Optimization of Residential Hydrogen Facilities with Waste Heat Recovery: Economic Feasibility across Various European Cities

Abstract

1. Introduction

1.1. Motivation

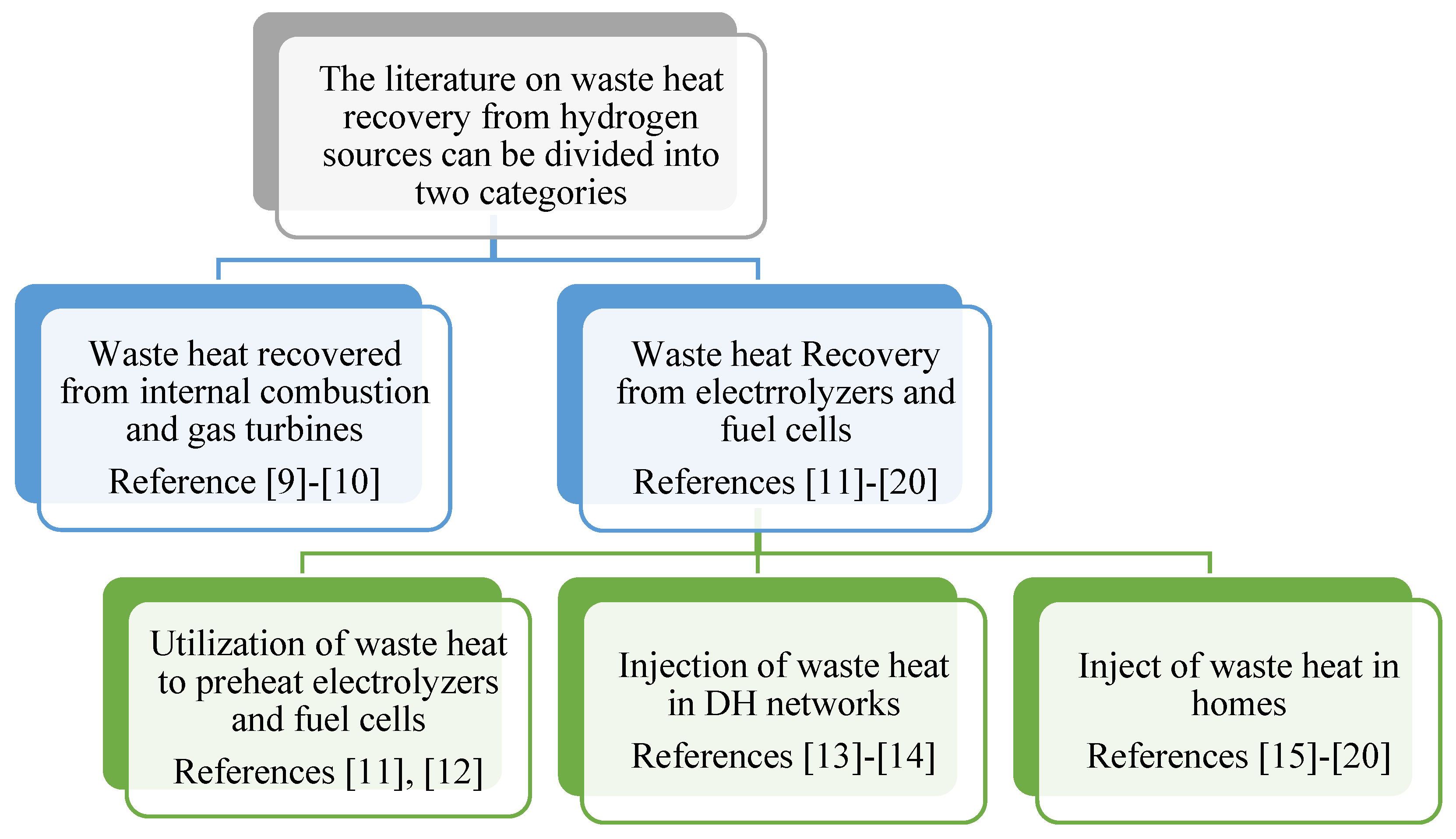

1.2. Literature Review

1.3. Research Gap and Contribution

- The development of an LP optimization formulation that determines the optimal capacities for all the components of residential solar–hydrogen systems involving waste heat recovery. This formulation aims to boost the owner’s economic returns, thereby enhancing the economic viability of residential hydrogen investments. It guarantees global optimality and avoids the pitfalls of local optima. Additionally, it incorporates an annual optimization horizon to account for all the temporal variations—hourly, daily, and seasonal—in solar variations and electric and thermal loads.

- A preliminary techno-economic feasibility assessment of residential solar–hydrogen systems across various European regions, which considers the diverse photovoltaic and thermal load profiles characteristic of different European locales.

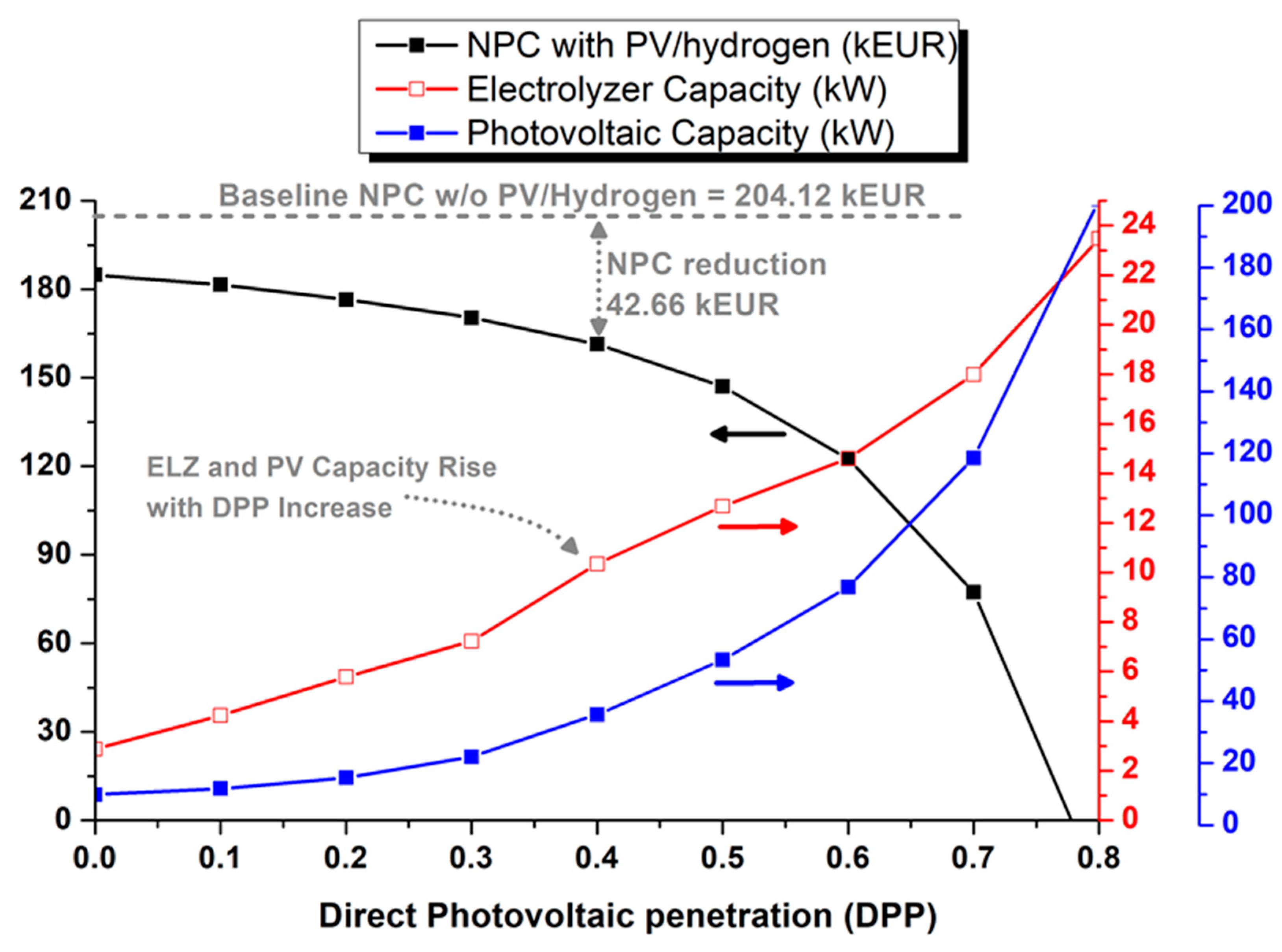

- It introduces a novel incentive policy that allows owners of solar–hydrogen systems to inject up to 20% of their total solar power output directly into the grid, bypassing hydrogen storage. This policy enables owners to capitalize on selling excess PV power during peak midday hours instead of curtailing it. Moreover, it facilitates a reduction in the size and cost of the electrolyzer. This strategy could significantly enhance investment in residential hydrogen systems, increase their adoption, and reduce costs more sustainably than traditional subsidy policies [21] that are designed to promote a hydrogen economy.

2. Proposed Optimization Approach

2.1. Objective Function

2.2. Constraints

- ▪

- Constant ELZ and FC Efficiencies: Despite evidence that the efficiencies of the ELZ and FC vary with current and temperature [14,26], we assume constant efficiencies to facilitate a linear problem formulation. This assumption simplifies the analysis by disregarding the influence of current and temperature variations on the ELZ and FC efficiencies.

- ▪

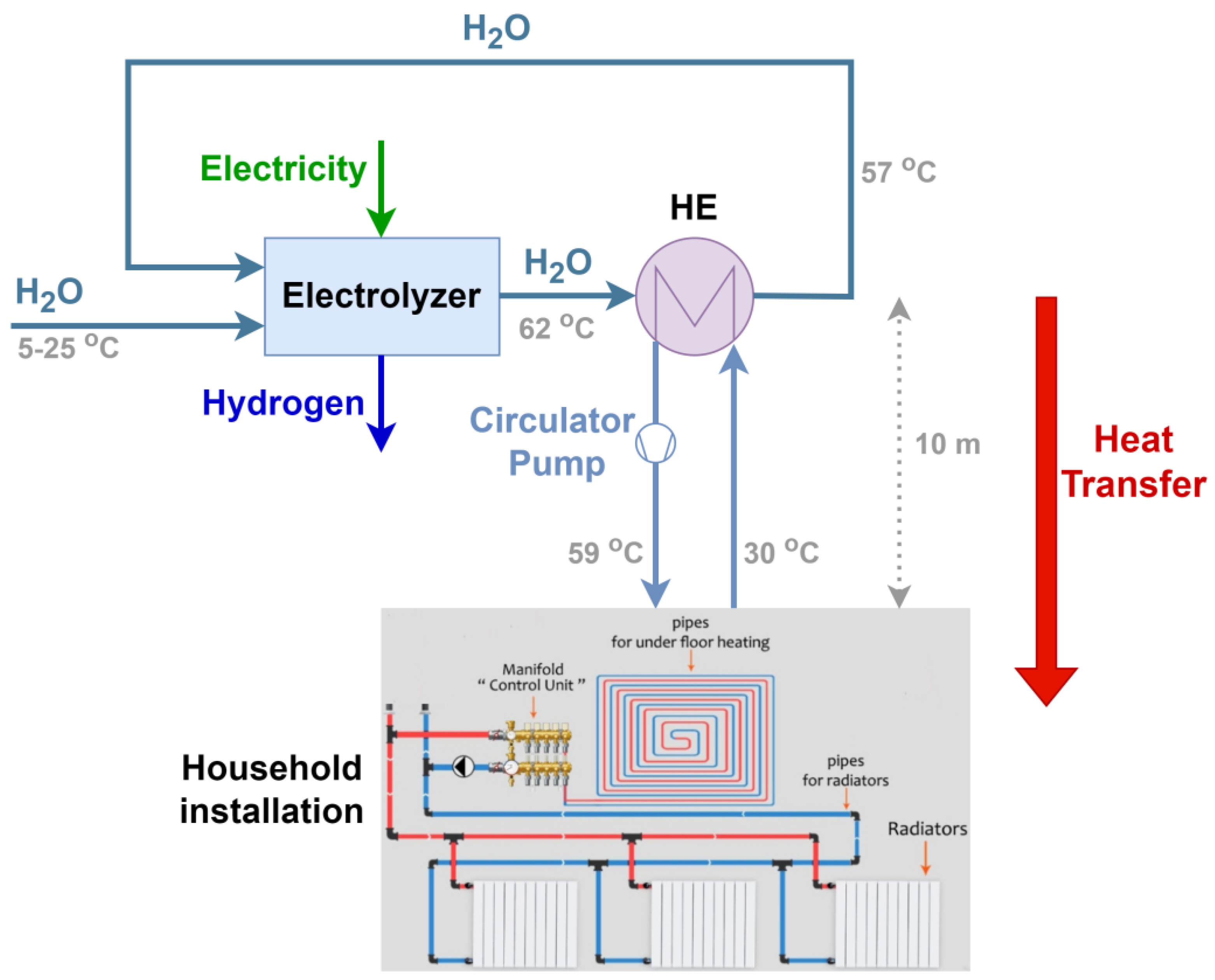

- No Heat Storage: The model does not account for the storage of heat. Heat generated by the ELZ and FC is either utilized within the home or dissipated externally.

- ▪

- ▪

- No Degradation and Aging: The model assumes a constant ELZ and FC efficiency throughout the facility’s operational life, despite a documented degradation rate of 0.19% per 1000 h [19].

- ▪

- No Heat Loss in Pipes: Given that the study focuses on household installations, where the heat is produced and consumed locally, the heat pipes are presumed to be very short. Consequently, heat losses through the pipes are considered negligible.

3. Results

4. Conclusions, Discussion, and Future Research

4.1. Conclusions and Discussion

4.2. Shortcomings and Future Research

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ELZ | electrolyzer |

| FC | fuel cell |

| FC-CHP | Fuel Cell Combined Heat and Power |

| PV | photovoltaic |

| DH | distinct heat |

| HE | heat exchanger |

| LP | linear programming |

| NPC | net present cost |

| HHV | Higher Heating Value (for Hydrogen) |

| h | hours |

| y | years |

| DPP | direct photovoltaic penetration |

Notations

| The notation ^ denotes a constant pre-specified variable. All variables without the notation ^ denote optimization (decision) variables. |

Nomenclature

| Installed (nominal) power of photovoltaics (kW) | |

| Per unit power of photovoltaics at time t (pu) | |

| Power of photovoltaics at time t (kW) | |

| Installed power of hydrogen tank (kWh) | |

| Installed power of Fuel cell (kW) | |

| Installed power of electrolyzer (kW) | |

| Installed power of waste heat recovery system of electrolyzer (kW) | |

| Installed power of waste heat recovery system of fuel cell (kW) | |

| Cost of solar installation (EUR/kW) | |

| Cost of hydrogen tank (EUR/kWh) | |

| Cost of fuel cell (EUR/kW) | |

| Cost of electrolyzer (EUR/kW) | |

| Cost of waste heat recovery system (EUR/kW) | |

| Solar power injected to the grid at time t (kW) | |

| Solar power injected to the home at time t (kW) | |

| Purchased heat power at time t (kW) | |

| Heat power produced from fuel cell at time t (kW) | |

| Heat power produced from electrolyzer at time t (kW) | |

| Electric power produced from electrolyzer at time t (kW) | |

| Electric power produced from fuel cell at time t (kW) | |

| Power supplied to the home from the electric grid at t (kW) | |

| Total electric load of the home at t (kW) | |

| Heat demand of the home at t (kW) | |

| ) | |

| ) | |

| ) | |

| Input power to hydrogen tank at time t (kW) | |

| Output power of hydrogen tank at time t (kW) | |

| Energy stored in the hydrogen tank at time t (kWh) | |

| Efficiency of fuel cell | |

| Efficiency of electrolyzer |

Appendix A

- -

- Total Cost .

- -

- Linearized Total Cost for .

References

- European Environment Agency. Available online: https://www.eea.europa.eu/en/analysis/indicators/greenhouse-gas-emissions-from-energy (accessed on 31 July 2024).

- European Commission. Available online: https://energy.ec.europa.eu/topics/energy-efficiency/energy-efficient-buildings/nearly-zero-energy-and-zero-emission-buildings_en (accessed on 31 July 2024).

- Lopez, V.M.; Ziar, H.; Haverkort, J.; Zeman, M.; Isabella, O. Dynamic operation of water electrolyzers: A review for applications in photovoltaic systems integration. Renew. Sustain. Energy Rev. 2023, 182, 113407. [Google Scholar] [CrossRef]

- Escamilla, A.; Sánchez, D.; García-Rodríguez, L. Assessment of power-to-power renewable energy storage based on the smart integration of hydrogen and micro gas turbine technologies. Int. J. Hydrogen Energy 2022, 47, 17505–17525. [Google Scholar] [CrossRef]

- PV Magazine, Electrolyzer Prices—What to Expect. Available online: https://www.pv-magazine.com/2024/03/21/electrolyzer-prices-what-to-expect/ (accessed on 4 June 2024).

- Sharshir, S.W.; Joseph, A.; Elsayad, M.M.; Tareemi, A.A.; Kandeal, A.W.; Elkadeem, M.R. A review of recent advances in alkaline ELZ for green hydrogen production: Performance improvement and applications. Int. J. Hydrogen Energy 2023, 360, 3199. [Google Scholar]

- Hossain, M.B.; Islam, M.R.; Muttaqi, K.M.; Sutanto, D.; Agalgaonkar, A.P. Advancement of fuel cells and ELZs technologies and their applications to renewable-rich power grids. J. Energy Storage 2023, 62, 106842. [Google Scholar] [CrossRef]

- Ramadhani, F.; Hussain, M.A.; Mokhlis, H. A Comprehensive Review and Technical Guideline for Optimal Design and Operations of Fuel Cell-Based Cogeneration Systems. Processes 2019, 7, 950. [Google Scholar] [CrossRef]

- Skordoulias, N.; Koytsoumpa, E.I.; Karellas, S. Techno-economic evaluation of medium scale power to hydrogen to combined heat and power generation systems. Int. J. Hydrogen Energy 2022, 47, 26871–26890. [Google Scholar] [CrossRef]

- Yu, S.; Fan, Y.; Shi, Z.; Li, J.; Zhao, X.; Zhang, T.; Chang, Z. Hydrogen-based combined heat and power systems: A review of technologies and challenges. Int. J. Hydrogen Energy 2023, 48, 34906–34929. [Google Scholar] [CrossRef]

- Nguyen, H.Q.; Aris, A.M.; Shabani, B. PEM fuel cell heat recovery for preheating inlet air in standalone solar-hydrogen systems for telecommunication applications: An exergy analysis. Int. J. Hydrogen Energy 2016, 41, 2987–3003. [Google Scholar] [CrossRef]

- Bilbao, D.C. Valorization of the waste heat given off in a system alkaline electrolyzer-photovoltaic array to improve hydrogen production performance: Case study Antofagasta, Chile. Int. J. Hydrogen Energy 2021, 46, 31108–31121. [Google Scholar] [CrossRef]

- Meriläinen, A.; Kosonen, A.; Jokisalo, J.; Kosonen, R.; Kauranen, P.; Ahola, J. Techno-economic evaluation of waste heat recovery from an off-grid alkaline water electrolyzer plant and its application in a district heating network in Finland. Energy 2024, 306, 132181. [Google Scholar] [CrossRef]

- Frassl, N.; Sistani, N.R.; Wimmer, Y.; Kapeller, J.; Maggauer, K.; Kathan, J. Techno-economic assessment of waste heat recovery for green hydrogen production: A simulation study. Elektrotech. Inftech. 2024, 141, 288–298. [Google Scholar] [CrossRef]

- Ozawa, A.; Kudoh, Y. Performance of residential fuel-cell-combined heat and power systems for various household types in Japan. Int. J. Hydrogen Energy 2018, 43, 15412–15422. [Google Scholar] [CrossRef]

- Romdhane, J.; Louahlia, H.; Marion, M. Dynamic modeling of an eco-neighborhood integrated micro-CHP based on PEMFC: Performance and economic analyses. Energy Build. 2018, 166, 93–108. [Google Scholar] [CrossRef]

- Huckebrink, D.; Bertsch, V. Decarbonising the residential heating sector: A techno-economic assessment of selected technologies. Energy 2022, 257, 124605. [Google Scholar] [CrossRef]

- Peppas, A.; Kollias, K.; Politis, A.; Karalis, L.; Taxiarchou, M.; Paspaliaris, I. Performance evaluation and life cycle analysis of RES-hydrogen hybrid energy system for office building. Int. J. Hydrogen Energy 2020, 46, 6286–6298. [Google Scholar] [CrossRef]

- van der Roest, E.; Bol, R.; Fens, T.; van Wijk, A. Utilisation of waste heat from PEM electrolyzers—Unlocking local optimization. Int. J. Hydrogen Energy 2023, 48, 27872–27891. [Google Scholar] [CrossRef]

- Hu, Q.; Lin, J.; Zeng, Q.; Fu, C.; Li, J. Optimal control of a hydrogen microgrid based on an experiment validated P2HH model. IET Renew. Power Gener. 2020, 14, 364–371. [Google Scholar] [CrossRef]

- Bozorgmehri, S.; Heidary, H.; Salimi, M. Market diffusion strategies for the PEM fuel cell-based micro-CHP systems in the residential sector: Scenario analysis. Int. J. Hydrogen Energy 2023, 48, 3287–3298. [Google Scholar] [CrossRef]

- Pompodakis, E.E.; Ahmed, A.; Alexiadis, M.C. A Three-Phase Weather-Dependent Power Flow Approach for 4-Wire Multi-Grounded Unbalanced Microgrids With Bare Overhead Conductors. IEEE Trans. Power Syst. 2021, 36, 2293–2303. [Google Scholar] [CrossRef]

- Pompodakis, E.E.; Ahmed, A.; Alexiadis, M.C. A Sensitivity-Based Three-Phase Weather-Dependent Power Flow Algorithm for Networks with Local Voltage Controllers. Energies 2022, 15, 1977. [Google Scholar] [CrossRef]

- Ahmed, A.; Pompodakis, E. Optimal conductor repositioning to mitigate adverse impacts of photovoltaics in LV networks. Electr. Power Syst. Res. 2023, 216, 109050. [Google Scholar] [CrossRef]

- Pompodakis, E.E.; Drougakis, I.A.; Lelis, I.S.; Alexiadis, M.C. Photovoltaic systems in low-voltage networks and overvoltage correction with reactive power control. IET Renew. Power Gener. 2016, 10, 410–417. [Google Scholar] [CrossRef]

- Wang, J.; Li, D.; Zhang, J.; Zhuang, G.; Gao, S. Mathematical Model and Working Characteristics Analysis of Alkaline Electrolyzer, The Proceedings of the 16th Annual Conference of China Electrotechnical Society; Lecture Notes in Electrical Engineering; Springer: Singapore, 2022; Volume 890. [Google Scholar] [CrossRef]

- Dataset on Hourly Load Profiles for a Set of 24 Facilities from Industrial, Commercial, and Residential End-Use Sectors. Available online: https://data.mendeley.com/datasets/rfnp2d3kjp/1 (accessed on 2 July 2024).

- Eurostat Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Natural_gas_price_statistics (accessed on 4 August 2024).

- Pfenninger, S.; Staffell, I. Renewable Ninja. 2020. Available online: https://www.renewables.ninja (accessed on 20 March 2023).

- Pfenninger, S.; Staffell, I. Long-term patterns of European PV output using 30 years of validated hourly reanalysis and satellite data. Energy 2016, 114, 1251–1265. [Google Scholar] [CrossRef]

- Statista. Electricity Prices for Households with an Annual Consumption of 2500 to 5000 kWh in the European Union in 2023, by Country. Available online: https://www.statista.com/statistics/1046505/household-electricity-prices-european-union-eu28-country/ (accessed on 4 August 2024).

- Ahmed, A.; Pompodakis, E.E.; Katsigiannis, Y.; Karapidakis, E.S. Optimizing the Installation of a Centralized Green Hydrogen Production Facility in the Island of Crete, Greece. Energies 2024, 17, 1924. [Google Scholar] [CrossRef]

- Moran, C.; Deane, P.; Yousefian, S.; Monaghan, R.F. The hydrogen storage challenge: Does storage method and size affect the cost and operational flexibility of hydrogen supply chains? Int. J. Hydrogen Energy 2024, 52, 1090–1100. [Google Scholar] [CrossRef]

- UPDATED: Rooftop Solar PV Country Comparison Report. Available online: https://caneurope.org/rooftop-solar-pv-comparison-report/ (accessed on 4 August 2024).

- Parra, D.; Valverde, L.; Pino, F.J.; Patel, M.K. A review on the role, cost and value of hydrogen energy systems for deep decarbonisation. Renew. Sustain. Energy Rev. 2019, 101, 279–294. [Google Scholar] [CrossRef]

- Maestre, V.; Ortiz, A.; Ortiz, I. Sustainable and self-sufficient social home through a combined PV-hydrogen pilot. Appl. Energy 2024, 363, 123061. [Google Scholar] [CrossRef]

- Huang, C.; Zong, Y.; You, S.; Træholt, C. Analytical Modeling and Control of Grid-Scale Alkaline Electrolyzer Plant for Frequency Support in Wind-Dominated Electricity-Hydrogen Systems. IEEE Trans. Sustain. Energy 2023, 14, 217–232. [Google Scholar] [CrossRef]

- Guo, L.; Su, J.; Wang, Z.; Shi, J.; Guan, X.; Cao, W.; Ou, Z. Hydrogen safety: An obstacle that must be overcome on the road towards future hydrogen economy. Int. J. Hydrogen Energy 2024, 51, 1055–1078. [Google Scholar] [CrossRef]

- da Silva, P.R.; Aragão, M.E.; Trierweiler, J.O.; Trierweiler, L.F. MILP Formulation for Solving and Initializing MINLP Problems Applied to Retrofit and Synthesis of Hydrogen Networks. Processes 2020, 8, 1102. [Google Scholar] [CrossRef]

- Asghari, M.; Fathollahi-Fard, A.M.; Mirzapour Al-E-Hashem, S.M.; Dulebenets, M.A. Transformation and Linearization Techniques in Optimization: A State-of-the-Art Survey. Mathematics 2022, 10, 283. [Google Scholar] [CrossRef]

- Polytherm Heating Systems. Available online: https://www.polytherm.ie/v4/0940aa0c-5421-4a9b-840d-c9a2ae5d95bb/uploads/PolythermCompletePricelist.pdf (accessed on 3 August 2024).

| Parameter | Description | Value |

|---|---|---|

| Heating threshold (°C) | Temperature below which heating is required | 22 |

| Heating power (kW/°C) | Heat per temperature drop below the heating threshold | 1 |

| Smoothing (days−1) | Constant for building’s thermal inertia | 0.5 |

| Solar gains (°C per W/m2) | The influence that sunshine has on the building’s temperature | 0.01 |

| Wind chill (°C per m/s) | The influence that wind has on the building’s temperature | −0.2 |

| Humidity discomfort (°C per g/kg) | The influence that humidity has on the perceived temperature | 0.05 |

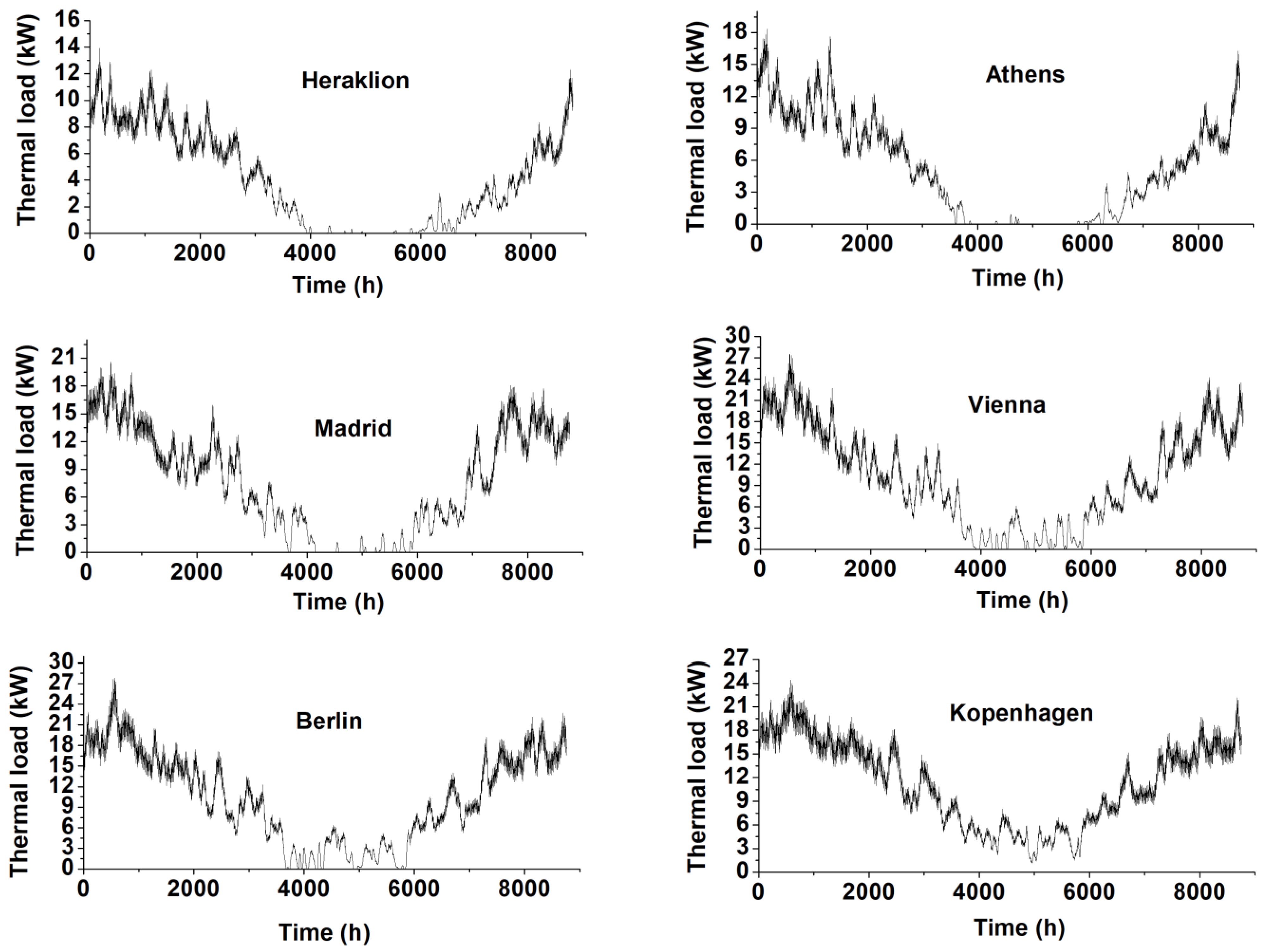

| Heraklion | Athens | Madrid | Vienna | Berlin | Copenhagen |

|---|---|---|---|---|---|

| 19.41% | 18.59% | 20.55% | 13.41% | 11.47% | 10.69% |

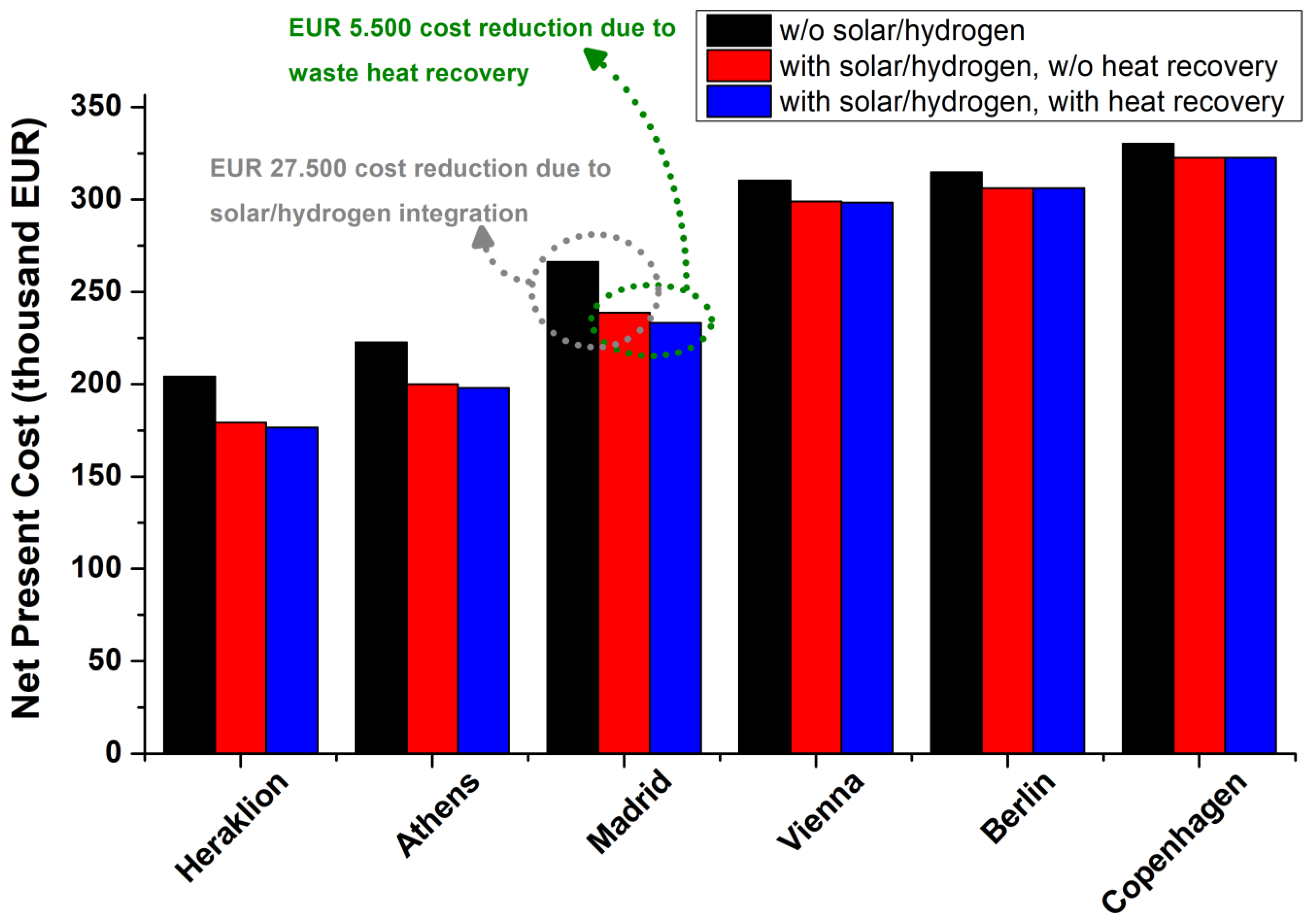

| City | Annual Electricity (kWh) | Annual Heat (kWh) | NPC (Thousand EUR) |

|---|---|---|---|

| Heraklion | 28,996 | 35,368 | 204.12 |

| Athens | 28,996 | 44,674 | 222.73 |

| Madrid | 28,996 | 66,431 | 266.24 |

| Vienna | 28,996 | 88,453 | 310.29 |

| Berlin | 28,996 | 90,710 | 314.80 |

| Copenhagen | 28,996 | 98,458 | 330.30 |

| City | NPC (Thousand EUR) | Photovoltaic Capacity (kW) | Electrolyzer Capacity (kW) | Fuel Cell Capacity (kW) | Hydrogen Tank (kWh) | Electrolyzer Heat Exchanger (kW) | Fuel Cell Heat Exchanger (kW) |

|---|---|---|---|---|---|---|---|

| Heraklion | 179.18 | 12.90 | 4.57 | 1.02 | 44.10 | - | - |

| Athens | 200.05 | 12.02 | 4.14 | 0.81 | 40.77 | - | - |

| Madrid | 238.80 | 15.42 | 6.43 | 1.48 | 53.03 | - | - |

| Vienna | 299.00 | 7.73 | 0.98 | 0.14 | 8.10 | - | - |

| Berlin | 306.16 | 6.57 | 0 | 0 | 0 | - | - |

| Copenhagen | 322.57 | 6.87 | 0 | 0 | 0 | - | - |

| Parameter | Description | Value | Reference |

|---|---|---|---|

| Cost of solar installation (EUR/kW) | 1200 EUR/kW | [32] | |

| Cost of hydrogen tank (EUR/kWh) | 10.5 EUR/kWh (≈350 EUR/kg H2) | [17,33] | |

| Cost of fuel cell (EUR/kW) | 1684 EUR/kW | [17] | |

| Cost of electrolyzer (EUR/kW) | 1295 EUR/kW | [17] | |

| Cost of waste heat recovery system (EUR/kW) | 1200 EUR/kW | See Appendix A | |

| - | Annual Operation and maintenance | 0.03 × installation cost | - |

| ) | 0.23 EUR/kWh | [31] | |

| ) | 0.10 EUR/kWh | [28] | |

| ) | 0.10 EUR/kWh | [34] | |

| Efficiency of fuel cell (HHV) | 50% | [17,35] | |

| Efficiency of electrolyzer (HHV) | 76% | [19,35] | |

| Lifetime | PV: 20 years | [32] | |

| ELZ: 80,000 h ≈ 20 years | [3,19,35] | ||

| FC: 80,000 h ≈ 20 years | [35,36] |

| City | NPC (Thousand EUR) | Photovoltaic Capacity (kW) | Electrolyzer Capacity (kW) | Fuel Cell Capacity (kW) | Hydrogen Tank (kWh) | Electrolyzer Heat Exchanger (kW) | Fuel Cell Heat Exchanger (kW) |

|---|---|---|---|---|---|---|---|

| Heraklion | 176.49 | 15.37 | 5.83 | 1.37 | 58.30 | 1.08 | 0.50 |

| Athens | 197.95 | 14.12 | 5.21 | 1.06 | 56.77 | 0.91 | 0.38 |

| Madrid | 233.33 | 20.14 | 9.05 | 2.08 | 105.64 | 1.73 | 0.83 |

| Vienna | 298.34 | 9.39 | 2.07 | 0.30 | 20.01 | 0.39 | 0.11 |

| Berlin | 306.10 | 7.06 | 0.44 | 0.05 | 4.14 | 0.08 | 0.02 |

| Copenhagen | 322.57 | 6.87 | 0 | 0 | 0 | 0 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pompodakis, E.E.; Ahmed, A.; Orfanoudakis, G.I.; Karapidakis, E.S. Optimization of Residential Hydrogen Facilities with Waste Heat Recovery: Economic Feasibility across Various European Cities. Processes 2024, 12, 1933. https://doi.org/10.3390/pr12091933

Pompodakis EE, Ahmed A, Orfanoudakis GI, Karapidakis ES. Optimization of Residential Hydrogen Facilities with Waste Heat Recovery: Economic Feasibility across Various European Cities. Processes. 2024; 12(9):1933. https://doi.org/10.3390/pr12091933

Chicago/Turabian StylePompodakis, Evangelos E., Arif Ahmed, Georgios I. Orfanoudakis, and Emmanuel S. Karapidakis. 2024. "Optimization of Residential Hydrogen Facilities with Waste Heat Recovery: Economic Feasibility across Various European Cities" Processes 12, no. 9: 1933. https://doi.org/10.3390/pr12091933

APA StylePompodakis, E. E., Ahmed, A., Orfanoudakis, G. I., & Karapidakis, E. S. (2024). Optimization of Residential Hydrogen Facilities with Waste Heat Recovery: Economic Feasibility across Various European Cities. Processes, 12(9), 1933. https://doi.org/10.3390/pr12091933