Research on Camellia oleifera Shell Mechanical–Structural Cracking Behavior During Collision Hulling with In Situ Testing

Abstract

1. Introduction

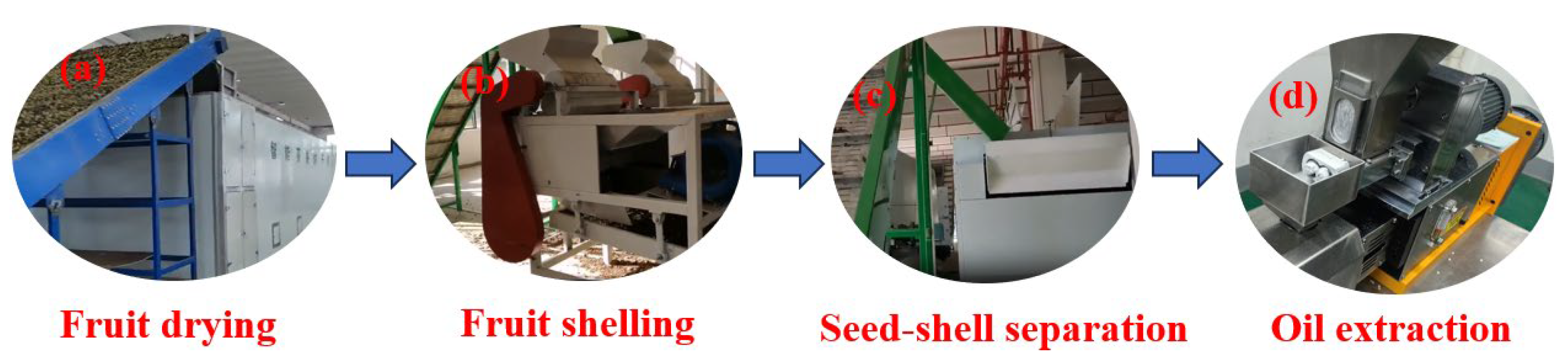

2. Materials and Methods

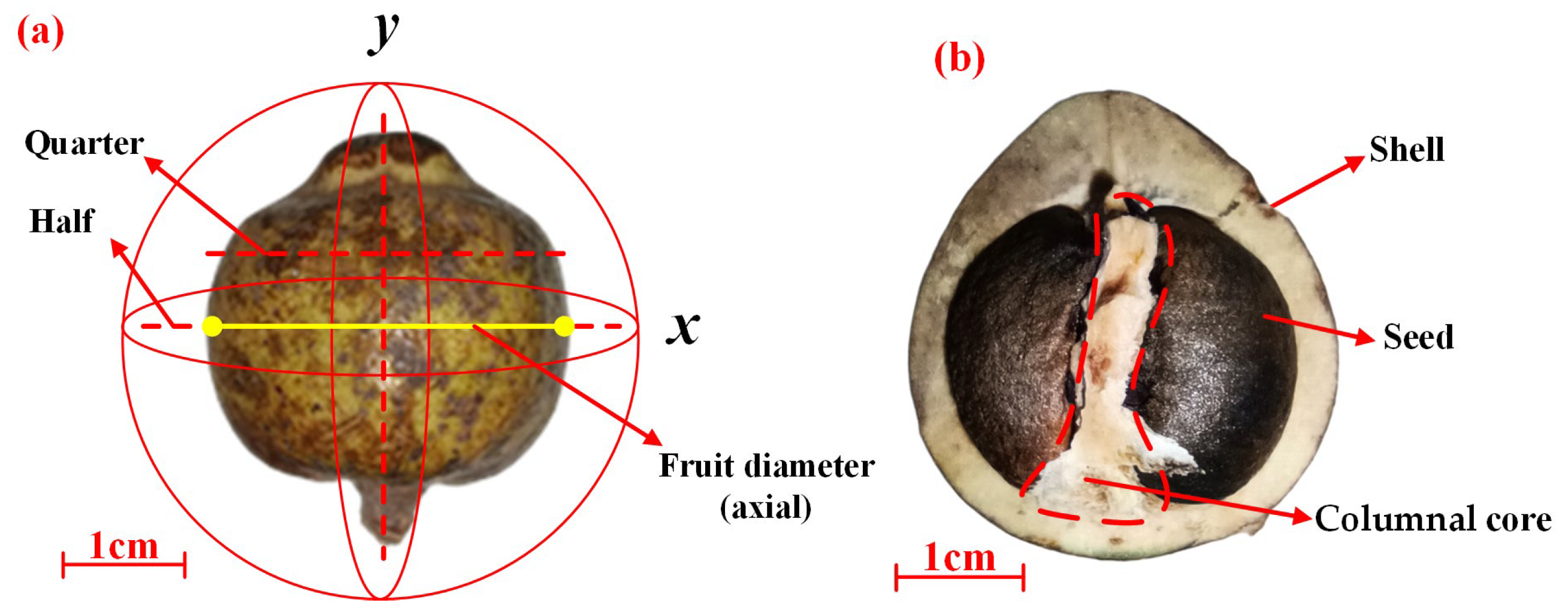

2.1. Experimental Materials

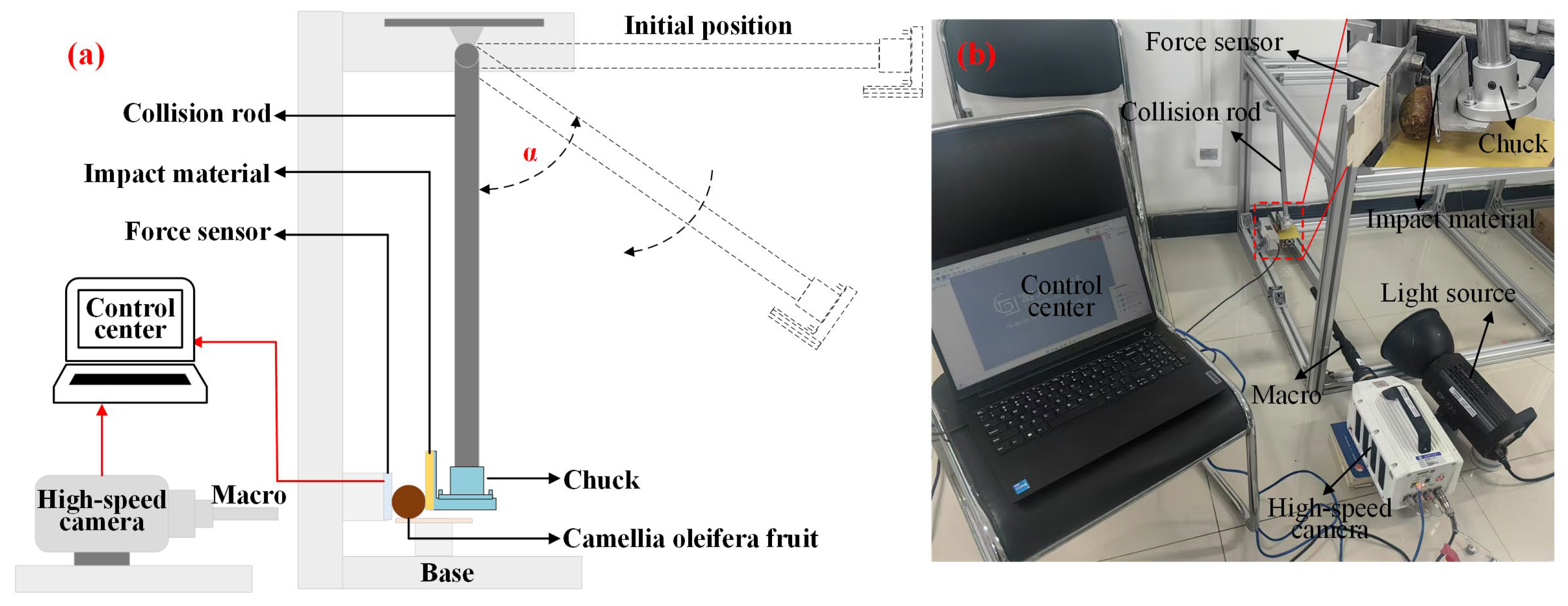

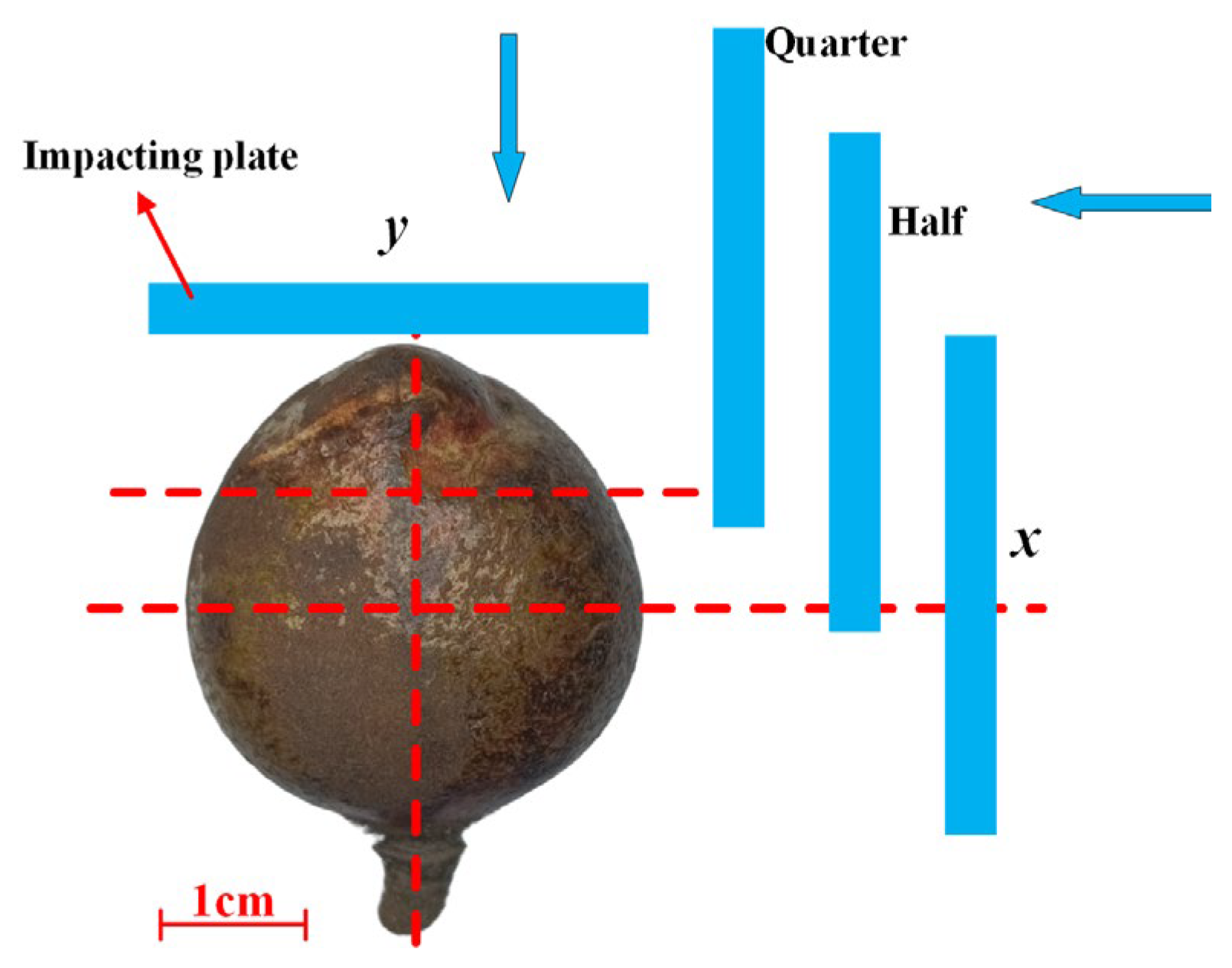

2.2. Experiment

3. Results and Discussion

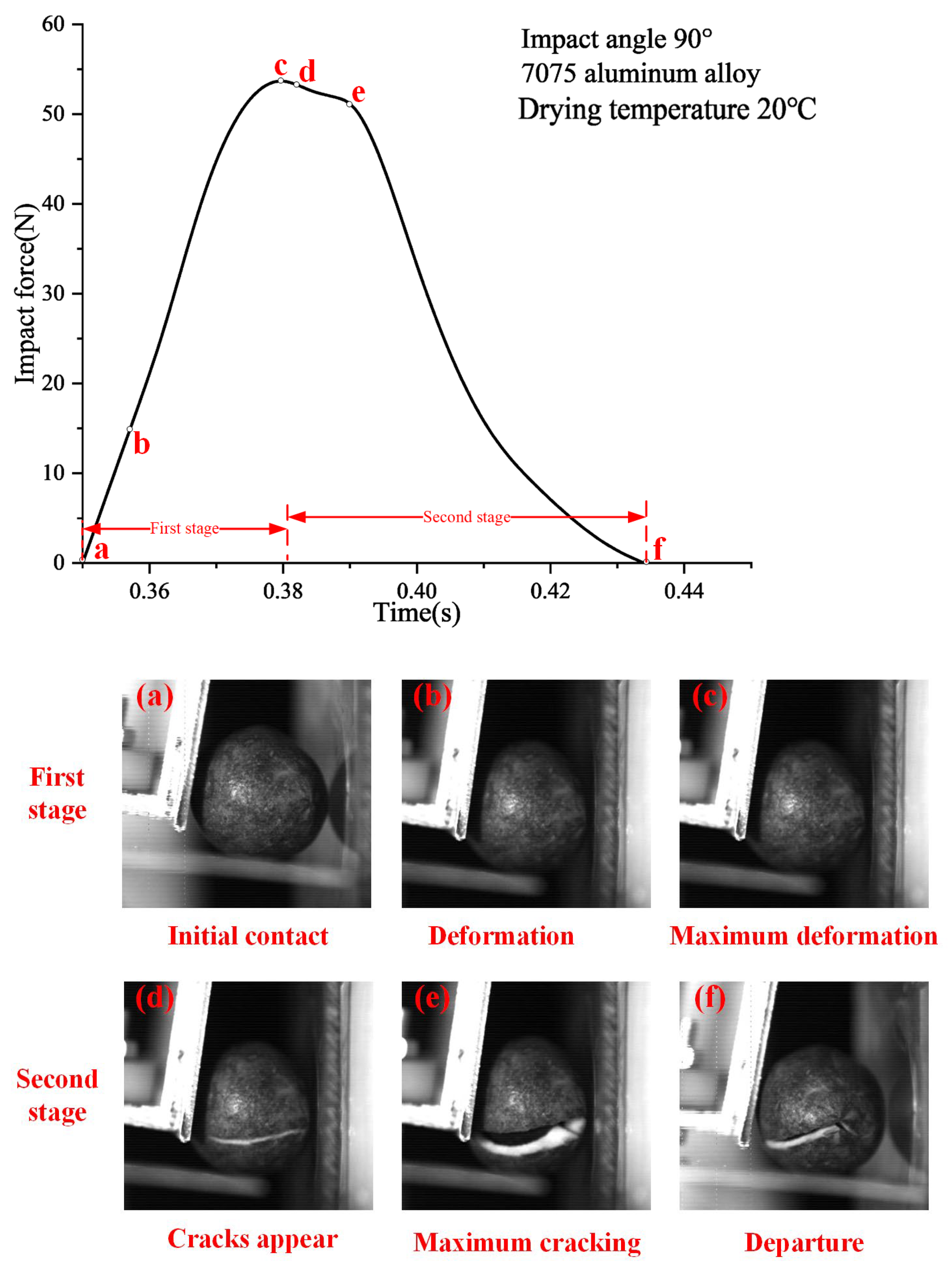

3.1. Mechanical–Structural Properties of Camellia oleifera Fruit During Collision

3.2. Influence of Different Collision Positions on Camellia oleifera Fruit Shelling

3.3. Influence of Different Collision Angles on Camellia oleifera Fruit Shelling

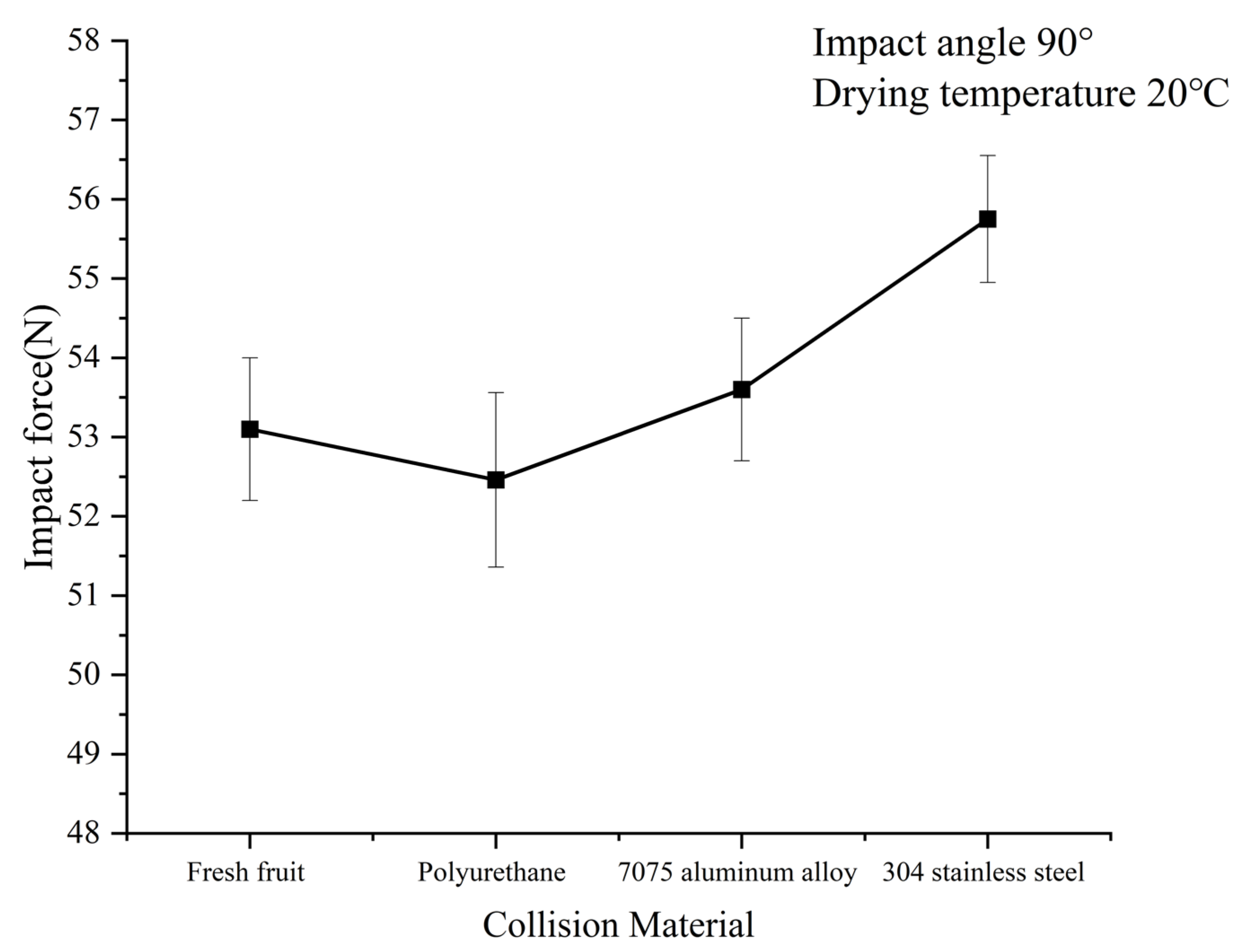

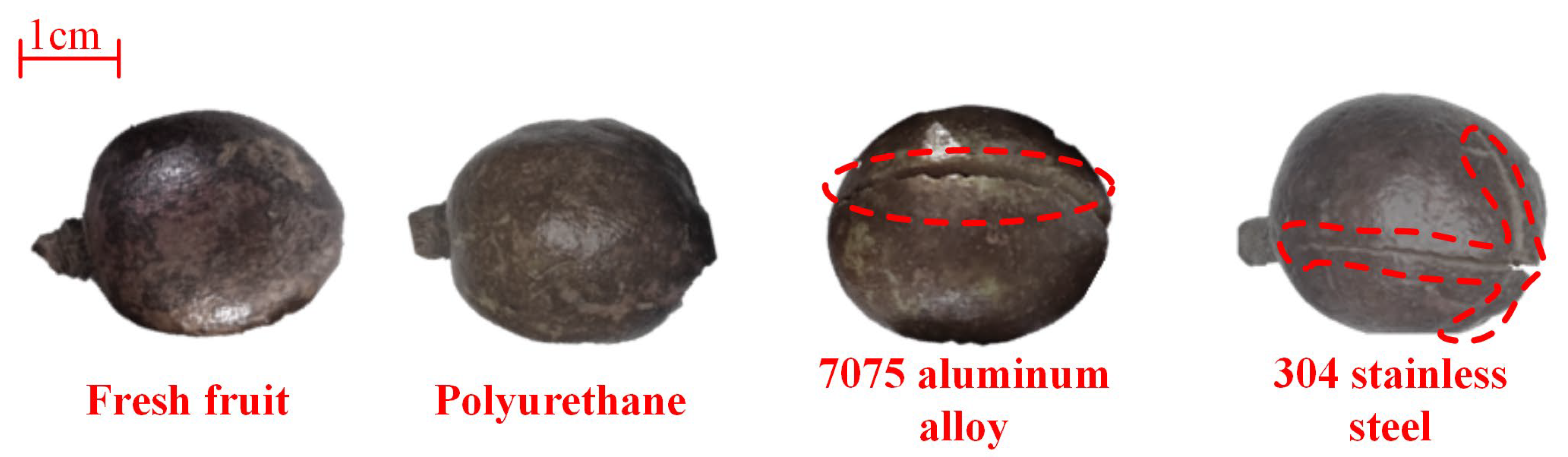

3.4. Influence of Different Collision Materials on Camellia oleifera Fruit Shelling

3.5. Influence of Drying Temperature on Camellia oleifera Fruit Shelling

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xing, K.-F.; Zou, Y.-J.; Xie, H.-X. Variation in Fruit Traits and Seed Nutrient Compositions of Wild Camellia oleifera: Implications for Camellia oleifera Domestication. Horticulturae 2024, 10, 450. [Google Scholar] [CrossRef]

- Liu, J.; Wu, L.; Chen, D. Development of a soil quality index for Camellia oleifera forestland yield under three different parent materials in Southern China. Soil Tillage Res. 2018, 176, 45–50. [Google Scholar] [CrossRef]

- Wang, Y.; Ma, J.; Xiong, R. Design on multi-channel pneumatic planer for Camellia oleifera shelling. Hubei Agric. Sci. 2018, 57, 100. [Google Scholar]

- Zhu, G.; Liu, H.; Xie, Y. Postharvest processing and storage methods for Camellia oleifera seeds. Food Rev. Int. 2020, 36, 319–339. [Google Scholar] [CrossRef]

- Zhang, J.; Gong, L.; Sun, K. Preparation of activated carbon from waste Camellia oleifera shell for supercapacitor application. J. Solid State Electrochem. 2012, 16, 2179–2186. [Google Scholar] [CrossRef]

- Zhang, F.; Zhu, F.; Chen, B. Composition, bioactive substances, extraction technologies and the influences on characteristics of Camellia oleifera oil: A review. Food Res. Int. 2022, 156, 111159. [Google Scholar] [CrossRef]

- Ndukwu, M.C.; Asoegwu, S.N. Functional performance of a vertical-shaft centrifugal palm nut cracker. Res. Agric. Eng. 2010, 56, 77–83. [Google Scholar] [CrossRef]

- Ibrahim, A.; Onwualu, A.P. Technologies for extraction of oil from oil-bearing agricultural products: A review. J. Agric. Eng. Technol. 2005, 13, 58–70. [Google Scholar]

- Yan, F.; Li, X.; Huang, G. Camellia oleifera fresh fruit harvesting in China. In Proceedings of the 2020 5th International Conference on Mechanical, Control and Computer Engineering (ICMCCE), Harbin, China, 25–27 December 2020; pp. 699–702. [Google Scholar]

- Kang, D.; Wang, Y.; Fan, Y. Research and development of Camellia oleifera fruit sheller and sorting machine. IOP Conf. Ser. Earth Environ. Sci. 2018, 108, 042051. [Google Scholar] [CrossRef]

- Peng, Y.; Zhou, H.; Zhang, A. Natural products from Camellia oleifera fruit and its comprehensive utilisation. Nat. Prod. Res. 2024, 20, 1–17. [Google Scholar] [CrossRef]

- Wei, X.; Chen, X.; Liao, P. Study on the Mechanical Properties and the Way of Breaking the Shell of Fresh Camellia oleifera Fruit. Horticulturae 2023, 9, 236. [Google Scholar] [CrossRef]

- Wang, F.; Liu, Z.; Ding, Y. Study on the splitting by hot-air drying of COF. Int. J. Food Eng. 2022, 18, 143–151. [Google Scholar] [CrossRef]

- Jinxiong, L.; Mei’e, Z.; Zhili, W. Low-Temperature Airflow-Drying Cracking Coupling with Flexible Mechanical Deshelling for Camellia oleifera Fruit: Process and Mechanism. Dry. Technol. 2024, 42, 871–879. [Google Scholar] [CrossRef]

- Jie, M.; Ang, L.; Xi, L. Structure design of Camellia oleifera fruit sheller by EBD method. IOP Conf. Ser. Earth Environ. Sci. 2020, 585, 012163. [Google Scholar]

- Lim, B.Y.; Shamsudin, R.; Baharudin, B. A review of processing and machinery for Jatropha curcas L. fruits and seeds in biodiesel production: Harvesting, shelling, pretreatment and storag. Renew. Sustain. Energy Rev. 2015, 52, 991–1002. [Google Scholar] [CrossRef]

- Wu, J.; Fan, X.; Huang, X. Effect of different drying treatments on the quality of Camellia oleifera seed oil. S.Afr. J. Chem. Eng. 2021, 35, 8–13. [Google Scholar] [CrossRef]

- Zhu, G.; Lei, D.; Xie, Y. Effects of postharvest piling up in bulk on qualities of Camellia oleifera seeds. J. Stored Prod. Res. 2024, 106, 102291. [Google Scholar] [CrossRef]

- Yang, P.; Fu, H.; Sun, P. Shell structure impacts Camellia oleifera fruit splitting during dehydration. Food Bioprod. Process. 2024, 148, 298–308. [Google Scholar] [CrossRef]

- Wang, X.; Bian, B.; Tuluhong, T. Experiments and parameter optimization of almond shell and kernel air separation device. Trans. Chin. Soc. Agric. Eng. 2021, 37, 299–306. [Google Scholar]

- Hay, F.R.; Rezaei, S.; Wolkis, D.; McGill, C. Determination andcontrol of seed moisture. Seed Sci. Technol. 2023, 51, 267–285. [Google Scholar] [CrossRef]

- Wen, Y.; Su, S.; Jia, T. Allocation of photoassimilates in bud and fruit from different leaf nodes of Camellia oleifera. HortScience 2021, 56, 469–477. [Google Scholar] [CrossRef]

- Yang, L.; Wang, Z.; Cui, B. Experimental and FEM research on Camellia oleifera shell structural–mechanical cracking behavior during hulling. J. Food Process Eng. 2024, 47, e14662. [Google Scholar] [CrossRef]

- Zhang, X.; He, C.; Yan, B. Effects of fruit load on growth, photosynthesis, biochemical characteristics, and fruit quality of Camellia oleifera. Sci. Hortic. 2023, 317, 112046. [Google Scholar] [CrossRef]

- Tang, H.; Zhu, G.; Wang, Z. Prediction method for maize kernel impact breakage based on high-speed camera and FEM. Powder Technol. 2024, 444, 120002. [Google Scholar] [CrossRef]

- Hinrichsen, P.F. A Simple Moment of Inertia Measurement. Phys. Teach. 2022, 60, 292–295. [Google Scholar] [CrossRef]

- Wang, Q.; Chang, S.; Tan, Y. Mesopore structure in Camellia oleifera shell. Protoplasma 2019, 256, 1145–1151. [Google Scholar] [CrossRef]

- Paris, P.C.; Sih, G.C. Stress analysis of cracks. ASTM Stp 1965, 381, 30–81. [Google Scholar]

- Flores-Johnson, E.A.; Carrillo, J.G.; Zhai, C. Microstructure and mechanical properties of hard Acrocomia mexicana fruit shell. Sci. Rep. 2018, 8, 9668. [Google Scholar] [CrossRef]

- Singh, S.M.; Rao, P.S. Impact Dehulling of Browntop Millet: Its Physical and Nutritional Characterization. J. Cereal Sci. 2024, 121, 104078. [Google Scholar] [CrossRef]

- Ye, D.; Xu, Y.; Xiao, L. Effects of low-cycle fatigue on static mechanical properties, microstructures and fracture behavior of 304 stainless steel. Mater. Sci. Eng. A 2010, 527, 4092–4102. [Google Scholar] [CrossRef]

- Kogelnik, H.J.; Huang, H.H.; Barnes, M. Comparison of the dynamic properties of solid polyurethane elastomers. J. Elastomers Plast. 1991, 23, 314–344. [Google Scholar] [CrossRef]

- Wang, F.; Guo, C.; Wen, J. Simulation of the splitting process by hot-air drying of Camellia oleifera fruit. Dry. Technol. 2024, 42, 1526–1539. [Google Scholar] [CrossRef]

- Wu, L.; Li, J.; Gu, Y. Effect of chilling temperature on chlorophyll florescence, leaf anatomical structure, and physiological and biochemical characteristics of two Camellia oleifera cultivars. Int. J. Agric. Biol. 2020, 23, 777–785. [Google Scholar]

- Yang, D.; Pan, S.; Ding, Y. Experimental evidence for negative turgor pressure in small leaf cells of Robinia pseudoacacia L versus large cells of Metasequoia glyptostroboides Hu et WC Cheng. 1. Evidence from pressure—Volume curve analysis of dead tissue. Plant Cell Environ. 2017, 40, 351–363. [Google Scholar] [CrossRef]

- Shang, L.; Yuan, R.; Liu, X. Precursor screening of fruit shell derived hard carbons for low-potential sodium storage: A low lignin content supports the formation of closed pores. Carbon 2024, 223, 119038. [Google Scholar] [CrossRef]

| Material | Hardness (HV) | Elastic Modulus (GPa) | Density (g/cm3) |

|---|---|---|---|

| Fresh fruit | 2.5 | 0.01 | 1.05 |

| Polyurethane | 85 | 0.03 | 1.20 |

| 7075 aluminum alloy | 175 | 71.7 | 2.81 |

| 304 stainless steel | 215 | 193 | 8.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xing, H.; Yang, L.; Zhao, M.; Ma, Z.; Wang, Z.; Shu, C.; Huang, P.; Cui, B. Research on Camellia oleifera Shell Mechanical–Structural Cracking Behavior During Collision Hulling with In Situ Testing. Processes 2025, 13, 856. https://doi.org/10.3390/pr13030856

Xing H, Yang L, Zhao M, Ma Z, Wang Z, Shu C, Huang P, Cui B. Research on Camellia oleifera Shell Mechanical–Structural Cracking Behavior During Collision Hulling with In Situ Testing. Processes. 2025; 13(3):856. https://doi.org/10.3390/pr13030856

Chicago/Turabian StyleXing, Honggen, Liu Yang, Menghao Zhao, Zhide Ma, Zhicheng Wang, Can Shu, Pingan Huang, and Bo Cui. 2025. "Research on Camellia oleifera Shell Mechanical–Structural Cracking Behavior During Collision Hulling with In Situ Testing" Processes 13, no. 3: 856. https://doi.org/10.3390/pr13030856

APA StyleXing, H., Yang, L., Zhao, M., Ma, Z., Wang, Z., Shu, C., Huang, P., & Cui, B. (2025). Research on Camellia oleifera Shell Mechanical–Structural Cracking Behavior During Collision Hulling with In Situ Testing. Processes, 13(3), 856. https://doi.org/10.3390/pr13030856