Controllable Preparation and Electrically Enhanced Particle Filtration Performance of Reduced Graphene Oxide Polyester Fiber Materials in Public Buildings

Abstract

1. Introduction

2. Methods

2.1. Material and Equipment

2.2. Preparation of Reduced Graphene Oxide Polyester Fiber Material

2.3. Performance Formula

3. Results and Discussion

3.1. Appearance Analysis of Reduced Graphene Oxide Polyester Fiber Material

3.2. Influence of Filtration Velocity

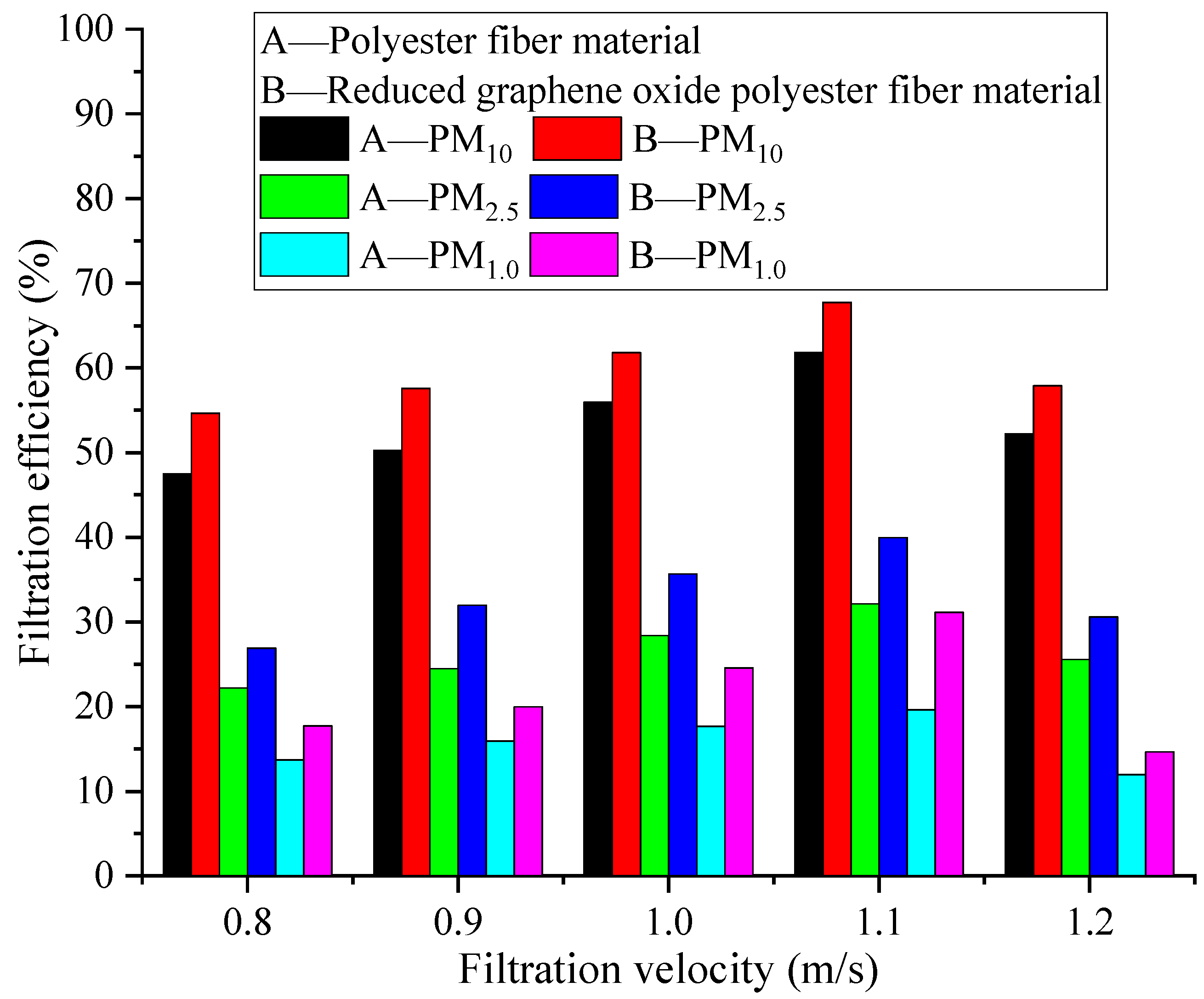

3.3. Influence of Voltage Magnitude

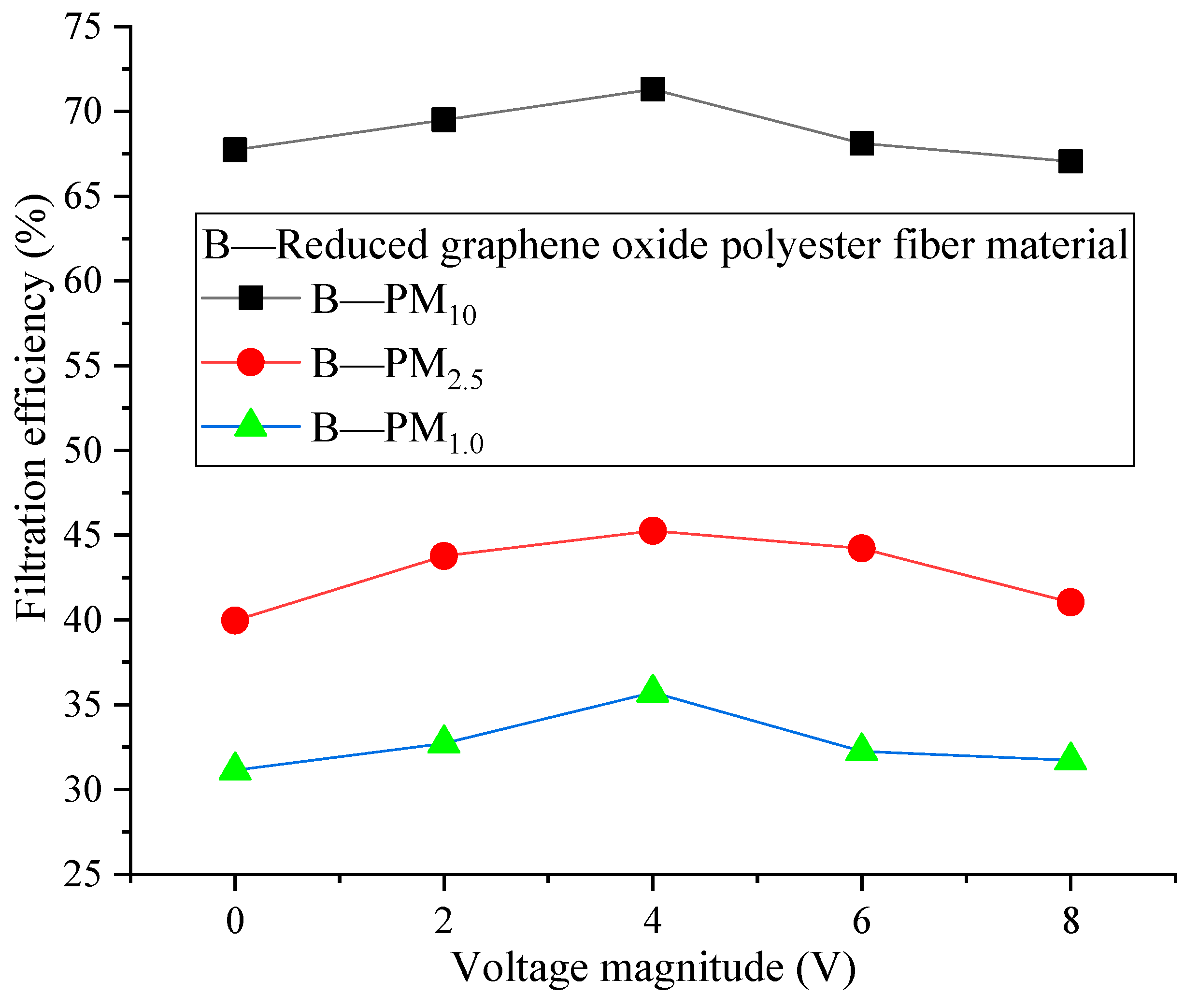

3.4. Influence of Power on Time

3.5. Influence of Voltage and Power on Time on Counting Filtration Efficiency

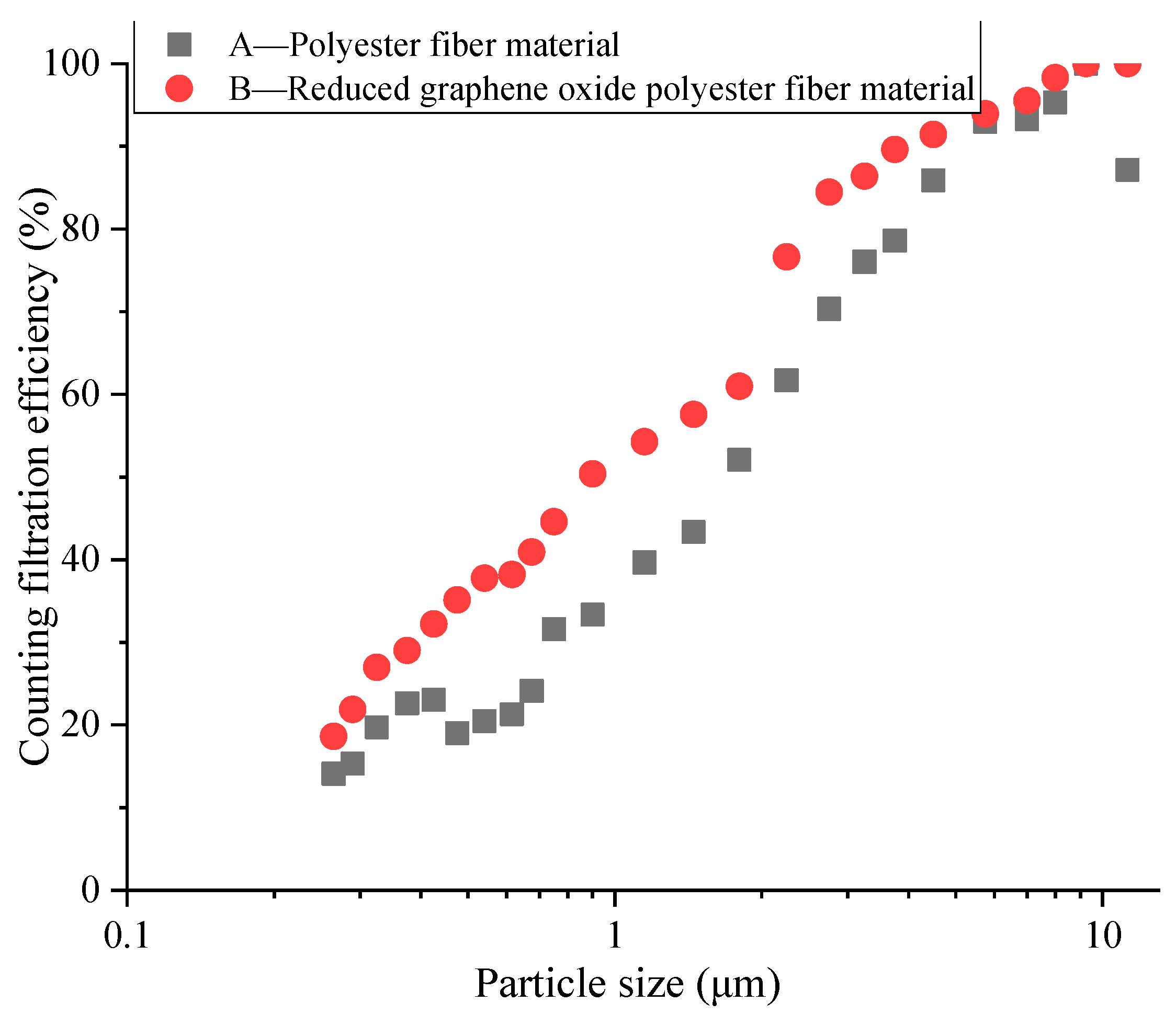

3.6. Influence of Voltage and Power on Time on Filtration Resistance

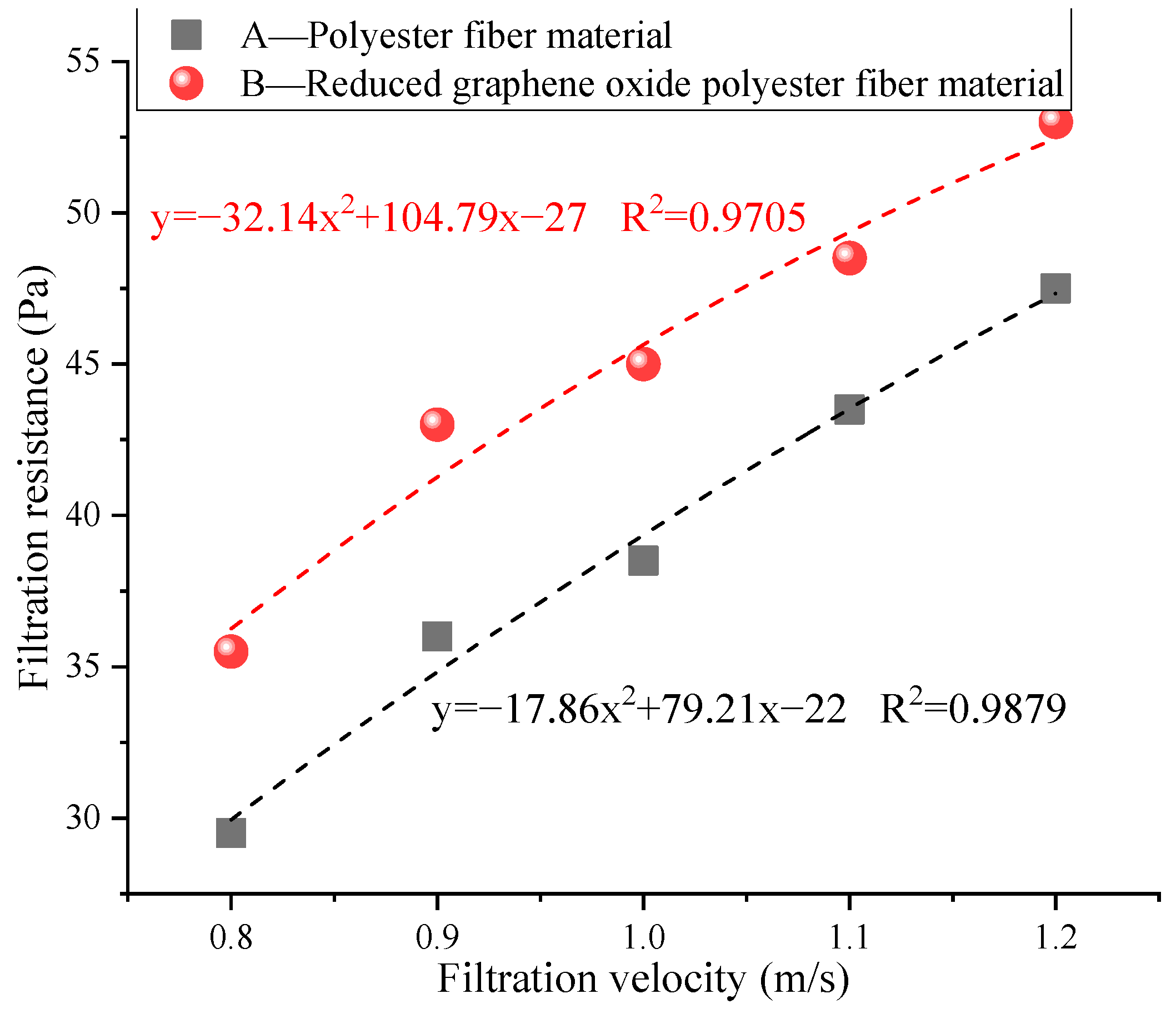

4. Conclusions

- The prepared reduced graphene oxide polyester fiber material improved the filtration efficiency of PM10, PM2.5, and PM1.0 by 5.6% to 7.3%, 4.7% to 7.8%, and 2.7% to 11.5%, respectively.

- The applied voltage was 4 V, and the new composite filter material had the highest weight filtration efficiency for the particulate matter, with filtration efficiencies of 71.3%, 45.3%, and 35.7% for PM10, PM2.5, and PM1.0.

- The filtration efficiency was the highest when the power on time was 80 s. At this time, the filtration efficiency of the filter material for PM10, PM2.5, and PM1.0 was 70.6%, 43.8%, and 35.3%.

- The new composite filter material had a significant lifting effect on particles with a diameter of 0–2.5 μm. It provides reference value for the research and application of new filtering materials.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wu, X.; Zhang, X.; Yu, X.; Liang, H.; Tang, S.; Wang, Y. Exploring the association between air pollution and the incidence of liver cancers. Ecotoxicol. Environ. Saf. 2025, 290, 117437. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.C.; Lin, Y.T.; Chen, C.R.; Lai, C.Y. Meteorological and traffic effects on air pollutants using Bayesian networks and deep learning. J. Environ. Sci. 2025, 152, 54–70. [Google Scholar] [CrossRef] [PubMed]

- Fan, H.; Zhao, C.; Yang, Y.; Yang, X. Rapid reduction of air pollution and short-term exposure risks in China. J. Environ. Sci. 2025, 149, 126–138. [Google Scholar] [CrossRef] [PubMed]

- Hilary, U.; Efeoghene, E.A.; Issac, A.O.; Sami, R.; Baakdah, F.; Pareek, S. Exposure to airborne pollutants in urban and rural areas: Levels of metals and microorganisms in PM10 and gaseous pollutants in ambient air. Air Qual. Atmos. Health 2024. [Google Scholar] [CrossRef]

- Nakhjirgan, P.; Kashani, H.; Kermani, M. Exposure to outdoor particulate matter and risk of respiratory diseases: A systematic review and meta-analysis. Environ. Geochem. Health 2024, 46, 20. [Google Scholar] [CrossRef]

- Sung, Y.Y.; Yang, W.K.; Kim, J.H.; Shin, D.; Son, S.J.; Kim, S.H. Reliea® combination of Codonopsis lanceolata and Chaenomeles sinensis extract alleviates airway inflammation on particulate matter 10 plus diesel exhaust particles (PM10D)-induced respiratory disease mouse model. Ecotoxicol. Environ. Saf. 2025, 290, 117538. [Google Scholar] [CrossRef]

- Hao, Y.; Xu, L.; Peng, M.; Yang, Z.; Wang, W.; Meng, F. Synergistic air pollution exposure elevates depression risk: A cohort study. Environ. Sci. Ecotechnology 2025, 23, 100515. [Google Scholar] [CrossRef]

- Amin, M.; Ramadhani, A.A.T.; Putri, R.M.; Auliani, R.; Torabi, S.E.; Hanami, Z.A.; Suryati, I.; Bachtiar, V.S. A review of particulate matter (PM) in Indonesia: Trends, health impact, challenges, and options. Environ. Monit. Assess. 2025, 197, 11. [Google Scholar] [CrossRef]

- Zhao, W.; Lestinen, S.; Kilpelainen, S.; Yuan, X.; Jokisalo, J.; Kosonen, R.; Guo, M. Exploring the potential to mitigate airborne transmission risks with convective and radiant cooling systems in an office. Build Environ. 2023, 245, 110936. [Google Scholar] [CrossRef]

- Hwang, S.H.; Won, J.; Park, W.M. Assessment of dust endotoxins, airborne bacteria, and PM2.5 at old-age nursing homes and children’s daycare centers in the Seoul metropolitan area, South Korea. Build Environ. 2025, 267, 112293. [Google Scholar] [CrossRef]

- Zacharias, N.; Haag, A.; Brang-Lamprecht, R.; Gebel, J.; Essert, S.M.; Kistemann, T.; Exner, M.; Mutters, N.T.; Engelhart, S. Air filtration as a tool for the reduction of viral aerosols. Sci. Total Environ. 2021, 772, 144956. [Google Scholar] [CrossRef] [PubMed]

- Berry, G.; Beckman, I.; Cho, H. A comprehensive review of particle loading models of fibrous air filters. J. Aerosol Sci. 2023, 167, 106078. [Google Scholar] [CrossRef]

- Zhang, X.; Ma, J.Y.; Wang, J.H.; Shi, H.X.; Guo, J.P.; Fan, Y.S.; Nie, X.X.; Guo, T.; Luo, X.X. Modifying the Fiber Structure and Filtration Performance of Polyester Materials Based on Two Different Preparation Methods. Langmuir 2023, 39, 3502–3511. [Google Scholar] [CrossRef]

- Chang, P.K.; Huang, S.H.; Chen, J.W.; Chun-Te Lin, J.; Hsiao, T.C. Submicron PAN and nanofiber CTA air filters: Fabrication, optimization, and performance. Sep. Purif. Technol. 2025, 352, 128111. [Google Scholar] [CrossRef]

- Ciorîță, A.; Suciu, M.; Coroş, M.; Varodi, C.; Pogăcean, F.; Măgeruşan, L.; Mirel, V.; Ștefan-van Staden, R.L.; Pruneanu, S. Antibacterial Enhancement of High-Efficiency Particulate Air Filters Modified with Graphene-Silver Hybrid Material. Microorganisms 2023, 11, 745. [Google Scholar] [CrossRef] [PubMed]

- Park, S.S.; Lee, Y.S.; Lee, S.W.; Repo, E.; Kim, T.H.; Park, Y.; Hwang, Y. Facile Surface Treatment of 3D-Printed PLA Filter for Enhanced Graphene Oxide Doping and Effective Removal of Cationic Dyes. Polymers 2023, 15, 269. [Google Scholar] [CrossRef]

- Cai, R.R.; Zhang, L.Z. Progress and perspective of polymer electret-based PM2.5 filtration: Efficiencies, regeneration, and energy implications. Energy 2023, 15, 128504. [Google Scholar] [CrossRef]

- Chen, M.; Zeng, Y.; Wang, H. PTFE foam coating ultrafine glass fiber composite filtration material with Ultra-Clean emissions. Sep. Purif. Technol. 2025, 352, 128219. [Google Scholar] [CrossRef]

- Wang, Y.; Li, J.; Wang, G.; Chen, G.; He, S. Prediction of diesel particulate filter regeneration conditions and diesel engine performance under regeneration mode using AMSO-BPNN and combined with XGBoost. Appl. Energ. 2025, 377, 124341. [Google Scholar] [CrossRef]

- Kwon, K.; Lee, Y.J.; Jung, Y.; Soltis, I.; Na, Y.; Romero, L.; Kim, M.C.; Rodeheaver, N.; Kim, H.; Lee, C.; et al. Smart filtering facepiece respirator with self-adaptive fit and wireless humidity monitoring. Biomaterials 2025, 314, 122866. [Google Scholar] [CrossRef]

- Moino, C.; Agostini, E.; Albano, A.; Bellini, M.; Bourlès, E.; Scutellà, B.; Boccardo, G.; Pisano, R. Analysis of the shear stresses in a filling line of parenteral products: The role of sterilizing filters. Sep. Purif. Technol. 2024, 344, 127248. [Google Scholar] [CrossRef]

- Bian, Y.; Niu, Z.L.; Wang, S.J.; Pan, Y.; Zhang, L.; Chen, C. Removal of Size-Dependent Submicron Particles Using Met-al−Organic Framework-Based Nanofiber Air Filters. ACS Appl. Mater. Interfaces 2022, 14, 23570–23576. [Google Scholar] [CrossRef] [PubMed]

- Zeng, Y.X.; Liu, Q.; Zhang, X.; Wang, Z.; Yu, T.; Ren, F.; He, P.C. Comparative Filtration Performance of Composite Air Filter Materials Synthesized Using Different Impregnated Porous Media. Materials 2023, 16, 4851. [Google Scholar] [CrossRef]

- Wang, M.-L.; Yu, D.-G.; Bligh, S.W.A. Progress in preparing electrospun Janus fibers and their applications. Appl. Mater. Today 2023, 31, 101766. [Google Scholar] [CrossRef]

- He, P.; Zhang, L.; Li, Y.; Xue, W.; Zhang, X. Differential Effects of Various Cleaning Solutions on the Cleaning and Regeneration Performance of Commonly Used Polyester Fiber Material Air Filters. Processes 2024, 12, 2703. [Google Scholar] [CrossRef]

- Gao, B.; Feng, X.; Zhang, Y.; Zhou, Z.; Wei, J.; Qiao, R.; Bi, F.; Liu, N.; Zhang, X. Graphene-based aerogels in water and air treatment: A review. Chem. Eng. J. 2024, 484, 149604. [Google Scholar] [CrossRef]

- Yang, M.; Yang, B.; Zhang, X.; Wu, S.S.; Yu, T.; Song, H.; Ren, F.; He, P.C.; Zhu, Y.H. Experimental Study of the Factors In-fluencing the Regeneration Performance of Reduced Graphite Oxide Filter Materials under Water Cleaning. Materials 2023, 16, 4033. [Google Scholar] [CrossRef]

- Kim, J.; Moon, D.; Kim, H.; van der Zande, A.M.; Lee, G.H. Ultrathin and Deformable Graphene Etch Mask for Fabrication of 3D Microstructures. ACS Nano 2024, 18, 12325–12332. [Google Scholar] [CrossRef]

- Rana, A.K.; Mostafavi, E.; Alsanie, W.F.; Siwal, S.S.; Thakur, V.K. Cellulose-based materials for air purification: A review. Ind. Crop. Prod. 2023, 194, 116331. [Google Scholar] [CrossRef]

- Sun, F.; Zhang, X.; Xue, T.; Cheng, P.; Yu, T. The Performance Testing and Analysis of Common New Filter Materials: A Case of Four Filter Materials. Materials 2024, 17, 2802. [Google Scholar] [CrossRef]

- EN 779; F7—Particulate Air Filters for General Ventilation—Classification. CEN: Brussels, Belgium, 2012.

- ISO9001; Quality Management Systems—Requirements. ISO: Geneva, Switzerland, 2015.

- Gao, Y.; Shi, H.; Zhang, X.; Ma, J.; Yu, T. Differences in Performance and Conductivity Persistence of New Reduced Graphene Oxide Air Filter Materials before and after Eliminating Static Electricity. Materials 2023, 16, 7146. [Google Scholar] [CrossRef] [PubMed]

- Song, H.; Dong, Y.H.; Yang, J.Y.; Zhang, X.; Nie, X.X.; Fan, Y.X. Concentration Characteristics and Correlations with Other Pollutants of Atmospheric Particulate Matter as Affected by Relevant Policies. Int. J. Environ. Res. Public Health 2023, 20, 1051. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Ma, J.; Nie, X.; Fan, Y.; Wang, H.; Cui, Y. Establishment of air fiber filtration model based on fractal theory and analysis of filtration performances. Mater. Today Commun. 2023, 34, 105301. [Google Scholar] [CrossRef]

- Rabiee, S.; Sohrabi, M.; Afarideh, H. Electrostatic surface potential stability of corona charged PTFE electret films by some parametric optimization for radiation protection dosimetry. J. Electrostat. 2025, 133, 104013. [Google Scholar] [CrossRef]

- Lin, X.; Sun, W.; Lin, M.; Chen, T.; Duan, K.; Lin, H.; Zhang, C.; Qi, H. Bicomponent core/sheath melt-blown fibers for air filtration with ultra-low resistance. RSC Adv. 2024, 14, 14100–14113. [Google Scholar] [CrossRef]

- Zhou, Z.Q.; You, T.; Wang, D.; Pan, Z.Y.; Xu, G.L.; Liang, Y.; Tang, M. Conformal Build-Up of Functionalized Air Filters with Improved Air Cleaning and Bioprotective Traps. Adv. Funct Mater. 2024, 34, 2306777. [Google Scholar] [CrossRef]

- Wu, S.; Ma, X.; Zhang, X.; Chen, J.; Yao, Y.; Li, D. Investigation into hydrogen induced fracture of cable bolts under deep stress corrosion coupling conditions. Tunn. Undergr. Space Technol. 2024, 147, 105729. [Google Scholar] [CrossRef]

- Liu, W.; Peng, X.; Liu, W.; Tong, K.; Shen, Y.; Zhao, Q.; Zhao, S.; Sun, W. Novel polyhydroxy cationic collector N-(2, 3-propanediol)-N-dodecylamine: Synthesis and flotation performance to hematite and quartz. Int. J. Min. Sci. Technol. 2023, 33, 115–122. [Google Scholar] [CrossRef]

- Wu, S.; Hao, W.; Yao, Y.; Li, D. Investigation into durability degradation and fracture of cable bolts through laboratorial tests and hydrogeochemical modelling in underground conditions. Tunn. Undergr. Space Technol. 2023, 138, 105198. [Google Scholar] [CrossRef]

- Wu, S.; Zhang, Z.; Chen, J.; Yao, Y.; Li, D. Characterisation of stress corrosion durability and time-dependent performance of cable bolts in underground mine environments. Eng. Fail Anal. 2023, 150, 107292. [Google Scholar] [CrossRef]

- Wu, S.; Li, J.; Guo, J.; Shi, G.; Gu, Q.; Lu, C. Stress corrosion cracking fracture mechanism of cold-drawn high-carbon cable bolts. Mater. Sci. Eng. A 2020, 769, 138479. [Google Scholar] [CrossRef]

| Type | Different Voltage Magnitudes (V) | Different Power on Time (s) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 2 | 4 | 6 | 8 | 0 | 40 | 80 | 120 | 160 | |

| Filtration resistance (Pa) | 48.5 | 50.5 | 49 | 51 | 50.5 | 48 | 46.5 | 47 | 49.5 | 50.5 |

| Average (Pa) | 49.9 | 48.3 | ||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sheng, X.; Yang, T.; Zhang, X.; Yu, T. Controllable Preparation and Electrically Enhanced Particle Filtration Performance of Reduced Graphene Oxide Polyester Fiber Materials in Public Buildings. Processes 2025, 13, 383. https://doi.org/10.3390/pr13020383

Sheng X, Yang T, Zhang X, Yu T. Controllable Preparation and Electrically Enhanced Particle Filtration Performance of Reduced Graphene Oxide Polyester Fiber Materials in Public Buildings. Processes. 2025; 13(2):383. https://doi.org/10.3390/pr13020383

Chicago/Turabian StyleSheng, Xiaolei, Tuo Yang, Xin Zhang, and Tao Yu. 2025. "Controllable Preparation and Electrically Enhanced Particle Filtration Performance of Reduced Graphene Oxide Polyester Fiber Materials in Public Buildings" Processes 13, no. 2: 383. https://doi.org/10.3390/pr13020383

APA StyleSheng, X., Yang, T., Zhang, X., & Yu, T. (2025). Controllable Preparation and Electrically Enhanced Particle Filtration Performance of Reduced Graphene Oxide Polyester Fiber Materials in Public Buildings. Processes, 13(2), 383. https://doi.org/10.3390/pr13020383