Production, Characterization Physical, Chemical, and Structural Analysis of Biochar Fines for Bio-Reinforcement in Composite Materials

Abstract

1. Introduction

2. Materials and Methods

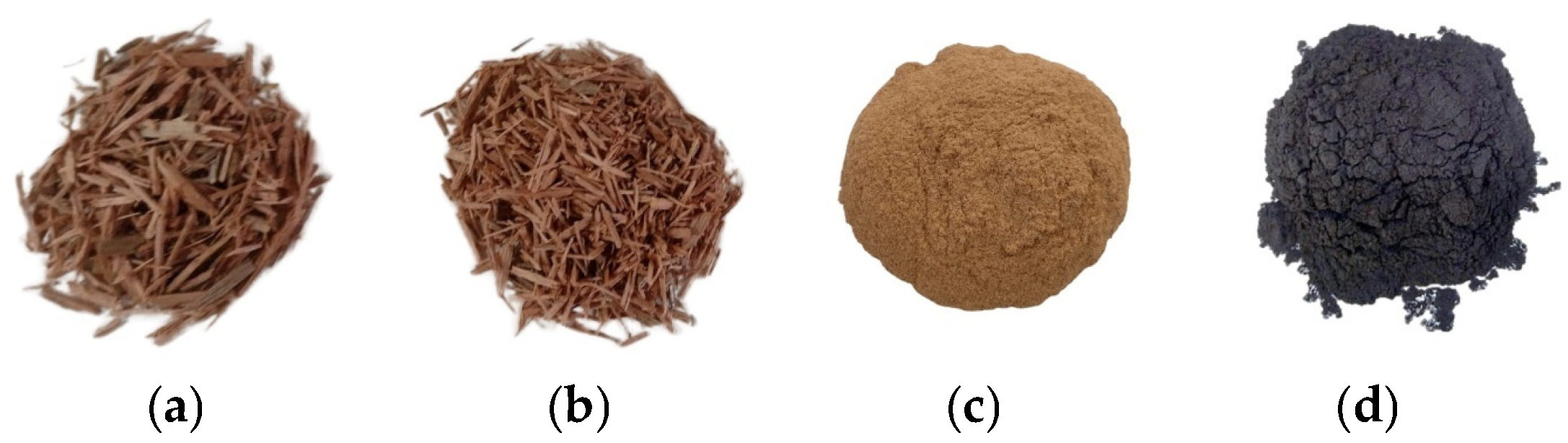

2.1. Production of Biochar Fines

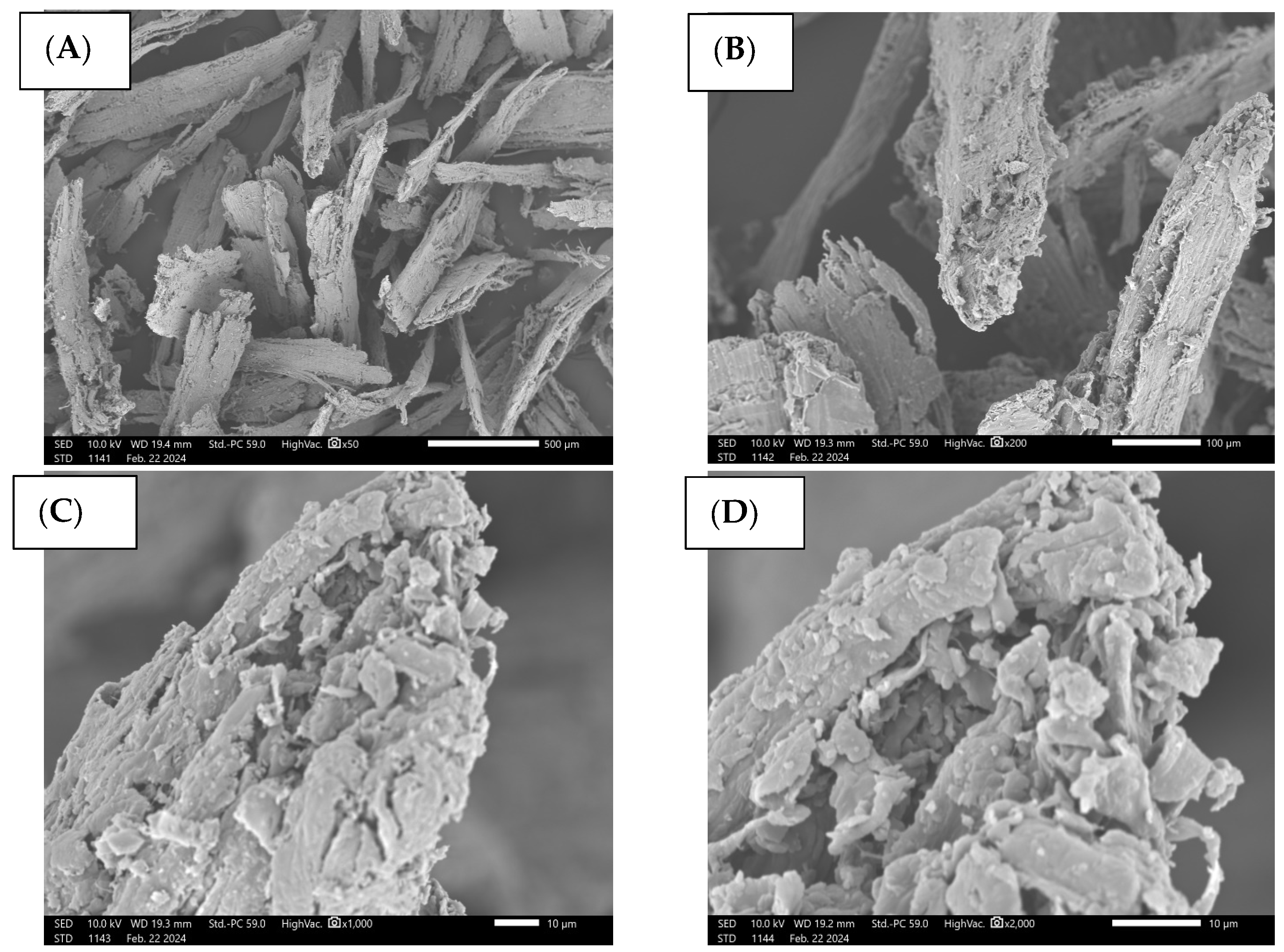

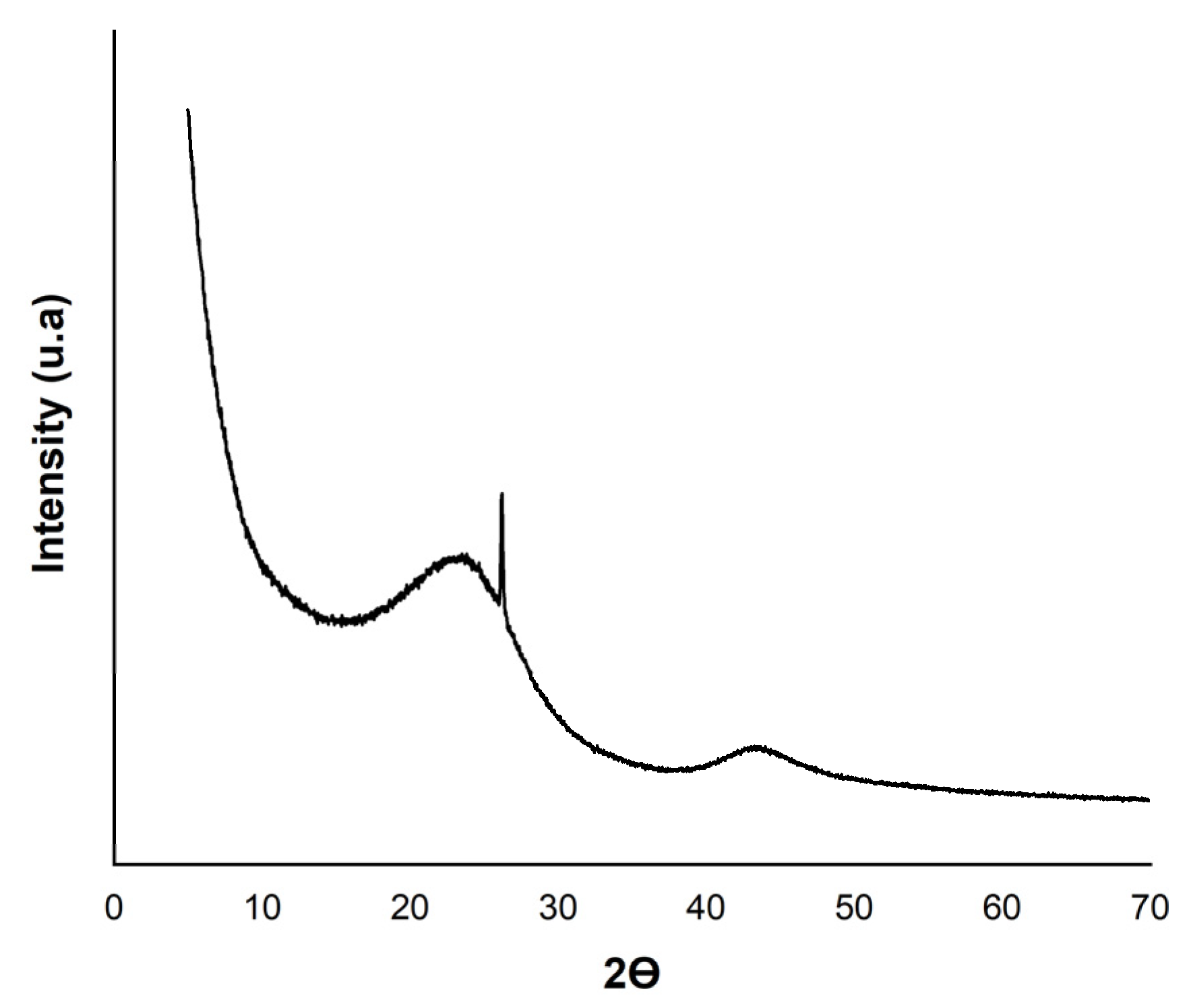

2.2. Characterization of Biochar Fines

3. Results

4. Conclusions

- The high fixed carbon content present in the biochar fines significantly contributes to the increased strength and thermal stability of the composites.

- The thermal resistance of the material is a crucial factor that broadens the applicability of composites, making them suitable for high-temperature environments.

- The biodegradable nature of biochar fines contributes to reducing the environmental impact of composites that utilize synthetic reinforcements, as it facilitates their natural decomposition and minimizes waste generation.

- The experimental data support the hypothesis that coal fines can be utilized as bio-reinforcement, contributing to the development of composite materials with enhanced mechanical properties and reduced environmental impact.

- This research opens new perspectives for the utilization of an industrial byproduct, promoting circular economy and sustainability. However, for the full exploration of the potential of biochar as a bio-reinforcement, more in-depth studies are essential regarding the optimization of the pyrolysis process and the characterization of the interfaces between the biochar and the polymeric matrix.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Das, S.C.; Ashek-E-Khoda, S.; Sayeed, M.A.; Paul, D.; Dhar, S.A.; Grammatikos, S.A. On the use of wood charcoal filler to improve the properties of natural fiber reinforced polymer composites. Mater. Today Proc. 2021, 44, 926–929. [Google Scholar] [CrossRef]

- Akaluzia, R.O.; Edoziuno, F.O.; Adediran, A.A.; Odoni, B.U.; Edibo, S.; Olayanju, T.M.A. Evaluation of the effect of reinforcement particle sizes on the impact and hardness properties of hardwood charcoal particulate-polyester resin composites. Mater. Today Proc. 2021, 38, 570–577. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Syamsir, A.; Ishak, M.R.; Sapuan, S.M.; Nurazzi, N.M.; Norrrahim, M.N.F.; Ilyas, R.A.; Khan, T.; Rashid, M.Z.A. Mechanical Properties of Hybrid Lignocellulosic Fiber-Reinforced Biopolymer Green Composites: A Review. Fibers Polym. 2023, 24, 337–353. [Google Scholar] [CrossRef]

- Indústria Brasileira de Árvores (IBÁ). Relatório Atual 2023. Available online: https://www.iba.org/publicacoes (accessed on 15 August 2024).

- Delatorre, F.M.; Cupertino, G.F.M.; Silva, Á.M.; Santos Junior, A.J.; Mesquita, J.G.; Júnior, A.F.D. Potencial energético dos finos de carvão vegetal. Ed. Científica Digit. 2020, 1, 639–653. [Google Scholar]

- Dias Júnior, A.F.; Pirola, L.P.; Takeshyta, S.; Lana, A.Q.; Brito, J.O.; Andrade, A.M. Higroscopicity of charcoal produced in different temperatures. Cerne 2016, 22, 423–430. [Google Scholar] [CrossRef]

- Li, S.; Li, X.; Deng, Q.; Li, D. Three kinds of charcoal powder reinforced ultra-high molecular weight polyethylene composites with excellent mechanical and electrical properties. Mater. Des. 2015, 85, 54–59. [Google Scholar] [CrossRef]

- Polok-Rubiniec, M.; Włodarczyk-Fligier, A. Polypropylene matrix composite with charcoal filler. J. Achiev. Mater. Manuf. Eng. 2020, 103, 60–66. [Google Scholar] [CrossRef]

- Das, O.; Sarmah, A.K.; Bhattacharyya, D. Biocomposites from Waste Derived Biochars: Mechanical, Thermal, Chemical, and Morphological Properties. Waste Manag. 2016, 49, 560–570. [Google Scholar] [CrossRef]

- Batista, E.M.C.C.; Shultz, J.; Matos, T.T.S.; Fornari, M.R.; Ferreira, T.M.; Szpoganicz, B.; de Freitas, R.A.; Mangrich, A.S. Effect of Surface and Porosity of Biochar on Water Holding Capacity Aiming Indirectly at Preservation of the Amazon Biome. Sci. Rep. 2018, 8, 10677. [Google Scholar] [CrossRef] [PubMed]

- Delatorre, F.M.; Cupertino, G.F.M.; Oliveira, M.P.; Gomes, F.S.; Profeti, L.P.R.; Profeti, D.; Dias Júnior, A.F. A novel approach to charcoal fine waste: Sustainable use as filling of polymeric matrices. Polymers 2022, 14, 5525. [Google Scholar] [CrossRef] [PubMed]

- Ren, Y.; Zhang, D.; Yin, Y.; Ye, Z.; Yin, Z.; Tu, S.; Zhao, S. Mechanically strong, thermostable, and flame-retardant composites enabled by Brown paper made from bamboo. Compos. Sci. Technol. 2022, 226, 109544. [Google Scholar] [CrossRef]

- Li, C.; Liao, H.; Gao, H.; Zhang, H.; Cheng, F. A facile green and cost-effective manufacturing process from coal gangue-reinforced composites. Compos. Sci. Technol. 2023, 233, 109908. [Google Scholar] [CrossRef]

- Dias Junior, A.F.; Esteves, R.P.; Silva, A.M.; Sousa Júnior, A.D.; Oliveira, M.P.; Brito, J.O.; Braga, B.M. Investigating the pyrolysis temperature to define the use of charcoal. Eur. J. Wood Wood Prod. 2020, 78, 193–204. [Google Scholar] [CrossRef]

- Kumar, R.; Gunjal, J.; Chauhan, S. Effect of carbonization temperature on properties of natural fiber and charcoal filled hybrid polymer composite. Compos. Part B Eng. 2021, 217, 108846. [Google Scholar] [CrossRef]

- Zhiwei Wang, K.G.; Burra, T.; Lei, A.K. Gupta. Co-pyrolysis of waste plastic and solid biomass for synergistic production of biofuels and chemicals-A review. Prog. Energy Combust. Science 2021, 84, 100899. [Google Scholar] [CrossRef]

- ABNT NBR 11941; Wood—Determination of Basic Density. Brazilian National Standards Organization: Rio de Janeiro, Brazil, 2003.

- ABNT NBR 9165; Carvão Vegetal: Determinação da Densidade Relativa Aparente, Relativa Verdadeira e Porosidade—Método de Ensaio. Brazilian National Standards Organization: Rio de Janeiro, Brazil, 1985.

- ASTM D 1762-84; Standard Method for Chemical Analyses of Wood Charcoal. American Society for Testing and Materials, ASTM: Conshohocken, PA, USA, 2021; p. 1042.

- Delatorre, F.M.; Pereira, A.K.S.; Silva, Á.M.; Souza, E.C.; Oliveira, M.P.; Profeti, D.; Dias Júnior, A.F. The addition of charcoal fines can increase the photodegradation resistance of polymeric biocomposites. Environ. Sci. Proc. 2021, 13, 8. [Google Scholar] [CrossRef]

- Loureiro, B.A.; Vieira, T.A.S.; Costa, L.J.; Silva, A.B.; Assis, M.R.D.; Trugilho, P.F. Selection of superior clones of Corymbia hybrids based on wood and charcoal properties. Maderas Cienc. Tecnol. 2019, 21, 619–630. [Google Scholar] [CrossRef]

- Ho, M.P.; Lau, K.T.; Wang, H.; Hui, D. Improvement on the Properties of Polylactic Acid (PLA) Using Bamboo Charcoal Particles. Compos. B Eng. 2015, 81, 14–25. [Google Scholar] [CrossRef]

- Assis, M.R.; Brancheriau, L.; Napoli, A.; Trugilho, P.F. Factors affecting the mechanics of carbonized wood: Literature review. Wood Sci. Technol. 2016, 50, 519–536. [Google Scholar] [CrossRef]

- Botrel, M.C.G.; Trugilho, P.F.; Rosado, S.C.S.; Silva, J.R.M. Melhoramento genético das propriedades do carvão vegetal de Eucalyptus. Rev. Árvore 2007, 31, 391–398. [Google Scholar] [CrossRef]

- Neves, T.A.; Protásio, T.P.; Couto, A.M.; Trugilho, P.F.; Silva, V.O.; Vieira, C.M.M. Avaliação de clones de Eucalyptus em diferentes locais visando à produção de carvão vegetal. Pesqui. Florest. Bras. 2011, 31, 319–330. [Google Scholar] [CrossRef]

- Souza, N.D.; Amodei, J.B.; Xavier, C.N.; Dias Júnior, A.F.; Carvalho, A.M.D. Estudo de caso de uma planta de carbonização: Avaliação de características e qualidade do carvão vegetal visando uso siderúrgico. Floresta Ambiente 2016, 23, 270–277. [Google Scholar] [CrossRef]

- Dufourny, A.; Van De Steene, L.; Humbert, G.; Guibal, D.; Martin, L.; Blin, J. Influence of pyrolysis conditions and the nature of the wood on the quality of charcoal as a 34 reducing agent. J. Anal. Appl. Pyrolysis 2019, 137, 1–13. [Google Scholar] [CrossRef]

- Mangrich, A.S.; Maia, C.M.B.F.; Novotny, E.H. Biocarvão: As terras pretas de índios e o sequestro de carbono. Ciência Hoje 2011, 281, 48–52. [Google Scholar]

- Trugilho, P.F.; da Silva, J.R.M.; Mori, F.A.; Lima, J.T.; Mendes, L.M.; de Barros Mendes, L.F. Rendimentos e características do carvão vegetal em função da posição radial de amostragem em clones de Eucalyptus. Cerne 2005, 11, 178–186. [Google Scholar]

- Mullani, N.; Ali, I.; Dongale, T.D.; Kim, G.H.; Choi, B.J.; Basit, M.A.; Park, T.J. Comportamento de comutação resistiva aprimorado de filme composto de nanotubos de carbono de paredes múltiplas/nanorods de TiO2 por reservatório de vacância de oxigênio aumentado. Mater. Sci. Semicond. Process. 2020, 108, 104907. [Google Scholar] [CrossRef]

- Gomes, F.S. Investigando a Temperatura de Pirólise e o Carvão Vegetal. Masters Thesis, Universidade Federal do Espírito Santo, Vitória, Brazil, 2019. [Google Scholar]

- Li, C.; Liao, H.; Gao, H.; Cheng, F. Effect of fixed carbon on the interfacial compatibility of coal gangue/polyethylene composites was investigated using anthracite as a model compound. Polym. Compos. 2024, 45, 8601–8612. [Google Scholar] [CrossRef]

- Martins, A.F.; Diniz, J.; Stahl, J.A.; Cardoso, A.D.L. Characterization of liquid products and char from the pyrolysis of eucalyptus sawdust. Química Nova 2007, 30, 873–878. [Google Scholar] [CrossRef]

- Ayrilmis, N.; Kwon, J.H.; Han, T.H.; Durmus, A. Effect of wood-derived charcoal content on properties of wood plastic composites. Mater. Res. 2015, 18, 654–659. [Google Scholar] [CrossRef]

- IUPAC. International Union of Pure and Applied Chemistry, 2011. Available online: https://iupac.org/ (accessed on 28 September 2024).

- Lee, S.H.; Kang, D.S.; Lee, S.M.; Roh, J.S. X-ray diffraction analysis of the effect of ball milling time on crystallinity of milled polyacrylonitrile-based carbon fiber. Carbon Lett. 2018, 26, 11–17. [Google Scholar]

- Fernandes, B.C.C.; Mendes, K.F.; Dias Júnior, A.F.; Caldeira, V.P.S.; Teófilo, T.M.S.; Silva, T.S.; Silva, D.V. Impact of pyrolysis temperature on the properties of eucalyptus wood-derived biochar. Materials 2020, 13, 5841. [Google Scholar] [CrossRef]

| Pyrolysis | GCV (%) |

|---|---|

| 1 | 29.20 |

| 2 | 27.35 |

| Mean | 28.27 |

| CVe | 4.63 |

| Repetitions | Apparent Density (kg/m3) | True Density (kg/m3) |

|---|---|---|

| 1 | 324 | 1278.3 |

| 2 | 300 | 998.1 |

| 3 | 296 | 1323.5 |

| 4 | 308 | 1194.8 |

| 5 | 304 | 1174.4 |

| Mean | 306.4 | 1193.82 |

| Standard deviation | 10.807 | 125.138 |

| Coefficient of variation | 3.527 | 10.482 |

| Repetitions | Volatile Matter Content (%) | Ash Content (%) | Fixed Carbon Content (%) |

|---|---|---|---|

| 1 | 10.66 | 0.25 | 89.09 |

| 2 | 10.48 | 0.05 | 89.47 |

| 3 | 9.51 | 0.11 | 90.38 |

| 4 | 12.93 | 0.15 | 86.92 |

| 5 | 10.87 | 0.61 | 88.52 |

| Mean | 10.89 | 0.23 | 88.87 |

| Standard deviation | 1.25 | 0.22 | 1.28 |

| Coefficient of variation | 11.49 | 95.08 | 1.44 |

| Average Pore Diameter (nm) | Surface Area (m2·g−1) | Total Pore Volume (m3·g−1) |

|---|---|---|

| 2.374 ± (0.683) | 293.136 ± (36.68) | 0.174 ± (0.0254) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dias, J.; Conceição, A.; Delatorre, F.M.; Siqueira, P. Production, Characterization Physical, Chemical, and Structural Analysis of Biochar Fines for Bio-Reinforcement in Composite Materials. Processes 2025, 13, 504. https://doi.org/10.3390/pr13020504

Dias J, Conceição A, Delatorre FM, Siqueira P. Production, Characterization Physical, Chemical, and Structural Analysis of Biochar Fines for Bio-Reinforcement in Composite Materials. Processes. 2025; 13(2):504. https://doi.org/10.3390/pr13020504

Chicago/Turabian StyleDias, Josinaldo, Amanda Conceição, Fabíola Martins Delatorre, and Paula Siqueira. 2025. "Production, Characterization Physical, Chemical, and Structural Analysis of Biochar Fines for Bio-Reinforcement in Composite Materials" Processes 13, no. 2: 504. https://doi.org/10.3390/pr13020504

APA StyleDias, J., Conceição, A., Delatorre, F. M., & Siqueira, P. (2025). Production, Characterization Physical, Chemical, and Structural Analysis of Biochar Fines for Bio-Reinforcement in Composite Materials. Processes, 13(2), 504. https://doi.org/10.3390/pr13020504