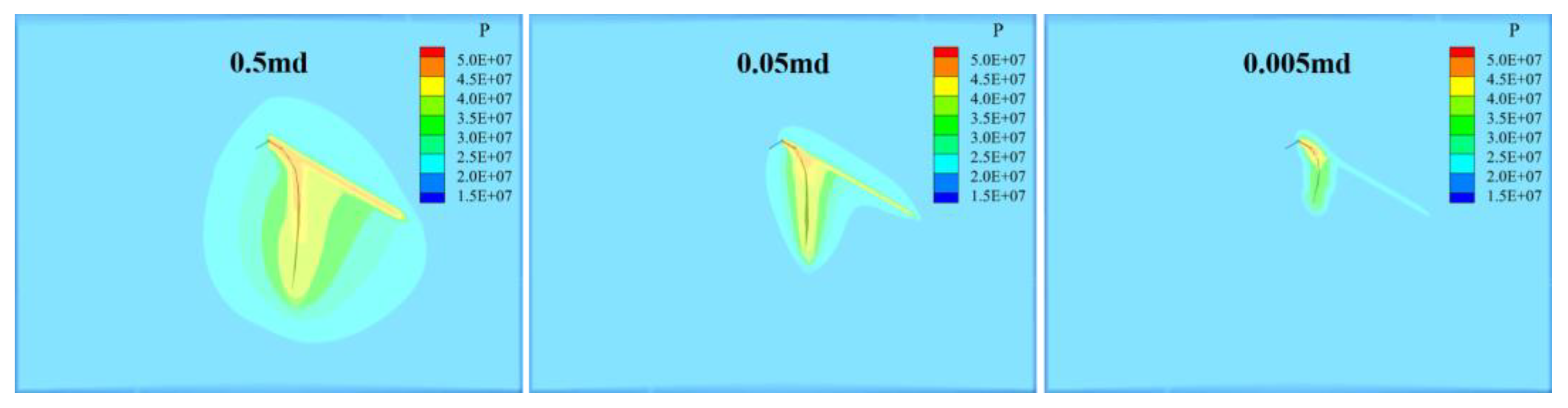

3.5. Effect of the Rock Matrix Permeability

4. Conclusions

- (1)

- Previously created fractures attract subsequently created fractures, influencing the fracture propagation of MRWF. A conceptual model is proposed to elucidate the variations of fracture propagation, highlighting three critical factors: the attraction effect, the orientation effect of the single radial wellbore, and the deflection effect of the maximum horizontal principal stress.

- (2)

- With radial wellbores symmetrically distributed along the minimum horizontal stress direction, increasing the azimuth decreases the deviation distance of stage-1 fractures, and initially decreases then increases the deviation distance of stage-2 fractures. For radial wellbores symmetrically distributed along the maximum horizontal stress direction, increasing the azimuth (50° to 88°) lifts the deviation distance of both stage-1 and stage-2 fractures (48.8% and 402.7%, respectively).

- (3)

- When the horizontal stress difference exceeds 0 MPa, reducing the difference increases the deviation distance of both stage-1 and stage-2 fractures. When the horizontal stress difference is 0 MPa, radial wellbores with 45° azimuth exhibit better guiding ability.

- (4)

- Higher rock matrix permeability leads to longer fracture propagation and a greater influence of stage-1 fractures on stage-2 fractures. When radial wellbores are distributed along the minimum horizontal stress direction, increased rock matrix permeability (0.005 to 0.5 mD) lifts the deviation distances of stage-2 fractures (45.8%).

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| body force | |

| diffusion flux of component within liquid phase | |

| Young’s modulus | |

| mass flux of component | |

| convective flux of component | |

| mass flux of phase | |

| diffusion flux of component k within liquid phase | |

| energy of fracture surface | |

| acceleration of gravity | |

| normal load on the external boundary | |

| absolute permeability | |

| relative permeability of | |

| stress intensity factor | |

| stress intensity factor | |

| distribution coefficient of the liquid phase | |

| radius relative to the tip of the fracture | |

| volume mass per unit of component | |

| hydraulic pressure loading on fracture surface | |

| fluid pressure of phase | |

| point source and point sink in | |

| saturation of phase | |

| time | |

| displacement field in solid | |

| unit normal to the external boundary | |

| any sub-region of the fluid system | |

| difference in displacement from the + to the − side of the fracture surface | |

| mass fraction of within liquid phase | |

| mass fraction of within phase | |

| three-dimensional solid body | |

| external boundary | |

| tiny face in | |

| stress | |

| maximum principal stress | |

| tensile strength of rock | |

| linear strain | |

| porosity of the flow system | |

| single liquid phase | |

| density of phase | |

| density of liquid phase | |

| density of rock skeleton | |

| Darcy velocity of | |

| kinetic viscosity | |

| dependent factor | |

| coefficient | |

| fracture propagation angle | |

| Kolosov constant | |

| Poisson’s ratio | |

| displacement differences at a distance | |

| displacement differences at |

References

- Landers, C.W. Method of and Apparatus for Horizontal Well. Drilling. Patents U.S. 5,853,056, 29 December 1998. [Google Scholar]

- Huang, Z.; Huang, Z.; Wu, L.; Su, Y.; Hong, C. Trajectory measurement of radial jet drilling wells: Improved tool and data processing. J. Energy Resour. Technol. 2020, 142, 032902. [Google Scholar] [CrossRef]

- Huang, Z.; Huang, Z.; Su, Y.; Bi, G.; Li, W.; Liu, X.; Jiang, T. A feasible method for the trajectory measurement of radial jet drilling laterals. SPE Drill. Complet. 2020, 35, 125–135. [Google Scholar] [CrossRef]

- Ragab, A.M.; Kamel, A.M. Radial drilling technique for improving well productivity in Petrobel-Egypt. In Proceedings of the North Africa Technical Conference and Exhibition: OnePetro, Cairo, Egypt, 15–17 April 2013. [Google Scholar]

- Maut, P.P.; Jain, D.; Mohan, R.; Talukdar, D.; Baruah, T.; Sharma, P.; Verma, S. Production enhancement in mature fields of Assam Arakan basin by radial jet drilling-a case study. In Proceedings of the SPE Symposium: Production Enhancement and Cost Optimisation: OnePetro, Kuala Lumpur, Malaysia, 7 November 2017. [Google Scholar]

- Li, Y.; Wang, C.; Shi, L.; Guo, W. Application and development of drilling and completion of the ultrashort-radius radial well by high pressure jet flow techniques. In Proceedings of the International Oil and Gas Conference and Exhibition in China: OnePetro, Beijing, China, 8–10 June 2010. [Google Scholar]

- Cinelli, S.D.; Kamel, A.H. Novel technique to drill horizontal laterals revitalizes aging field. In Proceedings of the SPE/IADC Drilling Conference: OnePetro, Amsterdam, The Netherlands, 5 March 2013. [Google Scholar]

- Abass, H.H.; Soliman, M.Y.; Al-Tahini, A.M.; Surjaatmadja, J.B.; Meadows, D.L.; Sierra, L. Oriented fracturing: A new technique to hydraulically fracture an openhole horizontal well. In Proceedings of the SPE Annual Technical Conference and Exhibition: OnePetro, New Orleans, Louisiana, 4–7 October 2009. [Google Scholar]

- Fu, X.; Li, G.; Huang, Z.; Liang, Y.; Xu, Z.; Jin, X. Experimental and numerical study of radial lateral fracturing for coalbed methane. J. Geophys. Eng. 2015, 12, 875–886. [Google Scholar] [CrossRef]

- Lu, Y.Y.; Zuo, S.J.; Ge, Z.L.; Xiao, S.; Cheng, Y. Experimental Study of Crack Initiation and Extension Induced by Hydraulic Fracturing in a Tree-Type Borehole Array. Energies 2016, 9, 514. [Google Scholar] [CrossRef]

- Liu, Q.; Tian, S.; Li, G.; Yu, W.; Sheng, M.; Fan, X.; Zhang, Z.; Sepehrnoori, K.; Guo, Z.; Geng, L. Fracture initiation and propagation characteristics for radial drilling-fracturing: An experimental study. In Proceedings of the Unconventional Resources Technology Conference, Houston, TX, USA, 23–25 July 2018; Society of Exploration Geophysicists, American Association of Petroleum: Tulsa, OK, USA, 2018; pp. 1059–1067. [Google Scholar]

- Yan, C.; Cheng, Y.; Deng, F.; Qimin, L.; Fei, T.; Qingchao, L. Experimental Study on the Hydraulic Fracturing of Radial Horizontal Wells. In Proceedings of the 4th ISRM Young Scholars Symposium on Rock Mechanics, Jeju, Korea, 10 May 2017. [Google Scholar]

- Guo, T.; Rui, Z.; Qu, Z.; Qi, N. Experimental study of directional propagation of hydraulic fracture guided by multi-radial slim holes. J. Petrol. Sci. Eng. 2018, 166, 592–601. [Google Scholar] [CrossRef]

- Guo, T.; Gong, F.; Shen, L.; Qu, Z.; Qi, N.; Wang, T. Multi-fractured stimulation technique of hydraulic fracturing assisted by radial slim holes. J. Petrol. Sci. Eng. 2019, 174, 572–583. [Google Scholar] [CrossRef]

- Guo, Z.Q.; Tian, S.C.; Yong, Y.N.; Ma, L.; Liu, Q.; Zhang, Y.; Yang, R. Fracture Geometries Influenced by Distances Between Adjacent Layers of Radial Boreholes for Hydraulic Fracturing. In Proceedings of the 55th US Rock Mechanics/Geomechanics Symposium: OnePetro, Online, 18–25 June 2021. [Google Scholar]

- Guo, Z.; Tian, S.; Liu, Q.; Ma, L.; Yong, Y.; Yang, R. Experimental investigation on the breakdown pressure and fracture propagation of radial borehole fracturing. J. Petrol. Sci. Eng. 2022, 208, 109169. [Google Scholar] [CrossRef]

- Seyedrahimi-Niaraq, M.; Bina, S.M.; Itoi, R. Numerical and thermodynamic modeling for estimating production capacity of NW Sabalan geothermal field, Iran. Geothermics 2021, 90, 101981. [Google Scholar] [CrossRef]

- Li, X.L.; Xiao, W.; Qu, Z.Q.; Guo, T.; Li, J.; Zhang, W.; Tian, Y. Rules of fracture propagation of hydraulic fracturing in radial well based on XFEM. J. Pet. Explor. Prod. Technol. 2018, 8, 1547–1557. [Google Scholar] [CrossRef]

- Guo, T.; Qu, Z.; Gong, F.; Wang, X. Numerical simulation of hydraulic fracture propagation guided by single radial boreholes. Energies 2017, 10, 1680. [Google Scholar] [CrossRef]

- Guo, T.; Qu, Z.; Gong, D.; Lei, X.; Liu, M. Numerical simulation of directional propagation of hydraulic fracture guided by vertical multi-radial boreholes. J. Nat. Gas. Sci. Eng. 2016, 35, 175–188. [Google Scholar] [CrossRef]

- Wang, T.; Guo, Z.; Li, G.; Zhengchao, M.; Yuning, Y.; CHANG, X.; Shouceng, T. Numerical simulation of three-dimensional fracturing fracture propagation in radial wells. Pet. Explor. Dev. 2023, 50, 699–711. [Google Scholar] [CrossRef]

- El Rabaa, W. Experimental study of hydraulic fracture geometry initiated from horizontal wells. In Proceedings of the SPE Annual Technical Conference and Exhibition: OnePetro, San Antonio, TX, USA, 8–11 October 1989. [Google Scholar]

- Tang, X.; Rutqvist, J.; Hu, M.; Rayudu, N.M. Modeling three-dimensional fluid-driven propagation of multiple fractures using TOUGH-FEMM. Rock. Mech. Rock. Eng. 2019, 52, 611–627. [Google Scholar] [CrossRef]

- Zhang, K.; Tang, M.; Wang, C.; Wang, G.; Dou, L.; Sun, H. Study on prediction method of tensile strength for tight sandstone formation. Progress. Geophys. 2021, 36, 318–324. [Google Scholar]

- Yang, B.; Wang, H.; Wang, B.; Shen, Z.; Zheng, Y.; Jia, Z.; Yan, W. Digital quantification of fracture in full-scale rock using micro-CT images: A fracturing experiment with N2 and CO2. J. Petrol. Sci. Eng. 2021, 196, 107682. [Google Scholar] [CrossRef]

- Liu, J.; Hui, C.; Fan, J.; Lyu, W.; Wang, J.; Yin, C.; Wang, H. Distribution characteristics of the present-day in-situ stress in the Chang 6 tight sandstone reservoirs of the Yanchang Formation in the Heshui Area, Ordos Basin, China and suggestions for development. Int. J. Geomech. 2021, 27, 31–39. [Google Scholar]

- Bian, H.; Wang, F.; Zhang, Y.; Yue, C. Experimental study of dynamic and static elastic parameters of tight sandstones under reservoir conditions. Chin. J. Rock. Mech. Eng. 2015, 34, 3045–3054. [Google Scholar]

- Zhang, Z.; Zhang, S.; Zou, Y.; Ma, X.; Li, N.; Liu, L. Experimental investigation into simultaneous and sequential propagation of multiple closely spaced fractures in a horizontal well. J. Petrol. Sci. Eng. 2021, 202, 108531. [Google Scholar] [CrossRef]

- Zheng, H.; Pu, C.; Xu, E.; Sun, C. Numerical investigation on the effect of well interference on hydraulic fracture propagation in shale formation. Eng. Fract. Mech. 2020, 228, 106932. [Google Scholar] [CrossRef]

- Gong, D.; Qu, Z.; Guo, T.; Tian, Y.; Tian, K. Variation rules of fracture initiation pressure and fracture starting point of hydraulic fracture in radial well. J. Petrol. Sci. Eng. 2016, 140, 41–56. [Google Scholar] [CrossRef]

- Hubbert, M.K.; Willis, D.G. Mechanics of hydraulic fracturing. Trans. AIME 1957, 210, 153–168. [Google Scholar] [CrossRef]

- Bruno, M.; Nakagawa, F. Pore pressure influence on tensile fracture propagation in sedimentary rock. Int. J. Rock. Mech. Min. Sci. 1991, 28, 261–273. [Google Scholar] [CrossRef]

| Parameters | Value | Unit |

|---|---|---|

| Formation | ||

| Density | 2467 | kg/m3 |

| Young’s modulus | 32 × 109 | Pa |

| Uniaxial tensile strength | 4.8 × 106 | Pa |

| Poisson’s ratio | 0.18 | — |

| Porosity | 0.08 | — |

| Permeability | 5 × 10−16 | m2 |

| Pore pressure | 15.6 × 106 | Pa |

| Maximum horizontal stress | 30 × 106 | Pa |

| Minimum horizontal stress | 25 × 106 | Pa |

| Weakened material | ||

| Density | 500 | kg/m3 |

| Young’s modulus | 32 × 105 | Pa |

| Poisson’s ratio | 0.25 | — |

| Porosity | 0.4 | — |

| Permeability | 1 × 10−12 | m2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yong, Y.; Guo, Z.; Zhou, X.; Tian, S.; Zhang, Y.; Wang, T. Fracture Propagation of Multi-Stage Radial Wellbore Fracturing in Tight Sandstone Reservoir. Processes 2024, 12, 1539. https://doi.org/10.3390/pr12071539

Yong Y, Guo Z, Zhou X, Tian S, Zhang Y, Wang T. Fracture Propagation of Multi-Stage Radial Wellbore Fracturing in Tight Sandstone Reservoir. Processes. 2024; 12(7):1539. https://doi.org/10.3390/pr12071539

Chicago/Turabian StyleYong, Yuning, Zhaoquan Guo, Xiaoxia Zhou, Shouceng Tian, Ye Zhang, and Tianyu Wang. 2024. "Fracture Propagation of Multi-Stage Radial Wellbore Fracturing in Tight Sandstone Reservoir" Processes 12, no. 7: 1539. https://doi.org/10.3390/pr12071539

APA StyleYong, Y., Guo, Z., Zhou, X., Tian, S., Zhang, Y., & Wang, T. (2024). Fracture Propagation of Multi-Stage Radial Wellbore Fracturing in Tight Sandstone Reservoir. Processes, 12(7), 1539. https://doi.org/10.3390/pr12071539