A Novel Intake Inflow Performance Relationship for Optimizing Pump Setting Depth in Low-Permeability Oil Wells

Abstract

1. Introduction

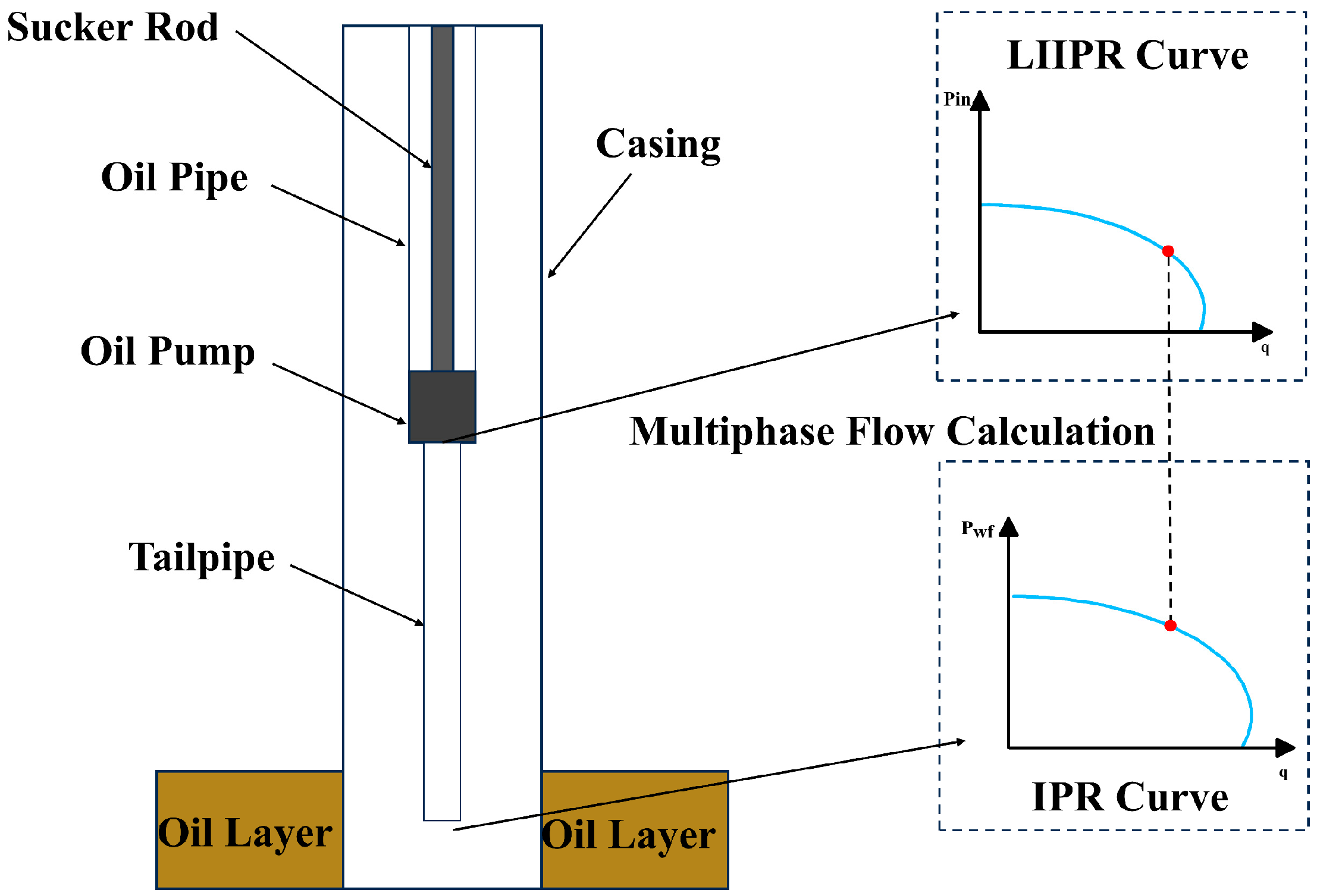

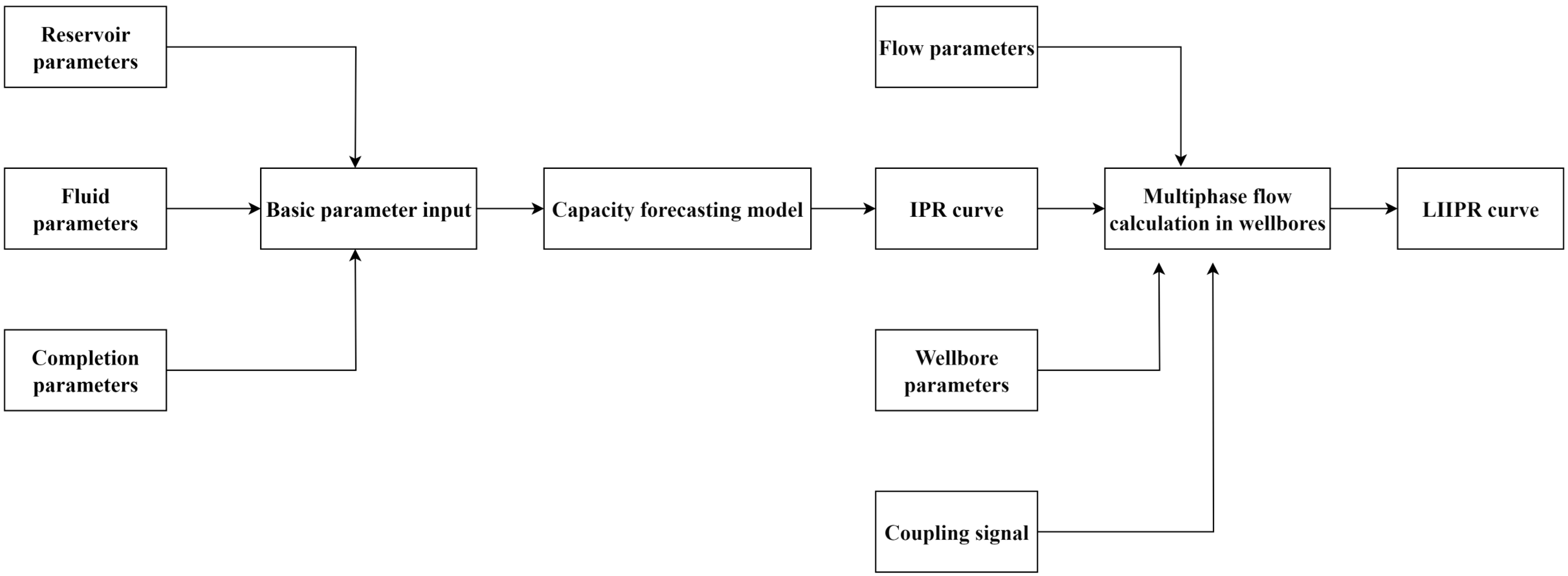

2. Methodology

- , : fracture and matrix permeability, mD;

- : fracture width, m;

- : reservoir thickness, m;

- : formation volume factor, dimensionless;

- : oil viscosity, mPa·s;

- : reservoir diffusivity, m2/s;

- : fracture half-length, m;

- c: total compressibility, MPa−1;

- : permeability modulus, MPa−1;

- , : reservoir pressure and bottomhole flowing pressure, MPa.

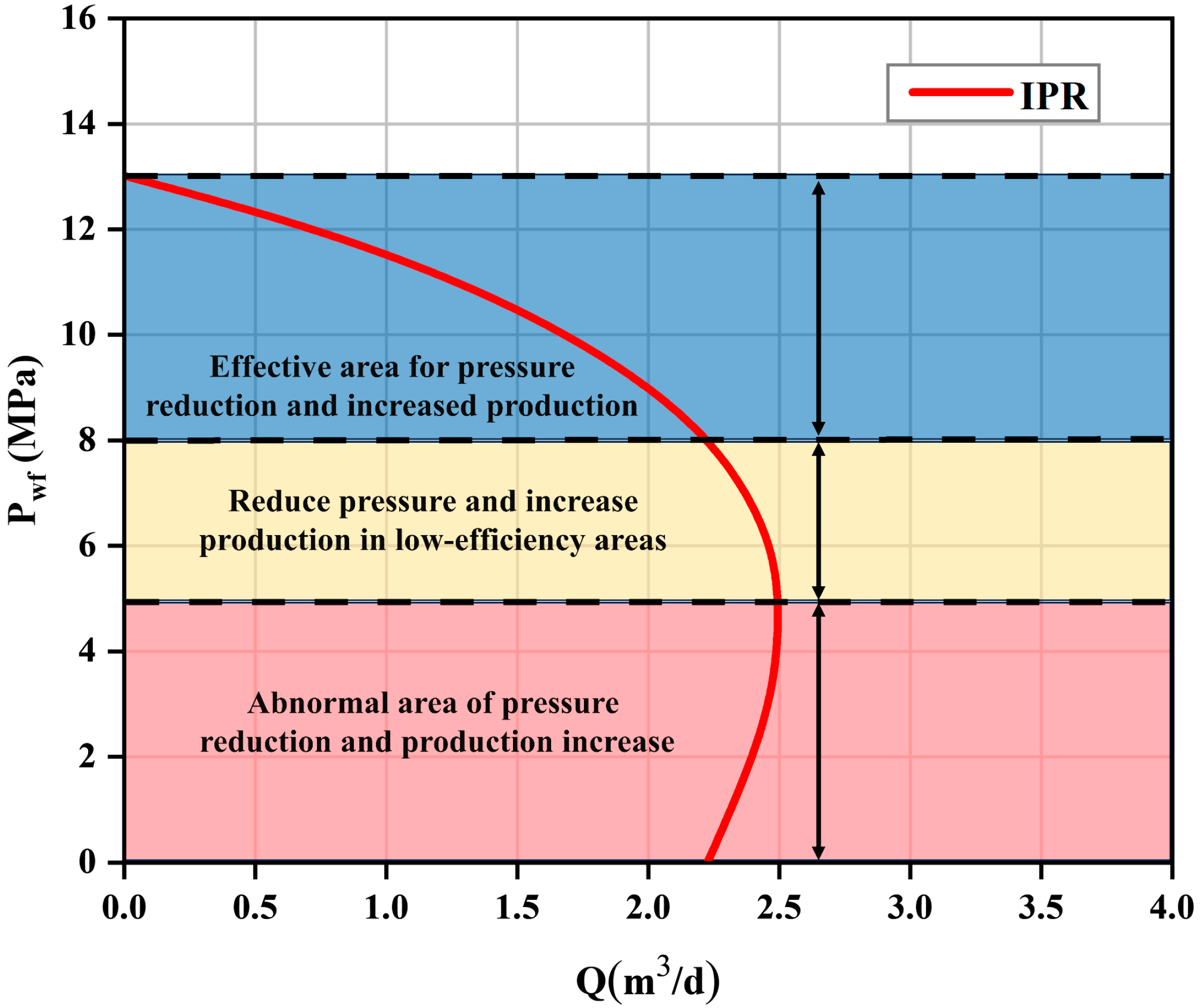

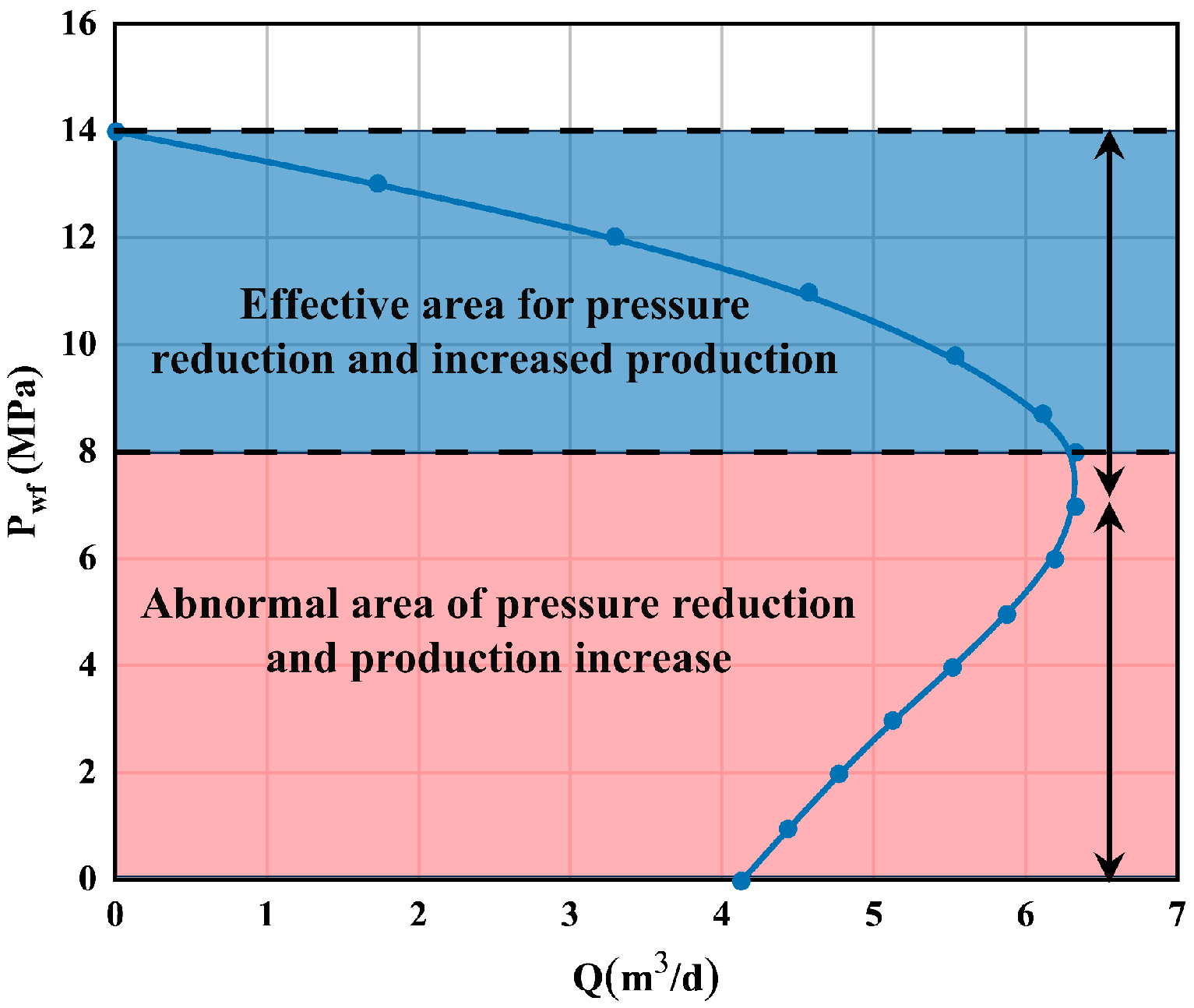

- Effective zone: a regime where pressure drawdown and productivity remain strongly correlated, indicating efficient fluid supply and optimal production conditions.

- Inefficient zone: a regime where further increases in drawdown result in diminishing productivity gains, reflecting declining system efficiency.

- Abnormal zone: a regime where LIIPR curves may bend backward or display inflection points, with productivity decreasing despite higher drawdown, often caused by stress sensitivity, liquid loading, or gas lock phenomena.

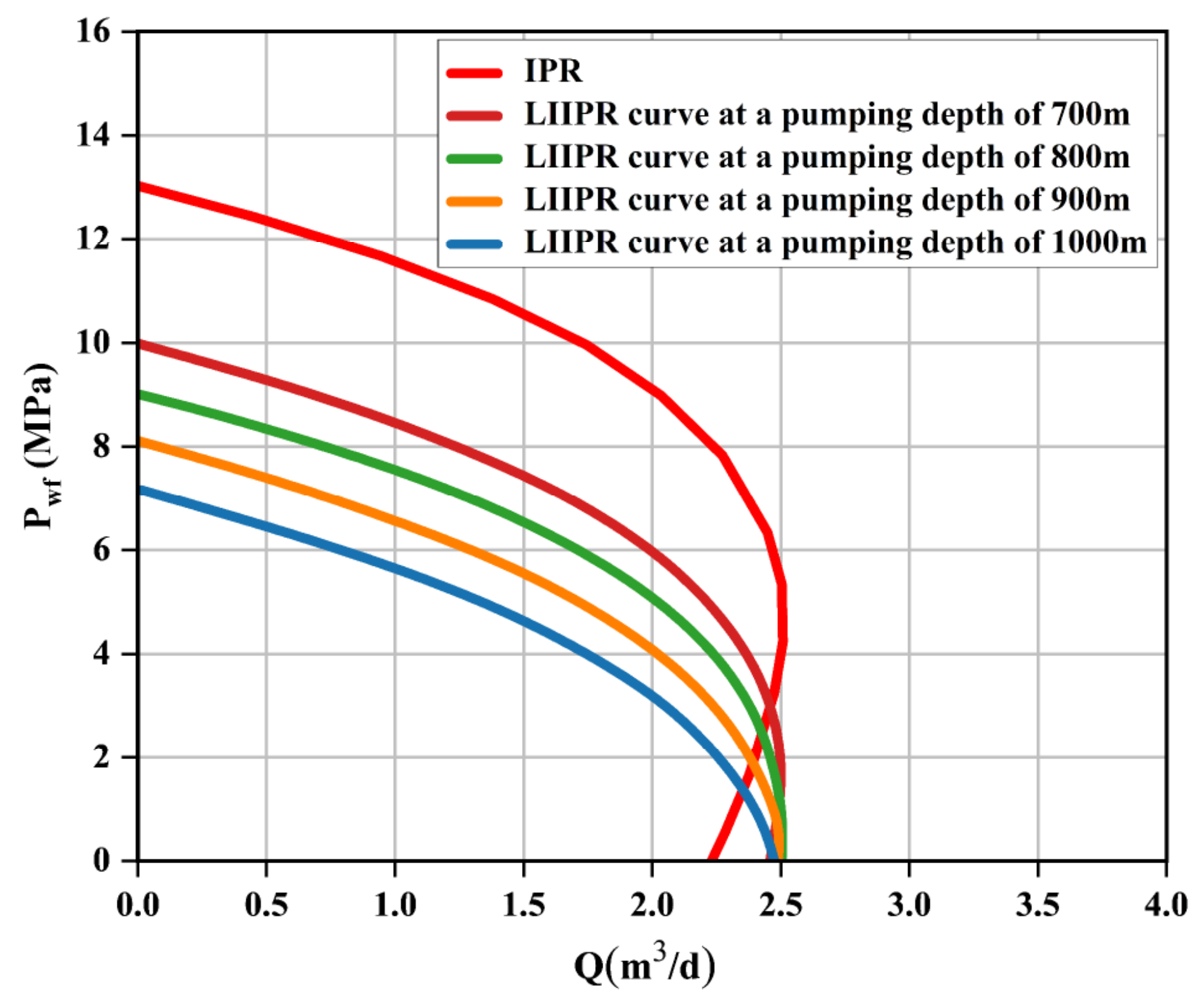

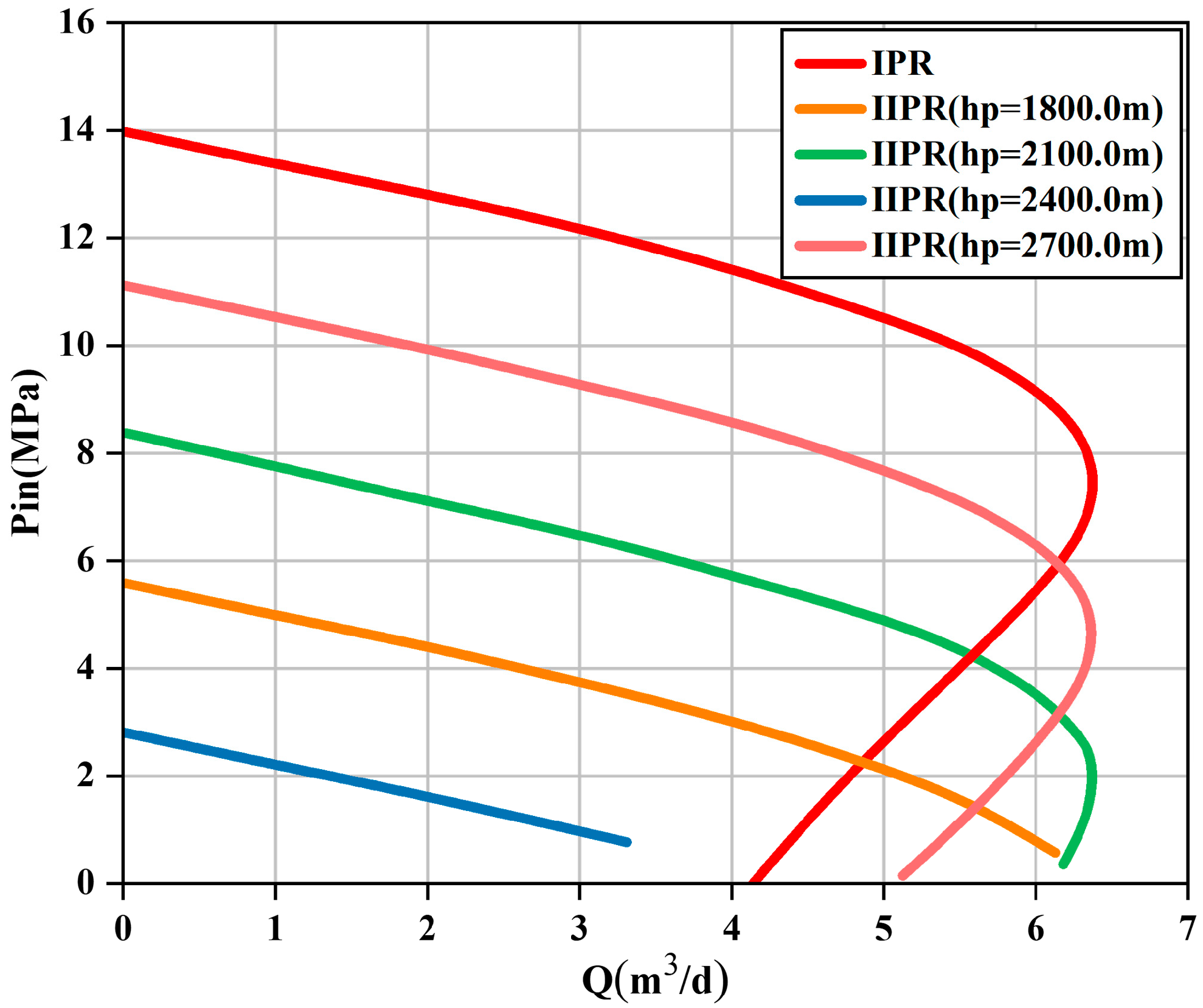

- Pump-depth curves, describing how LIIPR curves shift with varying pump depths and reflecting productivity trends;

- Intake–pressure curves, showing the variation in pump intake pressure with production rate, representing the coupling between flow losses and inflow performance;

- Coordination curves, formed by the intersections of LIIPR curves with wellbore outflow curves, identifying the stable operating points of the system.

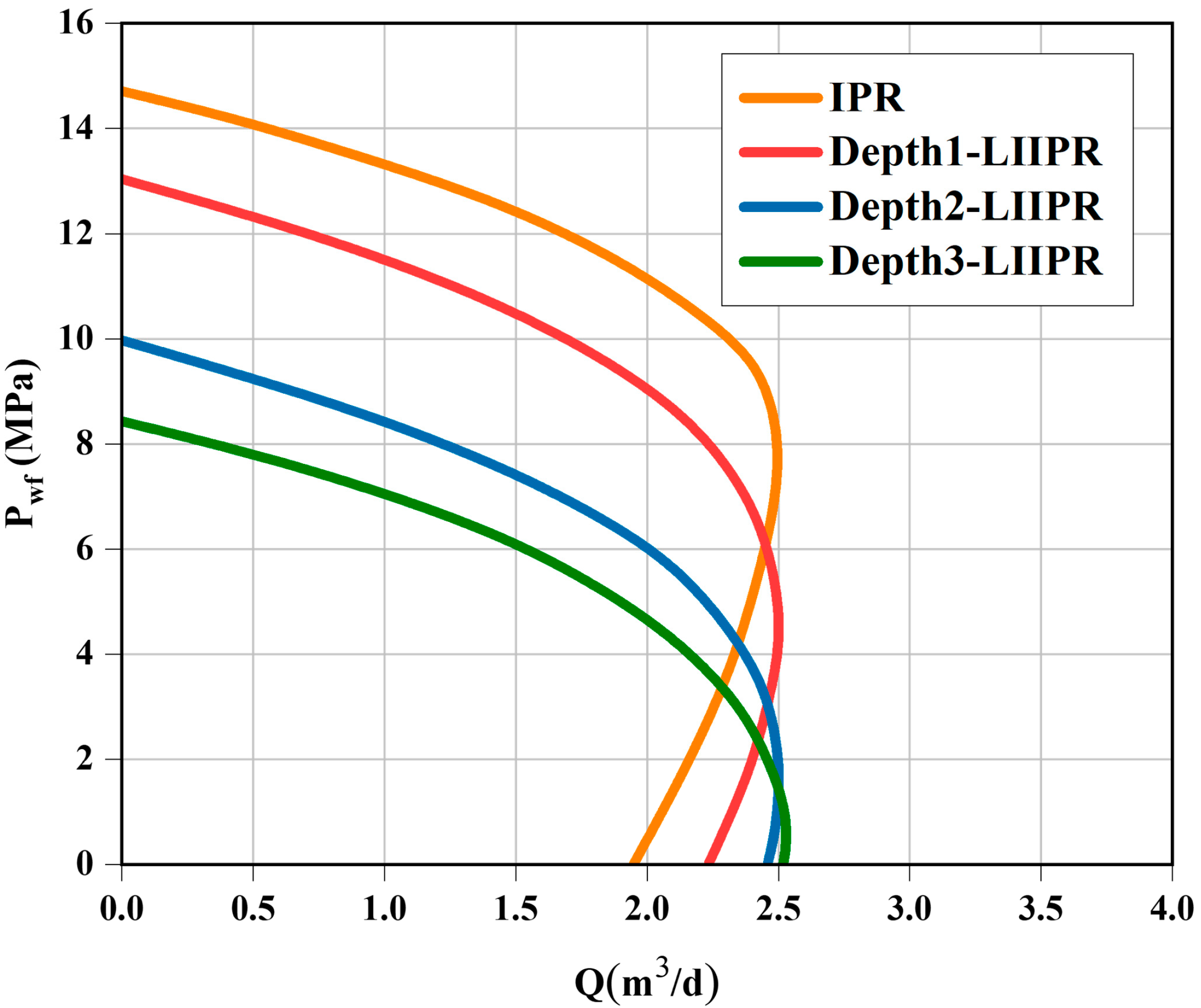

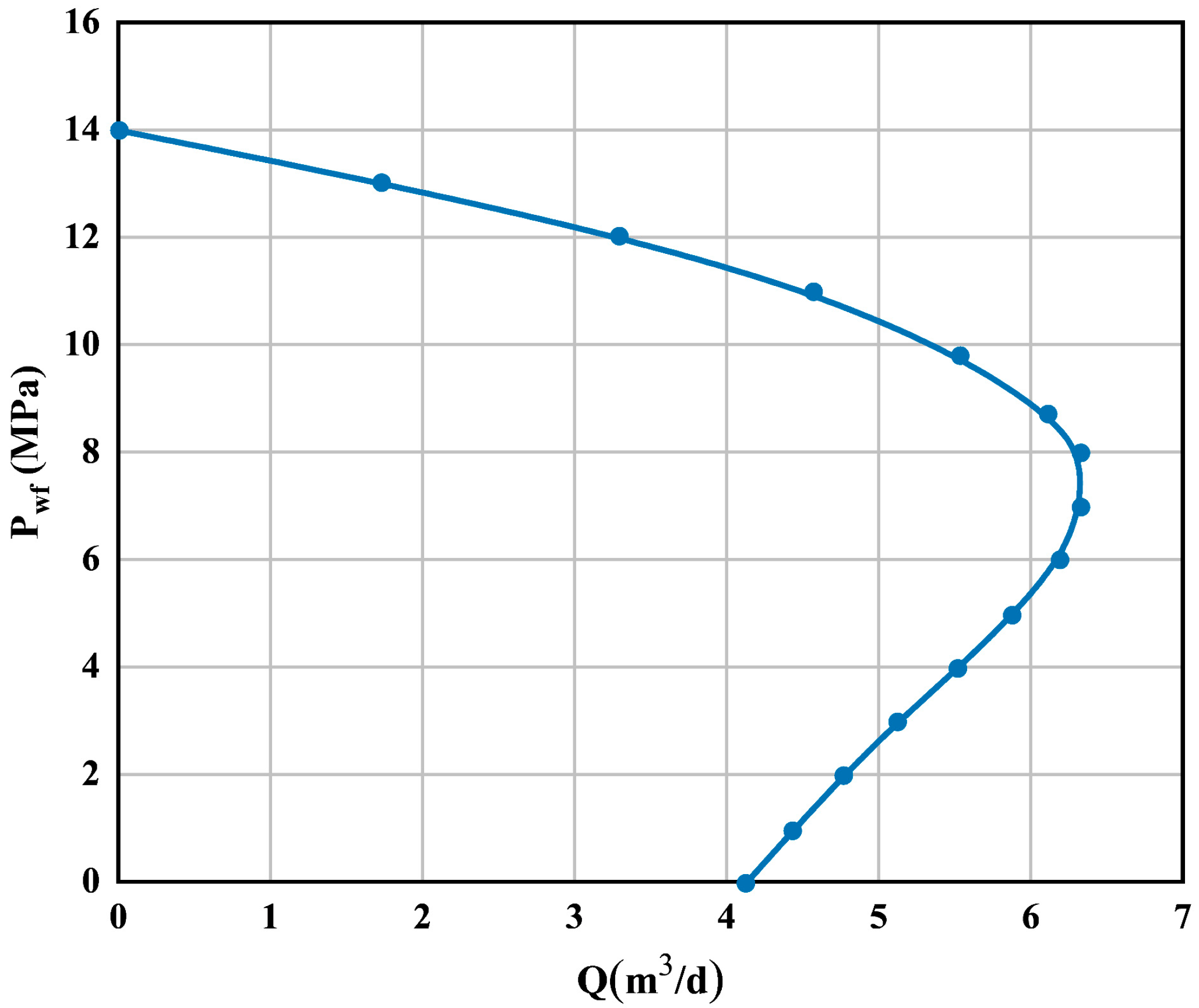

3. Results and Discussion

- : reservoir permeability, mD;

- : reservoir thickness, m;

- : formation volume factor, dimensionless;

- : oil viscosity, mPa·s;

- : drainage radius, m;

- : wellbore radius, m;

- : initial reservoir pressure, MPa;

- : bottomhole flowing pressure, MPa;

- , : stress sensitivity constants, dimensionless.

- When the pump setting depth is less than 2100 m, the LIIPR curve exhibits no inflection point (maximum value). In this case, no clear maximum production rate can be achieved regardless of how the operating regime is adjusted (e.g., stroke length or strokes per minute). Therefore, a pump setting depth greater than 2100 m is recommended.

- When the pump setting depth exceeds 2400 m, further increasing the depth results in almost no improvement in the maximum value (inflection point) of the LIIPR curve. Since the production gain becomes saturated while rod string costs and failure risks increase, it is not advisable to set the pump deeper than 2400 m.

4. Conclusions

- The three-zone classification of the IPR curve enables the identification of effective and abnormal operating regimes, providing clear criteria to avoid undesirable productivity decline.

- Multi-pump-depth analysis reveals the systematic influence of pump setting depth on well performance, indicating that pump depth has a feasible range, while excessively shallow or deep settings reduce efficiency.

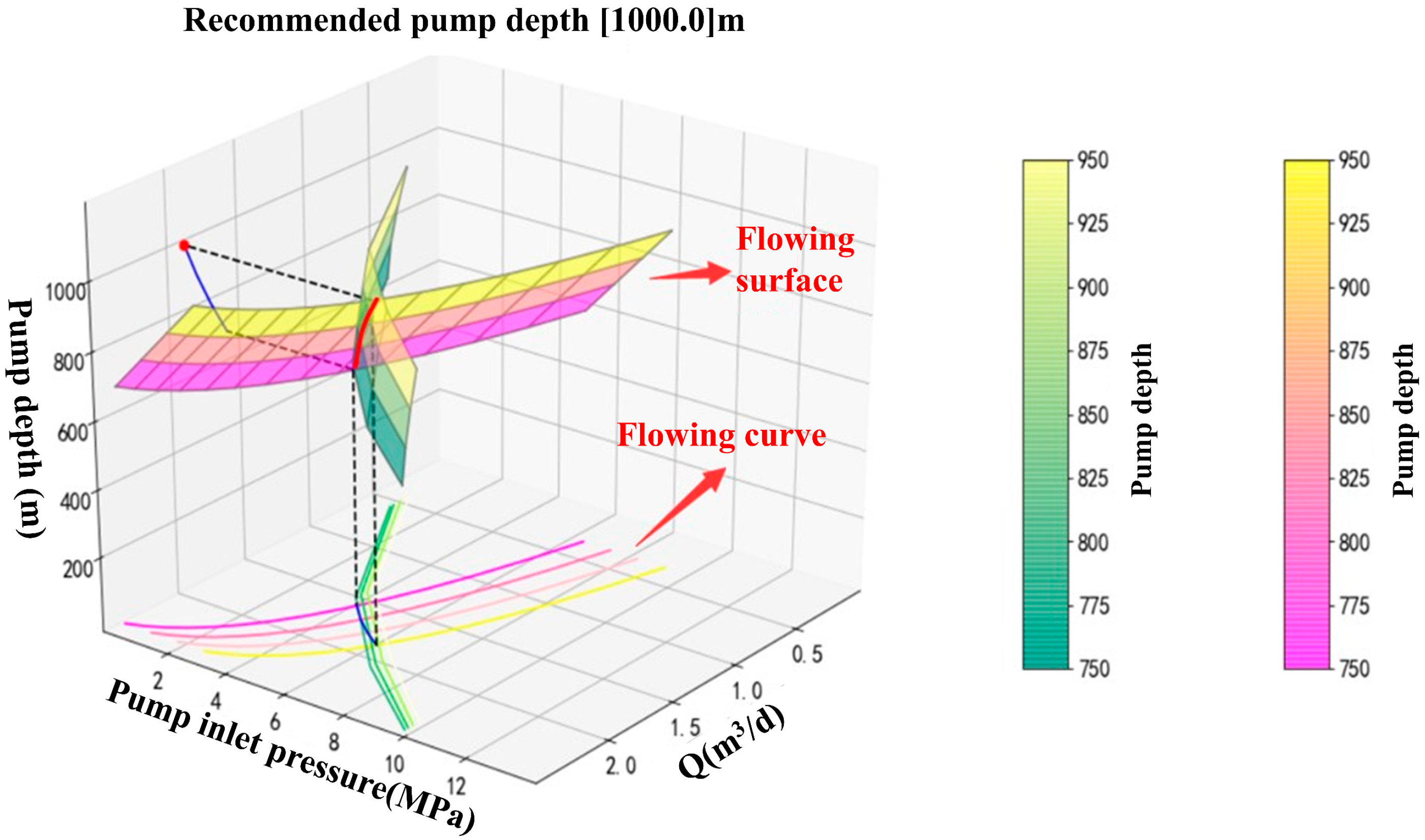

- The three-dimensional deep-pumping limit map unifies inflow and outflow processes within a single framework, offering an intuitive and systematic criterion for production optimization under complex field conditions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| IPR | Inflow Performance Relationship |

| EIPR | Enriched Inflow Performance Relationship |

| LIIPR | Low-Permeability Intake Inflow Performance Relationship |

| SPM | Strokes Per Minute |

| mD | millidarcy |

| MPa | Megapascal |

| mPa·s | millipascal-second |

| q | Production rate, m3/d |

| pi | Initial reservoir pressure, MPa |

| pw | Bottomhole flowing pressure, MPa |

| pintake | Pump intake pressure, MPa |

| k | Reservoir permeability, mD |

| kF | Fracture permeability, mD |

| kM | Matrix permeability, mD |

| w | Fracture width, m |

| h | Reservoir thickness, m |

| B | Formation volume factor, dimensionless |

| μ | Oil viscosity, mPa·s |

| η | Reservoir diffusivity, m2/s |

| Xf | Fracture half-length, m |

| c | Total compressibility, MPa−1 |

| γ | Permeability modulus, MPa−1 |

| re | Drainage radius, m |

| rw | Wellbore radius, m |

| a, b | Stress sensitivity constants, dimensionless |

| Arod | Rod cross-sectional area, m2 |

| Atubing | Tubing cross-sectional area, m2 |

| Lstroke | Stroke length, m |

| Pwellhead | Wellhead pressure, MPa |

| Dpump | Pump setting depth, m |

| Dsub | Submergence depth, m |

References

- Lightfoot-Boston, A. A Modelling Study of Horizontal Wells with Multiple Hydraulic Fractures in Low Permeability Formations. Master’s Thesis, West Virginia University, Morgantown, WV, USA, 2010. [Google Scholar]

- Nevmerzhitskiy, Y. Development of Production Decline Curves for Non-Darcy Oil Flow in Low-Permeability Reservoirs. J. Pet. Sci. Eng. 2022, 218, 111039. [Google Scholar] [CrossRef]

- Zekri, A.Y.; Harahap, B.A.; Al-Attar, H.H.; Lwisa, E.G. Effectiveness of Oil Displacement by Sequential Low-Salinity Waterflooding in Low-Permeability Fractured and Non-Fractured Chalky Limestone Cores. J. Pet. Explor. Prod. Technol. 2019, 9, 271–280. [Google Scholar] [CrossRef]

- Sukarno, P. Inflow Performance Relationship Curves in Two-Phase and Three-Phase Flow Conditions; University of Tulsa: Tulsa, OK, USA, 1985. Available online: https://www.osti.gov/biblio/7247549 (accessed on 16 September 2025).

- Mishra, A.; Ma, L.C.; Reddy, S.; Attanayake, J.; Haese, R.R. Pore-to-Darcy Scale Permeability Upscaling for Media with Dynamic Pore Structure Using Graph Theory. Appl. Comput. Geosci. 2024, 23, 100179. [Google Scholar] [CrossRef]

- Shanley, K.W.; Cluff, R.M.; Robinson, J.W. Factors Controlling Prolific Gas Production from Low-Permeability Sandstone Reservoirs: Implications for Resource Assessment, Prospect Development, and Risk Analysis. AAPG Bull. 2004, 88, 1083–1121. [Google Scholar] [CrossRef]

- Spacing of Hydraulically Fractured Horizontal Laterals in Low Permeability Formations-All Databases. Available online: https://webofscience.clarivate.cn/wos/alldb/full-record/PQDT:47005315 (accessed on 16 September 2025).

- Medeiros, F.; Ozkan, E.; Kazemi, H. Productivity and Drainage Area of Fractured Horizontal Wells in Tight Gas Reservoirs. SPE Reserv. Eval. Eng. 2008, 11, 902–911. [Google Scholar] [CrossRef]

- Aksoy, N. Optimization of Downhole Pump Setting Depths in Liquid-Dominated Geothermal Systems: A Case Study on the Balcova-Narlidere Field, Turkey. Geothermics 2007, 36, 436–458. [Google Scholar] [CrossRef]

- Oliva, G.B.; Galvão, H.L.; Silva, R.; Costa, R.O.; Carratore, P.R.; Maitelli, A.L.; Maitelli, C.W. Development and Application of a Control Strategy for Sucker Rod Pump Artificial Oil Lift System. IEEE Latin Am. Trans. 2018, 16, 2177–2183. [Google Scholar]

- Takahashi, S.; Kovscek, A.R. Spontaneous Countercurrent Imbibition and Forced Displacement Characteristics of Low-Permeability, Siliceous Shale Rocks. J. Pet. Sci. Eng. 2010, 71, 47–55. [Google Scholar] [CrossRef]

- Al-Rbeawi, S. Pseudo-Steady State Inflow Performance Relationship of Reservoirs Undergoing Multiphase Flow and Different Wellbore Conditions. J. Nat. Gas Sci. Eng. 2019, 68, 102912. [Google Scholar] [CrossRef]

- Aragon-Aguilar, A.; Barragan-Reyes, R.M.; Arellano-Gomez, V.M. Methodologies for Analysis of Productivity Decline: A Review and Application. Geothermics 2013, 48, 69–79. [Google Scholar] [CrossRef]

- Gallice, F.; Wiggins, M.L. A Comparison of Two-Phase Inflow Performance Relationships. SPE Prod. Fac. 2004, 19, 100–104. [Google Scholar] [CrossRef]

- Caicedo, S. Enriched Inflow Performance Relationship (EIPR) Curves for Simultaneous Selection of Target Rate & Pump Setting Depth While Visualizing Free Gas Conditions. In Abu Dhabi International Petroleum Exhibition and Conference; Society of Petroleum Engineers: Abu Dhabi, United Arab Emirates, 2015. [Google Scholar] [CrossRef]

- de Sousa, P.C.; Posenato, A.G.; Waltrich, P.J. A Transient Inflow Performance Relationship (Ipr) for the Early and Late Life of Gas Wells: The Dynamic Gas Ipr. In Proceedings of the ASME 36th International Conference on Ocean, Offshore and Arctic Engineering, 2017; The American Society of Mechanical Engineers: New York, NY, USA, 2017; Volume 8: Polar and Arctic Sciences and Technology; Petroleum Technology, UNSP V008T11A051. [Google Scholar]

- Pandey, V.J.; Agreda, A.J. New Fracture-Stimulation Designs and Completion Techniques Result in Better Performance of Shallow Chittim Ranch Wells. SPE Prod. Oper. 2014, 29, 288–308. [Google Scholar] [CrossRef]

- Nguyen, T.C.; Pande, S.; Bui, D.; Al-Safran, E.; Nguyen, H.V. Pressure Dependent Permeability: Unconventional Approach on Horizontal Well Performance. J. Pet. Sci. Eng. 2018, 193, 107358. [Google Scholar] [CrossRef]

- Cheng, C.; Bunger, A.P. Model-Based Evaluation of Methods for Maximizing Efficiency and Effectiveness of Hydraulic Fracture Stimulation of Horizontal Wells. Geophys. Res. Lett. 2019, 46, 12870–12880. [Google Scholar] [CrossRef]

- Ogunyomi, B.A.; Patzek, T.W.; Lake, L.W.; Kabir, C.S. History Matching and Rate Forecasting in Unconventional Oil Reservoirs with an Approximate Analytical Solution to the Double-Porosity Model. SPE Reserv. Eval. Eng. 2016, 19, 70–82. [Google Scholar] [CrossRef]

- Costantini, A.; Falcone, G.; Hewitt, G.F.; Alimonti, C. Using Transient Inflow Performance Relationships to Model the Dynamic Interaction Between Reservoir and Wellbore During Pressure Testing. J. Energy Resour. Technol.-Trans. ASME 2008, 130, 042901. [Google Scholar] [CrossRef]

- Al-Shawaf, A.; Kelkar, M.; Sharifi, M. A New Method to Predict the Performance of Gas-Condensate Reservoirs. SPE Reserv. Eval. Eng. 2014, 17, 177–189. [Google Scholar] [CrossRef]

- Tabatabaei, M.; Zhu, D. Generalized Inflow Performance Relationships for Horizontal Gas Wells. J. Nat. Gas Sci. Eng. 2010, 2, 132–142. [Google Scholar] [CrossRef]

- Kalantariasl, A.; Farhadi, I.; Farzani, S.; Keshavarz, A. A New Comprehensive Dimensionless Inflow Performance Relationship for Gas Wells. J. Petrol. Explor. Prod. Technol. 2022, 12, 2257–2269. [Google Scholar] [CrossRef]

- Yuan, B.; Moghanloo, R.G.; Shariff, E. Integrated Investigation of Dynamic Drainage Volume and Inflow Performance Relationship (Transient IPR) to Optimize Multistage Fractured Horizontal Wells in Tight/Shale Formations. J. Energy Resour. Technol.-Trans. ASME 2016, 138, 052901. [Google Scholar] [CrossRef]

- Ojo, I.; Fadairo, A. An Analytical Model for Predicting Composite Inflow Performance Relationship (IPR) for Fishbone Drilling Technology with N-Number of Ribholes. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 15 May 2025. [Google Scholar]

- Emami-Meybodi, H.; Ma, M.; Zhang, F.; Rui, Z.; Rezaeyan, A.; Ghanizadeh, A.; Hamdi, H.; Clarkson, C.R. Cyclic Gas Injection in Low-Permeability Oil Reservoirs: Progress in Modeling and Experiments. SPE J. 2024, 29, 6217–6250. [Google Scholar] [CrossRef]

- Ismadi, D.; Suthichoti, P.; Kabir, C.S. Understanding Well Performance with Surveillance Data. J. Pet. Sci. Eng. 2010, 74, 99–106. [Google Scholar] [CrossRef]

- Hamedi Shokrlu, Y.; Pathak, V.; Kumar, A.; Salazar, V. Integrated Production System Modelling and Optimization for Advanced EOR Application in Pre-Salt Offshore Carbonate Reservoir. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 15 May 2020. [Google Scholar] [CrossRef]

- Chaves, G.S.; Karami, H.; Ferreira Filho, V.J.M.; Vieira, B.F. A Comparative Study on the Performance of Multiphase Flow Models against Offshore Field Production Data. J. Pet. Sci. Eng. 2022, 208, 109762. [Google Scholar] [CrossRef]

- Boggs, K.G. Evaluation of Vertical Head Profiles in Water Production Wells during Pumping. Ground Water Monit. Remediat. 2008, 28, 75–80. [Google Scholar] [CrossRef]

| Parameter | Value | Unit |

|---|---|---|

| Initial reservoir pressure | 14 | MPa |

| Reservoir thickness | 3 | m |

| Drainage radius | 300 | m |

| Wellbore radius | 0.124 | m |

| Permeability | 150 | mD |

| Stress sensitivity constant (a) | 0.03 | – |

| Stress sensitivity constant (b) | 0.001 | – |

| Oil viscosity | 15 | mPa·s |

| Well depth | 3000 | m |

| Parameter | Value | Unit |

|---|---|---|

| Stroke length | 2.7 | m |

| Strokes per minute (SPM) | 6 | rpm |

| Rod cross-sectional area | 0.001 | m2 |

| Tubing cross-sectional area | 0.003019 | m2 |

| Wellhead pressure | 0.5 | MPa |

| Stroke Length (m) | Strokes per Minute (rpm) | Maximum Production (m3/d) | Recommended Submergence (m) | Recommended Pump Depth (m) |

|---|---|---|---|---|

| 2.7 | 6 | 7.2 | 129 | 2300 |

| 3 | 5 | 7.1 | 145 | 2300 |

| 3.5 | 3 | 6.9 | 238 | 2400 |

| 4.6 | 2.3 | 6.8 | 218 | 2400 |

| 4.6 | 1.8 | 6.8 | 300 | 2500 |

| 4.8 | 1.3 | 6.4 | 441 | 2500 |

| Well Example 1 | Well Example 2 | Well Example 3 | Well Example 4 | Well Example 5 | |

|---|---|---|---|---|---|

| First Adjustment | 2001.39 | 1769.42 | 1799.42 | 1809.7 | 2003.73 |

| Second Adjustment | 2206.5 | 2100.2 | 1914.52 | 2110.6 | 2301.2 |

| Third Adjustment | 2386.6 | -- | -- | 2106.1 | -- |

| Fourth Adjustment | -- | -- | -- | 2006.25 | -- |

| Recommended Setting Depth | 2300 | 1800–2100 | 2500 | 2500 | 2500 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, Q.; Li, J.; Wang, L.; Liu, B.; Shu, J.; Li, Y.; Han, G. A Novel Intake Inflow Performance Relationship for Optimizing Pump Setting Depth in Low-Permeability Oil Wells. Processes 2025, 13, 3316. https://doi.org/10.3390/pr13103316

Shi Q, Li J, Wang L, Liu B, Shu J, Li Y, Han G. A Novel Intake Inflow Performance Relationship for Optimizing Pump Setting Depth in Low-Permeability Oil Wells. Processes. 2025; 13(10):3316. https://doi.org/10.3390/pr13103316

Chicago/Turabian StyleShi, Qionglin, Junjian Li, Lei Wang, Bin Liu, Jin Shu, Yabo Li, and Guoqing Han. 2025. "A Novel Intake Inflow Performance Relationship for Optimizing Pump Setting Depth in Low-Permeability Oil Wells" Processes 13, no. 10: 3316. https://doi.org/10.3390/pr13103316

APA StyleShi, Q., Li, J., Wang, L., Liu, B., Shu, J., Li, Y., & Han, G. (2025). A Novel Intake Inflow Performance Relationship for Optimizing Pump Setting Depth in Low-Permeability Oil Wells. Processes, 13(10), 3316. https://doi.org/10.3390/pr13103316