Abstract

As one of the main chili varieties in Mexico, Yahualica chili requires year-round availability. This study examines the feasibility of five drying methods (open-air, solar, microwave, freeze-drying and shade drying) used to preserve this culturally and economically valuable product. The results show the drying duration and rate for solar drying with varying air temperatures (40, 50, 60, and 70 °C) and airflows (150, 200, 250, and 300 m3/h) and microwave drying with varying power levels (90, 160, 360, and 600 W). Convection drying efficiency increased with temperature and airflow, according to the findings. Microwave drying significantly reduced drying time, and higher powers further accelerated moisture removal. Open sun and shade drying was the slowest, and open sun drying was also susceptible to factors compromising quality. Total Phenolic Content (TPC), Total Capsaicinoids Content (TCC), and antioxidant activity had a positive effect, since the drying methodologies favored the release of these compounds.

1. Introduction

Chili pepper (Capsicum annuum L.) is an annual herbaceous plant in the Solanaceae family. Yahualica chili is a prized variety originating in Mexico. The specific growing region and traditional methods that Mexican producers employ are responsible for these characteristics. In the States of Jalisco and Zacatecas, Mexico, the Yahualica chili is one of the leading crops. Its fruit is mainly sold in its state as a particular ingredient in typical dishes of the national gastronomy, pickles, and sauces, as well as raw material for industrial use and the production of finished products, which has led to an increase in production [1,2]. The main varieties, including Capsicum annuum, Capsicum frutescens, Capsicum chinense, and Capsicum pubescens [3,4], are distinguished by health-promoting phytochemicals such as phenolics, flavonoids, and carotenoids, which reduce the risk of developing cardiovascular diseases and arthritis and exert antiaging and immunomodulatory activities [3,5,6]. Several reported biological properties have been attributed to plant secondary metabolites, such as phenols or capsaicinoids [7,8].

Worldwide, 36.3 million tons of chili peppers and peppers are produced, and Mexico contributed 3.11 million tons in 2022, making it one of the largest producers worldwide [9]. However, food loss and waste in Mexico is estimated to be over 30%; this global problem is due to inadequate infrastructure (such as storage and refrigeration facilities), weather conditions, labor shortages, and problems related to packaging and marketing systems [10,11]. In this sense, drying is one of the easiest conservation methods to apply, as it prevents the growth and reproduction of microorganisms and reduces losses in the harvest. On the other hand, the final product’s nutritional content and quality attributes are positively or negatively affected by drying, depending on the technique used [12,13]. Numerous drying techniques have been implemented to ensure the quality and improve the stability of bioactive compounds; for example, fluidized bed drying, heat pump drying, freeze-drying, and rotary drying with liquefied petroleum gas are some industrial conservation techniques. However, generally, these techniques use fossil fuels as a heat source, which makes the process expensive. Large-scale chili powder production often employs counter-current convection dehydration, but small- and medium-sized industries mainly use open sun drying, particularly in developing countries. The traditional preservation method is to spread the food on the ground when there is sufficient solar radiation. Hot air drying exhibits the disadvantages of loss of aroma and color, the occurrence of oxidation reactions, reduced rehydration capacity, and hardening of the epidermis [3,14]. Over the last three decades, numerous solar dryers (direct, indirect, and mixed) have been developed to dry fruits and vegetables. Some works have reported on the different solar drying systems at different scales of operation and their main characteristics [15]. Some have reported heating designs using biomass [16,17].

The sustainability aspects of chili drying encompass various dimensions that underline its environmental, economic, and social impacts [18,19]. It is important to consider the sustainability aspects of food drying, which highlight its environmental, economic, and social impacts [18,19]. From an environmental perspective, using solar energy to dehydrate food reduces the dependence on fossil fuels, mitigating greenhouse gas emissions and minimizing the carbon footprint. On the other hand, adopting sustainable drying methods increases the value and management of resources for chili producers, facilitating financial resilience and promoting long-term viability within the agricultural sector [15].

Evaluating different drying techniques focusing on product quality contributes to market competitiveness and sustainability of the value chain, improving economic opportunities for chili producers and promoting food security and income stability, especially in vulnerable communities. The quality of dried chilies is somewhat subjective and depends on consumer acceptance, mainly influenced by color, pungency, and aroma, particularly flavor and taste. Volatile organic compounds are associated with food aromas; identifying and quantifying these compounds can provide information on their quality once they have dried [3,6].

Previous research on chili pepper drying has primarily focused on the performance of various drying techniques, including conventional [3,20], direct solar [21], solar hybrid [22], indirect solar [23], and those incorporating thermal storage [17,24]. Emerging technologies such as microwave and vacuum drying have also been explored [25]. These studies have investigated the drying kinetics and their impact on chili peppers’ chemical and nutraceutical properties, including the degradation or release of secondary metabolites like phenolic compounds and capsaicinoids. While the phytochemical composition of related capsicum species, such as bell peppers, has been documented, the variation in capsaicin content, color, and nutrient profile among different chili cultivars remains an area of interest. Additionally, the influence of drying methods on preserving tocopherols and carotenoids in chili peppers has been reported [26,27].

Given the agricultural and commercial importance of Yahualica chili, a Mexican crop with a protected designation of origin, and the absence of previous studies on its physical and chemical assessment using different drying methods, this research aimed to evaluate the capsaicinoid content, total phenolic compounds, and antioxidant capacity of Yahualica chili using different drying methods, including open-air drying, solar drying, microwave drying, and shade drying. These drying methods were selected to cover conventional large-scale practices and alternative approaches.

2. Materials and Methods

2.1. Biological Material and Reagents

In August, fresh Yahualica chili peppers were purchased from Nochistlán de Mejía municipality, Zacatecas, Mexico. The average dimensions of the selected fruits were 8 cm in length, 1.5 g in weight, and 1 cm in diameter. A moisture analyzer (Ohaus, MB25, Nanikon, Switzerland) 5 mg/0.05% was used at 105 °C to determine the initial moisture content. After careful selection and washing, the chili peppers were stored at 4 °C until they were used in the experiments.

The reagents used were purchased from Sigma Aldrich (St. Louis, MO, USA), including Folin-Ciocalteu phenol, 6-hydroxy-2,5,7,8-tetramethylchromane-2-carboxylic acid (Trolox), gallic acid, formic acid, capsaicin, dihydrocapsaicin, ethanol, methanol, acetonitrile (HPLC grade), p-iodonitrotetrazolium chloride, 2,2-diphenyl-1-picrylhydrazyl (DPPH), and 2,2′-azino-bis (3-ethylbenzothiazoline-6-sulfonic acid) (ABTS). Ultrapure water purified using a Milli-Q filtration system (Millipore, Bedford, MA, USA) was used.

2.2. Drying Equipment

2.2.1. Indirect Forced Convection Solar Dryer

This study employed a solar dryer with a dedicated air collector and a drying chamber. To optimize air movement, a control panel, a fan, and an air duct were incorporated into the system (Figure 1 is a visual representation of the drying system). A dedicated inlet draws ambient air into the collector, where the air is warmed up before entering the drying chamber, eliminating moisture from the foods controlled by the control panel. Pre-heating the exhaust air enhances the overall drying efficiency by maintaining a uniform temperature distribution within the drying chamber.

Figure 1.

Convective indirect solar dryer utilized in the experiment [28].

2.2.2. Microwave Dryer

The microwave drying (MD) experiments utilized a modified microwave oven. This oven operated with standard household specifications: 230 V, 50 Hz, and a frequency of 2450 MHz. The system offered adjustable power levels, allowing us to conduct drying trials at 90 W, 160 W, 360 W, and 600 W. The dimensions of the microwave oven chamber are 370 mm × 327 mm × 207 mm. The drying chamber had a fan to ensure consistent airflow and maintain optimal magnetron cooling (Figure 2). The control panel allowed for simultaneous adjustment of microwave power and exposure time. The microwave drying experiments utilized power levels of 90 W, 160 W, 360 W, and 600 W.

Figure 2.

Schematic diagram of the microwave drying system.

2.3. Drying Modes

2.3.1. Solar Drying

The drying experiments were used to explore the drying kinetics at various conditions. We tested four temperature levels: 40, 50, 60, and 70 °C. Additionally, we examined airflow rates of 150 m3/h, 200 m3/h, 250 m3/h, and 300 m3/h. In this study, the solar drying of Yahualica chili was influenced by the temperature, relative humidity, and product weight. K-type thermocouples were used to monitor the temperature, while a humidity sensor and digital balance were used measure the relative humidity and mass, respectively. In order to achieve efficient mass measurement, a digital balance with an accuracy of ±1 g was positioned outside the drying chamber. The data collection intervals ranged from 5 to 30 min, with a higher frequency occurring during the final drying stages. A thermo-hygrometer HI 9564 was used to measure the temperature and relative humidity with an accuracy of ±0.1 °C and ±2%, respectively.

2.3.2. Microwave Drying

A digital balance was used to precisely monitor the product mass of 50 g of Yahualica chili peppers during microwave drying, with data collected at one-minute intervals using digital balance software. A dedicated outlet on the oven wall helped to extract the moisture generated within the drying chamber.

2.3.3. Open Sun Drying Process

A total of 150 g of Yahualica chili peppers were exposed to natural environmental conditions for open sun drying on a mesh in a random position. The product mass was recorded at 30 min intervals until a constant weight was reached.

2.3.4. Shade Drying Process

In a controlled laboratory environment, a mesh with 150 g of Yahualica chili peppers and ambient temperatures ranging from 18 °C to 25 °C were used for shade drying. The product mass was recorded every 24 h until a constant weight was achieved.

2.3.5. Freeze-Drying Process

The samples were freeze-dried using a freeze dryer (FreeZone 6 L Benchtop, Labconco, Kansas, MO, USA) using conditions of −50 °C and 130 mbars to obtain similar low moisture contents (5%), which were determined using a thermobalance (OHAUS, MB25, Nanikon, Switzerland). The results were used for phytochemical analysis comparisons.

2.4. Drying Kinetics Parameters

Moisture Ratio

The drying curves were plotted based on the moisture ratio (Mr) values obtained at different time intervals using the following equation:

where Mceq is the equilibrium moisture content of the product, and Mc0 is the initial moisture content.

2.5. Quality Parameters

2.5.1. Phytochemical Composition

The samples were pulverized in a mill (KRUPS, Model GX41000, Jalisco, Mexico) to a powder with a particle size of <500 μm. Finally, the samples were stored at room temperature until further analysis.

Total Phenolic Content (TPC)

The total phenolic compounds were extracted according to [29] Lyophilized powder (200 mg) was placed in 15 mL conical tubes (FalconT M) with 10 mL of ethanol/water (50/50 v/v), and extraction was carried out in an ultrasonic bath (Branson Ultrasonic Cleaner model 3510, purchased from Sigma Aldrich, St. Louis, MO, USA) for 40 min. Quantification was performed according to the methodology of [30] using the Folin–Ciocalteau reagent. Briefly, 250 μL of Folin–Ciocalteau reagent (1N) was mixed with 20 μL of each extract, 1250 μL of Na2CO3 (7.5%) was added to each sample, then 480 μL of distilled water was added. The absorbance of the reaction mixtures was measured at 760 nm using a UV–vis spectrophotometer (Thermo Fisher Scientific, Biomate 3S, Madison, WI, USA) after 30 min. The TPC analysis was performed in triplicate, and mean values were expressed as mg Gallic Acid Equivalents (GAE)/g dried wt.

Total Capsaicinoid Content (TCC) Determination

The extraction, identification, and quantification of capsaicinoids were performed based on chromatographic analysis [30] using a UPLC Acquity H Class (Waters, Milford, CA, USA) chromatographer. The official Analytical Method 21.3 of the American Spice Trade Association (ASTA) was used for capsaicin (CS) and dihidrocapsaicin (DHC) quantification. Additionally, calibration curves for the respective analytical standards ranging from 5 to 300 μg/mL were used. All measurements were performed in triplicate.

2.5.2. Antioxidant Activity

As García-Moreira et al. (2023) described, the ABTS and DPPH radical assays were used to determine the antioxidant activity in the evaluated treatments. The antioxidant activity of the samples was expressed as μEq of Trolox g-1 dry wt [29].

2.5.3. Color Determination as a Quality Parameter

A MiniScan EZ4500L colorimeter (Hunter Associates Laboratory, Inc., Reston, VA, USA) was used to determine the colors of CIELAB L* (0 = black; 100 = white), a* (negative—green; positive—red), and b* (negative—blue; positive—yellow). All of the measurements were performed in triplicate. In order to determine the color differences compared to the freeze-dried samples, according to Medina-Torres et al. (2021), the delta E (ΔE) (Equation (2)) hue anle (Equation (3)) and Chroma (Equation (4)) were also calculated [30].

2.5.4. Statistical Analysis

Each quality was tested in triplicate, and the findings were presented as means and standard deviations. One-way analyses of variance (ANOVA) were performed on the data, and Tuckey’s test was performed for comparison analysis. Significance was defined as p < 0.05. The Statgraphics Centurion XVI software (Statistical Graphics Corp., Manugistics, Inc., Cambridge, MA, USA) was used for data analysis.

To determine uncertainty, we utilized the following equation using the experimental errors of the measured parameters [31]:

where P = f(x1, x2, x3, …, xn) is a function of independent variables xn; and un represents the uncertainty in the variable.

3. Results and Discussion

An extensive evaluation was undertaken in September 2023 to enhance the value of Chili Yahualica. This investigation involved 13 trials, employing various combinations of drying air temperature, airflow rates, and drying methods (open-air drying, solar drying, microwave drying, and shade drying). The trials were conducted under fluctuating ambient conditions: the temperature ranged from 26.6 to 37.2 °C, the relative humidity varied between 8 and 30.5%, and the solar irradiance levels fluctuated between 39 and 874 W/m2. It is important to note that for solar drying, specifically, the drying air temperature range was narrowed to 40–70 °C. This study used a completely randomized design, where each factor varied independently, since the study involved multiple variables (e.g., drying methods, temperatures, airflow rates, and microwave power levels). During the drying experiment, we conducted 14 trials. Each experiment was replicated two times. Across all the trials, we used the same raw material (the same batch of Yahualica chili) and the same mass of approximately 150 g. Drying experiments of each mode were conducted separately.

3.1. Drying Experiments

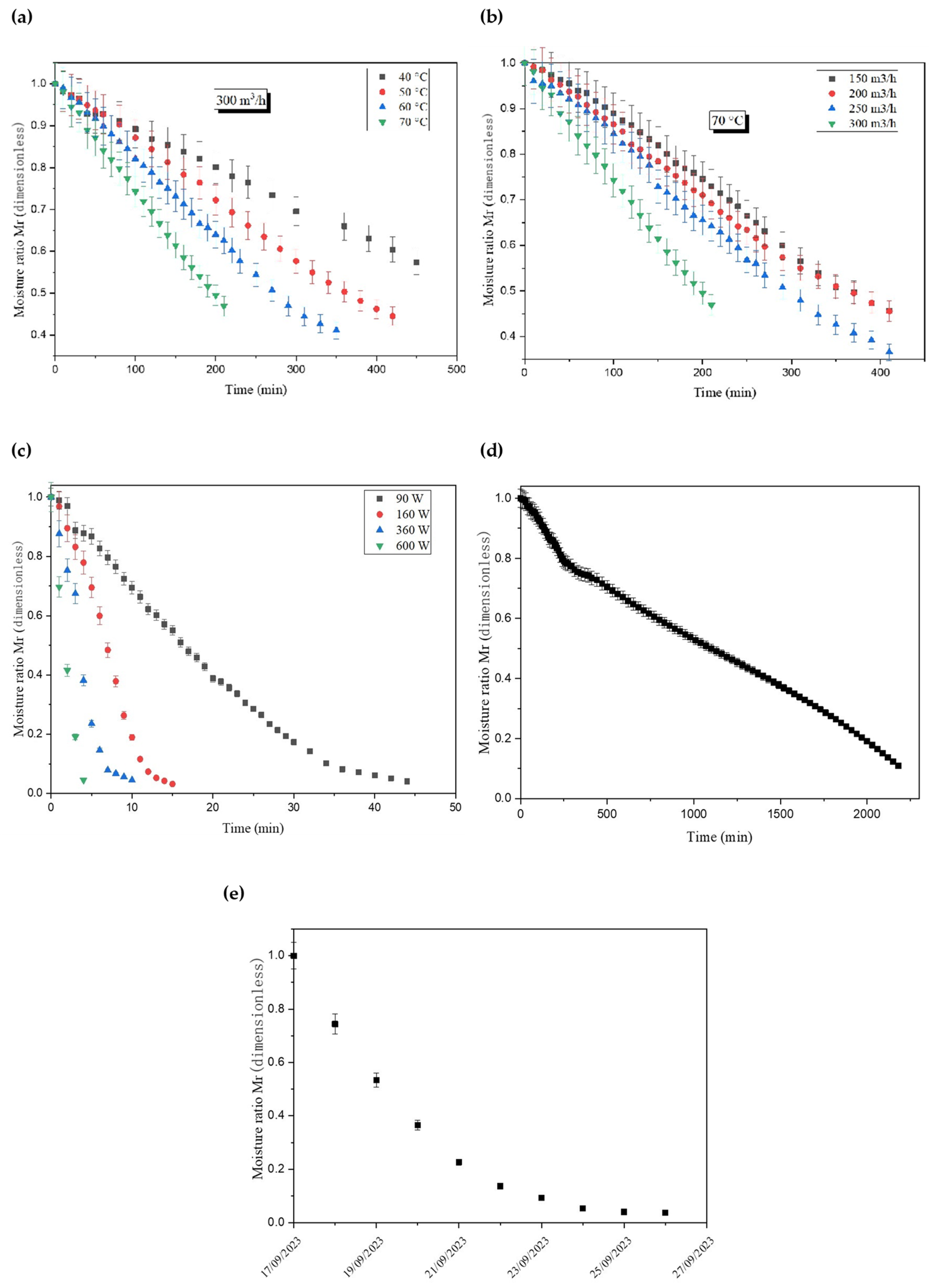

Figure 3a,b show the impact of temperature and airflow rate on drying speed. Higher values for both led to a faster decrease in the moisture ratio. Three drying phases were identified, with phases 0 and I sometimes being absent due to negligible temperature differences. Phase II, the falling rate period, was dominated by internal moisture diffusion. Here, airflow rate plays a crucial role—increased airflow enhances moisture removal by strengthening air currents within the drying chamber. The drying process can generally be divided into three distinct phases. The first phase, often called Phase 0 (the increasing drying phase), is when the product absorbs sensible heat. During this phase, the temperature of the material rises as it heats up. Pre-treatment can minimize or even eliminate this phase in some cases, such as with thin materials. The drying rate accelerates during this stage as free moisture is removed. In Phase I (the steady drying phase), free moisture remains on the product’s surface, and the drying rate stays relatively constant as moisture content decreases. During this period, the drying process is efficient, and the product’s temperature increases slowly and gradually. Finally, Phase II marks the point when moisture movement from the inner pores to the surface becomes the rate-limiting factor, leading to a decline in the drying rate. This stage is characterized by a more complex mechanism of moisture migration involving both liquid and vapor states. Water diffusion within the material becomes the critical factor governing the drying process during this final phase. In Figure 3, for solar drying, it can be observed that, with a constant airflow rate, the drying rate and moisture ratio are inversely related. As the air temperature increases, the moisture ratio declines. Likewise, when the air temperature is held steady, increasing the airflow rate causes the drying rate to drop, which can be attributed to the increased air velocity and enhanced heat transfer between the product and the air. This aligns with previous chili pepper drying studies using solar methods [12,32,33].

Figure 3.

(a) Effects of drying temperature on the moisture ratio under an airflow rate of 300 m3/h. (b) Effects of air flow rate on the variations in moisture content under a drying temperature of 70 °C. (c) Effects of electromagnetic power on the microwave drying. (d) Variations in moisture ration under open sun drying. (e) Variations in moisture ratio during shade drying of Chili Yahualica.

Microwaving significantly reduced the drying time compared to solar drying (Figure 3c). Steeper slopes in the moisture ratio curves indicate faster moisture loss with higher microwave power. Parallel to other food drying methods, a rapid initial decrease followed by a gradual decrease dominated the process. Microwave drying is quicker than solar drying because, in solar drying, moisture diffusion is driven by the temperature gradient. In contrast, microwave drying directly targets the water molecules within the product using electromagnetic energy, significantly shortening the drying time. The constant-rate phase was often difficult to distinguish for these thin samples. Overall, higher microwave power resulted in faster drying, as evidenced by the steeper curves, which is consistent with other chili pepper drying research [32,34,35].

The open sun drying shown in Figure 3d exhibited the longest drying time compared to other techniques. This method has several drawbacks: it takes considerably longer than other methods, leading to a slower decrease in moisture ratio, and it is susceptible to external factors, because the product is vulnerable to insect and bird damage, dust contamination, and fluctuating weather conditions, potentially affecting quality. In open sun drying, moisture removal occurs through natural convection due to direct solar radiation, which explains the slower moisture diffusion than the forced convection used in indirect solar drying. For shade drying, diffusion removal is even slower due to the absence of solar irradiation.

As shown in Figure 3e, shade drying is similar to open sun drying; shade drying presented the longest drying time among the studied techniques.

3.2. Phytochemical and Quality Parameters

3.2.1. Total Phenolic Content (TPC) and Antioxidant Activity

The total phenolic content was determined for all drying modes to evaluate their effects compared to fresh material dried without thermal treatment. The value of TPC for the Freeze Drying (FD) treatment was 9.49 ± 0.30 mg GAE/g dry wt. These values were the lowest among the evaluated modes, which provided values ranging from 9.4 to 19.2 mg GAE/g dry wt (Table 1). The OS drying mode presented values similar to the FD mode, suggesting that heating did not directly affect TPC. Nevertheless, treatments using 300 m3/h at 40, 50, and 60 °C presented higher values of TPC. This might be related to the degradation of some compounds at these relatively low and controlled temperatures and the apparent liberation of other phenolic compounds, as reported by Ornelas-Paz et al. (2010) for thermally treated chili peppers [36]. Compared to other fruits and peppers, Yahualica chili presented the same tendency to increase in TPC content at high temperatures, similar to beta vulgaris obtained via convective drying [37] and the TPC contents of cherry laurel fruit obtained via convective drying [38]. Nevertheless, the TPC values were found to be approximately ten times higher for the Yahualica chili dried samples than thermally processed samples of habanero, Manzano, serrano, jalapeño, caribe, chilaca, poblano, bell, and xcatic chili peppers [36,37,38,39]. Significant differences (p < 0.05) were also observed among all the drying modes studied.

Table 1.

Total phenolic content and antioxidant activity determined using ABTS and DPPH techniques for the different treatments of dried Yahualica chili.

The antioxidant activity values obtained using the ABTS method were higher than those reported using DPPH. The ABTS values also increased directly with the TPC values, which showed a linear correlation. For the ABTS method, the 300 m3/h 60 °C treatment presents the highest antioxidant activity, which is significantly different (p < 0.05) from the other treatments. The DPPH values presented values that were 4 to 6 times lower than the ABTS analysis, indicating that this last technique presents a better reaction of the ABTS radical due to its higher sensitivity to hydrophilic compounds, as reported by Shah et al. [40]. Furthermore, it is interesting to emphasize that the antioxidant activity of the different extracts of the dried Chili Yahualica was higher than that reported for habanero pepper [30], Xcatic pepper [39], and other foods that were thermally treated with sustainable technologies such as beta vulgaris [41].

3.2.2. Total Capsaicinoid Content (TCC)

The total capsaicinoid content is presented in Table 2 and expressed in Scoville units (SHU). As for the TPC results for the different drying samples, these samples were compared to the values of the FD treatment, reported as 36,000 SHU. The TCC values increased across all drying modes, presenting the highest value of 65,520 SHU with a drying temperature of 70 °C and flow rate of 250 m3/h, presenting significant differences (p < 0.05) among the treatments. The increment in capsaicinoid content after thermal treatment was also reported by [36], who indicated that thermal treatment, such as the grilling process, can increase the TCC by approximately 30% compared to the non-thermal treatment of habanero peppers. The initial value was 20,300 SHU, increasing to 31,300 SHU and 29,000 SHU for green peppers and 44,000 SHU for red ones. There was also an approximately 20% increase in TCC for Manzano and Serrano peppers, with an average TCC of 11,000 SHU. Furthermore, Li et al., 2024, reported significantly increased the capsaicinoid contents for Capsicum annuum var. conoides, commonly used for dried pepper production in China, indicating that this is related to rapid dehydration. However, after 800 min of processing using high temperatures, the heat favors alkyl cleavage, forming vanillin, 8-methyl-6-nonenoamide, and 8-methyl-6-nonenoic acid via further oxidation [42]. On the other hand, even though the boiling processes reported by [36] did not increase the TCC, it preserved the TCC values, as significant differences (p < 0.05) for TCC among these peppers were not observed in their work. Several factors may contribute to this increase. The thermal processing likely disrupted the food matrix, enhancing compound extractability through dehydration. This can be confirmed based on the reduction in the capsaicin values in the freeze-dried samples reported herein, when high temperatures were not applied, or based on the samples that were microwave dried with low watt values. Moreover, the liberation of conjugated capsaicinoids, the inactivation of capsaicinoid-degrading enzymes, and the intrinsic thermostability of these compounds might also play roles in both capsaicinoids evaluated [36].

Table 2.

Total capsaicinoid content (TCC), capsaicin, and dihydrocapsaicin contents of Yahualica chilis dried using different treatments and percentage of the increment of capsaicin (ΔCP) and dihydrocapsaicin (ΔDHC) compared to the freeze-dried samples used as reference.

Additionally, Si et al. (2014) reported that a higher initial content of capsaicinoids resulted in higher protection and stability of capsaicinoids during thermal treatment; this is related to the higher amount of destructive energy required for degrading capsaicinoid molecules. Furthermore, capsaicinoids may be more stable in the food matrix during heading, as many ingredients are present, causing a reduction in its destruction rate, as some additives could be more sensitive to heat [43]. The increment of TCC could also explain the increment in antioxidant activity related to capsaicinoid compounds. A deeper analysis of the specific capsaicinoid compounds revealed a 63% capsaicin content and 37% dihydrocapsaicin content; a relation that changes with thermal treatment in some cases by about 5%. The maximal capsaicin content was also obtained for a drying temperature of 70 °C and flow rate of 250 m3/h, and for the dihydrocapsaicin content, the open sun drying allowed for a better liberation for both cases, which was significantly different (p < 0.05). These results suggest that the capsaicinoid content will increase, regardless of the drying mode tested, when moderate temperatures are used, favoring the biological activity of the Yahualica chilis in most cases. Nevertheless, the maturity stage of the product may play a role in capsaicinoid content modification after the drying treatments, as several parameters are involved; for instance, higher initial contents are reported for different types such as Habanero, Cayenne, Jalapeño, Paprika, and Serrano, as reported by Bae et al. [44]. Additionally, the TCC for Yahualica chili peppers is higher than the values reported for habanero, manzano, serrano, jalapeño, caribe, chilaca, poblano, and bell chili peppers reported by [36] but lower than reported by [30] for habanero peppers, which are recognized as Mexican peppers with higher capsaicinoid contents with values of around 290,000 SHU. Although, there are several documents related to the stability of capsaicinoids during thermal treatment, few of them compare different methodologies for dried pepper production.

3.2.3. Color Parameters

The drying modes affected the L, a, and b parameters of the Yahualica chilis; in all cases, luminosity and yellowness decreased. Nevertheless, redness increased, revealing statistically significant differences (p < 0.05) among the treatments (Table 3). Significant changes in color (Table 4) were observed for the 300 m3/h 50 °C and 300 m3/h 60 °C treatments based on the chroma results. In the case of microwave drying, it presented a high luminosity (L); however, it showed a decrease in the red color and a constant yellow color. The drying process at 70 °C also showed high brightness; however, it also had the highest yellow shift compared to the other methods presented. It is well-studied that color changes are present during the food drying process [45,46,47]. However, this does not imply a reduction in the acceptability of the product by the consumer. In the particular case of chili peppers, since generally, dried chili peppers are well accepted in Mexican cuisine and are used in several traditional dishes, with their dried version known as chipotle chili or ancho chili—the dried versions of smoked dried jalapeño and dried poblano, respectively. However, consumers tend to select products with a more uniform color.

Table 3.

Color parameters in dried samples of Yahualica chili determined based on CIELAB representation.

Table 4.

Color difference comparison between the drying methods.

Moreover, consumers tend to select products with a more uniform color. Nevertheless, sensorial analysis should be conducted for future studies to ensure that color will not hinder the commercialization of Yahualica chilis. Due to the interplay between food color and human perception of food acceptability, including color–taste, color–olfactory, and color–flavor interactions, color is a quality indicator that reflects product condition. The drying process significantly impacts the physical properties of bioactive compounds, including color, flavor, texture, shrinkage, and chemical modifications. Maintaining color in the final product is a primary consideration for consumer acceptance [48].

4. Conclusions

Yahualica chili drying is usually based on a traditional open-air solar drying process. This chili is known for its characteristic flavor and moderate spiciness, which is why it is used in various dishes, sauces, and marinades. Given its commercial importance in Mexico, it is important to characterize the drying process and determine techniques that could provide a better quality than traditional drying. Drying initiatives focusing on the quality of dehydrated chili can empower rural communities, alleviate poverty, and promote equitable socioeconomic development by promoting a circular economy. The characterization of solar drying is necessary for the enrichment of the literature and is an essential tool for better understanding the behavior of food during the drying process.

Convective drying experiments revealed that higher temperatures and airflow rates resulted in faster drying. Microwaves significantly reduced drying times compared to solar drying, and increasing power accelerated moisture removal. Open sun drying and shade drying emerged as the slowest methods, with open sun drying being further susceptible to external factors that could compromise quality. Key findings indicate that solar drying is a promising method to preserve this economically valuable product using clean and renewable energy.

Thermal treatments affect the phytochemical composition parameters of the Yahualica chili; however, a positive effect was observed for TPC, TCC, and antioxidant activity, as the drying methodologies favored the release of these compounds, responsible for biological activities such as antioxidant activity. A relationship is shown between the total phenol content and antioxidant activity. The results suggest that an average temperature of 60 °C for convective drying and a power of 160 W for microwave drying are the methods that best preserve the antioxidant activity. Regarding capsaicin content, it was observed that high temperatures during convective drying promote a greater retention or even liberation of this compound, possibly for a shorter processing time. Additionally, the TCC for the Yahualica chili pepper was higher than the values reported for manzano, serrano, jalapeño, caribe, chilaca, poblano, and bell chili peppers. As expected, open-air solar drying resulted in the lowest values of the bioactive compounds evaluated.

The quality of dried chili peppers is contingent upon consumer acceptance, primarily influenced by color, pungency, and aroma. Particularly, the distinctive aroma of these products significantly impacts their sensory attributes. These results could be of interest to the industry dedicated to the extraction of these bioactive compounds. For future studies, it is necessary to evaluate the drying of Yahualica chilis, considering their maturity stage and its effect on the qualities that make it organoleptically and commercially attractive based on sensorial analysis.

Author Contributions

All authors contributed to this study’s conception and design. Experimentation: D.P.G.-M. and H.H.-G.; conceptualization: Y.B., N.P. and E.C.L.-V.; methodology: Z.T.; formal analysis and investigation: D.P.G.-M., N.P., E.C.L.-V. and Y.B.; writing—original draft preparation: D.P.G.-M., N.P., E.C.L.-V. and Y.B.; writing—review and editing: D.P.G.-M. and E.C.L.-V.; supervision: I.M. All authors commented on previous versions of the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available upon request from the corresponding author. The data reported will be part of a more extensive study on the drying of commercially important chili peppers in Mexico.

Acknowledgments

The authors thank Consejo Zacatecano de Ciencia y Tecnología (COZCYT) and the Universidad Autónoma de Zacatecas (UAZ) for providing support through the Solar Energy and Aromatic and Medicinal Plants Team. We thank Ismael Hernández Landeros, Jorge A. Escobedo Bretado, and Emanuel Herrera for helping with the experiments.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- De Jesús-Contreras, D.; Martínez-Salvador, L.E.; Ruvalcaba-Gómez, E.; Duhart, F. Agri-Food Routes as Tools for Sustainable Rural Development: The Case of Chili Route in Yahualica Denomination of Origin. In Food, Gastronomy, Sustainability, and Social and Cultural Development: Cross-Disciplinary Perspectives; Academic Press: Cambridge, MA, USA, 2023; pp. 169–183. [Google Scholar] [CrossRef]

- Arslan, D.; Özcan, M.M. Dehydration of Red Bell-Pepper (Capsicum annuum L.): Change in Drying Behavior, Colour and Antioxidant Content. Food Bioprod. Process. 2011, 89, 504–513. [Google Scholar] [CrossRef]

- Liu, M.; Hu, L.; Deng, N.; Cai, Y.; Li, H.; Zhang, B.; Wang, J. Food Chemistry: X Effects of Different Hot-Air Drying Methods on the Dynamic Changes in Color, Nutrient and Aroma Quality of Three Chili Pepper (Capsicum annuum L.) Varieties. Food Chem. 2024, 22, 101262. [Google Scholar] [CrossRef]

- Getahun, E.; Delele, M.A.; Gabbiye, N.; Fanta, S.W.; Vanierschot, M. Studying the Drying Characteristics and Quality Attributes of Chili Pepper at Different Maturity Stages: Experimental and Mechanistic Model. Case Stud. Therm. Eng. 2021, 26, 101052. [Google Scholar] [CrossRef]

- Mehta, D.; Prasad, P.; Bansal, V.; Siddiqui, M.W.; Sharma, A. Effect of Drying Techniques and Treatment with Blanching on the Physicochemical Analysis of Bitter-Gourd and Capsicum. Lwt 2017, 84, 479–488. [Google Scholar] [CrossRef]

- Souza, C.S.; Daood, H.; Duah, S.A.; Vinogradov, S.; Palotás, G.; Neményi, A.; Helyes, L.; Pék, Z. Stability of Carotenoids, Carotenoid Esters, Tocopherols and Capsaicinoids in New Chili Pepper Hybrids during Natural and Thermal Drying. Lwt 2022, 163, 113520. [Google Scholar] [CrossRef]

- Espino-Díaz, M.; Ornelas-Paz, J.D.J.; Martínez-Téllez, M.A.; Santillán, C.; Barbosa-Cánovas, G.V.; Zamudio-Flores, P.B.; Olivas, G.I. Development and Characterization of Edible Films Based on Mucilage of Opuntia Ficus-Indica (L.). J. Food Sci. 2010, 75, E347–E352. [Google Scholar] [CrossRef]

- Núñez-Ramírez, D.; López-Martínez, A.; Medina-Torres, L.; Calderas, F.; Martínez-Prado, M.; Lara, R.; Herrera-Valencia, E.; Anguiano-Vega, G.; Manero, O. Microencapsulation of Acidithiobacillus thiooxidans by Spray Drying Using Biopolymers as Wall Materials: A Potential Alternative for Its Application in the Mining Industry. Miner. Eng. 2021, 166, 106882. [Google Scholar] [CrossRef]

- FAOSTAT. Available online: https://www.fao.org/faostat/es/#data/QCL (accessed on 23 August 2024).

- Aguirre-Mancilla, C.L.; Iturriaga de la Fuente, G.; Ramírez-Pimentel, J.G.; Covarrubias-Prieto, J.; Chablé-Moreno, F.; Raya-Pérez, J.C. Chili cultivation and seed production. Cienc. Y Tecnol. Agrop. México 2017, 5, 19–27. [Google Scholar]

- Sánchez, C. RED BAMX. Available online: https://bamx.org.mx/dia-internacional-para-la-concienciacion-sobre-perdida-y-desperdicio-de-alimentos/ (accessed on 20 July 2024).

- Getahun, E.; Gabbiye, N.; Delele, M.A.; Fanta, S.W.; Vanierschot, M. Two-Stage Solar Tunnel Chili Drying: Drying Characteristics, Performance, Product Quality, and Carbon Footprint Analysis. Sol. Energy 2021, 230, 73–90. [Google Scholar] [CrossRef]

- Lozano, Á.G.B.; Gozález, G.G.; Ramírez, M.D.A. Tecnología de Producción de Chile Seco; Instituto Nacional de Investigaciones Forestales, Agrícolas y Pecuarias (INIFAP): Zacatecas, Mexico, 2007. [Google Scholar]

- Lakshmi, D.; Muthukumar, P.; Nayak, P.K. Experimental Investigations on Active Solar Dryers Integrated with Thermal Storage for Drying of Black Pepper. Renew. Energy 2021, 167, 728–739. [Google Scholar] [CrossRef]

- Goel, V.; Dwivedi, A.; Mehra, K.S.; Pathak, S.K.; Tyagi, V.; Bhattacharyya, S.; Pandey, A. Solar Drying Systems for Domestic/Industrial Purposes: A State-of-Art Review on Topical Progress and Feasibility Assessments. Sol. Energy 2024, 267, 112210. [Google Scholar] [CrossRef]

- Xue, K.; Li, J.; Chen, H.; Xu, G.; Liu, T. Development of a Novel Power Generation System Based on the Co-Combustion of Agriculture Biomass and Sludge Integrated with Solar-Aided Sludge Drying. Energy Convers. Manag. 2022, 253, 115185. [Google Scholar] [CrossRef]

- Babar, O.A.; Arora, V.K.; Nema, P.K.; Kasara, A.; Tarafdar, A. Effect of PCM Assisted Flat Plate Collector Solar Drying of Green Chili on Retention of Bioactive Compounds and Control of Aflatoxins Development Grooves for. Sol. Energy 2021, 229, 102–111. [Google Scholar] [CrossRef]

- Atalar, I.; Konar, N.; Dalabasmaz, S.; Kantemur, P.S.; Han, E. Drying and Characterization of Red Beet Color Liquid Process Waste to Develop a Novel Bulking Agent. J. Clean. Prod. 2024, 442, 141030. [Google Scholar] [CrossRef]

- Salve, S.; Fulambarkar, A. A Solar Dryer for Drying Green Chili in a Forced Convection for Increasing the Moisture Removing Rate. Mater. Today Proc. 2021, 45, 3170–3176. [Google Scholar] [CrossRef]

- Palma-Orozco, G.; Orozco-Álvarez, C.; Chávez-Villeda, A.A.; Mixtega-Martínez, A.; Castro-Muñoz, R. Capsaicin Content in Red Habanero Chilli (Capsicum chinense Jacq.) and Its Preservation after Drying Process. Future Foods 2021, 4, 100070. [Google Scholar] [CrossRef]

- Castillo-Téllez, M.; Pilatowsky-Figueroa, I.; López-Vidaña, E.C.; Sarracino-Martínez, O.; Hernández-Galvez, G. Dehydration of the Red Chilli (Capsicum annuum L., Costeño) Using an Indirect-Type Forced Convection Solar Dryer. Appl. Therm. Eng. 2017, 114, 1137–1144. [Google Scholar] [CrossRef]

- Goud, M.; Reddy, M.V.V.; Chandramohan, V.P.; Suresh, S. A Novel Indirect Solar Dryer with Inlet Fans Powered by Solar PV Panels: Drying Kinetics of Capsicum Annum and Abelmoschus Esculentus with Dryer Performance. Sol. Energy 2019, 194, 871–885. [Google Scholar] [CrossRef]

- Fudholi, A.; Sopian, K.; Yazdi, M.H.; Ruslan, M.H.; Gabbasa, M.; Kazem, H.A. Performance Analysis of Solar Drying System for Red Chili. Sol. Energy 2014, 99, 47–54. [Google Scholar] [CrossRef]

- Subrahmanyam, K.; Gul, K.; Paridala, S.; Sehrawat, R.; More, K.S.; Dwivedi, M.; Jaddu, S. Effect of Cold Plasma Pretreatment on Drying Kinetics and Quality Attributes of Apple Slices in Refractance Window Drying. Innov. Food Sci. Emerg. Technol. 2024, 92, 103594. [Google Scholar] [CrossRef]

- Kumar, V.; Devi, M.K. Impact of Different Drying Methods on Sensory and Physicochemical Analysis of Instant Green Bell Pepper Chutney Mix. Meas. Food 2023, 9, 100077. [Google Scholar] [CrossRef]

- Loizzo, M.R.; Pugliese, A.; Bonesi, M.; De Luca, D.; O’brien, N.; Menichini, F.; Tundis, R. Influence of Drying and Cooking Process on the Phytochemical Content, Antioxidant and Hypoglycaemic Properties of Two Bell Capsicum annum L. Cultivars. Food Chem. Toxicol. 2013, 53, 392–401. [Google Scholar] [CrossRef] [PubMed]

- Yaldiz, G.; Ozguven, M.; Sekeroglu, N. Variation in Capsaicin Contents of Different Capsicum Species and Lines by Varying Drying Parameters. Ind. Crops Prod. 2010, 32, 434–438. [Google Scholar] [CrossRef]

- Tagnamas, Z.; Bahammou, Y.; Kouhila, M.; Hilali, S.; Idlimam, A.; Lamharrar, A. Conservation of Moroccan Truffle (Terfezia boudieri) Using Solar Drying Method. Renew. Energy 2020, 146, 16–24. [Google Scholar] [CrossRef]

- García-Moreira, D.P.; Hernández-Guzmán, H.; Pacheco, N.; Cuevas-Bernardino, J.; Herrera-Pool, I.E.; Moreno, I.; López-Vidaña, E.C. Solar and Convective Drying: Modeling, Color, Texture, Total Phenolic Content, and Antioxidant Activity of Peach (Prunus persica (L.) Batsch) Slices. Processes 2023, 11, 1280. [Google Scholar] [CrossRef]

- Medina-Torres, N.; Cuevas-Benardino, J.C.; Ayora-Talavera, T.; Patrón-Vázquez, J.A.; Rodríguez-Buenfil I y Pacheco, N. Cambios en las propiedades fisicoquímicas, reológicas, biológicas y sensoriales de pastas de chile habanero afectadas por el estado de madurez, conservador natural y procesamiento térmico. Rev. Mex. Ing. Química 2021, 20, 197–214. [Google Scholar] [CrossRef]

- Tagnamas, Z.; Idlimam, A.; Lamharrar, A. Hygroscopic analysis of pre-dried madder roots (Rubia tinctorum L.) using a solar dryer: Implications for safe storage conditions. J. Clean. Prod. 2024, 434, 139848. [Google Scholar] [CrossRef]

- Handayani, S.; Mujiarto, I.; Siswanto, A.; Ariwibowo, D.; Atmanto, I.; Mustikaningrum, M. Drying Kinetics of Chilli under Sun and Microwave Drying. Mater. Today Proc. 2022, 63, S153–S158. [Google Scholar] [CrossRef]

- Fudholi, A.; Othman, M.Y.; Ruslan, M.H.; Sopian, K. Drying of Malaysian Capsicum Annuum L. (Red Chili) Dried by Open and Solar Drying. Int. J. Photoenergy 2013, 2013, 167895. [Google Scholar] [CrossRef]

- Horuz, E.; Bozkurt, H.; Karatas, H.; Maskan, M. Microwave-Conventional Drying Characteristics of Red Pepper: Modeling, Temperature Profile, Diffusivity and Activation Energy. J. Agric. Sci. Technol. 2020, 22, 425–437. [Google Scholar]

- Pinar, H.; Çetin, N.; Ciftci, B.; Karaman, K.; Kaplan, M. Biochemical Composition, Drying Kinetics and Chromatic Parameters of Red Pepper as Affected by Cultivars and Drying Methods. J. Food Compos. Anal. 2021, 102, 103976. [Google Scholar] [CrossRef]

- Ornelas-Paz, J.d.J.; Martínez-Burrola, J.M.; Ruiz-Cruz, S.; Santana-Rodríguez, V.; Ibarra-Junquera, V.; Olivas, G.I.; Pérez-Martínez, J.D. Effect of cooking on the capsaicinoids and phenolics contents of Mexican peppers. Food Chem. 2010, 119, 1619–1625. [Google Scholar] [CrossRef]

- Liu, Y.; Duan, Z.; Sabadash, S. Effect of hot air drying temperatures on drying characteristics and physicochemical properties of beetroot (Beta vulgaris) slices. IOP Conf. Ser. Earth Environ. Sci. 2020, 615, 012099. [Google Scholar] [CrossRef]

- Turkmen, F.; Karasu, S.; Karadag, A. Effects of Different Drying Methods and Temperature on the Drying Behavior and Quality Attributes of Cherry Laurel Fruit. Processes 2020, 8, 761. [Google Scholar] [CrossRef]

- Pacheco, N.; Herrera-Pool, E.; Castañeda-Valbuena, D.; Ramos-Diaz, A.; Ayora-Talavera, T. Phytochemical Compounds from Xcatik (Capsicum annuum L.) Chili Tissues Extracted by Uae: Biological Activity and Phenolic Profile. J. Mex. Chem. Soc. 2023, 67, 200–212. [Google Scholar] [CrossRef]

- Shah, P.; Modi, H.A. Comparative Study of DPPH, ABTS and FRAP Assays for Determination of Antioxidant Activity. Int. J. Res. Appl. Sci. Eng. Technol. 2015, 3, 636–641. [Google Scholar]

- Paciulli, M.; Medina-Meza, I.G.; Chiavaro, E.; Barbosa-Cánovas, G.V. Impact of thermal and high pressure processing on quality parameters of beetroot (Beta vulgaris L.). LWT—Food Sci. Technol. 2016, 68, 98–104. [Google Scholar] [CrossRef]

- Li, C.; Wu, Y.; Zhu, Q.; Xie, C.; Yan, Y. Alterations in physico-chemical properties, microstructure, sensory characteristics, and volatile compounds of red pepper (Capsicum annuum var. conoides) during various thermal drying durations. Food Chem. X 2024, 23, 101566. [Google Scholar] [CrossRef]

- Si, W.; Wa, S.; Chen, Z.; Yin, H. Stability of Capsaicinoid Content at Raised Temperatures. Nat. Prod. Commun. 2014, 9, 985–988. [Google Scholar] [CrossRef]

- Bae, H.; Jayaprakasha, G.K.; Crosby, K.; Yoo, K.S.; Leskovar, D.I.; Jifon, J.; Patil, B.S. Ascorbic acid, capsaicinoid, and flavonoid aglycone concentrations as a function of fruit matury stage in greenhouse-grown peppers. J. Food Compos. Anal. 2014, 33, 195–202. [Google Scholar] [CrossRef]

- Komonsing, N.; Reyer, S.; Khuwijitjaru, P.; Mahayothee, B.; Müller, J. Drying Behavior and Curcuminoids Changes in Turmeric Slices during Drying under Simulated Solar Radiation as Influenced by Different Transparent Cover Materials. Foods 2022, 11, 696. [Google Scholar] [CrossRef] [PubMed]

- Gokhale, S.V.; Lele, S.S. Optimization of convective dehydration of Beta vulgaris for color retention. Food Bioprocess Technol. 2012, 5, 868–878. [Google Scholar] [CrossRef]

- Tan, S.; Miao, Y.; Zhou, C.; Luo, Y.; Lin, Z.; Xie, R.; Li, W. Effects of Hot Air Drying on Drying Kinetics and Anthocyanin Degradation of Blood-Flesh Peach. Foods 2022, 11, 1596. [Google Scholar] [CrossRef] [PubMed]

- Garcia-Moreira, D.P.; Moreno, I.; Irigoyen-Campuzano, J.R.; Martin-Dominguez, I.; Garcia-Valladares, O.; Lopez-Vidana, E.C. Effect of convective drying in color, water activity, and browning index of peach slices. Rev. Mex. Ing. Química 2024, 23, Alim24188. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).