The Three-Dimensional Heterogeneous Simulation Study of CO2 Flooding in Low-Permeability Reservoirs

Abstract

:1. Introduction

2. Experimental Materials and Equipment

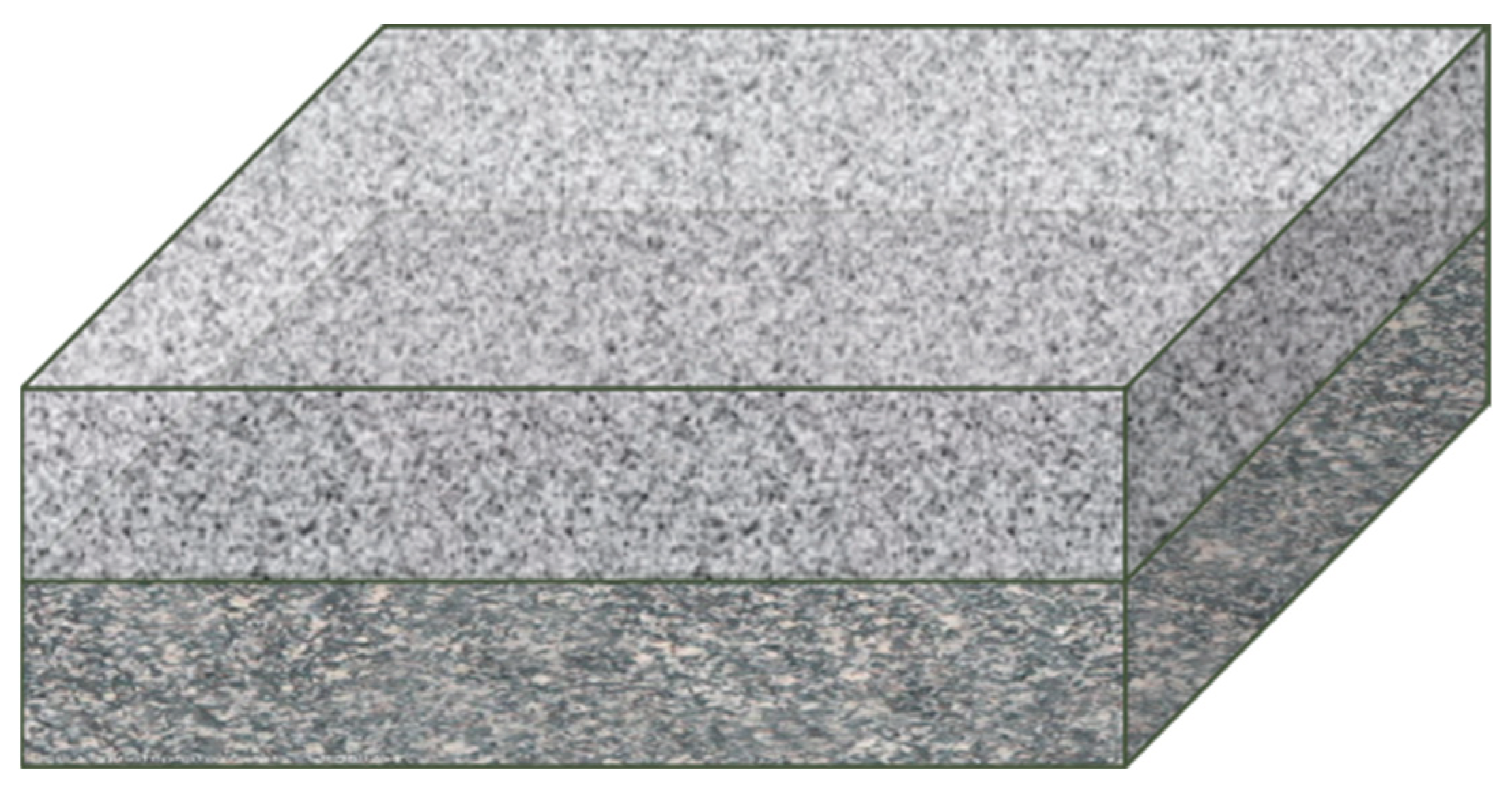

2.1. Experimental Core

2.2. Experimental Fluids

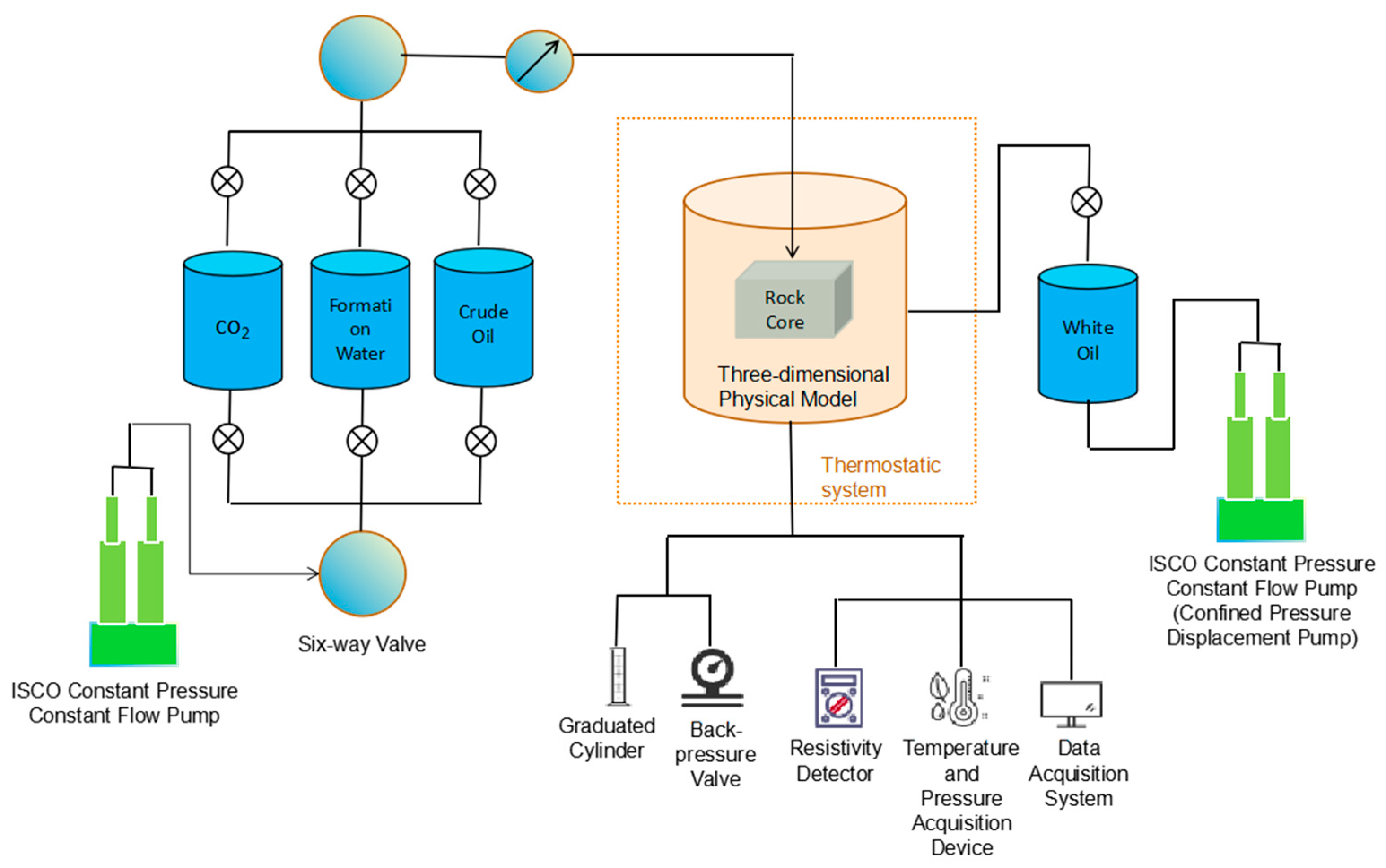

2.3. Experimental Equipment and Materials

3. Experimental Principles and Procedures

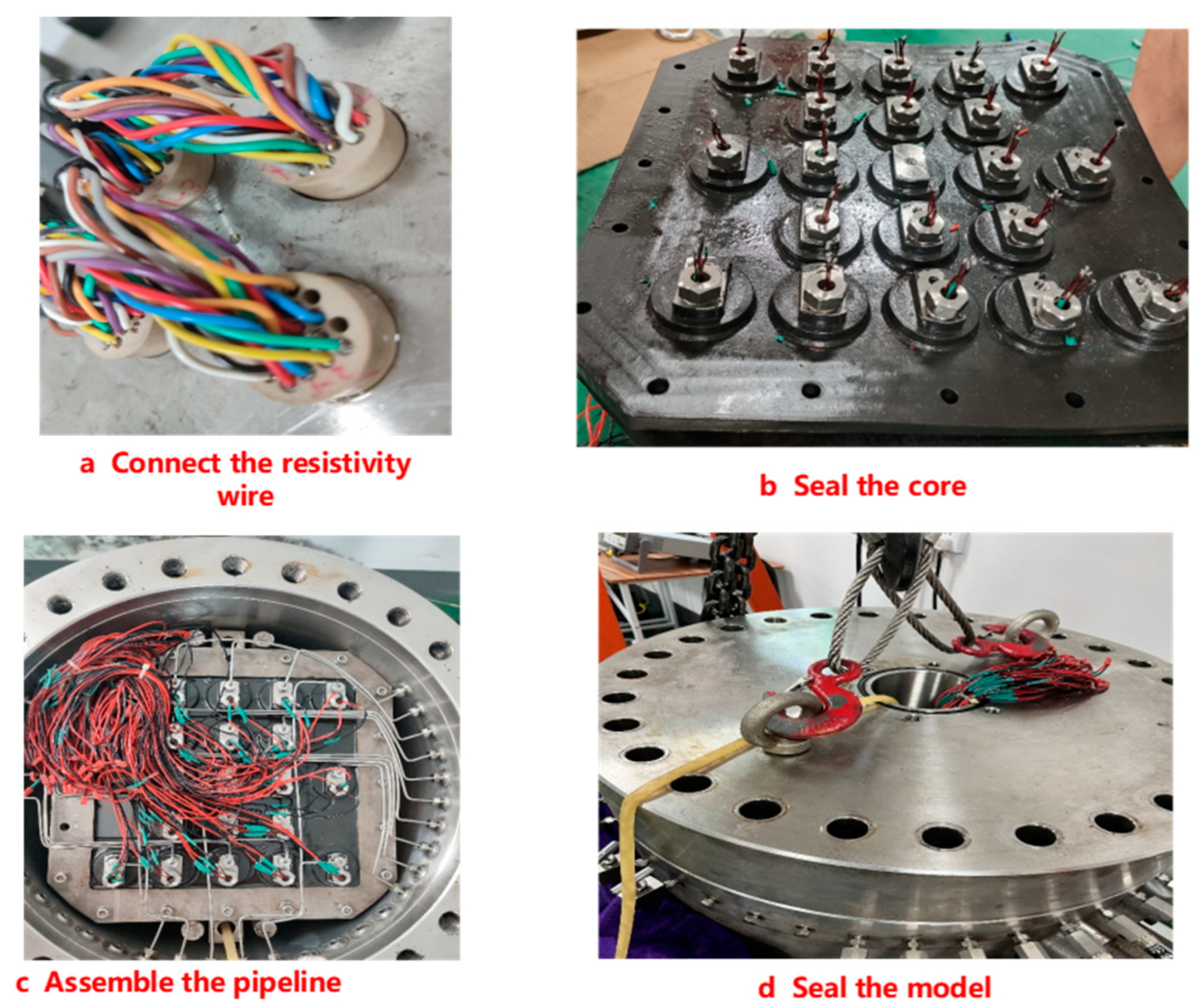

3.1. Installation and Debugging of Three-Dimensional Large Model

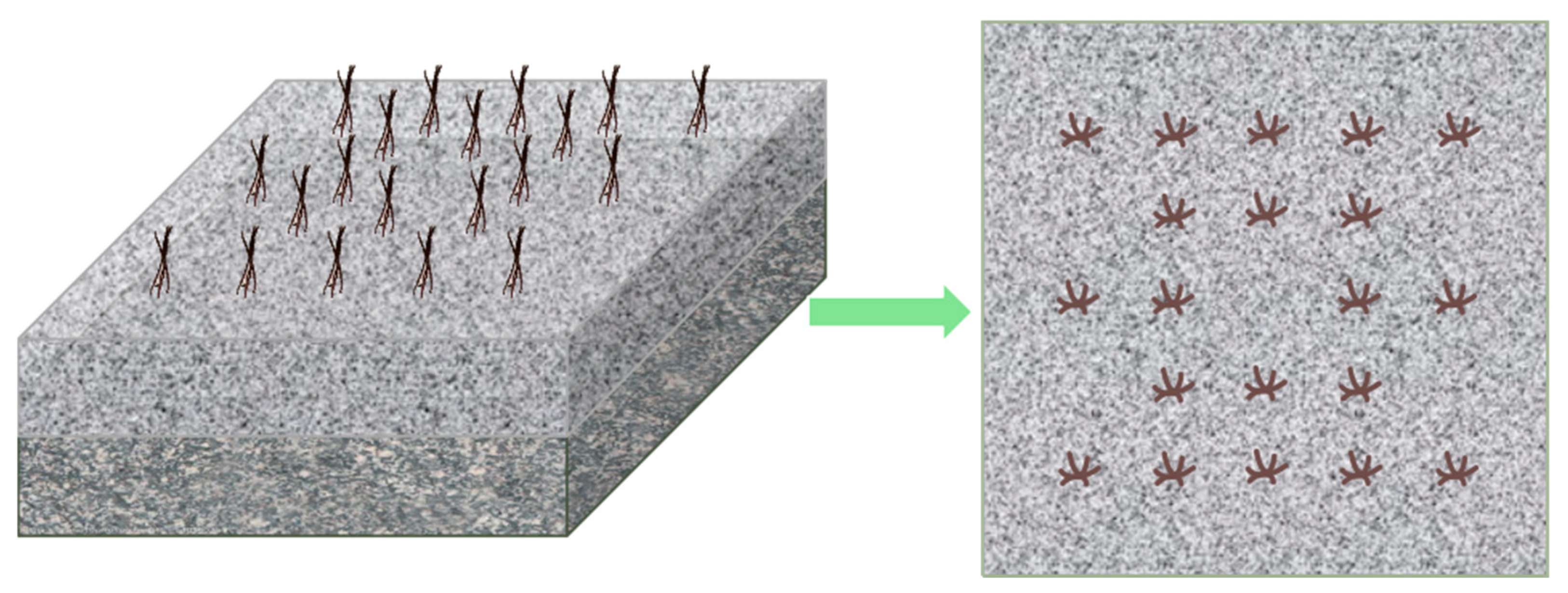

3.1.1. Embedding Probes into the Core

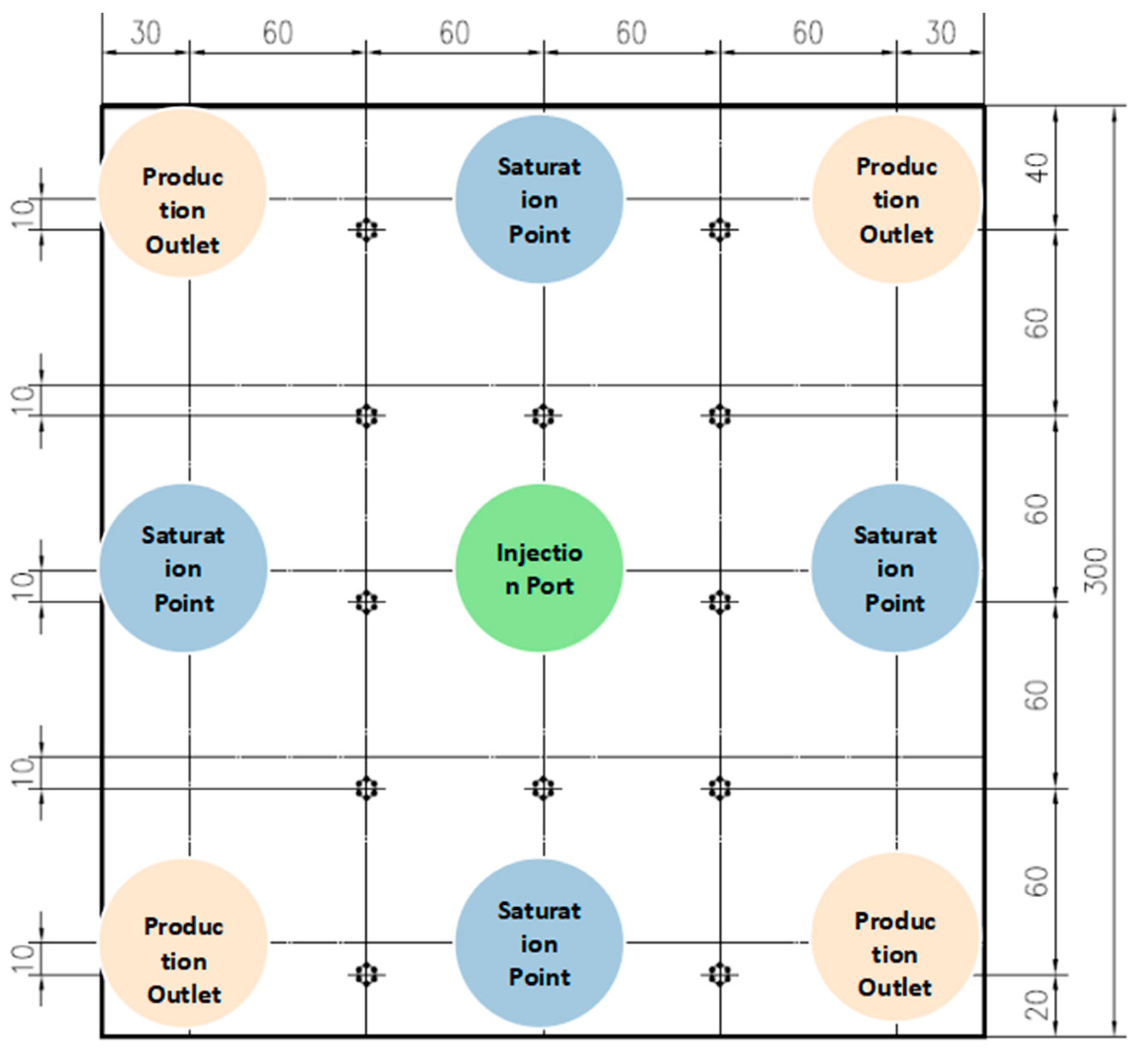

3.1.2. Core Sample Well Layout and Drilling

3.1.3. Three-Dimensional Model Debugging and Installation

3.1.4. Saturating the Core Sample

3.2. Experimental Plan

4. Experimental Results and Analysis

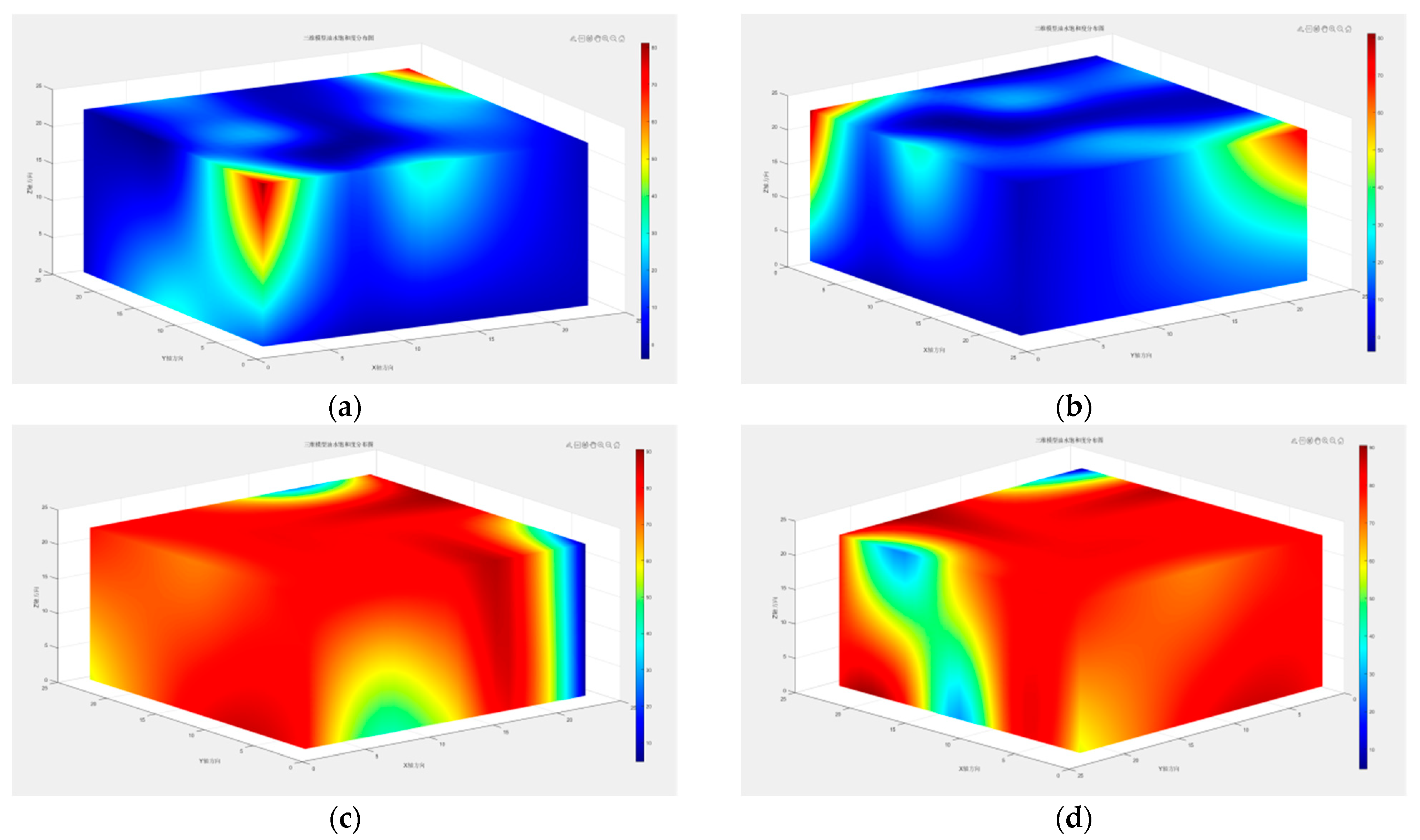

4.1. Residual Oil Distribution

4.2. Experimental Results and Analysis of Different Oil Displacement Methods in Three-Dimensional Models

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shi, W.; Gong, Y.; Tao, L.; Bai, J.; Xu, Z.; Zhu, Q.; Ma, Y. Research for Flow Behavior of Heavy Oil by CO2 Foam Viscosity Reducer-Assisted Steam (CFVAS) Flooding: Microscopic Displacement Experiment Study. Processes 2024, 12, 1582. [Google Scholar] [CrossRef]

- Wang, X.; Yang, H.; Wang, W.; Li, J.; Liang, Q. Advances in Enhanced Oil Recovery Techniques for Low-Permeability Reservoirs in Yanchang Oilfield. Pet. Geol. Recovery Effic. 2022, 29, 69–75. [Google Scholar]

- Chen, Z.; Dong, Y.; Hu, H.; Zhang, X.; Tang, S. Evaluation of the Synergistic Oil Displacement Effect of a CO2 Low Interfacial Tension Viscosity-Increasing System in Ultra-Low Permeability Reservoirs. Processes 2024, 12, 1476. [Google Scholar] [CrossRef]

- Kong, D.; Gao, Y.; Sarma, H.; Li, Y.; Guo, H.; Zhu, W. Experimental investigation of immiscible water-alternating-gas injection in ultra-high water-cut stage reservoir. Adv. Geo-Energy Res. 2021, 5, 139–152. [Google Scholar] [CrossRef]

- Zhang, T.; Sun, Z.; Feng, D.; Zhao, W. Advances in Enhancing Unconventional Oil/Gas Recovery. Processes 2024, 12, 1386. [Google Scholar] [CrossRef]

- Zhang, Y.; Feng, H.; Zhai, Y.; Zhou, X.; Liu, D.; Wang, K. Study on the Mechanism and Laws of Improving Oil Recovery by CO2 Pressure Drive in Low-Permeability Heavy Oil Reservoirs. Pet. Drill. Tech. 2024, 52, 1–18. [Google Scholar]

- Song, R.; Tang, Y.; Wang, Y.; Xie, R.; Liu, J. Pore-Scale Numerical Simulation of CO2–Oil Two-Phase Flow: A Multiple-Parameter Analysis Based on Phase-Field Method. Energies 2022, 16, 82. [Google Scholar] [CrossRef]

- Zhang, K.; Zhang, L.; Liu, D. Recent Trends and Development Recommendations for Oil and Gas Exploration and Development in China. Acta Pet. Sin. 2022, 43, 15–28+111. [Google Scholar]

- Wei, Y.; Dong, Y.; Chen, Z.; Zhang, X.; Hu, H.; Tang, S. Research Progress on CO2 Injection Techniques for Improving Oil Recovery in Oil and Gas Reservoirs. Fine Petrochem. 2024, 41, 69–74. [Google Scholar] [CrossRef]

- Du, Y.; Zhang, H.; Li, X.; Zhang, Y.; Yuan, S. A Molecular Dynamics Study On The Suitable Compatibility Conditions Of CO2-Cosolvent-Light Hydrocarbon System By Calculating the Solubility Parameters. Energy Fuels 2020, 34, 3483–3492. [Google Scholar] [CrossRef]

- Wang, Q.; Yang, S.; Bai, J.; Qian, K.; Li, J. Effects of CO2 Injection Methods on Oil Recovery and Reservoir Damage in Heterogeneous Multilayer Reservoirs. Acta Pet. Sin. 2020, 41, 875–884+902. [Google Scholar]

- Cao, C.; Chen, X.; Zhang, L.; Zhao, Y.; Wen, S.; Zhao, Z.; Yang, B.; Zhu, H. Research Progress on CO2 Injection for Improving Oil Recovery and Storage Evaluation Methods in Gas Reservoirs. Sci. Technol. Eng. 2024, 24, 7463–7475. [Google Scholar]

- Shi, Y.; Jia, Y.; Pan, W. Mechanism of Supercritical CO2 Injection for Enhanced Recovery in Low-Permeability Tight Gas Reservoirs. Oil Gas Geol. 2017, 38, 610–617. [Google Scholar]

- Li, R.; Jiang, P.; He, D.; Chen, X.; Xu, R. Experimental Investigation on the Behavior of Supercritical CO2 during Reservoir Depressurization. Environ. Ecience Technol. 2017, 51, 8869–8876. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Zhou, D.; Deng, J.; Deng, J.; Ray, R.; Jiang, Z. Experimental Study on Enhancing Recovery of Tight Oil Reservoirs Using Supercritical CO2 Flooding. Spec. Oil Gas Reserv. 2021, 28, 118–123. [Google Scholar]

- Zhang, J.; Li, J.; Zhang, W.; Sheng, G.; Dong, H. Experimental and Application Evaluation of CO2 Miscible Flooding for Enhanced Oil Recovery in Conglomerate Reservoirs. Daqing Pet. Geol. Dev. 2024, 1–10. [Google Scholar] [CrossRef]

- Jin, X.; Du, M.; Lv, W.; Hao, C.; Yao, L. Reservoir Characteristics of the Chang 6 Member in the Erdos Basin and Experimental Study on Improving Oil Recovery by CO2 Flooding. Oil Gas Geol. Recovery Effic. 2024, 1–13. Available online: http://kns.cnki.net/kcms/detail/37.1359.TE.20240513.1724.001.html (accessed on 2 August 2024).

- Qu, F.; Wang, Q.; Tong, S.; Deng, S. Mechanism and Parameter Optimization of CO2 Injection for Enhancing Oil Recovery in Gulong Shale Oil through Supplemental Energy. Daqing Pet. Geol. Dev. 2024, 1–7. [Google Scholar] [CrossRef]

- Liu, X.; Zheng, X.; Qian, D.; Gao, H.; Tan, T.; Pu, W. Laboratory Study on Enhanced Oil Recovery in Tahe Strong Bottom Water Sandstone Reservoirs by Gas-Water Alternating Injection with N_2 Mixed Gas. J. Yangtze Univ. (Nat. Sci. Ed.) 2022, 19, 57–64. [Google Scholar] [CrossRef]

- Zhang, G.; Li, D.; Jia, G.; Deng, C.; Jia, Z. Laboratory Study on CO2 Flooding in Long Cores from Huabei Oilfield. Pet. Geol. Eng. 2022, 36, 77–81. [Google Scholar]

- Zhang, L.; Tan, X.; Jiao, Y. Experimental and Numerical Simulation Study on Enhanced Oil Recovery by CO2 Micro-Foam Flooding in Offshore Low-Permeability Reservoirs. China Offshore Oil Gas 2023, 35, 145–153. [Google Scholar]

- Yuan, D. Three-Dimensional Physical Simulation Study on Enhanced Oil Recovery by N2 Foam/CO2 Cyclic Injection. Pet. Drill. Tech. 2022, 50, 126–132. [Google Scholar]

- Ren, S.; Du, X.; Sun, Z. Research Progress on Gas-Water Alternating Injection and Foaming Agent Systems for Enhanced Oil Recovery. J. China Univ. Pet. (Ed. Nat. Sci.) 2022, 46, 102–108. [Google Scholar]

- Zhang, L.; Xie, H.; Wang, R.; Fu, G.; Xu, S.; Deng, C. Development and Performance Study of High-Foaming and Strong Imbibition Displacement Agents for Tight Oil Reservoirs. Mod. Chem. Ind. 2024, 44, 155–162. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, S.; Cao, X.; Lyu, Q.; Lyu, G.; Zhang, C.; Li, Z.; Zhang, D.; Zheng, W. Theoretical Technology and Field Practice of CO2 High-Pressure Miscible Displacement and Sequestration in Shengli Oilfield. Pet. Explor. Dev. 2024, 1–12. Available online: http://kns.cnki.net/kcms/detail/11.2360.TE.20240731.1012.002.html (accessed on 3 August 2024).

- Yang, Z.; Wu, W.; Dong, Z.; Lin, M.; Zhang, S.; Zhang, J. Reducing the Minimum Miscibility Pressure of CO2 and Crude Oil Using Alcohols. Colloids Surf. A Physicochem. Eng. Asp. 2019, 568, 105–112. [Google Scholar] [CrossRef]

- Liu, H.; Zhao, J.; Zheng, J.; Wu, B.; Zuo, Q.; Hu, X.; Wu, Q. Experimental Study on the Feasibility of CO2 Miscible Flooding in Offshore Low-Permeability Reservoirs. Unconv. Oil Gas 2024, 11, 74–79. [Google Scholar] [CrossRef]

- Zhang, K.; Perdomo, M.E.; Kong, B.; Sebakhy, K.O.; Wu, K.; Jing, G.; Han, J.; Lu, X.; Hong, A.; Chen, Z. CO2 Near-Miscible Flooding for Tight Oil Exploitation. In Proceedings of the SPE Asia Pacific Unconventional Resources Conference and Exhibition, Nusa Dua, Bali, Indonesia, 9–11 November 2015. [Google Scholar]

- Yuan, S.; Ma, D.; Li, J.; Zhou, T.; Ji, Z.; Han, H. Progress and Prospect of Industrialization of Carbon Dioxide Capture, Oil Displacement, and Sequestration. Pet. Explor. Dev. 2022, 49, 828–834. [Google Scholar] [CrossRef]

- Li, Y.; Sui, X.; Li, B. Laboratory Study on Methods for Enhanced Oil Recovery After Polymer Flooding. Acta Pet. Sin. 2008, 3, 405–408. [Google Scholar]

- Lan, J.; Tang, F.; Xie, D.; Liang, X.; Wang, G. Experimental Study on CO2 Flooding for Enhanced Oil Recovery in Tight Oil Reservoirs. Contemp. Chem. Ind. 2023, 52, 997–1001. [Google Scholar] [CrossRef]

- Cao, J.; Li, N.; Wang, X. Current Status of CO2 Injection Technology for Enhanced Oil Recovery in Tight Oil Reservoirs. Shandong Chem. Ind. 2022, 51, 133–135. [Google Scholar] [CrossRef]

- Li, S.; Tang, Y.; Hou, C. Current Status and Development Trends of CO2 Injection Technology for Enhanced Oil Recovery. Reserv. Eval. Dev. 2019, 9, 1–8. [Google Scholar] [CrossRef]

- Hu, S.; Tao, S.; Yan, W.; Yang, Z.; Men, G.; Tang, Z.; Xue, J.; Chen, X.; Jia, X.; Jiang, T.; et al. Advances on Enrichment Law and Key Technologies of Exploration and Development of Continental Tight Oil in China (2016–2018). J. Nat. Gas Geosci. 2019, 4, 297–307. [Google Scholar] [CrossRef]

- Abedini, A.; Torabi, F. On the CO2 storage potential of cyclic CO2 injection process for enhanced oil recovery. Fuel 2014, 124, 14–27. [Google Scholar] [CrossRef]

- Rezk, M.G.; Foroozesh, J. Determination of mass transfer parameters and swelling factor of CO2-oil systems at high pressures. Int. J. Heat Mass Transf. 2018, 126, 380–390. [Google Scholar] [CrossRef]

- Mohamed, I.M.; Nasr-El-Din, H.A. Formation damage due to CO2 sequestration in deep saline carbonate aquifers. In Proceedings of the SPE International Symposium and Exhibition on Formation Damage Control, Society of Petroleum Engineers, Lafayette, LA, USA, 23–24 February 2022. [Google Scholar]

- Zhang, K.; Seetahal, S.; Alexander, D.; Lv, J.; Hu, Y.; Lu, X.; Zhang, D.; Wu, K.; Chen, Z. Effect of Confinement on Gas and Oil Relative Permeability During CO2 Flooding in Tight Oil Reservoirs. In Proceedings of the SPE Trinidad and Tobago Section Energy Resources Conference, Virtual, 13–15 June 2016. [Google Scholar]

- Huang, C.; Huo, L.; Wu, C. Progress and Prospect of CO2 Resource Utilization Technology Based on Unconventional Oil and Gas Development. Unconv. Oil Gas 2022, 9, 1–9. [Google Scholar] [CrossRef]

- Assef, Y.; Kantzas, A.; Almao, P.P. Numerical Modelling of Cyclic CO2 Injection in Unconventional Tight Oil Resources; Trivial Effects of Heterogeneity and Hysteresis in Bakken Formation. Fuel 2019, 236, 1512–1528. [Google Scholar] [CrossRef]

- Lv, G.; Li, Q.; Wang, S.; Li, X. Key Techniques of Reservoir Engineering and Injection-Production Process for CO2 Flooding in China’s SINOPEC Shengli Oilfield. J. CO2 Util. 2015, 11, 31–40. [Google Scholar] [CrossRef]

- Ding, M.; Wang, Y.; Wang, Y.; Gao, M.; Liu, D.; Chen, W. Experimental Investigation of Bypassed-Oil Recovery via CO2 Soaking and Huff and Puff Injection: Effects of Miscibility and Bypassed-Oil Size. Fuel 2019, 248, 152–160. [Google Scholar] [CrossRef]

- Zhang, B.; Nie, F.; Deng, X.; Wang, Y.; Hou, B. Evaluation of an Oxygen-Reduced Air Flooding Plugging System and Its Injection Method in the Honghe Oilfield. Energy Fuels 2022, 36, 12524–12532. [Google Scholar] [CrossRef]

- Zhou, J.; Zhang, B.; Lei, Z.; Shao, X.; Guan, Y.; Cao, R. Core Experiments and Oil Enhancement Mechanism of Unstable Water Injection in Low-Permeability Reservoirs. Xinjiang Pet. Geol. 2022, 43, 491–495. [Google Scholar]

| Ion Type | K+ + Na+ | Mg2+ | Ca2+ | HCO3− | SO42− | Cl− | Total Salinity | Water Type | pH |

|---|---|---|---|---|---|---|---|---|---|

| Salinity mg/L | 18,736.1 | 54.7 | 216.4 | 3624.5 | 178.1 | 1054.7 | 23,947.3 | NaHCO3 | 6.2 |

| Comparative Scheme | First Round Injection Volume (PV) | Second Round Injection Volume (PV) | Third Round Injection Volume (PV) | Fourth Round Injection Volume (PV) | Fifth Round Injection Volume (PV) | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Alternating displacement of CO2 and Water | CO2 | Water | CO2 | Water | CO2 | Water | CO2 | Water | CO2 | Water |

| 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | |

| Alternating CO2–Water combined with Foam flooding | CO2 | foam | CO2 | foam | CO2 | foam | CO2 | foam | CO2 | foam |

| 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | |

| Alternating CO2–Water combined with Surfactant flooding | CO2 | imbibition agent | CO2 | imbibition agent | CO2 | imbibition agent | CO2 | imbibition agent | CO2 | imbibition agent |

| 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Nie, F.; Zhang, B.; Liu, T.; Hong, Y. The Three-Dimensional Heterogeneous Simulation Study of CO2 Flooding in Low-Permeability Reservoirs. Processes 2024, 12, 1843. https://doi.org/10.3390/pr12091843

Liu Y, Nie F, Zhang B, Liu T, Hong Y. The Three-Dimensional Heterogeneous Simulation Study of CO2 Flooding in Low-Permeability Reservoirs. Processes. 2024; 12(9):1843. https://doi.org/10.3390/pr12091843

Chicago/Turabian StyleLiu, Yang, Fajian Nie, Bin Zhang, Tenglong Liu, and Yi Hong. 2024. "The Three-Dimensional Heterogeneous Simulation Study of CO2 Flooding in Low-Permeability Reservoirs" Processes 12, no. 9: 1843. https://doi.org/10.3390/pr12091843