Abstract

Improving user-level energy efficiency is critical for reducing the load on the power grid and addressing the challenges created by tight power balance when operating domestic air conditioning equipment under time-of-use (ToU) pricing. This paper presents a data-driven control method for HVAC (heating, ventilation, and air conditioning) systems that is based on model predictive control (MPC) and takes ToU electricity pricing into account. To describe building thermal dynamics, a multi-layer neural network is constructed using time-delayed embedding, with the rectified linear unit (ReLU) serving as the activation function for hidden layers. Using this piecewise affine approximation, an optimization model is developed within a receding horizon control framework, integrating the data-driven model and transforming it into a mixed-integer linear programming issue for efficient problem solving. Furthermore, this research suggests a hybrid optimization model for integrating air conditioning systems and battery energy storage systems. By employing a rolling time-domain control method, the proposed model minimizes the frequency of switching between charging and discharging states of the battery energy storage system, improving system reliability and efficiency. An Internet of Things (IoT)-based home energy management system is developed and validated in a real laboratory environment, complemented by a distributed integration solution for the energy management monitoring platform and other essential components. The simulation results and field measurements demonstrate the system’s effectiveness, revealing discernible pre-cooling and pre-charging behaviors prior to peak electricity pricing periods. This cooperative economic operation reduces electricity expenses by 13% compared to standalone operation.

1. Introduction

China’s need for electricity has steadily increased in recent years because of the country’s economic expansion, and the construction sector’s explosive growth has further taxed the country’s electrical grid. Building-integrated HVAC systems are essential for regulating internal temperatures and creating cozy areas. According to statistics, the structures generated 2.2 billion tons of carbon emissions during its active phase, 1.15 billion tons of which were attributable to energy use. It is interesting to note that just heating, ventilation, and air conditioning systems contributed almost 990 million tons of dangerous pollutants [1], or more than 45% of the total. Furthermore, the power system is significantly impacted by the seasonal energy consumption patterns of air conditioning loads, which makes it difficult to maintain supply–demand balance, especially in extreme weather. Improving the energy efficiency of HVAC systems and promoting orderly power consumption at times of high grid load are essential to meeting the growing demand for air cooling and guaranteeing the safe and stable functioning of urban power grids [2]. To promote energy-saving practices during times of heavy load, lower electricity consumption, and ease the strain on the power grid’s supply, major Chinese provinces started enacting time-of-use electricity pricing regulations in 2021 [3]. Because of their adaptable load characteristics, air conditioners may dynamically modify their operating points in response to variations in the surrounding temperature and indoor comfort requirements. They give the power grid flexible resources while utilizing buildings’ thermal storage capacity to adjust to time-of-use electricity rates. Indirectly, this flexibility encourages the use and consumption of renewable energy.

For distributed energy storage systems, time-of-use electricity pricing encourages multiple daily charge–discharge cycles, utilizing peak–valley price differences for economic benefits. However, most current air conditioning systems rely on 0–1 switch control or PID control strategies, which lack predictive energy management capabilities to adapt to environmental changes dynamically. Model Predictive Control (MPC) has been widely adopted in recent studies to address these limitations by combining system response characteristics with operational constraints, enabling dynamic trajectory planning for system operations and improving overall system performance [4]. For instance, reference [5] proposes an MPC-based control method for building HVAC systems that accounts for the impact of different thermal characteristics of building envelopes on control effectiveness. Reference [6] introduces a distribution network optimization model integrating HVAC clusters, utilizing flexible building loads to mitigate grid-side voltage fluctuations. Additionally, references [7,8] incorporate artificial neural networks into MPC frameworks to enhance prediction accuracy and control performance, demonstrating the potential for improved energy management and operational efficiency.

In this paper, the neural network is stimulated by a neural human system and used in different areas like optimization, control, pattern recognition, etc. The neural network stems from several processing units and guides the links between them [9]. A ReLU-based neural network is proposed to model the thermal dynamics of residential buildings. Unlike traditional approaches that rely on RC models or black-box neural networks, the ReLU network efficiently predicts future indoor temperatures with high accuracy by leveraging time-delayed embeddings and periodic features. Its piecewise linear affine nature allows it to be seamlessly integrated into the optimization framework, replacing traditional predictive models. This enables more precise modeling of building thermal behavior under dynamic time-of-use electricity pricing. By combining the ReLU network with a rolling time-domain optimization framework, the proposed method significantly enhances the predictive capabilities of household energy systems, optimizing both energy consumption and economic benefits.

Most of the above studies focus on commercial buildings. For residential buildings, their heat storage capacity is limited, and the air conditioning equipment is not capable of independently participating in the demand-side response. Generally, it is necessary to consider air conditioning clusters in residential buildings [10] or to operate them in conjunction with other equipment. Most modern smart buildings are equipped with battery energy storage systems (BESS), such as uninterrupted power supplies (UPS) or battery energy storage devices coupled with rooftop photovoltaics. Considering the low utilization rate of such equipment [11], the combined operation of battery energy storage and air conditioning systems can further increase the flexibility of regulation and improve the economic operation capacity of building operations. The composite system consisting of air conditioning and battery energy storage can effectively suppress the frequent purchase of electricity from the power grid during peak electricity price periods and use the characteristics of electricity price changes over time to reduce household electricity bills. Currently, the optimization of HVAC systems and battery energy storage equipment primarily focuses on modeling and algorithm development. Reference [2] proposed a building energy management model integrating HVAC systems and battery energy storage, conducting simulation analysis using Energy Plus. The results highlighted the benefits of the joint optimization of air conditioning and battery energy storage. Reference [12] examined the joint optimization strategy for building air conditioning, photovoltaics, and thermal and electrical energy storage in a grid demand-side response scenario. They introduced a two-step optimization framework to address the model’s feasibility under uncertainty, with simulation verification conducted using Energy Plus. Reference [13] explored the economic Model Predictive Control (MPC) strategy for complex residential energy systems, utilizing distributed algorithms to enable fast online optimization. Reference [14] assessed the support capacity of rooftop photovoltaics and associated energy storage for household air conditioning loads. Reference [15] proposed an intelligent management and control platform for HVAC systems based on big data and the Internet of Things (IoT).

However, most of these studies rely on simulation analysis, with limited empirical research and application of control strategies. While the literature [16,17] presents field test results for intelligent HVAC control, there is a lack of studies on the actual optimization of battery air conditioning systems in home scenarios. Although simulation analysis can offer insights into the control model’s effectiveness, the absence of real system operation data makes it challenging to validate the economic feasibility of costly energy storage equipment. This leads to skepticism among users about leveraging existing energy storage capacity to enhance building operational flexibility.

The optimum control of air conditioning systems and battery energy storage devices is the main topic of this study, which focuses on the energy management of household energy systems. In a rolling time-domain framework, it presents a joint optimization operation model that incorporates equipment start/stop time limitations. The optimization approach is created, implemented, and assessed using Hubei Province’s real time-of-use electricity price. A system implementation solution is also suggested in the article, which includes various temperature sensors, low-voltage energy storage devices, outdoor temperature forecasting services, and house air conditioning systems. A B2G (Building to Grid) intelligent energy management and control platform for residential energy systems is created using the Internet of Things. The effectiveness of the suggested approach and system is confirmed by test results from real-world situations, which show that the air conditioner can efficiently pre-cool and pre-charge while preserving indoor comfort. This lowers peak electricity consumption and, in turn, lowers household electricity costs. Under combined optimization operation, the air conditioning-battery energy storage system’s economic performance improves by more than 10% when compared to the conventional independent operating mode of air conditioning.

This study introduces a novel approach to optimizing the operation of household air conditioning systems and battery energy storage under time-of-use (ToU) electricity pricing. Unlike existing works that focus on individual components, this research emphasizes their integrated operation to enhance energy efficiency and economic performance. A ReLU-based neural network is employed to model building thermal dynamics, providing a highly accurate and computationally efficient prediction framework seamlessly integrated into a rolling time-domain Model Predictive Control (MPC) optimization strategy. The proposed system is implemented and validated through an IoT-based energy management platform, which bridges the gap between theoretical models and real-world applications. Experimental validation in a laboratory setting demonstrates the system’s ability to achieve significant cost savings, improve operational flexibility, and maintain indoor comfort, addressing a critical gap in residential energy management research.

2. Optimize Model Construction

When an air conditioning system and battery energy storage equipment operate jointly, the battery energy storage can charge from the grid during low electricity price periods, reducing the electricity demand from the air conditioner when electricity prices are high. Simultaneously, the air conditioning system can utilize the building’s thermal storage capacity to pre-cool or pre-heat the indoor environment. This strategy helps avoid significant energy consumption during peak electricity price periods, effectively reducing the overall operating cost of the system. To optimize the energy management of household air conditioning systems and energy storage equipment and consider the time-of-use (TOU) electricity pricing structure of the power grid, an optimization model is constructed within a rolling time domain control framework, as presented in Equations (1)–(9). Table 1 outlines the description of the variables and parameters used in the model. Here, t represents the current time and k represents the Kth time step after the current moment.

Table 1.

Model parameter description.

2.1. Objective Function

Household power expenses, battery energy storage system operating and maintenance costs, and battery degradation costs are all combined into the optimization model’s objective function. The goal of this design is to thoroughly assess the battery energy storage system’s economic cost throughout the course of its whole life cycle [18].

where indicates the household’s electricity purchase power, the electricity purchase cost is based on the time-of-use electricity price , represents the unit operating cost of battery energy storage, and represents the unit degradation cost coefficient of battery energy storage, which is used to measure the economic loss caused by each unit energy charge and discharge cycle to the battery life. Formula (3) normalizes the battery’s cycle life and divides the total energy into the energy extracted/consumed during each charge and discharge, where is the electric power when the air conditioner is running, assumed to be a constant value and and represent the state quantity of air conditioner heating and cooling. When the air conditioner starts heating or cooling, its value is 1, and when it stops, it value is 0. and are the charging and discharging powers of battery energy storage; , , and are the maximum, minimum, and rated values of the battery energy storage during operation; R is the life cycle cost; and LN is the total cycle life. The model distributes the battery’s full life cycle cost R evenly to each charge and discharge cycle and can calculate the degradation cost of each cycle, thereby quantifying the battery degradation process as an economic cost.

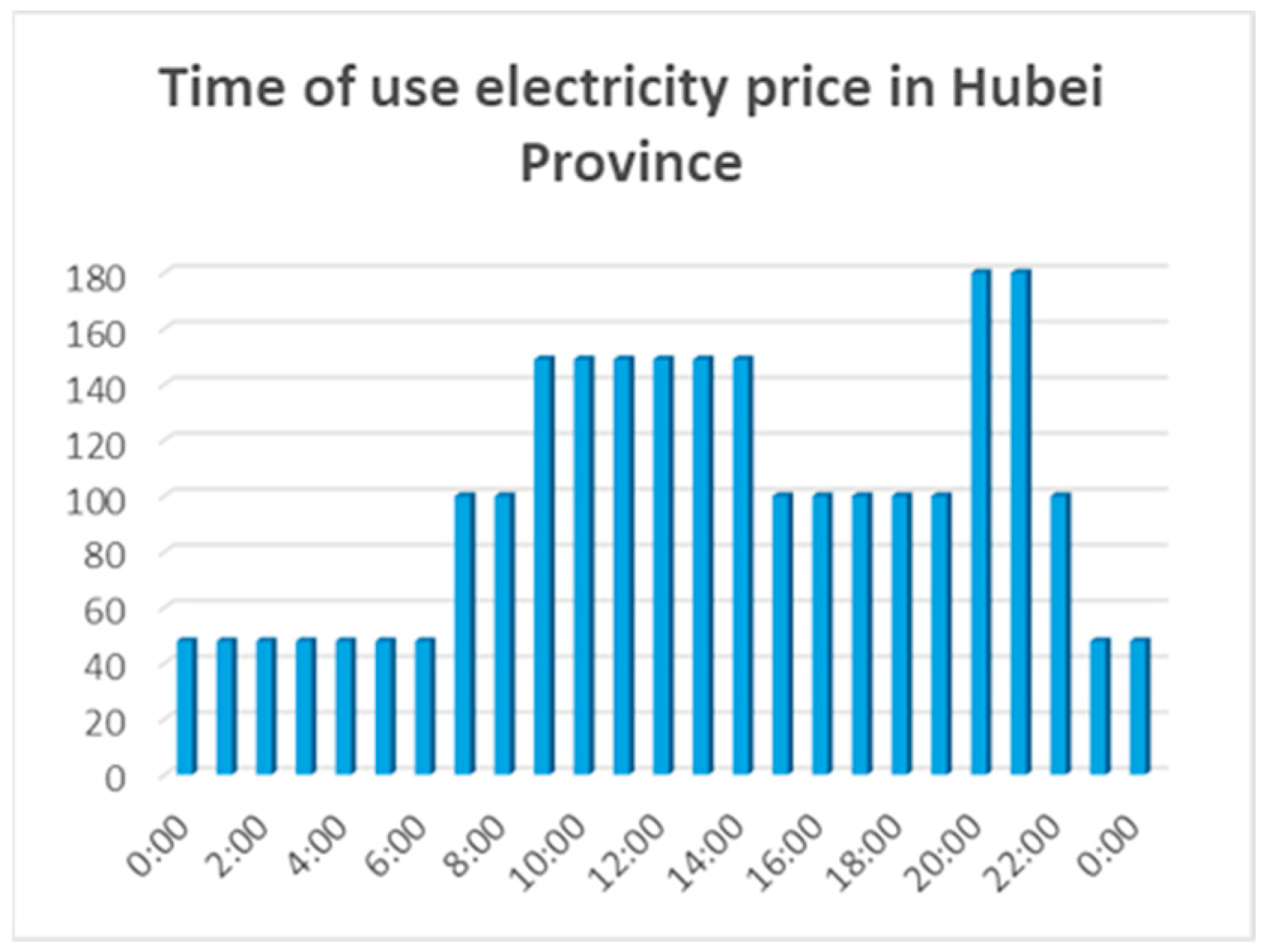

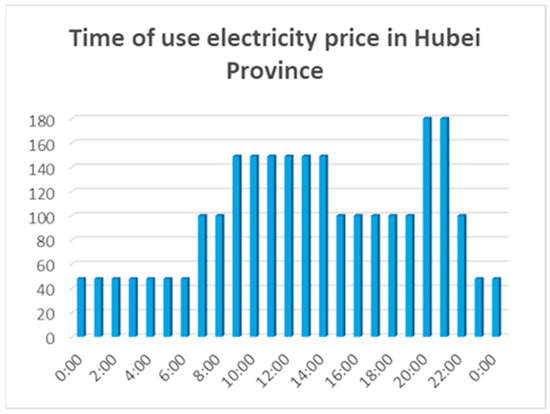

In this paper, actual time-of-use power price data in Hubei Province are analyzed with a focus on residential consumers with high electricity use. Table 2 displays the electricity costs for peak, valley, peak, and flat periods. The basic electricity price is 0.86 yuan/kWh, which is the usual electricity fee for groups in Hubei Province that consume a lot of power between 2020 and 2022 [19].

Table 2.

Time-of-use electricity price in Hubei Province.

2.2. Constraints

2.2.1. Air Conditioning System

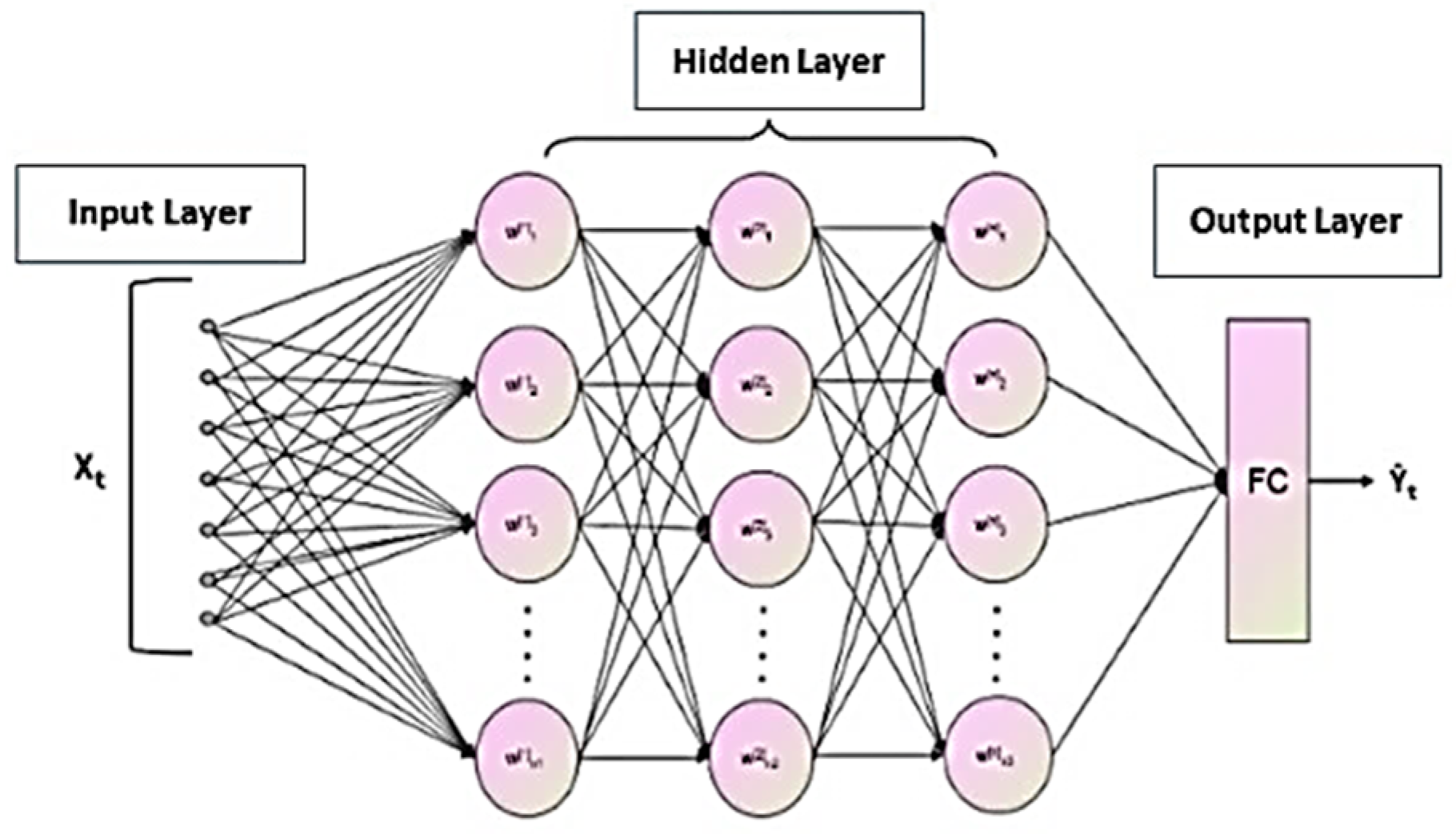

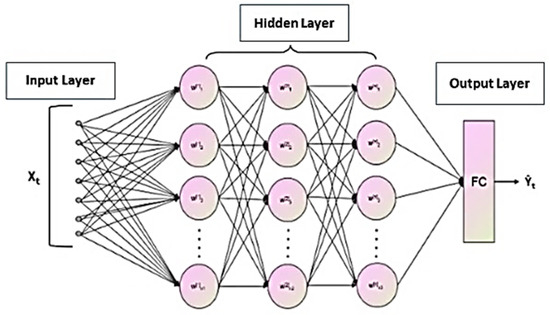

The thermal dynamics of a building involve heat exchange between various media, which traditional mechanism models with unknown parameters often struggle to capture accurately, particularly for multi-step temperature predictions. To address this, this paper employs a multi-layer neural network to model the building’s thermal dynamics, replacing traditional approaches. The neural network architecture is depicted in Figure 1, with the Rectified Linear Unit (ReLU) function serving as the activation function for the hidden layer neurons. Compared to commonly used activation functions such as Sigmoid and Tanh, ReLU networks are easier to train and exhibit greater robustness, particularly in high-dimensional optimization problems [20]. The output layer utilizes a Fully Connected (FC) layer to linearly map the hidden layer outputs to the desired target dimension, providing accurate multi-step predictions for the indoor temperature.

Figure 1.

Architecture of multi-layer ReLU network.

To accurately anticipate room temperature across a future W-step horizon, time-delayed embedding is used to create input features. The ReLU network’s inputs and outputs are as follows:

where represents the predicted indoor temperature at the next step, represents the neural network function represented by the ReLU activation mechanism, represents the input feature vector at time step k, which includes measured indoor temperatures , future outdoor temperatures , and air conditioning states , and represents the neural network parameters (weights and biases) [21,22].

In addition to the indoor and outdoor temperatures and the 0–1 state of the air conditioner, the time features are introduced into the feature vector to capture the periodic changes in the system [23].

The operating constraints of the air conditioning system are as follows:

The ReLU network produces the anticipated future indoor temperature, eliminating signals such as wall and window temperatures, which are not directly managed. The ReLU network functions as a piecewise linear affine system, which is theoretically represented as follows:

The input layer:

The hidden layer:

where and represent weight and bias for the i-th hidden layer max and (⋅,0) represents the ReLU activation function.

The output layer:

where (, ) represent the weight and bias for the fully connected layer. We select the Mean Squared Error (MSE) as the loss function [23,24].

where N is the number of training samples and is the predicted output of the ReLU network for sample n. is the actual system output for sample n, and the loss function represents the error between the output of the ReLU network and the actual output of the system. The training of the ReLU network uses the ADAM algorithm, which is suitable for large amounts of data and shows better performance in optimization problems with high feature dimensions [25,26].

By using the real time-of-use electricity costs in Hubei Province as an example, this article states that the basic electricity price is 0.86 yuan/kWh, and the prices for electricity during peak, valley, peak, and flat times are displayed in Table 1. The 24 h peak and valley electricity price in Hubei province is shown in Figure 2. Furthermore, the price of electricity sales is taken to be fixed at 1.1 yuan/kWh [27].

Figure 2.

Time of electricity use in Hubei Province.

2.2.2. Optimizing Battery Storage Systems

The battery energy storage system comprises a battery unit and a converter. Its dynamic behavior is represented by Equation (15):

Its operating constraints include the power and energy limitations of the energy storage system:

Formula (16) represents the mutual exclusivity constraint for the charging and discharging states of the battery energy storage system, ensuring that the system can only operate in either the charging or discharging state at any given time. Formulas (17) and (18) define the power constraints, while Formulas (19)–(21) establish the state of charge (SOC) constraints. These SOC constraints ensure that the battery operates within a safe and reasonable energy range, preventing deep charging and discharging, which could negatively impact the battery’s lifespan. To address these issues, energy relaxation variables are introduced in Formula (19) and battery energy feedback is incorporated in Formula (22).

Additionally, frequent charge–discharge cycles can degrade the internal components of the battery energy storage system, affecting its service life [27]. Therefore, the optimization model includes constraints on the duration of charging and discharging cycles to limit the frequent switching of the battery between operating states.

Formula (23) limits the charging duration of the battery energy storage, where represents the column vector composed of the battery energy storage charging state in the time domain range , and Mc is the minimum allowed charging time. It is worth noting that is a non-decision variable, which represents the historical charging and discharging state of the energy storage device. Formula (23) shows that when the battery energy storage is switched to the charging state at the time k-Mc, its charging state must be 1 within the time range , indicating that the battery is always working in the charging state; in other cases, the right side of the inequality (23) takes the value of 0 or −1, and the inequality must hold. Formula (24) constrains the discharge duration of the battery energy storage device, and the same can be obtained.

Equations (1)–(24) give the joint optimization operation model of household air conditioning and battery energy storage equipment. The optimization model is embedded in the MPC rolling time domain optimization framework to achieve an online solution of the optimization model and generate control instructions for the air conditioning system and battery energy storage equipment. MPC introduces a feedback mechanism in the optimization model to make the control strategy robust. In each control cycle, the optimization model is optimized and solved online, and the calculated are applied to the actual equipment. The above steps are repeated in the next control cycle.

3. Energy Management System for Home Air Conditioners

Based on the actual environment of the laboratory and the existing equipment, an IoT-based energy management system for the household air conditioning–battery energy storage system is built to realize the joint optimal operation of the air conditioner–battery energy storage system, and the optimization control strategy is measured and verified.

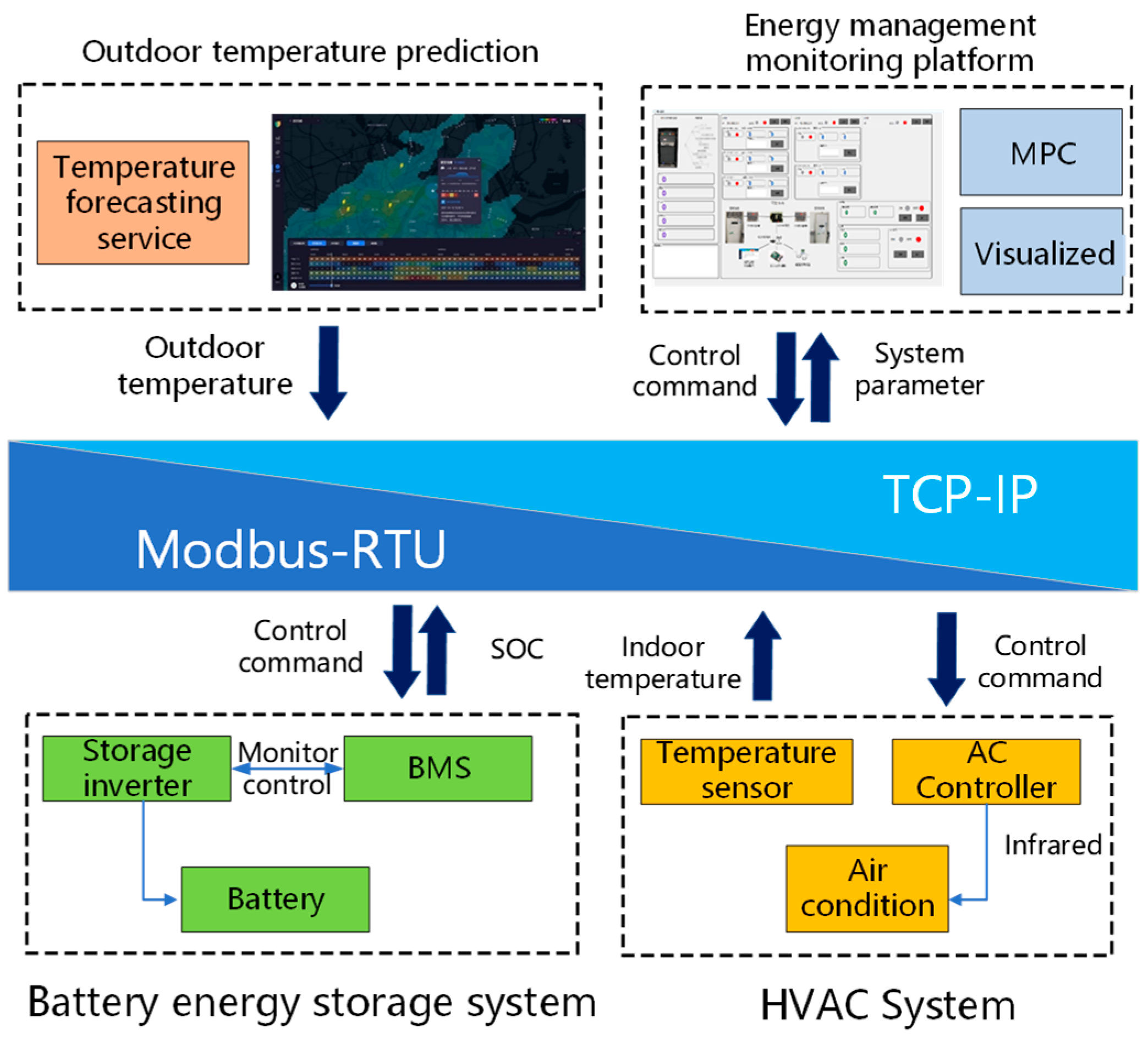

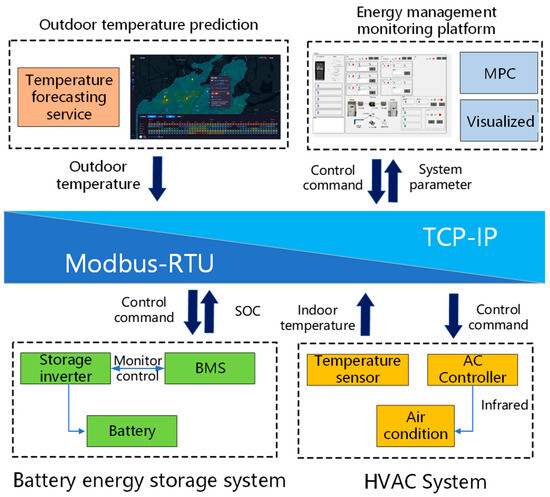

3.1. The Overall Architecture of the System

The general layout of the energy management system, which is built on an Internet of Things communication network with Modbus and TCP/IP protocols, is shown in Figure 3. To cooperatively complete energy management activities within the home, the air conditioner, sensor devices, battery energy storage system, and energy management platform are dispersed and connected. The energy management monitoring platform receives data on interior temperature and battery power status in real time from the Battery Management System (BMS) and the indoor temperature sensor. The model predictive control (MPC) optimization approach, which is implemented on the management platform, computes control instructions in real time by integrating these data with outdoor temperature projections. Through the serial port server, these commands are subsequently transmitted to the battery energy storage system and air conditioner for implementation.

Figure 3.

The structure of the IoT-based energy management system for residential HVAC and battery energy storage devices.

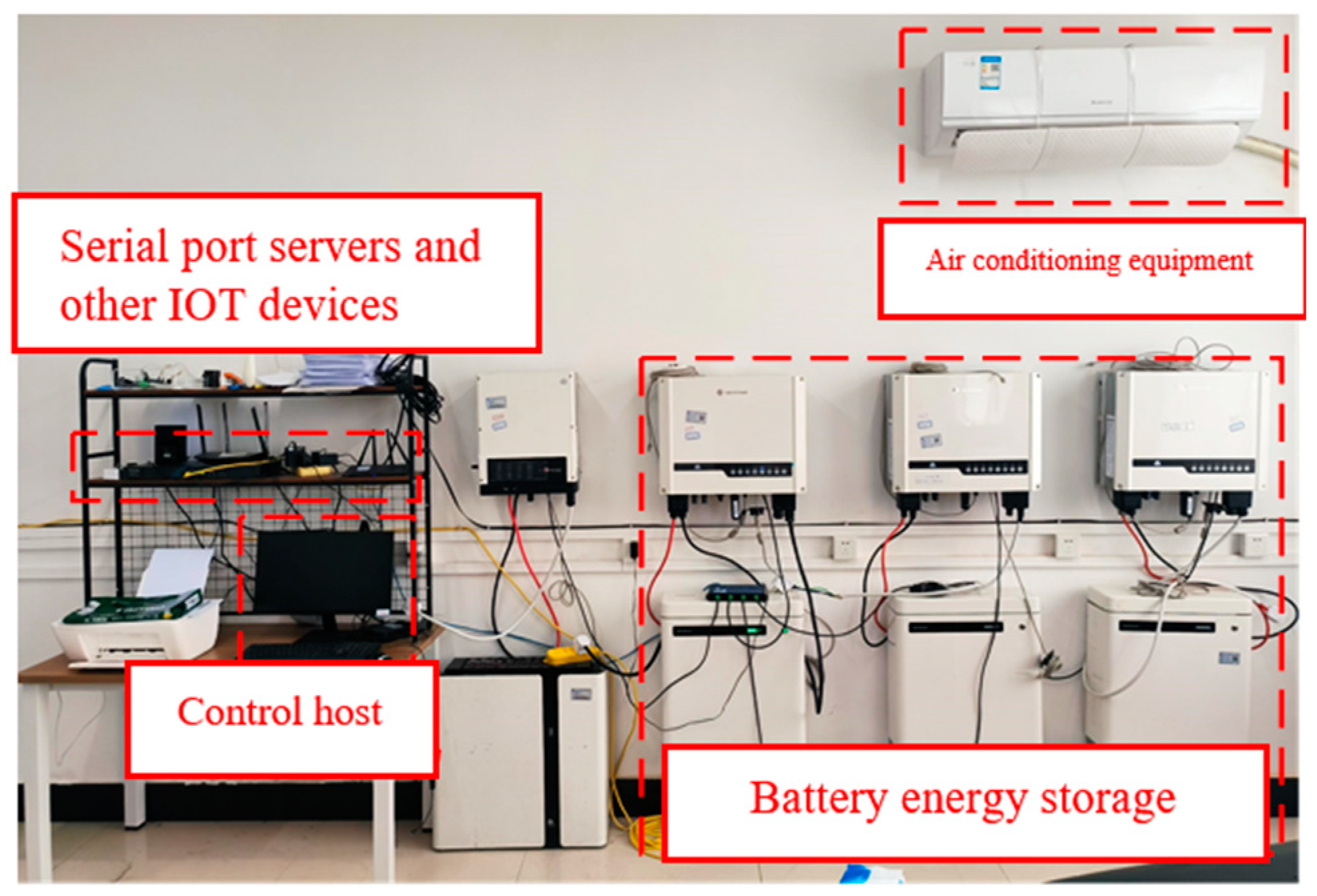

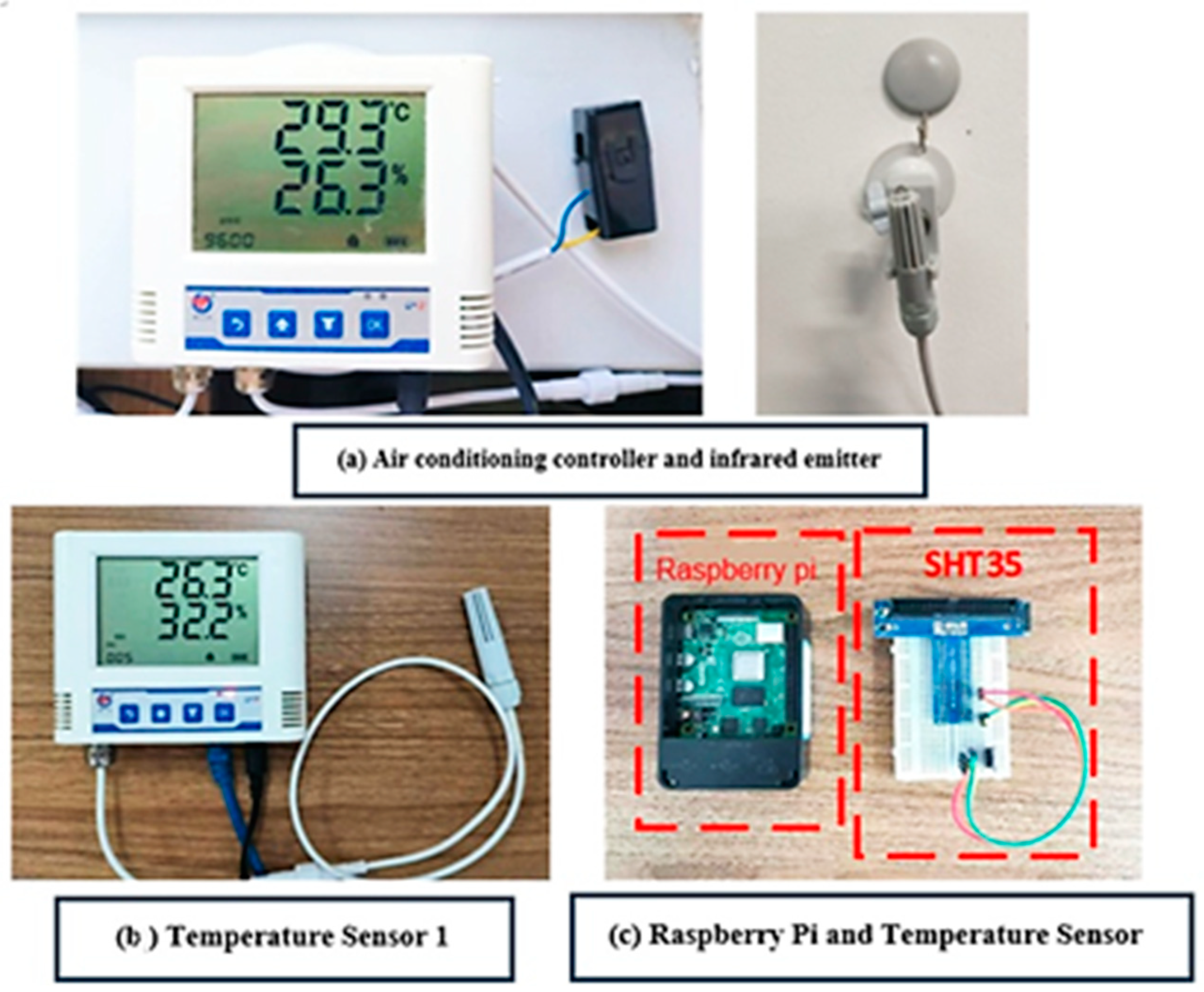

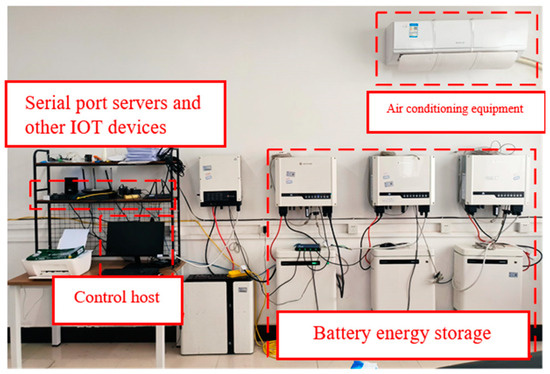

3.2. The Main Components of the System

The energy management monitoring platform, temperature sensors, temperature prediction service, battery energy storage devices, and air conditioning control system are some of the system’s specific parts. Figure 4 shows important equipment. The energy management monitoring platform, which is hosted and implemented on a central control system, shows the status data of various components. The operating state of the equipment can be managed and monitored in real time with this platform.

Figure 4.

Key components of the residential energy management system.

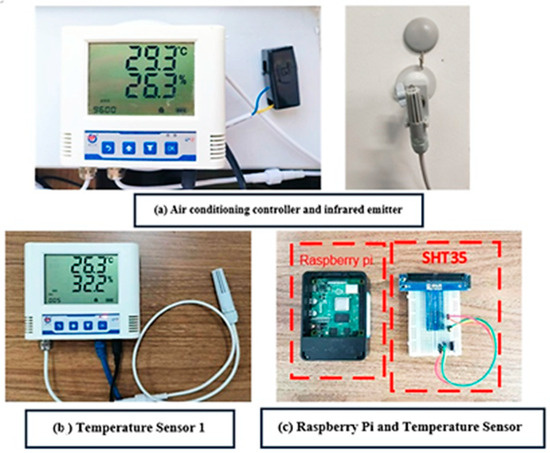

3.3. Air Conditioning Control System

The air conditioning control system primarily consists of household air conditioning equipment and an air conditioning controller. In the laboratory, a fixed-frequency air conditioner model KFR-72GW is used, which operates at a rated voltage of 220 V/50 Hz. The cooling and heating capacities are 7210 W and 9100 W, respectively, with rated cooling and heating input powers of 2.35 kW and 2.95 kW. To enable programmable control of the air conditioning unit, the system is equipped with Shandong Renke’s RS-KTC-N01 air conditioning remote control, as shown in Figure 5. This device can learn the control signals from the air conditioner’s remote control. Using the MODBUS-RTU protocol, it converts these control codes into infrared signals, allowing for remote and precise control of the household air conditioning system.

Figure 5.

Air conditioning remote controller and temperature sensor.

3.4. Temperature Sensor

As shown in Figure 5a,b, the system contains two temperature sensors, which are deployed at different locations indoors, and the indoor temperature measurement data are averaged to reflect the comprehensive adjustment effect of the room temperature. The sensors are the RS-WS-ETH-6 temperature and humidity sensor (range: −40 °C to 80 °C, accuracy: ±0.5 °C) and the SHT35 temperature and humidity measurement module (range: −40 °C to 125 °C, accuracy: ±0.2 °C) from Shandong Renke. The SHT35 module is connected to the Raspberry Pi control board through the I2C protocol, and the temperature measurement data are sent to the energy management monitoring platform through Raspberry Pi.

3.5. Temperature Forecasting Service

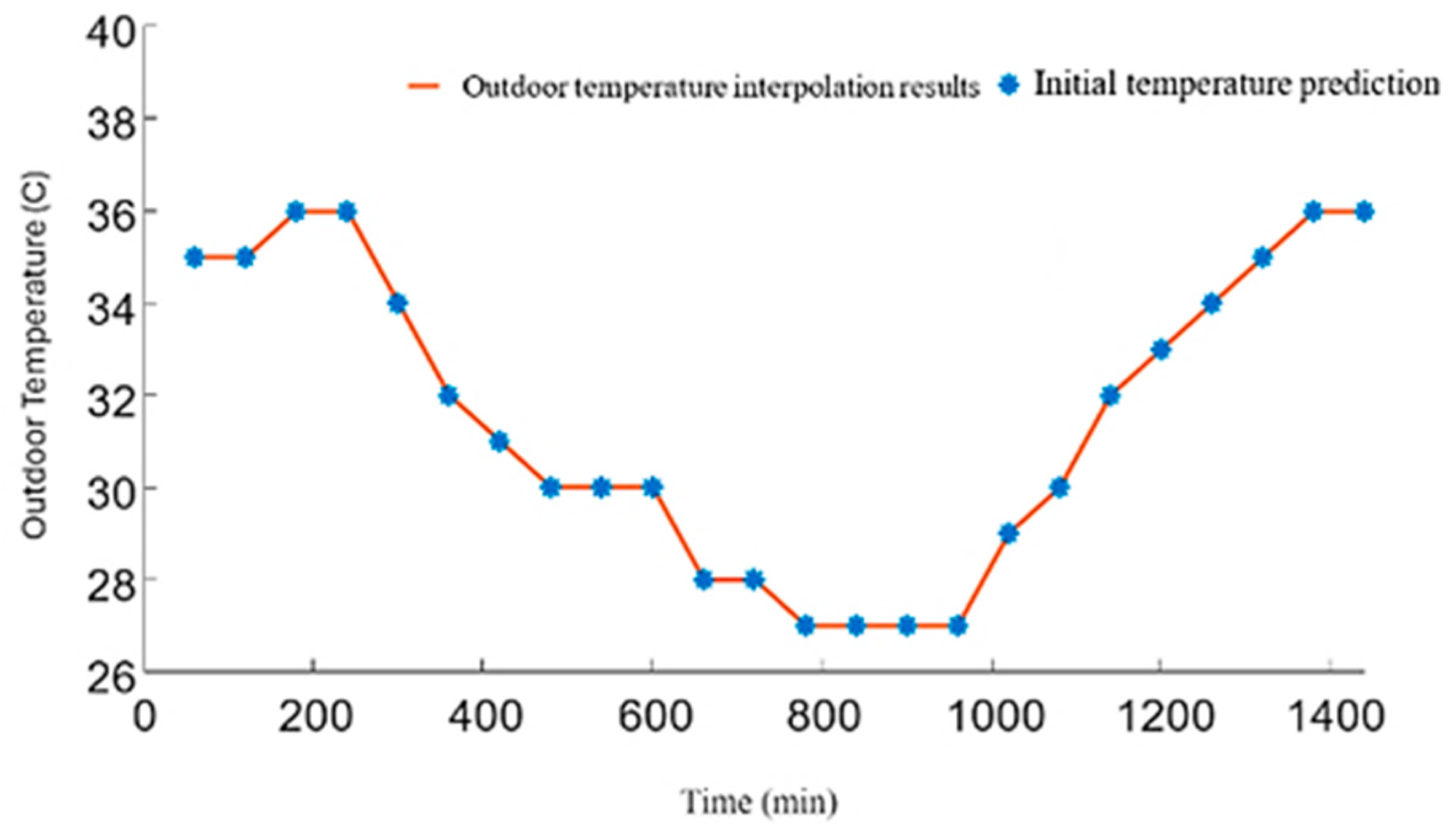

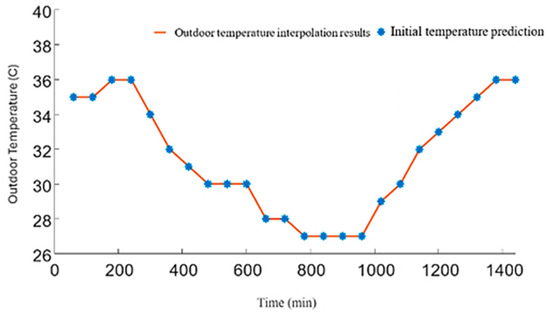

The Model Predictive Control (MPC) optimization model requires multi-step forecasting of outdoor ambient temperature. This is achieved through real-time retrieval of temperature prediction data by accessing the Application Programming Interface (API) [28] provided by the Xinzhi Weather Platform.

During each control cycle, the energy management monitoring platform sends a data request to the API, which responds with detailed meteorological data for the next 24 h. To align with the control system’s sampling intervals, the 24 h temperature data are interpolated. The resulting temperature prediction is illustrated in Figure 6.

Figure 6.

The calling method and prediction of out-door.

4. Battery Energy Storage Devices

The battery energy storage equipment adopts GoodWe’s low-voltage energy storage solution, including four sets of low-voltage batteries (model LX U5.4-L) and the corresponding energy storage inverter (model GW5048D-ES). The positive and negative poles of the battery are connected to the DC side of the inverter. In addition, the battery energy storage equipment has a built-in energy management system (BMS), which can feed back battery and inverter status information to the control host through IoT. Considering that the rated capacity of each battery group is 2.4 kW/5.4 kWh, which is close to the rated power of the air conditioning system and is equipped with an independent inverter, only one set of battery energy storage system is used in actual operation, and its charging and discharging are managed.

5. Energy Management Monitoring Platform

An energy management monitoring platform within the IoT framework is developed, leveraging the system’s hardware devices and communication network to provide integrated functions such as data acquisition, control, and visualization. Built using Python 3.9, the platform incorporates a graphical user interface, multi-threading, TCP/IP communication, and Panda power for power system simulation. This enables real-time simulation, monitoring, and control of devices, sensors, and power grid models.

6. Case Analysis

The verification and testing of the coordinated operating effect of the energy storage system and air conditioner under time-of-use electricity price is performed based on the study mentioned above. To guarantee the correctness of the temperature prediction model in MPC, this study first gathers system operating data and fits the parameters of a ReLU neural network. Simulated and experimental parameters and scenarios are simultaneously established based on the historical operating data of air conditioning equipment. The first experiment is a simulation test. The second experiment verifies the efficacy of the integrated solution through system real measurement. Under the same conditions, the economic improvement effect of air conditioning–battery system joint operation is compared with the independent operation of the air conditioning system.

The energy management monitoring platform is deployed on an ordinary PC (Core i5 processor and 16 GB memory). The control model is developed based on MATLAB R2023 a, and YALMIP is used to call CLPEX [29] to solve the optimization model. This paper considers the summer cooling scenario. The comfortable indoor temperature range is set to 24–28 °C, the sampling control cycle of the system is 5 min, and the prediction time of MPC is 90 min. In battery energy storage equipment, the allowable range of SOC is 20–80%, the minimum charge and discharge time is set to 30 min, the , and .

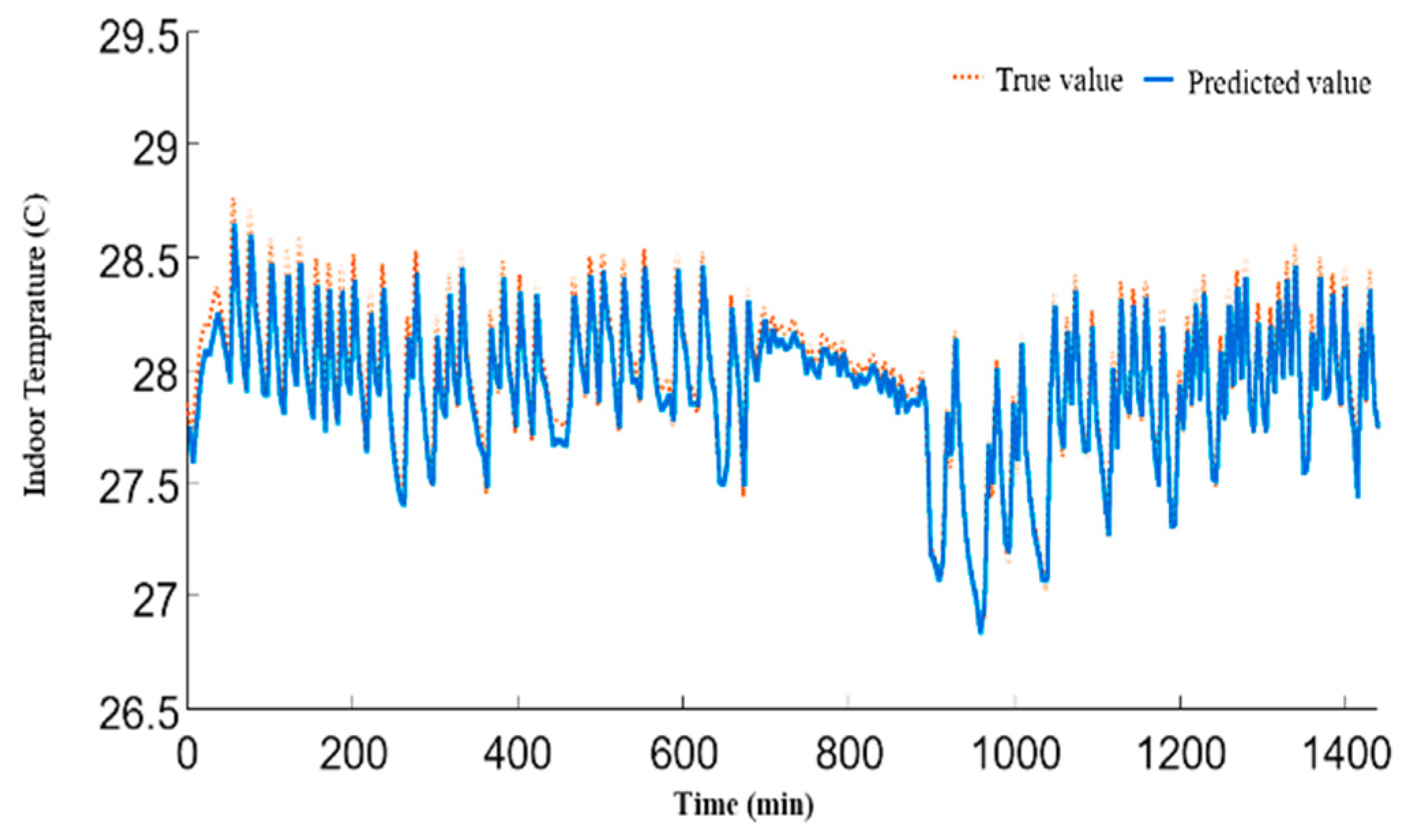

6.1. ReLU Model Identification

The air conditioning system’s indoor temperature dynamics are modeled in this article using a ReLU neural network. The following is the construction of the optimization model:

Here, w and b are the weights and biases of the ReLU neural network, which are optimized to minimize the mean square error (MSE) between the predicted and the measured value . The ReLU activation function introduces non-linearity and enables the model to effectively capture temperature fluctuations, which are significant under high summer temperatures.

The superscript m represents the measured value, such as , which is the measured value of the indoor temperature. Due to the high temperature in summer, the temperature fluctuates greatly. This paper uses the measured data from 25 July to 31 July to train the ReLU model, as this period fully reflects the operation of the air conditioning system under high-temperature conditions. The time series is split into (, data pairs, forming a dataset containing a total of 2016 data points.

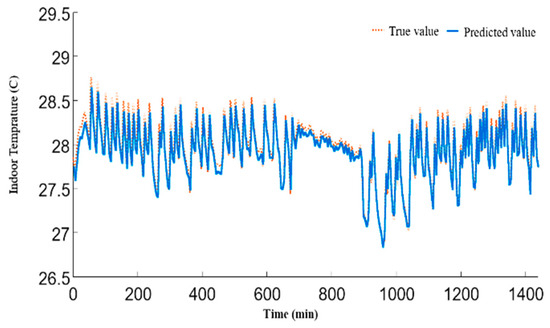

The system operation data from a new day are used to test the ReLU model’s forecast accuracy. The outcomes, which are displayed in Figure 7, show how effective the ReLU model is. The temperature prediction error is within ±0.14 °C, and the mean square error (MSE) is 0.0824.

Figure 7.

Temperature prediction of the proposed ReLU model.

6.2. Analysis of the Effect of System Control

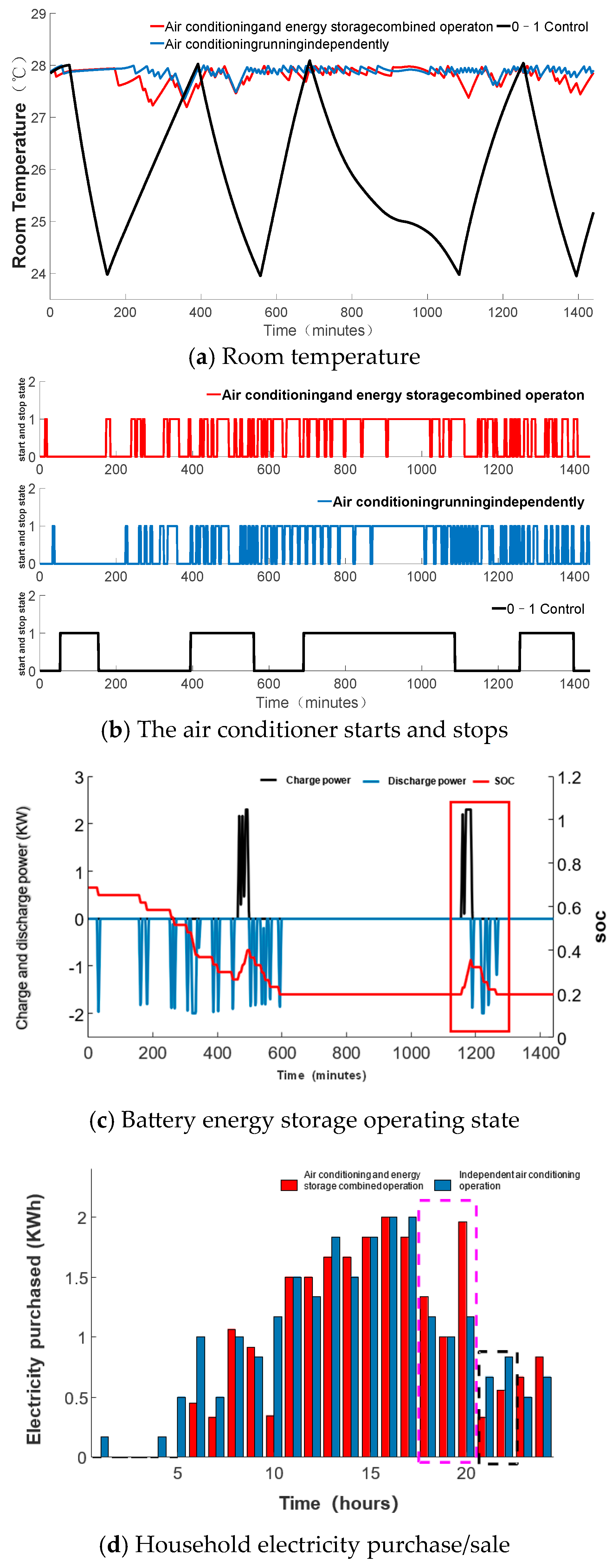

6.2.1. Experiment 1: Simulation Analysis

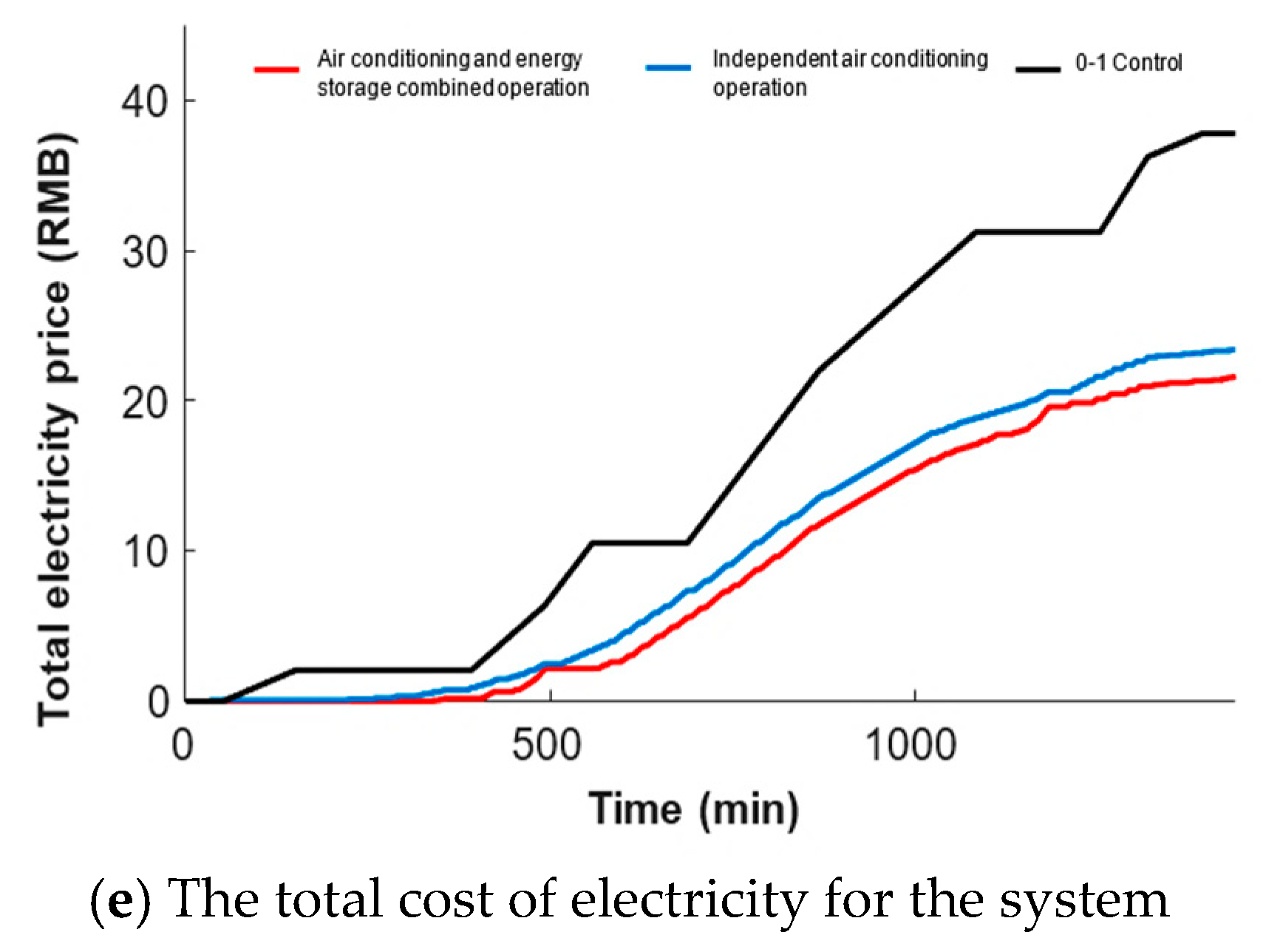

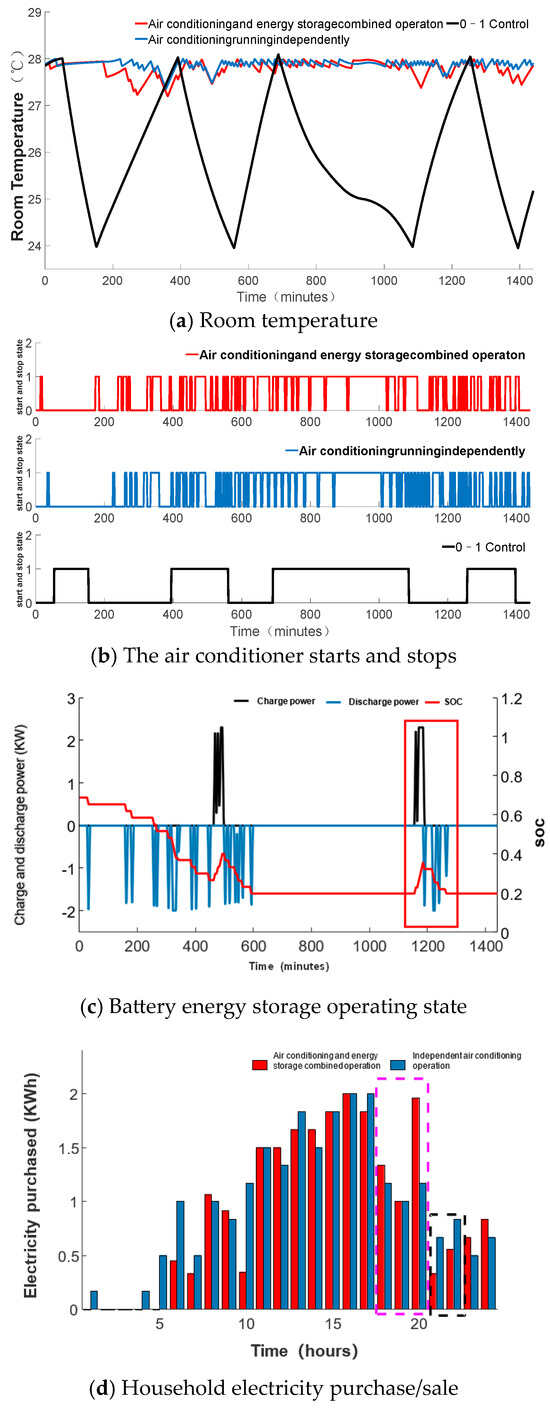

In Experiment 1, the effectiveness of the suggested control measures was contrasted and examined under the same circumstances. The simulation, which focused on assessing the benefits of the air conditioning–battery energy storage system operating together as opposed to the air conditioning system operating independently, was powered by historical outdoor temperature data from a particular day. Figure 8 shows the outcomes of the simulation.

Figure 8.

Electricity cost of the AC storage coordination in simulations.

Figure 8a illustrates how, from the standpoint of temperature control, MPC control keeps the indoor temperature closer to the upper limit, cutting down on the amount of time the air conditioner is in use and electricity expenses. However, doing so means turning on the air conditioner more frequently. On the other hand, Figure 8b shows that conventional 0–1 control simplifies the control process with its simple start-up and shutdown logic. The air conditioner runs longer between activations when this method is used. MPC, on the other hand, has a higher control frequency, which efficiently reduces electricity expenses while keeping the temperature within the permitted range.

Additionally, the financial advantages of using the energy storage system and air conditioner together were examined. Under MPC management, the energy storage system and air conditioning have lower daily electricity costs, as seen in Figure 8. The energy management system’s capacity to maximize battery storage utilization is responsible for this. As indicated by the red box in Figure 8c, using the battery’s stored energy is prioritized during times when electricity prices are at their highest.

Moreover, Figure 8c shows that the battery energy storage system often charges and discharges at a rated power while keeping the state of charge (SOC) within the permitted range. The power purchased by the air conditioner-energy storage system during periods of high electricity prices (black box) is only 0.9 kWh, which is 59.1% of the amount purchased when the air conditioner runs on its own, as shown in Figure 8d. On the other hand, the quantity of electricity purchased under the cooperative operation rises dramatically during times of low electricity prices, reaching 129.2% of the amount purchased when the air conditioner runs independently.

The expected payback period is 9.8 years, considering the 10,000-yuan investment cost of the battery energy storage system and the 2.8-yuan daily electricity savings made possible by the joint operation. This analysis shows that although the battery energy storage system requires a large initial investment, it can eventually pay for itself by saving electricity costs and offering customers continuous financial advantages.

6.2.2. Experiment 2: Physical Experimental Verification

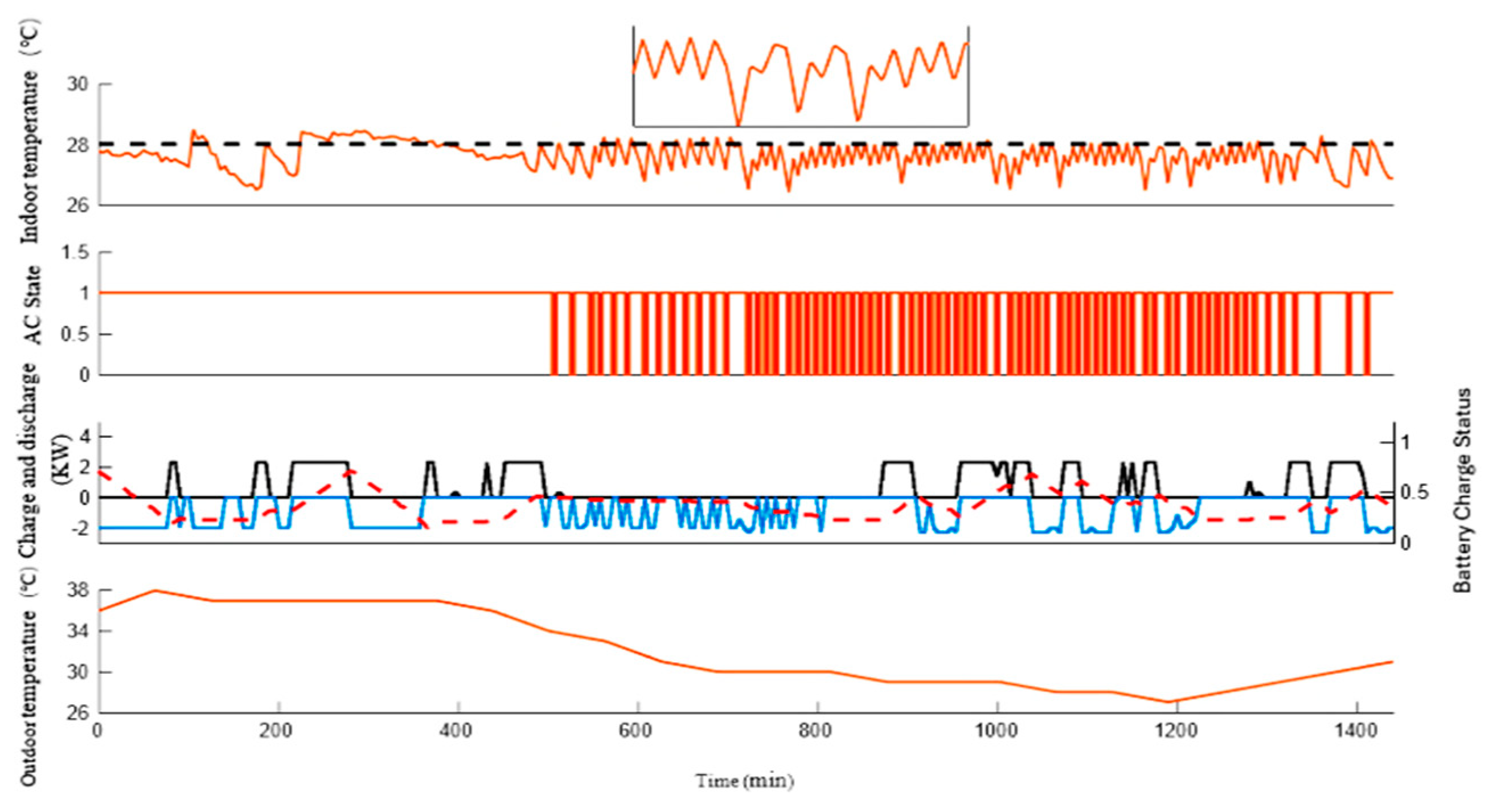

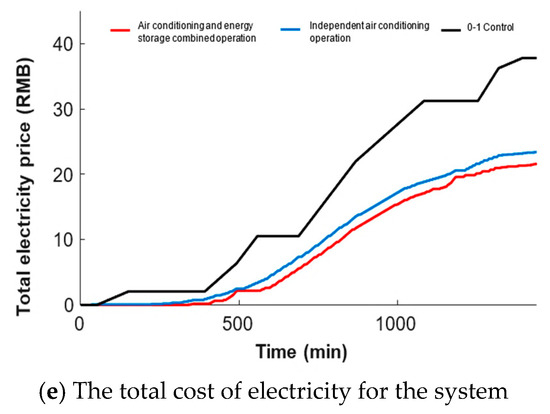

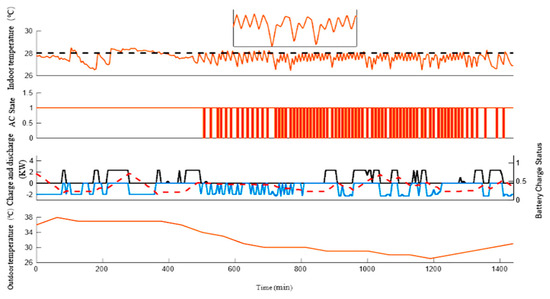

Building on Experiment 1, Experiment 2 used full-scale physical system experiments to validate the suggested control model and integration scheme. The system was set up in a real laboratory setting, and on a certain day in September, the experimental data were gathered and examined. Figure 9 displays the ambient temperature outside.

Figure 9.

Comparative analysis of the AC–storage coordination in reality.

Despite variations in the outside temperature, the control system successfully kept the indoor temperature within the comfortable range, as shown by the indoor temperature waveform in Figure 9. The technology also minimized power consumption by maintaining the indoor temperature as near to the upper limit as feasible. Notably, the control system demonstrated notable pre-cooling behavior before the period of peak electricity prices, as indicated by the green area of the enlarged portion of Figure 9.

Before the high electricity price time, the air conditioner ran regularly for cooling, as seen in Figure 9. However, during the peak electricity price period, it functioned much less frequently. The real functioning of the battery energy storage system is illustrated in Figure 9. Similar to the outcomes of the simulation, the system minimized the frequency of battery charging during periods of high electricity prices, charging during periods of low electricity prices (blue box), and discharging during periods of high electricity prices (red box). This strategy decreased power consumption and the system’s total operating costs.

The results demonstrate that the integrated system effectively balances energy efficiency and cost reduction while maintaining indoor comfort, confirming the effectiveness of the proposed control strategy in real-world scenarios.

6.3. Comparison of Physical Tests and Simulated Experiments

Simulation trials are essential to the entire optimization analysis of the energy storage–air conditioning system. They make it possible to verify different control strategies to maximize system performance and conduct thorough evaluations of system performance under idealized settings. Physical tests, on the other hand, carried out in laboratory settings, are unavoidably impacted by uncertainties and interfering issues.

Under both experimental situations, the control system effectively implements pre-cooling steps prior to periods of peak electricity prices while keeping the indoor temperature within the user’s comfort range, as shown in Figure 8a and Figure 9. Even while physical trials (as illustrated in Figure 9 are hampered by factors like battery aging and other environmental factors, battery energy storage systems are nevertheless able to effectively manage charging prior to periods of high electricity prices and supply power during peak hours.

Furthermore, important influencing aspects in real-world operations that are frequently missed in simulation models are revealed by physical trials. Reduced battery life and lower operating efficiency, for example, might result from problems like current collector corrosion, temperature-related performance changes, and power fluctuation interference during charging and discharging in battery energy storage systems. Similar difficulties are shown in Figure 9 for air conditioning systems, including compressor performance variations, equipment startup delays, and the effect of ambient humidity on cooling efficiency. Often overlooked or oversimplified in simulation models, these little but important aspects can have a big impact on the system’s overall performance and optimization efficacy in real-world operations.

7. Conclusions

This study proposed a novel joint optimization model for household air conditioning and battery energy storage systems under time-of-use (ToU) electricity pricing, utilizing a Model Predictive Control (MPC) framework. The integration of HVAC systems and battery energy storage demonstrated significant improvements in energy efficiency, achieving over a 10% reduction in electricity costs while maintaining indoor thermal comfort. The use of a ReLU-based neural network enabled accurate modeling of building thermal dynamics, which was seamlessly incorporated into the MPC framework for real-time optimization. The proposed system was validated through simulations and real-world experiments, showcasing effective pre-cooling and pre-charging strategies to reduce peak load consumption and alleviate strain on the power grid. These results highlight the practical potential of this approach in residential energy management. Future research could focus on integrating renewable energy sources, such as rooftop photovoltaics, and addressing uncertainties in outdoor temperature forecasts and user behavior to further enhance system robustness and economic performance.

Author Contributions

Conceptualization, A.S. and J.Z.; methodology, A.S.; software, A.S.; validation, A.S., J.Z., Y.H. and P.W.; formal analysis, A.S.; investigation, A.S.; resources, A.S.; data curation, A.S.; writing—original draft preparation, A.S.; writing—review and editing, A.S. and J.Z.; visualization, P.W.; supervision, J.Z.; project administration, J.Z.; funding acquisition, J.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data supporting the findings of this study are openly available at the reference of this article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Tan, J.; Peng, S.; Liu, E. Spatio-temporal distribution and peak prediction of energy consumption and carbon emissions of residential buildings in China. Appl. Energy 2024, 376, 124330. [Google Scholar] [CrossRef]

- Vedullapalli, D.T.; Hadidi, R.; Schroeder, B. Combined HVAC and Battery Scheduling for Demand Response in a Building. IEEE Trans. Ind. Appl. 2019, 55, 7008–7014. [Google Scholar] [CrossRef]

- Notice from the National Development and Reform Commission on Further Improving the Time of Use Electricity Pricing Mechanism [EB/OL]. Available online: https://www.gov.cn/zhengce/zhengceku/2021-07/29/content_5628297.htm (accessed on 26 July 2021).

- Maasoumy, M.; Vincentelli, A.S. Comparison of Control Strategies for Energy Efficient Building HVAC Systems. Available online: https://escholarship.org/uc/item/8r23v0rr (accessed on 15 December 2024).

- Li, Z.; Jin, X.; Jia, H.; Qi, F.; Mu, Y.; Yu, X. Model Predictive Control Method for the HVAC System of Buildings Considering the Thermal Dynamic Characteristics of the Envelope. Zhongguo Dianji Gongcheng Xuebao/Proc. Chin. Soc. Electr. Eng. 2020, 40, 3928–3939. [Google Scholar] [CrossRef]

- Zhang, S.; Zhou, L.; Huang, H.; Shi, S.; Xiao, X. Optimization Method of HVAC Load Group Distribution Network for Integrated Buildings Taking Into Account Occupancy Effects. Dianwang Jishu/Power Syst. Technol. 2024, 48, 4436–4444. [Google Scholar] [CrossRef]

- Xiao, W.; Qing, L.; Shakir, A. Energy Management Strategy for Heating, Ventilation, and Air Conditioning Systems in Buildings Based on Multi-layer Rectified Linear Unit Network. Autom. Electr. Power Syst. 2024, 48, 84–91. [Google Scholar] [CrossRef]

- Afram, A.; Janabi-Sharifi, F.; Fung, A.S.; Raahemifar, K. Artificial neural network (ANN) based model predictive control (MPC) and optimization of HVAC systems: A state of the art review and case study of a residential HVAC system. Energy Build. 2017, 141, 96–113. [Google Scholar] [CrossRef]

- Shakir, A.; Al-Thahab, O.Q.J.; Abdul-Rahaim, L.A. Design of LTE System by using Neural Network Adaptive Equalizer Based on Discrete Fourier and Wavelet Transforms. J. Eng. Appl. Sci. 2019, 14, 9358–9370. [Google Scholar] [CrossRef]

- Hao, H.; Wu, D.; Lian, J.; Yang, T. Optimal Coordination of Building Loads and Energy Storage for Power Grid and End User Services. IEEE Trans. Smart Grid 2018, 9, 4335–4345. [Google Scholar] [CrossRef]

- Kontorinis, V.; Zhang, L.E.; Aksanli, B. Managing Distributed UPS Energy for Effective Power Capping in Data Centers. ACM SIGARCH Comput. Arch. News 2012, 40, 488–499. [Google Scholar] [CrossRef]

- Bianchini, G.; Casini, M.; Pepe, D.; Vicino, A.; Zanvettor, G.G. An integrated model predictive control approach for optimal HVAC and energy storage operation in large-scale buildings. Appl. Energy 2019, 240, 327–334. [Google Scholar] [CrossRef]

- Kuboth, S.; Heberle, F.; König-Haagen, A.; Brüggemann, D. Economic model predictive control of combined thermal and electric residential building energy systems. Appl. Energy 2019, 240, 372–385. [Google Scholar] [CrossRef]

- Solano, J.C.; Olivieri, L.; Caamaño-Martín, E. Assessing the potential of PV hybrid systems to cover HVAC loads in a grid-connected residential building through intelligent control. Appl. Energy 2017, 206, 249–266. [Google Scholar] [CrossRef]

- Lee, T.; Jeon, S.; Kang, D.; Park, L.W.; Park, S. Design and implementation of intelligent HVAC system based on IoT and Bigdata platform. In Proceedings of the 2017 IEEE International Conference on Consumer Electronics, ICCE 2017, Las Vegas, NV, USA, 8–10 January 2017; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2017; pp. 398–399. [Google Scholar] [CrossRef]

- Ma, Y.; Kelman, A.; Daly, A.; Borrelli, F. Predictive control for energy efficient buildings with thermal storage: Modeling, stimulation, and experiments. IEEE Control. Syst. 2012, 32, 44–64. [Google Scholar] [CrossRef]

- Široký, J.; Oldewurtel, F.; Cigler, J.; Prívara, S. Experimental analysis of model predictive control for an energy efficient building heating system. Appl. Energy 2011, 88, 3079–3087. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, J.; Li, J. Optimization of economic operation for household battery energy storage systems considering degradation and maintenance costs. Appl. Energy 2021, 282, 116153. [Google Scholar] [CrossRef]

- Notice on Matters Related to Transmission and Distribution Price and Sales Price of Hubei Power Grid from 2020 to 2022. Available online: http://fgw.hubei.gov.cn/fbjd/zc/zcwj/tz/ (accessed on 15 December 2024).

- Glorot, X.; Bordes, A.; Bengio, Y. Deep Sparse Rectifier Neural Networks. In Proceedings of the Fourteenth International Conference on Artificial Intelligence and Statistics, Fort Lauderdale, FL, USA, 11–13 April 2011. [Google Scholar]

- Henze, G.P.; Kalz, D.E.; Ashrae, M.; Liu, S.; Felsmann, C. Experimental Analysis of Model-Based Predictive Optimal Control for Active and Passive Building Thermal Storage Inventory. HVAC&R Res. 2005, 11, 189–213. [Google Scholar]

- Zhao, H.X.; Magoulès, F. A review on the prediction of building energy consumption. Renew. Sustain. Energy Rev. 2012, 16, 3586–3592. [Google Scholar] [CrossRef]

- Erickson, V.L.; Cerpa, A.E. Thermovote: Participatory sensing for efficient building HVAC conditioning. In BuildSys 2012, Proceedings of the ACM Workshop on Embedded Systems for Energy Efficiency in Buildings, Toronto, ON, Canada, 6 November 2012; ACM: New York, NY, USA, 2012; pp. 9–16. [Google Scholar] [CrossRef]

- Period, R.; Henze, G.P.; Krarti, M. Final Report for Cooperative Agreement DE-FC26-01NT41255 Project Title: ‘Predictive Optimal Control of Active and Passive Building Thermal Storage Inventory’ ‘Predictive Optimal Control of Active and Passive Building Thermal Storage Inventory’ Final Report; University of Nebraska: Lincoln, NE, USA, 2001. [Google Scholar]

- Kingma, D.P.; Ba, J. Adam: A Method for Stochastic Optimization. December 2014. Available online: http://arxiv.org/abs/1412.6980 (accessed on 15 December 2024).

- Katz, J.; Pappas, I.; Avraamidou, S.; Pistikopoulos, E.N. The Integration of Explicit MPC and ReLU based Neural Networks. IFAC-PapersOnLine 2020, 53, 11350–11355. [Google Scholar] [CrossRef]

- Zhu, J.; Zhao, Y.; Xiong, J.; Zhang, Z.; Ge, C. Research on the optimization and configuration of integrated photovoltaic and energy storage systems in smart buildings considering the lifecycle costs. In Proceedings of the 2024 36th Chinese Control and Decision Conference (CCDC), Xi’an, China, 25–27 May 2024; pp. 2975–2980. [Google Scholar]

- 24-Hour Hourly Weather Forecast [EB/OL]. Available online: https://seniverse.yuque.com/hyper_data/api_v3/baom2y?#%20 (accessed on 21 August 2024).

- Lofberg, J. YALMIP a toolbox for modeling and optimization in MATLAB. In Proceedings of the 2004 IEEE International Conference on Robotics and Automation, Taipei, China, 26 April–1 May 2004. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).