Research for Flow Behavior of Heavy Oil by CO2 Foam Viscosity Reducer-Assisted Steam (CFVAS) Flooding: Microscopic Displacement Experiment Study

Abstract

:1. Introduction

2. Materials and Methods

2.1. Formation Water

2.2. Crude Oil

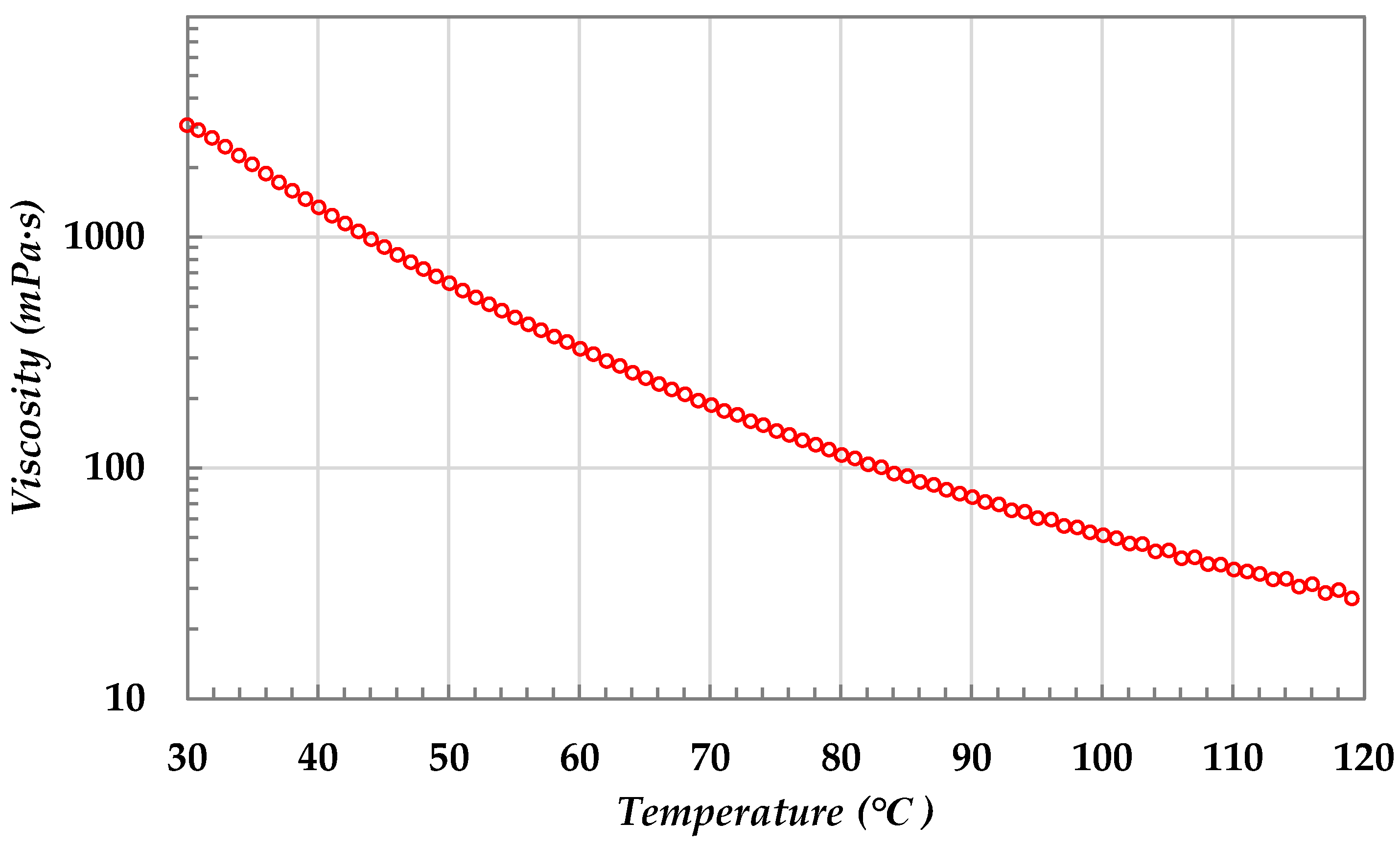

2.2.1. Crude Oil Viscosity

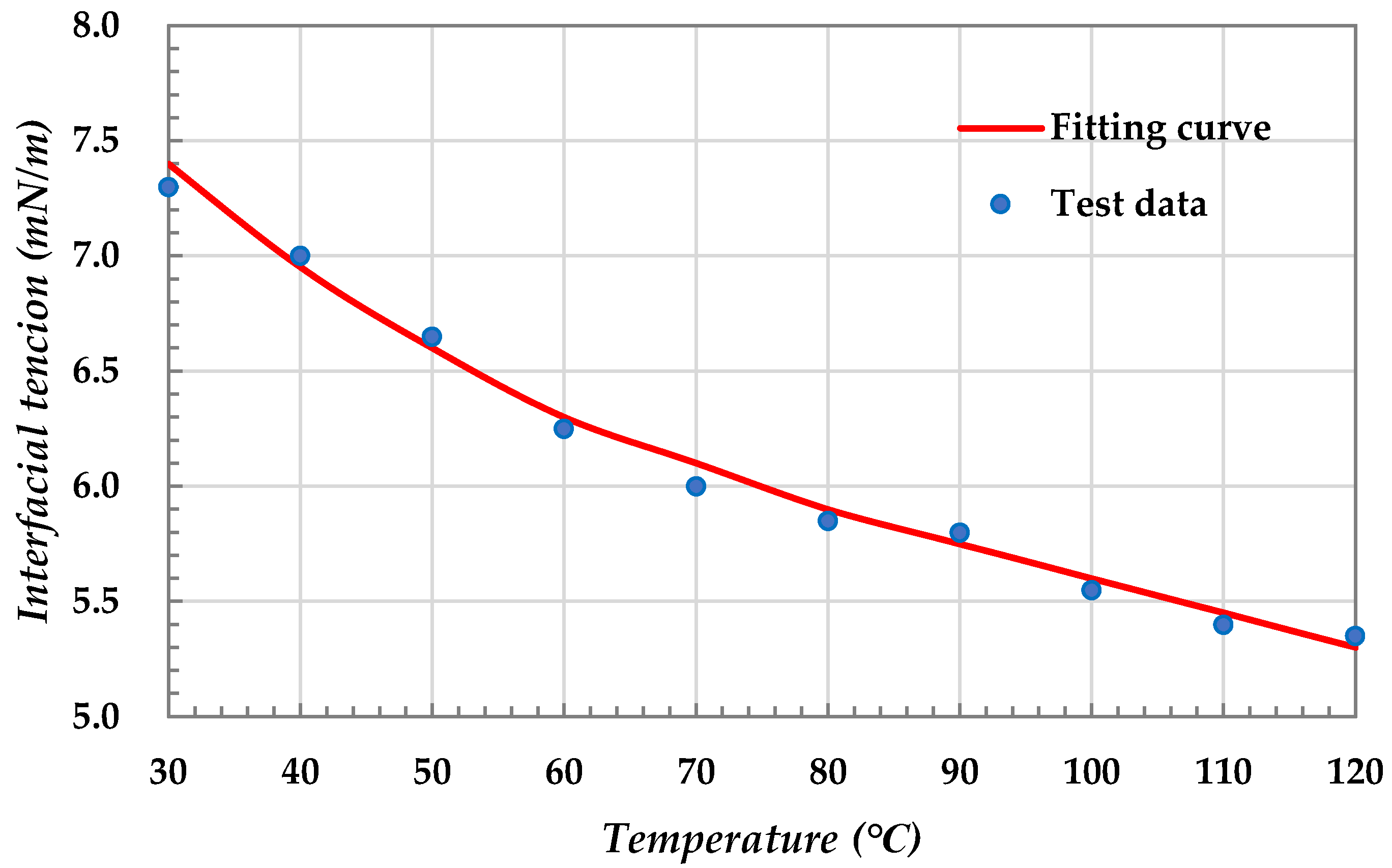

2.2.2. Oil–Water Interfacial Tension

2.3. Foam Viscosity Reducer

2.3.1. Preparation of Foam Viscosity Reducer

2.3.2. Foam Properties

- 1.

- Viscosity-reducing effect

- 2.

- Performance of foaming

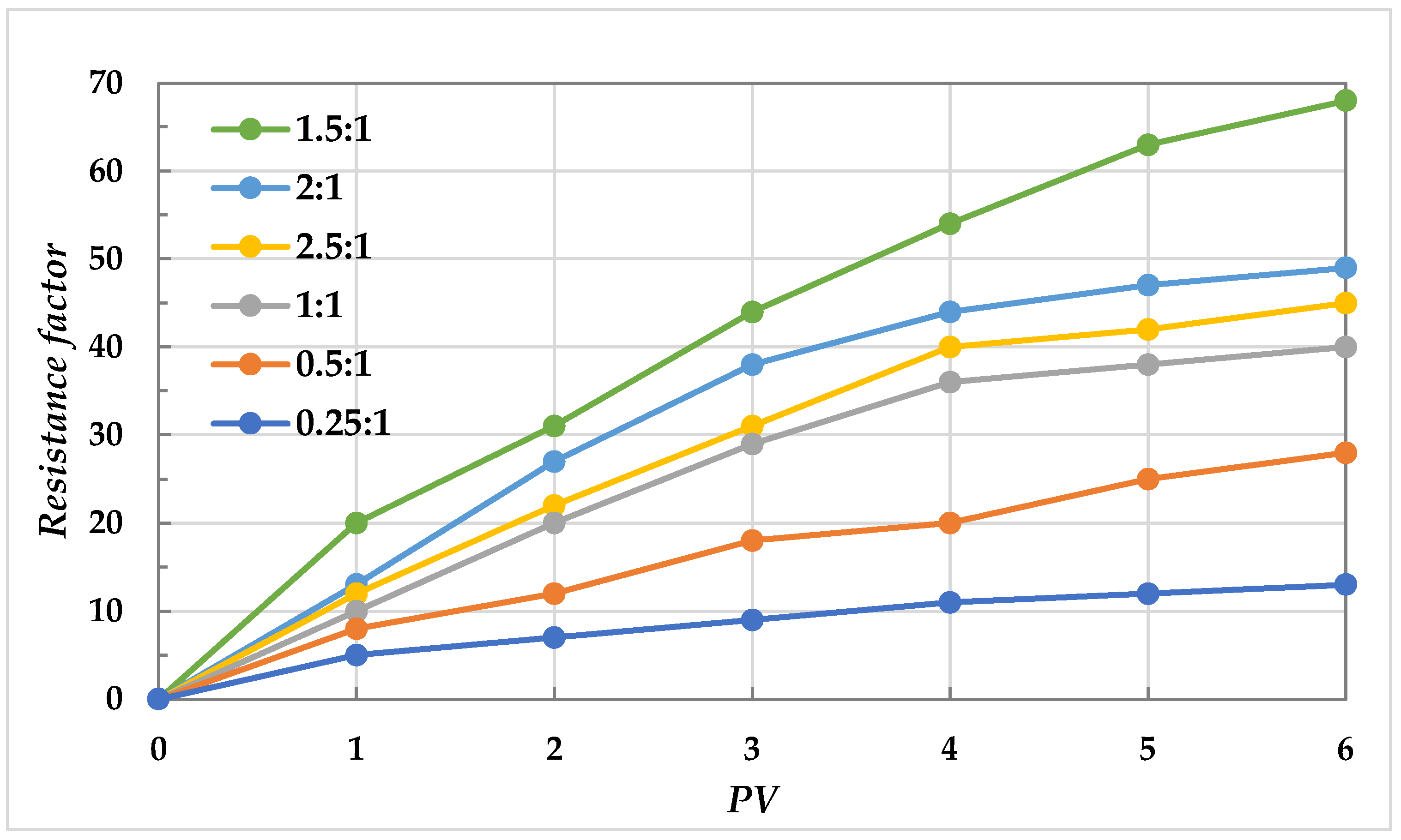

2.3.3. Optimization of CO2 and Foam Viscosity Reducer

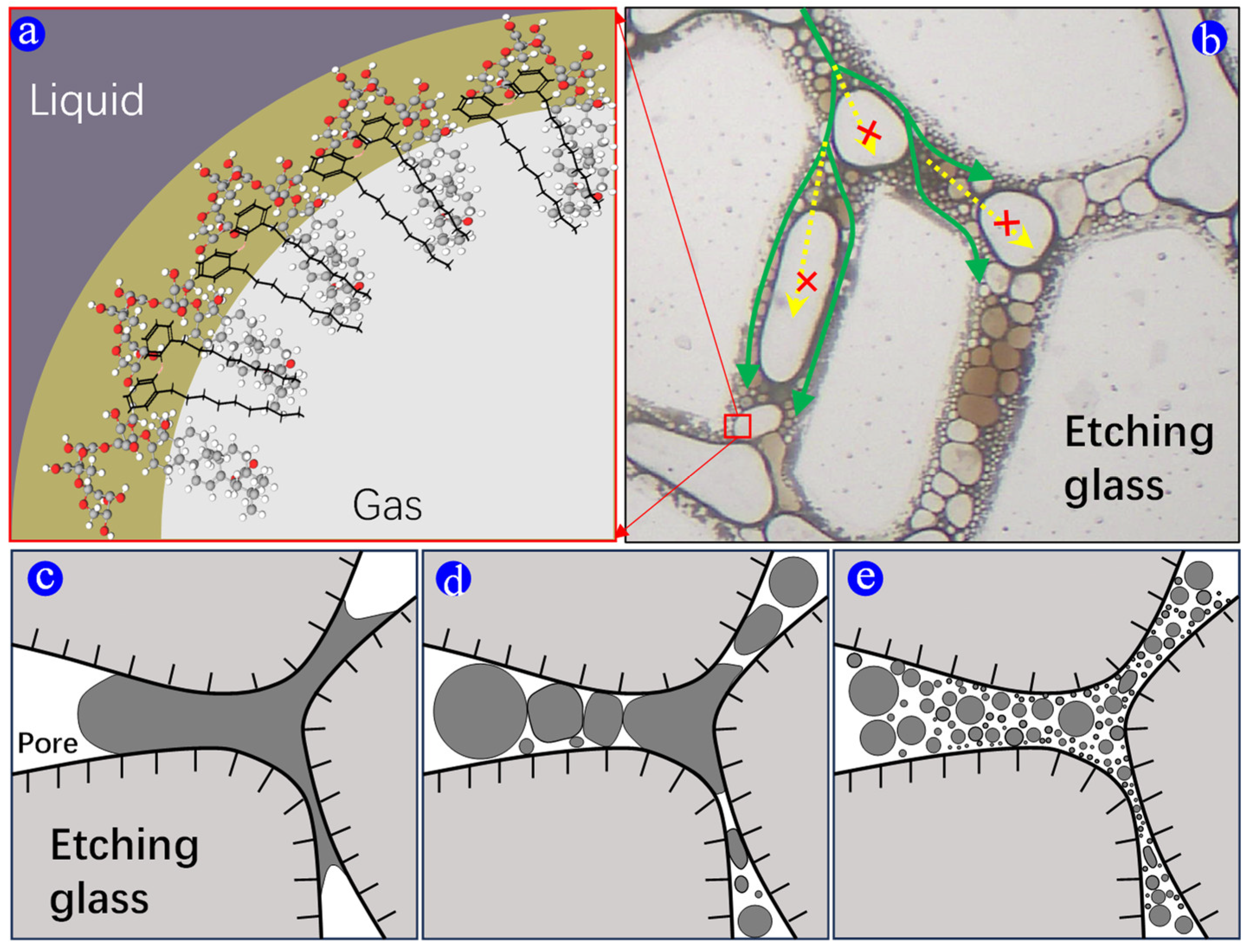

2.3.4. Mechanism of CO2 Foam Displacement

3. Experimental Procedures

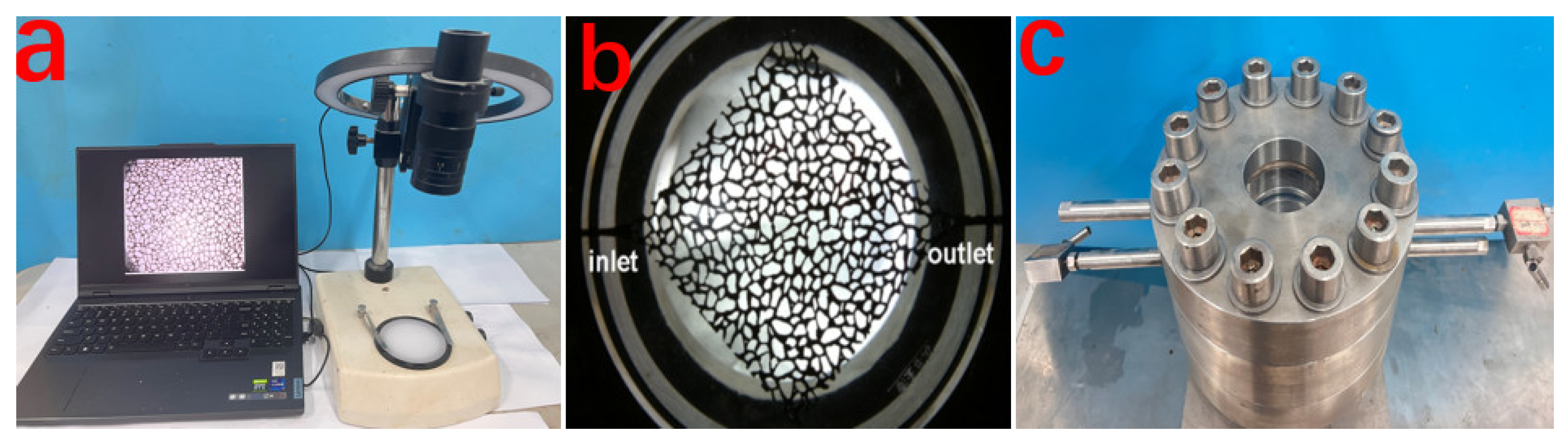

3.1. Experimental Equipment

3.2. Experimental Procedures

- Connect the experimental devices and pipelines. In particular, it is necessary to prepare several pipelines at the entrance of the high-temperature and high-pressure visualization experimental device to avoid pollution and blockage of the pipeline when oil and other chemical agents are injected.

- Set the confining pressure to 2 MPa. Connect the pressure gauge to the confining pressure pipeline of the high-temperature and high-pressure visualization experimental device, inject water into the device with a hand pump, slowly increase the confining pressure to 2 MPa, and close the valve. The confining pressure is not lower than the input–outlet pressure system.

- An ISCO pump is used to saturate the micro-etched glass with water first (remove possible impurities inside the pore, and then use the temperature controller to dry the glass model at high temperature). After the model is dried, an ISCO pump is used to saturate the crude oil sample. The injection rate is set at 0.025 mL/min, and the pressure difference between the inlet and the outlet should not be too large.

- Simulate steam displacement. The microscopic model temperature controller is used to heat the visualization experimental device, and hot steam is injected into the microscopic glass saturated with oil samples. The injection speed of the ISCO plunger pump is set to 0.01 mL/min, and the flow and state changes of oil samples in the microscopic etched glass are observed.

- Simulate heavy oil combined with thermal recovery and displacement. The one-way valve, dryer, and gas flow meter are, respectively, connected to the gas tank containing CO2. The CO2 injection rate is set to 0.025 mL/min with the gas flow meter and 0.013 mL/min with the foam viscosity reducer solution (0.8 wt%) with the ISCO plunger pump. At the same time, the CO2 and foam agent solution are injected into the foam generator. Foaming is carried out, and then the viscosity-reducing agent and foam are mixed and connected to the entrance of the high-temperature and high-pressure visualization experimental device, and the foam and viscosity-reducing agent are injected at the same time to observe the flow and state changes of oil samples in the micro-etched glass (for temperature fluctuations, the temperature controller is used to heat up the high temperature and high pressure visualization experimental device to 100 °C, and the ISCO pump is used to inject the crude oil at 0.025 mL/min).

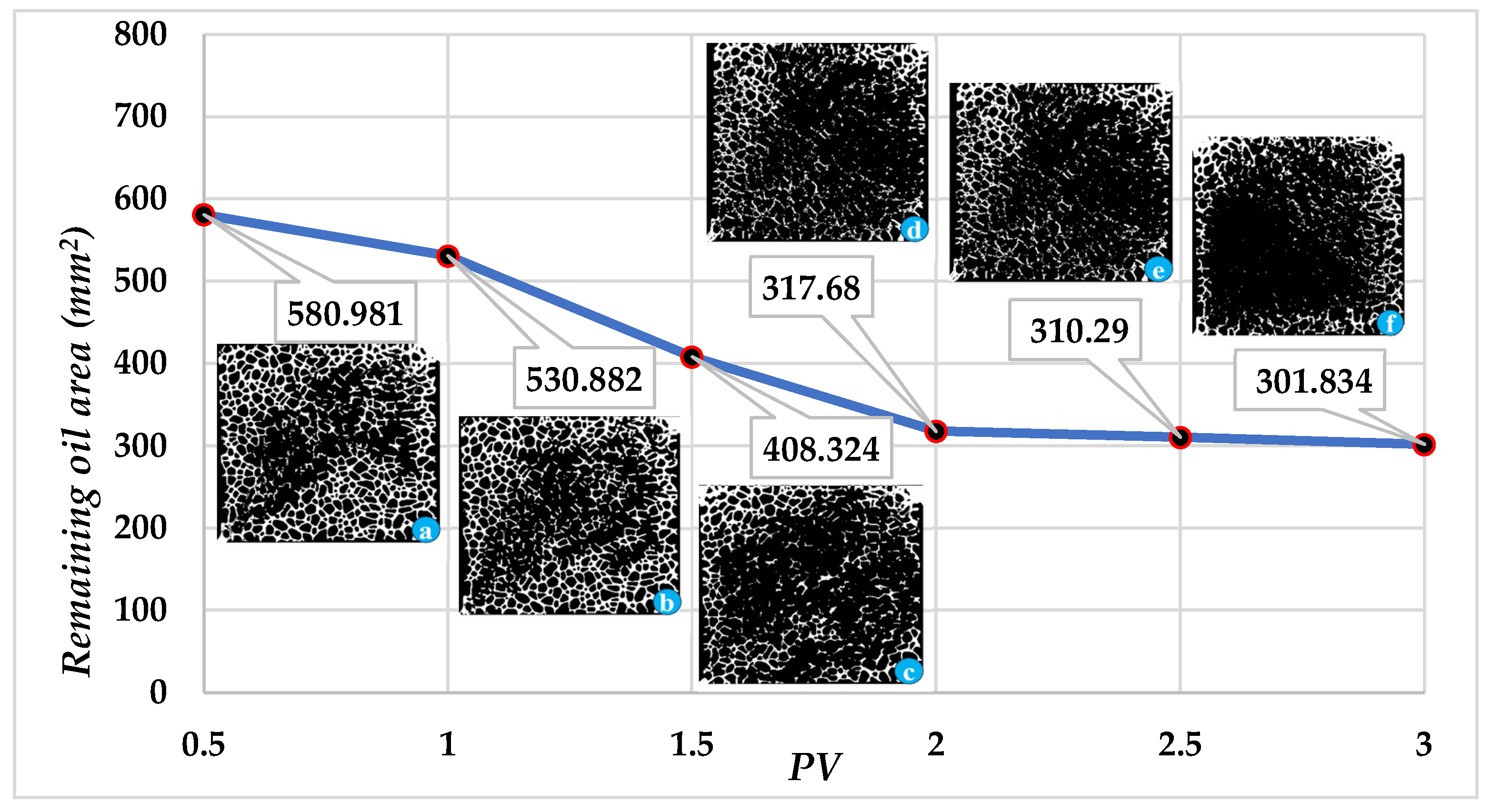

- Video and record the heavy oil flow and state in the steam displacing to composite thermal recovery displacing stage, and analyze the flow form, remaining oil state, and occurrence mode of heavy oil in the model, using Imagej image analysis software (Version 2.0) of automatic area measurement function; calculate the etching glass model under different injection PV numbers within the area of remaining oil.

3.3. Experimental Parameters

- During steam displacement, the temperature of the microscopic model temperature controller was set at 100~150 °C, the injection speed was 0.02 mL/min, and the injection PV number was from 0.5 to 1.5.

- For CO2, the temperature range was the same as that of the scheme (i). The injection rate of 0.017 mL/min for 0.08 wt% foam viscosity reducer and 0.034 mL/min for CO2 were used, both of which were injected simultaneously. The injection volume of this group of experiments was continued until 3.0 PV according to the cut-off injection PV number of the first group of experiments.

3.4. Analytical Method

3.4.1. Flow Zone Division

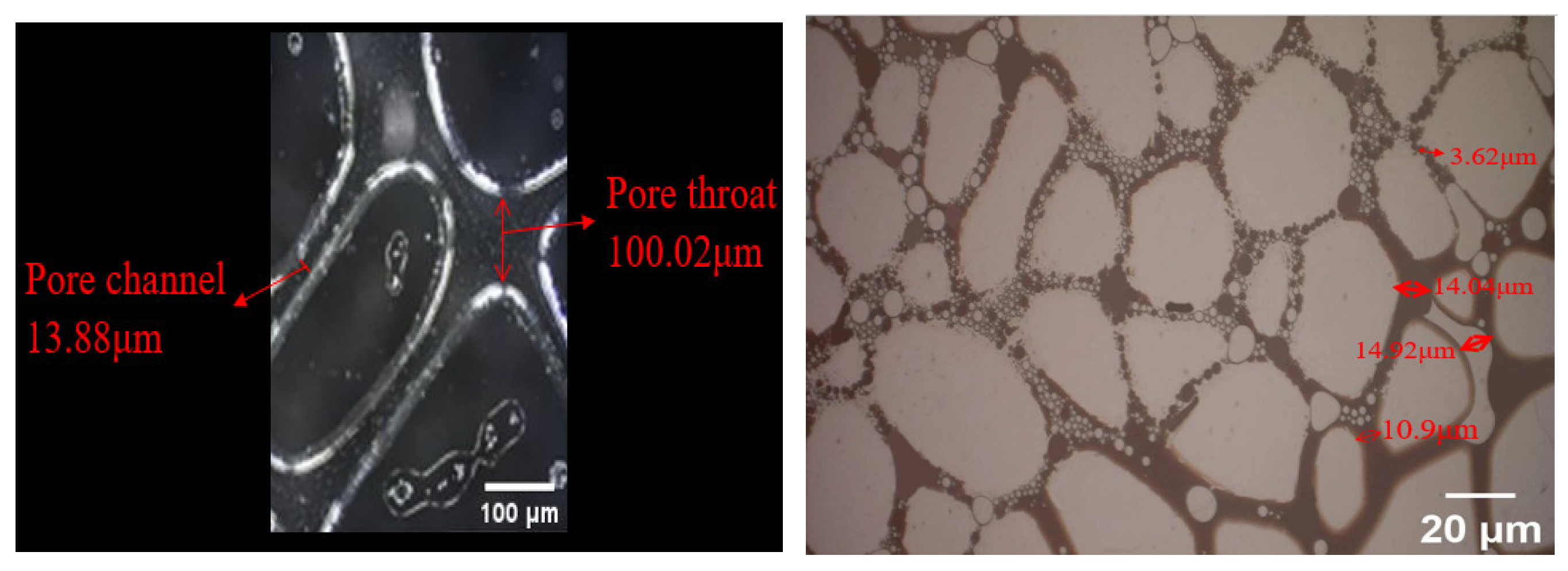

3.4.2. Pore Structure Division

3.4.3. Remaining Oil State Division

4. Results and Analysis

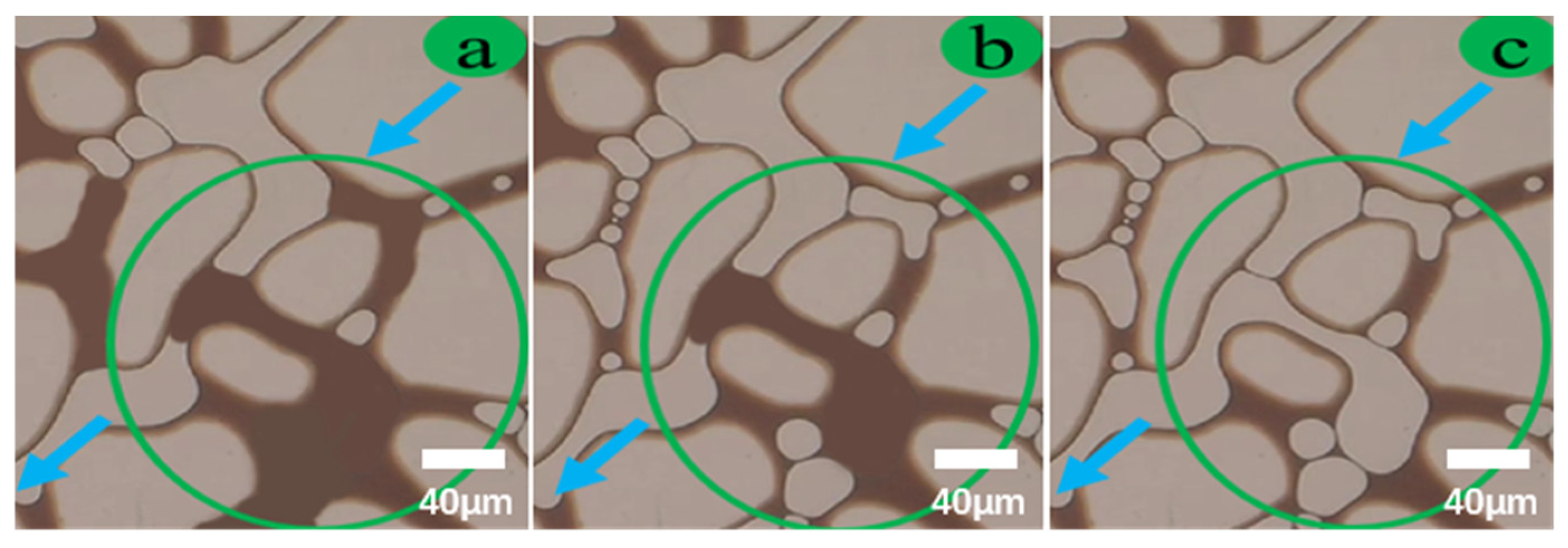

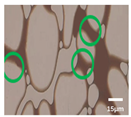

4.1. Steam Flooding Phase

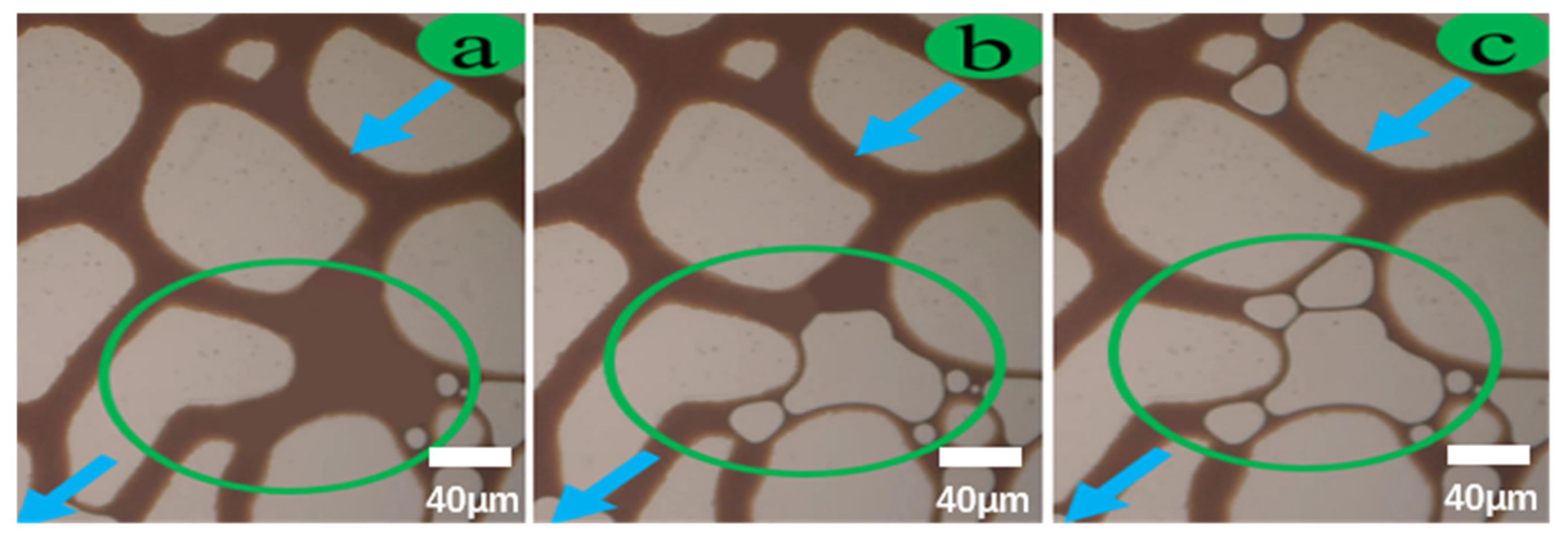

4.1.1. Main Channel Zone

- (1)

- Residual oil occurrence state

- (2)

- Residual oil occurrence pattern

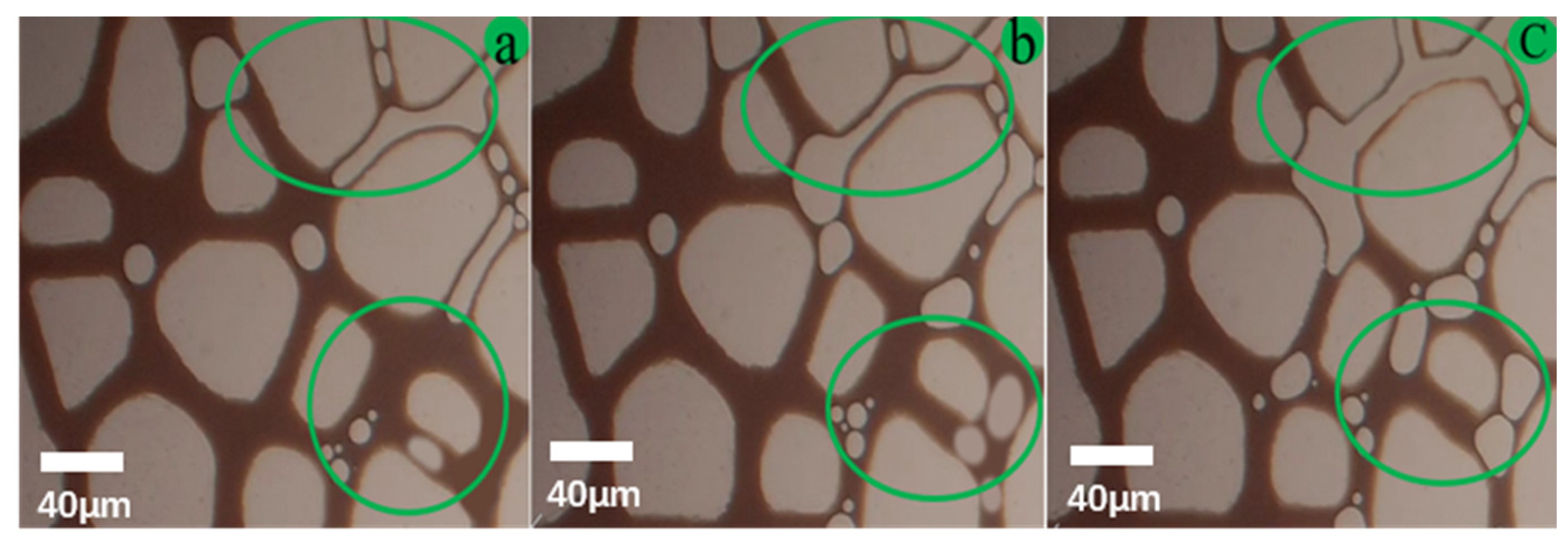

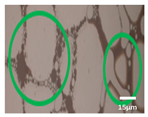

4.1.2. Near Channel Zone

- (1)

- Residual oil occurrence state

- (2)

- Residual Oil Occurrence Pattern

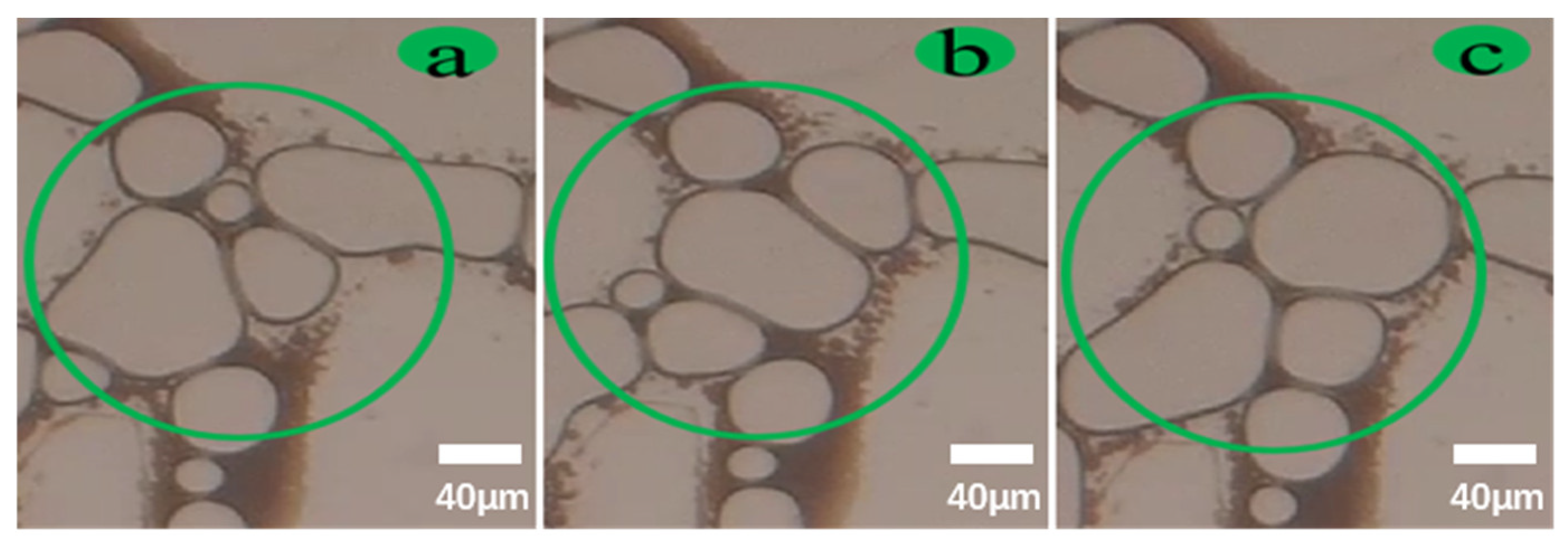

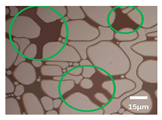

4.1.3. Far Channel Zone

- (1)

- Residual oil occurrence state

- (2)

- Residual oil occurrence pattern

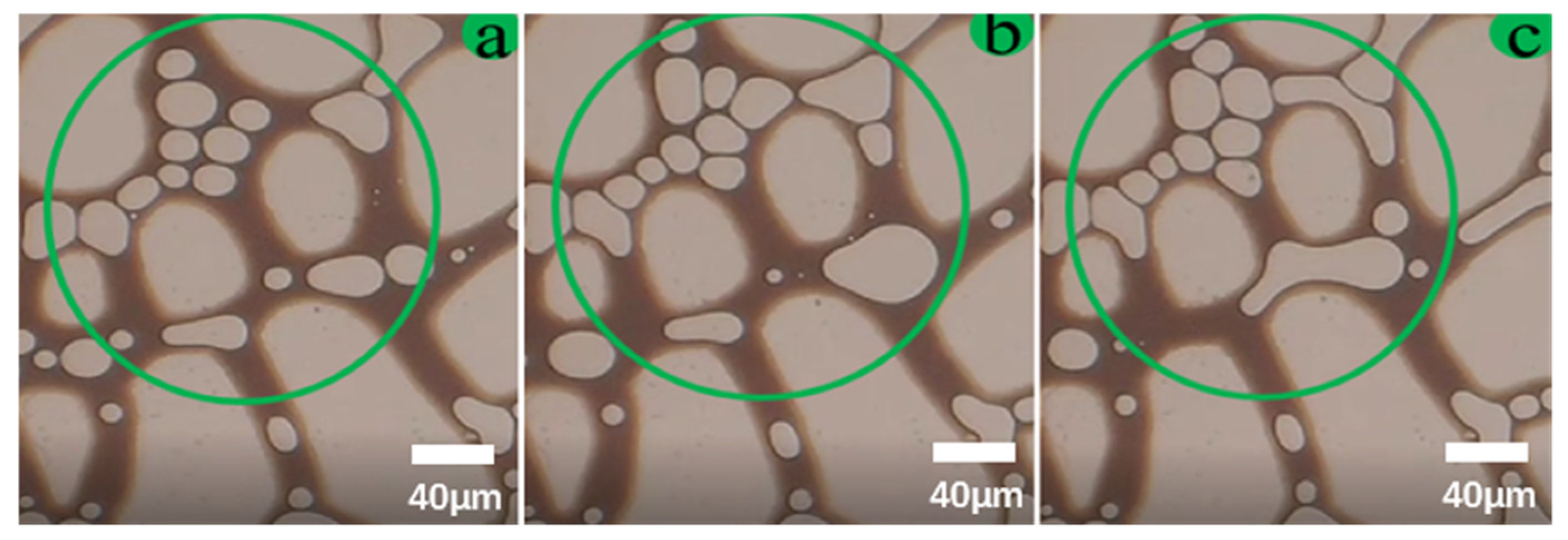

4.2. CFVAS Flooding Process

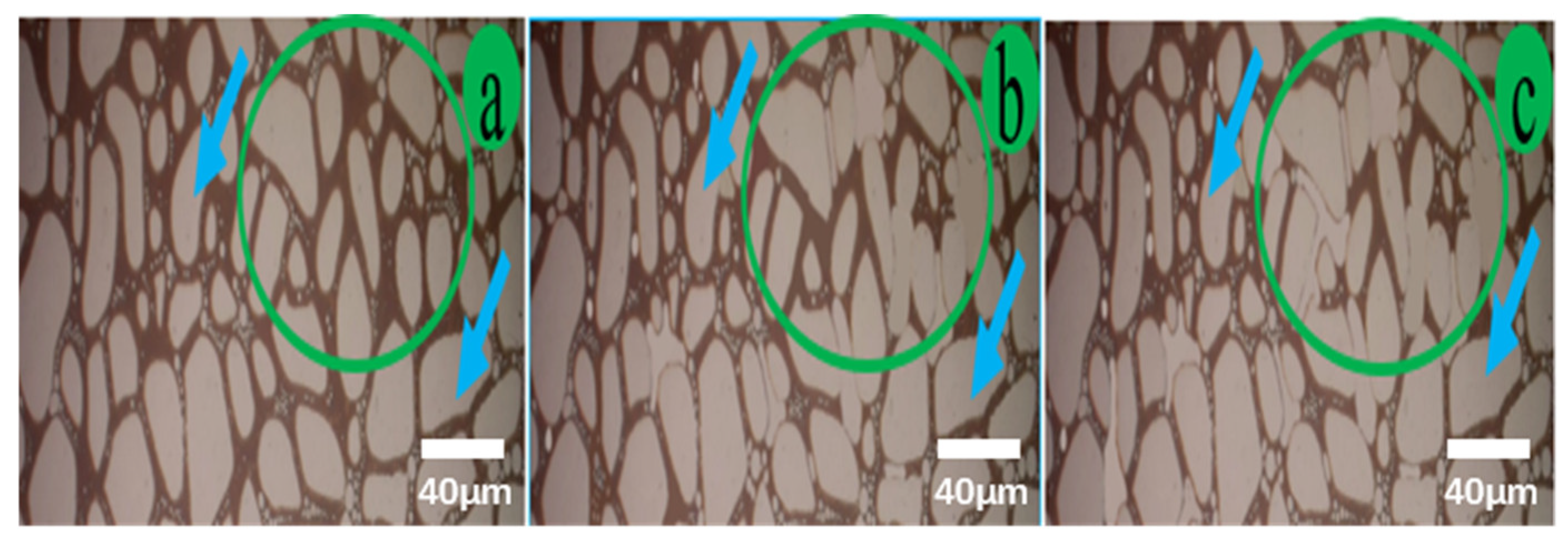

4.2.1. Main Channel Zone

- (1)

- Residual oil occurrence state

- (2)

- Residual oil occurrence pattern

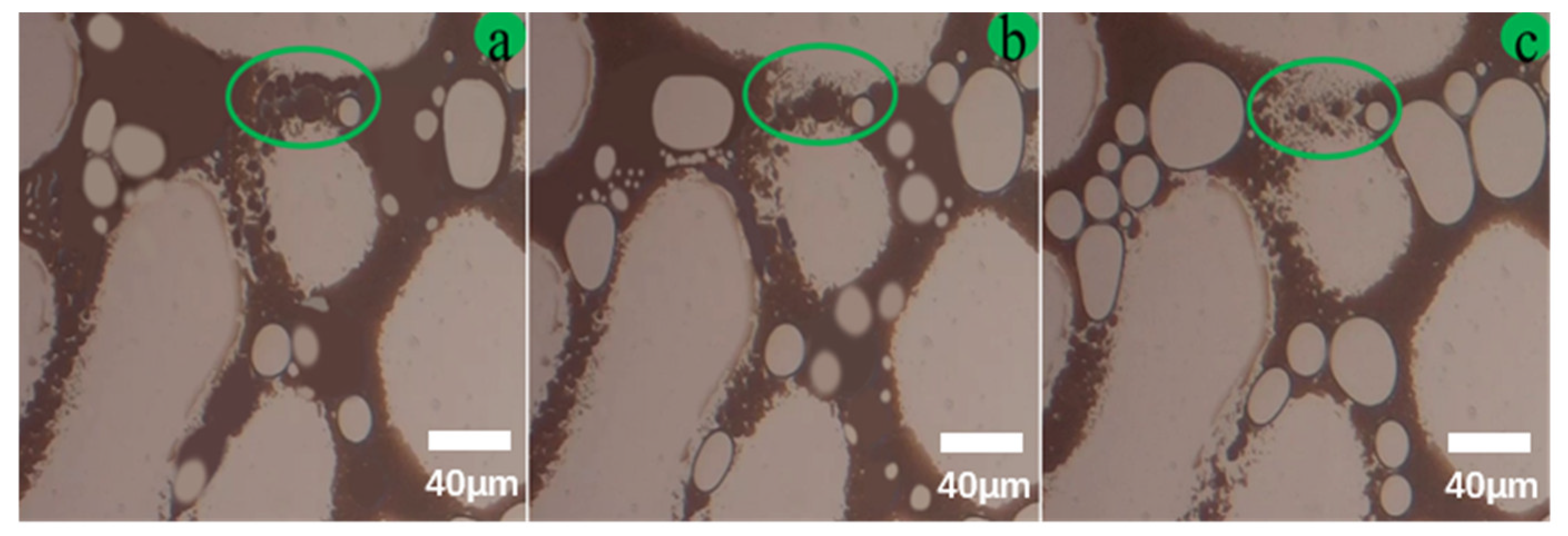

4.2.2. Near Channel Zone

- (1)

- Residual oil occurrence state

- (2)

- Residual oil occurrence pattern

4.2.3. Far Channel Zone

- (1)

- Residual oil occurrence state

- (2)

- Residual oil occurrence pattern

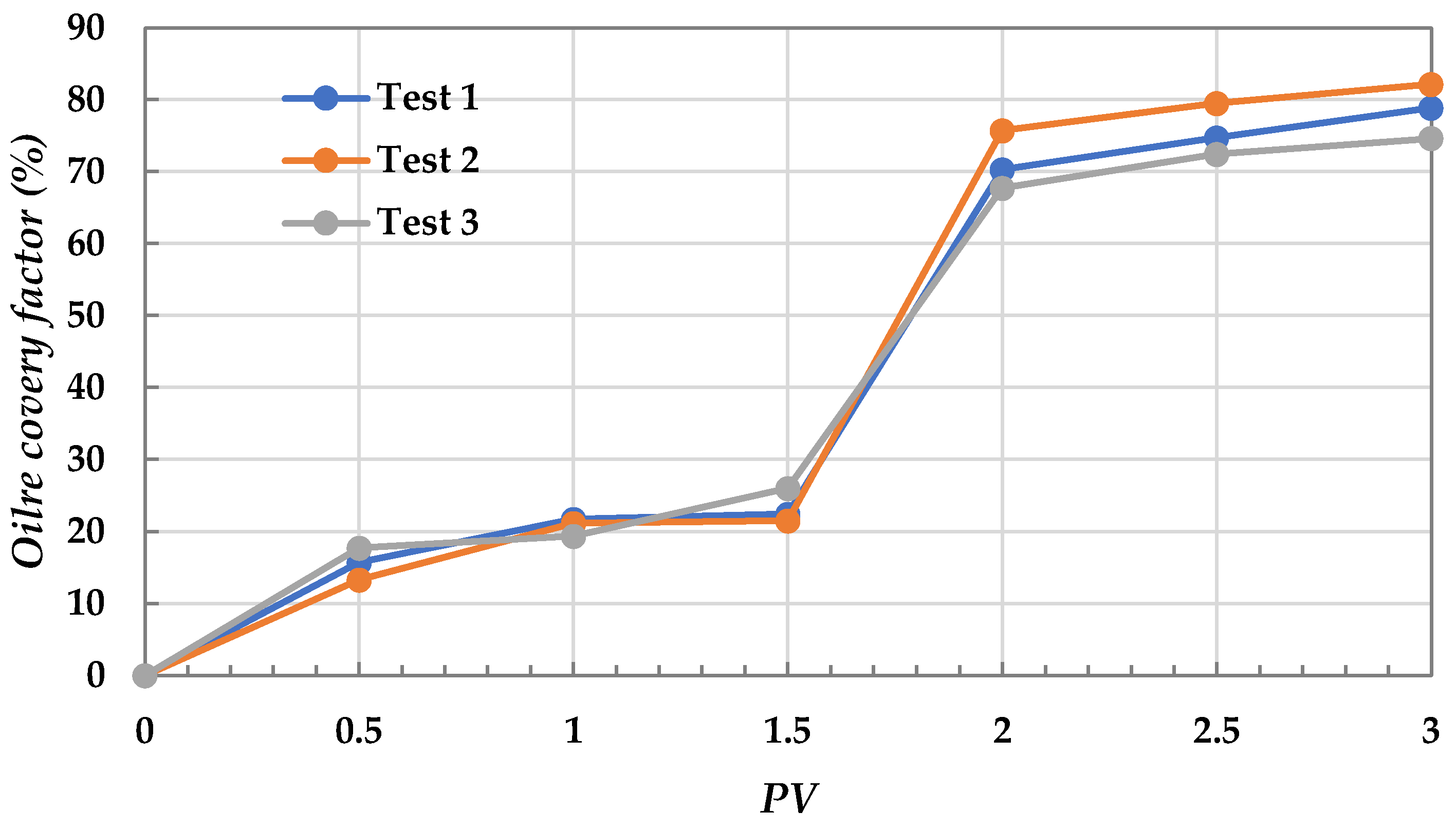

4.3. Comparison

5. Conclusions and Discussion

5.1. Conclusions

- From the two aspects of viscosity reduction effect and foam performance, the optimal concentration of foam viscosity reduction agent is 0.8 wt%, and the ratio of CO2 and foam viscosity reduction agent to gas and liquid is 1.5:1.

- The sweep range of steam flooding is small, and the oil displacement efficiency is low. The CFVAS flooding has a larger sweep area, can block the flow channel and reduce the interfacial tension, significantly improve the mobility of crude oil, and uniformly expand the displacement front. The recovery factor of CFVAS flooding is 40~55% higher than that of steam flooding.

- During CFVAS flooding, the remaining oil mainly exists in the form of an O/W emulsion or fully mixed state of oil, gas, and water, and a small part is in the form of discontinuous columns. The remaining oil form is related to the regional location, and the increase in injected PV number has a greater impact on CFVAS flooding but has little effect on the far and near flow channels

- After CFVAS flooding, crude oil in the fine pore throat is mostly emulsified and dispersed, while the residual oil in the coarse and middle pore throat is columnar with foam. In the main channel, the pores with PCNs of 3~4 were filled with foam and some O/W emulsions. In the near flow channel, O/W emulsions were mixed with a few small foams and gathered in pores with a PCN of 4. The remaining oil was characterized as O/W emulsions and columns. In the far flow channel, residual oil that is fully mixed with foam, oil, gas, and water is gathered in the pore with PCNs of 4~5.

5.2. Discussions

- Saponin is mainly extracted from tea cakes and tea waste. Tea cakes contain irritating elements that deteriorate the quality of the land. People mainly deal with it by incineration. Through our extraction and utilization, we can effectively protect the quality of the land and reduce carbon emissions. Although the effect of saponin is quite good, the extraction rate of saponin for tea seeds is only 15%.

- In terms of CO2, it can reduce CO2 emissions and promote carbon sequestration. On-site, we also recommend the use of captured CO2 injection to reduce the CO2 originally present in the atmosphere. The disadvantage is that the economic cost of captured CO2 is not low.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bernard, G.G.; Jacobs, W.L. Effect of Foam on Trapped Gas Saturation and on Permeability of Porous Media to Water. SPE J. 1965, 5, 295–300. [Google Scholar] [CrossRef]

- Wei, P.; Pu, W.; Sun, L.; Pu, Y.; Wang, S.; Fang, Z. Oil recovery enhancement in low permeable and severe heterogeneous oil reservoirs via gas and foam flooding. J. Pet. Sci. Eng. 2018, 163, 340–348. [Google Scholar] [CrossRef]

- JPT staff. CO2-Foam Floods: Foam Properties and Mobility- Reduction Effectiveness. J. Pet. Technol. 1998, 50, 69–70. [Google Scholar] [CrossRef]

- Kaleli, M.K.; Farouq, A.S.M. Controlling mobility ahead of a viscous oil bank. In Proceedings of the Annual Technical Meeting, San Antonio, TX, USA, 6–9 June 1987. Paper Number: PETSOC-87-38-64. [Google Scholar] [CrossRef]

- Rojas, G.A.; Ali, S. Dynamics of Subcritical CO2/Brine Floods for Heavy-Oil Recovery. SPE Reserv. Eng. 1988, 3, 35–44. [Google Scholar] [CrossRef]

- Ma, J.; Wang, X.; Gao, R.; Zeng, F.; Huang, C.; Tontiwachwuthikul, P.; Liang, Z. Enhanced light oil recovery from tight formations through CO2 huff and puff processes. Fuel 2021, 154, 35–44. [Google Scholar] [CrossRef]

- Alcorn, Z.P.; Fredriksen, S.B.; Sharma, M.; Rognmo, A.U.; Føyen, T.L.; Fernø, M.A.; Graue, A. An Integrated Carbon-Dioxide-Foam Enhanced-Oil-Recovery Pilot Program with Combined Carbon Capture, Utilization, and Storage in an Onshore Texas Heterogeneous Carbonate Field. SPE Reserv. Eval. Eng. 2019, 22, 1449–1466. [Google Scholar] [CrossRef]

- Koottungal, L. Special Report 2010 worldwide EOR survey. Oil Gas J. 2010, 108, 41–53. [Google Scholar]

- Jian, G.; Zhang, L.; Da, C.; Puerto, M. Evaluating the Transport Behavior of CO2 Foam in the Presence of Crude Oil under High-Temperature and High-Salinity Conditions for Carbonate Reservoirs. Energy Fuels 2022, 33, 6038–6047. [Google Scholar] [CrossRef]

- Bernard, G.G.; Holm, L.W.; Harvey, C.P. Use of Surfactant to Reduce CO2 Mobility in Oil Displacement. SPE J. 1980, 20, 281–292. [Google Scholar] [CrossRef]

- Li, S.; Wang, P.; Wang, Z.; Cheng, H.; Zhang, K. Strategy to enhance geological CO2 storage capacity in saline aquifer. Geophys. Res. Lett. 2023, 50, 101431. [Google Scholar] [CrossRef]

- Wang, Z.; Li, S.; Jin, Z. Oil and gas pathway to net-zero: Review and outlook. Energy Strategy Rev. 2023, 45, 101048. [Google Scholar] [CrossRef]

- Qin, J.; Song, J.; Tang, Y. Well applicability assessment based on fuzzy theory for CO2 sequestration in depleted gas reservoirs. Renew. Energy 2023, 206, 239–250. [Google Scholar] [CrossRef]

- Qin, J.; Zhong, Q.; Tang, Y.; Rui, Z. CO2 storage potential assessment of offshore saline aquifers in China. Fuel 2023, 341, 127681. [Google Scholar] [CrossRef]

- He, Y.; Qiao, Y.; Qin, J. A novel method to enhance oil recovery by inter-fracture injection and production through the same multi-fractured horizontal well. J. Energy Resour. Technol. 2022, 144, 043005. [Google Scholar] [CrossRef]

- Rishi, L.; Mandal, M.M. Enhanced oil recovery using polyaniline-sodium dodecyl sulfate-sodium hydroxide flooding. Chem. Eng. Technol. 2022, 45, 497–507. [Google Scholar] [CrossRef]

- Yu, Y.; García, B.F.; Saraji, S. Surfactant viscoelasticity as a key parameter to improve supercritical CO2 foam stability/foamability and performance in porous media. J. Non-Newton. Fluid Mech. 2022, 282, 104311. [Google Scholar] [CrossRef]

- Lib, W.T.; Wei, F.L.; Xiong, C.M. Effect of Salinities on Supercritical CO2 Foam Stabilized by a Betaine Surfactant for Improving Oil Recovery. Energy Fuels 2021, 33, 8312–8322. [Google Scholar]

- Yang, K.; Li, S.; Zhang, K. Synergy of hydrophilic nanoparticle and nonionic surfactant on stabilization of carbon dioxide-in-brine foams at elevated temperatures and extreme salinities. Fuel 2021, 288, 119624. [Google Scholar] [CrossRef]

- Wang, P.; You, Q.; Han, L. Experimental Study on the Stabilization Mechanisms of CO2 Foams by Hydrophilic Silica Nanoparticles. Energy Fuels 2021, 32, 3709–3715. [Google Scholar] [CrossRef]

- Lai, N.J.; He, X.; Wang, J.Q.; Tang, L. Study on the Stabilization Mechanism of Wormlike Micelle-CO2 Foams in High-Temperature and High-Salt Oil Reservoirs. Energy Fuels 2023, 37, 10939–10950. [Google Scholar] [CrossRef]

- Mathew, E.S.; Shaik, A.R.; Sumaiti, A.A.; AlAmeri, W. Effect of Oil Presence on CO2 Foam Based Mobility Control in High Temperature High Salinity Carbonate Reservoirs. Energy Fuels 2018, 32, 2983–2992. [Google Scholar] [CrossRef]

- Li, W.; Zeng, H. Effect of temperature on the stability of supercritical CO2 foam stabilized with a betaine surfactant at high pressure. Colloids Surf. A Physicochem. Eng. Asp. 2022, 649, 129362. [Google Scholar] [CrossRef]

- Zhu, D.; Li, B.; Chen, L.; Zhang, C.; Zheng, L.; Chen, W.; Li, Z. Experimental investigation of CO2 foam flooding-enhanced oil recovery in fractured low-permeability reservoirs: Core-scale to pore-scale. Fuel 2024, 362, 130792. [Google Scholar] [CrossRef]

- Gümrah, F.; Baĝcı, S. Steam-CO2 drive experiments using horizontal and vertical wells. J. Pet. Sci. Eng. 1997, 18, 113–129. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, Q.; Trivedi, J.; Li, Y.; Liu, J.; Liu, Z.; Liu, S. Investigation on enhanced oil recovery and CO2 storage efficiency of temperature-resistant CO2 foam flooding. Fuel 2024, 364, 130870. [Google Scholar] [CrossRef]

- Wei, B.; Pang, S.; Pu, W.; Lu, L.; Wang, C.; Kong, L. Mechanisms of N2 and CO2 Assisted Steam Huff-n-Puff Process in Enhancing Heavy Oil Recovery: A Case Study Using Experimental and Numerical Simulation. In Proceedings of the SPE Middle East Oil & Gas Show and Conference, Manama, Bahrain, 18–21 March 2017. Paper Number: SPE-183871-MS. [Google Scholar] [CrossRef]

- Majeed, T.; Kamal, M.S.; Zhou, X.M.; Solling, T.A. Review on Foam Stabilizers for Enhanced Oil Recovery. Energy Fuels 2021, 35, 5594–5612. [Google Scholar] [CrossRef]

- Stone, T.; Malcolm, J.D. Simulation of a large steam-CO2 co-injection experiment. J. Can. Pet. Technol. 1985, 24, 51–59. [Google Scholar] [CrossRef]

- Whelan, W.J. New Technology for Cold Lake. J. Can. Pet. Technol. 1984, 23. [Google Scholar] [CrossRef]

- Ding, M.C.; Li, Q.; Yuan, Y.J. Permeability and heterogeneity adaptability of surfactant-alternating-gas foam for recovering oil from low-permeability reservoirs. Pet. Sci. 2022, 19, 1185–1197. [Google Scholar] [CrossRef]

- Jia, B.; Xian, C.; Tsau, J.S.; Zuo, X.; Jia, W. Status and Outlook of Oil Field Chemistry-Assisted Analysis during the Energy Transition Period. Energy Fuels 2022, 36, 12917–12945. [Google Scholar] [CrossRef]

- Mohammed-Singh, L.J.; Singhal, A.K.; Sim, S.K. Screening Criteria for CO2 Huff-n-Puff Operations. In Proceedings of the SPE/DOE Symposium on Improved Oil Recovery, Tulsa, OK, USA, 22–26 April 2006. Paper Number: SPE-100044-MS. [Google Scholar] [CrossRef]

| Name | Chemical Formula | Mass Percentage |

|---|---|---|

| Sodium tripolyphosphate | Na5P3O10 | 3% |

| Sodium nonylphenol polyoxyethylene ether sulfate | C30H46O·OSO3Na+ | 12% |

| Sapindus saponins | C46H74O16 | 8% |

| Coconut oil diethanolamine | C4H11NO2 | 5% |

| Distilled water | H2O | 72% |

| Continuous Residual Oil | Dispersed Residual Oil | ||

|---|---|---|---|

| Clusters form | Columniform | Film shape | Isolated island shape |

|  |  |  |

| Displacement Stage | Flow Channel | Residual Oil Status | Residual Oil Pattern | Effect of Injection PV Number |

|---|---|---|---|---|

| Steam flooding | Main channel | Clusters form, columniform, film shape | Mostly in the fine throat | The amount of film remaining oil increases |

| Near channel | Columniform, film shape | Mostly in the fine throat and small hole | Columnar remaining oil increases in the small hole | |

| Far channel | Clusters form, a few are columnar and film-shape | Mostly distributed in coarse, middle-throat | The clusters are transformed into film shapes and columns | |

| CFVAS flooding | Main channel | O/W emulsion | Distributed in the thick and middle throat | The O/W emulsion in the pores gradually flows into the throat |

| Near channel | O/W emulsions and columns | The number of O/W emulsions increases | ||

| Far channel | Columnar and fully mixed state of oil, gas, and water |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, W.; Gong, Y.; Tao, L.; Bai, J.; Xu, Z.; Zhu, Q.; Ma, Y. Research for Flow Behavior of Heavy Oil by CO2 Foam Viscosity Reducer-Assisted Steam (CFVAS) Flooding: Microscopic Displacement Experiment Study. Processes 2024, 12, 1582. https://doi.org/10.3390/pr12081582

Shi W, Gong Y, Tao L, Bai J, Xu Z, Zhu Q, Ma Y. Research for Flow Behavior of Heavy Oil by CO2 Foam Viscosity Reducer-Assisted Steam (CFVAS) Flooding: Microscopic Displacement Experiment Study. Processes. 2024; 12(8):1582. https://doi.org/10.3390/pr12081582

Chicago/Turabian StyleShi, Wenyang, Yunpeng Gong, Lei Tao, Jiajia Bai, Zhengxiao Xu, Qingjie Zhu, and Yunpeng Ma. 2024. "Research for Flow Behavior of Heavy Oil by CO2 Foam Viscosity Reducer-Assisted Steam (CFVAS) Flooding: Microscopic Displacement Experiment Study" Processes 12, no. 8: 1582. https://doi.org/10.3390/pr12081582