Control Mechanism of Earthquake Disasters Induced by Hard–Thick Roofs’ Breakage via Ground Hydraulic Fracturing Technology

Abstract

:1. Introduction

2. HTRGFT for Mine Earthquake Disasters in Workfaces

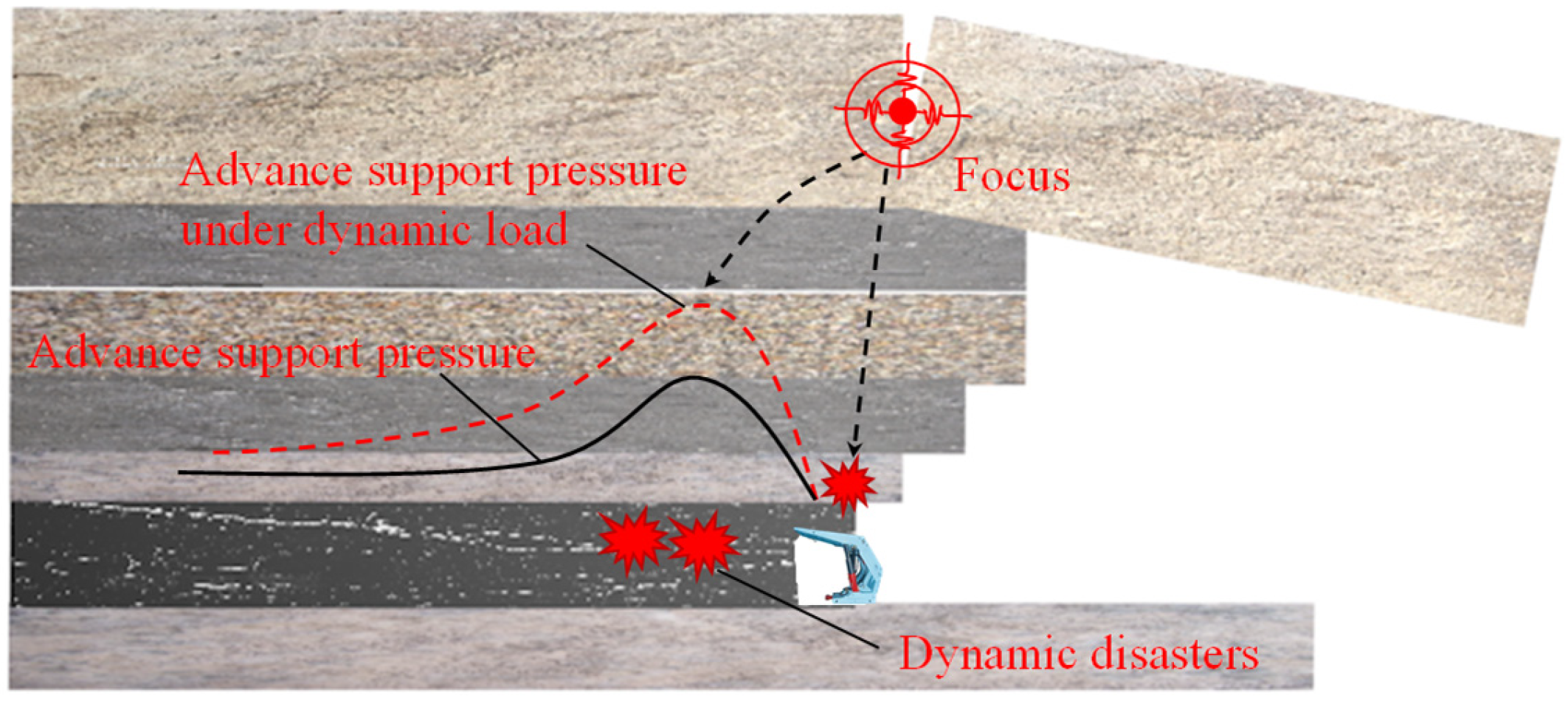

2.1. Mechanism of Mine Earthquake Disaster Occurrence in Workfaces Due to HTRs’ Periodic Breakage

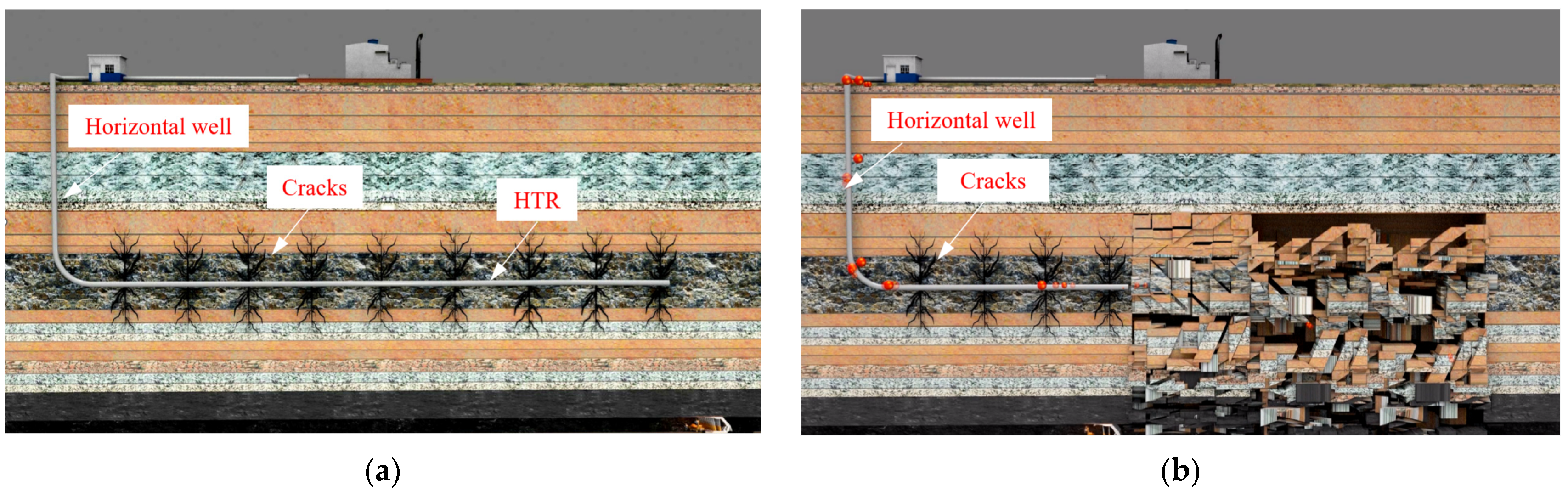

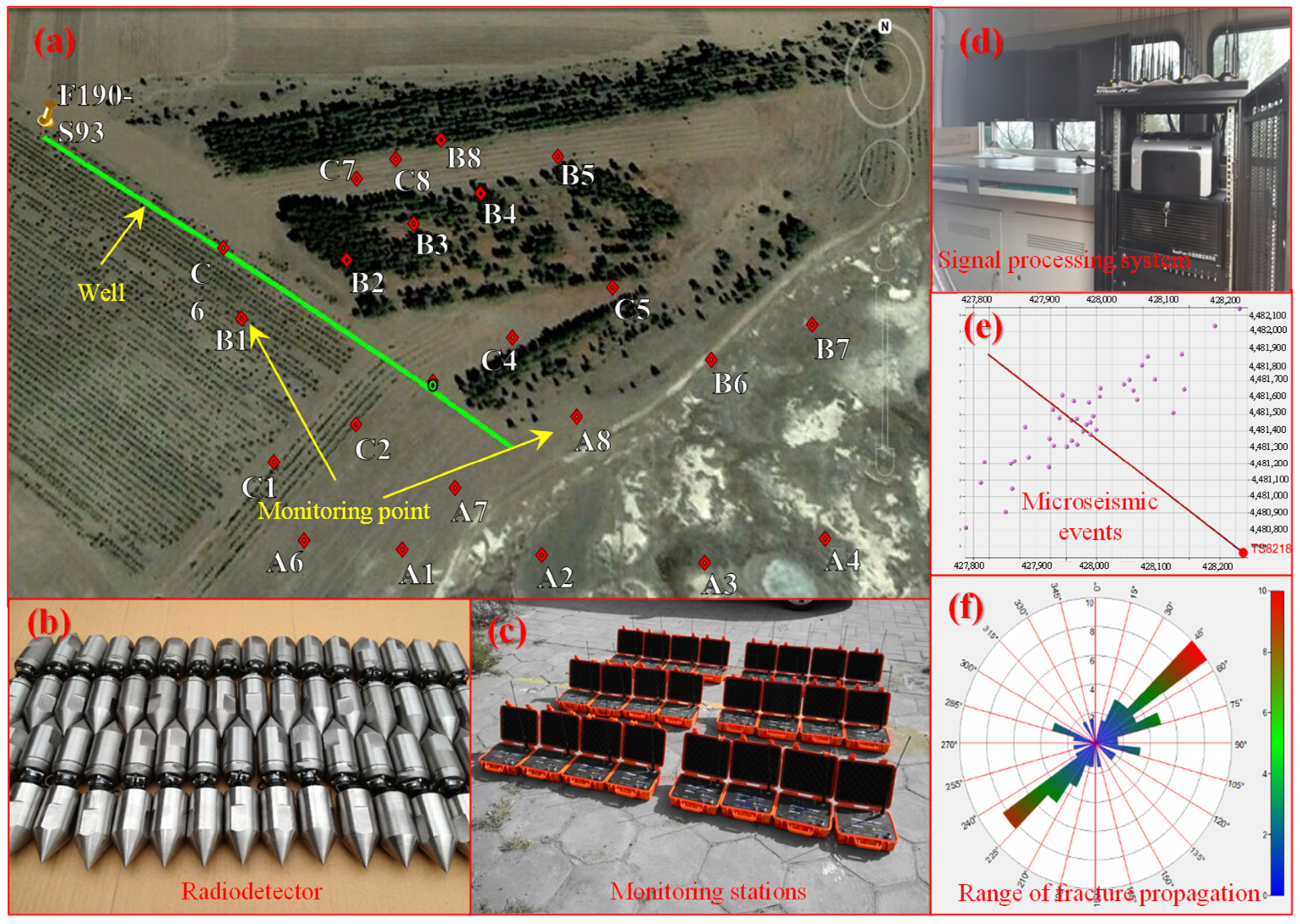

2.2. HTR Ground Fracturing Technology (HTRGFT)

2.3. Strata Weakening Mechanism of the HTRGFT

3. Model of the Influent of Mine Earthquake on Impact Load During HTRs’ Periodic Breakage

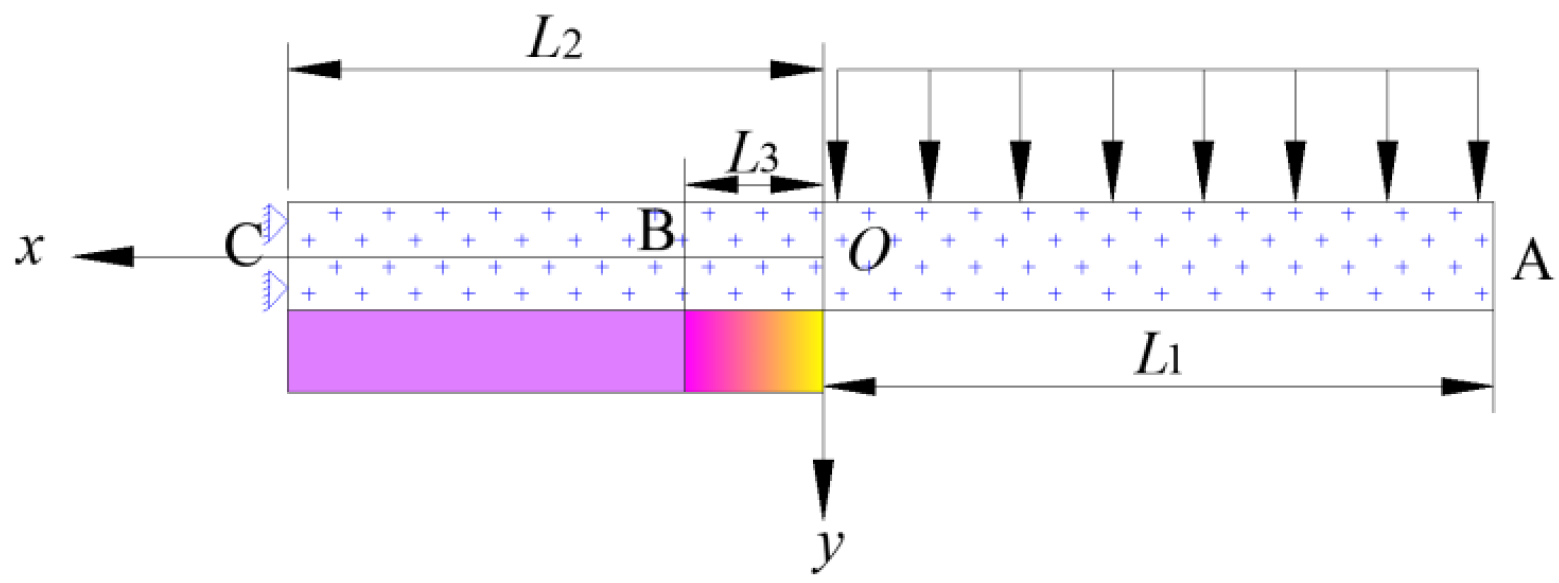

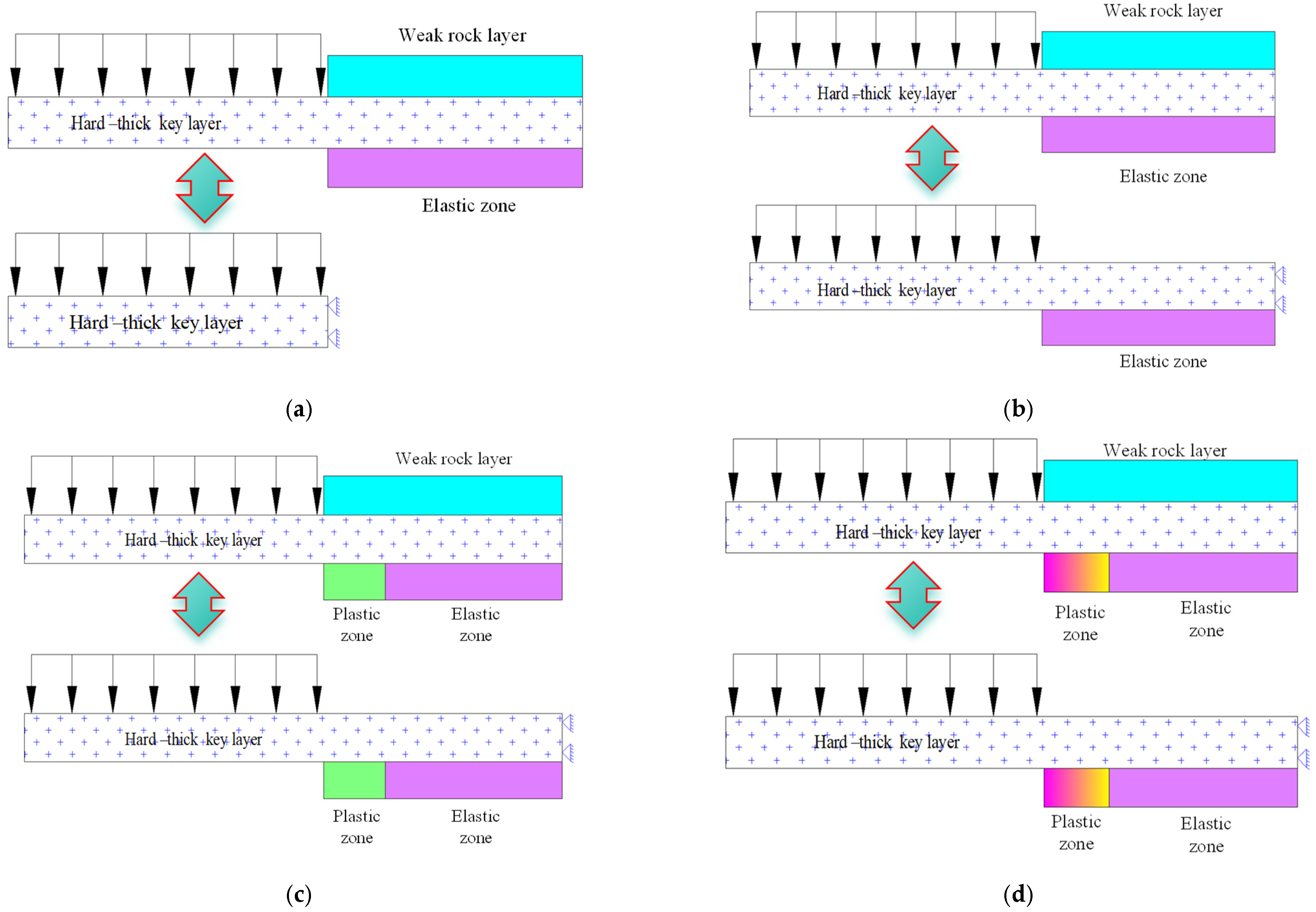

3.1. Periodic Breaking Mechanical Model of HTRs

3.2. Timoshenko Beam Theory on Winkler Foundation

3.3. Boundary Conditions

3.4. Energy of HTRs During Periodic Breakage

3.5. Relationship Between Accumulated Energy of HTRs and Dynamic Disasters During Periodic Breakage

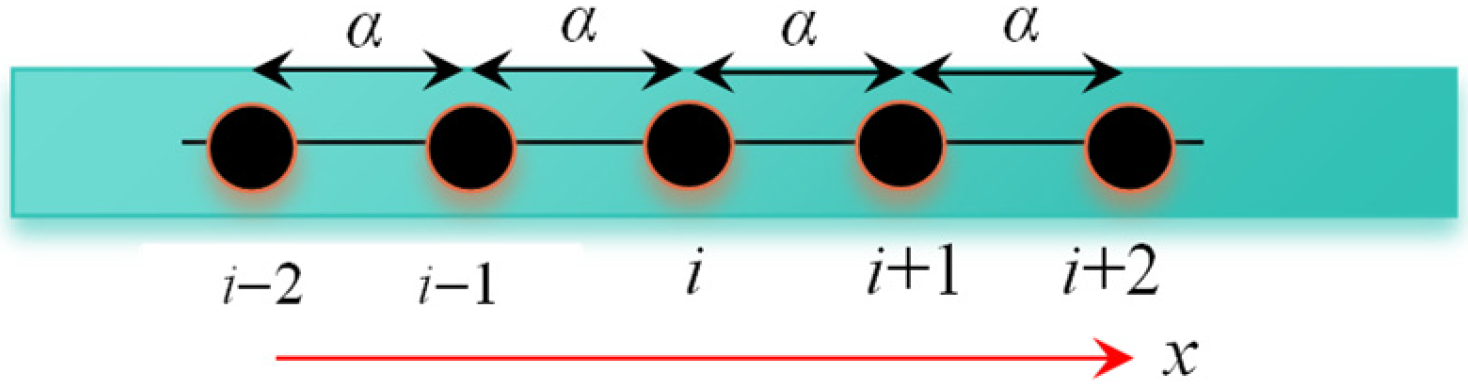

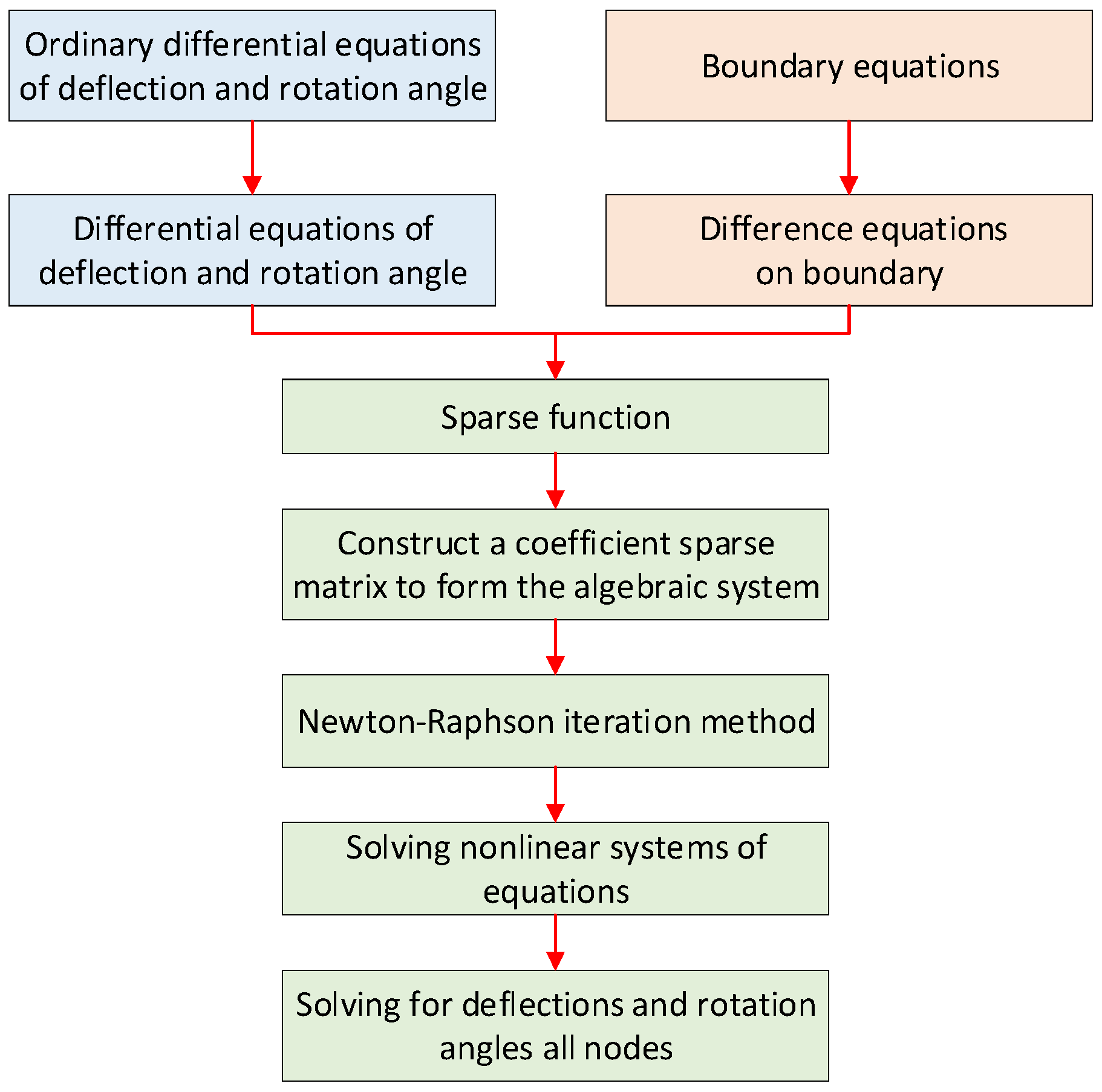

4. Finite Difference Method for a Timoshenko Beam on Winkler Foundation

4.1. Differential Equations of Control Equations

4.2. Difference Equations on Boundary

4.3. Difference Equations of the HTRs’ Energy During Periodic Breakage

4.4. Solving for the HTRs’ Energy During Periodic Breakage

5. Verification of the Finite Difference Method

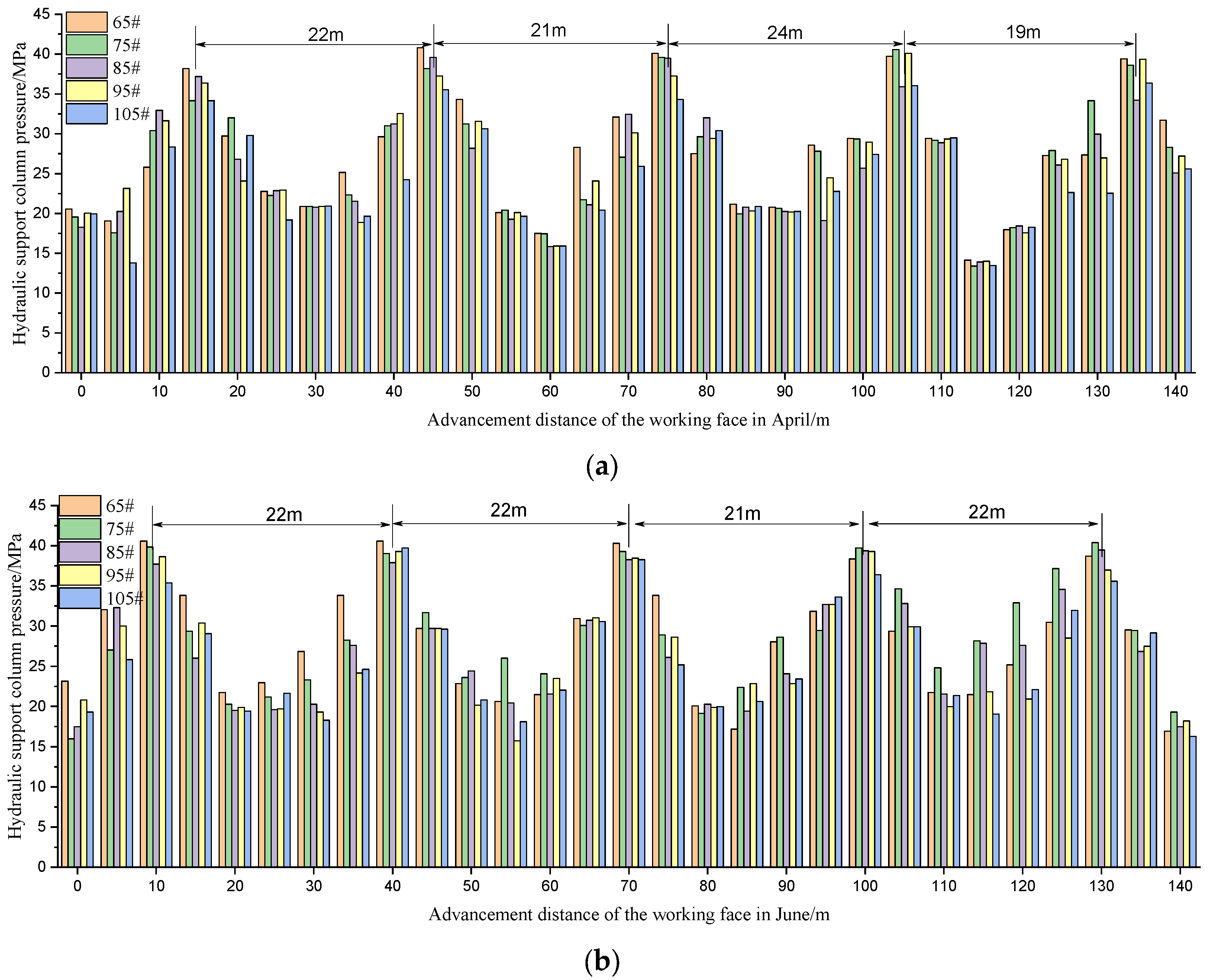

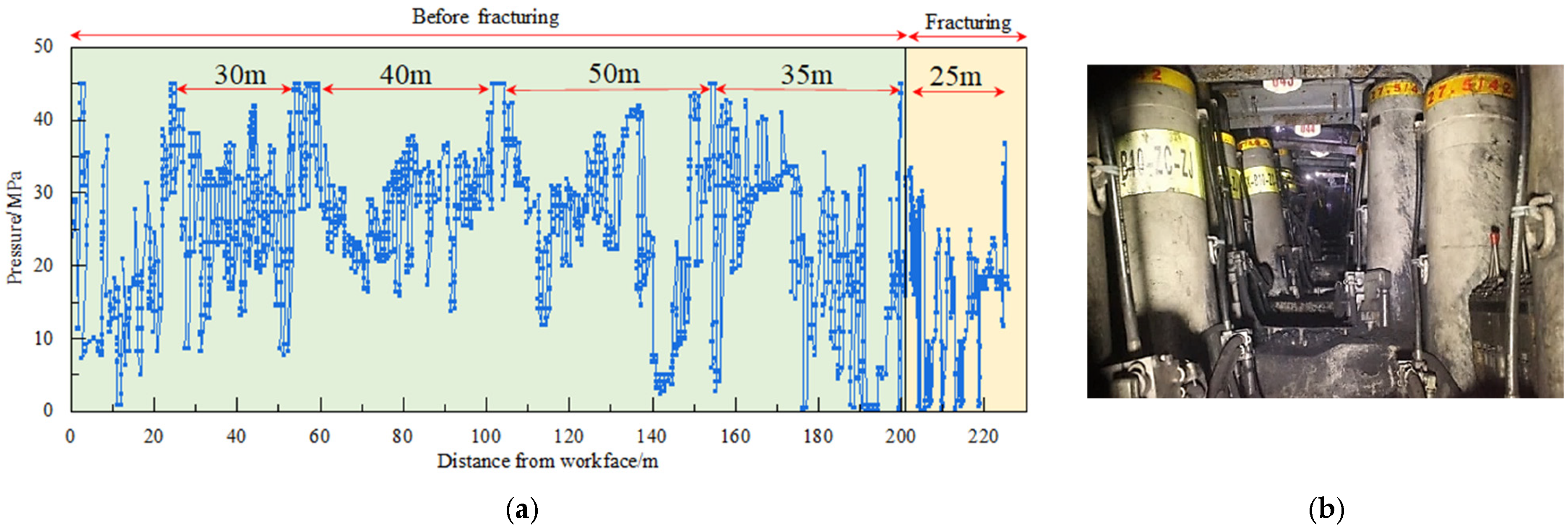

5.1. PBSD of HTR and the Impact Load Borne by Hydraulic Supports

5.2. Comparison of Key Parameters During HTRs’ Periodic Breakage

6. Results

6.1. Research Plan

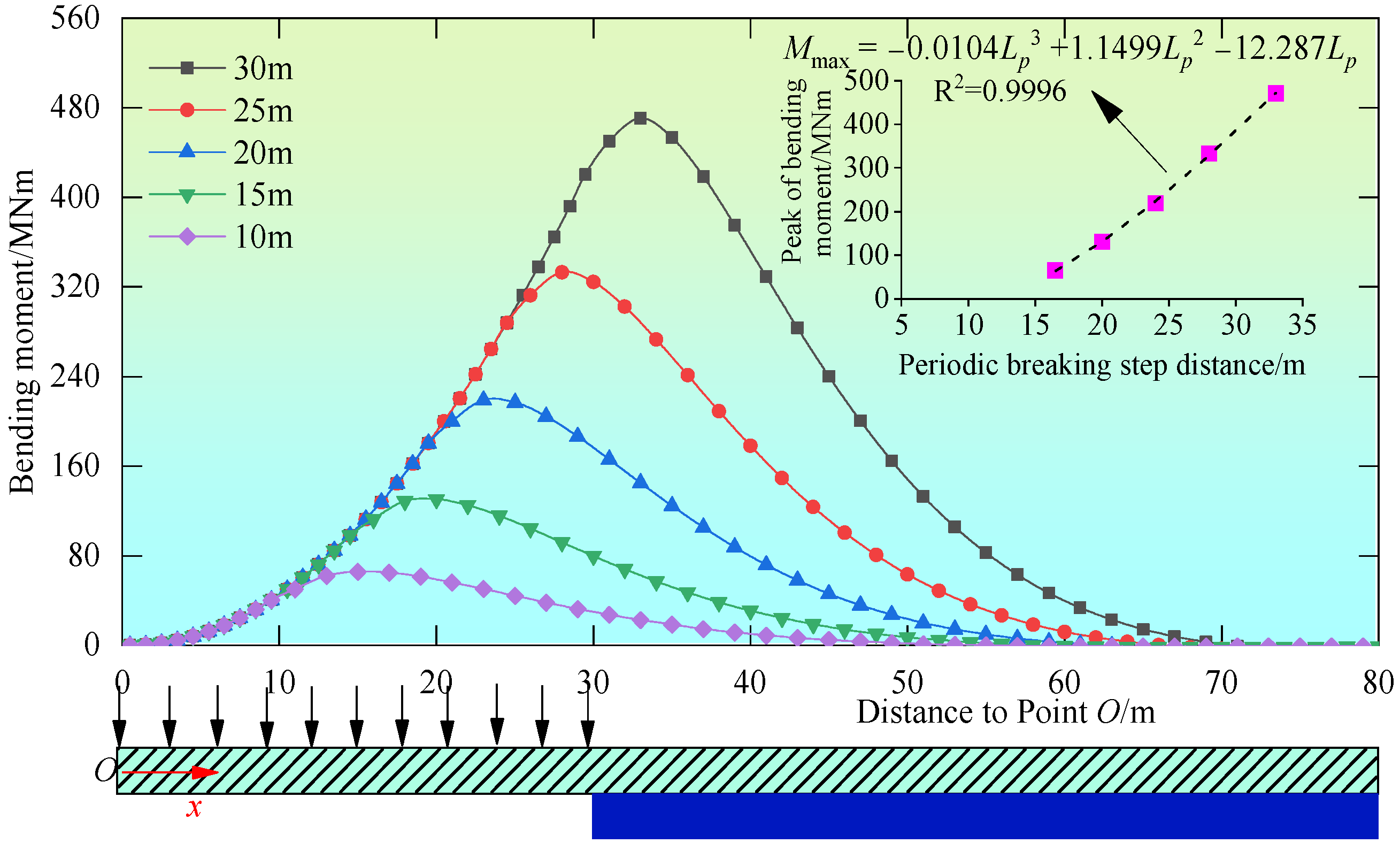

6.2. The Influence of the Cantilever Beam Length of the HTR on the Bending Moment Distribution

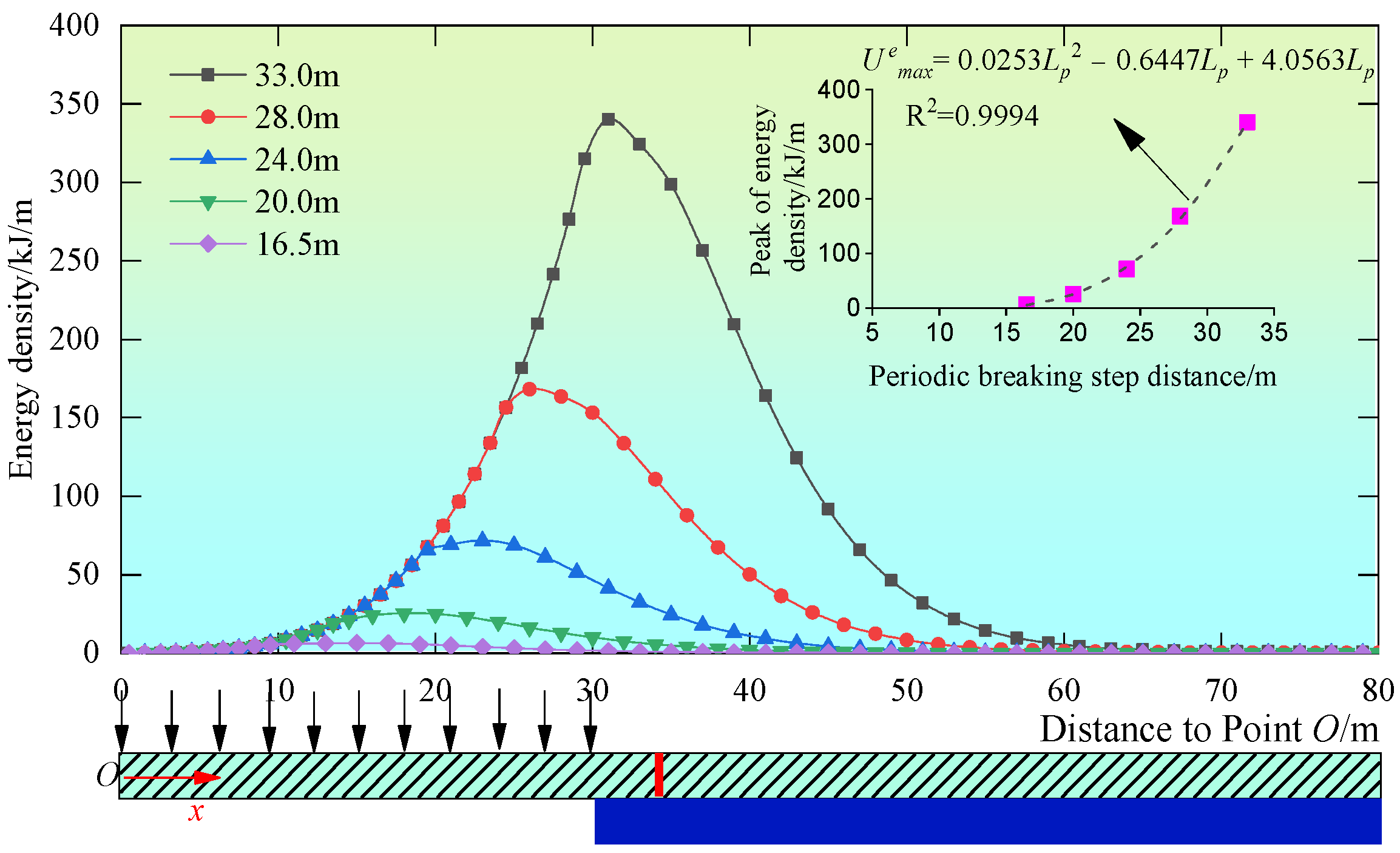

6.3. The Influence of PBSD on the Distribution of Elastic Deformation Energy Density in HTRs

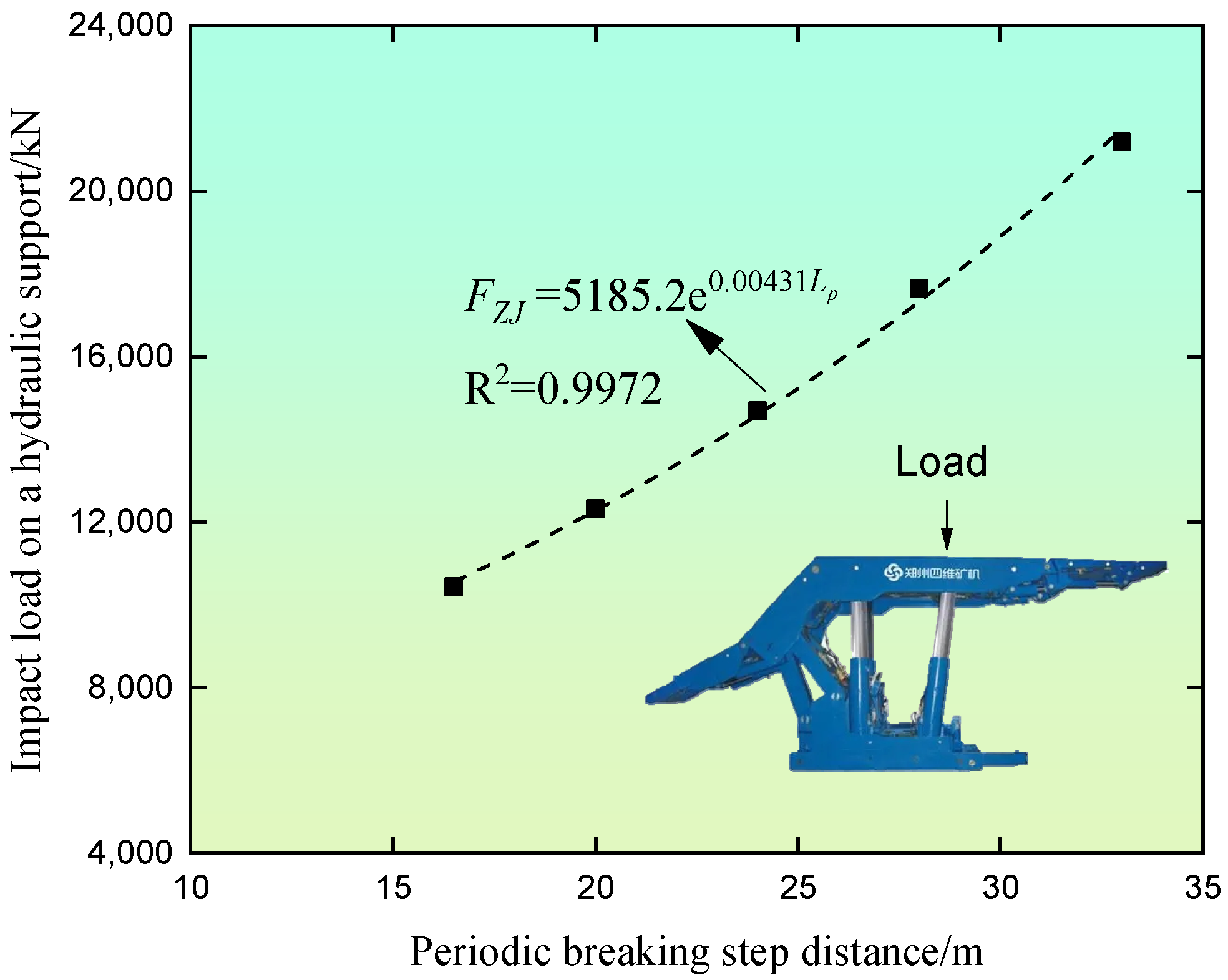

6.4. The Influence of the PBSD on the Impact Load of the Workface

7. Discussions

- (1)

- Drilling. Using a three-cone bit and screw drill bit for construction, drilling is completed in three stages. First stage uses a Φ444.5 mm drill bit to drill to a depth of 50 m and then lower it, and to cement a Φ339.7 × 9.65 mm casing; in the next stage, a Φ311.5 mm drill bit Manufactured by Shijiazhuang Shanlang Technology Co., Ltd., Shijiazhuang, China is used to drill to a depth of 128 m, and then a Φ244.5 × 8.94 mm casing is lowered and cemented; then, a Φ216 mm drill bit is used to drill to the target fracturing layer at 772 m, and a Φ139.7 × 7.72 mm casing is lowered, with a horizontal well length of 700 m.

- (2)

- Perforation. The selected perforation process is used, i.e., connecting a downhole perforating gun with a cable, lowering the tool string into the well under a closed construction state, reaching the target layer, and lifting the cable to ignite and complete multiple clusters of perforation. The perforating gun model is 89-16DP-60-105, with an outer diameter of 89 mm, hole density of 16 per/m, and working pressure of 105 MPa; the perforating bullet model is SDP41RDX25-2, with RDX (Hexogen) selected as the explosive.

- (3)

- Fracturing. Hydraulic fracturing involves using high-pressure pump trucks on the surface to inject fluid at high speed into the well, generating high pressure at the well’s bottom. This pressure fractures the rock layer, creating cracks. When gas extraction from underground is required through surface operations, liquid is injected into the fractured formation after the pump truck stops. To prevent pressure from dropping and the cracks from closing, sand—much denser than the formation—is mixed with the fluid. The sand enters the cracks and remains there permanently, keeping the cracks open.

8. Conclusions

- (1)

- This paper proposes a boundary treatment method that considers the elastoplastic and strain-softening mechanical behavior of coal–rock masses, establishes a stiffness calculation formula for the coal–rock mass during compression, constructs a Timoshenko beam model on a Winkler foundation for the energy concentration and dispersion during the HTRs’ periodic breakage, and then derives differential equations of control equations, stress components, boundary conditions, and energy, ultimately providing a method for calculating the PBSD of the HTR and the impact load on hydraulic supports.

- (2)

- Based on the method proposed in this paper, it was calculated that the periodic breaking step distance is 23 m for the 15.8 m thick HTR of the 61,304 Workface full-mechanized caving workface in the Tangjiahui coal mine, and that the impact load on the hydraulic support is 15,308 kN. These results differ from the on-site measured data by 4.5% and 4.8% respectively, thus proving the accuracy of the method proposed in the paper.

- (3)

- During the periodic breakage, both the distribution of the bending moment and the elastic deformation energy density of the HTR showed a unimodal pattern, with their peak values being 1.0 to 6.5 m ahead of the cantilever endpoint O, while the positions where the bending moment and elastic deformation energy density are zero are 40 to 41 m ahead of the cantilever endpoint O, thus determining the breaking position of the HTR and the area of advanced influence.

- (4)

- During the periodic break, the relationship between the PBSD and the peak values of the bending moment and elastic deformation energy density of the HTR is cubic, while its relationship with the impact load on the hydraulic support is exponential, that is, .

- (5)

- The comparative evaluation of theoretical calculation and measured results shows that reducing the HTRs’ PBSD is one of the best ways to control impact load. The HTRGFT weakens the HTR’ strength, reducing its periodic breaking step distance, thus effectively controlling the impact load on the workface and avoiding the occurrence of mine earthquake disasters.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| HTRs | Hard–thick roofs |

| HTRGFT | Hard–thick roof ground hydraulic fracturing technology |

| PBSD | the periodic breaking step distance |

References

- Xie, S.-R.; Chen, D.-D.; Sun, Y.-D.; Gao, M.-M.; Sun, Y.-J.; Shi, W. Analysis on thin plate model of basic roof at elastic foundation boundary(I): First breaking. J. China Coal Soc. 2016, 41, 1360–1368. [Google Scholar]

- Du, J.; Chen, J.; Pu, Y.; Jiang, D.; Chen, L.; Zhang, Y. Risk assessment of dynamic disasters in deep coal mines based on multi-source, multi-parameter indexes, and engineering application. Process Saf. Environ. Prot. 2021, 155, 575–586. [Google Scholar] [CrossRef]

- Zheng, J.; Huang, G.; Cheng, Q.; Jia, J.; Cai, Z. A Novel Experimental Apparatus for Evaluating Coal-and-Gas Outburst Risk. Nat. Resour. Res. 2022, 31, 535–550. [Google Scholar] [CrossRef]

- Ning, J.; Wang, J.; Jiang, L.; Jiang, N.; Liu, X.; Jiang, J. Fracture analysis of double-layer hard and thick roof and the controlling effect on strata behavior: A case study. Eng. Fail Anal. 2017, 81, 117–134. [Google Scholar] [CrossRef]

- Wang, K.; Zhang, X.; Wang, L.; Li, L.; Zhang, M.; Zhou, A. Experimental study on propagation law of shock wave and airflow induced by coal and gas outburst in mine ventilation network. Process Saf. Environ. Prot. 2021, 151, 299–310. [Google Scholar] [CrossRef]

- Zhou, A.; Fan, L.; Wang, K.; Elsworth, D. Multiscale modeling of shock wave propagation induced by coal and gas outbursts. Process Saf. Environ. Prot. 2019, 125, 164–171. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, E.; Feng, X.; Wang, C.; Qiu, L.; Wang, H. Assessment of Rockburst Risk in Deep Mining: An Improved Comprehensive Index Method. Nat. Resour. Res. 2021, 30, 1817–1834. [Google Scholar] [CrossRef]

- Liu, B.; Zhao, Y.; Wang, H.; Gao, Y.; Sun, Z. Tensile Properties and Multiparameter Response Characteristics of Coal under Different Loading Rates. Nat. Resour. Res. 2022, 31, 2787–2803. [Google Scholar] [CrossRef]

- Li, S.; You, M.; Li, D.; Liu, J. Identifying coal mine safety production risk factors by employing text mining and Bayesian network techniques. Process Saf. Environ. Prot. 2022, 162, 1067–1081. [Google Scholar] [CrossRef]

- Zhou, A.; Wang, K.; Feng, T.; Wang, J.; Zhao, W. Effects of fast-desorbed gas on the propagation characteristics of outburst shock waves and gas flows in underground roadways. Process Saf. Environ. Prot. 2018, 119, 295–303. [Google Scholar] [CrossRef]

- Lu, S.; Wang, C.; Liu, Q.; Zhang, Y.; Liu, J.; Sa, Z.; Wang, L. Numerical assessment of the energy instability of gas outburst of deformed and normal coal combinations during mining. Process Saf. Environ. Prot. 2019, 132, 351–366. [Google Scholar] [CrossRef]

- Li, Z.-Q.; Xue, Y.; Li, G.; Qiu, D.; Xu, L.; Liu, Q.; Fu, K. Probabilistic determination and application of rock thickness resisting water inrush from karst cave. Process Saf. Environ. Prot. 2023, 172, 462–472. [Google Scholar] [CrossRef]

- Fu, G.; Xie, X.; Jia, Q.; Tong, W.; Ge, Y. Accidents analysis and prevention of coal and gas outburst: Understanding human errors in accidents. Process Saf. Environ. Prot. 2020, 134, 1–23. [Google Scholar] [CrossRef]

- Li, B.; Wang, E.; Shang, Z.; Liu, X.; Li, Z.; Dong, J. Deep learning and heterogeneous signal fusion approach to precursor feature recognition and early warning of coal and gas outburst. Process Saf. Environ. Prot. 2023, 178, 995–1008. [Google Scholar] [CrossRef]

- He, J.; Dou, L.-M.; Mu, Z.-L.; Cao, A.-Y.; Gong, S.-Y. Numerical simulation study on hard-thick roof inducing rock burst in coal mine. J. Cent. South Univ. 2016, 23, 2314–2320. [Google Scholar] [CrossRef]

- Li, Q.; Li, Q.C.; Cao, H.Q.; Wu, J.J.; Wang, F.L.; Wang, Y.L. The Crack Propagation Behaviour of CO2 Fracturing Fluid in Unconventional Low Permeability Reservoirs: Factor Analysis and Mechanism Revelation. Processes 2025, 13, 159. [Google Scholar] [CrossRef]

- Yu, B.; Tai, Y.; Kuang, T.; Gao, R.; Yang, J.; Xia, B.; Zhu, W.; Li, Y. Theory and technical system of control of far-near field hard roofs from ground and underground in a large space stope. J. China Coal Soc. 2023, 48, 1875–1893. [Google Scholar] [CrossRef]

- He, Z.-L.; Lu, C.-P.; Zhang, X.-F.; Guo, Y.; Meng, Z.-H.; Xia, L. Numerical and Field Investigations of Rockburst Mechanisms Triggered by Thick-Hard Roof Fracturing. Rock Mech. Rock Eng. 2022, 55, 6863–6886. [Google Scholar] [CrossRef]

- Zuo, J.; Yu, M.; Sun, Y.; Wu, G. Analysis of fracture mode transformation mechanism and mechanical model of rock strata with different thicknesses. J. China Coal Soc. 2023, 48, 1449–1463. [Google Scholar] [CrossRef]

- Pan, J.; Kang, H.; Yan, Y.; Ma, X.; Ma, W.; Lu, C.; Lu, D.; Xu, G.; Feng, M.; Xia, Y.; et al. The method, mechanism and application of preventing rock burst by artificial liberation layer of roof. J. China Coal Soc. 2023, 48, 636–648. [Google Scholar] [CrossRef]

- Zhou, N.; Xu, J.; Zhang, J.; Ma, D.; Li, Z.; Yao, Y. Study on the weakening mechanism of hard overburden rock burst disaster by backfilling. Chin. J. Rock Mech. Eng. 2023, 42, 2412–2415. [Google Scholar] [CrossRef]

- Xu, B.; Xu, W.; Zhang, Y. Experimental Study on the Characteristics of Overlying Rock Movement in Mining Area. Geotech. Geol. Eng. 2023, 42, 1779–1791. [Google Scholar] [CrossRef]

- Li, Y.; Tai, Y.; Yu, B.; Kuang, T.; Gao, R.; Liu, J. Evolution and control technology of energy aggregation and dissipation of a high hard roof during breakage and destabilization. Int. J. Fract. 2023, 245, 1–23. [Google Scholar] [CrossRef]

- Chen, F.; Liang, Z.; Cao, A. ConvLSTM for Predicting Short-Term Spatiotemporal Distribution of Seismic Risk Induced by Large-Scale Coal Mining. Nat. Resour. Res. 2023, 32, 1459–1479. [Google Scholar] [CrossRef]

- Zhao, S.; Sui, Q.; Cao, C.; Wang, X.; Wang, C.; Zhao, D.; Wang, Y.; Zhao, Y. Mechanical model of lateral fracture for the overlying hard rock strata along coal mine goaf. Geomech. Eng. 2021, 27, 75–85. [Google Scholar] [CrossRef]

- Zhao, T.; Liu, C.; Yetilmezsoy, K.; Zhang, B.; Zhang, S. Fractural structure of thick hard roof stratum using long beam theory and numerical modeling. Environ. Earth Sci. 2017, 76, 751. [Google Scholar] [CrossRef]

- Huang, B.; Wang, Y.; Cao, S. Cavability control by hydraulic fracturing for top coal caving in hard thick coal seams. Int. J. Rock Mech. Min. Sci. 2015, 74, 45–57. [Google Scholar] [CrossRef]

- Ramstad, R.K.; Hilmo, B.O.; Brattli, B.; Skarphagen, H. Ground source energy in crystalline bedrock-increased energy extraction using hydraulic fracturing in boreholes. Bull. Eng. Geol. Environ. 2007, 66, 493–503. [Google Scholar] [CrossRef]

- Wu, Q.; Jiang, J.; Wu, Q.; Xue, Y.; Kong, P.; Gong, B. Study on the Fracture of Hard and Thick Sandstone and the Distribution Characteristics of Microseismic Activity. Geotech. Geol. Eng. 2018, 36, 3357–3373. [Google Scholar] [CrossRef]

- Lyu, S.; Wang, S.; Chen, X.; Wang, S.; Wang, T.; Shi, X.; Dong, Q.; Li, J. Natural fractures in soft coal seams and their effect on hydraulic fracture propagation: A field study. J. Pet. Sci. Eng. 2020, 192, 107255. [Google Scholar] [CrossRef]

- Bazoune, A. Combined influence of rotary inertia and shear coefficient on flexural frequencies of Timoshenko beam: Numerical experiments. Acta Mech. 2023, 234, 4997–5013. [Google Scholar] [CrossRef]

- Yee, K.; Khaniki, H.B.; Ghayesh, M.H.; Ng, C.T. Free vibrations of cracked functionally graded graphene platelets reinforced Timoshenko beams based on Hu-Washizu-Barr variational method. Eng. Struct. 2023, 293, 116587. [Google Scholar] [CrossRef]

- Alibert, J.J.; Barchiesi, E.; dell’Isola, F.; Seppecher, P. A Class of One Dimensional Periodic Microstructures Exhibiting Effective Timoshenko Beam Behavior. ESAIM Control. Optim. Calc. Var. 2023, 29, 53. [Google Scholar] [CrossRef]

- Simoncelli, M.; Zucca, M.; Stochino, F. Fire Resistance of Steel Rack Frames: Assessment, Reinforcement and Collapse Mitigation Strategies. Fire Technol. 2024, 1664, 1–23. [Google Scholar] [CrossRef]

- Shakya, N.K.; Padhee, S.S. Asymptotic analysis of Timoshenko-like orthotropic beam with elliptical cross-section. Eur. J. Mech.-ASolids 2023, 102, 105100. [Google Scholar] [CrossRef]

- Cao, G.W.; Chian, S.C.; Ding, X.M.; Luan, L.B.; Zheng, C.J.; Zhou, P. Horizontal Static Impedances for OWT Monopiles Based on Timoshenko Beam Theory. Int. J. Geomech. 2023, 23, 04023202. [Google Scholar] [CrossRef]

- Singh, B.; Mukhopadhyay, S. Thermoelastic vibration of Timoshenko beam under the modified couple stress theory and the Moore-Gibson-Thompson heat conduction model. Math Mech. Solids 2023, 29, 436–451. [Google Scholar] [CrossRef]

- Benzid, A.; Tati, A. Static and buckling behaviors analysis of FG beams using a three unknowns finite element based on enhanced Timoshenko theory. Mech. Adv. Mater. Struc. 2023, 31, 9322–9333. [Google Scholar] [CrossRef]

- Chen, D.; Wu, X.; Xie, S.; Sun, Y.; Zhang, Q.; Wang, E.; Sun, Y.; Wang, L.; Li, H.; Jiang, Z.; et al. Study on the Thin Plate Model with Elastic Foundation Boundary of Overlying Strata for Backfill Mining. Math. Probl. Eng. 2020, 2020, 8906091. [Google Scholar] [CrossRef]

- He, F.; He, W.; Chen, D.; Xie, S.; Li, H.; He, C. First fracture structure characteristics of main roof plate considering elastic-plastic deformation of coal. J. China Coal Soc. 2020, 45, 2704–2717. [Google Scholar] [CrossRef]

- Chen, D.; Wu, Y.; Xie, S.; He, F.; Sun, Y.; Shi, S.; Jiang, Z. Study on the first fracture of the main roof plate structure with one side goaf and elastic-plastic foundation boundary. J. China Coal Soc. 2021, 46, 3090–3105. [Google Scholar] [CrossRef]

- Safari, M.; Mohammadimehr, M.; Ashrafi, H. Forced vibration of a sandwich Timoshenko beam made of GPLRC and porous core. Struct. Eng. Mech. 2023, 88, 1–12. [Google Scholar] [CrossRef]

- Borri, A.; Carravetta, F.; Palumbo, P. Quadratized Taylor series methods for ODE numerical integration. Appl. Math. Comput. 2023, 458, 128237. [Google Scholar] [CrossRef]

- Yadav, M.; Sadasivan, A.L. Taylor series solutions for area ratio and Prandtl-Meyer inverses using differential transform method. Int. J. Adv. Eng. Sci. Appl. Math. 2023, 15, 110–114. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, F.; Peng, M.; Meng, X.; Tai, Y.; Yu, B. Control Mechanism of Earthquake Disasters Induced by Hard–Thick Roofs’ Breakage via Ground Hydraulic Fracturing Technology. Processes 2025, 13, 919. https://doi.org/10.3390/pr13030919

Guo F, Peng M, Meng X, Tai Y, Yu B. Control Mechanism of Earthquake Disasters Induced by Hard–Thick Roofs’ Breakage via Ground Hydraulic Fracturing Technology. Processes. 2025; 13(3):919. https://doi.org/10.3390/pr13030919

Chicago/Turabian StyleGuo, Feilong, Mingxian Peng, Xiangbin Meng, Yang Tai, and Bin Yu. 2025. "Control Mechanism of Earthquake Disasters Induced by Hard–Thick Roofs’ Breakage via Ground Hydraulic Fracturing Technology" Processes 13, no. 3: 919. https://doi.org/10.3390/pr13030919

APA StyleGuo, F., Peng, M., Meng, X., Tai, Y., & Yu, B. (2025). Control Mechanism of Earthquake Disasters Induced by Hard–Thick Roofs’ Breakage via Ground Hydraulic Fracturing Technology. Processes, 13(3), 919. https://doi.org/10.3390/pr13030919