Artificial Intelligence in Manufacturing Industry Worker Safety: A New Paradigm for Hazard Prevention and Mitigation

Abstract

1. Introduction

1.1. Research Objectives and Methodology

1.1.1. Objectives

1.1.2. Research Questions

- How is AI currently applied to worker safety in manufacturing environments?

- What are the strengths and limitations of these AI-based safety systems?

- What regulatory, ethical, and technical challenges must be addressed for the large-scale adoption of AI in manufacturing?

- What role can policy frameworks play in shaping responsible AI integration in the manufacturing sector?

1.1.3. Methodology

- 1.

- Published between 2018 and 2025.

- 2.

- Focused on applications in the manufacturing sector.

- 3.

- Address issues related to safety, ethics, or governance in AI deployment.

- 4.

- Written in English.

- 1.

- Sources focused on non-manufacturing sector use cases.

- 2.

- Duplicates or secondary sources lacking credibility.

- 3.

- Non-peer-reviewed sources (unless government- or standards-based, and select pre-prints on reliable servers).

2. Understanding Manufacturing Hazards

2.1. Manufacturing Safety Standards

2.2. Productivity Methodologies in Manufacturing

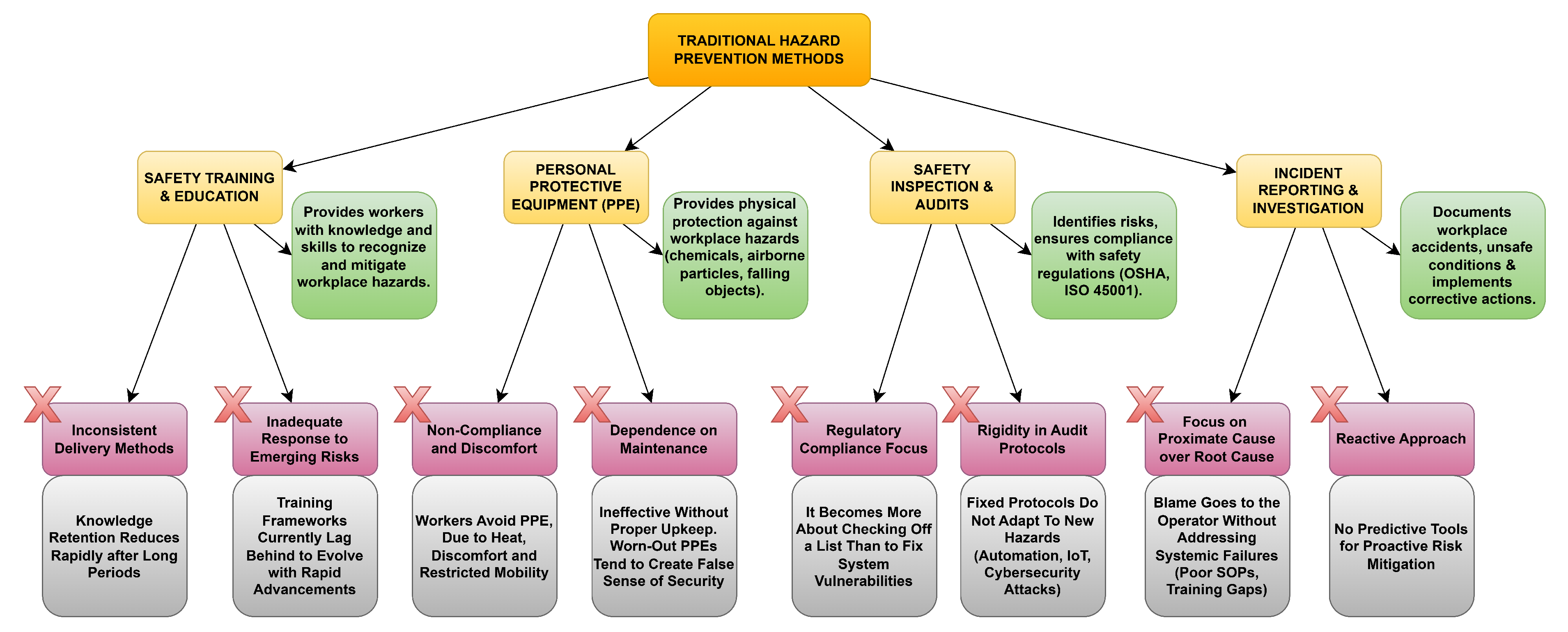

2.3. Traditional Approaches to Hazard Prevention in Manufacturing and Their Limitations

| Hazard Type | Specific Details of the Hazards Reported | Description | Traditional Method of Prevention | Limitation | Ref. |

|---|---|---|---|---|---|

| Chemical hazards | Toxic substances | These substances lead to acute or chronic poisoning, if exposed |

| Lack of hazard awareness stemming from poor training regarding health and safety in a particular setting leads to increased risk | [46,47] |

| Flammable and explosive chemicals | Fire and explosion hazards |

| Current prevention strategies may not fully address the risk of fire or explosion in all scenarios | [46,47] | |

| Carcinogenic substance | Some chemicals used in manufacturing processes may have carcinogenic properties |

| Long-term effects of exposure to carcinogens may not be immediately apparent, making prevention challenging | [47] | |

| Corrosive substances | Can cause severe burns and tissue damage upon contact |

| Accidental spills or splashes can still occur, potentially causing immediate harm before preventive measures can be activated | [46,47] | |

| Physical hazards | Noise | Prolonged exposure to noise at or above 85dBA can lead to permanent hearing loss, tinnitus, and difficulty understanding speech in noise |

| Defining “hazardous noise” based on sound level alone is insufficient | [46,48,49] |

| Vibration | Hand–arm vibration (HAV) can lead to various occupational health hazards for workers |

| Symptoms may not appear until after significant exposure (typically 2000 hours), which can delay early intervention and prevention efforts | [48,50,51] | |

| Ionizing radiation | Ionizing radiation exposure is a frequent occupational hazard |

| The current system of dose limitation may not fully address the optimization of protection in all scenarios | [46,52] | |

| Heat | Heat stress is associated with a spectrum of heat-related illnesses, including heat stroke, which can lead to death |

|

| [46,48,53] | |

| Physical hazards | Mechanical maintenance hazards | Operation and maintenance of machinery can lead to injuries such as entanglement, crushing, or impact |

|

| [48,54,55] |

| Operational hazards | Industrial operations expose workers to hazardous materials, ergonomic risks, and unsafe work practices that can lead to injuries or health issues |

|

| [48,54,55] | |

| Electrical hazards | Electrical hazards involve risks associated with electrical systems and equipment |

|

| [45,48,56] | |

| Fire and explosion risks | Flammable materials, improper storage practices, and inadequate fire prevention measures in industrial settings |

|

| [45,57] | |

| Ergonomic hazards | Repetitive motions | Repetitive motion causes muscle fatigue and can eventually result in long-term damage to workers |

| Effectiveness of current prevention methods may not be accurate | [58,59,60] |

| Awkward postures | Awkward postures are risk factors for neck/shoulder pain (NSP) and low back pain (LBP) |

|

| [61] | |

| Heavy lifting | Occupational lifting, especially for extended durations and with higher loads, increases the risk of long-term sickness absence (LTSA) |

|

| [62,63] | |

| Psychosocial hazards | Work-related stress | Stress is an individual’s response to high-intensity work, affecting cognitive, physical, mental, and emotional status. It can lead to mental health problems such as anxiety, depression, and burnout. |

|

| [64,65,66] |

2.4. Comparison of Traditional and AI-Based Safety Methods

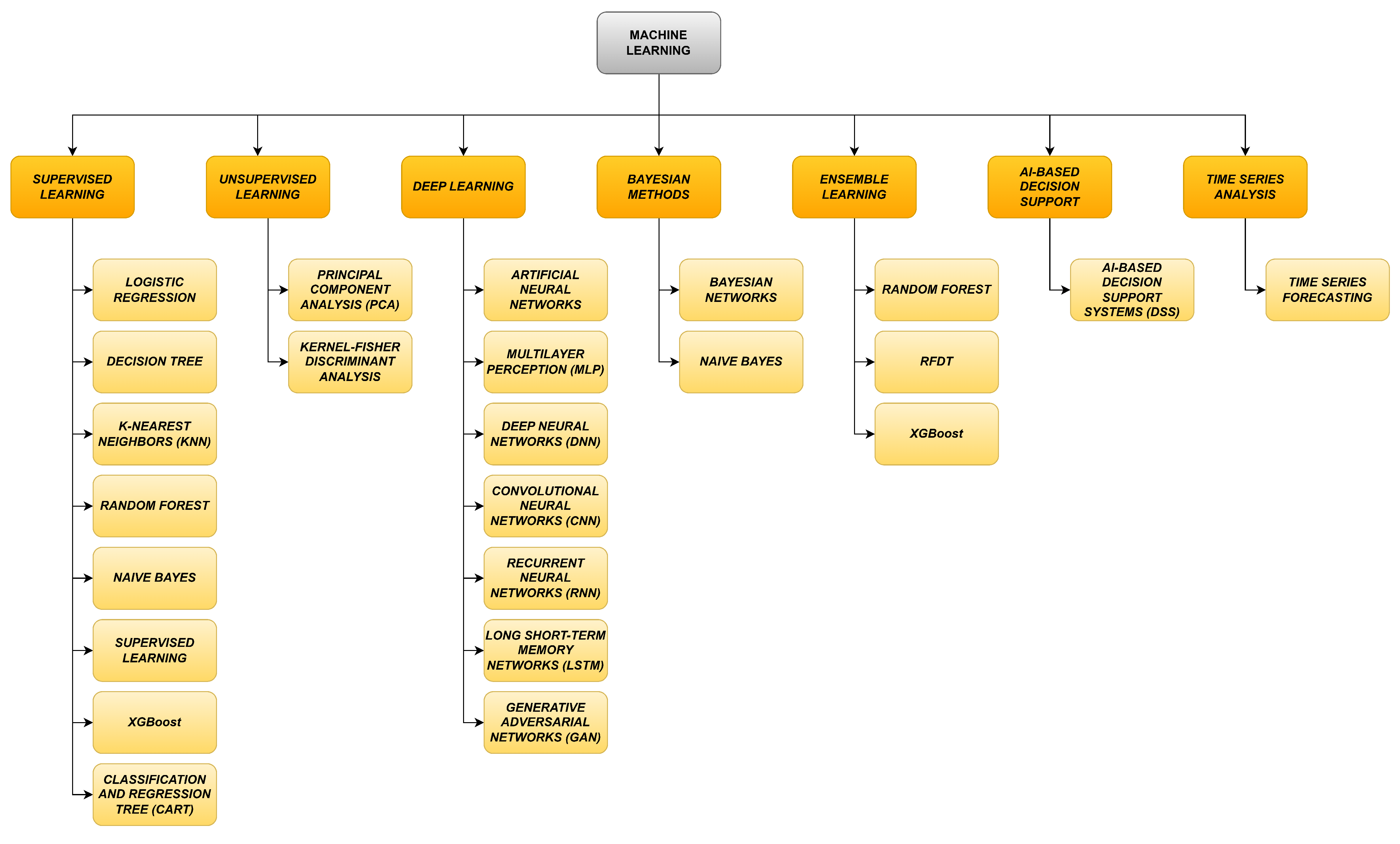

3. AI Techniques Transforming Safety Standards

3.1. Predictive Analytics

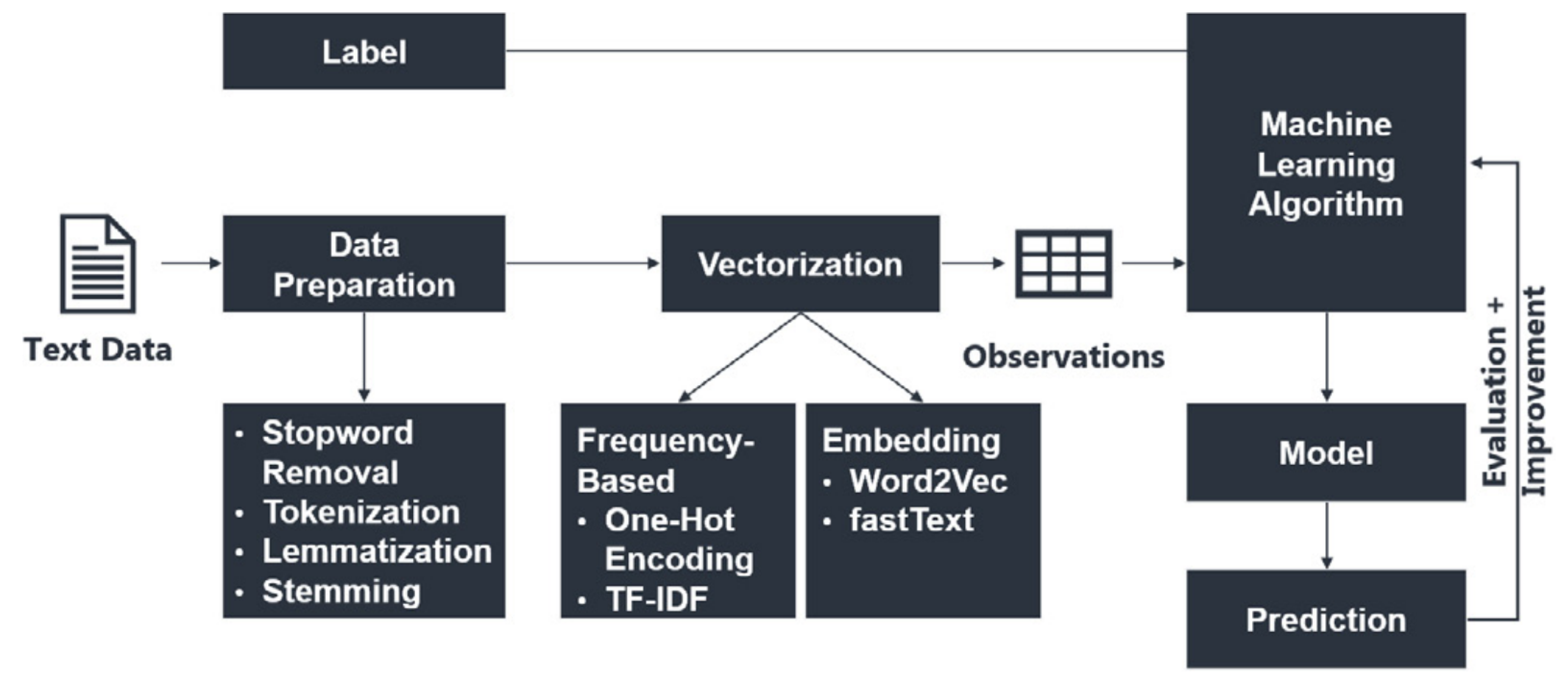

3.1.1. Machine Learning Techniques for Predictive Analytics

3.1.2. Enhancing Worker Safety Through Predictive Analytics

3.1.3. Other Applications of Predictive Analytics in Worker Safety

- Predictive Maintenance and Fault Diagnosis: Predictive maintenance minimizes equipment failures that could lead to worker injuries. In the metal-cutting industry, neural networks predict power consumption based on cutting parameters, optimizing tool performance and preventing malfunctions [84]. Predictive analytics is also applied in manufacturing system control, quality assurance, and defect mitigation, using Bayesian networks and ANNs to diagnose faults in industrial equipment such as power transformers and transceiver stations [85]. In smelting operations, a multivariate time series deep learning model predicts furnace temperatures in electric arc furnaces, improving process stability and preventing hazardous temperature fluctuations [86].

- Workplace Environmental Monitoring: Predictive analytics enhances workplace conditions by ensuring optimal temperature, humidity, and air quality. HVAC systems use predictive models to detect faults and optimize energy consumption [87,88]. Deep neural networks are used to predict HVAC failures, maintaining safe temperature ranges in heat-intensive work environments [81,87]. Additionally, ANN-MLP algorithms monitor and predict smoke emissions from malfunctioning machines, triggering a tiered alert system to prevent worker exposure to hazardous fumes [89].

- Sustainable Manufacturing Practices: Sustainability in manufacturing is another area where predictive analysis is valuable. Multi-criteria decision models use regression analysis and ANNs to optimize material consumption, energy efficiency, recyclability, and production costs, promoting sustainable and safer manufacturing practices [90].

3.1.4. Limitations and Biases in Predictive Analytics in Manufacturing

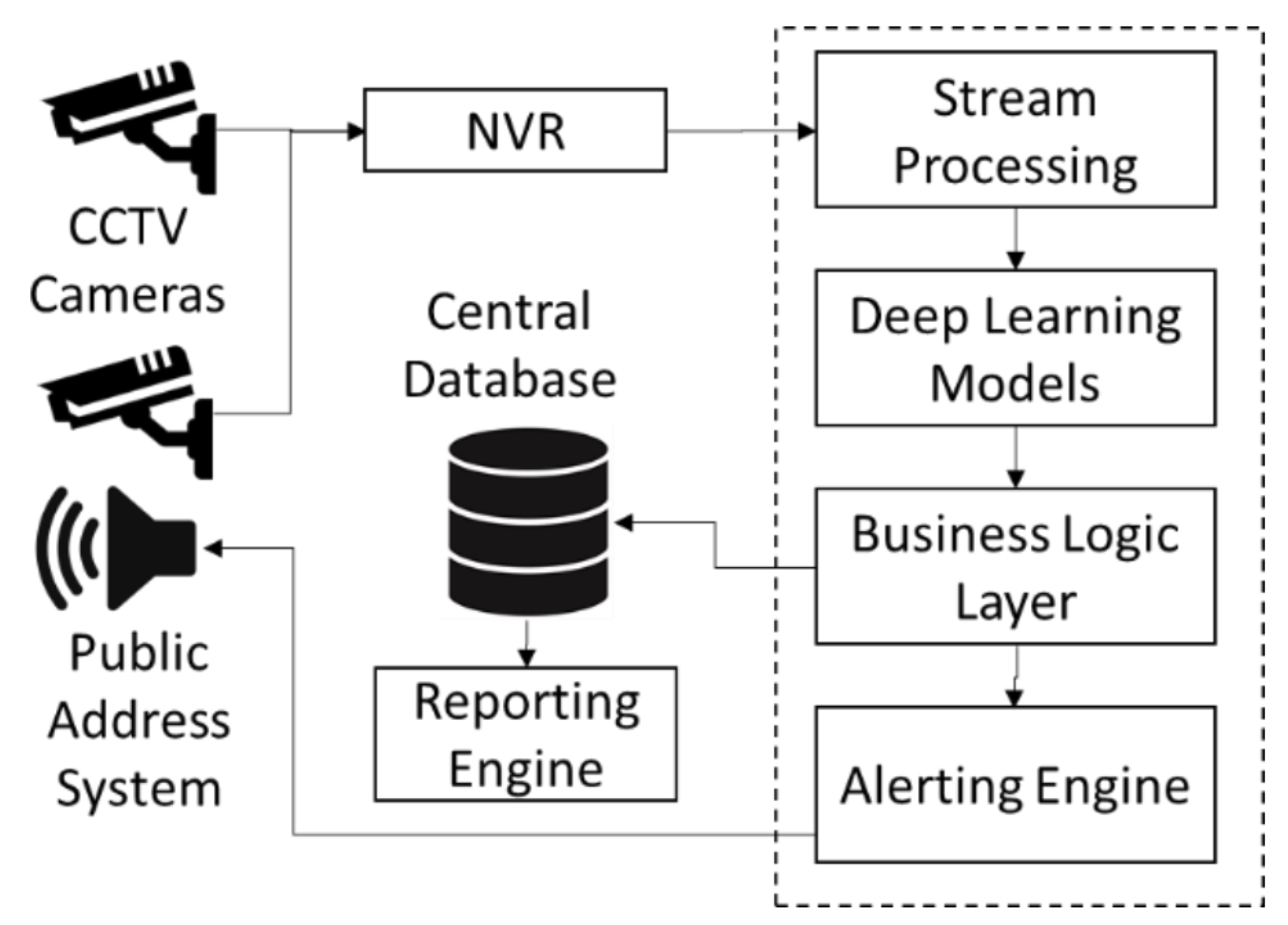

3.2. Real-Time Intelligent Surveillance Using Computer Vision

3.3. Enhancing Workplace Safety Through NLP-Powered Communication

3.4. Real Industrial Case Studies

3.4.1. Case Study 1: Collaborative Robots (Ford Motor Company, Tesla, General Motors Company)

3.4.2. Case Study 2: AI-Facilitated CCTV Infrastructure (SeeWise.AI, Intenseye, Linfox)

3.4.3. Case Study 3: Nvidia Virtual Factories

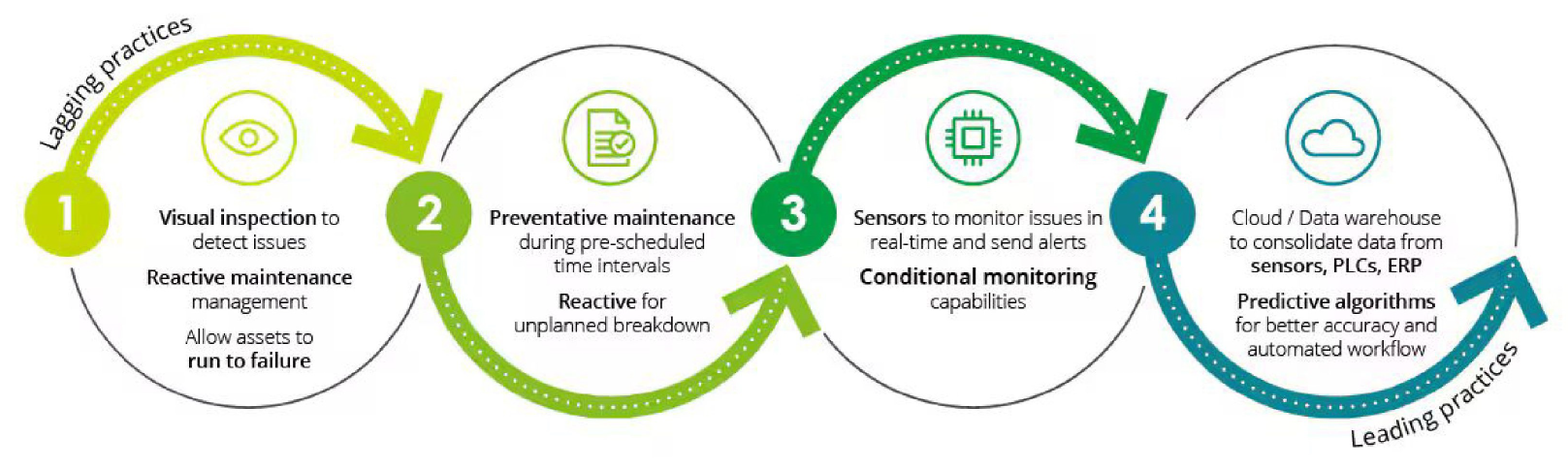

4. Predictive Maintenance and Risk Mitigation

- 1.

- Corrective Maintenance (CM): Restores equipment upon fault detection.

- 2.

- Preventative Maintenance (PM): Analyzes historical data to minimize breakdowns.

- 3.

- Risk-Based Maintenance (RM): Prioritizes assets posing the greatest risk in case of failure.

- 4.

- Condition-Based Maintenance (CBM): Uses sensor data to trigger maintenance upon performance decline.

- 5.

- Predetermined Maintenance (PtM): Follows manufacturer guidelines and historical data to schedule maintenance.

5. Real-Time Hazard Detection and Response

5.1. Ensuring Worker Health and Safety

5.2. Maintaining Operational Efficiency

5.3. Preventing Costly Accidents

| Classification of Deficiencies | Example Specification | Description | Possible Complications | How AI, in General, could Regulate Such Factors | Limitations of AI in This Case | Ref. |

|---|---|---|---|---|---|---|

| Housekeeping deficiencies | Workplace dust buildup | Excess dust buildup accumulating around in the work environment. |

|

|

| [195,196,197,198] |

| Unclean Surfaces | Poor cleanup or housekeeping may lead to unclean surfaces. This may include greasy, wet, dusty, unsanitary surfaces, etc. |

|

|

| [199] | |

| Operational | Failure in hazard identification | Lack of or inappropriate risk assessment |

|

|

| [200] |

| Automatnineon Errors | An automation error may arise from factors such as mechanical, programming, calibration, etc. |

|

|

| [200,201,202] | |

| Organizational | Deviation from protocol | Any action, such as skipping a step in a safety procedure, is not acceptable according to organizational standards |

|

|

| [203,204] |

| Equipment failure | Sudden or gradual equipment failure |

|

|

| [205] | |

| Worker health | Worker exhaustion | Factors such as overworking, monotonous work, or physical exertion may result in exhaustion |

|

|

| [206,207,208,209] |

| Chronic hazards | Long-term exposure to hazards; chemicals, dust, non-ergonomic worker practices |

|

|

| [209,210,211,212] |

5.4. AI-Powered Surveillance and Anomaly Detection

5.5. Automated Emergency Protocols and Alerts

6. Human-Centric AI for Worker Safety

6.1. Wearable AI Devices for Health Monitoring

6.2. Enhancing Safety Through Human–AI Collaboration

6.2.1. Training Using Different Methods

6.2.2. LLM Models Used in Safety Standard Assessments

6.2.3. Engineering Education

6.2.4. Quality Management and Control

6.2.5. Human–AI Trust

6.3. Benchmark Technologies of Human–AI Collaboration

7. Challenges and Ethical Considerations

7.1. Ethical Considerations

7.2. Data Privacy and Worker Consent

7.3. Reliability and Biases in AI Systems

7.4. Grey Areas of Current Policies and Their Future

| Region | Country | Principal Organizations of OSH | Principal OSH Legislation | Year Enacted | Major Updates or Changes Made to the Standards | Pitfalls of these Standards for Worker Safety | Remarks | How AI Can Benefit These Policies? |

|---|---|---|---|---|---|---|---|---|

| Americas | Canada | Canadian Center for Occupational Health and Safety (CCOHS) [303] | Canada Labour Code [304] | 1985 | A 2024 amendment brought new employer requirements regarding employee treatment in termination and benefits. The Canada Labour Code is continuously updated each year [305]. |

| CCOHS provides guidance and educational tools to use codes such as the Workplace Hazardous Materials Information System (WHMIS) [307]. |

|

| United States | Occupational Safety and Health Administration (OSHA) [29] | Occupational Safety and Health Act of 1970 [308] | 1970 | Several amendments have been implemented since 1970 [309] | OSHA serves as the principal enforcing agency to implement worker laws. The principal enforcement legislation is the Occupational Safety and Health Act of 1970 [308,312]. |

| ||

| Europe | Switzerland | Federal Coordination Commission for Occupational Safety (EKAS) [68,313] | Arbeitsgesetz (ArG) (The Labour Act) [67] | 1964 | Switzerland has recently implemented many new policies regarding healthy work culture and overtime [314,315]. |

| The EKAS is defined as the central ruling organization. Each Swiss canton has its specific OSH organization managed by the EKAS. The Arbeitsgesetz (ArG) is the main Federal Labour Law, outlining worker practices and OSH [70,316]. |

|

| Germany | Bundesanstalt für Arbeitsschutz und Arbeitsmedizin (BAuA) [69] | Arbeitsschutzgesetz (ArbSchG) [317] | 1996 | Several amendments have been implemented since 1996 [317]. |

| The BAuA serves as the Federal Institute for OSH in Germany, which facilitates laws and regulations such as ArbSchG [318,319,320] |

| |

| Asia | Japan | Japan Organization of Occupational Health and Safety (JNIOSH) [321] | Japanese Industrial Safety and Health Act | 1972 | A 2006 amendment was established with an emphasis on addressing the issue of work–life balance [322] | While JNIOSH serves as the principal OSH organization within Japan, societies such as JSOH aim to promote education and research about worker health and safety. Their legislation is outlined by the Japanese Industrial Safety and Health Act [324]. |

| |

| China | State Administration of Work Safety (SAWS) [325] | Work Safety Law [326] | 2002 | The Worker Safety Law has undergone three amendments; in 2009, 2014, and 2021 [327]. |

| SAWS acts as the main OSH organization in China while facing the challenge of huge economic and social growth [329] China’s Work Safety Law and Law on Prevention and Control of Occupational Diseases (2001) serve as the principal OSH legislation |

| |

| India | Ministry of Labour and Employment [330] | Factories Act [331] | 1948 | The Factories Amendment Bill in 2016 was amended to increase overtime hours [332] | India’s Factories Act is amongst many specialized workplace acts. In 2020, the Occupational Safety, Health, and Working Conditions Code was enacted to amend laws regarding OSH and workplace incidents [332,335]. These are all consolidated by the Ministry of Labour and Employment. |

|

7.4.1. Open Areas for AI Governance

- ISO 45001: This international standard provides a management framework for occupational health and safety [27]. It can be extended to include AI-based risk detection, human-AI collaboration, and real-time safety feedback systems. AI governance can fit within existing clauses on continuous improvement, hazard identification, and performance evaluation.

- Europe AI Act (2024): This act, established in 2024, provides a risk-based regulatory framework for AI systems [275]. Classifies workplace AI safety systems as “High Risk”, requiring conformity assessments, human oversight, and regular documentation.

- OECD AI Principles: These international ethical guidelines, updated in 2024, emphasize accountability, robustness, and transparency in AI systems [336]. They are followed by OECD countries, the European Union, the United States, and the United Nations.

- NIST AI Risk Management Framework (USA): This voluntary toolkit from the National Institute of Standards and Technology (NIST) guides the implementation of trustworthy AI practices in manufacturing [337].

- ILO OSH Code of Practice: This international framework informs workers about their rights [338]. It can be expanded to include worker rights in AI-monitored environments.

- 1.

- Data Privacy and Surveillance Consent: AI systems that process worker data, such as through computer vision or biometric tracking, must comply with the data protection laws of the country or regions, as applicable. Organizations should implement a privacy-by-design approach, offering opt-in consent and ensuring data anonymization within the system.

- 2.

- AI Auditability and Traceability: High-risk AI systems should maintain logs of decisions and actions for audit purposes to trace any inconsistencies. Model explainability must be ensured, particularly during incident investigations.

- 3.

- Human-in-the-Loop Oversight: AI systems used for critical tasks, such as predictive maintenance or real-time behavior monitoring, should require mandatory human involvement and oversight to avoid fully autonomous decision-making that could impact workers or lead to unwanted hazards.

- 4.

- Governance Accessibility for SMEs: National standardization agencies or industry consortiums should provide simplified AI governance frameworks for SMEs, along with subsidized training and open-source compliance checklists, similar to the NIST AI Risk Management Toolkit.

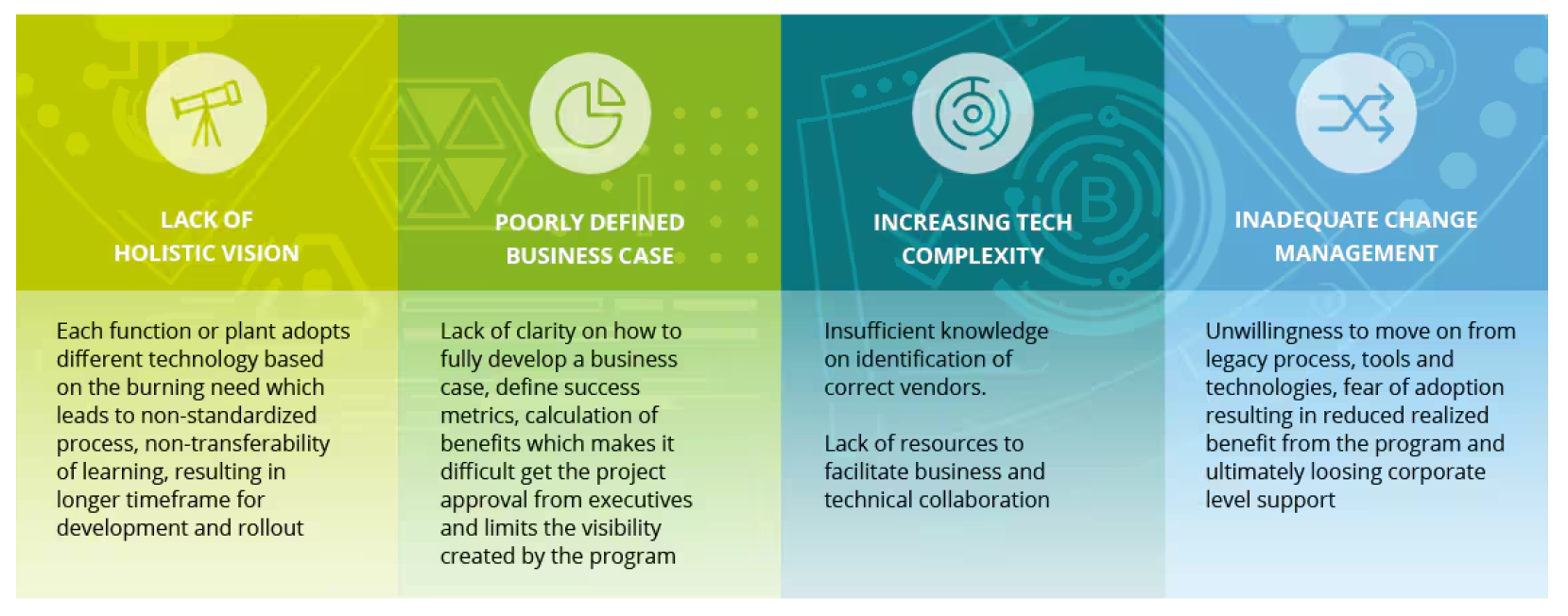

7.5. Adoption and Integration Challenges

7.6. Challenges and Solutions for SMEs

8. Future Directions in AI-Driven Worker Safety

9. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Murtaza, A.A.; Saher, A.; Zafar, M.H.; Moosavi, S.K.R.; Aftab, M.F.; Sanfilippo, F. Paradigm shift for predictive maintenance and condition monitoring from Industry 4.0 to Industry 5.0: A systematic review, challenges and case study. Results Eng. 2024, 24, 102935. [Google Scholar] [CrossRef]

- Li, B.h.; Hou, B.c.; Yu, W.t.; Lu, X.b.; Yang, C.w. Applications of artificial intelligence in intelligent manufacturing: A review. Front. Inf. Technol. Electron. Eng. 2017, 18, 86–96. [Google Scholar] [CrossRef]

- Acemoglu, D.; Restrepo, P. Artificial intelligence, automation, and work. In The Economics of Artificial Intelligence: An Agenda; University of Chicago Press: Chicago, IL, USA, 2018; pp. 197–236. [Google Scholar]

- Kusiak, A. Data mining: Manufacturing and service applications. Int. J. Prod. Res. 2006, 44, 4175–4191. [Google Scholar] [CrossRef]

- Gupta, P.; Krishna, C.; Rajesh, R.; Ananthakrishnan, A.; Vishnuvardhan, A.; Patel, S.S.; Kapruan, C.; Brahmbhatt, S.; Kataray, T.; Narayanan, D.; et al. Industrial internet of things in intelligent manufacturing: A review, approaches, opportunities, open challenges, and future directions. Int. J. Interact. Des. Manuf. (IJIDEM) 2022, 1–23. [Google Scholar] [CrossRef]

- Predictive Maintenance Solutions. Available online: https://www2.deloitte.com/us/en/pages/operations/articles/predictive-maintenance-and-the-smart-factory.htm (accessed on 22 January 2025).

- Revolutionizing OEM Manufacturing with AI. Available online: https://www.oemmagazine.org/engineering/automation/article/22883168/revolutionizing-oem-manufacturing-with-ai (accessed on 22 January 2025).

- Pires, F.; Cachada, A.; Barbosa, J.; Moreira, A.P.; Leitão, P. Digital twin in industry 4.0: Technologies, applications and challenges. In Proceedings of the 2019 IEEE 17th international conference on industrial informatics (INDIN), Helsinki-Espoo, Finland, 22–25 July 2019; Volume 1, pp. 721–726. [Google Scholar]

- Fu, Y.; Downey, A.R.; Yuan, L.; Zhang, T.; Pratt, A.; Balogun, Y. Machine learning algorithms for defect detection in metal laser-based additive manufacturing: A review. J. Manuf. Processes 2022, 75, 693–710. [Google Scholar] [CrossRef]

- Acemoglu, D.; Restrepo, P. Tasks, automation, and the rise in US wage inequality. Econometrica 2022, 90, 1973–2016. [Google Scholar] [CrossRef]

- Das, A.; Panda, S.; Datta, S.; Naskar, S.; Misra, P.; Chattopadhyay, T. AI based safety system for employees of manufacturing industries in developing countries. arXiv 2018, arXiv:1811.12185. [Google Scholar]

- Vernim, S.; Bauer, H.; Rauch, E.; Ziegler, M.T.; Umbrello, S. A value sensitive design approach for designing AI-based worker assistance systems in manufacturing. Procedia Comput. Sci. 2022, 200, 505–516. [Google Scholar] [CrossRef]

- Khandelwal, P.; Khandelwal, A.; Agarwal, S.; Thomas, D.; Xavier, N.; Raghuraman, A. Using computer vision to enhance safety of workforce in manufacturing in a post covid world. arXiv 2020, arXiv:2005.05287. [Google Scholar]

- Petit, N.; De Cooman, J. Models of Law and Regulation for AI. In The Routledge Social Science Handbook of AI; Routledge: London, UK, 2021; pp. 199–221. [Google Scholar]

- Hoffmann-Riem, W. Artificial intelligence as a challenge for law and regulation. In Regulating Artificial Intelligence; Springer: Cham, Switzerland, 2020; pp. 1–29. [Google Scholar]

- Schuett, J. Defining the scope of AI regulations. Law Innov. Technol. 2023, 15, 60–82. [Google Scholar] [CrossRef]

- Chohan, J.S.; Bilga, P.S. Occupational health hazards in small scale steel manufacturing industries: A case study. Int. J. Manuf. Technol. Manag. 2011, 24, 182–192. [Google Scholar] [CrossRef]

- Reinhold, K.; Tint, P. Hazard profile in manufacturing: Determination of risk levels towards enhancing the workplace safety. J. Environ. Eng. Landsc. Manag. 2009, 17, 69–80. [Google Scholar] [CrossRef]

- Nenonen, S. Fatal workplace accidents in outsourced operations in the manufacturing industry. Saf. Sci. 2011, 49, 1394–1403. [Google Scholar] [CrossRef]

- Pacana, A. Comparative occupational risk assessment in a CNC machine tool operator position. Prod. Eng. Arch. 2017, 16, 28–31. [Google Scholar] [CrossRef]

- Willquist, P.; Törner, M. Identifying and analysing hazards in manufacturing industry—A review of selected methods and development of a framework for method applicability. Int. J. Ind. Ergon. 2003, 32, 165–180. [Google Scholar] [CrossRef]

- Dobrzyńska, E.; Kondej, D.; Kowalska, J.; Szewczyńska, M. State of the art in additive manufacturing and its possible chemical and particle hazards. Indoor Air 2021, 31, 1733–1758. [Google Scholar] [CrossRef]

- Amirah, N.A.; Him, N.F.N.; Rashid, A.; Rasheed, R.; Zaliha, T.N.; Afthanorhan, A. Fostering a safety culture in manufacturing through safety behavior: A structural equation modelling approach. J. Saf. Sustain. 2024, 1, 108–116. [Google Scholar] [CrossRef]

- Darabont, D.C.; Antonov, A.E.; Bejinariu, C. Key elements on implementing an occupational health and safety management system using ISO 45001 standard. MATEC Web Conf. 2017, 121, 11007. [Google Scholar] [CrossRef]

- International Labour Organization. Safety and Health in the Non-Ferrous Metals Industries. Available online: https://www.ilo.org/resource/other/safety-and-health-non-ferrous-metals-industries (accessed on 18 January 2025).

- International Labour Organization. Safety and Health in Shipbuilding and Ship Repair. Available online: https://www.ilo.org/resource/other/safety-and-health-shipbuilding-and-ship-repair-revised-edition (accessed on 15 January 2025).

- International Organization for Standardization. Occupational Health and Safety Management Systems: Requirements with Guidance for Use; ISO: Geneva, Switzerland, 2018. [Google Scholar]

- Robins, T.G.; Klitzman, S. Hazard communication in a large US manufacturing firm: The ecology of health education in the workplace. Health Educ. Q. 1988, 15, 451–472. [Google Scholar] [CrossRef]

- Kim, Y.; Park, J.; Park, M. Creating a culture of prevention in occupational safety and health practice. Saf. Health Work 2016, 7, 89–96. [Google Scholar] [CrossRef]

- Herron, C.; Braiden, P.M. A methodology for developing sustainable quantifiable productivity improvement in manufacturing companies. Int. J. Prod. Econ. 2006, 104, 143–153. [Google Scholar] [CrossRef]

- Gupta, S.; Jain, S.K. A literature review of lean manufacturing. Int. J. Manag. Sci. Eng. Manag. 2013, 8, 241–249. [Google Scholar] [CrossRef]

- National Health Service, England. Lean Six Sigma: Some Basic Concepts. Available online: https://www.england.nhs.uk/improvement-hub/wp-content/uploads/sites/44/2017/11/Lean-Six-Sigma-Some-Basic-Concepts.pdf (accessed on 20 January 2025).

- U.S. Environmental Protection Agency. Lean Thinking and Methods: Kaizen. Available online: https://www.epa.gov/sustainability/lean-thinking-and-methods-kaizen (accessed on 15 January 2025).

- Cheng, T.; Podolsky, S. Just-In-Time Manufacturing: An Introduction; Springer Science & Business Media: Berlin/Heidelberg, Germany, 1996. [Google Scholar]

- American Society for Quality. Six Sigma. Available online: https://asq.org/quality-resources/six-sigma (accessed on 19 January 2025).

- Rajurkar, K.; Hadidi, H.; Pariti, J.; Reddy, G. Review of sustainability issues in non-traditional machining processes. Procedia Manuf. 2017, 7, 714–720. [Google Scholar] [CrossRef]

- Ellington, L.E.; Becerra, R.; Mallma, G.; da Fieno, J.T.; Nair, D.; Onchiri, F.; Nielsen, K.R. Knowledge acquisition and retention after a high flow training programme in Peru: A quasi-experimental single group pre–post design. BMJ Open 2020, 10, e035125. [Google Scholar] [CrossRef]

- Çetintepe, S. Occupational health assessment and risks in automotive and wood manufacturing industries: A retrospective study. Ann. Med. Res. 2024, 31, 141–146. [Google Scholar]

- Wang, L.; Dai, W.; Sun, D.; Zhao, Y. Risk evaluation for a manufacturing process based on a directed weighted network. Entropy 2020, 22, 699. [Google Scholar] [CrossRef] [PubMed]

- Tabor, J. Occupational Hazard Prevention in Manufacturing Systems. Appl. Mech. Mater. 2015, 718, 227–232. [Google Scholar] [CrossRef]

- Ikumapayi, O.; Omietimi, B.; Onu, P.; Ogedengbe, T.; Oluwafemi, J.; Afolalu, S.; Akinlabi, E. Non-Traditional Machining Techniques in Manufacturing Industries–An Overview. E3S Web Conf. 2023, 430, 01213. [Google Scholar] [CrossRef]

- Elsheikh, A.; Ali, A.B.; Saba, A.; Faqeha, H.; Alsaati, A.A.; Maghfuri, A.M.; Abd-Elaziem, W.; El Ashmawy, A.A.; Ma, N. A review on sustainable machining: Technological advancements, health and safety considerations, and related environmental impacts. Results Eng. 2024, 24, 103042. [Google Scholar] [CrossRef]

- Onawumi, A.; Olojede, M.; Agboola, O.; Ikubanni, P.; Odunola, A. Investigation into combined occupational hazards among automobile repairs workmen in Nigeria. Int. J. Hum. Factors Ergon. 2022, 9, 143–162. [Google Scholar] [CrossRef]

- Du, D.l.; Qiu, J.; Zhao, H.y. Risk assessment study of manufacturing green supply chain based on grey theory. In Proceedings of the Proceedings of International Conference on Information Systems for Crisis Response and Management (ISCRAM), Washington, DC, USA, 25–27 November 2011; pp. 234–240. [Google Scholar]

- Dyreborg, J.; Lipscomb, H.J.; Nielsen, K.; Törner, M.; Rasmussen, K.; Frydendall, K.B.; Bay, H.; Gensby, U.; Bengtsen, E.; Guldenmund, F.; et al. Safety interventions for the prevention of accidents at work: A systematic review. Campbell Syst. Rev. 2022, 18, e1234. [Google Scholar] [CrossRef] [PubMed]

- Fatemi, F.; Dehdashti, A.; Jannati, M. Implementation of chemical health, safety, and environmental risk assessment in laboratories: A case-series study. Front. Public Health 2022, 10, 898826. [Google Scholar] [CrossRef]

- California Department of Public Health. Introduction to Toxic Substances. Available online: https://www.cdph.ca.gov/Programs/CCDPHP/DEODC/OHB/HESIS/CDPH%20Document%20Library/introtoxsubstances.pdf (accessed on 25 January 2025).

- Rout, B.; Sikdar, B. Hazard identification, risk assessment, and control measures as an effective tool of occupational health assessment of hazardous process in an iron ore pelletizing industry. Indian J. Occup. Environ. Med. 2017, 21, 56–76. [Google Scholar] [CrossRef] [PubMed]

- Themann, C.L.; Masterson, E.A. Occupational noise exposure: A review of its effects, epidemiology, and impact with recommendations for reducing its burden. J. Acoust. Soc. Am. 2019, 146, 3879–3905. [Google Scholar] [CrossRef]

- Chidambaram, V.; Gopalsamy, M.M.; Zindani, D.; Chandan, G.K.; Aslam, M.; Kanchan, B.K. Worker Exposure to Hand-Arm Vibration in Fettling Shop: An Experimental Study in Foundry. Eng. Proc. 2024, 61, 47. [Google Scholar] [CrossRef]

- Weir, E.; Lander, L. Hand–arm vibration syndrome. Cmaj 2005, 172, 1001–1002. [Google Scholar] [CrossRef]

- Baudin, C.; Vacquier, B.; Thin, G.; Chenene, L.; Guersen, J.; Partarrieu, I.; Louet, M.; Ducou Le Pointe, H.; Mora, S.; Verdun-Esquer, C.; et al. Occupational exposure to ionizing radiation in medical staff: Trends during the 2009–2019 period in a multicentric study. Eur. Radiol. 2023, 33, 5675–5684. [Google Scholar] [CrossRef] [PubMed]

- Tustin, A.W. Evaluation of occupational exposure limits for heat stress in outdoor workers—United States, 2011–2016. MMWR. Morb. Mortal. Wkly. Rep. 2018, 67, 733–737. [Google Scholar] [CrossRef]

- Dubik, K.; Akasika, C.; Naawie, N.; Dery, F.; Abunkudugu, F.A. Impact of Safety-Maintenance Practices on the Overall Performance of an Industry. World J. Eng. Technol. 2024, 12, 759–774. [Google Scholar] [CrossRef]

- Park, D.U.; Zoh, K.E.; Jeong, E.K.; Koh, D.H.; Lee, K.H.; Lee, N.; Ha, K. Assessment of occupational health risks for maintenance work in fabrication facilities: Brief review and recommendations. Saf. Health Work 2024, 15, 87–95. [Google Scholar] [CrossRef]

- Tabor, J. Use of safety analysis in industrial maintenance management. Qual. Prod. Improv.-QPI 2021, 3, 162–172. [Google Scholar]

- Costella, M.F.; Dalcanton, F.; Cardinal, S.M.; Vilbert, S.S.; Pelegrini, G.A. Maintenance, occupational health and safety: A systematic review of the literature. Gestão Produção 2020, 27, e3922. [Google Scholar] [CrossRef]

- Yan, T.; Ji, F.; Bi, M.; Wang, H.; Cui, X.; Liu, B.; Niu, D.; Li, L.; Lan, T.; Xie, T.; et al. Occupational stress and associated risk factors among 13,867 industrial workers in China. Front. Public Health 2022, 10, 945902. [Google Scholar] [CrossRef] [PubMed]

- Hadler, N.M. Repetitive upper-extremity motions in the workplace are not hazardous. J. Hand Surg. 1997, 22, 19–29. [Google Scholar] [CrossRef]

- Barthelme, J.; Sauter, M.; Mueller, C.; Liebers, F. Association between working in awkward postures, in particular overhead work, and pain in the shoulder region in the context of the 2018 BIBB/BAuA Employment Survey. Bmc Musculoskelet. Disord. 2021, 22, 1–12. [Google Scholar] [CrossRef]

- Lohne, F.K.; Xu, K.; Fimland, M.S.; Palarea-Albaladejo, J.; Redzovic, S. Association between musculoskeletal pain and exposures to awkward postures during work: A compositional analysis approach. Ann. Work Expo. Health 2024, 68, 522–534. [Google Scholar] [CrossRef]

- Bláfoss, R.; Skovlund, S.V.; Skals, S.; Sundstrup, E.; López-Bueno, R.; Calatayud, J.; Andersen, L.L. Duration and intensity of occupational lifting and risk of long-term sickness absence: Prospective cohort study with register follow-up among 45 000 workers. Scand. J. Work Environ. Health 2023, 49, 283. [Google Scholar] [CrossRef]

- Al-Otaibi, S.T. Prevention of occupational back pain. J. Fam. Community Med. 2015, 22, 73–77. [Google Scholar] [CrossRef]

- Chen, B.; Wang, L.; Li, B.; Liu, W. Work stress, mental health, and employee performance. Front. Psychol. 2022, 13, 1006580. [Google Scholar] [CrossRef]

- Noblet, A.; LaMontagne, A.D. The role of workplace health promotion in addressing job stress. Health Promot. Int. 2006, 21, 346–353. [Google Scholar] [CrossRef]

- Catapano, P.; Cipolla, S.; Sampogna, G.; Perris, F.; Luciano, M.; Catapano, F.; Fiorillo, A. Organizational and individual interventions for managing work-related stress in healthcare professionals: A systematic review. Medicina 2023, 59, 1866. [Google Scholar] [CrossRef] [PubMed]

- Government of Switzerland. Swiss Labour Laws and Occupational Safety Regulations. Available online: https://www.fedlex.admin.ch/eli/cc/1966/57_57_57/de (accessed on 15 January 2025).

- European Agency for Safety and Health at Work. OSH System at National Level—Switzerland. Available online: https://oshwiki.osha.europa.eu/en/themes/osh-system-national-level-switzerland (accessed on 15 January 2025).

- Federal Ministry of Labour and Social Affairs. Occupational Safety and Health. Available online: https://www.bmas.de/EN/Labour/Occupational-Safety-and-Health/occupational-safety-and-health.html (accessed on 15 January 2025).

- Federal Coordination Commission for Occupational Safety. EKAS: Occupational safety and health in Switzerland. Available online: https://www.ekas.ch/index-en.php?frameset=1 (accessed on 15 January 2025).

- Çınar, Z.M.; Abdussalam Nuhu, A.; Zeeshan, Q.; Korhan, O.; Asmael, M.; Safaei, B. Machine learning in predictive maintenance towards sustainable smart manufacturing in industry 4.0. Sustainability 2020, 12, 8211. [Google Scholar] [CrossRef]

- Rashid, A.B.; Kausik, A.K. AI revolutionizing industries worldwide: A comprehensive overview of its diverse applications. Hybrid Adv. 2024, 7, 100277. [Google Scholar] [CrossRef]

- Rahman, M.M.; Hossain, A.; Sikder, M.A. Machine Learning Applications in Industry Safety: Analysis and Prediction of Industrial Accidents. In Proceedings of the 2024 International Conference on Smart Systems for applications in Electrical Sciences (ICSSES), Tumakuru, India, 3–4 May 2024; pp. 1–6. [Google Scholar]

- Bokonda, P.L.; Ouazzani-Touhami, K.; Souissi, N. Predictive analysis using machine learning: Review of trends and methods. In Proceedings of the 2020 International Symposium on Advanced Electrical and Communication Technologies (ISAECT), Marrakech, Morocco, 25–27 November 2020; pp. 1–6. [Google Scholar]

- Vukicevic, A.M.; Petrovic, M.N.; Knezevic, N.M.; Jovanovic, K.M. Deep learning-based recognition of unsafe acts in manufacturing industry. IEEE Access 2023, 11, 103406–103418. [Google Scholar] [CrossRef]

- Hou, C.K.J.; Behdinan, K. Neural Networks with Input Dimensionality Reduction for Efficient Temperature Distribution Prediction in a Warm Stamping Process. J. Appl. Comput. Mech. 2022, 8, 1431–1444. [Google Scholar]

- Hou, C.K.J.; Behdinan, K. Neural networks with dimensionality reduction for predicting temperature change due to plastic deformation in a cold rolling simulation. AI EDAM 2023, 37, e1. [Google Scholar] [CrossRef]

- Hou, C.K.J.; Behdinan, K. Neural networks with dimensionality reduction for efficient springback prediction in deep drawing of multi-material cylindrical cups. J. Exp. Theor. Artif. Intell. 2025, 37, 111–130. [Google Scholar] [CrossRef]

- Kazemi, Z.; Steeves, C.A. Machine learning for characterizing uncertain elastic properties of fused filament fabricated materials for topology optimization applications. arXiv 2024, arXiv:2408.05850. [Google Scholar]

- Kazemi, Z.; Steeves, C.A. Uncertainty quantification in material properties of additively manufactured materials for application in topology optimization. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Columbus, OH, USA, 30 October–3 November 2022; Volume 86656, p. V003T04A009. [Google Scholar]

- Sachdeva, I.; Ramesh, S.; Chadha, U.; Punugoti, H.; Selvaraj, S.K. Computational AI models in VAT photopolymerization: A review, current trends, open issues, and future opportunities. Neural Comput. Appl. 2022, 34, 17207–17229. [Google Scholar] [CrossRef]

- Kakhki, F.D.; Freeman, S.A.; Mosher, G.A. Applied machine learning in agro-manufacturing occupational Incidents. Procedia Manuf. 2020, 48, 24–30. [Google Scholar] [CrossRef]

- Ni, L.; Chen, F.; Ran, R.; Li, X.; Jin, N.; Zhang, H.; Peng, B. A deep learning-based model for predicting abnormal liver function in workers in the automotive manufacturing industry: A cross-sectional survey in Chongqing, China. Int. J. Environ. Res. Public Health 2022, 19, 14300. [Google Scholar] [CrossRef]

- Shin, S.J.; Woo, J.; Rachuri, S. Predictive analytics model for power consumption in manufacturing. Procedia Cirp 2014, 15, 153–158. [Google Scholar] [CrossRef]

- Lechevalier, D.; Narayanan, A.; Rachuri, S. Towards a domain-specific framework for predictive analytics in manufacturing. In Proceedings of the 2014 IEEE International Conference on Big Data (Big Data), Washington, DC, USA, 27–30 October 2014; pp. 987–995. [Google Scholar]

- Leon-Medina, J.X.; Camacho, J.; Gutierrez-Osorio, C.; Salomón, J.E.; Rueda, B.; Vargas, W.; Sofrony, J.; Restrepo-Calle, F.; Pedraza, C.; Tibaduiza, D. Temperature prediction using multivariate time series deep learning in the lining of an electric arc furnace for ferronickel production. Sensors 2021, 21, 6894. [Google Scholar] [CrossRef] [PubMed]

- Bouabdallaoui, Y.; Lafhaj, Z.; Yim, P.; Ducoulombier, L.; Bennadji, B. Predictive maintenance in building facilities: A machine learning-based approach. Sensors 2021, 21, 1044. [Google Scholar] [CrossRef]

- Mawson, V.J. Coupling Simulation with Machine Learning for the Development of a Proactive HVAC System in the Manufacturing Sector. Ph.D. Thesis, University of Strathclyde, Glasgow, UK, 2020. [Google Scholar]

- Massaro, A. Multi-level decision support system in production and safety management. Knowledge 2022, 2, 682–701. [Google Scholar] [CrossRef]

- Relich, M. Predictive and prescriptive analytics in identifying opportunities for improving sustainable manufacturing. Sustainability 2023, 15, 7667. [Google Scholar] [CrossRef]

- Belkin, M.; Hsu, D.; Ma, S.; Mandal, S. Reconciling modern machine-learning practice and the classical bias–variance trade-off. Proc. Natl. Acad. Sci. USA 2019, 116, 15849–15854. [Google Scholar] [CrossRef]

- Aliferis, C.; Simon, G. Overfitting, underfitting and general model overconfidence and under-performance pitfalls and best practices in machine learning and AI. In Artificial Intelligence and Machine Learning in Health Care and Medical Sciences: Best Practices and Pitfalls; Springer: Cham, Switzerland, 2024; pp. 477–524. [Google Scholar]

- Montesinos López, O.A.; Montesinos López, A.; Crossa, J. Overfitting, model tuning, and evaluation of prediction performance. In Multivariate Statistical Machine Learning Methods for Genomic Prediction; Springer: Cham, Switzerland, 2022; pp. 109–139. [Google Scholar]

- Luo, X.; Li, X.; Goh, Y.M.; Song, X.; Liu, Q. Application of machine learning technology for occupational accident severity prediction in the case of construction collapse accidents. Saf. Sci. 2023, 163, 106138. [Google Scholar] [CrossRef]

- Gudivada, V.; Apon, A.; Ding, J. Data quality considerations for big data and machine learning: Going beyond data cleaning and transformations. Int. J. Adv. Softw. 2017, 10, 1–20. [Google Scholar]

- Martin, K. Predatory predictions and the ethics of predictive analytics. J. Assoc. Inf. Sci. Technol. 2023, 74, 531–545. [Google Scholar] [CrossRef]

- Lu, J.; Liu, A.; Dong, F.; Gu, F.; Gama, J.; Zhang, G. Learning under concept drift: A review. IEEE Trans. Knowl. Data Eng. 2018, 31, 2346–2363. [Google Scholar] [CrossRef]

- Žliobaitė, I.; Pechenizkiy, M.; Gama, J. An overview of concept drift applications. In Big Data Analysis: New Algorithms for a New Society; Springer: Cham, Switzerland, 2016; pp. 91–114. [Google Scholar]

- Chen, Z.; Liu, B. Lifelong Machine Learning; Morgan & Claypool Publishers: San Rafael, CA, USA, 2018. [Google Scholar]

- Liu, Z.; Xie, K.; Li, L.; Chen, Y. A paradigm of safety management in Industry 4.0. Syst. Res. Behav. Sci. 2020, 37, 632–645. [Google Scholar] [CrossRef]

- Al-Bayati, A.J.; Rener, A.T.; Listello, M.P.; Mohamed, M. PPE non-compliance among construction workers: An assessment of contributing factors utilizing fuzzy theory. J. Saf. Res. 2023, 85, 242–253. [Google Scholar] [CrossRef] [PubMed]

- Podgorski, D.; Majchrzycka, K.; Dąbrowska, A.; Gralewicz, G.; Okrasa, M. Towards a conceptual framework of OSH risk management in smart working environments based on smart PPE, ambient intelligence and the Internet of Things technologies. Int. J. Occup. Saf. Ergon. 2017, 23, 1–20. [Google Scholar] [CrossRef]

- Yousif, I.; Samaha, J.; Ryu, J.; Harik, R. Safety 4.0: Harnessing computer vision for advanced industrial protection. Manuf. Lett. 2024, 41, 1342–1356. [Google Scholar] [CrossRef]

- Yousif, I.; Burns, L.; El Kalach, F.; Harik, R. Leveraging computer vision towards high-efficiency autonomous industrial facilities. J. Intell. Manuf. 2024, 1–26. [Google Scholar] [CrossRef]

- Töreyin, B.U.; Dedeoğlu, Y.; Güdükbay, U.; Cetin, A.E. Computer vision based method for real-time fire and flame detection. Pattern Recognit. Lett. 2006, 27, 49–58. [Google Scholar] [CrossRef]

- Geetha, S.; Abhishek, C.; Akshayanat, C. Machine vision based fire detection techniques: A survey. Fire Technol. 2021, 57, 591–623. [Google Scholar] [CrossRef]

- Jeelani, I.; Asadi, K.; Ramshankar, H.; Han, K.; Albert, A. Real-time vision-based worker localization & hazard detection for construction. Autom. Constr. 2021, 121, 103448. [Google Scholar]

- Fang, W.; Ding, L.; Zhong, B.; Love, P.E.; Luo, H. Automated detection of workers and heavy equipment on construction sites: A convolutional neural network approach. Adv. Eng. Inform. 2018, 37, 139–149. [Google Scholar] [CrossRef]

- Jiang, D.; Li, G.; Tan, C.; Huang, L.; Sun, Y.; Kong, J. Semantic segmentation for multiscale target based on object recognition using the improved Faster-RCNN model. Future Gener. Comput. Syst. 2021, 123, 94–104. [Google Scholar] [CrossRef]

- He, H.; Xu, H.; Zhang, Y.; Gao, K.; Li, H.; Ma, L.; Li, J. Mask R-CNN based automated identification and extraction of oil well sites. Int. J. Appl. Earth Obs. Geoinf. 2022, 112, 102875. [Google Scholar] [CrossRef]

- Terven, J.; Córdova-Esparza, D.M.; Romero-González, J.A. A comprehensive review of yolo architectures in computer vision: From yolov1 to yolov8 and yolo-nas. Mach. Learn. Knowl. Extr. 2023, 5, 1680–1716. [Google Scholar] [CrossRef]

- Liu, W.; Anguelov, D.; Erhan, D.; Szegedy, C.; Reed, S.; Fu, C.Y.; Berg, A.C. Ssd: Single shot multibox detector. In Proceedings of the Computer Vision–ECCV 2016: 14th European Conference, Amsterdam, The Netherlands, 11–14 October 2016; Proceedings, Part I 14. Springer: Cham, Switzerland, 2016; pp. 21–37. [Google Scholar]

- Wang, M.; Wong, P.; Luo, H.; Kumar, S.; Delhi, V.; Cheng, J. Predicting safety hazards among construction workers and equipment using computer vision and deep learning techniques. In Proceedings of the 36th ISARC, Proceedings of the International Symposium on Automation and Robotics in Construction, Banff, Canada, 21–24 May 2019; Volume 36, pp. 399–406. [Google Scholar]

- Lohani, D.; Crispim-Junior, C.; Barthélemy, Q.; Bertrand, S.; Robinault, L.; Tougne Rodet, L. Perimeter intrusion detection by video surveillance: A survey. Sensors 2022, 22, 3601. [Google Scholar] [CrossRef] [PubMed]

- Tahir, G.A. Ethical Challenges in Computer Vision: Ensuring Privacy and Mitigating Bias in Publicly Available Datasets. arXiv 2024, arXiv:2409.10533. [Google Scholar]

- Xiang, A. Being “Seen” Versus “Mis-Seen”: Tensions Between Privacy and Fairness in Computer Vision. Harv. Jl Tech. 2022, 36, 1. [Google Scholar]

- Ragot, M.; Martin, N.; Cojean, S. Ai-generated vs. human artworks. a perception bias towards artificial intelligence? In Proceedings of the Extended Abstracts of the 2020 CHI Conference on Human Factors in Computing Systems, Honolulu, HI, USA, 25–30 April 2020; pp. 1–10. [Google Scholar]

- Saini, D.K.; Ahir, D.; Ganatra, A. Techniques and challenges in building intelligent systems: Anomaly detection in camera surveillance. In Proceedings of the First International Conference on Information and Communication Technology for Intelligent Systems: Volume 2; Springer: Cham, Switzerland, 2016; pp. 11–21. [Google Scholar]

- Zhu, L.; Menon, M.; Santillo, M.; Linkowski, G. Occlusion handling for industrial robots. In Proceedings of the 2020 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Las Vegas, NV, USA, 25–29 October 2020; pp. 10663–10668. [Google Scholar]

- Youssef, S.M.; Hamza, M.A.; Fayed, A.F. Detection and tracking of multiple moving objects with occlusion in smart video surveillance systems. In Proceedings of the 2010 5th IEEE International Conference Intelligent Systems, London, UK, 7–9 July 2010; pp. 120–125. [Google Scholar]

- Yang, T.; Chen, F.; Kimber, D.; Vaughan, J. Robust people detection and tracking in a multi-camera indoor visual surveillance system. In Proceedings of the 2007 IEEE International Conference on Multimedia and Expo, Beijing, China, 2–5 July 2007; pp. 675–678. [Google Scholar]

- Kumar, C.; Singh, S. Security standards for real time video surveillance and moving object tracking challenges, limitations, and future: A case study. Multimed. Tools Appl. 2024, 83, 30113–30144. [Google Scholar] [CrossRef]

- Moorthy, R.; Upadhya, V.; Holla, V.V.; Shetty, S.S.; Tantry, V.V. Challenges encountered in building a fast and efficient surveillance system: An overview. In Proceedings of the 2020 Fourth International Conference on I-SMAC (IoT in Social Mobile, Analytics and Cloud) (I-SMAC), Palladam, India, 7–9 October 2020; pp. 731–737. [Google Scholar]

- Ricketts, J.; Barry, D.; Guo, W.; Pelham, J. A scoping literature review of natural language processing application to safety occurrence reports. Safety 2023, 9, 22. [Google Scholar] [CrossRef]

- Zhou, Y.; She, J.; Huang, Y.; Li, L.; Zhang, L.; Zhang, J. A design for safety (DFS) semantic framework development based on natural language processing (NLP) for automated compliance checking using BIM: The case of China. Buildings 2022, 12, 780. [Google Scholar] [CrossRef]

- Baker, H.; Smith, S.; Masterton, G.; Hewlett, B. Data-led learning: Using natural language processing (NLP) and machine learning to learn from construction site safety failures. In Proceedings of the 36th Annual ARCOM Conference: Association of Researchers in Construction Management, Leeds, UK, 7-8 September 2020; ARCOM: Leeds, UK, 2020; pp. 356–365. [Google Scholar]

- Brundage, M.P.; Sexton, T.; Hodkiewicz, M.; Dima, A.; Lukens, S. Technical language processing: Unlocking maintenance knowledge. Manuf. Lett. 2021, 27, 42–46. [Google Scholar] [CrossRef]

- Xu, H.; Liu, Y.; Shu, C.M.; Bai, M.; Motalifu, M.; He, Z.; Wu, S.; Zhou, P.; Li, B. Cause analysis of hot work accidents based on text mining and deep learning. J. Loss Prev. Process Ind. 2022, 76, 104747. [Google Scholar] [CrossRef]

- Jahin, M.A.; Talapatra, S. A natural language processing-based classification and mode-based ranking of musculoskeletal disorder risk factors. Decis. Anal. J. 2024, 11, 100464. [Google Scholar] [CrossRef]

- May, M.C.; Neidhöfer, J.; Körner, T.; Schäfer, L.; Lanza, G. Applying natural language processing in manufacturing. Procedia CIRP 2022, 115, 184–189. [Google Scholar] [CrossRef]

- Ray, P.P. ChatGPT: A comprehensive review on background, applications, key challenges, bias, ethics, limitations and future scope. Internet Things Cyber-Phys. Syst. 2023, 3, 121–154. [Google Scholar] [CrossRef]

- Gallegos, I.O.; Rossi, R.A.; Barrow, J.; Tanjim, M.M.; Kim, S.; Dernoncourt, F.; Yu, T.; Zhang, R.; Ahmed, N.K. Bias and fairness in large language models: A survey. Comput. Linguist. 2024, 50, 1097–1179. [Google Scholar] [CrossRef]

- Bender, E.M.; Friedman, B. Data statements for natural language processing: Toward mitigating system bias and enabling better science. Trans. Assoc. Comput. Linguist. 2018, 6, 587–604. [Google Scholar] [CrossRef]

- Ford’s Cobots: Innovating Automotive Manufacturing Efficiency. Available online: https://profwurzer.com/fords-use-of-collaborative-robots (accessed on 10 April 2025).

- Taylor, A. How Tesla and Ford Use Robotics to Revolutionize Manufacturing Efficiency. Available online: https://www.cleverence.com/articles/business-blogs/how-tesla-and-ford-use-robotics-to-revolutionize-manufacturing-efficiency/ (accessed on 10 April 2025).

- Bi, Z.M.; Luo, C.; Miao, Z.; Zhang, B.; Zhang, W.J.; Wang, L. Safety assurance mechanisms of collaborative robotic systems in manufacturing. Robot. Comput.-Integr. Manuf. 2021, 67, 102022. [Google Scholar] [CrossRef]

- Pauliková, A.; Gyurák Babel’ová, Z.; Ubárová, M. Analysis of the impact of human–cobot collaborative manufacturing implementation on the occupational health and safety and the quality requirements. Int. J. Environ. Res. Public Health 2021, 18, 1927. [Google Scholar] [CrossRef]

- Ford Motor Enters Digital Era with Its Advanced Manufacturing Center. Available online: https://connectedmanufacturing.wbresearch.com/blog/ford-motor-company-advanced-manufacturing-center-strategy (accessed on 10 April 2025).

- Shelby, L. Accelerating Tesla’s Safety Culture. 2020. Available online: https://www.tesla.com/en_ca/blog/accelerating-teslas-safety-culture (accessed on 10 April 2025).

- Industrial Computer Vision: Turn Your Regular CCTV into Smart AI Cameras—SeeWise.AI. 2023. Available online: https://www.seewise.ai/blogs/ai-to-ensure-safety-compliance-in-manufacturing.html (accessed on 10 April 2025).

- How Intenseye Uses AI for Safety|Wire Journal International. Available online: https://www.intenseye.com/interviews/intenseye-qa-on-the-use-of-ai-for-safety (accessed on 10 April 2025).

- Swire Coca-Cola: 27% decrease in LDR with Intenseye. Available online: https://www.intenseye.com/case-studies/swire-coca-cola (accessed on 10 April 2025).

- Intenseye—Transforming Workplace Safety with AI. Available online: https://www.intenseye.com/ (accessed on 10 April 2025).

- Koçtaş: Managing Missing PPE and Work at Height Risks with AI. Available online: https://www.intenseye.com/case-studies/koctas-managing-missing-ppe-and-work-at-height-risks-with-ai (accessed on 10 April 2025).

- Burgess, M. AI Enhances Safety and Security in Asia—Linfox. Available online: https://www.linfox.com/ai-enhances-safety-and-security-in-asia/ (accessed on 10 April 2025).

- Nikolakis, N.; Alexopoulos, K.; Xanthakis, E.; Chryssolouris, G. The digital twin implementation for linking the virtual representation of human-based production tasks to their physical counterpart in the factory-floor. Int. J. Comput. Integr. Manuf. 2019, 32, 1–12. [Google Scholar] [CrossRef]

- Hovanec, M.; Korba, P.; Vencel, M.; Al-Rabeei, S. Simulating a digital factory and improving production efficiency by using virtual reality technology. Appl. Sci. 2023, 13, 5118. [Google Scholar] [CrossRef]

- Use Case: NVIDIA Computing Platforms for Humanoid Robots. Available online: https://www.nvidia.com/en-us/use-cases/humanoid-robots/ (accessed on 10 April 2025).

- Yang, X.; Deines, E.; Lauer, C.; Aurich, J.C. A human-centered virtual factory. In Proceedings of the MSIE 2011, Harbin, China, 8–9 January 2011; pp. 1138–1142. [Google Scholar]

- Wang, H.; Lv, L.; Li, X.; Li, H.; Leng, J.; Zhang, Y.; Thomson, V.; Liu, G.; Wen, X.; Sun, C.; et al. A safety management approach for Industry 5.0’ s human-centered manufacturing based on digital twin. J. Manuf. Syst. 2023, 66, 1–12. [Google Scholar] [CrossRef]

- What Are AI Agents? Available online: https://www.nvidia.com/en-us/glossary/ai-agents/ (accessed on 10 April 2025).

- Bernardi, M.L.; Cimitile, M.; Pecori, R. Automatic Job Safety Report Generation using RAG-based LLMs. In Proceedings of the 2024 International Joint Conference on Neural Networks (IJCNN), Yokohama, Japan, 30 June–5 July 2024; pp. 1–8. [Google Scholar]

- Lee, J.; Ahn, S.; Kim, D.; Kim, D. Performance comparison of retrieval-augmented generation and fine-tuned large language models for construction safety management knowledge retrieval. Autom. Constr. 2024, 168, 105846. [Google Scholar] [CrossRef]

- NVIDIA Omniverse. Available online: https://www.nvidia.com/en-us/omniverse/ (accessed on 10 April 2025).

- Home|Continental. Available online: https://www.continental.com/en/ (accessed on 10 April 2025).

- Simulating Factories of the Future With Hyper-Scale, Hyper-Reality Digital Twins|GTC 24 2024|NVIDIA On-Demand. Available online: https://www.nvidia.com/en-us/on-demand/session/gtc24-s62623/ (accessed on 10 April 2025).

- Wistron. Available online: https://www.wistron.com/en (accessed on 10 April 2025).

- McKenna, J. What Is a Virtual Factory, and How They’re Making Industrial Digitalization a Reality. Available online: https://blogs.nvidia.com/blog/virtual-factories-industrial-digitalization/ (accessed on 10 April 2025).

- Zonta, T.; Da Costa, C.A.; da Rosa Righi, R.; de Lima, M.J.; Da Trindade, E.S.; Li, G.P. Predictive maintenance in the Industry 4.0: A systematic literature review. Comput. Ind. Eng. 2020, 150, 106889. [Google Scholar] [CrossRef]

- Hijry, H.; Naqvi, S.M.R.; Javed, K.; Albalawi, O.H.; Olawoyin, R.; Varnier, C.; Zerhouni, N. Real Time Worker Stress Prediction in a Smart Factory Assembly Line. IEEE Access 2024, 12, 116238–116249. [Google Scholar] [CrossRef]

- Henkes, A.; Herrmann, L.; Wessels, H.; Kollmannsberger, S. Generative adversarial networks enable outlier detection and property monitoring for additive manufacturing of complex structures. Eng. Appl. Artif. Intell. 2024, 136, 108993. [Google Scholar] [CrossRef]

- Mumbelli, J.D.; Guarneri, G.A.; Lopes, Y.K.; Casanova, D.; Teixeira, M. An application of Generative Adversarial Networks to improve automatic inspection in automotive manufacturing. Appl. Soft Comput. 2023, 136, 110105. [Google Scholar] [CrossRef]

- Goodfellow, I.; Pouget-Abadie, J.; Mirza, M.; Xu, B.; Warde-Farley, D.; Ozair, S.; Courville, A.; Bengio, Y. Generative adversarial networks. Commun. ACM 2020, 63, 139–144. [Google Scholar] [CrossRef]

- Zhang, L.; Wu, X.; Skibniewski, M.J.; Zhong, J. Dynamic risk assessment in construction projects using Bayesian networks. In Proceedings of the 31st ISARC, Proceedings of the International Symposium on Automation and Robotics in Construction, Sydney, Australia, 9–11 July 2014; Volume 31, p. 1. [Google Scholar]

- Punyamurthula, S.; Badurdeen, F. Assessing production line risk using bayesian Belief networks and system dynamics. Procedia Manuf. 2018, 26, 76–86. [Google Scholar] [CrossRef]

- Pereira, J.; Fragoso, M.; Todorov, M. Risk assessment using bayesian belief networks and analytic hierarchy process applicable to jet engine high pressure turbine assembly. IFAC-PapersOnLine 2016, 49, 133–138. [Google Scholar] [CrossRef]

- Kang, K.; Ryu, H. Predicting types of occupational accidents at construction sites in Korea using random forest model. Saf. Sci. 2019, 120, 226–236. [Google Scholar] [CrossRef]

- Hosseinzadeh, A.; Chen, F.F.; Shahin, M.; Bouzary, H. A predictive maintenance approach in manufacturing systems via AI-based early failure detection. Manuf. Lett. 2023, 35, 1179–1186. [Google Scholar] [CrossRef]

- Lalwani, P.; Ramasamy, G. Human activity recognition using a multi-branched CNN-BiLSTM-BiGRU model. Appl. Soft Comput. 2024, 154, 111344. [Google Scholar] [CrossRef]

- Shoorkand, H.D.; Nourelfath, M.; Hajji, A. A hybrid CNN-LSTM model for joint optimization of production and imperfect predictive maintenance planning. Reliab. Eng. Syst. Saf. 2024, 241, 109707. [Google Scholar] [CrossRef]

- Borré, A.; Seman, L.O.; Camponogara, E.; Stefenon, S.F.; Mariani, V.C.; Coelho, L.d.S. Machine fault detection using a hybrid CNN-LSTM attention-based model. Sensors 2023, 23, 4512. [Google Scholar] [CrossRef] [PubMed]

- Sii, H.S.; Ruxton, T.; Wang, J. A fuzzy-logic-based approach to qualitative safety modelling for marine systems. Reliab. Eng. Syst. Saf. 2001, 73, 19–34. [Google Scholar] [CrossRef]

- Sun, W.; Jin, Y.; Dai, K.; Guo, Z.; Ma, F. Flexible manipulator trajectory tracking based on an improved adaptive particle swarm optimization algorithm with fuzzy PD control. Mech. Sci. 2025, 16, 125–141. [Google Scholar] [CrossRef]

- Achouch, M.; Dimitrova, M.; Ziane, K.; Sattarpanah Karganroudi, S.; Dhouib, R.; Ibrahim, H.; Adda, M. On predictive maintenance in industry 4.0: Overview, models, and challenges. Appl. Sci. 2022, 12, 8081. [Google Scholar] [CrossRef]

- Cadence PCB Solutions. Types of Predictive Maintenance. Cadence PCB Design & Analysis Blog. 2023. Available online: https://resources.pcb.cadence.com/blog/2023-types-of-predictive-maintenance (accessed on 15 January 2025).

- Poór, P.; Basl, J.; Zenisek, D. Predictive Maintenance 4.0 as next evolution step in industrial maintenance development. In Proceedings of the 2019 International Research Conference on Smart Computing and Systems Engineering (SCSE), Colombo, Sri Lanka, 28 March 2019; pp. 245–253. [Google Scholar]

- Ayvaz, S.; Alpay, K. Predictive maintenance system for production lines in manufacturing: A machine learning approach using IoT data in real-time. Expert Syst. Appl. 2021, 173, 114598. [Google Scholar] [CrossRef]

- Nacchia, M.; Fruggiero, F.; Lambiase, A.; Bruton, K. A systematic mapping of the advancing use of machine learning techniques for predictive maintenance in the manufacturing sector. Appl. Sci. 2021, 11, 2546. [Google Scholar] [CrossRef]

- Behera, P.K.; Sahoo, B.S. Leverage of multiple predictive maintenance technologies in root cause failure analysis of critical machineries. Procedia Eng. 2016, 144, 351–359. [Google Scholar] [CrossRef]

- Aljohani, A. Predictive analytics and machine learning for real-time supply chain risk mitigation and agility. Sustainability 2023, 15, 15088. [Google Scholar] [CrossRef]

- Nexteng Enviro Pvt Ltd. AI/ML Based Predictive Maintenance. Available online: https://nextengineering.in/solutions/ai-ml-based-predictive-maintenance/ (accessed on 2 January 2025).

- Baumung, W.; Baumung, V. Application of Machine Learning and Vision for real-time condition monitoring and acceleration of product development cycles. Procedia Manuf. 2020, 52, 61–66. [Google Scholar] [CrossRef]

- Bourou, S.; Maniatis, A.; Kontopoulos, D.; Karkazis, P.A. Smart detection system of safety hazards in industry 5.0. Telecom 2023, 5, 1–20. [Google Scholar] [CrossRef]

- Canadian Centre for Occupational Health and Safety. Hazard and Risk—Risk Assessment. Available online: https://www.ccohs.ca/oshanswers/hsprograms/hazard/risk_assessment.html (accessed on 29 December 2024).

- Occupational Safety and Health Administration. Hazard Identification and Assessment. Available online: https://www.osha.gov/safety-management/hazard-identification (accessed on 12 January 2025).

- Albery, S.; Borys, D.; Tepe, S. Advantages for risk assessment: Evaluating learnings from question sets inspired by the FRAM and the risk matrix in a manufacturing environment. Saf. Sci. 2016, 89, 180–189. [Google Scholar] [CrossRef]

- Oregon State University, Environmental Health and Safety. Hazard Identification and Control. Available online: https://ehs.oregonstate.edu/sites/ehs.oregonstate.edu/files/pdf/si/hazard_identification_and_control_si.pdf (accessed on 29 December 2024).

- Occupational Safety and Health Administration. Right to refuse dangerous work. Available online: https://www.osha.gov/workers/right-to-refuse (accessed on 21 January 2025).

- SafeStart. How to Navigate Ambiguity—A Threat to Stop-Work Authority 2024. Available online: https://safestart.com/news/ambiguity-threat-to-stop-work-authority/ (accessed on 21 January 2025).

- Business Development Bank of Canada. What Is Operational Efficiency? Available online: https://www.bdc.ca/en/articles-tools/operations/operational-efficiency/3-critical-factors-operational-efficiency (accessed on 23 January 2025).

- Supply Chain Mechanic. Basics of smoothing the manufacturing plan. SupplyChainMechanic.com. 2010. Available online: https://supplychain-mechanic.com/?p=314 (accessed on 23 January 2025).

- U.S. Chemical Safety and Hazard Investigation Board. Hayes Lemmerz Dust Explosions and Fire. Available online: https://www.csb.gov/hayes-lemmerz-dust-explosions-and-fire/ (accessed on 23 January 2025).

- U.S. Chemical Safety and Hazard Investigation Board. Chevron Richmond Refinery Fire. Available online: https://www.csb.gov/chevron-richmond-refinery-fire/ (accessed on 23 January 2025).

- Rai, R.; Tiwari, M.K.; Ivanov, D.; Dolgui, A. Machine learning in manufacturing and industry 4.0 applications. Int. J. Prod. Res. 2021, 59, 4773–4778. [Google Scholar] [CrossRef]

- Zehnder Clean Air Solutions. How Dust is Formed in Manufacturing. Available online: https://www.zehnder-cleanairsolutions.com/en/blog/how-dust-is-formed-in-manufacturing (accessed on 23 January 2025).

- Canadian Centre for Occupational Health and Safety. Health and Safety Report—March 2016. Available online: https://www.ccohs.ca/newsletters/hsreport/issues/2016/03/ezine.html (accessed on 23 January 2025).

- Canadian Centre for Occupational Health and Safety. Combustible Dust. Available online: https://www.ccohs.ca/oshanswers/chemicals/combustible_dust.html (accessed on 23 January 2025).

- Dustcontrol. How Dust Harms Manufacturing and Productivity. Available online: https://dustcontrol.com/how-dust-harms-manufacturing-and-productivity/ (accessed on 23 January 2025).

- Canadian Centre for Occupational Health and Safety. Workplace Housekeeping—Basic Guide. Available online: https://www.ccohs.ca/oshanswers/hsprograms/housekeeping/house.html (accessed on 20 January 2025).

- Yaseen, A. Reducing industrial risk with AI and automation. Int. J. Intell. Autom. Comput. 2021, 4, 60–80. [Google Scholar]

- Chinniah, Y.; Bourbonniere, R. Automation safety. Prof. Saf. 2006, 51, 26–33. [Google Scholar]

- Negnevitsky, M.; Tomin, N.V.; Rehtanz, C. Preventing large-scale emergencies in modern power systems: AI approach. J. Adv. Comput. Intell. Intell. Inform. 2014, 18, 714–727. [Google Scholar] [CrossRef]

- Hickok, M.; Maslej, N. A policy primer and roadmap on AI worker surveillance and productivity scoring tools. AI Ethics 2023, 3, 673–687. [Google Scholar] [CrossRef]

- Rebbitt, D. When undetected deviation becomes an incident. Can. Occup. Saf. 2014. Available online: https://www.thesafetymag.com/ca/news/opinion/when-undetected-deviation-becomes-an-incident/187069 (accessed on 24 January 2025).

- Qi, R.; Zhang, J.; Spencer, K. A review on data-driven condition monitoring of industrial equipment. Algorithms 2022, 16, 9. [Google Scholar] [CrossRef]

- Northwestern University McCormick School of Engineering. Improving the Occupational Health of Manufacturing Workers. Available online: https://www.mccormick.northwestern.edu/news/articles/2024/10/improving-the-occupational-health-of-manufacturing-workers/ (accessed on 24 January 2025).

- Psico Smart. The Role of Artificial Intelligence in Enhancing Labor Fatigue Management Systems. Available online: https://psico-smart.com/en/blogs/blog-the-role-of-artificial-intelligence-in-enhancing-labor-fatigue-management-systems-170861 (accessed on 11 January 2025).

- Hooda, R.; Joshi, V.; Shah, M. A comprehensive review of approaches to detect fatigue using machine learning techniques. Chronic Dis. Transl. Med. 2021, in press. [CrossRef] [PubMed]

- Fiegler-Rudol, J.; Lau, K.; Mroczek, A.; Kasperczyk, J. Exploring Human–AI Dynamics in Enhancing Workplace Health and Safety: A Narrative Review. Int. J. Environ. Res. Public Health 2025, 22, 199. [Google Scholar] [CrossRef]

- Chokor, A.; Naganathan, H.; Chong, W.K.; El Asmar, M. Analyzing Arizona OSHA injury reports using unsupervised machine learning. Procedia Eng. 2016, 145, 1588–1593. [Google Scholar] [CrossRef]

- Khusainov, R.; Azzi, D.; Achumba, I.E.; Bersch, S.D. Real-time human ambulation, activity, and physiological monitoring: Taxonomy of issues, techniques, applications, challenges and limitations. Sensors 2013, 13, 12852–12902. [Google Scholar] [CrossRef]

- International Labour Organization. Exposure to Hazardous Chemicals at Work and Resulting Health Impacts: A Global Review. 2021. Available online: https://www.ilo.org/sites/default/files/wcmsp5/groups/public/@ed_dialogue/@lab_admin/documents/publication/wcms_795460.pdf (accessed on 24 January 2025).

- Khan, A.; Gupta, S.; Gupta, S.K. Multi-hazard disaster studies: Monitoring, detection, recovery, and management, based on emerging technologies and optimal techniques. Int. J. Disaster Risk Reduct. 2020, 47, 101642. [Google Scholar] [CrossRef]

- Sivapriya, J.; Ramani, D.R.; Srivastava, R.P.; Kumar, K.; Nair, R.V. AI-Powered Anomaly and Threat Detection for Surveillance Footage Analysis. In Proceedings of the 2024 8th International Conference on Inventive Systems and Control (ICISC), Coimbatore, India, 29–30 July 2024; pp. 240–247. [Google Scholar]

- Alghushairy, O.; Alsini, R.; Soule, T.; Ma, X. A review of local outlier factor algorithms for outlier detection in big data streams. Big Data Cogn. Comput. 2020, 5, 1. [Google Scholar] [CrossRef]

- Liu, X.; Zhu, S.; Yang, F.; Liang, S. Research on unsupervised anomaly data detection method based on improved automatic encoder and Gaussian mixture model. J. Cloud Comput. 2022, 11, 58. [Google Scholar] [CrossRef]

- Nassif, A.B.; Talib, M.A.; Nasir, Q.; Dakalbab, F.M. Machine learning for anomaly detection: A systematic review. IEEE Access 2021, 9, 78658–78700. [Google Scholar] [CrossRef]

- Primartha, R.; Tama, B.A. Anomaly detection using random forest: A performance revisited. In Proceedings of the 2017 International conference on data and software engineering (ICoDSE), Palembang, Indonesia, 1–2 November 2017; pp. 1–6. [Google Scholar]

- Ogbuke, N.J.; Yusuf, Y.Y.; Dharma, K.; Mercangoz, B.A. Big data supply chain analytics: Ethical, privacy and security challenges posed to business, industries and society. Prod. Plan. Control 2022, 33, 123–137. [Google Scholar] [CrossRef]

- Phan, T.C.; Tran, H.C. Consideration of data security and privacy using machine learning techniques. Int. J. Data Inform. Intell. Comput. 2023, 2, 20–32. [Google Scholar]

- Devineni, S.K.; Kathiriya, S.; Shende, A. Machine learning-powered anomaly detection: Enhancing data security and integrity. J. Artif. Intell. Cloud Comput. 2023, 184, 2–9. [Google Scholar] [CrossRef]

- Elmrabit, N.; Zhou, F.; Li, F.; Zhou, H. Evaluation of machine learning algorithms for anomaly detection. In Proceedings of the 2020 International Conference on Cyber Security and Protection of Digital Services (Cyber Security), Dublin, Ireland, 15–19 June 2020; pp. 1–8. [Google Scholar]

- Li, N.; Sun, M.; Bi, Z.; Su, Z.; Wang, C. A new methodology to support group decision-making for IoT-based emergency response systems. Inf. Syst. Front. 2014, 16, 953–977. [Google Scholar] [CrossRef]

- Rodriguez, M.; Mohammed, M.; Mohammed, R.; Pasam, P.; Karanam, R.; Vennapusa, S.; Boinapalli, N. Oracle EBS and Digital Transformation: Aligning Technology with Business Goals. Technol. Manag. Rev. 2019, 4, 49–63. [Google Scholar]

- Bazargan-Lari, M.R. Real-time response to contamination emergencies of urban water networks. Iran. J. Sci. Technol. Trans. Civ. Eng. 2018, 42, 73–83. [Google Scholar] [CrossRef]

- Zhao, L. Business intelligence implementation in the framework of enhanced learning application. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Krasnoyarsk, Russia, 4–6 April 2019; Volume 563, p. 032015. [Google Scholar]

- Caiazzo, B.; Murino, T.; Petrillo, A.; Piccirillo, G.; Santini, S. An IoT-based and cloud-assisted AI-driven monitoring platform for smart manufacturing: Design architecture and experimental validation. J. Manuf. Technol. Manag. 2023, 34, 507–534. [Google Scholar] [CrossRef]

- Nahavandi, D.; Alizadehsani, R.; Khosravi, A.; Acharya, U.R. Application of artificial intelligence in wearable devices: Opportunities and challenges. Comput. Methods Programs Biomed. 2022, 213, 106541. [Google Scholar] [CrossRef]

- Kiral-Kornek, I.; Roy, S.; Nurse, E.; Mashford, B.; Karoly, P.; Carroll, T.; Payne, D.; Saha, S.; Baldassano, S.; O’Brien, T.; et al. Epileptic seizure prediction using big data and deep learning: Toward a mobile system. EBioMedicine 2018, 27, 103–111. [Google Scholar] [CrossRef]

- Roy, S.; Kiral-Kornek, I.; Harrer, S. ChronoNet: A deep recurrent neural network for abnormal EEG identification. In Proceedings of the Artificial Intelligence in Medicine: 17th Conference on Artificial Intelligence in Medicine, AIME 2019, Poznan, Poland, 26–29 June 2019; Proceedings 17. Springer: Cham, Switzerland, 2019; pp. 47–56. [Google Scholar]

- Ulate-Campos, A.; Coughlin, F.; Gaínza-Lein, M.; Fernández, I.S.; Pearl, P.; Loddenkemper, T. Automated seizure detection systems and their effectiveness for each type of seizure. Seizure 2016, 40, 88–101. [Google Scholar] [CrossRef]

- Harrer, S.; Shah, P.; Antony, B.; Hu, J. Artificial intelligence for clinical trial design. Trends Pharmacol. Sci. 2019, 40, 577–591. [Google Scholar] [CrossRef]

- Mirmomeni, M.; Fazio, T.; von Cavallar, S.; Harrer, S. From wearables to THINKables: Artificial intelligence-enabled sensors for health monitoring. In Wearable Sensors; Elsevier: London, UK, 2021; pp. 339–356. [Google Scholar]

- Reynolds, M.; A Medical-Grade Smartwatch Is Helping People Live with Epilepsy. WIRED 2018. Available online: https://www.wired.com/story/empatica-embrace-epilepsy-wearable-medical-device/ (accessed on 1 February 2025).

- Sabry, F.; Eltaras, T.; Labda, W.; Alzoubi, K.; Malluhi, Q. Machine learning for healthcare wearable devices: The big picture. J. Healthc. Eng. 2022, 2022, 4653923. [Google Scholar] [CrossRef]

- Mamdiwar, S.D.; R, A.; Shakruwala, Z.; Chadha, U.; Srinivasan, K.; Chang, C.-Y. Recent advances on IoT-assisted wearable sensor systems for healthcare monitoring. Biosensors 2021, 11, 372. [Google Scholar] [CrossRef] [PubMed]

- Awotunde, J.B.; Ajagbe, S.A.; Florez, H. Internet of things with wearable devices and artificial intelligence for elderly uninterrupted healthcare monitoring systems. In Proceedings of the International Conference on Applied Informatics, Arequipa, Peru, 27–29 October 2022; pp. 278–291. [Google Scholar]

- Ratushnyi, V. Determinants of Safe Evacuation of Large Production Factories. Available online: https://wsb.edu.pl/files//pages/634/security_forum_2_2023_doi_10_26410_sf_2_23_8.pdf (accessed on 18 April 2025).

- Ruggiero, L. A review of augmented reality applications for building evacuation. arXiv 2018, arXiv:1804.04186. [Google Scholar]

- Doolani, S.; Wessels, C.; Kanal, V.; Sevastopoulos, C.; Jaiswal, A.; Nambiappan, H.; Makedon, F. A review of extended reality (xr) technologies for manufacturing training. Technologies 2020, 8, 77. [Google Scholar] [CrossRef]

- Forkan, A.R.M.; Montori, F.; Georgakopoulos, D.; Jayaraman, P.P.; Yavari, A.; Morshed, A. An industrial IoT solution for evaluating workers’ performance via activity recognition. In Proceedings of the 2019 IEEE 39th International Conference on Distributed Computing Systems (ICDCS), Dallas, TX, USA, 7–10 July 2019; pp. 1393–1403. [Google Scholar]

- Manzi, A.; Hirschhorn, L.R.; Sherr, K.; Chirwa, C.; Baynes, C.; Awoonor-Williams, J.K. Mentorship and coaching to support strengthening healthcare systems: Lessons learned across the five Population Health Implementation and Training partnership projects in sub-Saharan Africa. BMC Health Serv. Res. 2017, 17, 5–16. [Google Scholar] [CrossRef] [PubMed]

- Venusamy, K.; Rajagopal, N.K.; Yousoof, M. A study of human resources development through chatbots using artificial intelligence. In Proceedings of the 2020 3rd International Conference on Intelligent Sustainable Systems (ICISS), Thoothukudi, India, 3–5 December 2020; pp. 94–99. [Google Scholar]

- Wolter, S.C.; Ryan, P. Apprenticeship. In Handbook of the Economics of Education; Elsevier: Amsterdam, The Netherlands, 2011; Volume 3, pp. 521–576. [Google Scholar]

- Gorowara, N.; Prakash, A.; Correa, F.S.; Malik, V.; Mittal, R. AI Personalizing Training and Reskilling Employees for the Digital Age. In Proceedings of the 2024 International Conference on Emerging Smart Computing and Informatics (ESCI), Pune, India, 5–7 March 2024; pp. 1–6. [Google Scholar]

- Sun, Y.; Ji, F. An Embodied Intelligence System for Coal Mine Safety Assessment Based on Multi-Level Large Language Models. Sensors 2025, 25, 488. [Google Scholar] [CrossRef] [PubMed]

- Collier, Z.A.; Gruss, R.J.; Abrahams, A.S. How good are large language models at product risk assessment? Risk Anal. 2024. [Google Scholar] [CrossRef]

- Strasser, A. Pitfalls (and advantages) of sophisticated large language models. In Ethics in Online AI-Based Systems; Elsevier: London, UK, 2024; pp. 195–210. [Google Scholar]

- Moreira, G.; Pleffken, D.; Santos, W.; Cerqueira, C.; Gotelip, M. Using LLMs to Automate Means of Compliance Assignment in Aerospace Defense Systems. TechRxiv 2024. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, H.; Jiang, H.; Pan, Y.; Liu, Z.; Wu, Z.; Shu, P.; Tian, J.; Yang, T.; Xu, S.; et al. Large language models for manufacturing. arXiv 2024, arXiv:2410.21418. [Google Scholar]

- Garcia, C.I.; DiBattista, M.A.; Letelier, T.A.; Halloran, H.D.; Camelio, J.A. Framework for LLM applications in manufacturing. Manuf. Lett. 2024, 41, 253–263. [Google Scholar] [CrossRef]

- Jędrych, E.; Rzepka, A. Organizational Development, Innovation, and Economy 5.0: Challenges in the Digital Era; Taylor & Francis: Abingdon, UK, 2024. [Google Scholar]

- Nguyen, T.; Nguyen, D.H.; Nguyen, Q.T.; Tran, K.D.; Tran, K.P. Human-Centered Edge AI and Wearable Technology for Workplace Health and Safety in Industry 5.0. In Artificial Intelligence for Safety and Reliability Engineering: Methods, Applications, and Challenges; Springer: Cham, Switzerland, 2024; pp. 171–183. [Google Scholar]

- Shah, I.A.; Mishra, S. Artificial intelligence in advancing occupational health and safety: An encapsulation of developments. J. Occup. Health 2024, 66, uiad017. [Google Scholar] [CrossRef]

- Molek, N. The future of labour: How ai, robotics, and automation are redefining EU labour markets. In Analysis of the State of the Art on the Future of Human Workforce; Fakultet za organizacijske študije v Novem mestu: Novo Mesto, Slovenia, 2024; pp. 21–48. Available online: https://transform-euproject.eu/wp-content/uploads/2024/12/Analysis-of-the-State-o-the-Art-on-the-future-of-human-workforce.pdf#page=22 (accessed on 18 April 2025).

- Dehghani, F.; Dibaji, M.; Anzum, F.; Dey, L.; Basdemir, A.; Bayat, S.; Boucher, J.C.; Drew, S.; Eaton, S.E.; Frayne, R.; et al. Trustworthy and Responsible AI for Human-Centric Autonomous Decision-Making Systems. arXiv 2024, arXiv:2408.15550. [Google Scholar]

- International Organization for Standardization. Ergonomics of Human-System Interaction: Part 210: Human-Centred Design for Interactive Systems; ISO: Geneva, Switzerland, 2010. [Google Scholar]

- IEEE. Ethical Considerations of Autonomous Intelligent Systems (AIS). 2023. Available online: https://standards.ieee.org/wp-content/uploads/2023/08/ieee-ethical-considerations-ais-policy.pdf (accessed on 8 February 2025).

- Trivedi, P.; Alqahtani, F.M. The advancement of artificial intelligence (AI) in occupational health and safety (OHS) across high-risk industries. J. Infrastruct. Policy Dev. 2024, 8, 6889. [Google Scholar] [CrossRef]

- Sundaram, S.; Zeid, A. Artificial intelligence-based smart quality inspection for manufacturing. Micromachines 2023, 14, 570. [Google Scholar] [CrossRef] [PubMed]

- Rydzi, S.; Zahradnikova, B.; Sutova, Z.; Ravas, M.; Hornacek, D.; Tanuska, P. A predictive quality inspection framework for the manufacturing process in the context of industry 4.0. Sensors 2024, 24, 5644. [Google Scholar] [CrossRef]

- Silva, A.C.; Machado, J.; Sampaio, P. Predictive quality model for customer defects. Tqm J. 2024, 36, 155–174. [Google Scholar] [CrossRef]

- Chadha, U.; Abraham, A.; Anilkumar, K.; Kuriyakkattil, V.; Singh, H.; Bane, S.; Chadha, A.; Armstrong, S.; Patterson, A. Synergizing Lean Six Sigma Framework Using Artificial Intelligence, Internet of Things, and Blockchain for Sustainable Manufacturing Excellence. TechRxiv 2024. [Google Scholar] [CrossRef]

- Letourneau-Guillon, L.; Camirand, D.; Guilbert, F.; Forghani, R. Artificial intelligence applications for workflow, process optimization and predictive analytics. Neuroimaging Clin. N. Am. 2020, 30, e1–e15. [Google Scholar] [CrossRef]

- Afroogh, S.; Akbari, A.; Malone, E.; Kargar, M.; Alambeigi, H. Trust in AI: Progress, challenges, and future directions. Humanit. Soc. Sci. Commun. 2024, 11, 1–30. [Google Scholar] [CrossRef]

- Bedué, P.; Fritzsche, A. Can we trust AI? An empirical investigation of trust requirements and guide to successful AI adoption. J. Enterp. Inf. Manag. 2022, 35, 530–549. [Google Scholar] [CrossRef]

- Mehri, V.A.; Ilie, D.; Tutschku, K. Privacy and DRM requirements for collaborative development of AI applications. In Proceedings of the 13th International Conference on Availability, Reliability and Security, Hamburg, Germany, 27–30 August 2018; pp. 1–8. [Google Scholar]

- Hintze, M. Science and privacy: Data protection laws and their impact on research. Wash. J. Law Tech. Arts 2018, 14, 103. [Google Scholar]

- Wilson, R. Cambridge analytica, Facebook, and Influence Operations: A case study and anticipatory ethical analysis. In Proceedings of the European Conference on Cyber Warfare and Security; Academic Conferences International: London, UK, 2019; pp. 587–595. [Google Scholar]

- John Lopez. Samsung Employees Use ChatGPT at Work, Unknowingly Leak Critical Source Codes. 2023. Available online: https://www.techtimes.com/articles/289996/20230404/samsung-employees-used-chatgpt-work-unknowingly-leaked-critical-source-codes.htm (accessed on 9 April 2025).

- Tschopp, M. Is Artificial Intelligence Worth the Risk? 2019. Available online: https://www.scip.ch/en/?labs.20190718 (accessed on 9 April 2025).

- Daugherty, P.; Wilson, H. Human+ Machine: Reimagining Work in the Age of AI; Harv. Bus. Rev. Press: Boston, MA, USA, 2018. [Google Scholar]

- Brown, A. Biased algorithms learn from biased data: 3 kinds of biases found in AI datasets. Forbes 2020, 7. Available online: https://www.forbes.com/sites/cognitiveworld/2020/02/07/biased-algorithms/ (accessed on 18 April 2025).

- Freedman, R. ACLU Asks FTC to Probe Aon AI Employment Assessment Tools for Bias. 2024. Available online: https://www.legaldive.com/news/aclu-ftc-complaint-aon-ai-employment-assessment-tools-biased/717662/ (accessed on 9 April 2025).

- Madiega, T. Artificial Intelligence Act; European Parliament; European Parliamentary Research Service: Bruxelles, Brussel, 2021. [Google Scholar]

- Srivastava, B.; Rossi, F. Towards composable bias rating of AI services. In Proceedings of the 2018 AAAI/ACM Conference on AI, Ethics, and Society, New Orleans, LA, USA, 2–3 February 2018; pp. 284–289. [Google Scholar]

- Agarwal, A.; Lohia, P.; Nagar, S.; Dey, K.; Saha, D. Automated test generation to detect individual discrimination in AI models. arXiv 2018, arXiv:1809.03260. [Google Scholar]

- Celis, L.E.; Deshpande, A.; Kathuria, T.; Vishnoi, N.K. How to be fair and diverse? arXiv 2016, arXiv:1610.07183. [Google Scholar]

- Mueller, S.T.; Hoffman, R.R.; Clancey, W.; Emrey, A.; Klein, G. Explanation in human-AI systems: A literature meta-review, synopsis of key ideas and publications, and bibliography for explainable AI. arXiv 2019, arXiv:1902.01876. [Google Scholar]