Optimized Machining Parameters for High-Speed Turning Process: A Comparative Study of Dry and Cryo+MQL Techniques

Abstract

:1. Introduction

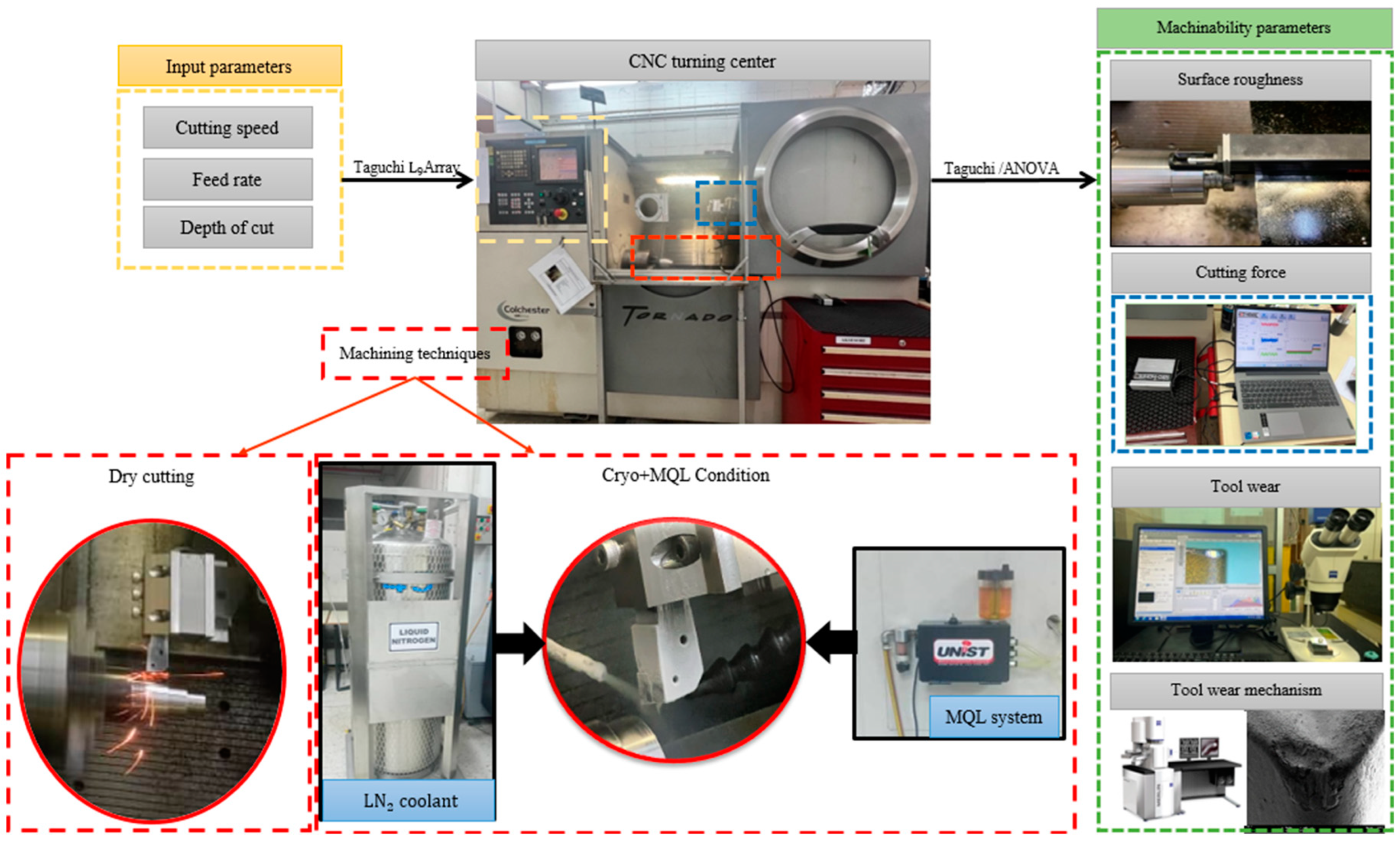

2. Materials and Methods

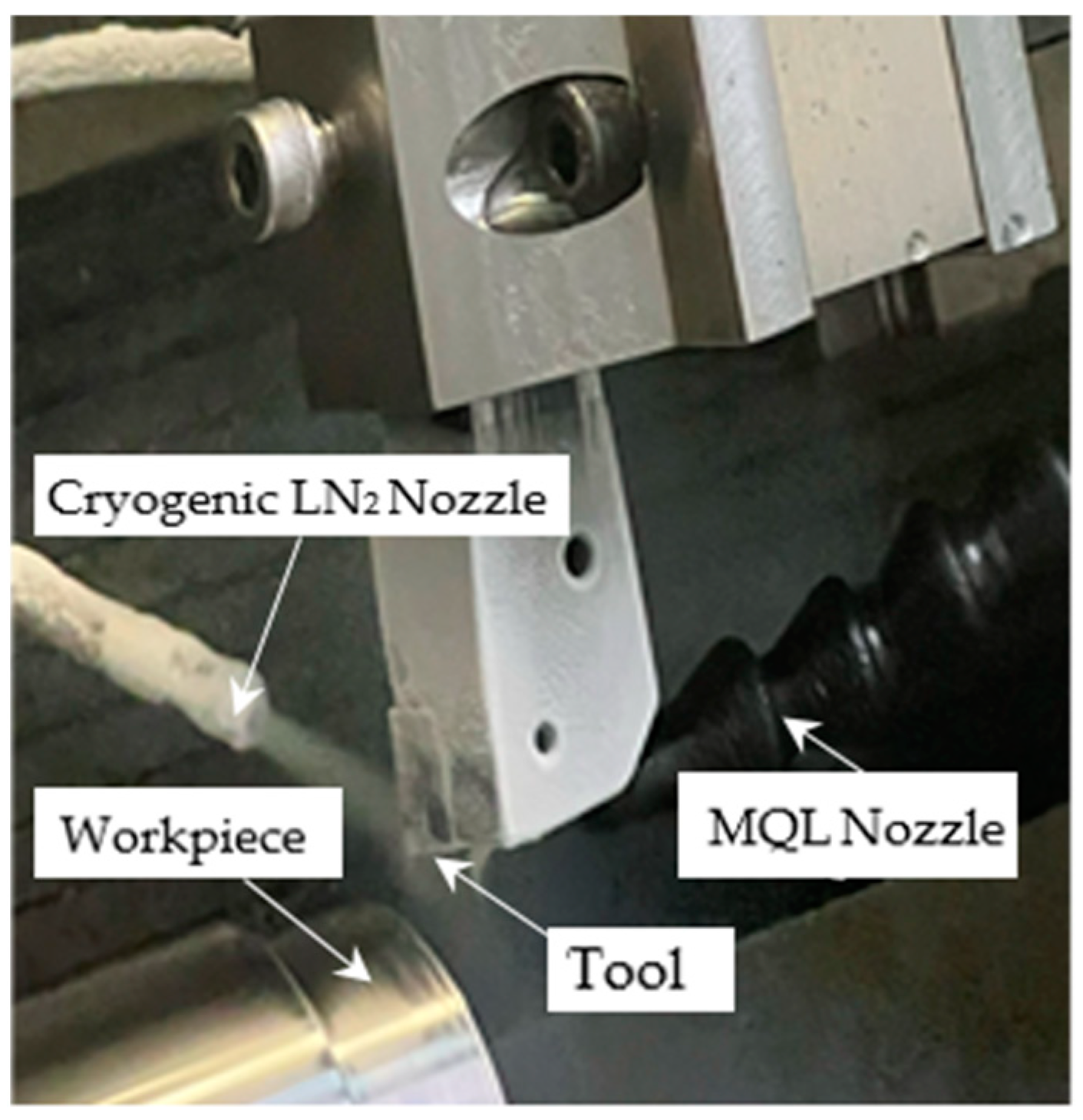

2.1. Experimental Apparatus and Material

| Mechanical Properties | Values |

|---|---|

| Tensile strength | 951 MPa |

| Elongation | 13% |

| Hardness | 282 BHN |

| Impact strength | 44 J |

| Yield Strength | 651 MPa |

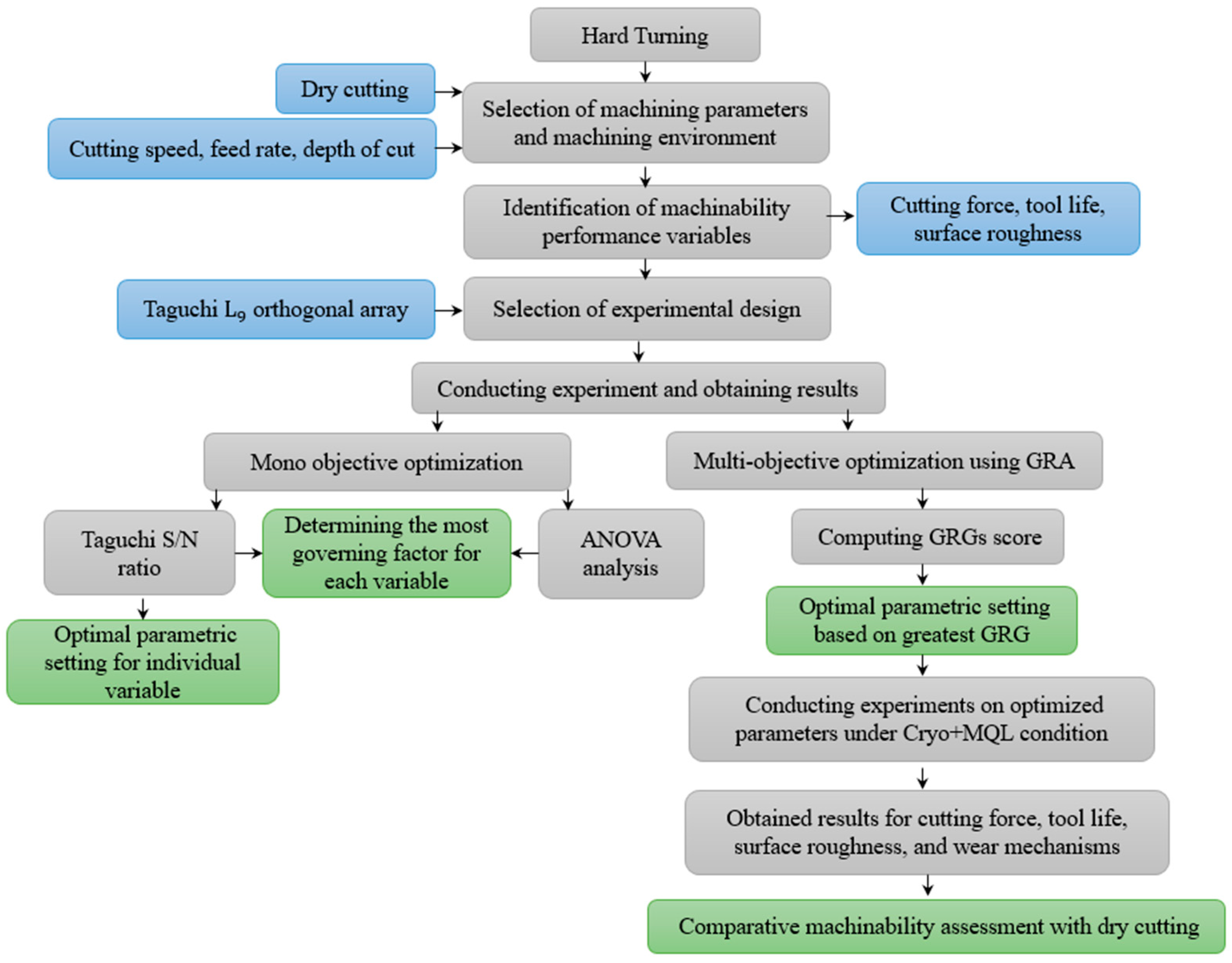

2.2. Design of Experiment

3. Results and Discussion

3.1. Cutting Force (Fc)

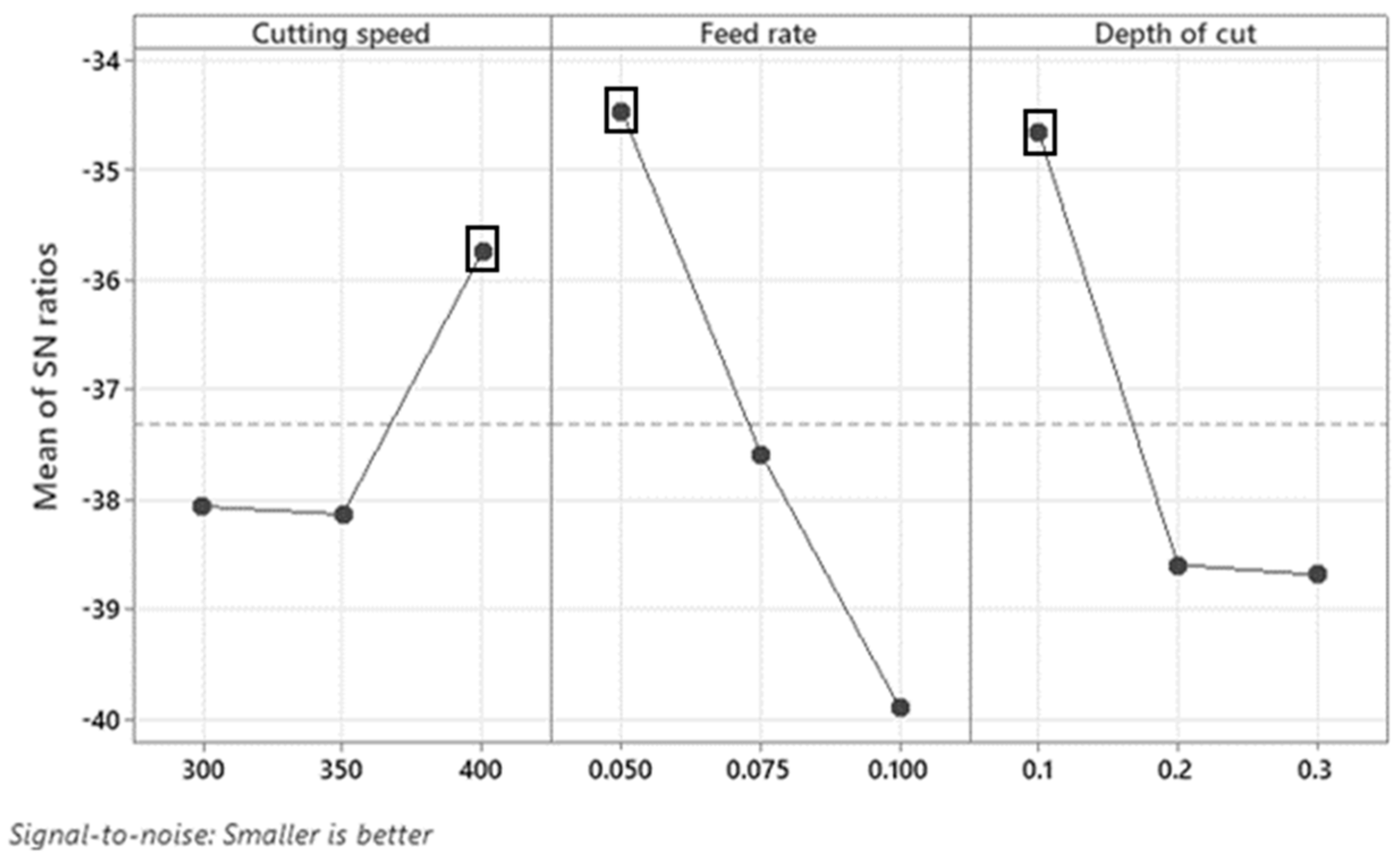

3.2. Surface Roughness

3.3. Tool Life

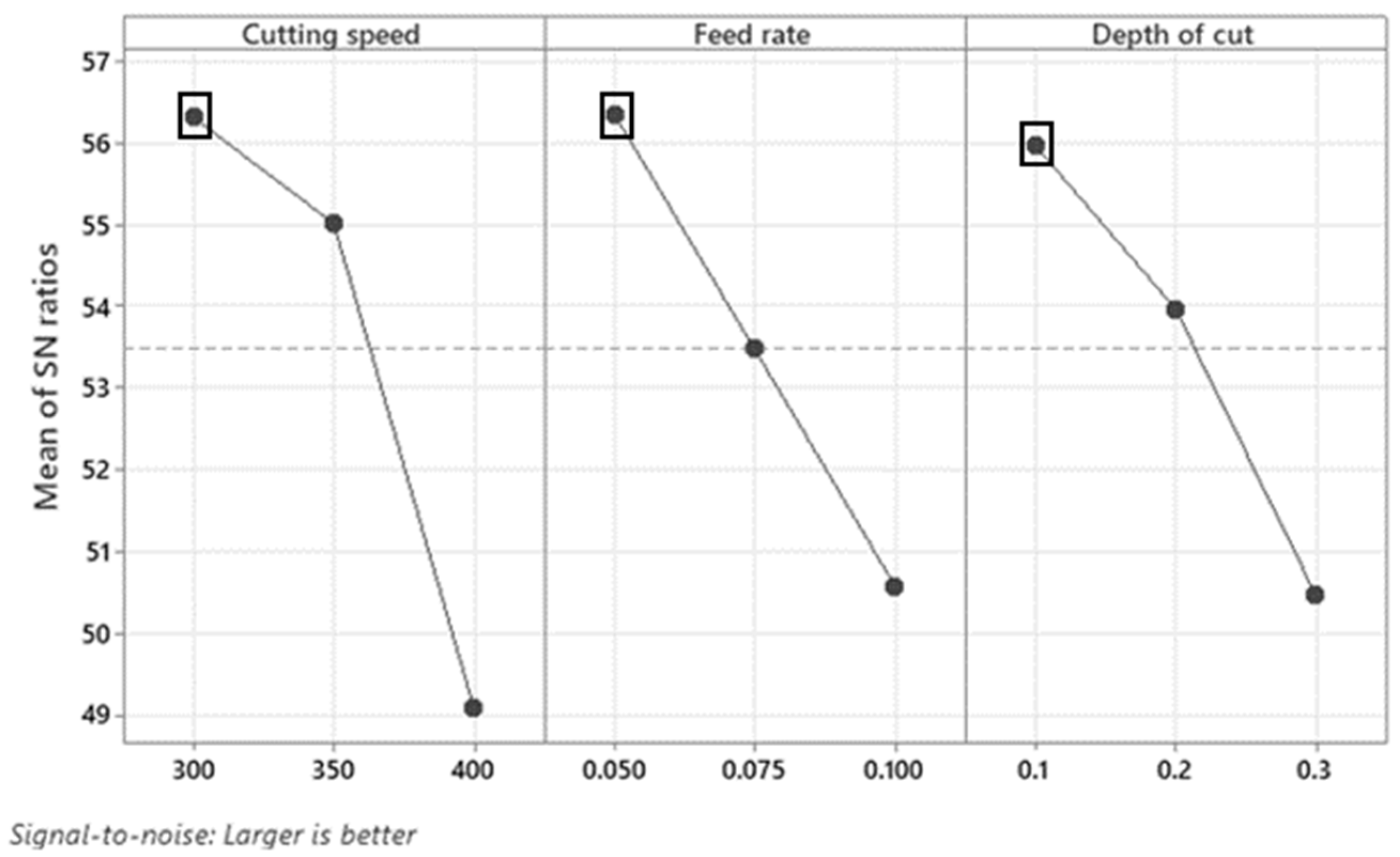

3.4. Multi-Objective Optimization Studies for Best Parametric Setting

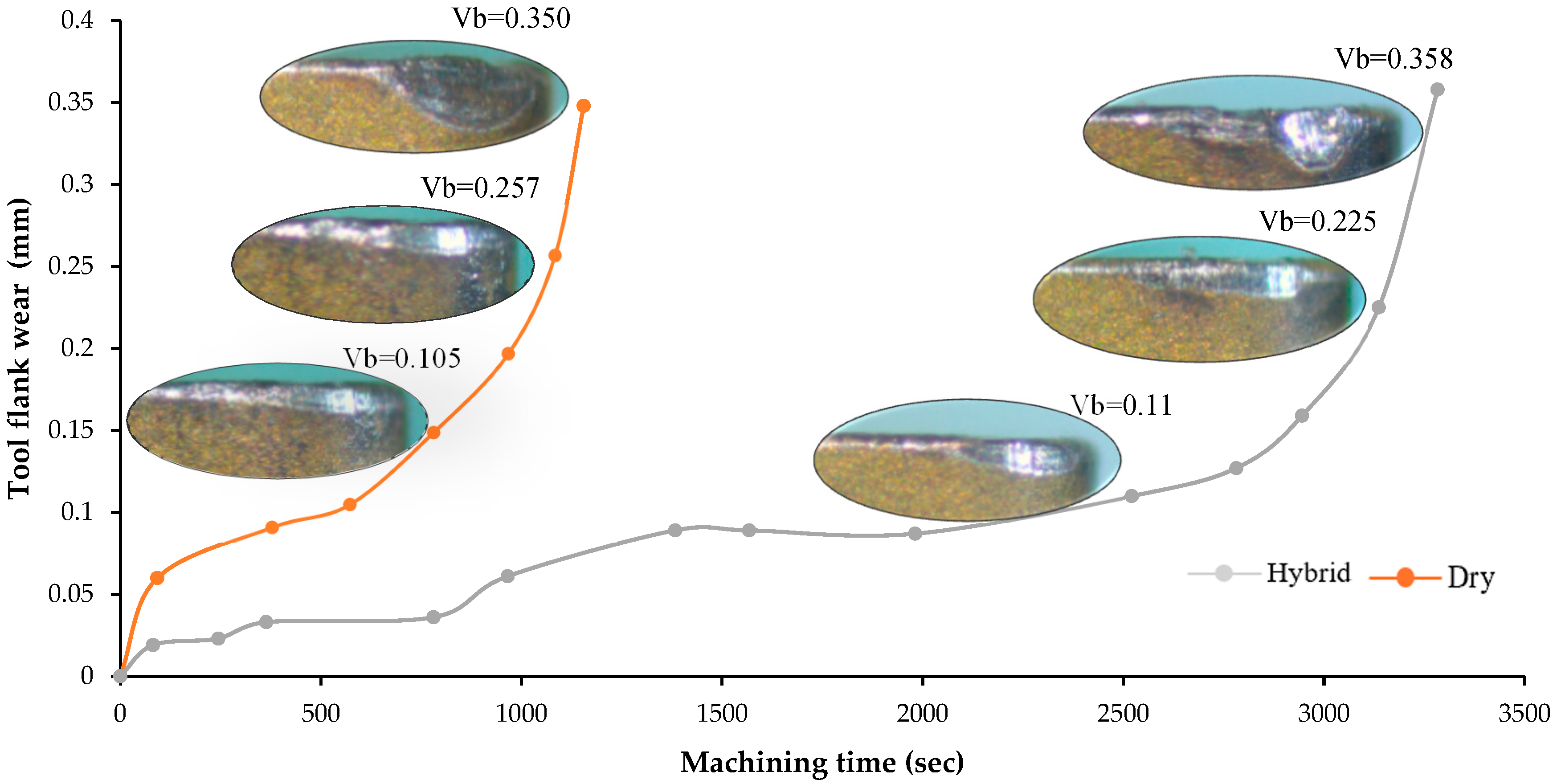

3.5. Application of Cryo+MQL Lubrication and Its Comparative Analysis with Dry Conditions

4. Conclusions

- The experimental results showed the lowest cutting force of 43.3 N and the longest tool life of 1155 s at the lowest machining settings: a cutting speed of 300 m/min, a feed rate of 0.05 mm/rev, and a depth of cut of 0.1 mm. However, the lowest surface roughness of 0.305 µm was achieved at a moderate cutting speed of 350 m/min, a depth of cut of 0.2 mm, and the lowest feed rate of 0.05 mm/rev. Mono-optimization using the Taguchi signal-to-noise (S/N) ratio revealed that a high cutting speed and the lowest feed rate are favorable for minimizing cutting force and improving surface roughness, whereas a low cutting speed and feed rate are optimal for maximizing tool life in a dry environment;

- Statistical inference using ANOVA revealed that feed rate was the most significant factor, contributing 50.69% to cutting force and 80.03% to surface roughness, while cutting speed was the primary factor influencing tool life, with a contribution rate of 39.73% during the dry turning of hardened AISI 4340 alloy steel;

- Multi-objective optimization using GRA showed that a cutting speed of 300 m/min, a feed rate of 0.05 mm/rev, and a depth of cut of 0.1 mm yielded the highest GRG score of 0.879, confirming this combination as the optimal setting for the selected machinability criteria. These parameters provided a balanced trade-off, ensuring a smooth surface finish, low cutting forces, and extended tool life;

- The application of hybrid lubrication significantly improved surface roughness by 48% and extended tool life by 184.5%, which are attributed to the enhanced lubrication and cooling efficiency of the system. This demonstrates that concurrent cooling and lubrication are more effective than dry cutting in reducing machining heat. However, a 4.6% increase in cutting force was observed, likely due to the reduced temperature from LN2 cooling. In contrast, dry cutting typically results in higher temperatures, leading to material softening. Consequently, the lower temperatures in LN2 cooling may have contributed to surface hardening, increasing cutting force;

- Fracturing at the cutting edge and excessive material adhesion are key factors influencing tool performance in dry cutting. The cooling effect of the Cryo+MQL lubrication approach significantly mitigates thermal and mechanical stresses on the tool, reducing coating delamination and adhesion while maintaining tool integrity and enhancing edge stability.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mallick, R.; Kumar, R.; Panda, A.; Sahoo, A.K. Current Status of Hard Turning in Manufacturing: Aspects of Cooling Strategy and Sustainability. Lubricants 2023, 11, 108. [Google Scholar] [CrossRef]

- Mane, P.A.; Kallol, A.N.; Doiphode, R.L.; Khadtare, A.N. CuO Nanoparticle Size Effect on Inconel-718 Turning with Nanofluid Minimum Quantity Lubrication. Int. J. Miner. Metall. Mater. 2023, 25, 190–208. [Google Scholar] [CrossRef]

- Anand, A.; Behera, A.K.; Das, S.R. An Overview on Economic Machining of Hardened Steels by Hard Turning and Its Process Variables. Manuf. Rev. 2019, 6, 4. [Google Scholar] [CrossRef]

- Shalaby, M.; Veldhuis, S. New Observations on High-Speed Machining of Hardened AISI 4340 Steel Using Alumina-Based Ceramic Tools. J. Manuf. Mater. Process. 2018, 2, 27. [Google Scholar] [CrossRef]

- Mbangu Tambwe, G.; Pons, D. Optimization of Surface Roughness of Aluminium RSA 443 in Diamond Tool Turning. J. Manuf. Mater. Process. 2024, 8, 61. [Google Scholar] [CrossRef]

- Yaqoob, S.; Ghani, J.A.; Jouini, N.; Juri, A.Z.; Haron, C.H.C. Multi-Objective Optimization Using Grey Relational Analysis (GRA) for the High-Speed Orthogonal Turning of Heat-Treated Alloy Steel. J. Tribol. 2024, 43, 1–16. [Google Scholar]

- Sen, B.; Bhowmik, A.; Rachchh, N.; Patil, N.; Khatibi, A.; Kumar, R. Exploring Cryo-MQL Medium for Hard Machining of Hastelloy C276: A Multi-Objective Optimization Approach. Int. J. Interact. Des. Manuf. 2024, 18, 1–14. [Google Scholar] [CrossRef]

- Şirin, E. Evaluation of Tribological Performance of MQL Technique Combined with LN2, CO2, N2 Ecological Cooling/Lubrication Techniques When Turning of Hastelloy C22 Superalloy. Tribol. Int. 2023, 188, 108786. [Google Scholar] [CrossRef]

- Wu, S.; Liu, G.; Zhang, W.; Chen, W.; Wang, C. High-Speed Milling of Hardened Steel under Minimal Quantity Lubrication with Liquid Nitrogen. J. Manuf. Process. 2023, 95, 351–368. [Google Scholar] [CrossRef]

- Wang, B.; Pan, Q.W.; Xu, Z.K.; Zhang, P.; Yan, Y.; Gu, X.Z.; Li, Y.; Hong, C.; Li, X.W.; Zhang, Z.F. Investigation on the Fatigue Crack Growth Behaviors of AISI 4340 Steel with Different Strength–Toughness Combinations. Adv. Eng. Mater. 2024, 26, 2301692. [Google Scholar] [CrossRef]

- Da Silva, L.R.; Couto, D.A.; Dos Santo, F.V.; Duarte, F.J.; Mazzaro, R.S.; Veloso, G.V. Evaluation of Machined Surface of the Hardened AISI 4340 Steel through Roughness and Residual Stress Parameters in Turning and Grinding. Int. J. Adv. Manuf. Technol. 2020, 107, 791–803. [Google Scholar] [CrossRef]

- Roy, S.; Pradhan, A.; Padhan, S.; Das, A.; Das, S.R.; Dhupal, D. ANALYSIS ON POWER CONSUMPTION FOR LIFE CYCLE SUSTAINABILITY ASSESSMENT IN HARD TURNING OF AISI 4140 STEEL USING SPPP—AlTiSiN-COATED CARBIDE TOOL UNDER VARIOUS CUTTING ENVIRONMENTS. Surf. Rev. Lett. 2024, 31, 2450043. [Google Scholar] [CrossRef]

- Roy, S.; Kumar, R.; Das, R.K.; Sahoo, A.K. A Comprehensive Review on Machinability Aspects in Hard Turning of AISI 4340 Steel. IOP Conf. Ser. Mater. Sci. Eng. 2018, 390, 012009. [Google Scholar] [CrossRef]

- Gunjal, S.U.; Patil, N.G. Experimental Investigations into Turning of Hardened AISI 4340 Steel Using Vegetable Based Cutting Fluids under Minimum Quantity Lubrication. Procedia Manuf. 2018, 20, 18–23. [Google Scholar] [CrossRef]

- Noor, N.D.M.; Hadi, M.A.; Mekatronik, U.M.P. Study of Tool Wear Progression Using Nano-Hybrid Cryogenic MQL in Milling Titanium Alloy. J. Tribol. 2023, 37, 76–83. [Google Scholar]

- Khare, S.K.; Agarwal, S. Optimization of Machining Parameters in Turning of AISI 4340 Steel under Cryogenic Condition Using Taguchi Technique. Procedia CIRP 2017, 63, 610–614. [Google Scholar] [CrossRef]

- Ochengo, D.; Liang, L.; Wei, Z.; Ning, H. Optimization of Surface Quality and Power Consumption in Machining Hardened AISI 4340 Steel. Adv. Mater. Sci. Eng. 2022, 2022, 2675003. [Google Scholar] [CrossRef]

- Kumar, J.P.; Kishore, K.P.; Kumar, M.R.; Karthick, K.R.S.; Gowtham, S.V. Experimental Investigation on Hard Turning of AISI 4340 Steel Using Cemented Coated Carbide Insert. IOP Conf. Ser. Mater. Sci. Eng. 2018, 314, 012004. [Google Scholar] [CrossRef]

- Vaishnavi, B.; Kanchana, J.; Senthilkumar, M.; Siva Kumar, M. Sustainable Machining of AISI 4340 Steel Using Semi-Vegetable Oil Blends. Mater. Manuf. Process. 2024, 39, 1881–1893. [Google Scholar] [CrossRef]

- Yaqoob, S.; Ghani, J.A.; Jouini, N.; Juri, A.Z. Performance Evaluation of PVD and CVD Multilayer-Coated Tools in Machining High-Strength Steel. Coatings 2024, 14, 865. [Google Scholar] [CrossRef]

- Dennison, M.S.; Barik, D.; Ponnusamy, S. Turning Operation of AISI 4340 Steel in Flooded, near-Dry and Dry Conditions: A Comparative Study on Tool-Work Interface Temperature. Mech. Mech. Eng. 2019, 23, 172–182. [Google Scholar] [CrossRef]

- Kónya, G.; Csorba, B.; Szabó, N.; Kovács, Z.F. The Effects of Cutting Parameters on Cutting Force and Tribological Properties of Machined Surface Under Dry Turning of AISI304L Austenitic Stainless Steel. J. Manuf. Mater. Process. 2024, 8, 257. [Google Scholar] [CrossRef]

- Sivaraman, V.; Sankaran, S.; Vijayaraghavan, L. The Effect of Cutting Parameters on Cutting Force During Turning Multiphase Microalloyed Steel. Procedia CIRP 2012, 4, 157–160. [Google Scholar] [CrossRef]

- Tanvir, M.H.; Hussain, A.; Rahman, M.M.T.; Ishraq, S.; Zishan, K.; Rahul, S.T.T.; Habib, M.A. Multi-Objective Optimization of Turning Operation of Stainless Steel Using a Hybrid Whale Optimization Algorithm. J. Manuf. Mater. Process. 2020, 4, 64. [Google Scholar] [CrossRef]

- Demirpolat, H.; Binali, R.; Patange, A.D.; Pardeshi, S.S.; Gnanasekaran, S. Comparison of Tool Wear, Surface Roughness, Cutting Forces, Tool Tip Temperature, and Chip Shape during Sustainable Turning of Bearing Steel. Materials 2023, 16, 4408. [Google Scholar] [CrossRef]

- Taylan, F.; Ermergen, T. The Effect of High-Pressure Jet Cooling on Surface Roughness, Cutting Force and Chip Formation of Ti-6Al-4V ELI in High-Speed Turning. Mach. Sci. Technol. 2023, 27, 453–471. [Google Scholar] [CrossRef]

- Gundarneeya, T.P.; Golakiya, V.D.; Ambaliya, S.D.; Patel, S.H. Experimental Investigation of Process Parameters on Surface Roughness and Dimensional Accuracy in Hard Turning of EN24 Steel. Mater. Today Proc. 2022, 57, 674–680. [Google Scholar] [CrossRef]

- Jouini, N.; Revel, P.; Bigerelle, M. Relevance of Roughness Parameters of Surface Finish in Precision Hard Turning. Scanning 2014, 36, 86–94. [Google Scholar] [CrossRef]

- Ranjan Das, S.; Panda, A.; Dhupal, D. Hard Turning of AISI 4340 Steel Using Coated Carbide Insert: Surface Roughness, Tool Wear, Chip Morphology and Cost Estimation. Mater. Today Proc. 2018, 5, 6560–6569. [Google Scholar] [CrossRef]

- Özbek, O.; Saruhan, H. The Effect of Vibration and Cutting Zone Temperature on Surface Roughness and Tool Wear in Eco-Friendly MQL Turning of AISI D2. J. Mater. Res. Technol. 2020, 9, 2762–2772. [Google Scholar] [CrossRef]

- Yaqoob, S.; A. Ghani, J.; Jouini, N.; Sheik Muhamad, S.; Che Haron, C.H.; Juri, A. High-Speed Turning of AISI 4340 Alloy Steel Using Carbide Tools in a Sustainable Minimum Quantity Lubrication Environment. Ind. Lubr. Tribol. 2024. [Google Scholar] [CrossRef]

- Uzun, M.; Usca, Ü.A.; Kuntoğlu, M.; Gupta, M.K. Influence of Tool Path Strategies on Machining Time, Tool Wear, and Surface Roughness during Milling of AISI X210Cr12 Steel. Int. J. Adv. Manuf. Technol. 2022, 119, 2709–2720. [Google Scholar] [CrossRef]

- Roy, S.; Kumar, R.; Sahoo, A.K.; Panda, A. Cutting Tool Failure and Surface Finish Analysis in Pulsating MQL-Assisted Hard Turning. J Fail. Anal. Preven. 2020, 20, 1274–1291. [Google Scholar] [CrossRef]

- Grzesik, W.; Denkena, B.; Żak, K.; Grove, T.; Bergmann, B. Energy Consumption Characterization in Precision Hard Machining Using CBN Cutting Tools. Int. J. Adv. Manuf. Technol. 2016, 85, 2839–2845. [Google Scholar] [CrossRef]

- Özdemir, M. Optimization with Taguchi Method of Influences on Surface Roughness of Cutting Parameters in CNC Turning Processing. Mech 2019, 25, 397–405. [Google Scholar] [CrossRef]

- Sivaiah, P.; Sudheera, M.; Muralidhar Singh, M.; Yuvaraj, C.; Chengal Reddy, V.; Lakshmi Narasimhamu, K.; Dilip Kumar, M. Investigation on Turning Process Performance during Machining of 15-5PH Stainless Steel Material with Eco-Friendly Machining Technique. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Shokrani, A.; Al-Samarrai, I.; Newman, S.T. Hybrid Cryogenic MQL for Improving Tool Life in Machining of Ti-6Al-4V Titanium Alloy. J. Manuf. Process. 2019, 43, 229–243. [Google Scholar] [CrossRef]

- Liu, M.; Li, C.; Zhang, Y.; An, Q.; Yang, M.; Gao, T.; Mao, C.; Liu, B.; Cao, H.; Xu, X.; et al. Cryogenic Minimum Quantity Lubrication Machining: From Mechanism to Application. Front. Mech. Eng. 2021, 16, 649–697. [Google Scholar] [CrossRef]

- Zainol, A.; Yazid, M.Z.A. The Effect of Portable MQL Applicator onto Carbide Insert during Turning Inconel 718. J. Mech. Eng. Sci. 2018, 12, 3605–3613. [Google Scholar] [CrossRef]

- Aslan, A.; Salur, E.; Kuntoğlu, M. Evaluation of the Role of Dry and MQL Regimes on Machining and Sustainability Index of Strenx 900 Steel. Lubricants 2022, 10, 301. [Google Scholar] [CrossRef]

- Yaqoob, S.; Ghani, J.A.; Juri, A.Z.; Muhamad, S.S.; Haron, C.H.C.; Jouini, N. A Review of Sustainable Hybrid Lubrication (Cryo-MQL) Techniques in Machining Processes. Int. J. Adv. Manuf. Technol. 2024, 131, 151–169. [Google Scholar] [CrossRef]

- Duc, T.M.; Ngoc, T.B.; Tuan, N.M.; Trang, D.T.H.; Long, T.T. A Study on Mechanisms of Saw-Tooth Chip Formation in Hard Turning under Hybrid Nanofluid-Assisted MQL Environment. Adv. Mech. Eng. 2024, 16, 1–13. [Google Scholar] [CrossRef]

| Element | Wt% |

|---|---|

| Fe | Balance |

| C | 0.39 |

| Mn | 0.71 |

| P | 0.015 |

| S | 0.006 |

| Si | 0.26 |

| Ni | 1.73 |

| Cr | 0.80 |

| Mo | 0.22 |

| Specifications | CVD Tool |

|---|---|

| Grade | P-grade |

| Coating | Al2O3/TiCN |

| Coating thickness | 18 µm |

| Hardness of substrate | 90.5 HRA |

| Nose radius | 0.4 mm |

| Rake angle | −6° |

| Cutting edge angle | 95° |

| Factors/Level | 1 | 2 | 3 |

|---|---|---|---|

| Cutting speed, V (m/min) | 300 | 350 | 400 |

| Feed rate, f (mm/rev) | 0.05 | 0.075 | 0.1 |

| Depth of cut, doc (mm) | 0.1 | 0.2 | 0.3 |

| Experiment | V (m/min) | f (mm/rev) | doc (mm) |

|---|---|---|---|

| 1 | V 1 | f 1 | doc 1 |

| 2 | V 1 | f 2 | doc 2 |

| 3 | V 1 | f 3 | doc 3 |

| 4 | V 2 | f 1 | doc 2 |

| 5 | V 2 | f 2 | doc 3 |

| 6 | V 2 | f 3 | doc 1 |

| 7 | V 3 | f 1 | doc 3 |

| 8 | V 3 | f 2 | doc 1 |

| 9 | V 3 | f 3 | doc 2 |

| No. | Cutting Force Fc (N) | Surface Roughness Ra (µm) | Tool Life T (s) | |||

|---|---|---|---|---|---|---|

| Measured Value | S/N Ratio | Measured Value | S/N Ratio | Measured Value | S/N Ratio | |

| 1 | 43.3 | −32.7298 | 0.465 | 6.6509 | 1155 | 61.256 |

| 2 | 91.59 | −39.2370 | 0.685 | 3.2862 | 713 | 57.059 |

| 3 | 128.8 | −42.1983 | 0.895 | 0.9635 | 339 | 50.064 |

| 4 | 68.88 | −36.7619 | 0.305 | 10.314 | 847 | 58.553 |

| 5 | 99.22 | −39.9320 | 0.541 | 5.3361 | 380 | 51.604 |

| 6 | 76.65 | −37.6902 | 0.696 | 3.1478 | 554 | 54.876 |

| 7 | 49.55 | −33.9009 | 0.307 | 10.2572 | 290 | 49.242 |

| 8 | 47.68 | −33.5667 | 0.535 | 5.4329 | 388 | 51.767 |

| 9 | 97.3 | −39.7623 | 0.726 | 2.7813 | 206 | 46.294 |

| Parameter | DF Value | Seq SS | Adj SS | Adj MS | F Value | p Value | % Contribution |

|---|---|---|---|---|---|---|---|

| V | 2 | 11.0364 | 11.0364 | 5.5182 | 18.25 | 0.052 | 12.61% |

| f | 2 | 44.3830 | 44.3830 | 22.1915 | 73.38 | 0.013 * | 50.69% |

| doc | 2 | 31.5308 | 31.5308 | 15.7654 | 52.13 | 0.019 * | 36.01% |

| Residual Error | 2 | 0.6048 | 0.6048 | 0.3024 | |||

| Total | 8 | 87.551 |

| Parameter | DF Value | Seq SS | Adj SS | Adj MS | F Value | p Value | % Contribution |

|---|---|---|---|---|---|---|---|

| V | 2 | 13.099 | 13.099 | 6.6549 | 16.04 | 0.059 | 15.59% |

| f | 2 | 70.8848 | 70.8848 | 35.4424 | 85.40 | 0.012 * | 83.03% |

| doc | 2 | 0.3454 | 0.3454 | 0.1727 | 0.42 | 0.706 | 0.40% |

| Residual Error | 2 | 0.8300 | 0.8300 | 0.4150 | |||

| Total | 8 | 85.370 |

| Parameters | DF Value | Seq SS | Adj SS | Adj MS | F Value | p Value | % Contribution |

|---|---|---|---|---|---|---|---|

| V | 2 | 304342 | 304342 | 152171 | 43.30 | 0.023 * | 39.73% |

| f | 2 | 247172 | 247172 | 123586 | 35.16 | 0.028 * | 32.26% |

| doc | 2 | 207461 | 207461 | 103731 | 29.51 | 0.033 * | 27.08% |

| Residual Error | 2 | 7029 | 7029 | 3515 | |||

| Total | 8 | 766004 |

| Exp. No | Normalized Values | Grey Relation Coefficient | Grey Relation Grade (GRG) | Ranking | ||||

|---|---|---|---|---|---|---|---|---|

| Ra | Fc | TL | Ra | Fc | TL | |||

| 1 | 0.729 | 1.000 | 1.000 | 0.648 | 1.000 | 1.000 | 0.879 | 1.0 |

| 2 | 0.356 | 0.435 | 0.534 | 0.437 | 0.470 | 0.517 | 0.473 | 6.0 |

| 3 | 0.000 | 0.000 | 0.140 | 0.333 | 0.333 | 0.368 | 0.343 | 9.0 |

| 4 | 1.000 | 0.701 | 0.674 | 1.000 | 0.626 | 0.606 | 0.741 | 2.0 |

| 5 | 0.600 | 0.346 | 0.183 | 0.556 | 0.433 | 0.380 | 0.455 | 7.0 |

| 6 | 0.337 | 0.610 | 0.367 | 0.430 | 0.562 | 0.441 | 0.476 | 5.0 |

| 7 | 0.997 | 0.927 | 0.088 | 0.993 | 0.872 | 0.354 | 0.738 | 3.0 |

| 8 | 0.610 | 0.949 | 0.191 | 0.562 | 0.907 | 0.382 | 0.615 | 4.0 |

| 9 | 0.286 | 0.368 | 0.000 | 0.412 | 0.442 | 0.333 | 0.394 | 8.0 |

| Output Variable | Dry Condition | Cryo+MQL Condition | Remarks |

|---|---|---|---|

| Cutting force (N) | 43.3 | 45.4 | A 4.6% increase in main cutting force is noticed when machining was performed with hybrid lubrication. |

| Surface roughness (µm) | 0.465 | 0.24 | A 48% decrease in surface roughness was realized with hybrid environment. |

| Tool life (s) | 1155 | 3288 | A 184.5% improvement in tool life results was achieved with hybrid lubrication. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jouini, N.; A. Ghani, J.; Yaqoob, S.; Juri, A.Z. Optimized Machining Parameters for High-Speed Turning Process: A Comparative Study of Dry and Cryo+MQL Techniques. Processes 2025, 13, 739. https://doi.org/10.3390/pr13030739

Jouini N, A. Ghani J, Yaqoob S, Juri AZ. Optimized Machining Parameters for High-Speed Turning Process: A Comparative Study of Dry and Cryo+MQL Techniques. Processes. 2025; 13(3):739. https://doi.org/10.3390/pr13030739

Chicago/Turabian StyleJouini, Nabil, Jaharah A. Ghani, Saima Yaqoob, and Afifah Zakiyyah Juri. 2025. "Optimized Machining Parameters for High-Speed Turning Process: A Comparative Study of Dry and Cryo+MQL Techniques" Processes 13, no. 3: 739. https://doi.org/10.3390/pr13030739

APA StyleJouini, N., A. Ghani, J., Yaqoob, S., & Juri, A. Z. (2025). Optimized Machining Parameters for High-Speed Turning Process: A Comparative Study of Dry and Cryo+MQL Techniques. Processes, 13(3), 739. https://doi.org/10.3390/pr13030739