A New Bayesian Inversion Method for Thixotropic Model Parameters of Waxy Crude Oil

Abstract

1. Introduction

2. Thixotropic Models and Experimental Data

2.1. Thixotropic Models

2.2. Experimental Data

3. A New Inversion Method for Thixotropic Model Parameters

3.1. ADE-Based Bayesian Inversion Method

- (1)

- Initial Parameter Estimation Using ADE Algorithm

- (2)

- Bayesian Parameter Inversion

- (3)

- Algorithm Parameter Configuration

3.2. Least Squares Method

4. Results and Discussion

- (1)

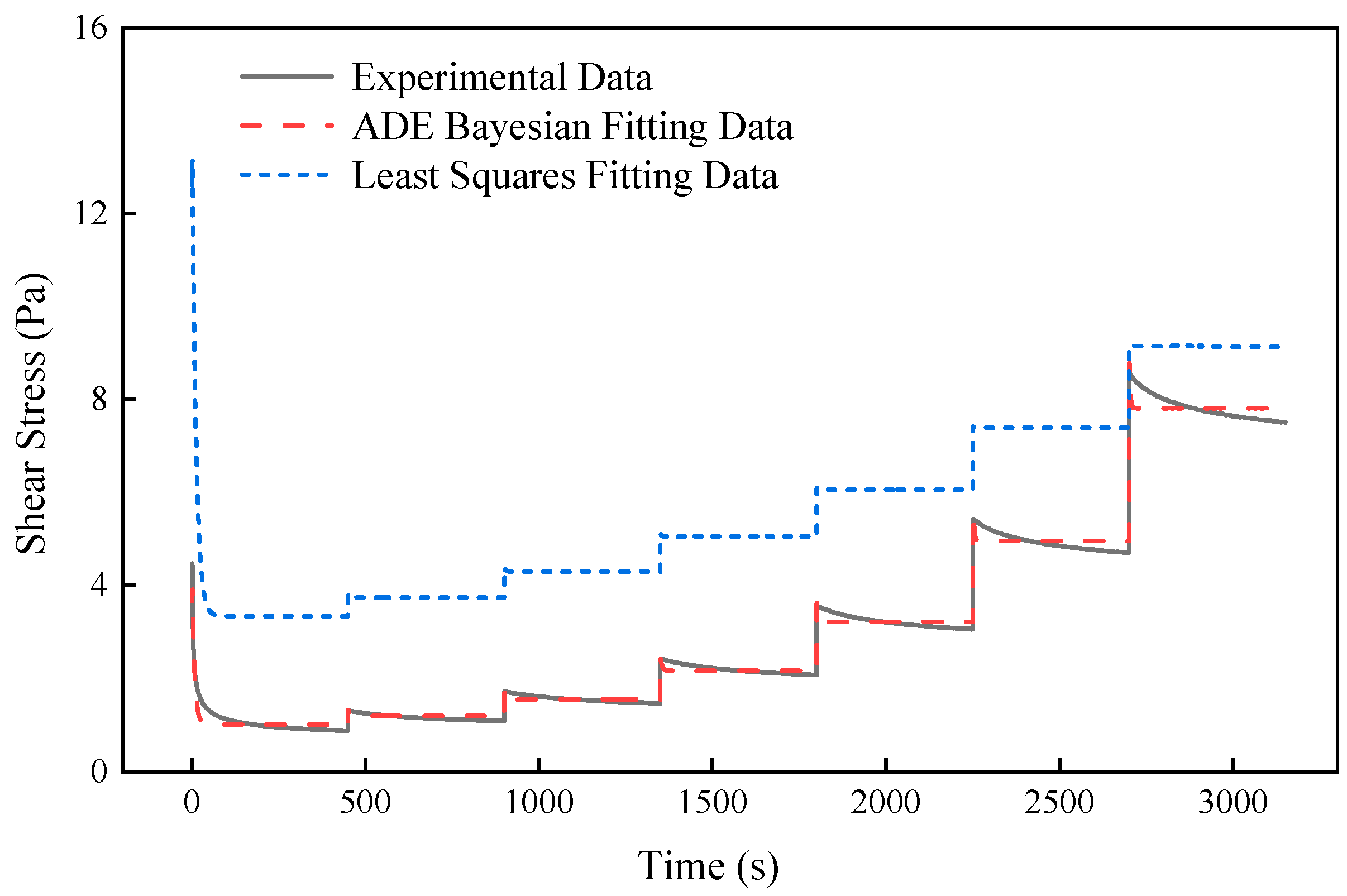

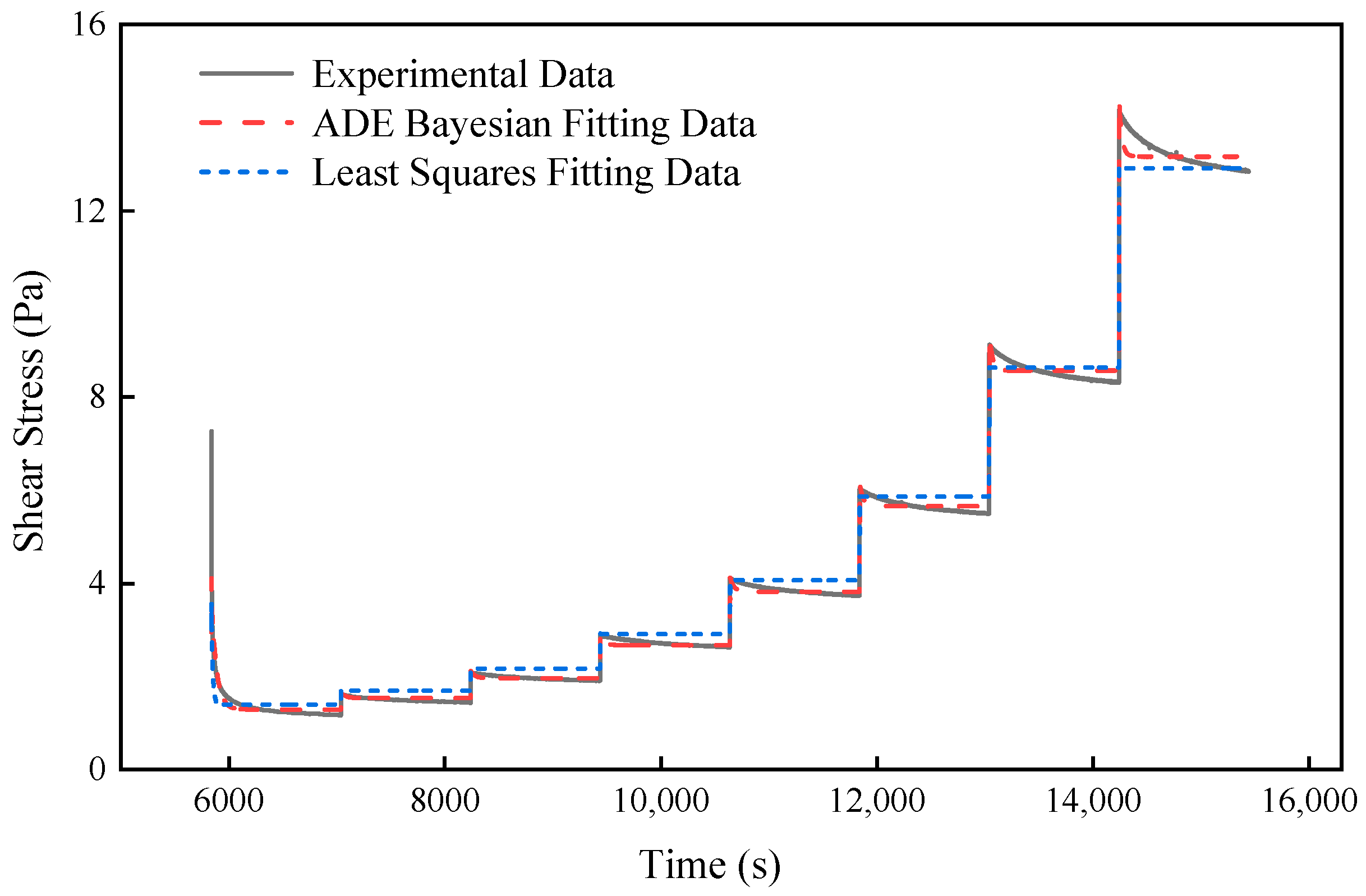

- The thixotropic test results of Daqing and Xianhe waxy crude oils were utilized to assess the fitting accuracy, computational efficiency, and convergence stability of the proposed parameter inversion method. This evaluation provides quantitative metrics to validate the method’s effectiveness in capturing complex rheological behaviors.

- (2)

- A series of initial parameter perturbation experiments were conducted to verify the robustness of the proposed inversion methodology. Furthermore, we analyzed the temperature-dependent variations in the fitted model parameters to elucidate their physical significance.

4.1. Validation of the New Parameter Inversion Method

4.1.1. Stepwise Increases in Shear Rate Tests

4.1.2. Hysteresis Loop Tests

4.2. Robust Analysis

4.3. Stability Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Moud, A.A. Asphaltene induced changes in rheological properties: A review. Fuel 2022, 316, 123372. [Google Scholar] [CrossRef]

- Li, M.; Chen, X.; Wang, Q.; Diao, D.; Zhang, Y.; Wang, C.; Zhang, L. Studying the effects of asphaltene oxidation on wax crystallization and rheological properties in waxy crude oils. Fuel 2024, 362, 130767. [Google Scholar] [CrossRef]

- Ruwoldt, J.; Kurniawan, M.; Sørland, G.H.; Simon, S.; Sjöblom, J. Influence of wax inhibitor molecular weight: Fractionation and effect on crystallization of polydisperse waxes. J. Dispers. Sci. Technol. 2020, 41, 1201–1216. [Google Scholar] [CrossRef]

- Zhao, S.; Cheng, Q.; Wang, S.; Liu, Y.; Qi, Y.; Wang, X. Molecular dynamics simulation of the microcosmic mechanism of resin effect on the gelling process of waxy crude oil. Fuel 2025, 384, 133927. [Google Scholar] [CrossRef]

- Guo, L.; Han, X.; Lei, Y.; Wang, L.; Yu, P. Research on nonlinear rheological properties of waxy crude oil based on large amplitude oscillatory shearing. J. Pet. Sci. Eng. 2022, 213, 110444. [Google Scholar] [CrossRef]

- Yin, X.; Liu, H.; Yang, C. Research Status and Prospect of Rheology of Waxy Crude Oil. Chem. Technol. Fuels Oils 2024, 60, 954–969. [Google Scholar] [CrossRef]

- Houska, M. Engineering Aspects of the Rheology of Thixotropic Liquids. Ph.D. Thesis, Czech Technical University of Prague, Prague, Czech Republic, 1981. [Google Scholar]

- Guo, L.; Zhang, J.; Sun, G.; Bao, Y. Thixotropy and its estimation of water-in-waxy crude emulsion gels. J. Pet. Sci. Eng. 2015, 131, 86–95. [Google Scholar] [CrossRef]

- Dullaert, K.; Mewis, J. Thixotropy: Build-up and breakdown curves during flow. J. Rheol. 2005, 49, 1213–1230. [Google Scholar] [CrossRef]

- Zhu, C.; Smay, J.E. Thixotropic rheology of concentrated alumina colloidal gels for solid freeform fabrication. J. Rheol. 2011, 55, 655–672. [Google Scholar] [CrossRef]

- Van Der Geest, C.; Guersoni, V.C.B.; Merino-Garcia, D.; Bannwart, A.C. A modified elasto-viscoplastic thixotropic model for two commercial gelled waxy crude oils. Rheol. Acta 2015, 54, 545–561. [Google Scholar] [CrossRef]

- Yahaya, J.; Kumam, P. New hybrid conjugate gradient algorithm for vector optimization problems. Comput. Appl. Math. 2025, 44, 163. [Google Scholar] [CrossRef]

- Yuan, Q.; Liu, H.; Li, J.; Yu, B.; Wu, C. Study on the parametric regression of a multiparameter thixotropic model for waxy crude oil. Energy Fuels 2018, 32, 5020–5032. [Google Scholar] [CrossRef]

- Yuan, Q.; Li, J.; Liu, H.; Yu, B.; Sun, D.; Deng, Y. Parametric regression of a multiparameter thixotropic model for waxy crude oil based on multiobjective strategy. J. Pet. Sci. Eng. 2019, 173, 287–297. [Google Scholar] [CrossRef]

- Zhou, H.; Chen, C.; Feng, F.; Zhou, C.; Zhang, W.; Wu, W.-T. Study of Thixotropic Characteristics of a Kerosene Gel Propellant by Bayesian Optimization. Gels 2022, 9, 15. [Google Scholar] [CrossRef]

- Ran, R.; Pradeep, S.; Acharige, S.K.; Blackwell, B.C.; Kammer, C.; Jerolmack, D.J.; Arratia, P.E. Understanding the rheology of kaolinite clay suspensions using Bayesian inference. J. Rheol. 2023, 67, 241–252. [Google Scholar] [CrossRef]

- Ran, W.; Yue, B.; Liang, Y.; Guangming, D. Bayesian Compressive Sensing Identification of Mono-Frequency Sound Modes for In-Pipe Fan Noise. Acta Acust. 2025, 50, 187–200. (In Chinese) [Google Scholar] [CrossRef]

- Ferragina, A.; de los Campos, G.; Vazquez, A.I.; Cecchinato, A.; Bittante, G. Bayesian regression models outperform partial least squares methods for predicting milk components and technological properties using infrared spectral data. J. Dairy Sci. 2015, 98, 8133–8151. [Google Scholar] [CrossRef]

- Ennouri, K.; Ben Ayed, R.; Mazzarello, M.; Ottaviani, E.; Hertelli, F.; Azzouz, H. Classical and Bayesian predictions applied to Bacillus toxin production. 3 Biotech 2016, 6, 206. [Google Scholar] [CrossRef][Green Version]

- Brest, J.; Greiner, S.; Boskovic, B.; Mernik, M.; Zumer, V. Self-adapting control parameters in differential evolution: A comparative study on numerical benchmark problems. IEEE Trans. Evol. Comput. 2006, 10, 646–657. [Google Scholar] [CrossRef]

- Brest, J.; Sepesy Maučec, M. Population size reduction for the differential evolution algorithm. Appl. Intell. 2008, 29, 228–247. [Google Scholar] [CrossRef]

- Teng, H.; Zhang, J. Modeling the viscoelasto-plastic behavior of waxy crude. Pet. Sci. 2013, 10, 395–401. [Google Scholar] [CrossRef][Green Version]

| T (°C) | RMSE | MRE | ||

|---|---|---|---|---|

| LSM | Novel Method | LSM | Novel Method | |

| 32 | 1.37 | 0.97 | 10.48% | 8.48% |

| 33 | 1.04 | 0.57 | 17.47% | 6.81% |

| 34 | 2.48 | 0.33 | 75.30% | 6.18% |

| 35 | 3.05 | 0.14 | 158.64% | 4.79% |

| T (°C) | RMSE | MRE | ||

|---|---|---|---|---|

| LSM | Novel Method | LSM | Novel Method | |

| 34 | 0.30 | 0.17 | 9.37% | 3.60% |

| 35 | 1.10 | 0.07 | 91.18% | 3.15% |

| 36 | 1.36 | 0.04 | 257.08% | 3.41% |

| 37 | 1.32 | 0.03 | 413.31% | 3.75% |

| T (°C) | RMSE | MRE | ||

|---|---|---|---|---|

| LSM | Novel Method | LSM | Novel Method | |

| 32 | 2.14 | 2.01 | 10.30% | 9.13% |

| 33 | 1.16 | 1.13 | 8.62% | 7.87% |

| 34 | 0.60 | 0.56 | 8.85% | 8.57% |

| 35 | 0.24 | 0.19 | 9.32% | 8.01% |

| T (°C) | RMSE | MRE | ||

|---|---|---|---|---|

| LSM | Novel Method | LSM | Novel Method | |

| 34 | 0.71 | 0.68 | 6.06% | 5.76% |

| 35 | 0.25 | 0.21 | 5.91% | 5.09% |

| 36 | 0.06 | 0.05 | 5.50% | 2.40% |

| 37 | 0.02 | 0.01 | 14.63% | 10.08% |

| Initial Value | τy0 | τy1 | K | ∆K | n | a | b | m |

|---|---|---|---|---|---|---|---|---|

| Initial Value 1 | 5.0000 | 20.0000 | 1.0000 | 7.0000 | 0.8000 | 0.1000 | 0.1000 | 0.5000 |

| Initial Value 2 | 1.7715 | 20.0000 | 1.5681 | 5.7495 | 0.5373 | 0.0120 | 0.060 | 0.6739 |

| Initial Value 3 | 1.2180 | 5.7823 | 1.0429 | 2.9948 | 0.5977 | 0.0062 | 0.0517 | 0.5643 |

| Initial Value 4 | 0.6644 | 3.5645 | 0.5177 | 0.2400 | 0.6580 | 0.0004 | 0.0434 | 0.4547 |

| Initial Value | RMSE | MRE | ||

|---|---|---|---|---|

| LSM | Novel Method | LSM | Novel Method | |

| Initial Value 1 | 7.30 | 0.14 | 406.30% | 4.79% |

| Initial Value 1 | 3.05 | 0.14 | 158.64% | 4.79% |

| Initial Value 1 | 1.43 | 0.14 | 68.62% | 4.79% |

| Initial Value 1 | 0.15 | 0.14 | 5.14% | 4.79% |

| T (°C) | τy0 | τy1 | K | ∆K | n | a | b | m |

|---|---|---|---|---|---|---|---|---|

| 32 | 0.3368 | 27.7009 | 2.0708 | 0.0120 | 0.4857 | 0.0125 | 0.0670 | 0.6488 |

| 33 | 0.7146 | 13.1443 | 1.0986 | 0.9600 | 0.5850 | 0.0094 | 0.0593 | 0.6786 |

| 34 | 0.0332 | 7.6314 | 0.8312 | 0.1244 | 0.6018 | 0.0135 | 0.0702 | 0.6369 |

| 35 | 0.0330 | 2.8256 | 0.2077 | 0.9600 | 0.7733 | 0.0276 | 0.1068 | 0.2052 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Teng, H.; Li, X.; Li, L.; Chen, T. A New Bayesian Inversion Method for Thixotropic Model Parameters of Waxy Crude Oil. Processes 2025, 13, 1320. https://doi.org/10.3390/pr13051320

Teng H, Li X, Li L, Chen T. A New Bayesian Inversion Method for Thixotropic Model Parameters of Waxy Crude Oil. Processes. 2025; 13(5):1320. https://doi.org/10.3390/pr13051320

Chicago/Turabian StyleTeng, Houxing, Xiao Li, Liangyao Li, and Tianpeng Chen. 2025. "A New Bayesian Inversion Method for Thixotropic Model Parameters of Waxy Crude Oil" Processes 13, no. 5: 1320. https://doi.org/10.3390/pr13051320

APA StyleTeng, H., Li, X., Li, L., & Chen, T. (2025). A New Bayesian Inversion Method for Thixotropic Model Parameters of Waxy Crude Oil. Processes, 13(5), 1320. https://doi.org/10.3390/pr13051320