Optimizing Film Cooling Hole Arrangement Along Conjugate Isotherms on Turbine Vanes: A Combined Numerical and Experimental Investigation

Abstract

1. Introduction

2. Numerical Calculation Methods and Experimental System

2.1. Cascade Model and Mesh Generation

2.2. Boundary Conditions and Computational Procedures

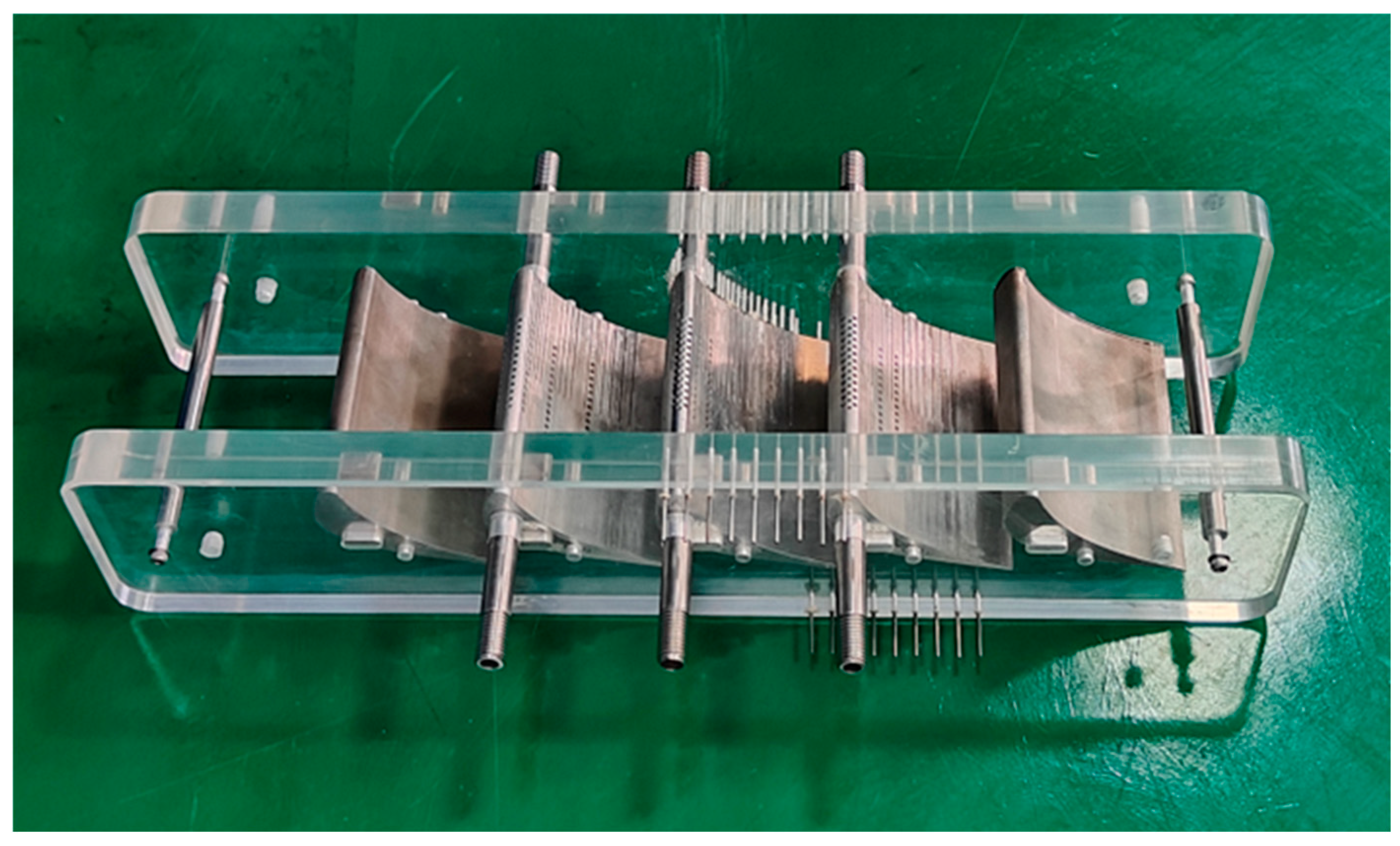

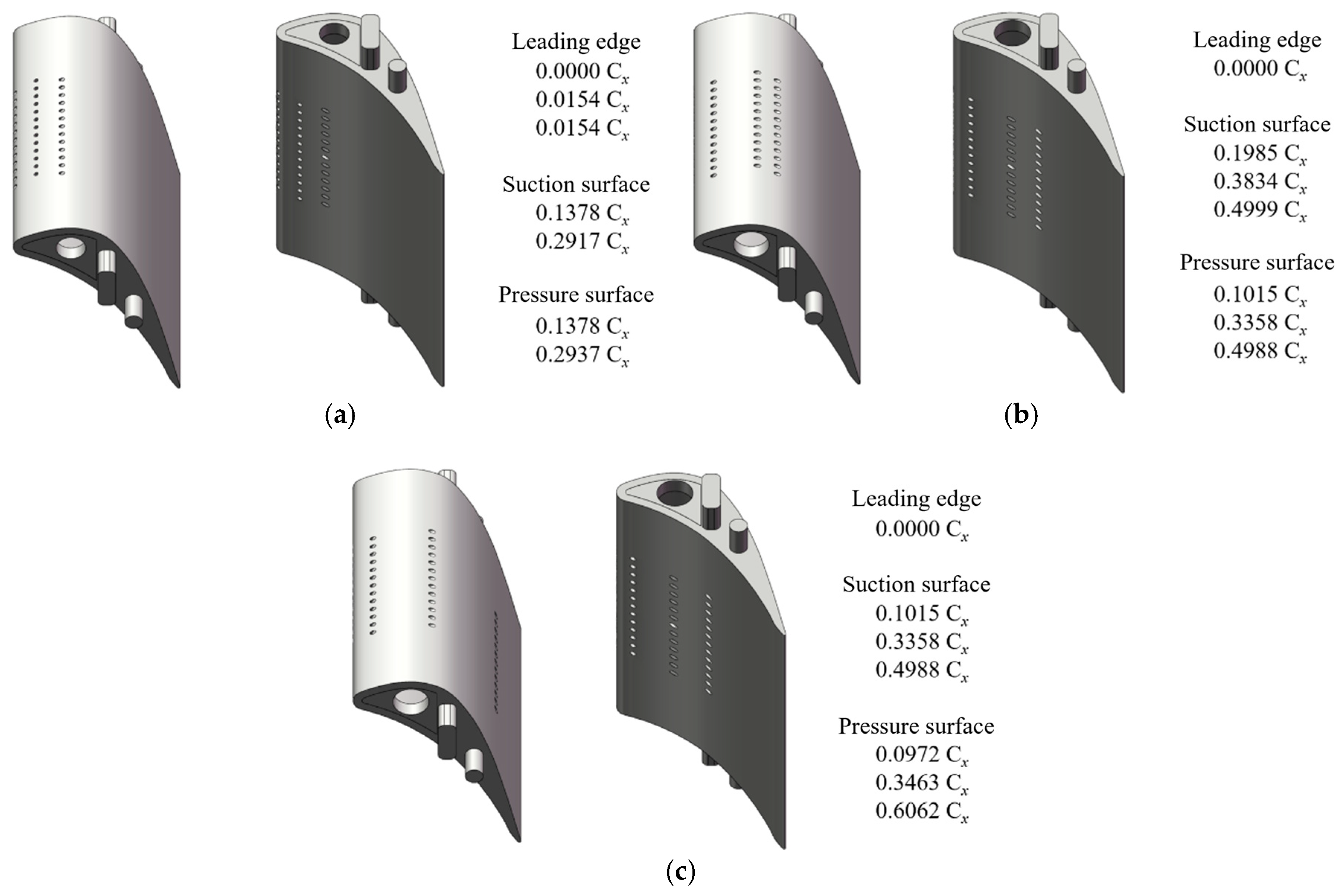

2.3. Experimental Blade Model and Pressure–Temperature Measurement System

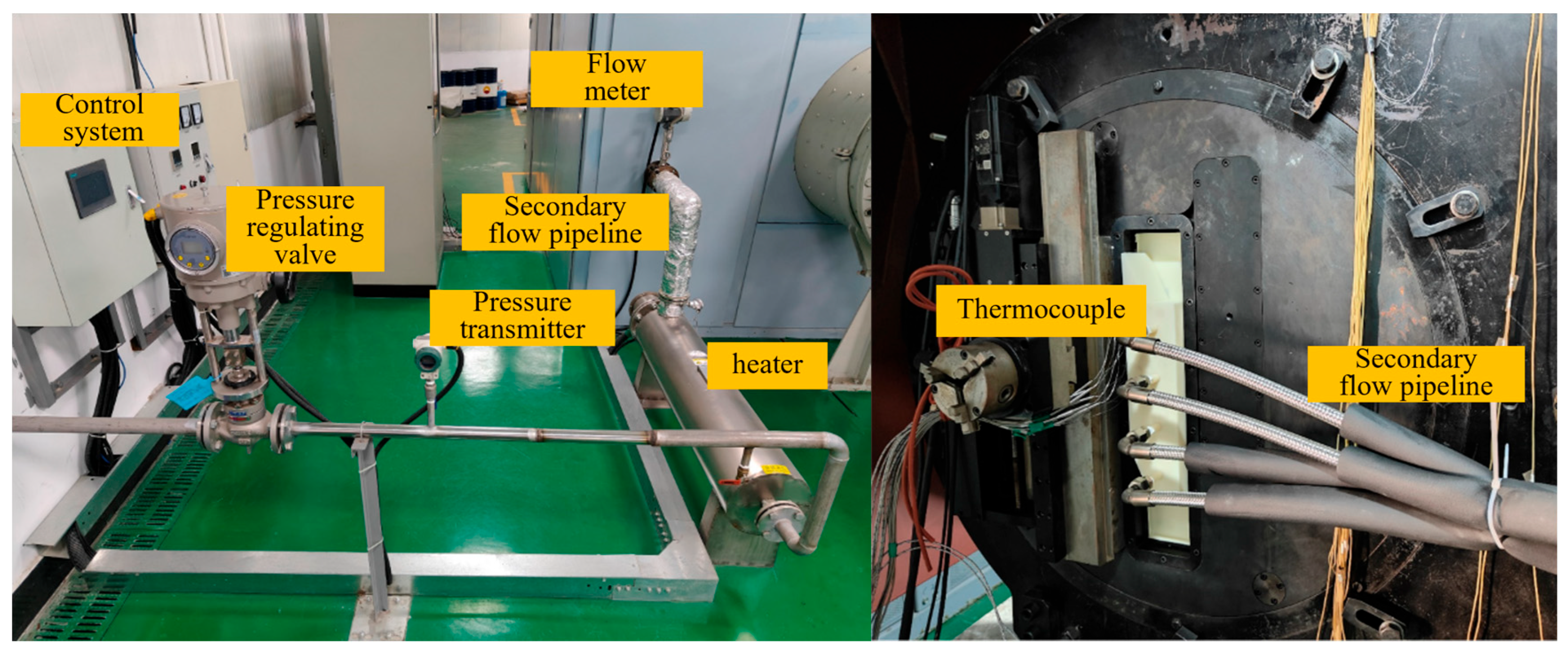

2.4. Wind Tunnel and Experimental Setup

3. Uncertainty Analysis and Turbulence Model Validation

3.1. Uncertainty Analysis of Integrated Cooling Effectiveness

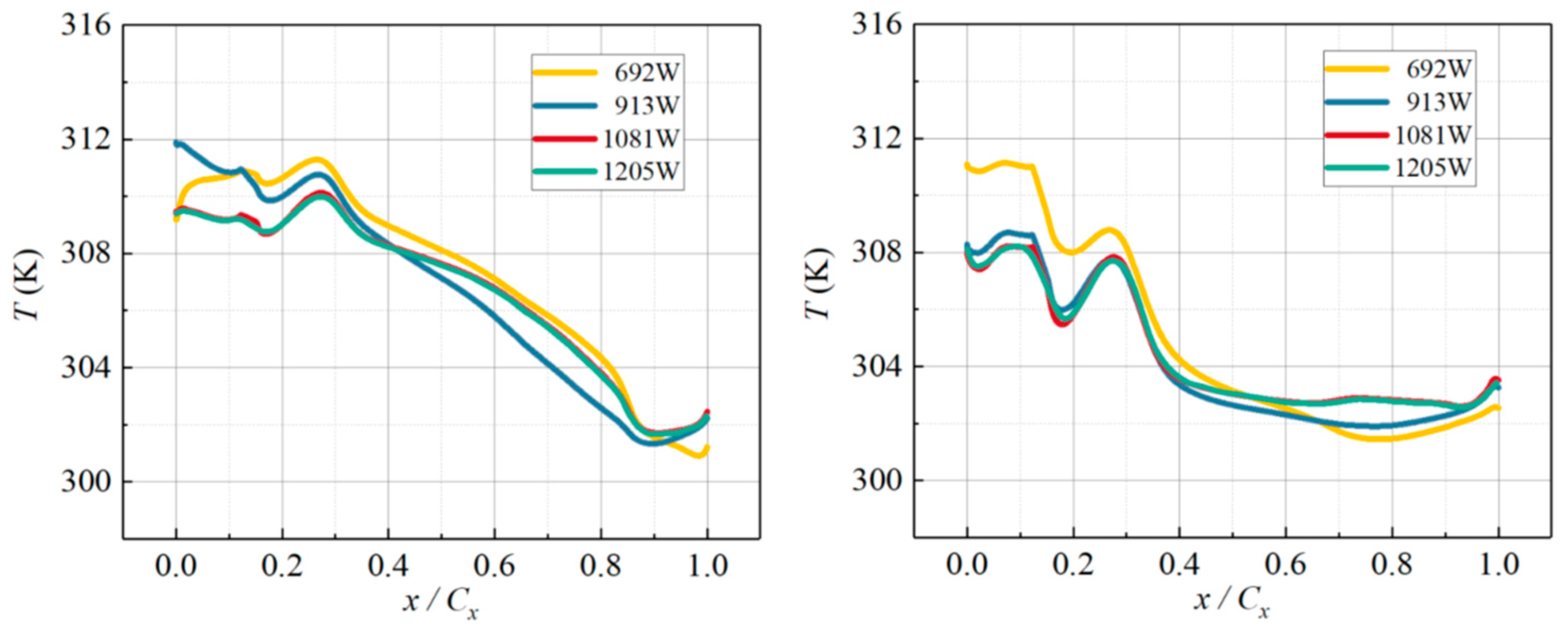

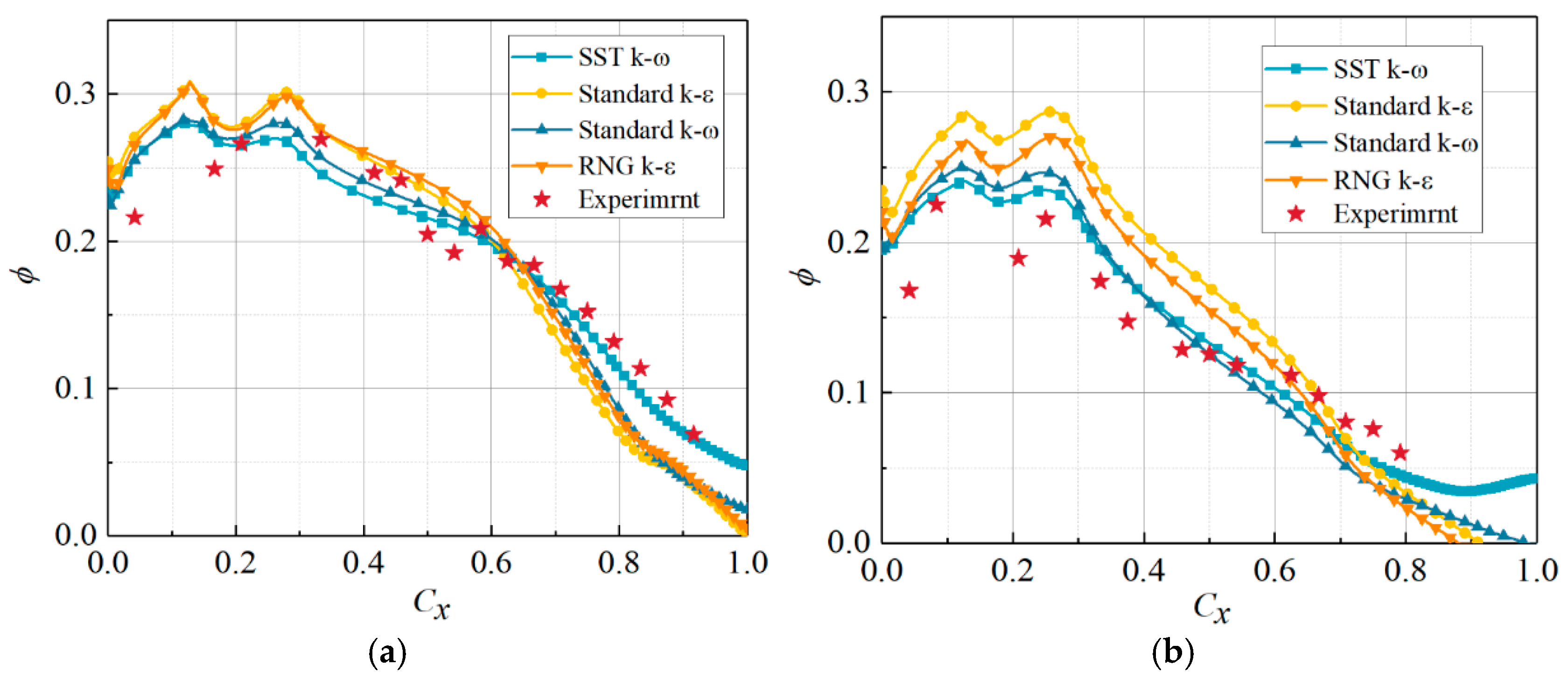

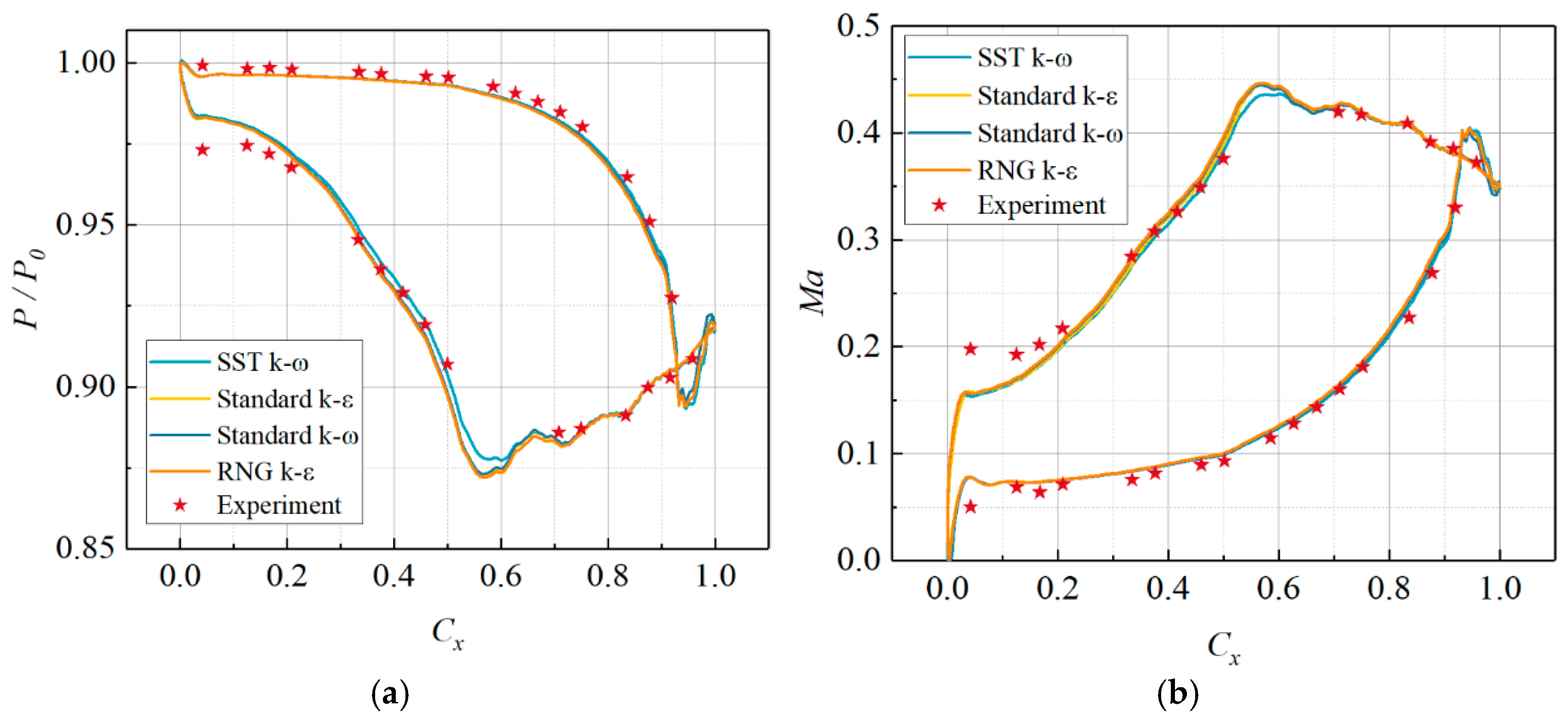

3.2. Turbulence Model Validation for Heat Transfer and Aerodynamic Performance

4. Results and Discussion

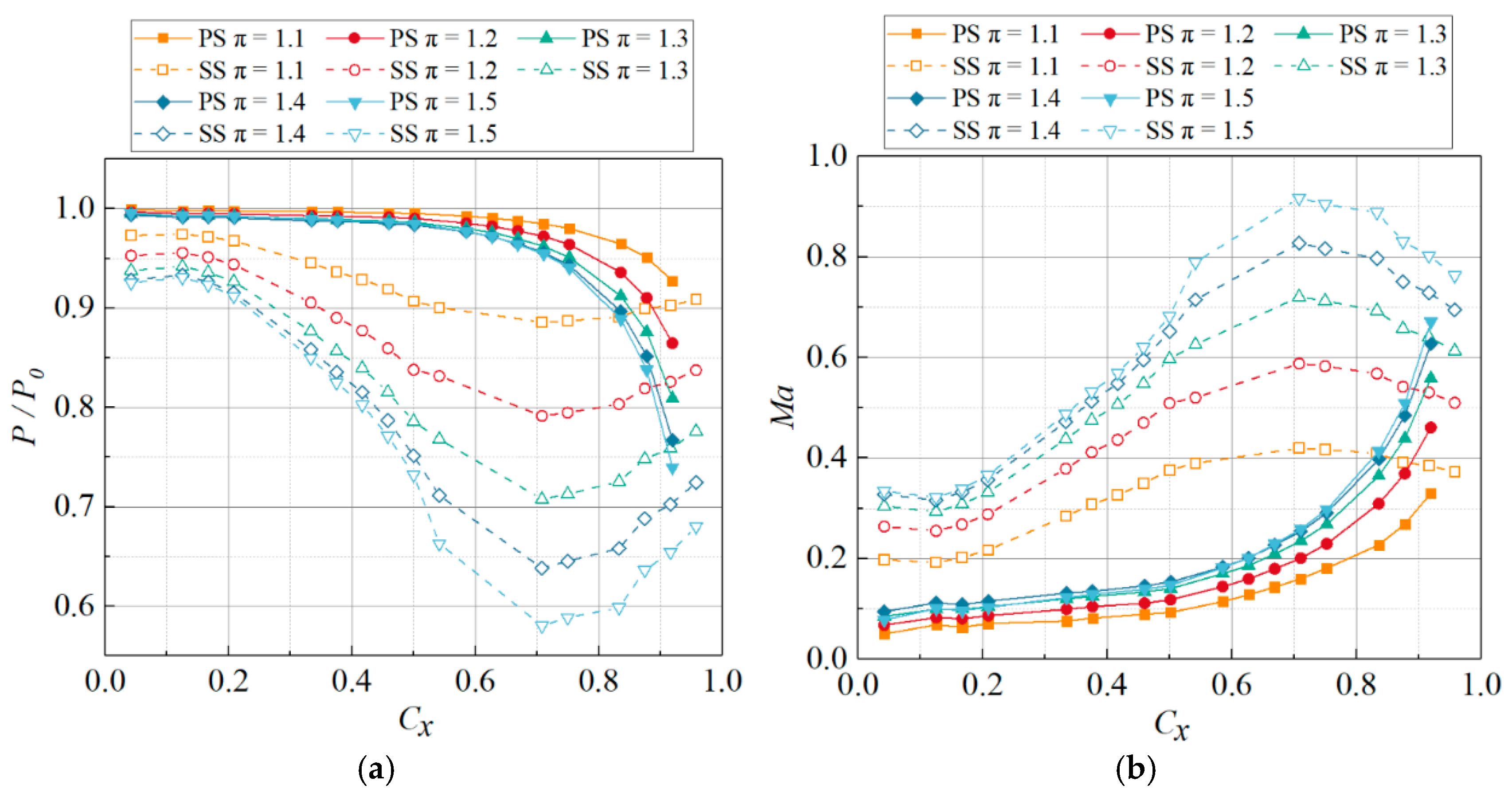

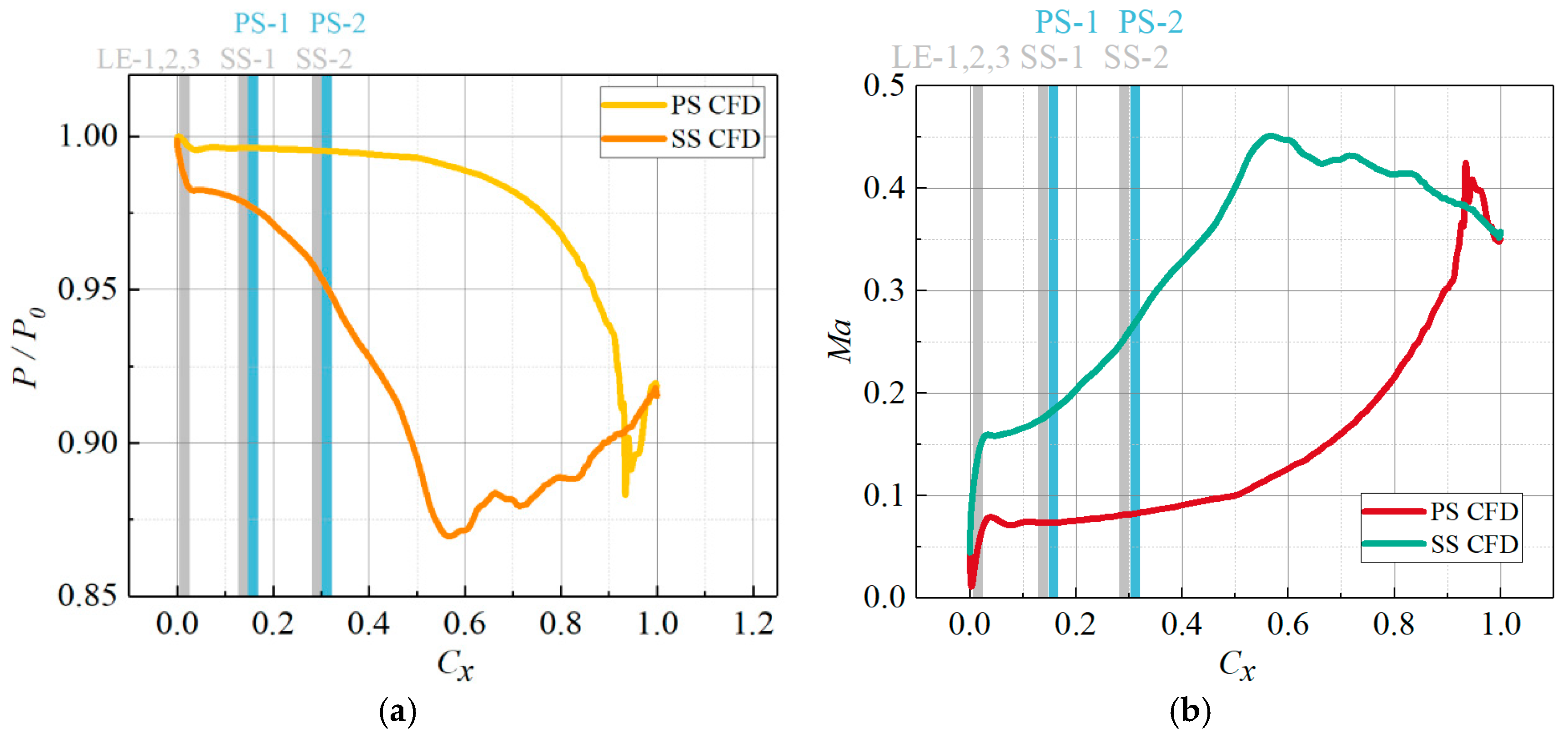

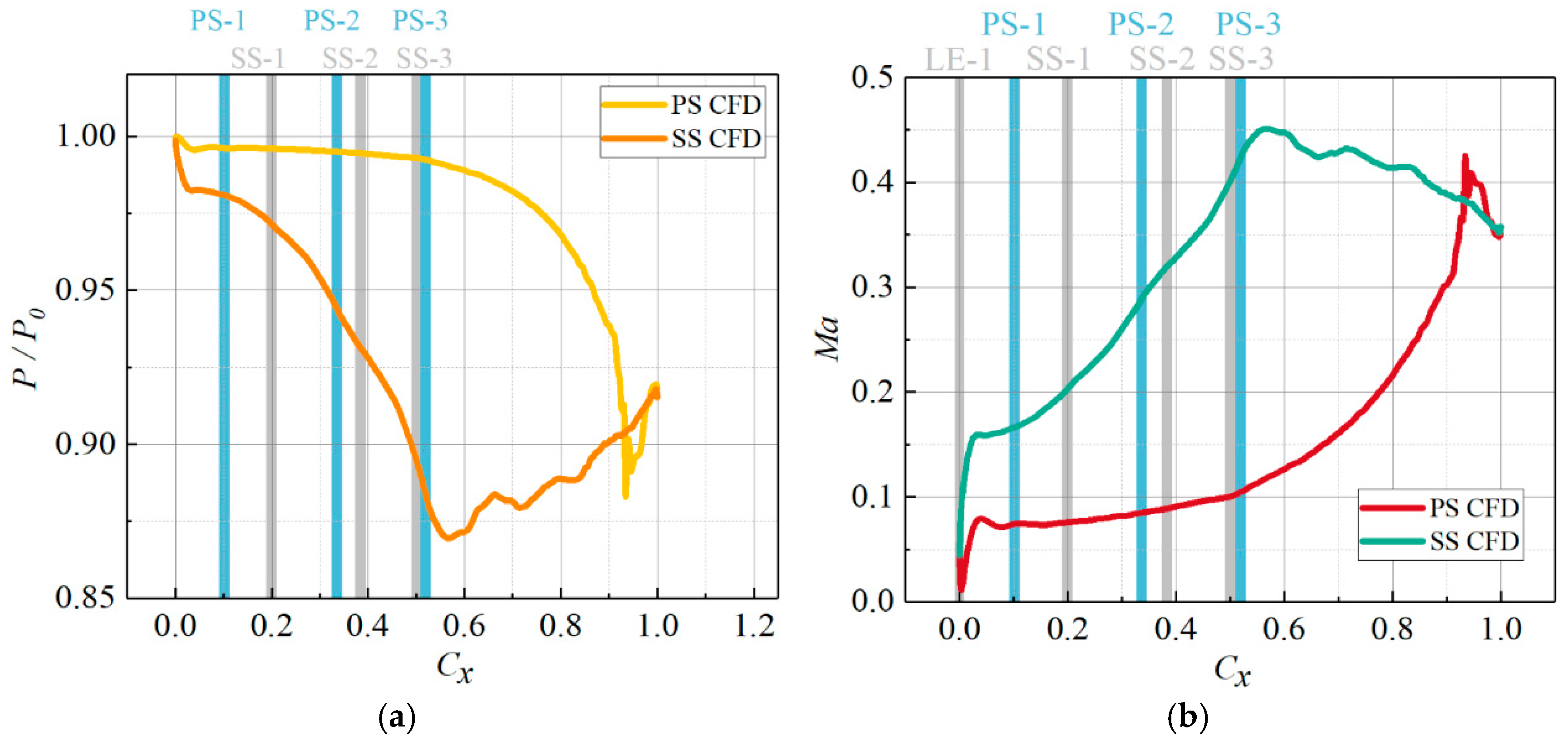

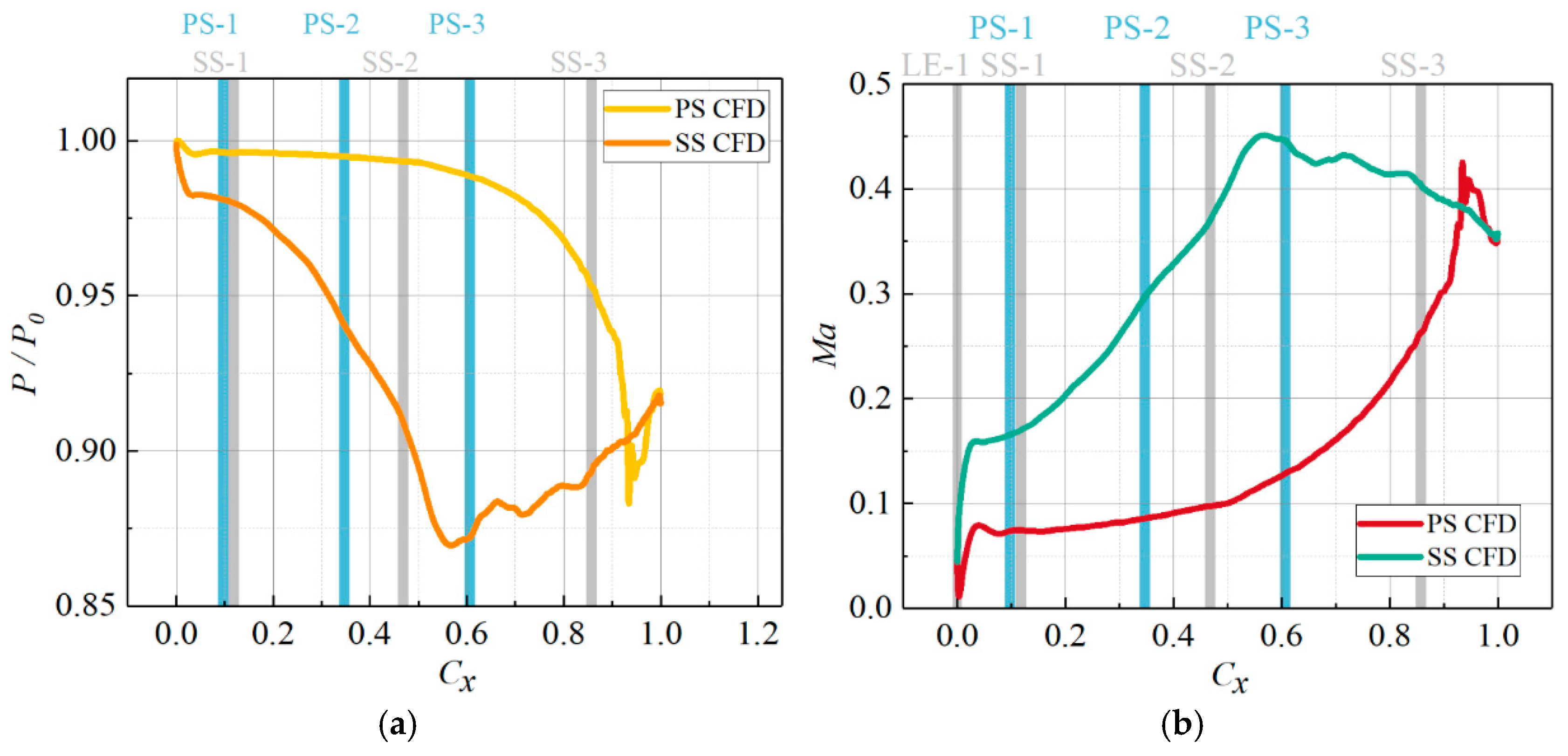

4.1. Analysis of Aerodynamic Performance of Turbine Vanes

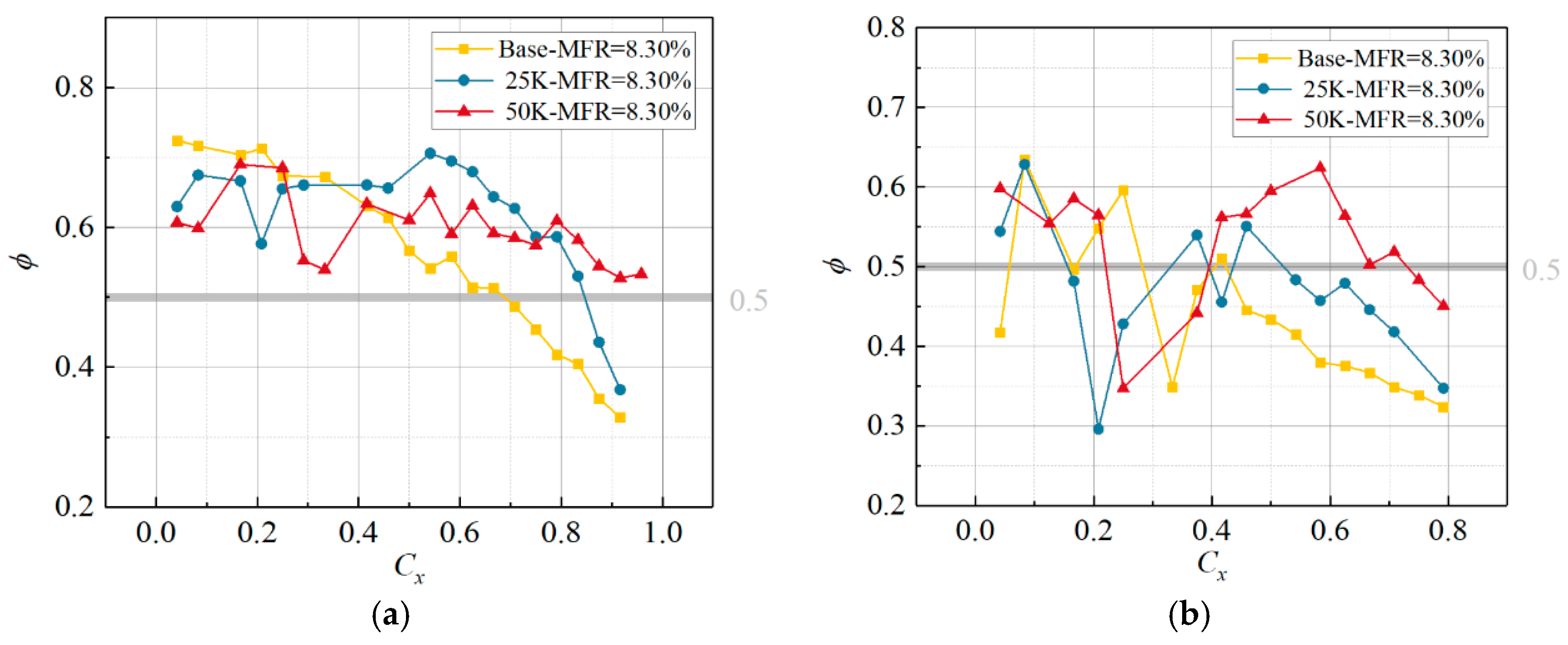

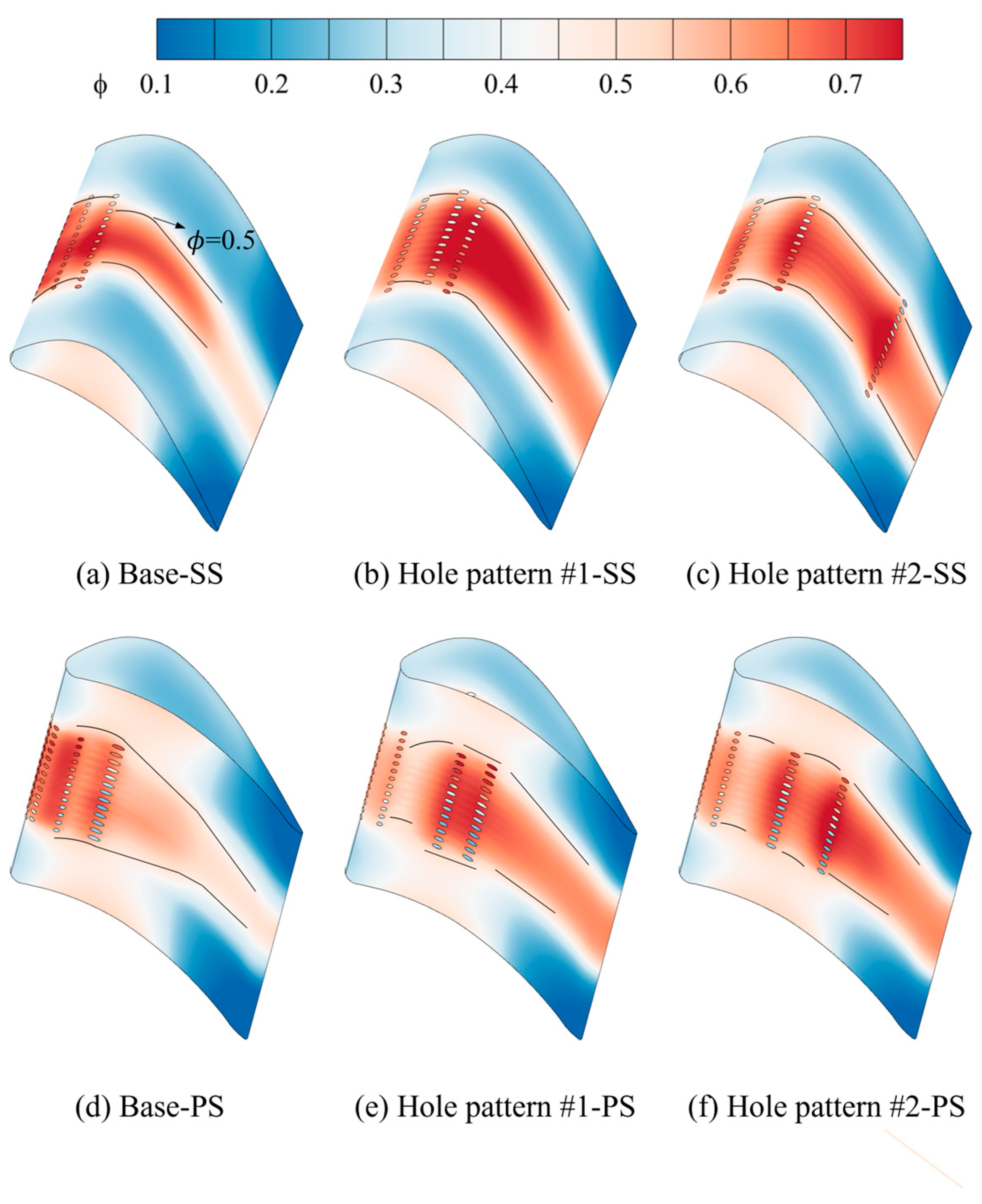

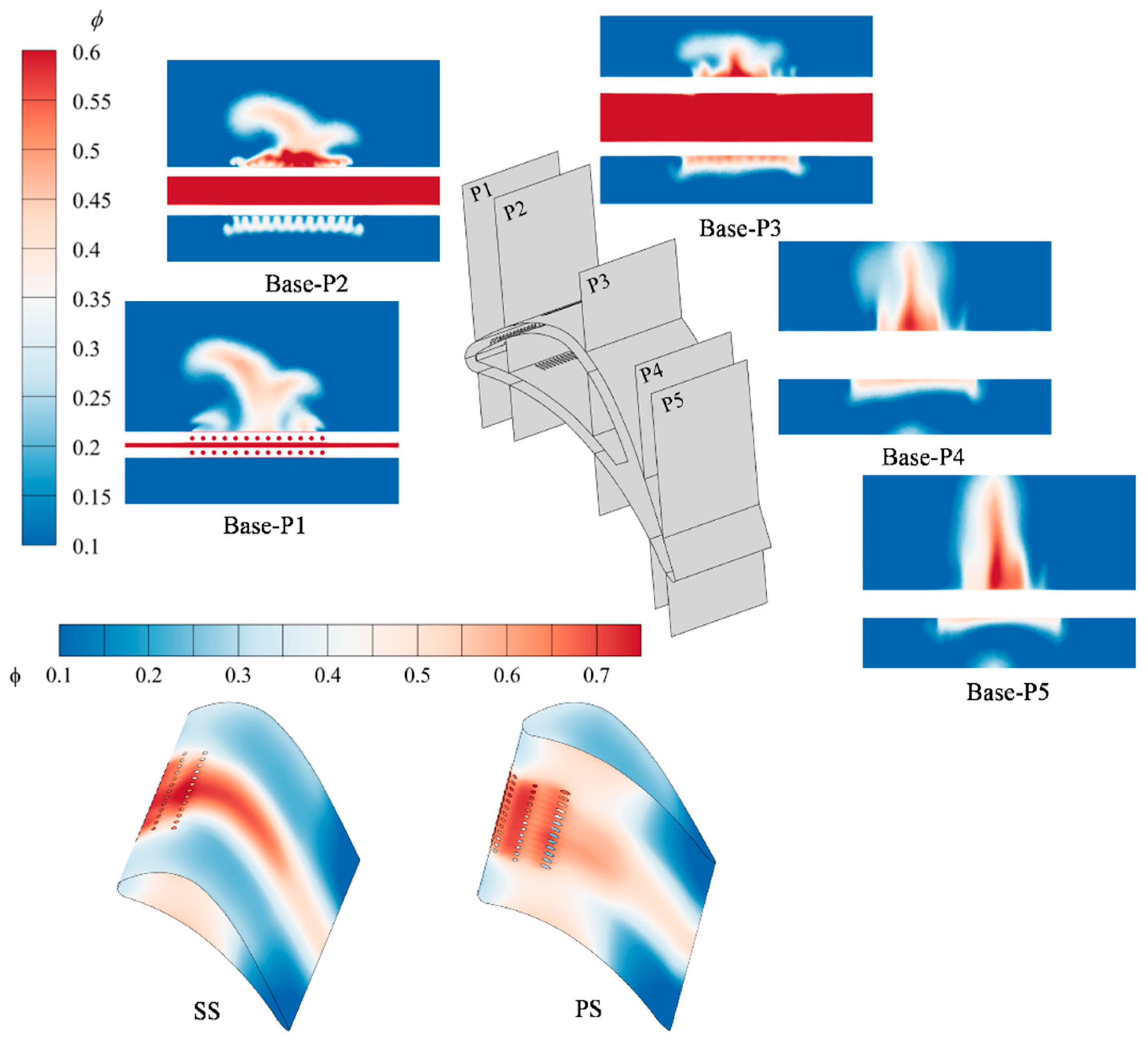

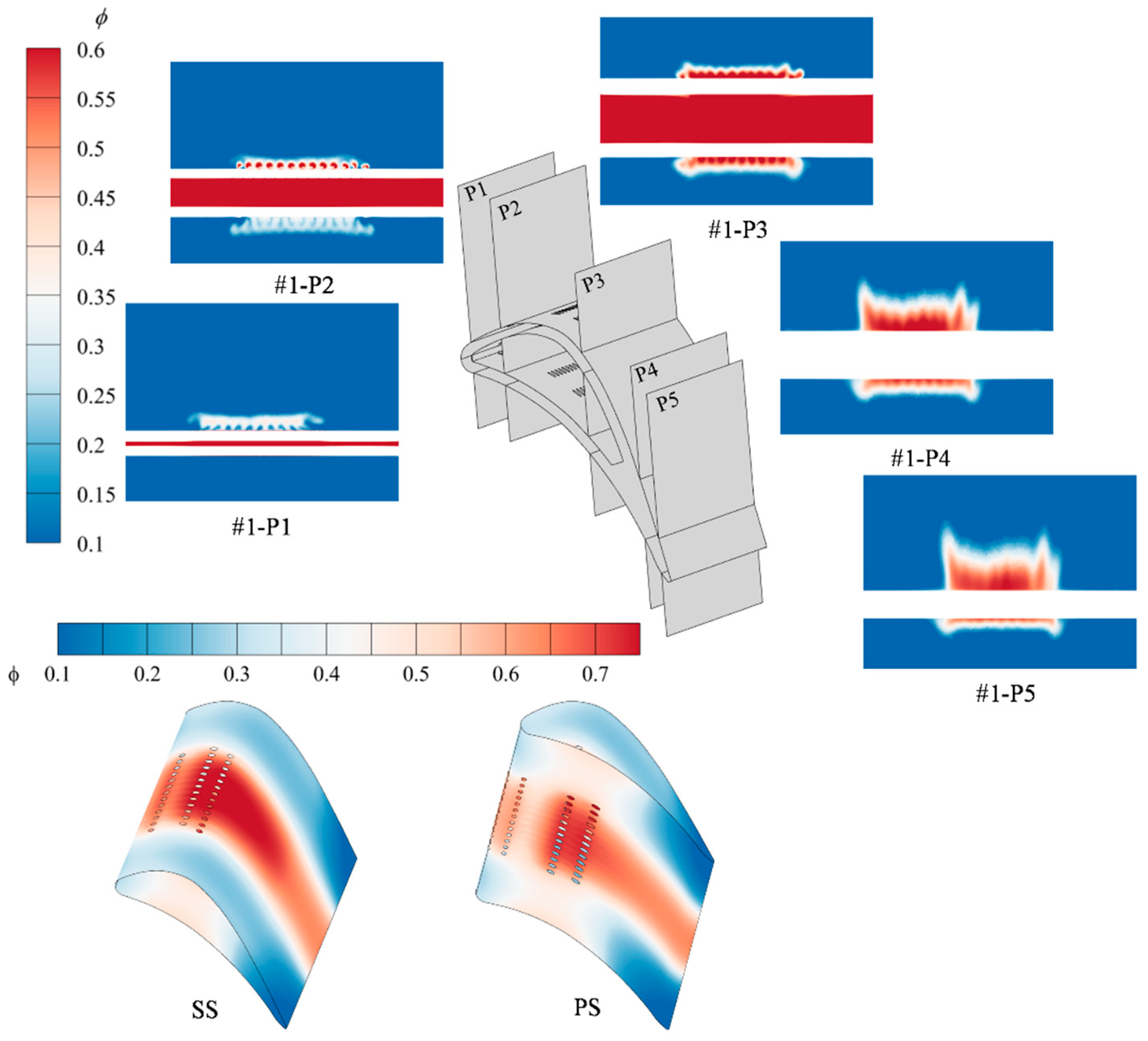

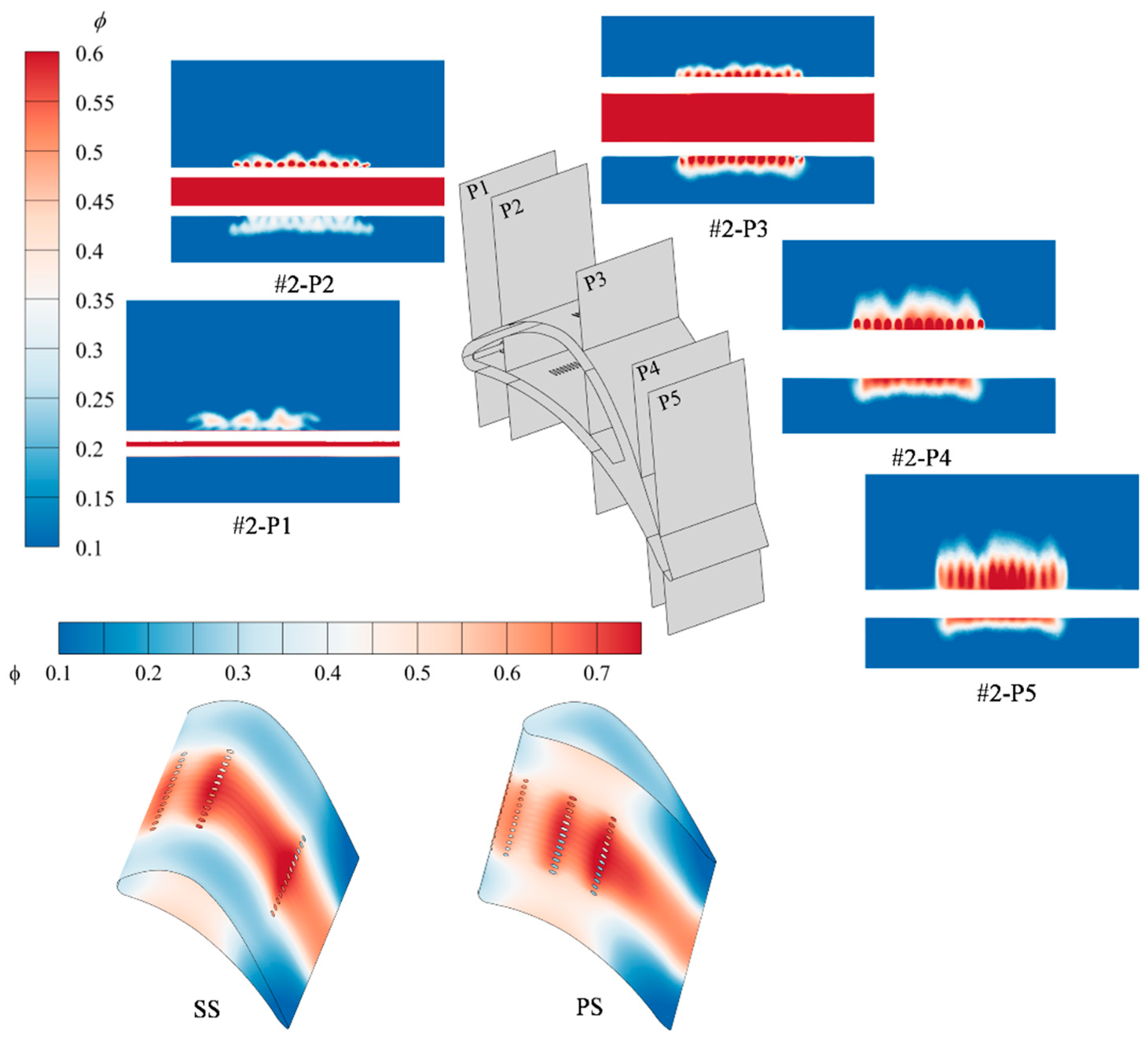

4.2. Exploring Variations in Cooling Effectiveness with Various Film Hole Configurations

4.3. Flow-Field Analysis and Mechanism Exploration Based on Simulation Results

5. Conclusions

- (1)

- An increase in turbine expansion ratio lowers the blade-surface static pressure and raises the local Mach number. The pressure on the front half of the blade is insensitive to the expansion-ratio change, whereas the rear half shows a much sharper pressure variation. The suction side experiences a greater impact from changes in the expansion ratio compared to the pressure side.

- (2)

- At a relatively low mass-flow rate, the “showerhead cooling” of Base greatly enhanced the cooling effectiveness along the leading edge on the suction side, but it also markedly reduced the trailing-edge cooling. The film holes in Hole pattern #1 and Hole pattern #2 were distributed more uniformly over the blade. This layout offset the limited streamwise coverage of a single-row film. The suction side showed a rising trailing-edge cooling effectiveness for Hole pattern #2, 83.04% higher than Base and 29.18% higher than Hole pattern #1. On the pressure side, the enhancements were 17.71% and 55.03%, respectively.

- (3)

- For both aerodynamic and heat transfer applications, numerical computation reliably predicted the experimentally measured trends of blade-surface pressure distribution and overall cooling effectiveness. The aerodynamic prediction error was within 3.81%. The heat-transfer prediction error was within 8.3%.

- (4)

- Changing the film-hole arrangement modified the flow inside the coolant cavity. Distinct vortex patterns formed near film hole exits as a result of the internal flow interacting with the external flow, consequently influencing the film cooling effectiveness. On the suction side, the conventional layout produced a high-effectiveness region mainly at the leading edge and its vicinity. For Hole pattern #1, the high-effectiveness region was primarily in the middle part of the blade. Pattern #2 displayed a more uniform cooling effectiveness distribution on the blade surface compared to Pattern #1, as there was no clearly defined high-effectiveness zone. Even though both patterns featured a single row of film holes at the leading edge, Pattern #2 offered superior leading-edge cooling effectiveness.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, J.; Zhang, S. Recent advances in film cooling enhancement: A review. Chin. J. Aeronaut. 2020, 33, 1119–1136. [Google Scholar] [CrossRef]

- Zakaria, M. Unsteady simulation of flow and heat transfer in a transonic turbine stage under non-uniform inlet conditions. Int. Commun. Heat Mass Transf. 2021, 129, 105660. [Google Scholar] [CrossRef]

- Wang, B.; Wang, F.; Zhang, X.; Wang, J.; Xue, T. Numerical analysis of cooling efficiency for turboshaft engines with converging-diverging film cooling holes. Int. J. Therm. Sci. 2023, 185, 108044. [Google Scholar] [CrossRef]

- Zhang, W.; Zeng, R.; Jing, L.; Liu, S.; Haiyong, C.; Li, G. Investigation of cooling performance degradation of impingement/effusion structure on pressure side of nozzle guide vane. Case Stud. Therm. Eng. 2022, 33, 101991. [Google Scholar] [CrossRef]

- Li, G.; Wan, L. Film cooling improvement of dovetail hole compared to cylindrical hole at different hole row locations on nozzle guide vane. Case Stud. Therm. Eng. 2023, 45, 103015. [Google Scholar] [CrossRef]

- Goldstein, R.J.; Eckert, E.R.G.; Ramsey, J.W. Film cooling with injection through holes: Adiabatic wall temperatures downstream of a circular hole. J. Eng. Gas Turbines Power 1968, 90, 384–393. [Google Scholar] [CrossRef]

- Gritsch, M.; Colban, W.; Schär, H.; Döbbeling, K. Effect of hole geometry on the thermal performance of fan-shaped film cooling holes. J. Turbomach. 2005, 127, 718–725. [Google Scholar] [CrossRef]

- Jia, Y.; Liu, Y.; Meng, Z.; He, X.; Liu, Y. The film cooling performance of spiral-channel holes on turbine guide vane. Case Stud. Therm. Eng. 2023, 53, 103846. [Google Scholar] [CrossRef]

- Jackson, D.J.; Lee, K.L.; Ligrani, P.M.; Johnson, P.D. Transonic aerodynamic losses due to turbine airfoil, suction surface film cooling. J. Turbomach. 2000, 122, 317–326. [Google Scholar] [CrossRef]

- Zhang, G.; Liu, J.; Sundén, B.; Xie, G. Comparative study on the adiabatic film cooling performances with elliptical or super-elliptical holes of various length-to-width ratios. Int. J. Therm. Sci. 2020, 153, 106360. [Google Scholar] [CrossRef]

- Yusop, N.M.; Ali, A.H.; Abdullah, M.Z. Computational study of a new scheme for a film-cooling hole on convex surface of turbine blades. Int. Commun. Heat Mass Transf. 2013, 43, 90–99. [Google Scholar] [CrossRef]

- Sargison, J.E.; Oldfield, M.L.G.; Guo, S.M.; Lock, G.D.; Rawlinson, A.J. Flow visualisation of the external flow from a converging slot-hole film-cooling geometry. Exp. Fluids 2005, 38, 304–318. [Google Scholar] [CrossRef]

- Okita, Y.; Nishiura, M. Film effectiveness performance of an arrowhead-shaped film-cooling hole geometry. J. Turbomach. 2007, 129, 331–339. [Google Scholar] [CrossRef]

- Huang, Y.; Zhang, J.Z.; Wang, C.H. Shape-optimization of round-to-slot holes for improving film cooling effectiveness on a flat surface. Heat Mass Transf. Waerme Stoffuebertragung 2018, 54, 1741–1754. [Google Scholar] [CrossRef]

- Zhu, X.D.; Zhang, J.Z.; Tan, X.M. Numerical assessment of round-to-slot film cooling performances on a turbine blade under engine representative conditions. Int. Commun. Heat Mass Transf. 2019, 100, 98–100. [Google Scholar] [CrossRef]

- Sargison, J.E.; Guo, S.M.; Oldfield, M.L.G.; Lock, G.D.; Rawlinson, A.J. A converging slot-hole film-cooling geometry-Part 1: Low-speed flat-plate heat transfer and loss. J. Turbomach. 2002, 124, 453–460. [Google Scholar] [CrossRef]

- Dai, P.; Lin, F. Numerical study on film cooling effectiveness from shaped and crescent holes. Heat Mass Transf. Waerme Stoffuebertragung 2011, 47, 147–154. [Google Scholar] [CrossRef]

- Lu, Y. Effect of Hole Configurations on Film Cooling From Cylindrical Inclined Holes for the Application To Gas Turbine Blades. Ph.D. Thesis, Louisiana State University and Agricultural & Mechanical College, Baton Rouge, LA, USA, 2007. [Google Scholar]

- Bunker, R.S. Film cooling effectiveness due to discrete holes within a transverse surface slot. In Proceedings of the Turbo Expo 2002: Power for Land, Sea, and Air, Amsterdam, The Netherlands, 3–6 June 2002; American Society of Mechanical Engineers: New York, NY, USA; International Gas Turbine Institute: Houston, TX, USA, 2002. [Google Scholar]

- Zhang, B.L.; Zhu, H.R.; Liu, C.L.; Wei, J.-S. Experimental Study on the Film-Cooling Characteristics of the Cylindrical Holes Embedded in Sine-Wave Shaped Trench. J. Eng. Gas Turbines Power 2020, 142, 101003. [Google Scholar] [CrossRef]

- Na, S.; Shih, T.I.P. Increasing adiabatic film-cooling effectiveness by using an upstream ramp. J. Heat Transf. 2007, 129, 464–471. [Google Scholar] [CrossRef]

- Zhou, W.; Peng, D.; Wen, X.; Liu, Y.; Hu, H. Unsteady analysis of adiabatic film cooling effectiveness behind circular, shaped, and sand-dune-inspired film cooling holes: Measurement using fast-response pressure-sensitive paint. Int. J. Heat Mass Transf. 2018, 125, 1003–1016. [Google Scholar] [CrossRef]

- Benabed, M. Computational optimization of Coanda effect on film-cooling performance. J. Thermophys. Heat Transf. 2015, 29, 757–765. [Google Scholar] [CrossRef]

- Meng, Z.; Liu, Y.; Li, Y.; Yu, Y. A study on cooling performance of surface-modified TBC-film cooling system with bio-inspired micro-riblets. Int. J. Therm. Sci. 2022, 172, 107340. [Google Scholar] [CrossRef]

- Ou, S.; Rivir, R.B. Leading edge film cooling heat transfer with high free stream turbulence using a transient liquid crystal image method. Int. J. Heat Fluid Flow 2001, 22, 614–623. [Google Scholar] [CrossRef]

- Jiang, H.W.; Han, J.C. Effect of film hole row location on film effectiveness on a gas turbine blade. J. Heat Transf. 1996, 118, 327–333. [Google Scholar] [CrossRef]

- Liu, C.; Zhu, H.; Fu, Z.; Xu, R.-H. The effects of inlet Reynolds number, exit Mach number and incidence angle on leading edge film cooling effectiveness of a turbine blade in a linear transonic cascade. In Proceedings of the Turbo Expo: Power for Land, Sea, and Air, Montréal, QC, Canada, 15–19 June 2015; American Society of Mechanical Engineers: New York, NY, USA, 2015; Volume 56727, p. V05BT12A025. [Google Scholar]

- Zhang, L.; Moon, H.K. Turbine blade film cooling study: The effects of film hole location on the pressure side. In Proceedings of the Turbo Expo: Power for Land, Sea, and Air, Montréal, QC, Canada, 14–17 May 2007; Volume 47934, pp. 497–506. [Google Scholar]

- Mhetras, S.; Han, J.C.; Rudolph, R. Film-cooling effectiveness from shaped film cooling holes for a gas turbine blade. In Proceedings of the Turbo Expo: Power for Land, Sea, and Air, Berlin, Germany, 9–13 June 2008; Volume 43147, pp. 837–848. [Google Scholar]

- Mhetras, S.; Han, J.C.; Rudolph, R. Effect of flow parameter variations on full coverage film-cooling effectiveness for a gas turbine blade. J. Turbomach. 2011, 134, 93–103. [Google Scholar] [CrossRef]

- Liu, K.; Yang, S.F.; Han, J.C. Influence of coolant density on turbine blade film-cooling with axial and compound shaped holes. J. Heat Transf. 2014, 136, 044501. [Google Scholar] [CrossRef]

- Rallabandi, A.P.; Li, S.J.; Han, J.C. Unsteady wake and coolant density effects on turbine blade film cooling using pressure sensitive paint technique. J. Heat Transf. 2012, 134, 081701. [Google Scholar] [CrossRef]

- Narzary, D.P.; Liu, K.C.; Rallabandi, A.P.; Han, J.-C. Influence of coolant density on turbine blade film-cooling using pressure sensitive paint technique. J. Turbomach. 2011, 134, 031006. [Google Scholar] [CrossRef]

- Fu, Z.; Zhu, H.; Cheng, L.; Han, J.-C. Experimental Investigation on the Effect of Mainstream Turbulence on Full Coverage Film Cooling Effectiveness for a Turbine Guide Vane. J. Therm. Sci. 2019, 28, 145–157. [Google Scholar] [CrossRef]

- Li, W.; Li, X.; Ren, J.; Jiang, H. Experimental investigation of wall thickness and hole shape variation effects on full-coverage film cooling performance for a gas turbine vane. Appl. Therm. Eng. 2018, 144, 349–361. [Google Scholar] [CrossRef]

- Jia, Y.H.; Liu, Y.B.; Meng, Z.W.; Yin, W.; Hua, W. Numerical study on film cooling effectiveness from spiral-channel hole. Int. Commun. Heat Mass Transf. 2023, 143, 106716. [Google Scholar] [CrossRef]

- Yuhao, J.; Yongbao, L.; Xing, H.; Zewei, M.; Shuai, Z. Arrangement guideline of film holes along conjugate temperature difference in turbine guide vanes. Chin. J. Aeronaut. 2025, 38, 103400. [Google Scholar] [CrossRef]

| Key Experimental Parameters | Typical Operating Conditions | Uncertainties |

|---|---|---|

| Ma | 0.6 | 3% |

| MFR | 1.87% | |

| Tc = 60 °C Tc = 150 °C | 5.42% 2.04% |

| Layouts | LE-1 | LE-2 | LE-3 | SS-1 | SS-2 | SS-3 | PS-1 | PS-2 | PS-3 |

|---|---|---|---|---|---|---|---|---|---|

| Base | 2.83 | 1.37 | 4.96 | 1.36 | 1.14 | — | 3.21 | 2.73 | — |

| Hole pattern #1 | 1.68 | — | — | 0.82 | 0.85 | 0.75 | 1.84 | 1.59 | 1.27 |

| Hole pattern #2 | 1.47 | — | — | 0.62 | 0.74 | 0.79 | 1.65 | 1.42 | 1.08 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, Z.; Liu, C.; Jia, Y.; He, X.; Xia, G.; Liu, Y. Optimizing Film Cooling Hole Arrangement Along Conjugate Isotherms on Turbine Vanes: A Combined Numerical and Experimental Investigation. Processes 2025, 13, 3344. https://doi.org/10.3390/pr13103344

Shi Z, Liu C, Jia Y, He X, Xia G, Liu Y. Optimizing Film Cooling Hole Arrangement Along Conjugate Isotherms on Turbine Vanes: A Combined Numerical and Experimental Investigation. Processes. 2025; 13(10):3344. https://doi.org/10.3390/pr13103344

Chicago/Turabian StyleShi, Zhengyu, Changxin Liu, Yuhao Jia, Xing He, Ge Xia, and Yongbao Liu. 2025. "Optimizing Film Cooling Hole Arrangement Along Conjugate Isotherms on Turbine Vanes: A Combined Numerical and Experimental Investigation" Processes 13, no. 10: 3344. https://doi.org/10.3390/pr13103344

APA StyleShi, Z., Liu, C., Jia, Y., He, X., Xia, G., & Liu, Y. (2025). Optimizing Film Cooling Hole Arrangement Along Conjugate Isotherms on Turbine Vanes: A Combined Numerical and Experimental Investigation. Processes, 13(10), 3344. https://doi.org/10.3390/pr13103344