Bimetallic Fe, Co-Modified TiO2 Derived from NH2-MIL-125(Ti) as an Efficient Photocatalyst for N2 Fixation

Abstract

:1. Introduction

2. Experimental Section

2.1. Preparation of NH2-MIL-125(Ti)

2.2. Preparation of FC@TiO2

2.3. Characterizations

2.4. Electrochemical Measurement

2.5. Photocatalytic Reaction

3. Results and Discussion

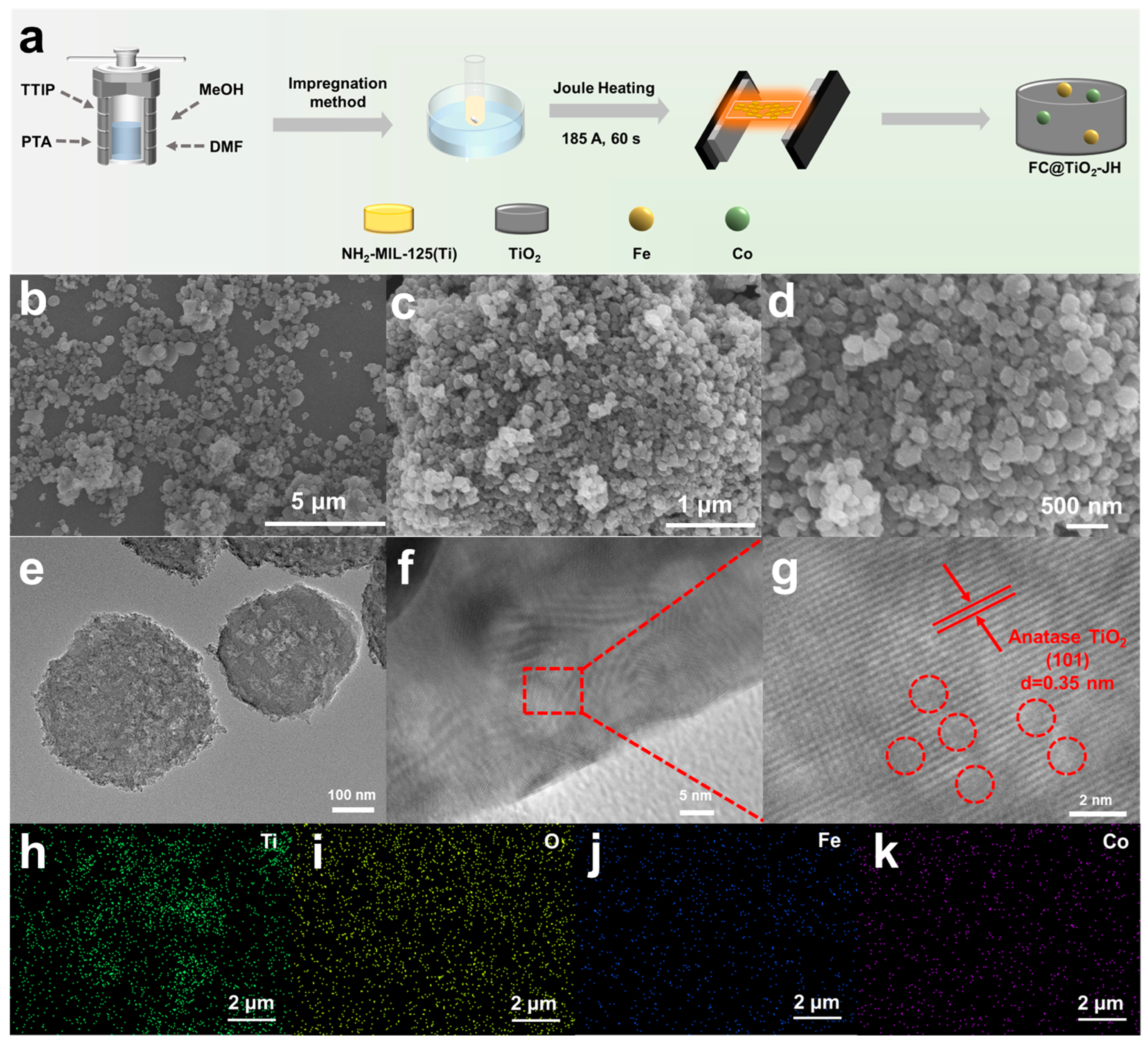

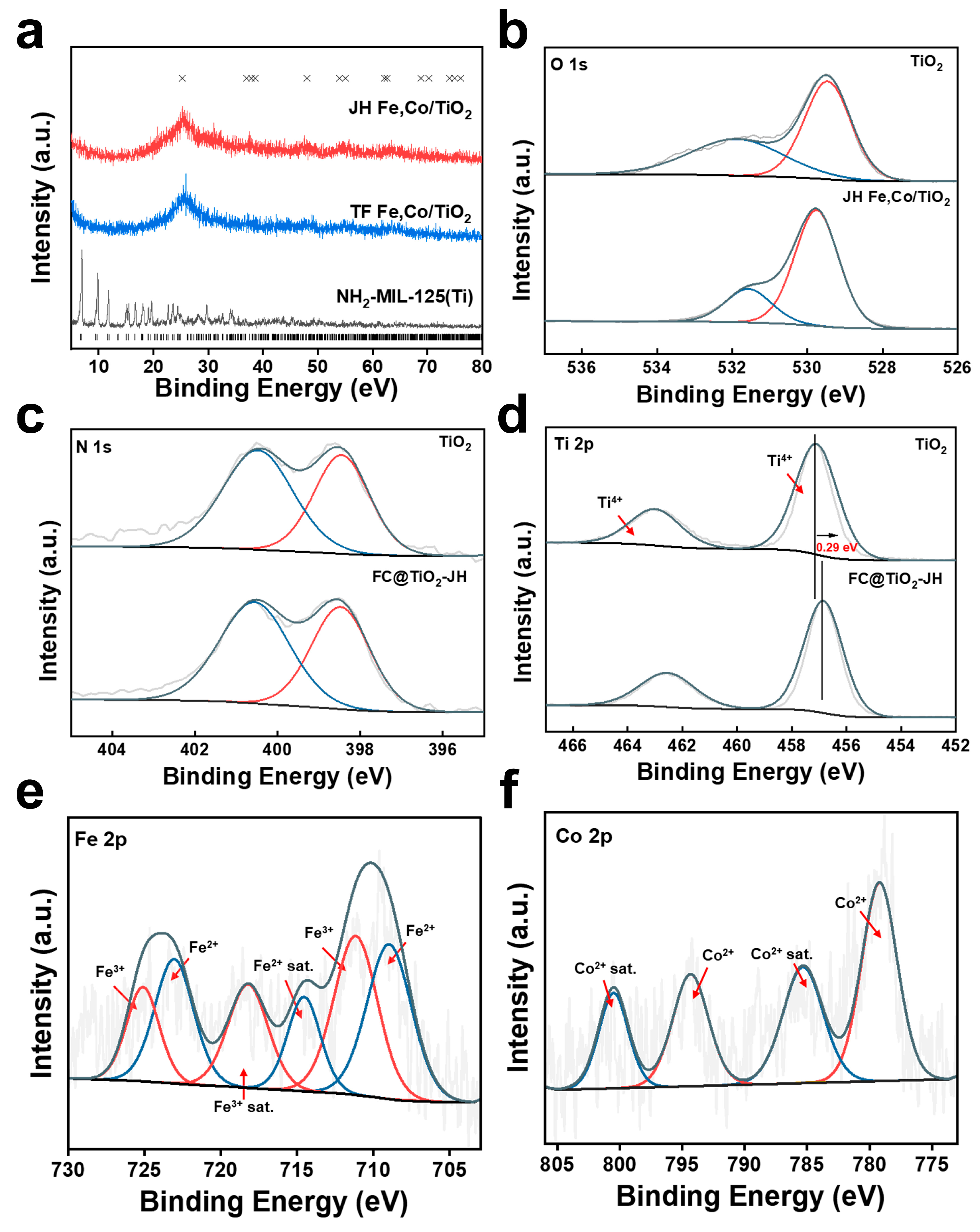

3.1. Morphology and Structural Properties

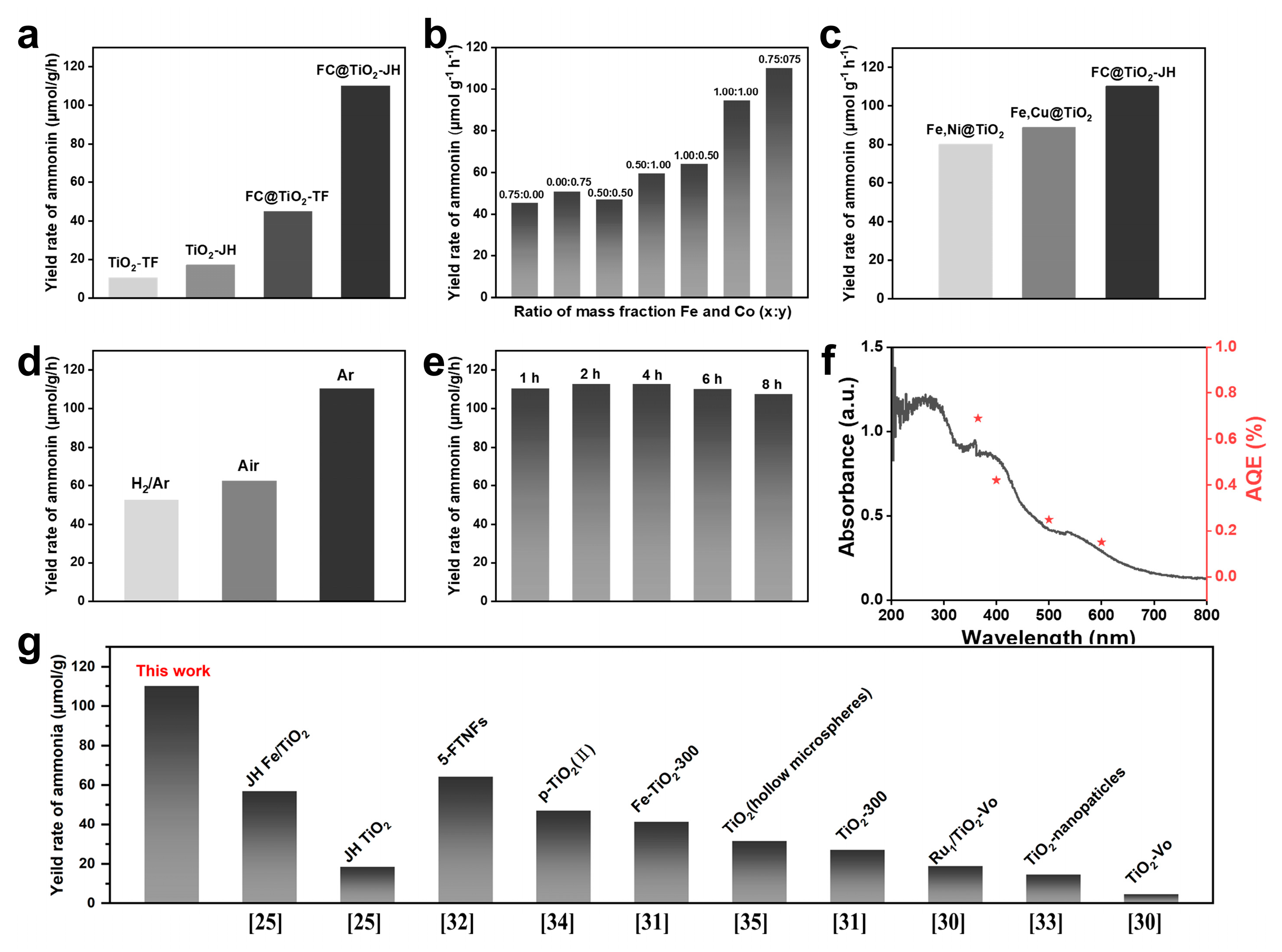

3.2. Photocatalytic Nitrogen Fixation Test

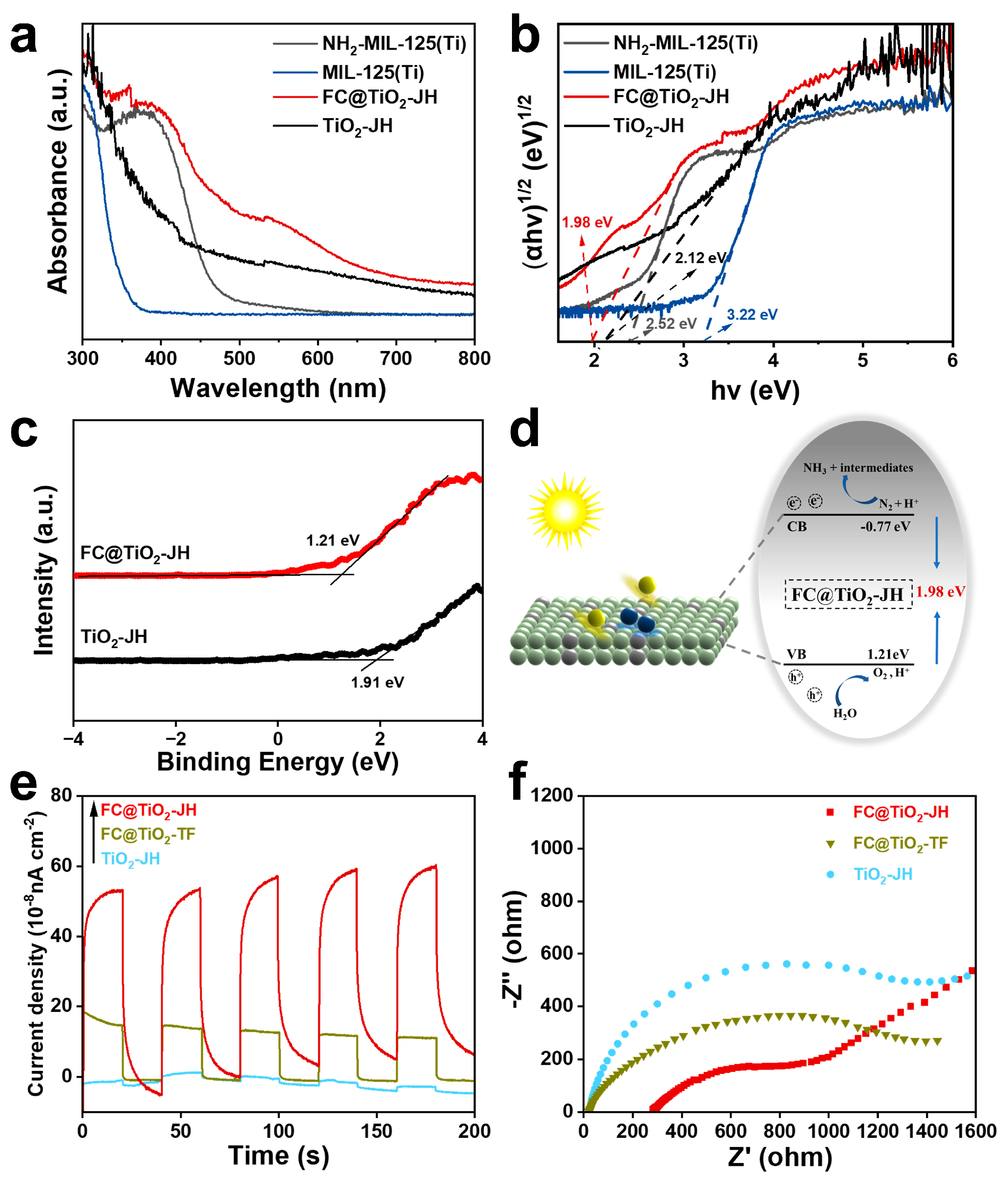

3.3. Optical and Electronic Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Naderi, M.; Bagheri, H.; Naderi, M.; Yazdanabad, S.K. Catalyst: Ammonia as an energy carrier. In Progresses in Ammonia: Science, Technology and Membranes; Elsevier: Amsterdam, The Netherlands, 2024; pp. 17–47. [Google Scholar]

- Yapicioglu, A.; Dincer, I. A review on clean ammonia as a potential fuel for power generators. Renew. Sustain. Energy Rev. 2019, 103, 96–108. [Google Scholar] [CrossRef]

- Olabi, A.; Abdelkareem, M.A.; Al-Murisi, M.; Shehata, N.; Alami, A.H.; Radwan, A.; Wilberforce, T.; Chae, K.-J.; Sayed, E.T. Recent progress in Green Ammonia: Production, applications, assessment; barriers, and its role in achieving the sustainable development goals. Energy Convers. Manag. 2023, 277, 116594. [Google Scholar] [CrossRef]

- Feng, H.; Xu, Q.; Lv, T.; Liu, H. Bimetallic NH2-MIL-101(Fe, Co) as highly efficient photocatalyst for nitrogen fixation. Appl. Catal. B Environ. Energy 2024, 351, 123949. [Google Scholar] [CrossRef]

- Kim, J.; Huh, C.; Seo, Y. End-to-end value chain analysis of isolated renewable energy using hydrogen and ammonia energy carrier. Energy Convers. Manag. 2022, 254, 115247. [Google Scholar] [CrossRef]

- Kubacka, A.; Fernandez-Garcia, M.; Colon, G. Advanced nanoarchitectures for solar photocatalytic applications. Chem. Rev. 2012, 112, 1555–1614. [Google Scholar] [CrossRef] [PubMed]

- Guo, W.; Guo, T.; Zhang, Y.; Yin, L.; Dai, Y. Progress on simultaneous photocatalytic degradation of pollutants and production of clean energy: A review. Chemosphere 2023, 339, 139486. [Google Scholar] [CrossRef]

- Yue, K.; Zhang, X.; Jiang, S.; Chen, J.; Yang, Y.; Bi, F.; Wang, Y. Recent advances in strategies to modify MIL-125 (Ti) and its environmental applications. J. Mol. Liq. 2021, 335, 116108. [Google Scholar] [CrossRef]

- Zhang, P.; Wang, T.; Chang, X.; Gong, J. Effective charge carrier utilization in photocatalytic conversions. Accounts Chem. Res. 2016, 49, 911–921. [Google Scholar] [CrossRef]

- Jiao, L.; Seow, J.Y.R.; Skinner, W.S.; Wang, Z.U.; Jiang, H.-L. Metal–organic frameworks: Structures and functional applications. Mater. Today 2019, 27, 43–68. [Google Scholar] [CrossRef]

- Shen, Y.; Pan, T.; Wang, L.; Ren, Z.; Zhang, W.; Huo, F. Programmable logic in metal–organic frameworks for catalysis. Adv. Mater. 2021, 33, 2007442. [Google Scholar] [CrossRef]

- Hussain, M.Z.; Yang, Z.; Huang, Z.; Jia, Q.; Zhu, Y.; Xia, Y. Recent advances in metal–organic frameworks derived nanocomposites for photocatalytic applications in energy and environment. Adv. Sci. 2021, 8, 2100625. [Google Scholar] [CrossRef]

- Dang, S.; Zhu, Q.-L.; Xu, Q. Nanomaterials derived from metal–organic frameworks. Nat. Rev. Mater. 2017, 3, 17075. [Google Scholar] [CrossRef]

- Baluk, M.A.; Mazierski, P.; Pieczyńska, A.; Nikiforow, K.; Trykowski, G.; Klimczuk, T.; Zaleska-Medynska, A. MOF/TiO2 erythrocyte-like heterostructures decorated by noble metals for use in hydrogen photogeneration and pollutant photodegradation. Catal. Sci. Technol. 2023, 13, 5033–5047. [Google Scholar] [CrossRef]

- Qian, Z.; Zhang, R.; Xiao, Y.; Huang, H.; Sun, Y.; Chen, Y.; Ma, T.; Sun, X. Trace to the source: Self-tuning of MOF photocatalysts. Adv. Energy Mater. 2023, 13, 2300086. [Google Scholar] [CrossRef]

- Villa, K.; Galán-Mascarós, J.R.; López, N.; Palomares, E. Photocatalytic water splitting: Advantages and challenges. Sustain. Energy Fuels 2021, 5, 4560–4569. [Google Scholar] [CrossRef]

- Sharma, S.; Kumar, R.; Raizada, P.; Ahamad, T.; Alshehri, S.M.; Nguyen, V.-H.; Thakur, S.; Nguyen, C.C.; Kim, S.Y.; Van Le, Q.; et al. An overview on recent progress in photocatalytic air purification: Metal-based and metal-free photocatalysis. Environ. Res. 2022, 214, 113995. [Google Scholar] [CrossRef]

- Jing, Y.; Gong, F.; Wang, S.; Wang, W.; Yang, P.; Fu, E.; Xiao, R. Activating the synergistic effect in Ni-Co bimetallic MOF for enhanced plasma-assisted ammonia synthesis. Fuel 2024, 368, 131686. [Google Scholar] [CrossRef]

- Sun, X.; Li, L.; Jin, S.; Shao, W.; Wang, H.; Zhang, X.; Xie, Y. Interface boosted highly efficient selective photooxidation in Bi3O4Br/Bi2O3 heterojunctions. eScience 2023, 3, 100095. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, L.; Zhu, Z.; Wang, M.; Li, N.; Qian, T.; Yan, C.; Lu, J. Optimizing Intermediate Adsorption over PdM (M=Fe, Co, Ni, Cu) Bimetallene for Boosted Nitrate Electroreduction to Ammonia. Angew. Chem. Int. Ed. 2024, 163, e202319029. [Google Scholar]

- Duan, D.; Huo, J.; Chen, J.; Chi, B.; Chen, Z.; Sun, S.; Zhao, Y.; Zhao, H.; Cui, Z.; Liao, S. Hf and Co Dual Single Atoms Co-Doped Carbon Catalyst Enhance the Oxygen Reduction Performance. Small 2024, 20, e2310491. [Google Scholar] [CrossRef]

- Zhao, Y.; Tian, Z.; Wang, W.; Deng, X.; Tseng, J.-C.; Wang, G. Size-dependent activity of Fe-N-doped mesoporous carbon nanoparticles towards oxygen reduction reaction. Green Carbon 2024, 2, 221–230. [Google Scholar] [CrossRef]

- Yang, H.; Ren, G.; Li, Z.; Zhang, Z.; Meng, X. Energy, Fast Joule heating for transformation of Fe-MIL-125(Ti) to Fe/TiO2 with enhanced photocatalytic activity in N2 fixation. Appl. Catal. B Environ. Energy 2024, 347, 123795. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, J.; Ao, D. Construction of heterostructured ZnIn2S4@NH2-MIL-125(Ti) nanocomposites for visible-light-driven H2 production. Appl. Catal. B Environ. 2018, 221, 433–442. [Google Scholar] [CrossRef]

- Hu, S.; Qiao, P.; Zhang, L.; Jiang, B.; Gao, Y.; Hou, F.; Wu, B.; Li, Q.; Jiang, Y.; Tian, C.; et al. Assembly of TiO2 ultrathin nanosheets with surface lattice distortion for solar-light-driven photocatalytic hydrogen evolution. Appl. Catal. B Environ. 2018, 239, 317–323. [Google Scholar] [CrossRef]

- Yang, F.; Dong, J.; Chen, Y.; Wang, H.; Li, Z.; Wang, Z. Sonication to remove organic dyes with the aid of NH2-MIL-125(Ti) and carbonization derivatives. J. Water Process Eng. 2023, 55, 104182. [Google Scholar] [CrossRef]

- Hussain, M.Z.; Bahri, M.; Heinz, W.R.; Jia, Q.; Ersen, O.; Kratky, T.; Fischer, R.A.; Zhu, Y.; Xia, Y. An in situ investigation of the thermal decomposition of metal-organic framework NH2-MIL-125 (Ti). Microporous Mesoporous Mater. 2021, 316, 110957. [Google Scholar] [CrossRef]

- Li, W.; Zhao, Y.; Liu, Y.; Sun, M.; Waterhouse, G.I.; Huang, B.; Zhang, K.; Zhang, T.; Lu, S. Exploiting Ru-induced lattice strain in CoRu nanoalloys for robust bifunctional hydrogen production. Angew. Chem. 2021, 133, 3327–3335. [Google Scholar] [CrossRef]

- Ding, W.; Li, X.; Su, S.; Liu, Z.; Cao, Y.; Meng, L.; Yuan, S.; Wei, W.; Luo, M. Cationic vacancy engineering of p-TiO2 for enhanced photocatalytic nitrogen fixation. Nanoscale 2023, 15, 4014–4021. [Google Scholar] [CrossRef]

- Ren, G.; Shi, M.; Liu, S.; Li, Z.; Zhang, Z.; Meng, X. Molecular-level insight into photocatalytic reduction of N2 over Ruthenium single atom modified TiO2 by electronic Metal-support interaction. Chem. Eng. J. 2023, 454, 140158. [Google Scholar] [CrossRef]

- Ding, J.; Zhong, Q.; Gu, H. Iron-titanium dioxide composite nanoparticles prepared with an energy effective method for efficient visible-light-driven photocatalytic nitrogen reduction to ammonia. J. Alloys Compd. 2018, 746, 147–152. [Google Scholar] [CrossRef]

- Bo, Y.; Wang, H.; Lin, Y.; Yang, T.; Ye, R.; Li, Y.; Hu, C.; Du, P.; Hu, Y.; Liu, Z.; et al. Altering hydrogenation pathways in photocatalytic nitrogen fixation by tuning local electronic structure of oxygen vacancy with dopant. Angew. Chem. Int. Ed. 2021, 60, 16085–16092. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Wang, S.; Li, M.; Yang, X.; Li, F.; Xu, L.; Zou, Y. Constructing oxygen vacancies and linker defects in MIL-125@TiO2 for efficient photocatalytic nitrogen fixation. J. Alloys Compd. 2022, 909, 164751. [Google Scholar] [CrossRef]

- Li, C.; Gu, M.; Gao, M.; Liu, K.; Zhao, X.; Cao, N.; Feng, J.; Ren, Y.; Wei, T.; Zhang, M. N-doping TiO2 hollow microspheres with abundant oxygen vacancies for highly photocatalytic nitrogen fixation. J. Colloid Interface Sci. 2022, 609, 341–352. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, H.; Meng, X. Bimetallic Fe, Co-Modified TiO2 Derived from NH2-MIL-125(Ti) as an Efficient Photocatalyst for N2 Fixation. Processes 2024, 12, 1879. https://doi.org/10.3390/pr12091879

Yang H, Meng X. Bimetallic Fe, Co-Modified TiO2 Derived from NH2-MIL-125(Ti) as an Efficient Photocatalyst for N2 Fixation. Processes. 2024; 12(9):1879. https://doi.org/10.3390/pr12091879

Chicago/Turabian StyleYang, Huiying, and Xiangchao Meng. 2024. "Bimetallic Fe, Co-Modified TiO2 Derived from NH2-MIL-125(Ti) as an Efficient Photocatalyst for N2 Fixation" Processes 12, no. 9: 1879. https://doi.org/10.3390/pr12091879