A Numerical Study on Key Thermal Parameters and NOx Emissions of a Hydrogen-Fueled Double-Channel Outlet Micro Cylindrical Combustor Employing a Heat-Recirculating Configuration for Thermophotovoltaic Applications

Abstract

:1. Introduction

2. Numerical Methodology

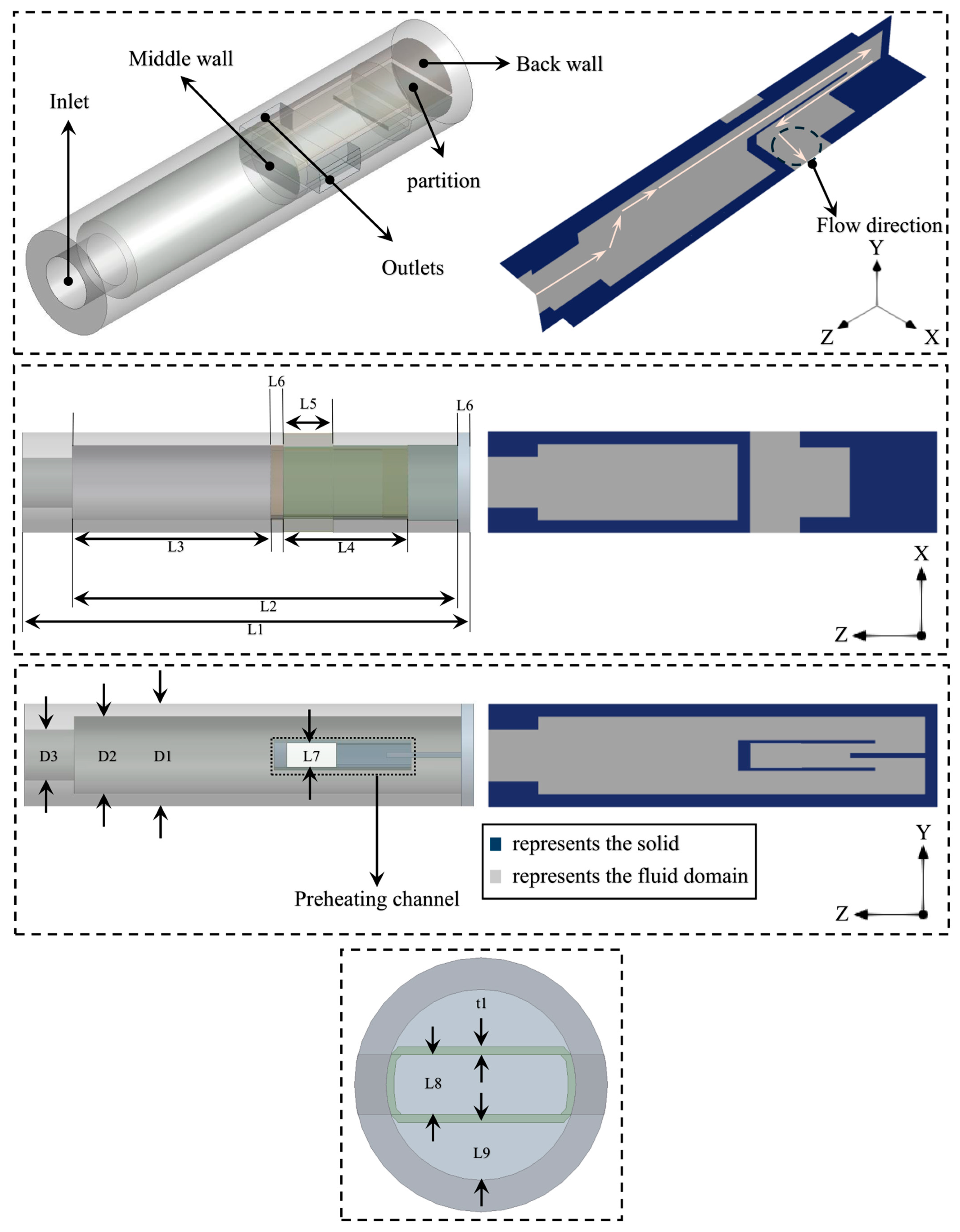

2.1. Geometric Model

2.2. Governing Equations

2.3. Numerical Setup and Boundary Conditions

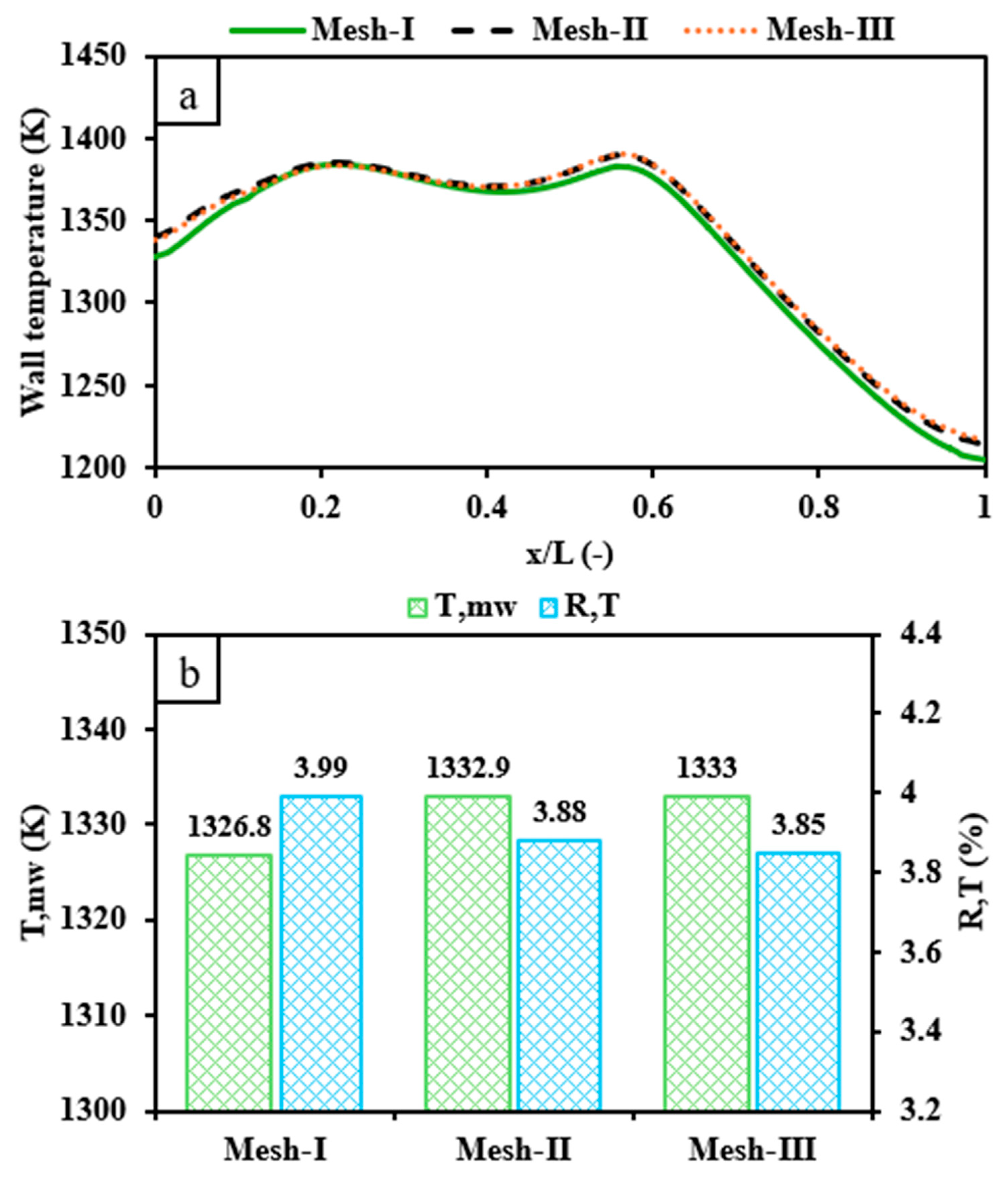

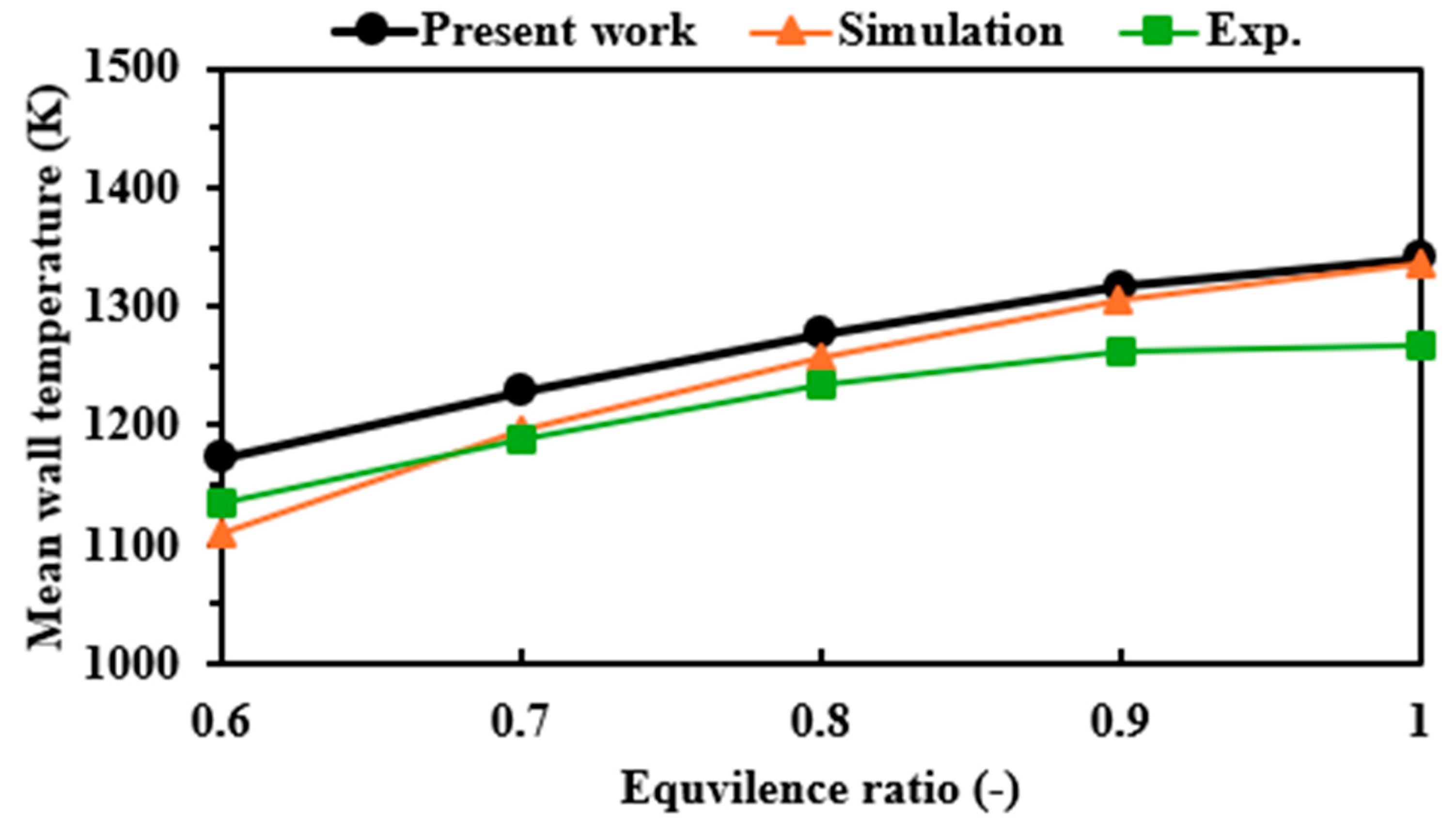

2.4. Mesh Sensitivity Analysis and Model Validation

3. Results

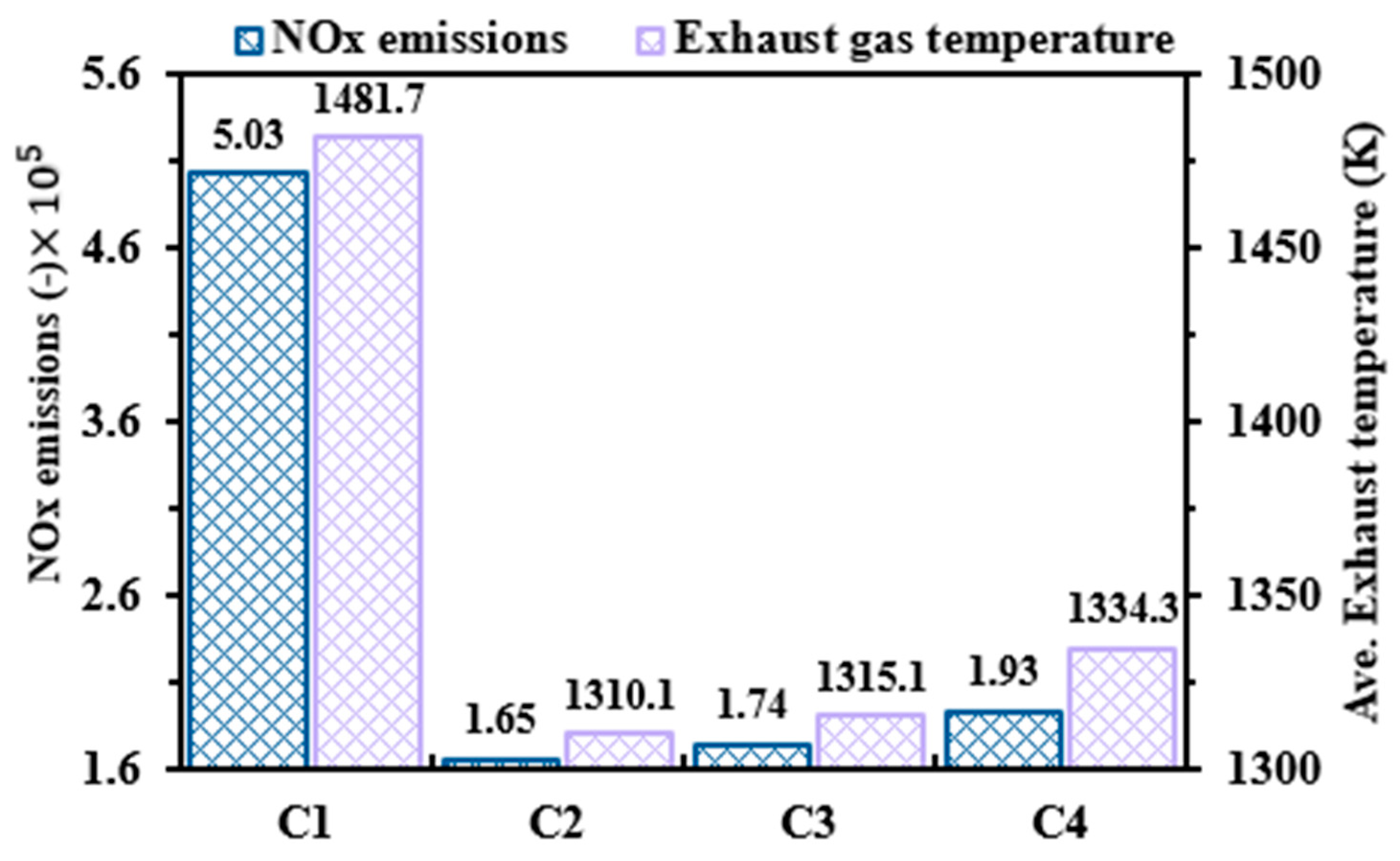

3.1. Effects of Newly Proposed Design and Preheating Channel Lengths

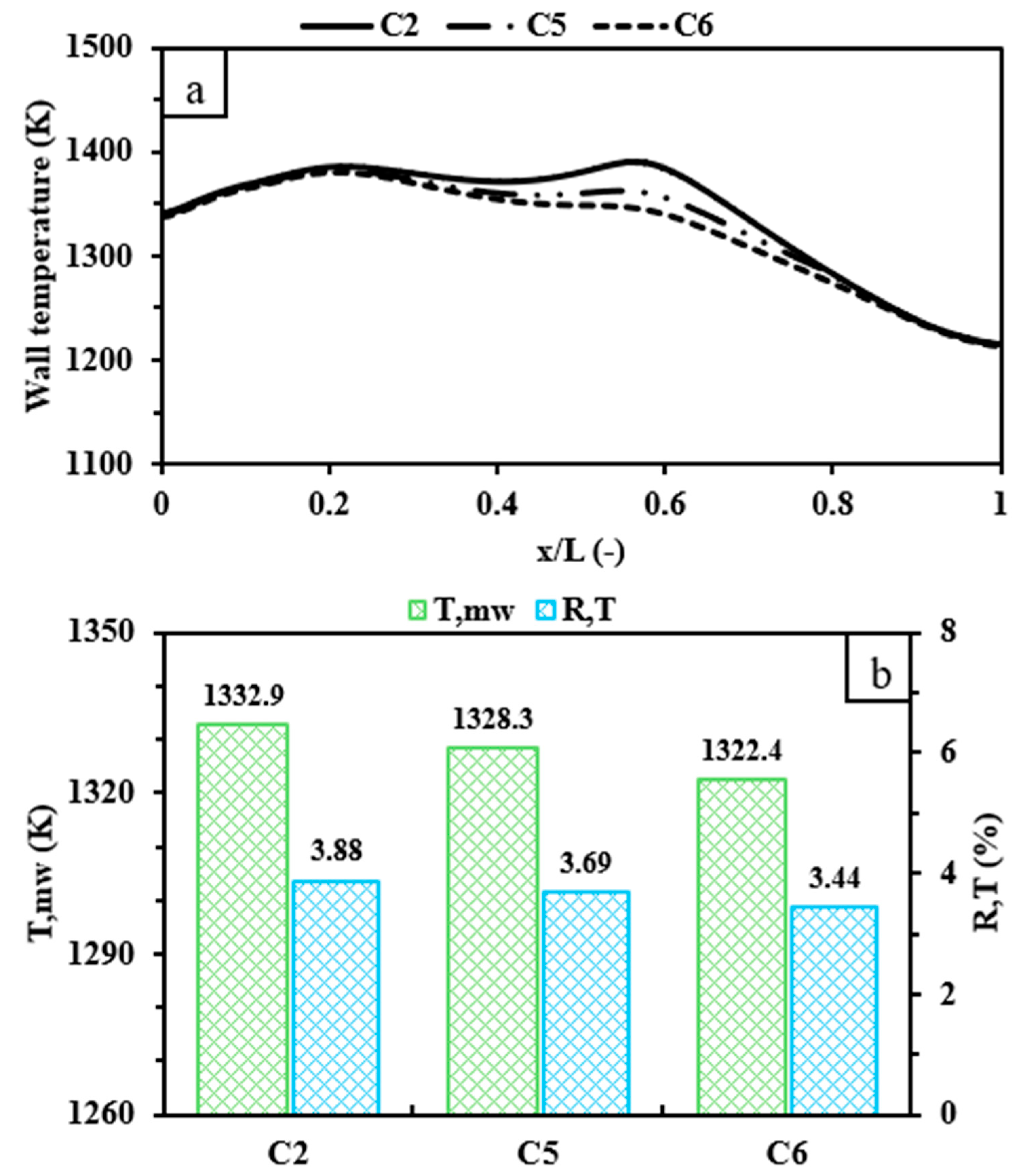

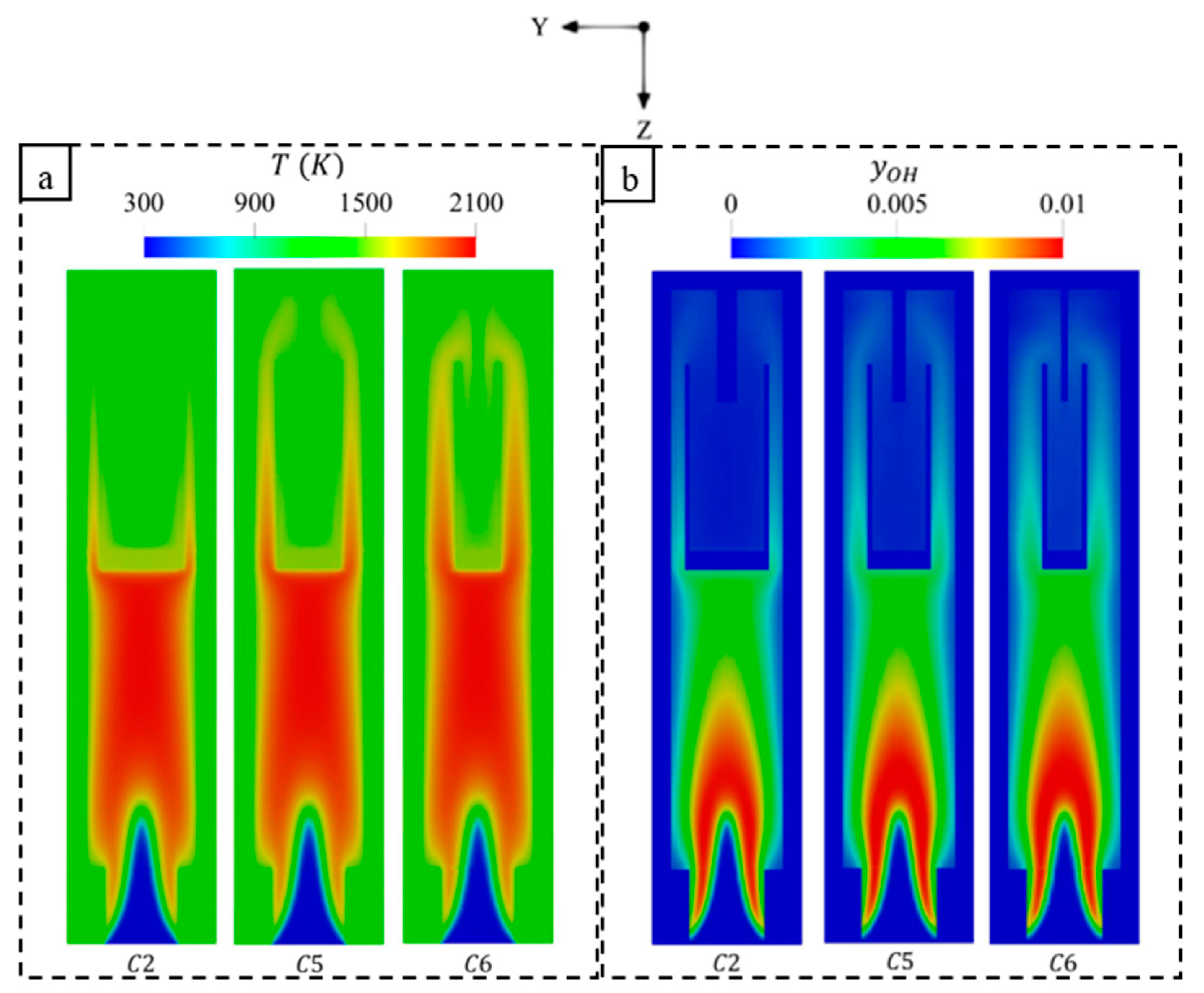

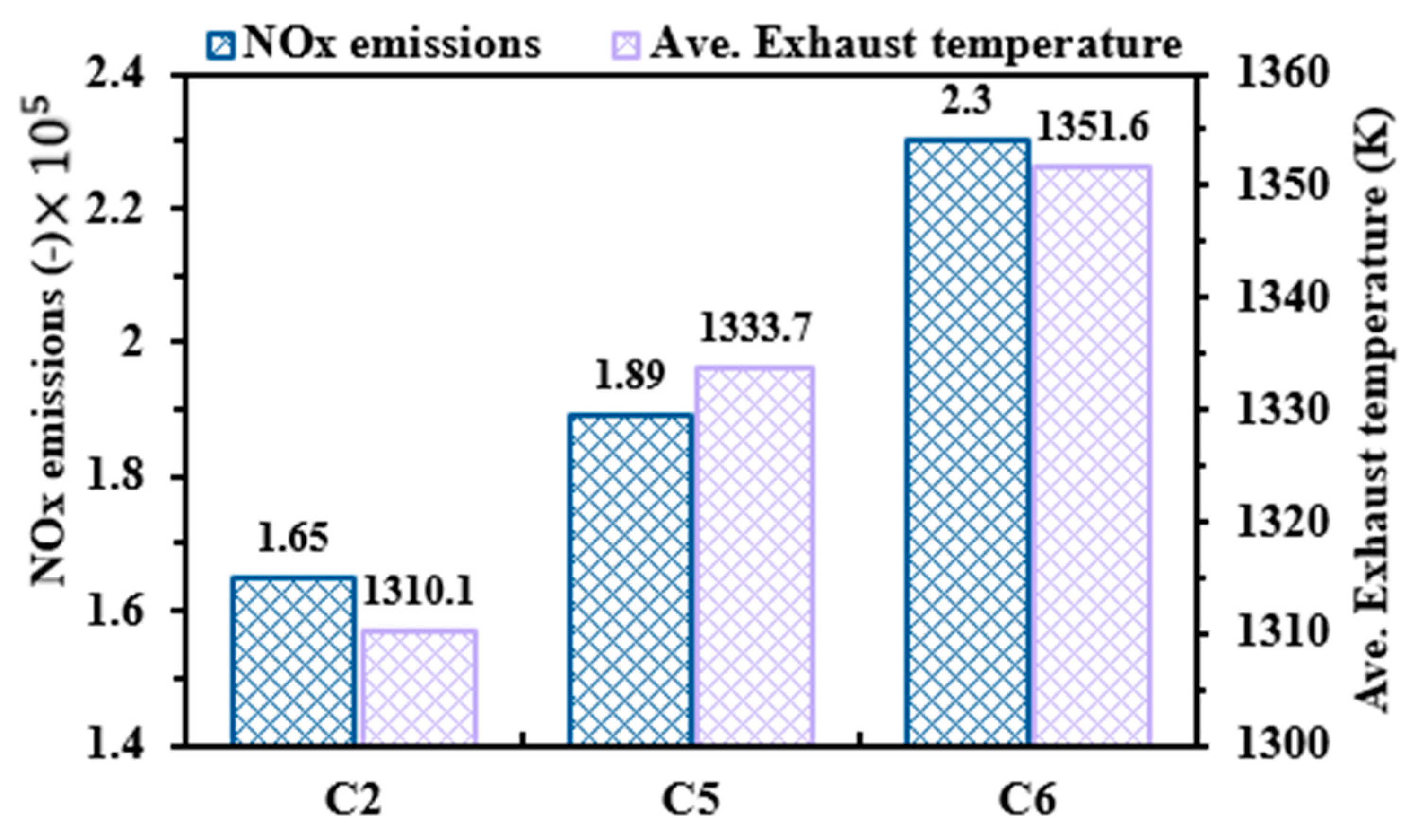

3.2. Effects of Preheating Channel Width

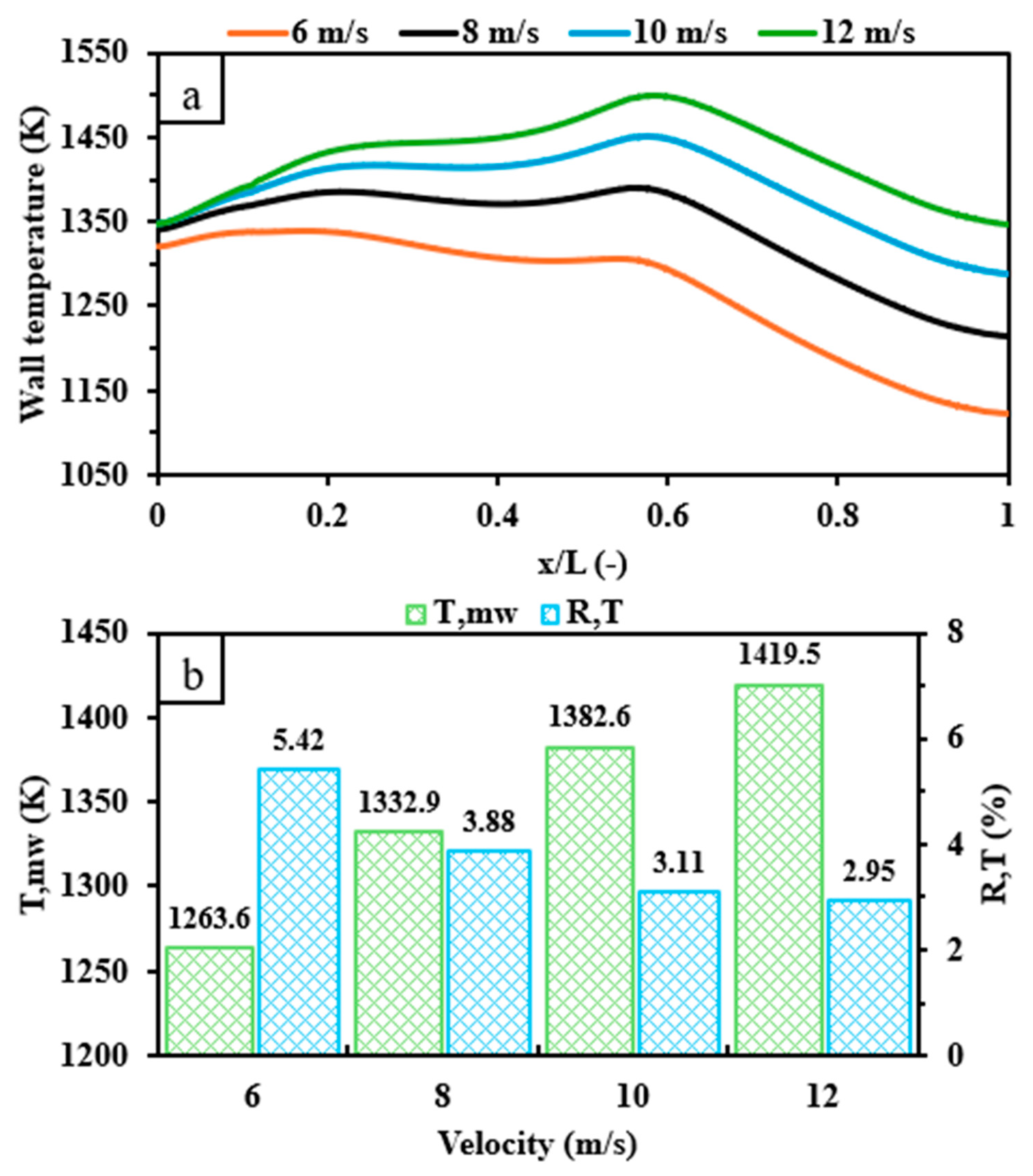

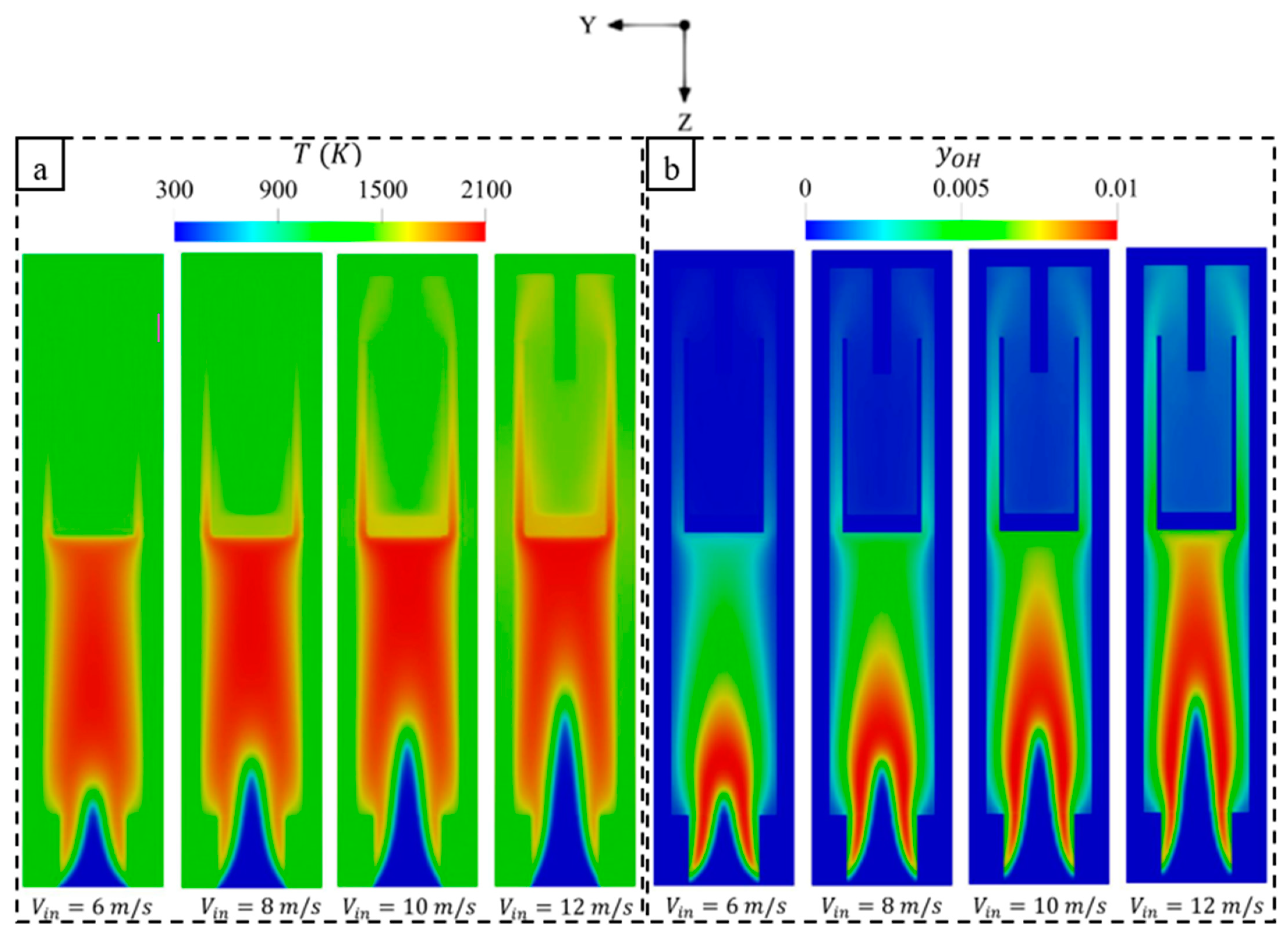

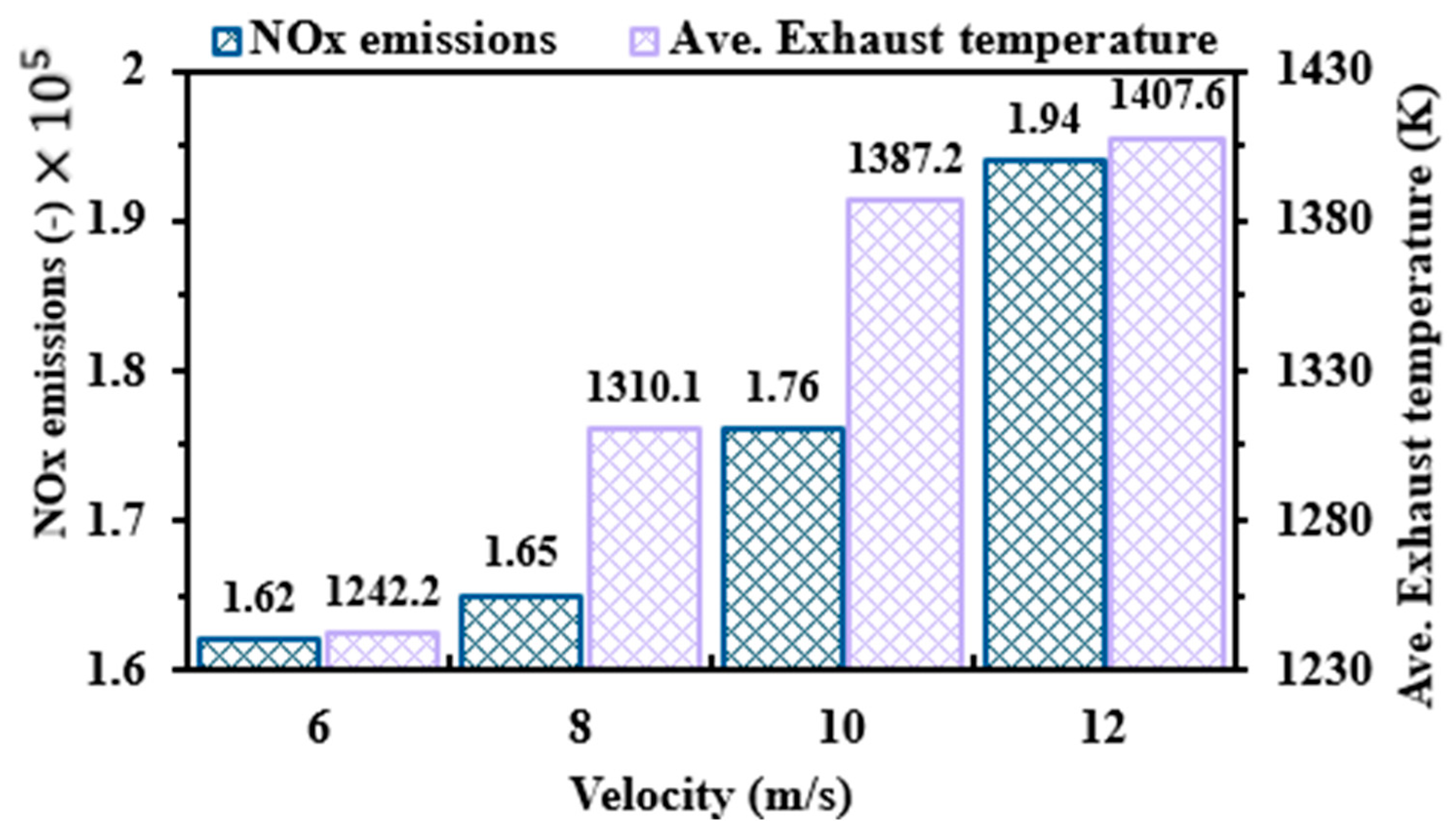

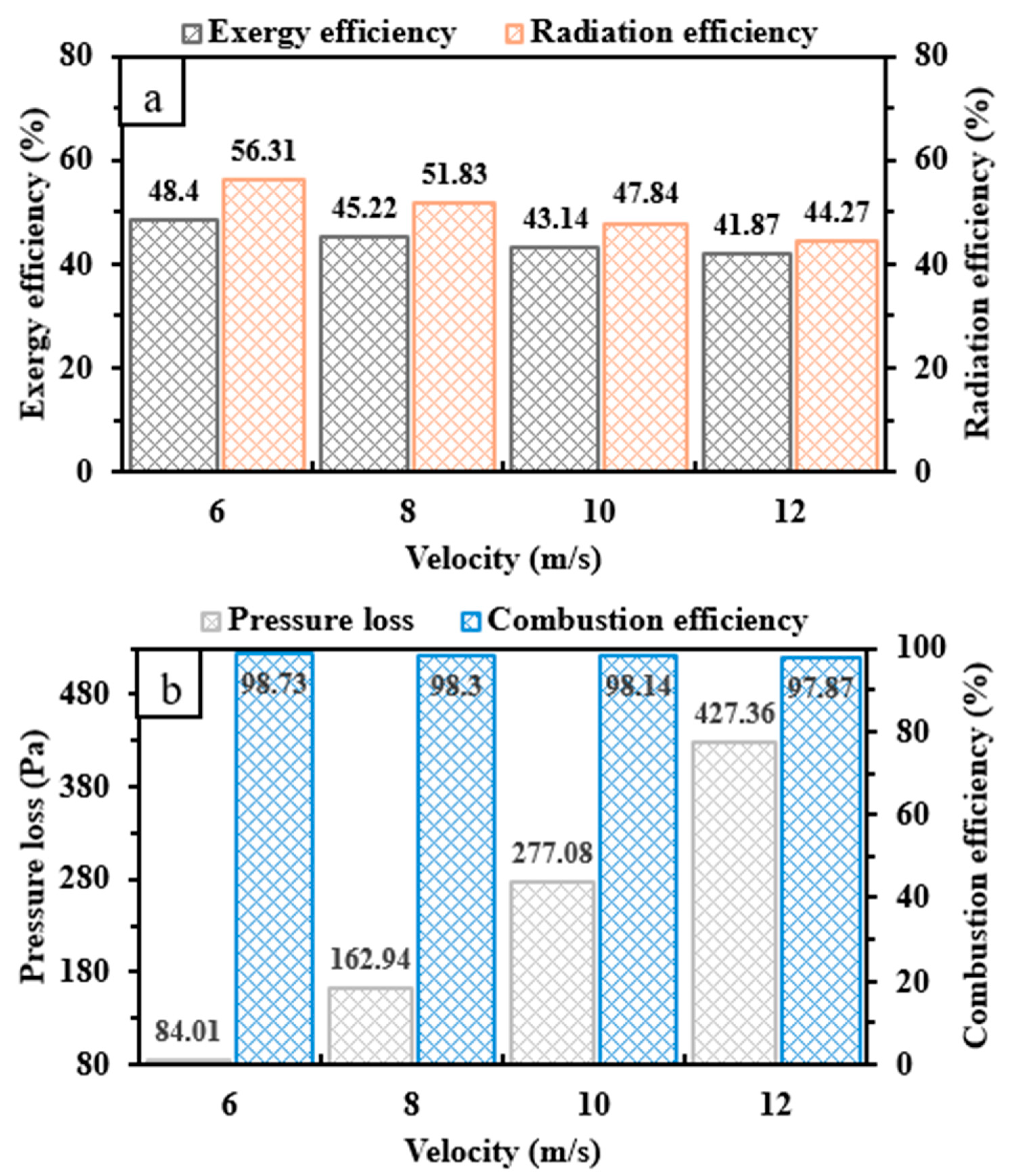

3.3. Effects of Inlet Velocity

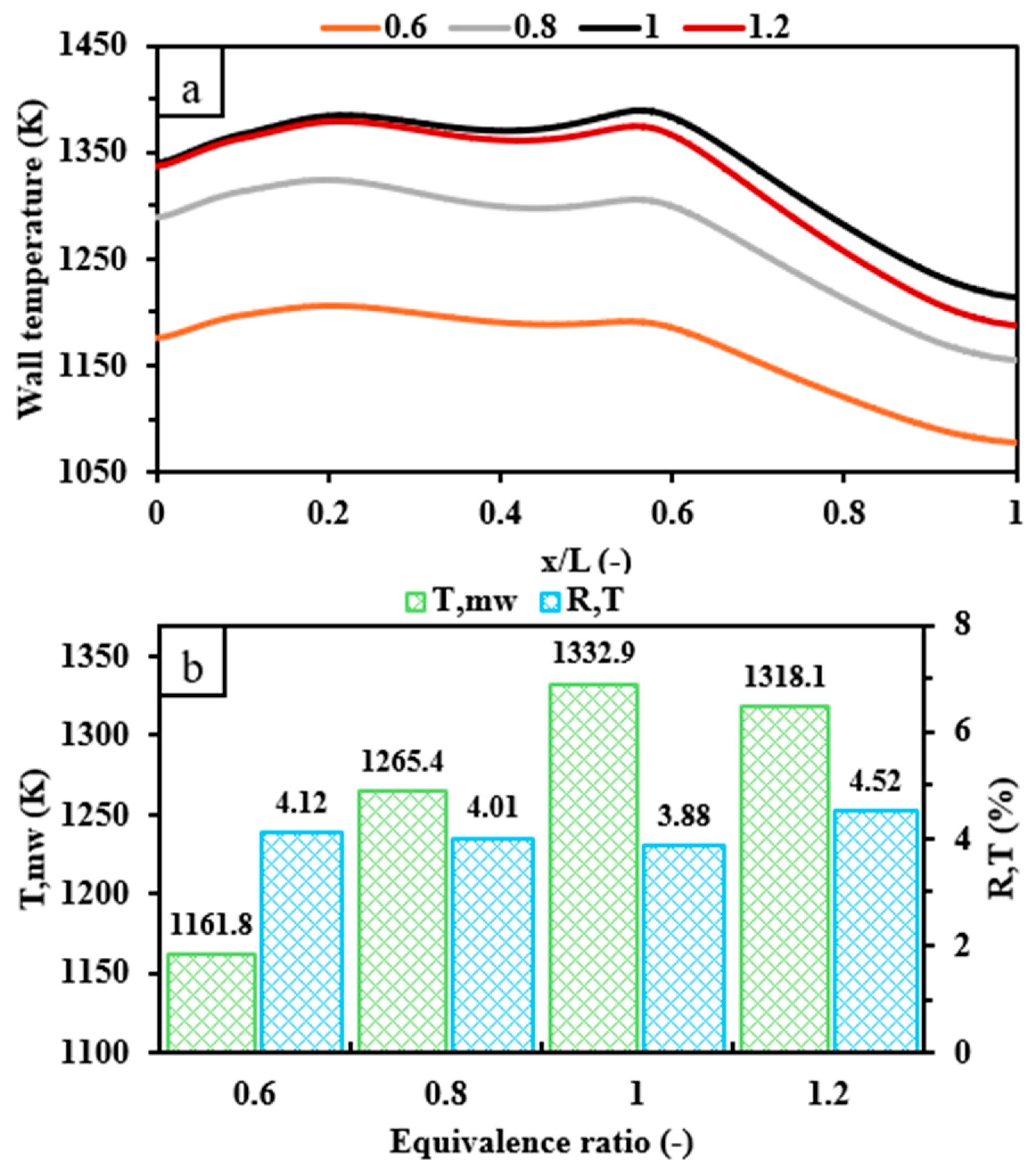

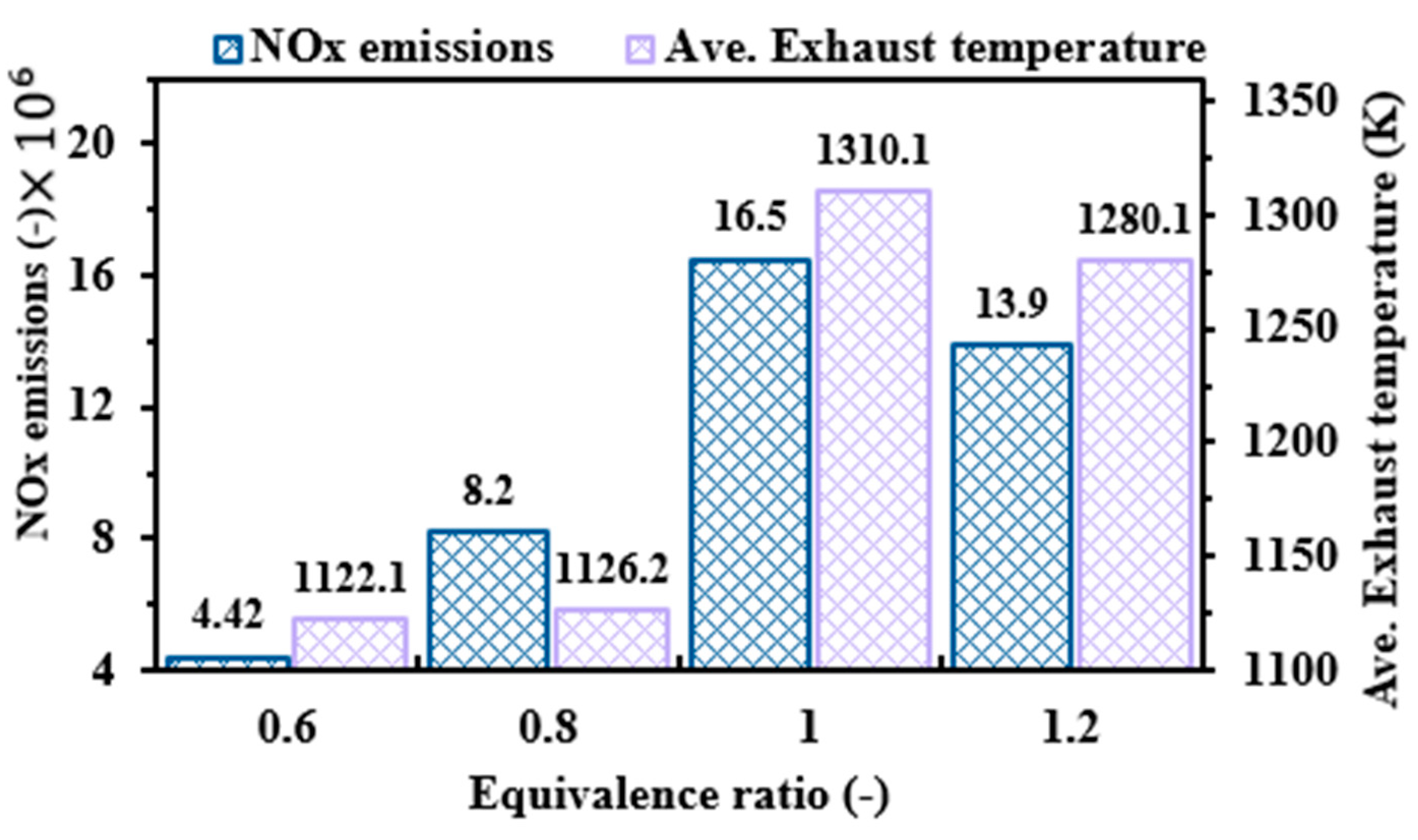

3.4. Effects of Inlet Equivalence Ratio

4. Conclusions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Velocity vector, | |

| Static pressure, | |

| Unit tensor | |

| Effective conductivity, | |

| Mass fraction of species i | |

| Fuel mass fractions at the inlet | |

| Fuel mass fractions at the outlet | |

| Reaction net rate of production of species i | |

| Enthalpy of species j, | |

| Enthalpy source term of fluid, | |

| Total heat loss, | |

| Heat losses by convection, | |

| Heat losses by radiation, | |

| Natural convection heat transfer coefficient | |

| Surface area of the outer wall, | |

| Outer wall area of cell i, | |

| Inlet exergy, | |

| Total exergy losses, | |

| Uncounted exergy destruction, | |

| Energy loss from the combustion exhaust gas, | |

| Exhaust gas temperature, | |

| Area-weighted-mean wall temperature, | |

| Temperature of external wall, | |

| Ambient temperature, | |

| Outer wall temperature of cell i, | |

| Wall temperature uniformity | |

| Mass flow rate of fuel, | |

| Mass flow rate of inlet flow, | |

| Lower heating value | |

| Greek letters | |

| Mixture gas density, | |

| Molecular viscosity, | |

| Emissivity of the solid surface | |

| Stephan–Boltzmann constant, | |

| Equivalence ratio | |

| Exergy efficiency | |

| Radiation efficiency | |

| Combustion efficiency |

References

- Nicoletti, G.; Arcuri, N.; Nicoletti, G.; Bruno, R. A Technical and Environmental Comparison between Hydrogen and Some Fossil Fuels. Energy Convers. Manag. 2015, 89, 205–213. [Google Scholar] [CrossRef]

- Fu, J.; Liu, J.; Feng, R.; Yang, Y.; Wang, L.; Wang, Y. Energy and Exergy Analysis on Gasoline Engine Based on Mapping Characteristics Experiment. Appl. Energy 2013, 102, 622–630. [Google Scholar] [CrossRef]

- Shindell, D.; Smith, C.J. Climate and Air-Quality Benefits of a Realistic Phase-out of Fossil Fuels. Nature 2019, 573, 408–411. [Google Scholar] [CrossRef]

- Xue, Z.; Yan, Y.; He, Z.; Shen, K.; Zhang, C. Comprehensive Numerical Insight the Thermal Performance Improvement of the Micro Combustors with Internal Bionic Y-Shaped Fins for Micro-Thermal Voltaic System Applications. Fuel 2022, 318, 123610. [Google Scholar] [CrossRef]

- Kobayashi, H.; Hayakawa, A.; Somarathne, K.D.K.A.; Okafor, E.C. Science and Technology of Ammonia Combustion. Proc. Combust. Inst. 2019, 37, 109–133. [Google Scholar] [CrossRef]

- Staffell, I.; Scamman, D.; Abad, A.V.; Balcombe, P.; Dodds, P.E.; Ekins, P.; Shah, N.; Ward, K.R. The Role of Hydrogen and Fuel Cells in the Global Energy System. Energy Environ. Sci. 2019, 12, 463–491. [Google Scholar] [CrossRef]

- Yang, Y.; Tong, L.; Yin, S.; Liu, Y.; Wang, L.; Qiu, Y.; Ding, Y. Status and Challenges of Applications and Industry Chain Technologies of Hydrogen in the Context of Carbon Neutrality. J. Clean. Prod. 2022, 376, 134347. [Google Scholar] [CrossRef]

- Meher Kotay, S.; Das, D. Biohydrogen as a Renewable Energy Resource—Prospects and Potentials. Int. J. Hydrogen Energy 2008, 33, 258–263. [Google Scholar] [CrossRef]

- Hoang, A.T.; Foley, A.M.; Nižetić, S.; Huang, Z.; Ong, H.C.; Ölçer, A.I.; Pham, V.V.; Nguyen, X.P. Energy-Related Approach for Reduction of CO2 Emissions: A Critical Strategy on the Port-to-Ship Pathway. J. Clean. Prod. 2022, 355, 131772. [Google Scholar] [CrossRef]

- Mohanakrishna, G.; Sneha, N.P.; Rafi, S.M.; Sarkar, O. Dark Fermentative Hydrogen Production: Potential of Food Waste as Future Energy Needs. Sci. Total Environ. 2023, 888, 163801. [Google Scholar] [CrossRef]

- Koten, H. Hydrogen Effects on the Diesel Engine Performance and Emissions. Int. J. Hydrogen Energy 2018, 43, 10511–10519. [Google Scholar] [CrossRef]

- Zeldovich, I.B.; Barenblatt, G.I.; Librovich, V.B.; Makhviladze, G.M. Mathematical Theory of Combustion and Explosions; Consultants Bureau: New York, NY, USA, 1985. [Google Scholar]

- Sirignano, W.; Merzhanov, A.; Luca, L.D. Advances in Combustion Science: In Honor of Ya. B. Zel’dovich; AIAA: Reston, VA, USA, 1997; ISBN 978-1-56347-178-0. [Google Scholar]

- Chia, L.C.; Feng, B. The Development of a Micropower (Micro-Thermophotovoltaic) Device. J. Power Sources 2007, 165, 455–480. [Google Scholar] [CrossRef]

- Chen, N.; Gan, Y.; Luo, Y.; Jiang, Z. A Review on the Technology Development and Fundamental Research of Electrospray Combustion of Liquid Fuel at Small-Scale. Fuel Process. Technol. 2022, 234, 107342. [Google Scholar] [CrossRef]

- Ju, Y.; Maruta, K. Microscale Combustion: Technology Development and Fundamental Research. Prog. Energy Combust. Sci. 2011, 37, 669–715. [Google Scholar] [CrossRef]

- Maruta, K. Micro and Mesoscale Combustion. Proc. Combust. Inst. 2011, 33, 125–150. [Google Scholar] [CrossRef]

- Shirsat, V.; Gupta, A.K. A Review of Progress in Heat Recirculating Meso-Scale Combustors. Appl. Energy 2011, 88, 4294–4309. [Google Scholar] [CrossRef]

- Yilmaz, H.; Cam, O.; Tangoz, S.; Yilmaz, I. Effect of Different Turbulence Models on Combustion and Emission Characteristics of Hydrogen/Air Flames. Int. J. Hydrogen Energy 2017, 42, 25744–25755. [Google Scholar] [CrossRef]

- Chou, S.K.; Yang, W.M.; Chua, K.J.; Li, J.; Zhang, K.L. Development of Micro Power Generators—A Review. Appl. Energy 2011, 88, 1–16. [Google Scholar] [CrossRef]

- Peng, Q.; Yang, W.; E, J.; Xu, H.; Li, Z.; Tay, K.; Zeng, G.; Yu, W. Investigation on Premixed H2/C3H8/Air Combustion in Porous Medium Combustor for the Micro Thermophotovoltaic Application. Appl. Energy 2020, 260, 114352. [Google Scholar] [CrossRef]

- Wang, F.; Li, X.; Feng, S.; Yan, Y. Influence of Porous Media Aperture Arrangement on CH4/Air Combustion Characteristics in Micro Combustor. Processes 2021, 9, 1747. [Google Scholar] [CrossRef]

- Qian, P.; Liu, M.; Li, X.; Xie, F.; Huang, Z.; Luo, C.; Zhu, X. Effects of Bluff-Body on the Thermal Performance of Micro Thermophotovoltaic System Based on Porous Media Combustion. Appl. Therm. Eng. 2020, 174, 115281. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, Z.; Yang, W.; Zhou, J.; Liu, J.; Wang, Z.; Cen, K. Instability of Flame in Micro-Combustor under Different External Thermal Environment. Exp. Therm. Fluid Sci. 2011, 35, 1451–1457. [Google Scholar] [CrossRef]

- Norton, D.G.; Wetzel, E.D.; Vlachos, D.G. Fabrication of Single-Channel Catalytic Microburners: Effect of Confinement on the Oxidation of Hydrogen/Air Mixtures. Ind. Eng. Chem. Res. 2004, 43, 4833–4840. [Google Scholar] [CrossRef]

- Tang, A.; Pan, J.; Yang, W.; Xu, Y.; Hou, Z. Numerical Study of Premixed Hydrogen/Air Combustion in a Micro Planar Combustor with Parallel Separating Plates. Int. J. Hydrogen Energy 2015, 40, 2396–2403. [Google Scholar] [CrossRef]

- Rong, H.; Zhao, D.; Cai, T.; Becker, S. Enhancing Thermal and Exergy Performances in a CO2-Free Micro-Combustor with Reverse Flow Double-Channel Outlet Structure. Appl. Therm. Eng. 2023, 233, 121180. [Google Scholar] [CrossRef]

- Zhao, H.; Zhao, D.; Becker, S. Thermal Performances Investigation on an Ammonia-Fuelled Heat-Recirculating Micro-Combustor with Reduced Chemical Mechanism. Appl. Therm. Eng. 2024, 236, 121685. [Google Scholar] [CrossRef]

- Rong, H.; Zhao, H.; Cai, T. Thermodynamic and Emission Analysis of an Ammonia Fueled Micro-Combustor with Double-Channel Reverse Flow Structure. Int. J. Hydrogen Energy 2024, 49, 1303–1314. [Google Scholar] [CrossRef]

- Cai, T.; Zhao, D.; Sun, Y.; Ni, S.; Li, W.; Guan, D.; Wang, B. Evaluation of NOx Emissions Characteristics in a CO2-Free Micro-Power System by Implementing a Perforated Plate. Renew. Sustain. Energy Rev. 2021, 145, 111150. [Google Scholar] [CrossRef]

- ANSYS Fluent User’s Guide, Release 23.1; ANSYS, Inc.: Canonsburg, PA, USA, 2023.

- Zeldovich, Y.B. Selected Works of Yakov Borisovich Zeldovich; Princeton University Press: Princeton, NJ, USA, 2014. [Google Scholar]

- Fenimore, C.P. Formation of Nitric Oxide in Premixed Hydrocarbon Flames. Symp. Int. Combust. 1971, 13, 373–380. [Google Scholar] [CrossRef]

- Ni, S.; Zhao, D.; Sellier, M.; Li, J.; Chen, X.; Li, X.; Cao, F.; Li, W. Thermal Performances and Emitter Efficiency Improvement Studies on Premixed Micro-Combustors with Different Geometric Shapes for Thermophotovoltaics Applications. Energy 2021, 226, 120298. [Google Scholar] [CrossRef]

- Yang, X.; Yu, B.; Peng, X.; Zhou, H. Investigation of Thermal Performance and Energy Conversion in a Novel Planar Micro-Combustor with Four-Corner Entrances for Thermo-Photovoltaic Power Generators. J. Power Sources 2021, 515, 230625. [Google Scholar] [CrossRef]

- Sun, Y.; Cai, T.; Zhao, D. Thermal Performance and NOx Emission Characteristics Studies on a Premixed Methane-Ammonia-Fueled Micro-Planar Combustor. Fuel 2021, 291, 120190. [Google Scholar] [CrossRef]

- Kuo, C.H.; Ronney, P.D. Numerical Modeling of Non-Adiabatic Heat-Recirculating Combustors. Proc. Combust. Inst. 2007, 31, 3277–3284. [Google Scholar] [CrossRef]

- Shih, T.-H.; Liou, W.W.; Shabbir, A.; Yang, Z.; Zhu, J. A New k-ϵ Eddy Viscosity Model for High Reynolds Number Turbulent Flows. Comput. Fluids 1995, 24, 227–238. [Google Scholar] [CrossRef]

- Zhao, H.; Zhao, D.; Becker, S.; Zhang, Y. NO Emission and Enhanced Thermal Performances Studies on Counter-Flow Double-Channel Hydrogen/Ammonia-Fuelled Microcombustors with Oval-Shaped Internal Threads. Fuel 2023, 341, 127665. [Google Scholar] [CrossRef]

- Mousavi, S.M.; Sotoudeh, F.; Jun, D.; Lee, B.J.; Esfahani, J.A.; Karimi, N. On the Effects of NH3 Addition to a Reacting Mixture of H2/CH4 under MILD Combustion Regime: Numerical Modeling with a Modified EDC Combustion Model. Fuel 2022, 326, 125096. [Google Scholar] [CrossRef]

- Cai, T.; Zhao, D.; Karimi, N. Optimizing Thermal Performance and Exergy Efficiency in Hydrogen-Fueled Meso-Combustors by Applying a Bluff-Body. J. Clean. Prod. 2021, 311, 127573. [Google Scholar] [CrossRef]

- Ni, S.; Zhao, D.; You, Y.; Huang, Y.; Wang, B.; Su, Y. NOx Emission and Energy Conversion Efficiency Studies on Ammonia-Powered Micro-Combustor with Ring-Shaped Ribs in Fuel-Rich Combustion. J. Clean. Prod. 2021, 320, 128901. [Google Scholar] [CrossRef]

- Ni, S.; Zhao, D.; Wu, W.; Guan, Y. NOx Emission Reduction Reaction of Ammonia-Hydrogen with Self-Sustained Pulsating Oscillations. Therm. Sci. Eng. Prog. 2020, 19, 100615. [Google Scholar] [CrossRef]

- Wan, J.; Fan, A.; Yao, H.; Liu, W. Flame-Anchoring Mechanisms of a Micro Cavity-Combustor for Premixed H2/Air Flame. Chem. Eng. J. 2015, 275, 17–26. [Google Scholar] [CrossRef]

- Yang, W.M.; Chua, K.J.; Pan, J.F.; Jiang, D.Y.; An, H. Development of Micro-Thermophotovoltaic Power Generator with Heat Recuperation. Energy Convers. Manag. 2014, 78, 81–87. [Google Scholar] [CrossRef]

- Li, J.; Chou, S.K.; Li, Z.W.; Yang, W.M. Characterization of Wall Temperature and Radiation Power through Cylindrical Dump Micro-Combustors. Combust. Flame 2009, 156, 1587–1593. [Google Scholar] [CrossRef]

- Li, J.; Chou, S.K.; Huang, G.; Yang, W.M.; Li, Z.W. Study on Premixed Combustion in Cylindrical Micro Combustors: Transient Flame Behavior and Wall Heat Flux. Exp. Therm. Fluid Sci. 2009, 33, 764–773. [Google Scholar] [CrossRef]

- Cai, T.; Zhao, D. Effects of Fuel Composition and Wall Thermal Conductivity on Thermal and NOx Emission Performances of an Ammonia/Hydrogen-Oxygen Micro-Power System. Fuel Process. Technol. 2020, 209, 106527. [Google Scholar] [CrossRef]

- Li, J.; Huang, J.; Chen, X.; Zhao, D.; Shi, B.; Wei, Z.; Wang, N. Effects of Heat Recirculation on Combustion Characteristics of N-Heptane in Micro Combustors. Appl. Therm. Eng. 2016, 109, 697–708. [Google Scholar] [CrossRef]

- He, Z.; Yan, Y.; Zhao, T.; Feng, S.; Li, X.; Zhang, L.; Zhang, Z. Heat Transfer Enhancement and Exergy Efficiency Improvement of a Micro Combustor with Internal Spiral Fins for Thermophotovoltaic Systems. Appl. Therm. Eng. 2021, 189, 116723. [Google Scholar] [CrossRef]

- Sahoo, B.B.; Saha, U.K.; Sahoo, N. Diagnosing the Effects of Pilot Fuel Quality on Exergy Terms in a Biogas Run Dual Fuel Diesel Engine. Int. J. Exergy 2012, 10, 77–93. [Google Scholar] [CrossRef]

- Stepanov, V.S. Chemical Energies and Exergies of Fuels. Energy 1995, 20, 235–242. [Google Scholar] [CrossRef]

- Tong, J.; Cai, T. Enhancing Thermal Performance, Exergy and Thermodynamics Efficiency of Premixed Methane/Air Micro-Planar Combustor in Micro-Thermophotovoltaic Systems. Energies 2023, 16, 118. [Google Scholar] [CrossRef]

- Rahbari, A.; Homayoonfar, S.; Valizadeh, E.; Aligoodarz, M.R.; Toghraie, D. Effects of Micro-Combustor Geometry and Size on the Heat Transfer and Combustion Characteristics of Premixed Hydrogen/Air Flames. Energy 2021, 215, 119061. [Google Scholar] [CrossRef]

- Peng, Q.; Yang, W.; E, J.; Li, Z.; Xu, H.; Fu, G.; Li, S. Investigation on H2/Air Combustion with C3H8 Addition in the Combustor with Part/Full Porous Medium. Energy Convers. Manag. 2021, 228, 113652. [Google Scholar] [CrossRef]

- Wenming, Y.; Siawkiang, C.; Chang, S.; Hong, X.; Zhiwang, L. Effect of Wall Thickness of Micro-Combustor on the Performance of Micro-Thermophotovoltaic Power Generators. Sens. Actuators Phys. 2005, 119, 441–445. [Google Scholar] [CrossRef]

- Zuo, W.; Zhang, Y.; Li, Q.; Li, J.; He, Z. Numerical Investigations on Hydrogen-Fueled Micro-Cylindrical Combustors with Cavity for Micro-Thermophotovoltaic Applications. Energy 2021, 223, 120098. [Google Scholar] [CrossRef]

- De Robbio, R.; Mancaruso, E. Hydrogen Combustion Analysis via Infrared and Visible Optical Diagnostics Combined with CFD in a Dual Fuel Engine at Low Load. Int. J. Hydrogen Energy 2024, 81, 418–435. [Google Scholar] [CrossRef]

- Rajak, U.; Panchal, M.; Viswanath Allamraju, K.; Nashine, P.; Nath Verma, T.; Pugazhendhi, A. A Numerical Investigation on a Diesel Engine Characteristic Fuelled Using 3D CFD Approach. Fuel 2024, 368, 131488. [Google Scholar] [CrossRef]

- Ranga Dinesh, K.K.J.; Shalaby, H.; Luo, K.H.; van Oijen, J.A.; Thévenin, D. High Hydrogen Content Syngas Fuel Burning in Lean Premixed Spherical Flames at Elevated Pressures: Effects of Preferential Diffusion. Int. J. Hydrogen Energy 2016, 41, 18231–18249. [Google Scholar] [CrossRef]

- Köse, H.; Ciniviz, M. An Experimental Investigation of Effect on Diesel Engine Performance and Exhaust Emissions of Addition at Dual Fuel Mode of Hydrogen. Fuel Process. Technol. 2013, 114, 26–34. [Google Scholar] [CrossRef]

- Bajelani, M.; Ansari, M.R.; Nadimi, E. A Comprehensive Study of Effective Parameters on the Thermal Performance of Porous Media Micro Combustor in Thermo Photovoltaic Systems. Appl. Therm. Eng. 2023, 231, 120846. [Google Scholar] [CrossRef]

| Variables | Value (mm) | ||||||

|---|---|---|---|---|---|---|---|

| Case 1 | Case 2 | Case 3 | Case 4 | Case 5 | Case 6 | ||

| Length | L1 | 18 | 18 | 18 | 18 | 18 | 18 |

| L2 | NA | 15.5 | 15.5 | 15.5 | 15.5 | 15.5 | |

| L3 | NA | 4 | 6 | 8 | 8 | 8 | |

| L4 | NA | 9 | 7 | 5 | 5 | 5 | |

| L5 | NA | 2 | 2 | 2 | 2 | 2 | |

| L6 | NA | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | |

| L7 | NA | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | |

| L8 | NA | 1.95 | 1.95 | 1.95 | 1.45 | 0.95 | |

| L9 | NA | 0.4 | 0.4 | 0.4 | 0.65 | 0.9 | |

| Diameter | D1 | 4 | 4 | 4 | 4 | 4 | 4 |

| D2 | 3 | 3 | 3 | 3 | 3 | 3 | |

| D3 | 2 | 2 | 2 | 2 | 2 | 2 | |

| Thickness | t1 | NA | 0.125 | 0.125 | 0.125 | 0.125 | 0.125 |

| Parameter | Method |

|---|---|

| Flow | Turbulent |

| Chemistry–turbulence interaction | Eddy dissipation concept (EDC) |

| Discretization | Second-order UPWIND scheme |

| Pressure–velocity coupling | SIMPLE algorithm |

| Segregate | Segregate/implicit (under-relaxation method) |

| Software | ANSYS Fluent R1 2023 |

| Mixture physical properties | Density: incompressible-ideal-gas law |

| Specific heat: mixing-law | |

| Thermal conductivity: ideal gas mixing law | |

| Viscosity: ideal gas mixing law | |

| Mass diffusivity: kinetic theory |

| Property | Unit | Values |

|---|---|---|

| Density | 8000 | |

| Thermal conductivity | 12 | |

| Specific heat | 503 | |

| Emissivity | - | 0.85 |

| Boundary | Parameters | Values |

|---|---|---|

| Inlet | Velocity | 6, 8, 10, 12 m/s |

| Gauge pressure | 0 Pa | |

| Turbulent intensity | 5% | |

| Hydraulic diameter | 2 mm | |

| Temperature | 300 K | |

| Outlet | Gauge pressure | 0 Pa |

| Turbulent intensity | 5% | |

| Hydraulic diameter | 2 mm | |

| Inner wall | Interface No-slip | Zero-flux for all species |

| Thermal condition | Coupled | |

| Material | Steel | |

| Outer wall | Heat transfer coefficient | 10 W/m2·K |

| Emissivity | 0.85 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Almutairi, F. A Numerical Study on Key Thermal Parameters and NOx Emissions of a Hydrogen-Fueled Double-Channel Outlet Micro Cylindrical Combustor Employing a Heat-Recirculating Configuration for Thermophotovoltaic Applications. Processes 2024, 12, 1848. https://doi.org/10.3390/pr12091848

Almutairi F. A Numerical Study on Key Thermal Parameters and NOx Emissions of a Hydrogen-Fueled Double-Channel Outlet Micro Cylindrical Combustor Employing a Heat-Recirculating Configuration for Thermophotovoltaic Applications. Processes. 2024; 12(9):1848. https://doi.org/10.3390/pr12091848

Chicago/Turabian StyleAlmutairi, Faisal. 2024. "A Numerical Study on Key Thermal Parameters and NOx Emissions of a Hydrogen-Fueled Double-Channel Outlet Micro Cylindrical Combustor Employing a Heat-Recirculating Configuration for Thermophotovoltaic Applications" Processes 12, no. 9: 1848. https://doi.org/10.3390/pr12091848