Enhancing Oil Recovery in Vertical Heterogeneous Sandstone Reservoirs Using Low-Frequency Pulsating Water Injection

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

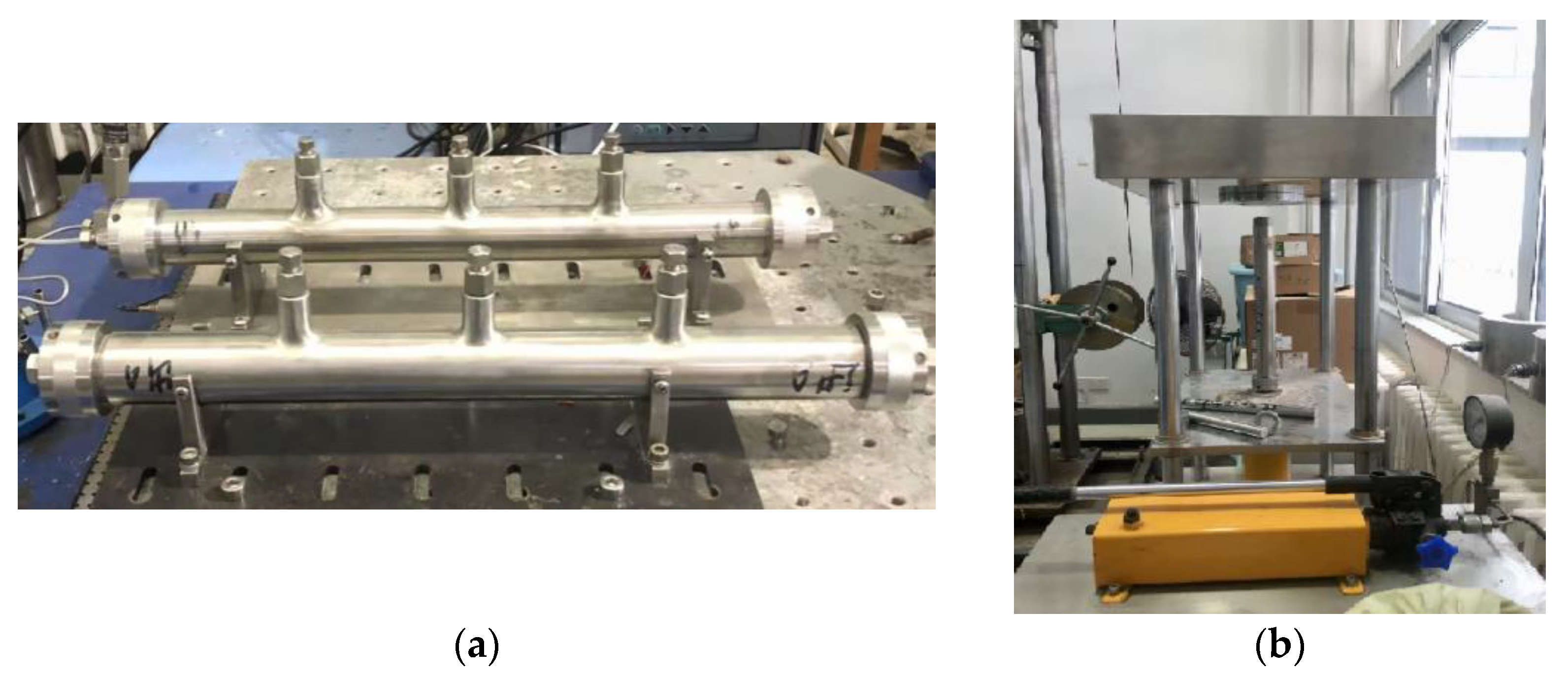

2.1.1. Experimental Core

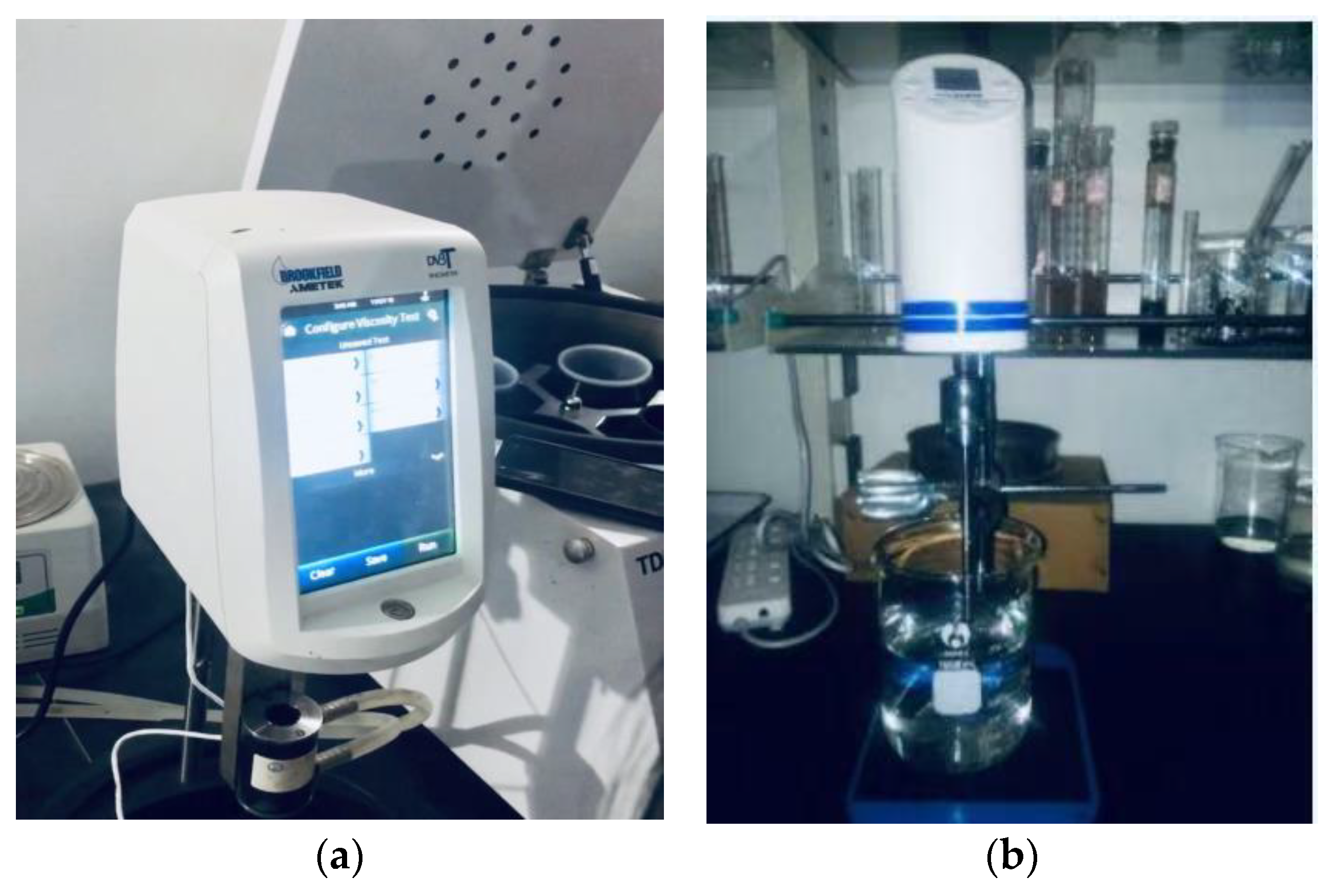

2.1.2. Fluid System

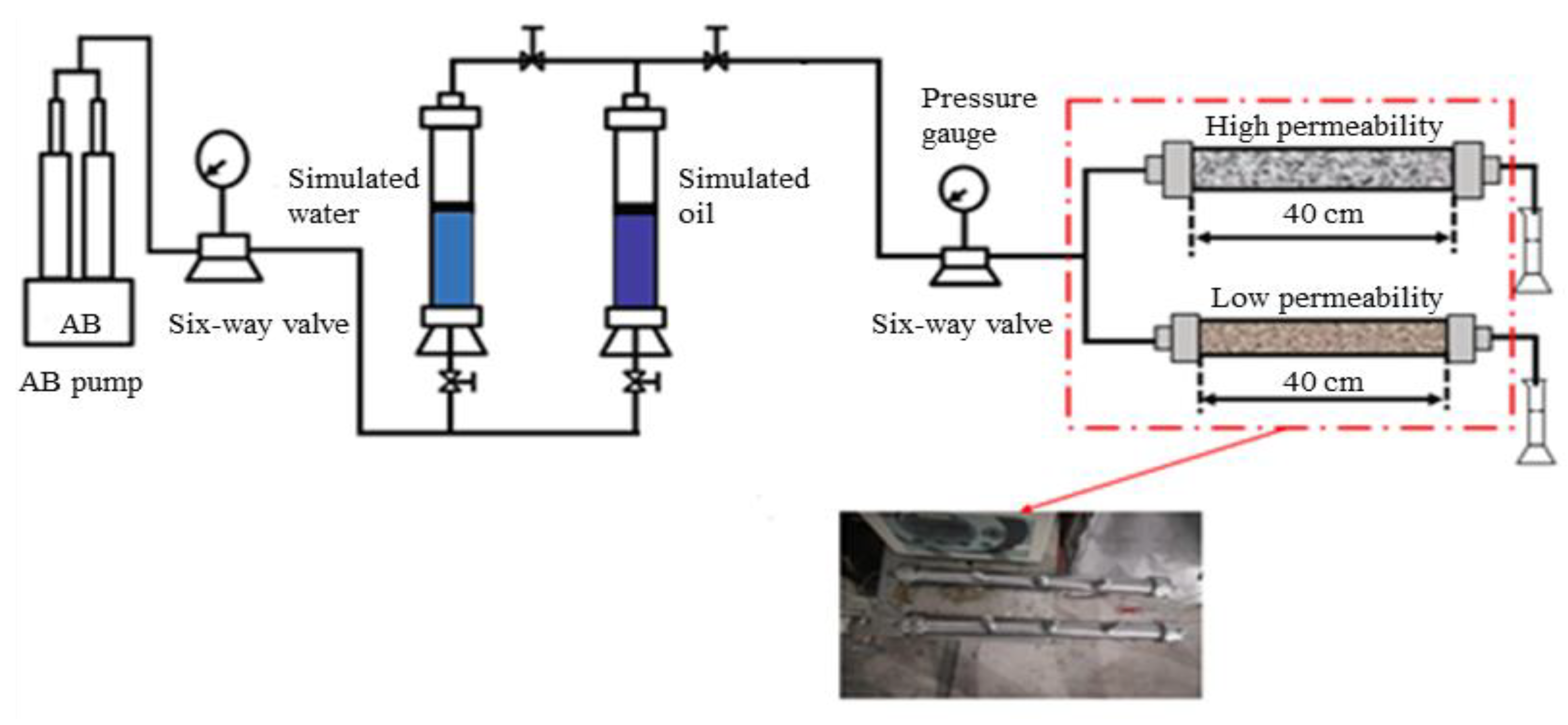

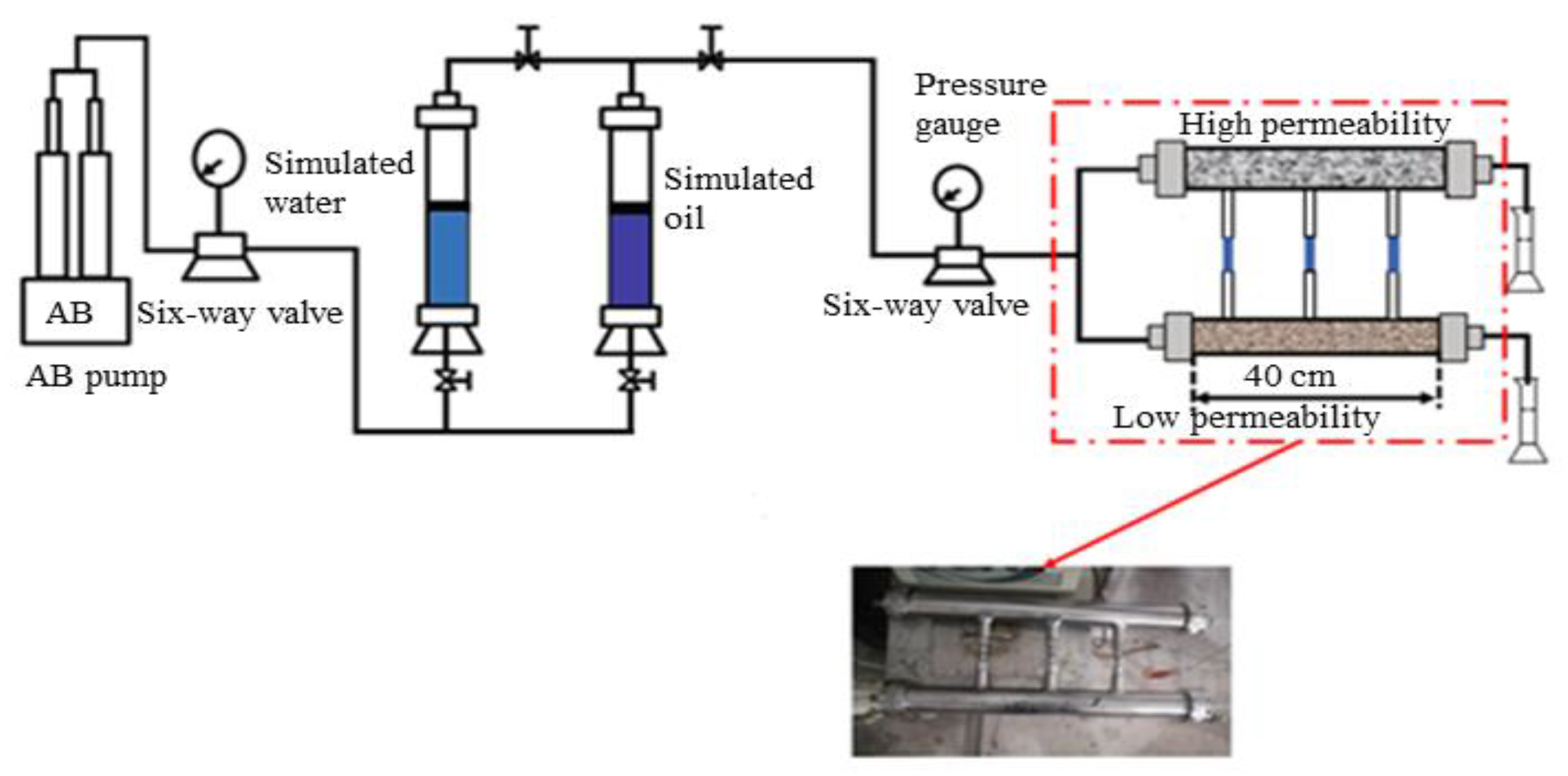

2.1.3. Injection System

2.1.4. Experimental Uncertainty

2.2. Methodology

3. Experimental Results and Discussions

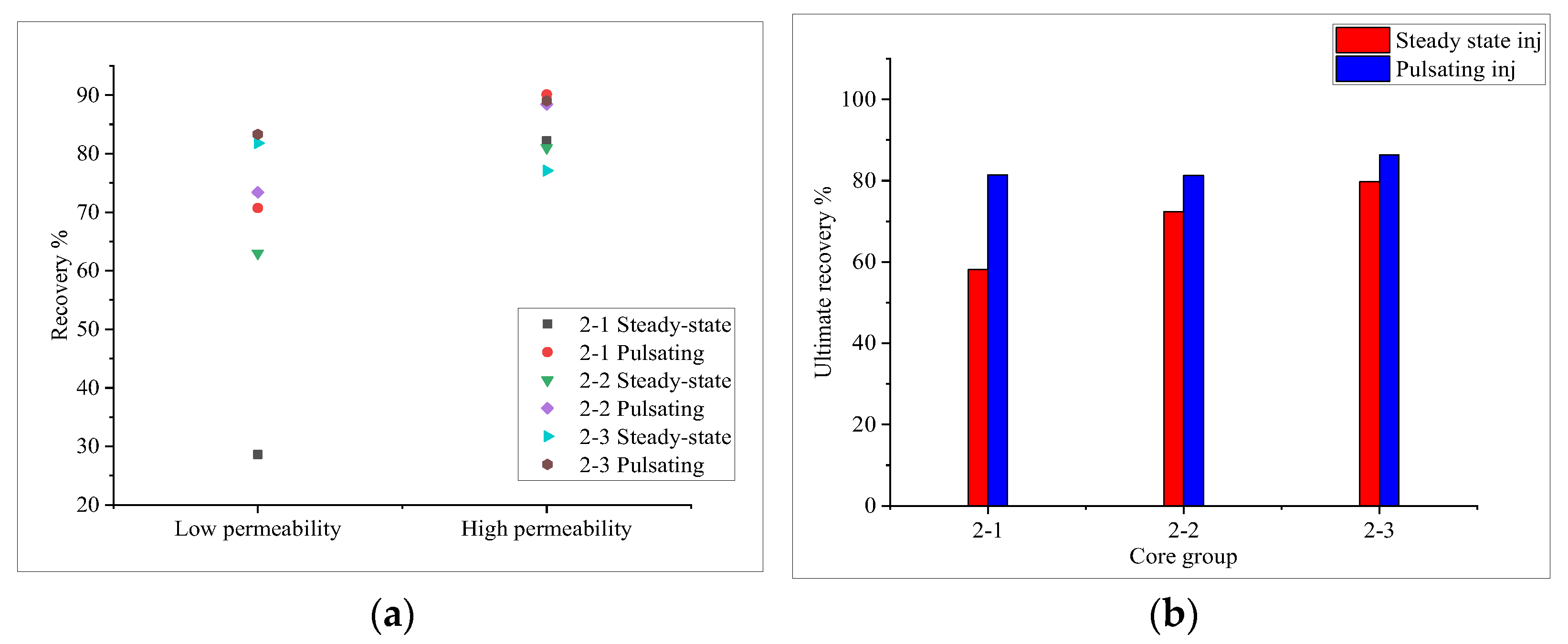

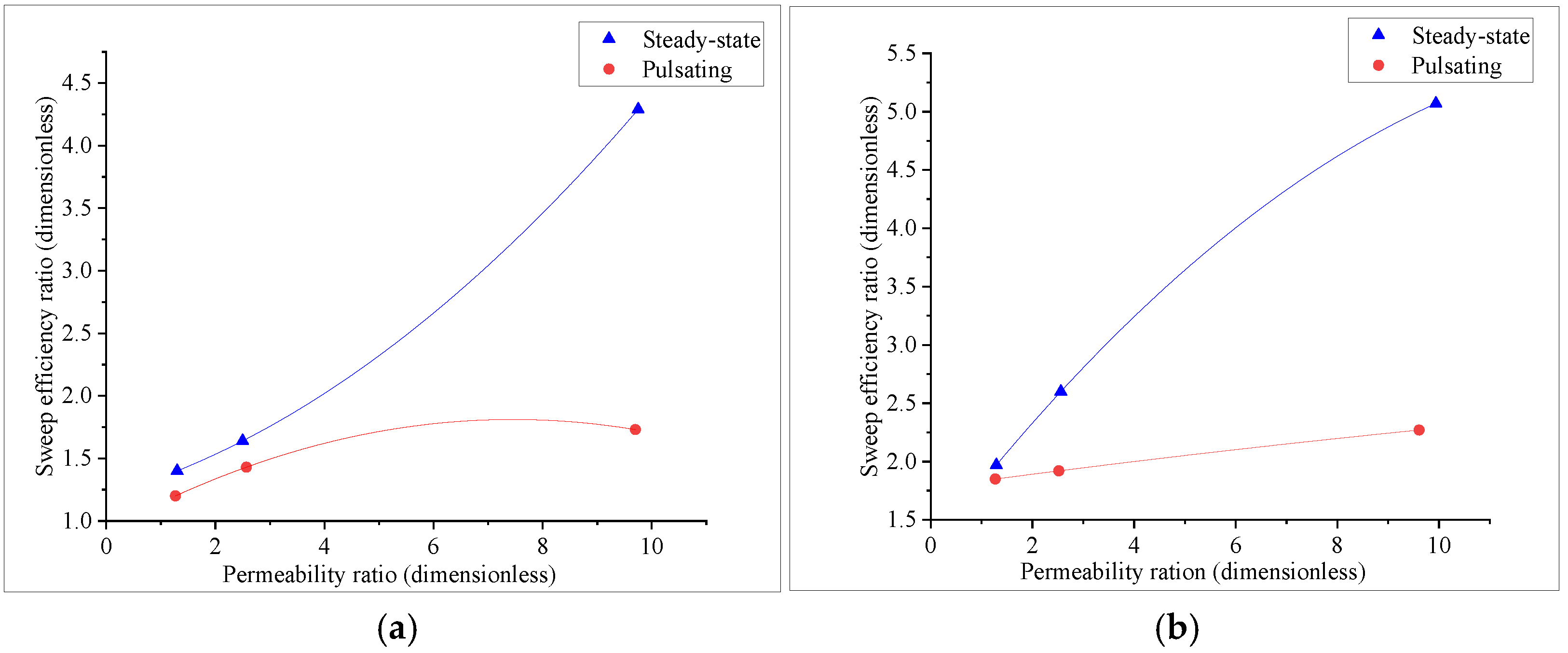

3.1. Interlayer Heterogeneity Experiments

3.2. Inlayer Heterogeneity Experiments

3.3. Driving Mechanisms of Pulsating Water Flooding in Heterogeneous Reservoirs

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ibrahim, A.S. Investigation of the mobilization of residual oil using micromodels. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 4–7 October 2009. [Google Scholar]

- Xu, Z.X.; Li, S.Y.; Li, B.F.; Chen, D.Q.; Liu, Z.Y.; Li, Z.M. A review of development methods and EOR technologies for carbonate reservoirs. Pet. Sci. 2020, 17, 990–1013. [Google Scholar] [CrossRef]

- Manrique, E.; Thomas, C.; Ravikiran, R.; Izadi, M.; Lantz, M.; Romero, J.; Alvarado, V. Current status and opportunities. In Proceedings of the SPE Improved Oil Recovery Symposium, Tulsa, OK, USA, 24–28 April 2010. [Google Scholar]

- Kazemzadeh, Y.; Shojaei, S.; Riazi, M.; Sharifi, M. Review on the application of nanoparticles for EOR purposes: A critical review of the opportunities and challenges. Chin. J. Chem. Eng. 2019, 27, 237–246. [Google Scholar] [CrossRef]

- Tan, Y.; Zhang, Y.; Hui, C.; Yu, C.; Tian, S.; Wang, T.; Wang, F. Resonance-Enhanced Pulsing Water Injection for Improved Oil Recovery: Micromodel Experiments and Analysis. Processes 2023, 11, 957. [Google Scholar] [CrossRef]

- Wang, K.; Zheng, W.; He, Y.; Tang, C.; Pan, Y.; Li, J.; Jiang, J.; Cai, S.; Li, J. Analysis of Inter-Layer Interference in Multi-Layer Reservoir Commingled Production Wells. Processes 2024, 12, 1644. [Google Scholar] [CrossRef]

- Zhang, Z.; Gan, H.; Zhang, C.; Jia, S.; Yu, X.; Zhang, K.; Zhong, X.; Zheng, X.; Shen, T.; Qu, L.; et al. Experimental Study on Improving Oil Recovery Mechanism of Injection–Production Coupling in Complex Fault-Block Reservoirs. Energies 2024, 17, 1505. [Google Scholar] [CrossRef]

- Zhao, L.; Li, L.; Wu, Z.; Zhang, C. Analytical model of waterflood sweep efficiency in vertical heterogeneous reservoirs under constant pressure. Math. Probl. Eng. 2016, 10, 6273492. [Google Scholar] [CrossRef]

- Li, M.; Qu, Z.; Wang, M.; Ran, W. The Influence of Micro-Heterogeneity on Water Injection Development in Low-Permeability Sandstone Oil Reservoirs. Minerals 2023, 13, 1533. [Google Scholar] [CrossRef]

- Liu, Y.; Luo, X.; Kang, K.; Li, T.; Jiang, S.; Zhang, J.; Zhang, Z.; Li, Y. Permeability characterization and directional wells initial productivity prediction in the continental multilayer sandstone reservoirs: A case from Penglai 19-3 oil field, Bohai Bay Basin. Pet. Explor. Dev. 2017, 44, 97–104. [Google Scholar] [CrossRef]

- Weimann, P.A.; Sanchez, A.; Espinosa-Vázquez, L.A.; Davidson, B.; Martinez, R.G. Effective Well Stimulation Using Fluid Pulsing to Inject Surfactant Solutions. In Proceedings of the Heavy Oil Latin America Conference & Exhibition, Puerto Vallarta, Mexico, 24–26 September 2013. [Google Scholar]

- Al-Shalabi, E.W.; Ghosh, B. Effect of Pore-Scale Heterogeneity and Capillary-Viscous Fingering on Commingled Waterflood Oil Recovery in Stratified Porous Media. J. Pet. Eng. 2016, 1708929. [Google Scholar] [CrossRef]

- Xue, L.; Liu, P.; Zhang, Y. Status and Prospect of Improved Oil Recovery Technology of High Water Cut Reservoirs. Water 2023, 15, 1342. [Google Scholar] [CrossRef]

- Yang, H.; Lao, J.; Tong, D.; Song, H. Numerical Investigation on EOR in Porous Media by Cyclic Water Injection with Vibration Frequency. Water 2022, 14, 3961. [Google Scholar] [CrossRef]

- Wang, Y.; Song, X.; Tian, C.; Shi, C.; Li, J.; Hui, G.; Hou, J.; Gao, C.; Wang, X.; Liu, P. Dynamic fractures are an emerging new development geological attribute in water-flooding development of ultra-low permeability reservoirs. Pet. Explor. Dev. 2015, 42, 247–253. [Google Scholar] [CrossRef]

- Mai, A.; Kantzas, A. Heavy oil waterflooding: Effects of flow rate and oil viscosity. J. Can. Pet. Technol. 2009, 48, 42–51. [Google Scholar] [CrossRef]

- Rostami, P.; Sharifi, M.; Aminshahidy, B.; Fahimpour, J. The effect of nanoparticles on wettability alteration for enhanced oil recovery: Micromodel experimental studies and CFD simulation. Pet. Sci. 2019, 16, 859–873. [Google Scholar] [CrossRef]

- Groenenboom, J.; Wong, S.-W.; Meling, T.; Zschuppe, R.; Davidson, B. Pulsed Water Injection during water flooding. In Proceedings of the SPE International Improved Oil Recovery Conference in Asia Pacific, Kuala Lumpur, Malaysia, 6–9 October 2003. [Google Scholar]

- Hu, L.Z.; Sun, L.; Zhao, J.Z.; Wei, P.; Pu, W.F. Influence of formation heterogeneity on foam flooding performance using 2D and 3D models: An experimental study. Pet. Sci. 2020, 17, 734–748. [Google Scholar] [CrossRef]

- Spanos, T.; Davidson, B.; Dusseault, M.; Shand, D.; Samaroo, M. Pressure pulsing at the reservoir scale: A new IOR approach. J. Can. Pet. Technol. 2003, 42, 16–27. [Google Scholar] [CrossRef]

- Sivrikoz, A. Enhance Oil Recovery Modelling Using a Pressure Pulse-Geomechanical Black Oil Simulator. Ph.D. Thesis, University of Alberta, Edmonton, AB, Canada, 2009. [Google Scholar]

- Zhu, T.; Xutao, H.; Vajjha, P. Downhole Harmonic Vibration Oil-Displacement System: A New IOR Tool. In Proceedings of the SPE Western Regional Meeting, Irvine, CA, USA, 30 March–1 April 2005. [Google Scholar]

- Gale, T. A Field and Numerical Investigation of the Pressure Pulsing Reagent Delivery Approach. Master’s Thesis, University of Waterloo, Waterloo, ON, Canada, 2011. [Google Scholar]

- Huh, C. Improved oil recovery by seismic vibration: A preliminary assessment of possible mechanisms. In Proceedings of the SPE International Oil Conference and Exhibition in Mexico, Cancun, Mexico, 31 August–2 September 2006. [Google Scholar]

- Elkhoury, J.E.; Brodsky, E.E.; Agnew, D.C. Seismic waves increase permeability. Nature 2006, 441, 1135–1138. [Google Scholar] [CrossRef]

- Kalinski, M.E. Effect of Vibroseis Arrays on Ground Vibrations: A Numerical Study Effect of Vibroseis Arrays on Ground Vibrations: A Numerical Study. J. Environ. Eng. Geophys. 2007, 12, 281–287. [Google Scholar] [CrossRef]

- Guo, X.; Du, Z.; Li, G.; Shu, Z.; Oilfield. High-Frequency Vibration Recovery Enhancement Technology in the Heavy Oil Fields of China. In Proceedings of the SPE International Thermal Operations and Heavy Oil Symposium and Western Regional Meeting, Bakersfield, CA, USA, 16–18 March 2004. [Google Scholar]

- Davidson, B. Fluid-Pulse Technology Boosts Oil Recovery. J. Pet. Technol. 2013, 65, 34–35. [Google Scholar] [CrossRef]

- Kostrov, S.; Wooden, W. Possible Mechanisms and Case Studies for Enhancement of Oil Recovery and Production Using In-Situ Seismic Stimulation. In Proceedings of the SPE Symposium on Improved Oil Recovery, Tulsa, OK, USA, 20–23 April 2008. [Google Scholar]

- Atamanchuk, I. Pressure Pulsing Potential During Waterflooding and CO2 Flooding of Heavy Oil Reservoirs. Master’s Thesis, University of Regina, Regina, SK, Canada, 2014. [Google Scholar]

- Wang, J.; Dusseault, M.B. Fluid enhancement under liquid pressure pulsing at low frequency. In Proceedings of the 7th Unitar International Conference on Heavy Crude and Tar Sands, Beijing, China, 27–30 October 1998. [Google Scholar]

- Yan, W.; Sun, J.; Zhang, J.; Golsanami, N.; Hao, S. A novel method for estimation of remaining oil saturations in water-flooded layers. Interpretation 2017, 5, SB9-23. [Google Scholar] [CrossRef]

- Amro, M.; Al-Mobarky, M.; Al-Homadhi, E. Improved Oil Recovery by Application of Ultrasound Waves to Waterflooding. In Proceedings of the SPE Middle East Oil and Gas Show and Conference, Manama, Bahrain, 10–13 March 2007. [Google Scholar]

- Hamida, T.; Babadagli, T. Capillary Interaction of Different Oleic and Aqueous Phases Between Matrix and Fracture Under Ultrasonic Waves. In Proceedings of the SPE Europec/EAGE Annual Conference, Madrid, Spain, 13 June 2005. [Google Scholar]

- Hamida, T.; Babadagli, T. Effect of ultrasonic waves on the capillary-imbibition recovery of oil. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, Jakarta, Indonesia, 5–7 April 2005. [Google Scholar]

- Iassonov, P.P.; Beresnev, I.A. Mobilization of entrapped organic fluids by elastic waves and vibrations. SPE J. 2008, 13, 465–473. [Google Scholar] [CrossRef]

- Yeganeh, M.; Hegner, J.; Lewandowski, E.; Mohan, A.; Lake, L.W.; Cherney, D.; Jusufi, A.; Jaishankar, A. Capillary Desaturation Curve Fundamentals. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OK, USA, 11–13 April 2016. [Google Scholar]

- Liu, C.; Chen, T.; Yu, Z.; Yang, Z.; Yin, J. Pressure Attenuation Law of Low-Frequency Pulse Pressure Flooding and Its Influence on Oil Recovery. ACS Omega 2021, 6, 35272–35283. [Google Scholar] [CrossRef]

- Zheng, W.; Wang, K.; Li, J.; Jiang, J.; Tang, C.; He, Y.; Guan, Y.; Li, J. A Study on the Mechanism and Influencing Factors of Interlayer Injection–Production Coupling in a Heterogeneous Sandstone Reservoir. Processes 2024, 12, 2054. [Google Scholar] [CrossRef]

- Gong, Q.; Liu, Z.; Zhu, C.; Wang, B.; Jin, Y.; Shi, Z.; Xie, L.; Wu, J. Heterogeneity of a Sandy Conglomerate Reservoir in Qie12 Block, Qaidam Basin, Northwest China and Its Influence on Remaining Oil Distribution. Energies 2023, 16, 2972. [Google Scholar] [CrossRef]

- Rashid, B.; Muggeridge, A.H.; Bal, A.; Williams, G. Quantifying the impact of permeability heterogeneity on secondary-recovery performance. SPE J. 2012, 17, 455–468. [Google Scholar] [CrossRef]

- Salimi, H.; Bruining, J. The influence of heterogeneity, wetting, and viscosity ratio on oil recovery from vertically fractured reservoirs. SPE J. 2011, 16, 411–428. [Google Scholar] [CrossRef]

- Zhan, L.; Kuchuk, F.; Ma, S.M.; Al-Shahri, A.M.; Ramakrishnan, T.S.; Altundas, Y.B.; Zeybek, M.; Manin, Y.; Tartaras, E.; de Loubens, R.; et al. Characterization of reservoir heterogeneity through fluid movement monitoring with deep electromagnetic and pressure measurements. SPE J. 2010, 6, 509–522. [Google Scholar] [CrossRef]

- Yan, G.; Rui, S.; Fang, Z.; Baojiang, D.; Jingnan, Z. Research on Waterflood Sweep Law in Low Permeability Vertical Heterogeneous Reservoir. Int. J. Digit. Content Technol. Its Appl. 2013, 7, 698–705. [Google Scholar]

- Meng, X.; Zhang, Q.; Dai, X.; Xue, S.; Feng, X.; Zhang, Y.; Tu, B.; Li, X. Experimental and simulation investigations of cyclic water injection in low-permeability reservoir. Arab. J. Geosci. 2021, 14, 791. [Google Scholar] [CrossRef]

- Liu, Y.; Nie, F.; Zhang, B.; Liu, T.; Hong, Y. The Three-Dimensional Heterogeneous Simulation Study of CO2 Flooding in Low-Permeability Reservoirs. Processes 2024, 12, 1843. [Google Scholar] [CrossRef]

- Avagnina, N.; Segura, R.J.; Muniategui, M.E.; Sanchez Lona, A.; Keshka, A.; Kolli, K.R.; Wegmann-Sanchez, J. An Innovative Waterflood Optimization Method for Unconsolidated Sandstone Reservoirs to Increase Oil Production, Lower Water-Cut, and Improve or Stabilize Base Oil Decline Rate. In Proceedings of the Pan American Mature Fields Congress, Veracruz, Mexico, 20–22 January 2015. [Google Scholar]

- Beresnev, I.; Gaul, W.; Vigil, R.D. Direct pore-level observation of permeability increase in two-phase flow by shaking. Geophys. Res. Lett. 2011, 38, 2–6. [Google Scholar] [CrossRef]

- Jeong, C.; Kallivokas, L.F.; Huh, C.; Lake, L.W. Estimation of oil production rates in reservoirs exposed to focused vibrational energy. In Proceedings of the SPE Improved Oil Recovery Symposium, Tulsa, OK, USA, 12–16 April 2014. [Google Scholar]

- Abdullahi, M.B.; Jufar, S.R.; Dzulkarnain, I.; Al-shami, T.M.; Le, M.D.D. Seismic Wave Excitation of Mature Oil Reservoirs for Green EOR Technology. J. Adv. Res. Fluid Mech. Therm. Sci. 2023, 103, 180–196. [Google Scholar] [CrossRef]

- Vogler, E.T.; Chrysikopoulos, C.V. Experimental investigation of acoustically enhanced solute transport in porous media. Geophys. Res. Lett. 2002, 29, 2–5. [Google Scholar] [CrossRef]

- Sun, Q.; Retnanto, A.; Amani, M. Seismic vibration for improved oil recovery: A comprehensive review of the literature. Int. J. Hydrogen Energy 2020, 45, 14756–14778. [Google Scholar] [CrossRef]

- Pen’kovskiy, V.I.; Korsakova, N.K.; Kuvshinov, V.A.; Altunina, L.K. Oil recovery enhancement by wave action and treatment with an oil-displacing composition of the near-well zone. In Proceedings of the AIP Conference Proceedings, Tomsk, Russia, 1–5 October 2018; Volume 2051. [Google Scholar]

- Yang, M.; Zhang, F.; Li, S.; Xi, W. Research on parameter optimization design of unstable water injection for heterogeneous reservoir. Adv. Mater. Res. 2014, 827, 105–111. [Google Scholar] [CrossRef]

- Elkhoury, J.E.; Niemeijer, A.; Brodsky, E.E.; Marone, C. Laboratory observations of permeability enhancement by fluid pressure oscillation of in situ fractured rock. J. Geophys. Res. 2011, 116, 1–15. [Google Scholar] [CrossRef]

- Nikolaevskiy, V.N.; Lopukhov, G.P.; Liao, Y.; Economides, M.J. Residual oil reservoir recovery with seismic vibrations. SPE Prod. Facil. 1996, 11, 89–94. [Google Scholar] [CrossRef]

| Core | Relative Permeability | Dry Weight g | Porosity % | Permeability × 10−3 μm2 |

|---|---|---|---|---|

| 2-1 | Low | 398.8 | 26.0 | 35.7 |

| High | 398 | 31.9 | 348.5 | |

| Low | 398.7 | 25.8 | 34.8 | |

| High | 398.1 | 31.5 | 337.8 | |

| 2-2 | Low | 398.4 | 30.3 | 127.4 |

| High | 397.9 | 31.3 | 318.9 | |

| Low | 398.5 | 29.5 | 125.4 | |

| High | 398.3 | 31.0 | 321.7 | |

| 2-3 | Low | 398.9 | 29.4 | 251.8 |

| High | 398.4 | 31.7 | 327.3 | |

| Low | 398.7 | 30.2 | 259.4 | |

| High | 397.5 | 31.8 | 330.4 | |

| 2-4 | Low | 398.9 | 25.8 | 34.5 |

| High | 397.1 | 31.6 | 342.6 | |

| Low | 398.4 | 26.1 | 35.2 | |

| High | 397.5 | 31.4 | 338.7 | |

| 2-5 | Low | 398.2 | 29.7 | 125.4 |

| High | 397.5 | 31.3 | 320.4 | |

| Low | 397.8 | 30.0 | 127.8 | |

| High | 397.6 | 31.0 | 321.7 | |

| 2-6 | Low | 398.3 | 27.6 | 247.2 |

| High | 397.8 | 30.4 | 318.5 | |

| Low | 397.8 | 30.5 | 264.8 | |

| High | 387.4 | 31.9 | 336.4 |

| Core | Injection Mode | Permeability Contrast × 10−3 μm2 | Relative Permeability | Dry Weight g | Porosity % | Permeability × 10−3 μm2 | Original Oil Volume mL | Produced Oil Volume mL |

|---|---|---|---|---|---|---|---|---|

| 2-1 | Steady state | 312.8 | Low | 398.8 | 26.0 | 35.7 | 51.1 | 14.6 |

| High | 398 | 31.9 | 348.5 | 62.6 | 51.5 | |||

| Pulsating | 303.0 | Low | 398.7 | 25.8 | 34.8 | 50.7 | 35.8 | |

| High | 398.1 | 31.5 | 337.8 | 61.9 | 55.7 | |||

| 2-2 | Steady state | 191.5 | Low | 398.4 | 30.3 | 127.4 | 59.5 | 37.5 |

| High | 397.9 | 31.3 | 318.9 | 61.5 | 49.8 | |||

| Pulsating | 196.3 | Low | 398.5 | 29.5 | 125.4 | 57.9 | 42.5 | |

| High | 398.3 | 31.0 | 321.7 | 60.9 | 53.8 | |||

| 2-3 | Steady state | 75.5 | Low | 398.9 | 29.4 | 251.8 | 57.7 | 44.5 |

| High | 398.4 | 31.7 | 327.3 | 62.2 | 50.9 | |||

| Pulsating | 71.0 | Low | 398.7 | 30.2 | 259.4 | 59.3 | 42.8 | |

| High | 397.5 | 31.8 | 330.4 | 62.4 | 52.0 |

| Core | Injection Mode | Permeability Contrast × 10−3 μm2 | Relative Permeability | Dry Weight g | Porosity % | Permeability × 10−3 μm2 | Original Oil Volume mL | Produced Oil Volume mL |

|---|---|---|---|---|---|---|---|---|

| 2-4 | Steady state | 308.1 | Low | 398.9 | 25.8 | 34.5 | 50.7 | 10.6 |

| High | 397.1 | 31.6 | 342.6 | 62.0 | 53.7 | |||

| Pulsating | 303.5 | Low | 398.4 | 26.1 | 35.2 | 51.2 | 24.5 | |

| High | 397.5 | 31.4 | 338.7 | 61.7 | 55.7 | |||

| 2-5 | Steady state | 195.0 | Low | 398.2 | 29.7 | 125.4 | 58.3 | 19.8 |

| High | 397.5 | 31.3 | 320.4 | 61.5 | 51.4 | |||

| Pulsating | 193.9 | Low | 397.8 | 30.0 | 127.8 | 58.9 | 28.7 | |

| High | 397.6 | 31.0 | 321.7 | 60.9 | 55.2 | |||

| 2-6 | Steady state | 71.3 | Low | 398.3 | 27.6 | 247.2 | 54.2 | 25.3 |

| High | 397.8 | 30.4 | 318.5 | 59.7 | 49.8 | |||

| Pulsating | 71.6 | Low | 397.8 | 30.5 | 264.8 | 59.7 | 30.7 | |

| High | 397.4 | 31.9 | 336.4 | 62.6 | 56.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mwangupili, O.; Pu, C. Enhancing Oil Recovery in Vertical Heterogeneous Sandstone Reservoirs Using Low-Frequency Pulsating Water Injection. Processes 2025, 13, 296. https://doi.org/10.3390/pr13020296

Mwangupili O, Pu C. Enhancing Oil Recovery in Vertical Heterogeneous Sandstone Reservoirs Using Low-Frequency Pulsating Water Injection. Processes. 2025; 13(2):296. https://doi.org/10.3390/pr13020296

Chicago/Turabian StyleMwangupili, Osmund, and Chunsheng Pu. 2025. "Enhancing Oil Recovery in Vertical Heterogeneous Sandstone Reservoirs Using Low-Frequency Pulsating Water Injection" Processes 13, no. 2: 296. https://doi.org/10.3390/pr13020296

APA StyleMwangupili, O., & Pu, C. (2025). Enhancing Oil Recovery in Vertical Heterogeneous Sandstone Reservoirs Using Low-Frequency Pulsating Water Injection. Processes, 13(2), 296. https://doi.org/10.3390/pr13020296