Analysis of Sand Production Mechanisms in Tight Gas Reservoirs: A Case Study from the Wenxing Gas Area, Northwestern Sichuan Basin

Abstract

1. Introduction

2. Experimental Methodology

2.1. Sample Preparation and Experimental Parameters

2.2. Experimental Conditions and Procedures

- (1)

- The split API cells were installed into the flow chamber. Quartz sand proppant with different mesh sizes was placed between the plates at a concentration of 5 kg/m2 to form an initial propped fracture. A hydraulic press was used to apply the target closure stress, and the fracture width was recorded once the pressure stabilized.

- (2)

- The heaters on the preheater, intermediate container, and flow chamber were turned on. The system was heated to the target test temperature and maintained under constant thermal conditions.

- (3)

- A constant-rate, constant-pressure pump was started at an initial flow rate of 5 mL/min to inject preheated flowback fluid from the intermediate container into the flow chamber, fully saturating the API cells and proppant pack.

- (4)

- The outlet valve of the chamber was opened, and the proppant filter was removed to collect any proppant particles forced out by the applied pressure.

- (5)

- The injection rate was gradually increased in steps of 0.5 mL/min until proppant flowback was observed at the outlet. The flow rate was then stabilized until no additional flowback occurred.

- (6)

- The real-time weight of the sand-laden fluid was recorded using data acquisition software. By subtracting the known fluid mass, the change in sand mass versus displacement rate was obtained.

- (7)

- The critical sand production rate was converted into a critical sand production velocity using a defined equation.

3. Results and Discussion

3.1. Experimental Results and Analysis

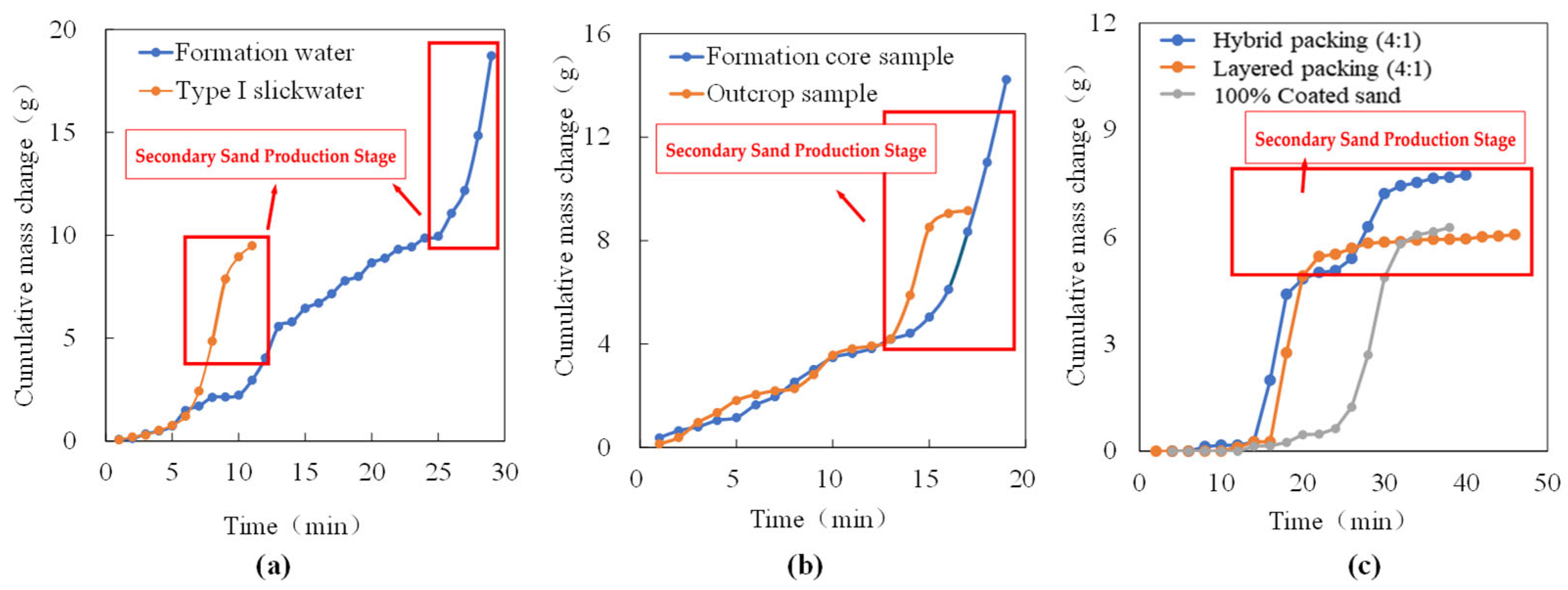

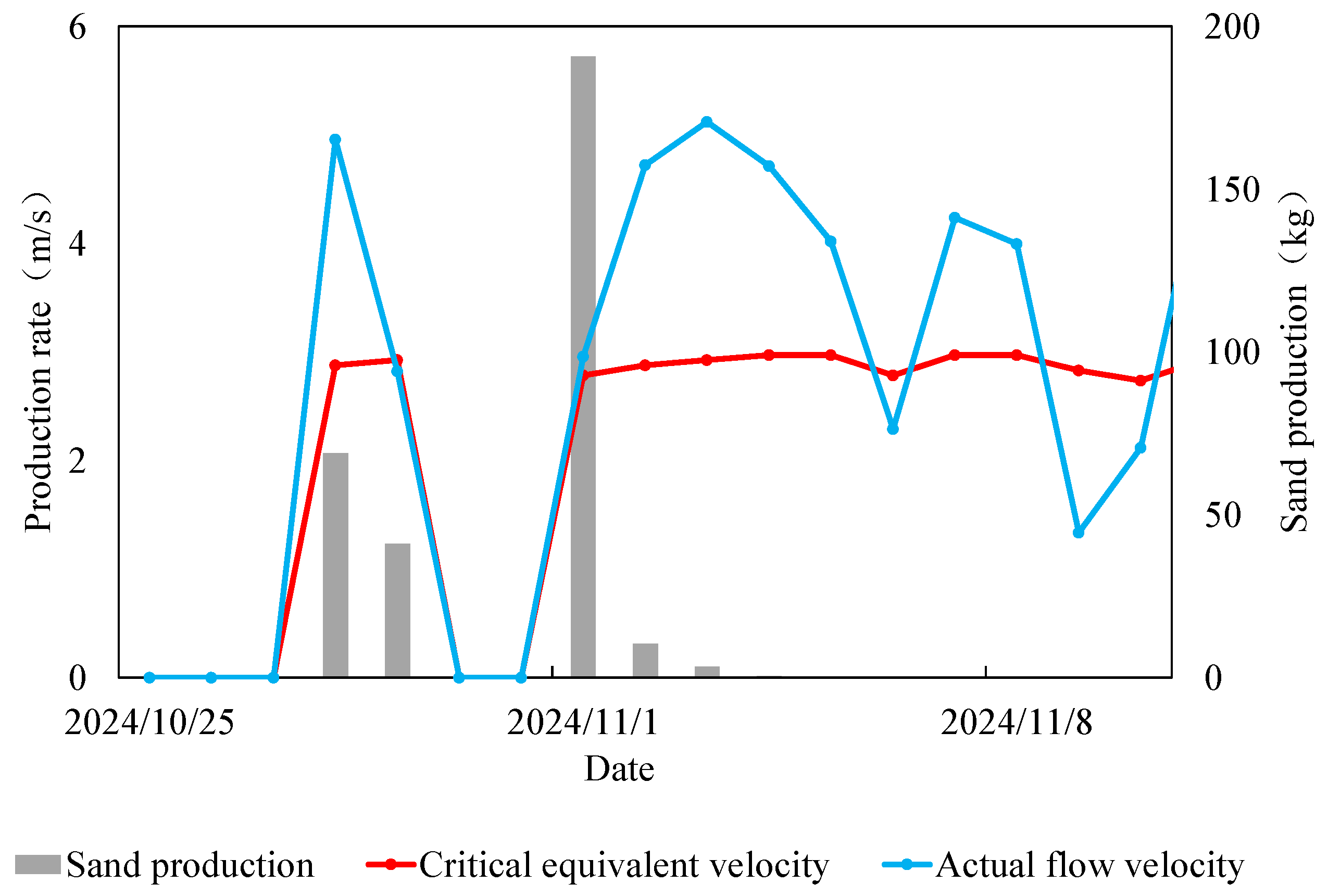

3.2. Mechanism of Secondary Sand Production

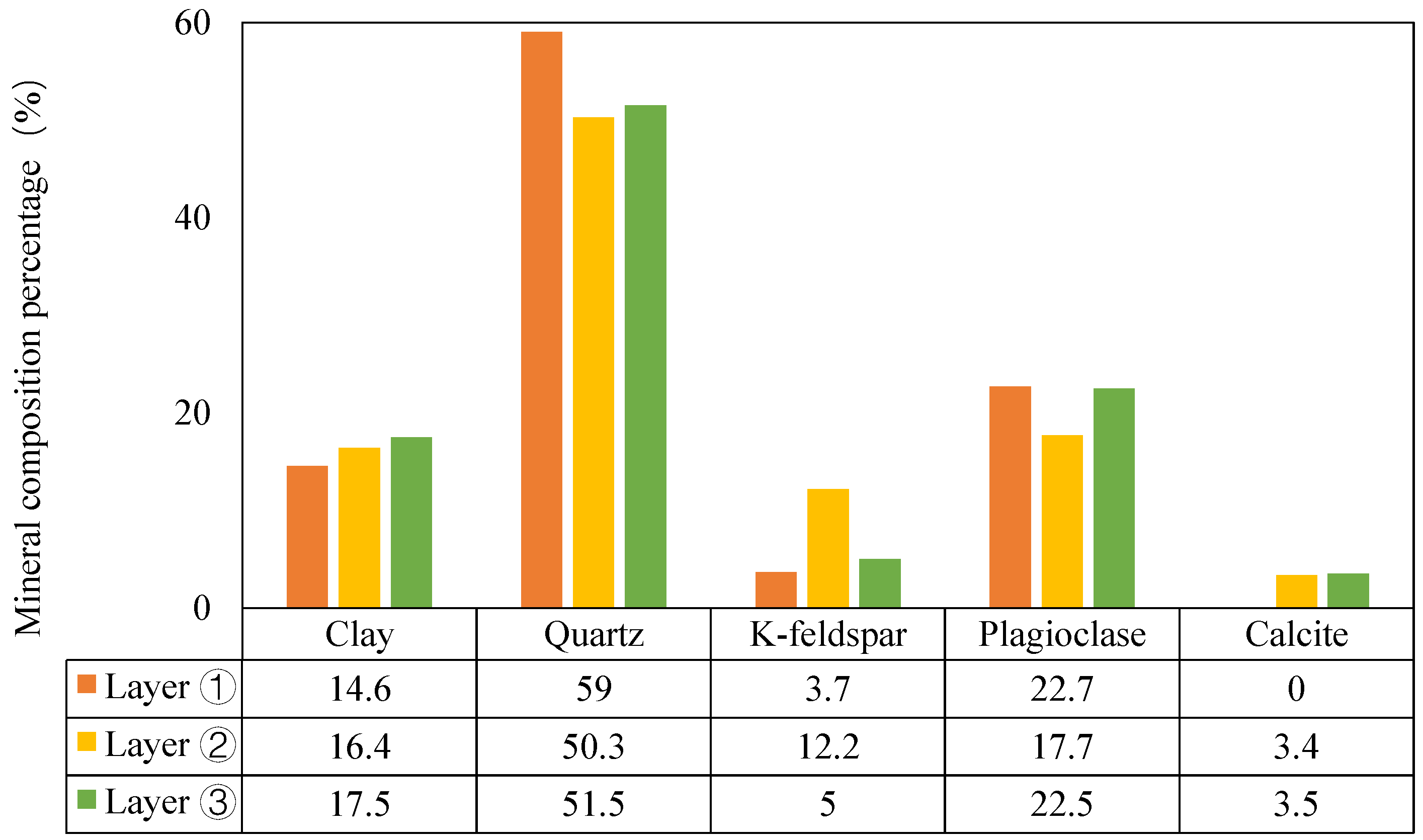

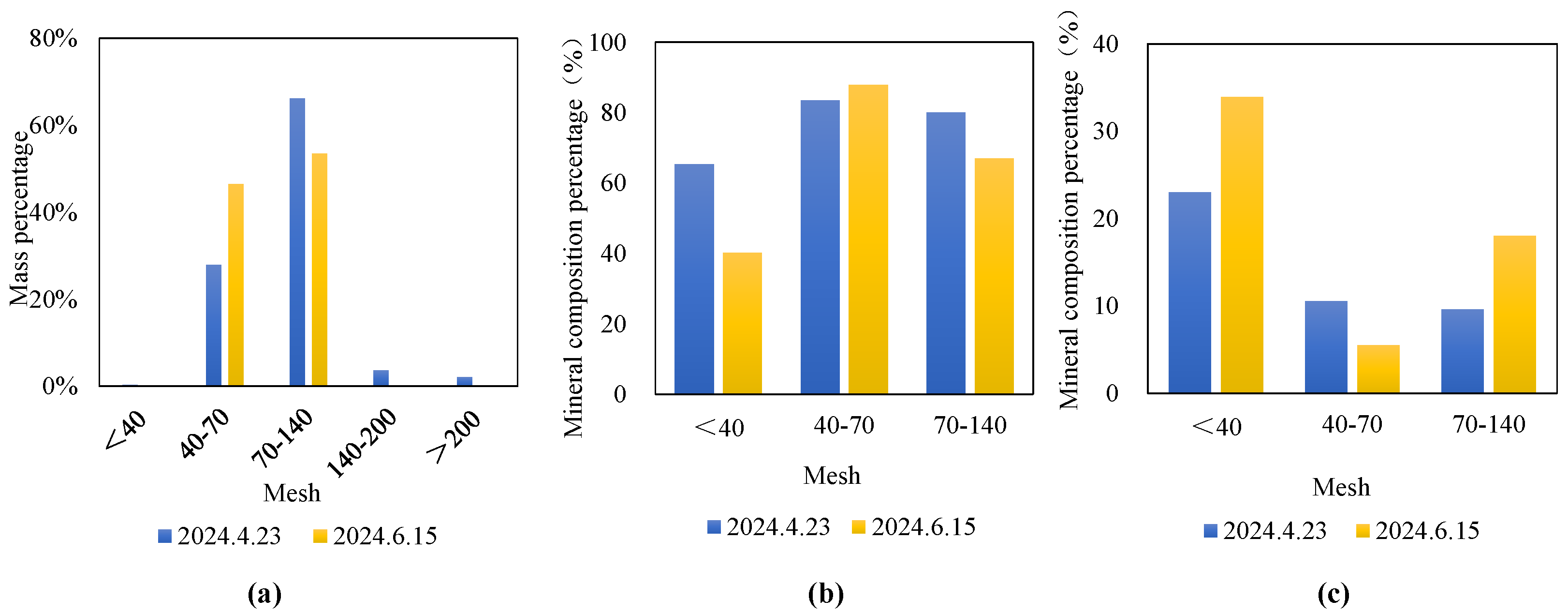

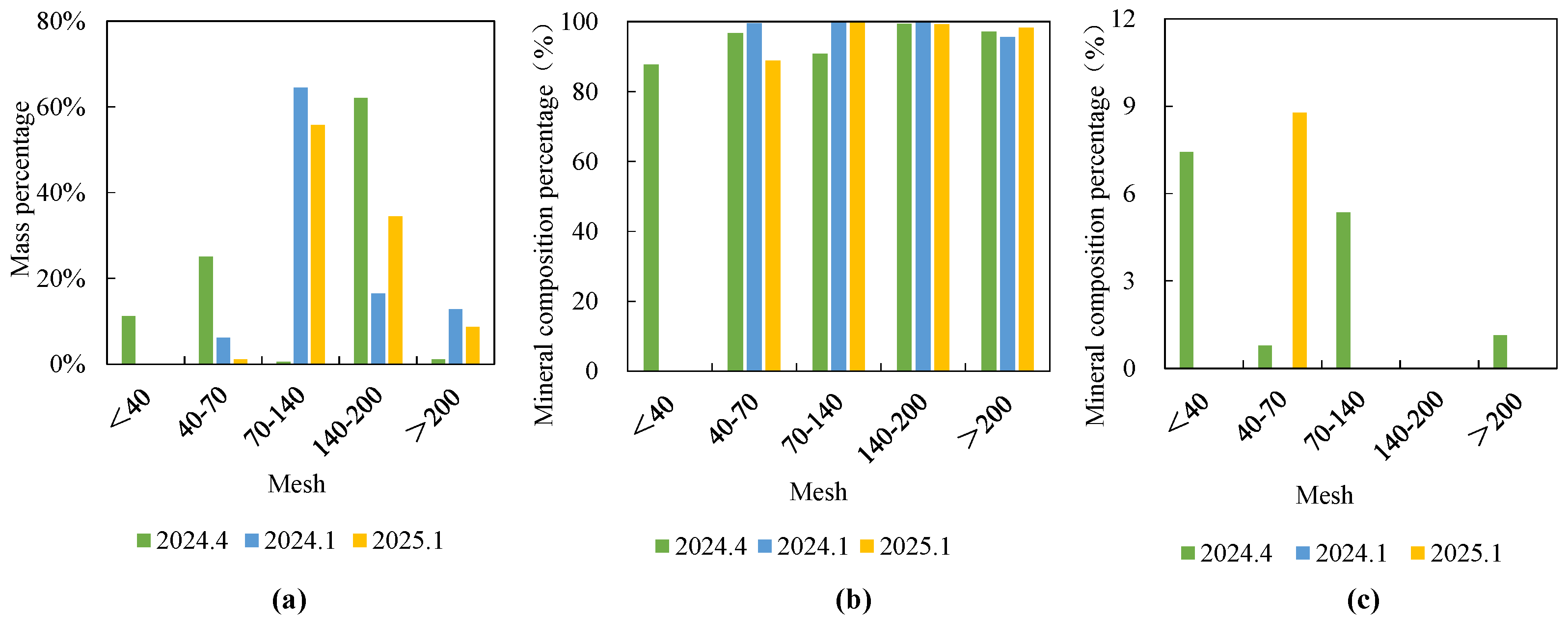

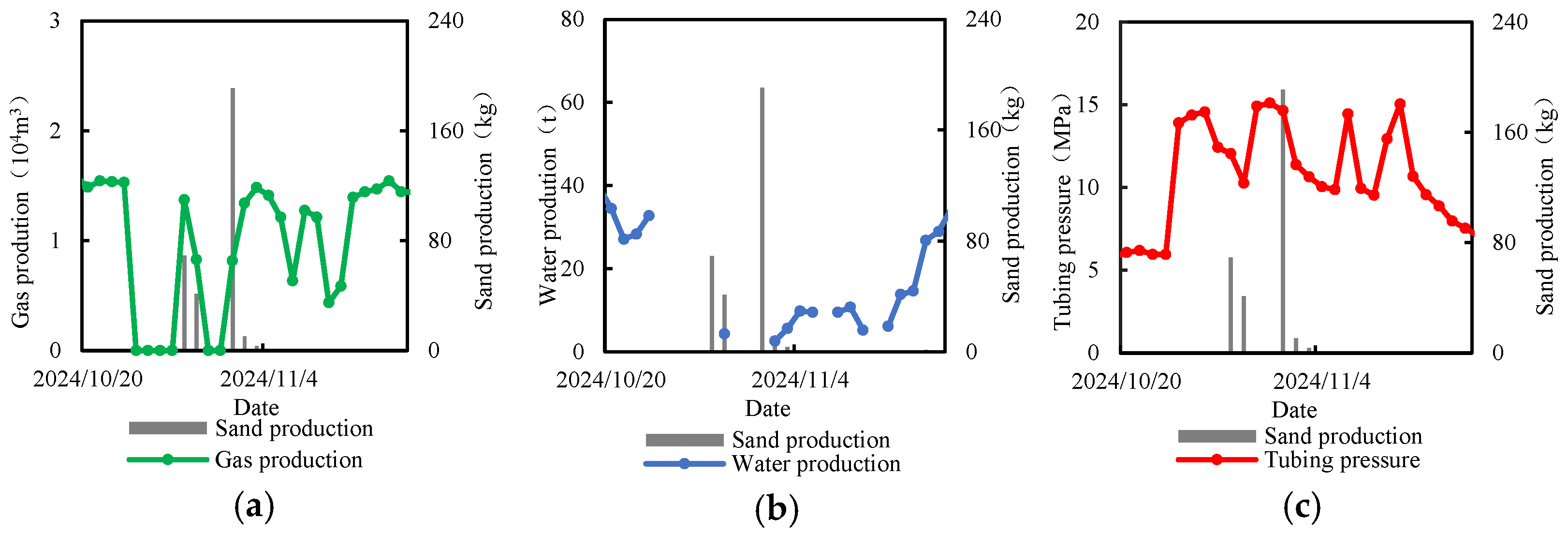

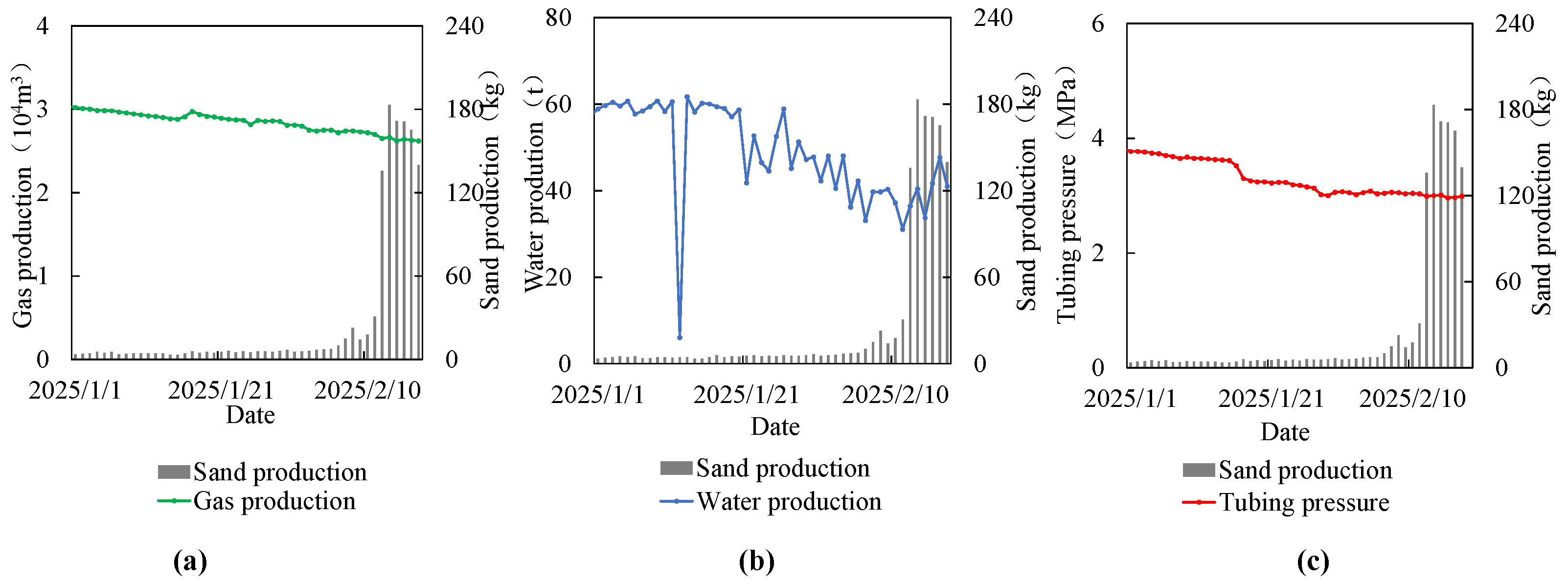

3.3. Analysis of Sand Production Mechanisms in Field Wells

3.4. Analysis of Sand Production Factors

3.5. Critical Sand Production Velocity Model

4. Discussion

5. Conclusions

- (1)

- The displacement fluid viscosity significantly influences proppant flowback. When using high-viscosity slickwater (5 mPa·s), the critical sand production velocity decreased by 66% compared to formation water (1.15 mPa·s), indicating that increased viscosity helps stabilize the proppant pack.

- (2)

- Compared to mixed placement, pure coated proppant raised the critical velocity by nearly threefold, mainly due to enhanced proppant consolidation and interlocking under closure stress.

- (3)

- Excessive increases in flow rate after surpassing the critical threshold may lead to secondary sand production, especially in compacted proppant beds, which highlights the importance of flowback rate control during well cleanup.

- (4)

- Field cases from wells X-1 and X-2 in the Wenxing gas area showed that proppant detachment and crushing are the dominant causes of sand production, respectively. Model calculations matched field observations, validating the experimental findings and providing a practical reference for optimizing flowback strategies.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, C.W. Research on Proppant Flowback and Control in Fracturing Gas Well Production. Master’s Thesis, Southwest Petroleum University, Chengdu, China, 2018. [Google Scholar]

- Lv, M.K.; Guo, T.K.; Chen, M.J.; Jia, X.; Yang, R.; Jia, H.; Qu, Z. Numerical Simulation of Proppant Transport and Backflow in Unconventional Reservoir Hydraulic Fractures Based on CFD-DEM. In Proceedings of the Geomechanics Symposium, Golden, CO, USA, 23 June 2024. [Google Scholar] [CrossRef]

- Zhang, K.S.; Chen, B.C.; Wu, Y.; Ma, X.X.; Mou, C.G.; Wang, W.X.; He, F.Y.; Wang, H.; Lv, Y.J. DEM-CFD Simulation of Proppant Particles Scoured by Fracturing Fluid Backflow. J. Eng. Thermophys. 2023, 44, 1009–1014. [Google Scholar]

- Li, D. Research on Productivity Prediction Based on Fracturing Tracer Flowback Law. Master’s Thesis, China University of Petroleum (East China), Qingdao, China, 2021. [Google Scholar]

- Wijaya, N.; Sheng, J. Effects of Imbibition and Compaction during Well Shut-in on Ultimate Shale Oil Recovery: A Numerical Study. SPE Reserv. Eval. Eng. 2021, 24, 859–873. [Google Scholar] [CrossRef]

- Liu, B.; Yao, J.; Sun, H.; Zhang, L. Effects of Natural Fracture Reopening on Proppant Transport in Supercritical CO2 Fracturing: A CFD-DEM Study. Geoenergy Sci. Eng. 2024, 238, 212906. [Google Scholar] [CrossRef]

- Cao, G.S.; Bai, Y.J.; Du, T.; Yang, T.; Yan, H. Study on Proppant Backflow Based on Finite Element Simulation. Xinjiang Pet. Geol. 2019, 40, 218–222. [Google Scholar] [CrossRef]

- Garagash, I.A.; Osiptsov, A.A.; Boronin, S.A. Dynamic Bridging of Proppant Particles in a Hydraulic Fracture. Int. J. Eng. Sci. 2019, 135, 86–101. [Google Scholar] [CrossRef]

- He, J.Y.; Okere, C.J.; Su, G.D.; Hu, P.; Zhang, L.; Xiong, W.; Li, Z. Formation Damage Mitigation Mechanism for Coalbed Methane Wells via Refracturing with Fuzzy-Ball Fluid as Temporary Blocking Agents. J. Nat. Gas Sci. Eng. 2021, 90, 103956. [Google Scholar] [CrossRef]

- Huang, J.; Hao, Y.; Settgast, R.R.; White, J.A.; Mateen, K.; Gross, H. Validation and Application of a Three-Dimensional Model for Simulating Proppant Transport and Fracture Conductivity. Rock Mech. Rock Eng. 2023, 56, 7091–7113. [Google Scholar] [CrossRef]

- Qu, Z.Q.; Wang, J.W.; Guo, T.K.; Shen, L.; Liao, H.; Liu, X.; Fan, J.; Hao, T. Optimization on Fracturing Fluid Flowback Model After Hydraulic Fracturing in Oil Well. J. Pet. Sci. Eng. 2021, 204, 108703. [Google Scholar] [CrossRef]

- Yang, P.; Zhang, S.C.; Zou, Y.S.; Zhong, A.; Yang, F.; Zhu, D.; Chen, M. Numerical Simulation of Integrated Three-Dimensional Hydraulic Fracture Propagation and Proppant Transport in Multi-Well Pad Fracturing. Comput. Geotech. 2024, 167, 106075. [Google Scholar] [CrossRef]

- Shor, R.J.; Sharma, M.M. Reducing Proppant Flowback from Fractures: Factors Affecting the Maximum Flowback Rate. In Proceedings of the SPE Hydraulic Fracturing Technology Conference, The Woodlands, TX, USA, 4 February 2014. [Google Scholar] [CrossRef]

- Guo, T.; Tang, S.; Liu, S.; Liu, X.; Xu, J.; Qi, N.; Rui, Z. Physical Simulation of Hydraulic Fracturing of Large-sized Tight Sandstone Outcrops. SPE J. 2021, 26, 372–393. [Google Scholar] [CrossRef]

- Zhao, Z.; He, Y.; Guo, J.; Liu, Z.; Zhou, X.; Zhang, R. Research on The Flowback Mechanism of Fiber-controlled Proppant Based on Fiber Strength Force. Phys. Fluids 2024, 36, 053319. [Google Scholar] [CrossRef]

- Wang, L.; Wen, H.; Zhang, S.C.; Ma, X.F.; Mou, J.Y. Experimental Research on Proppant Backflow Influenced by Effective Closure Pressure. Xinjiang Oil Gas 2020, 16, 54–58+7. [Google Scholar] [CrossRef]

- McLennan, J.; Walton, I.; Moore, J.; Brinton, D.; Lund, J. Proppant Backflow: Mechanical and Flow Considerations. Geothermics 2015, 57, 224–237. [Google Scholar] [CrossRef]

- Wu, T.; Song, M.M.; Yuan, X. Variation Laws of Proppant Backflow and Fracture Conductivity of Flowback After Fracturing in Shale Reservoir. Pet. Geol. Oilfield Dev. Daqing 2025, 44, 167–174. [Google Scholar] [CrossRef]

- Guo, J.C.; Tang, T.; Zhang, T.; Zhou, H.Y.; Liu, Y.X.; Li, M.F.; Yang, R.Y. Migration and Distribution Laws of Proppant in Multi-scale Fractures during Deep Shale Fracturing. Nat. Gas Ind. 2024, 44, 1–11. [Google Scholar] [CrossRef]

- Goel, N.; Shah, S.N. Experimental Investigation of Proppant Flowback Phenomena Using a Large Scale Fracturing Simulator. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 3 October 1999. [Google Scholar] [CrossRef]

- Guo, T.; Wang, Y.; Chen, M.; Qu, Z.; Tang, S.; Wen, D. Multi-stage and Multi-well Fracturing and Induced Stress Evaluation: An Experiment Study. Geoenergy Sci. Eng. 2023, 230, 212271. [Google Scholar] [CrossRef]

- Potapenko, D.; Theuveny, B.; Williams, R.; Moncada, K.; Campos, M.; Spesivtsev, P.; Willberg, D. State of the Art of Flow Management for Frac Plug Drillout and Flowback. In Proceedings of the SPE Annual Technical Conference and Exhibition, Calgary, AB, Canada, 23 September 2019. [Google Scholar] [CrossRef]

- Yin, H.C.; Xu, L.J.; Lyu, Z.Y.; Pang, J.; Tang, W.; Chen, Y.Y. Prediction Method of Critical Sand Production Rate from Shale Gas Wells. Spec. Oil Gas Reserv. 2023, 30, 135–140. [Google Scholar] [CrossRef]

- Zhang, F.S.; Zhu, H.Y.; Zhou, H.G.; Guo, J.; Huang, B. Discrete-Element-Method/Computational-Fluid-Dynamics Coupling Simulation of Proppant Embedment and Fracture Conductivity After Hydraulic Fracturing. SPE J. 2017, 22, 632–644. [Google Scholar] [CrossRef]

- Maity, D.; Ciezobka, J. An Interpretation of Proppant Transport Within the Stimulated Rock Volume at the Hydraulic-Fracturing Test Site in the Permian Basin. SPE Res. Eval. Eng. 2019, 22, 477–491. [Google Scholar] [CrossRef]

- Li, K.; Gao, Y.; Lyu, Y.; Wang, M. New mathematical models for calculating proppant embedment and fracture conductivity. SPE J. 2015, 20, 496–507. [Google Scholar] [CrossRef]

- Liang, X.Y.; Zhou, F.J.; Liang, T.B.; Huang, Y.; Wei, D.; Ma, S. The Effect of Combined Proppants upon the Fracture Conductivity in Tight Gas Reservoirs. Energy Rep. 2020, 6, 879–884. [Google Scholar] [CrossRef]

- Qi, Z.L.; Jiao, G.Y. Method to Predict Proppant Flowback in Fractured Gas Well. Procedia Environ. Sci. 2012, 12, 325–332. [Google Scholar] [CrossRef]

- Zoback, M.D. Reservoir Geomechanics; Cambridge University Press: Cambridge, UK, 2007. [Google Scholar] [CrossRef]

- Tang, H.; Winterfeld, P.H.; Wu, Y.S.; Huang, Z.-Q.; Di, Y.; Pan, Z.; Zhang, J. Integrated Simulation of Multi-stage Hydraulic Fracturing in Unconventional Reservoirs. J. Nat. Gas Sci. Eng. 2016, 36, 875–892. [Google Scholar] [CrossRef]

| Well ID | Horizon | SU | Top (m) | Base (m) | Net Pay (m) | POR (%) | PERM (mD) | Interpretation | Gas Class |

|---|---|---|---|---|---|---|---|---|---|

| X-1 | Sha-1 | 4# | 2881.8 | 2905.1 | 15.6 | 8.2 | 0.350 | Pay Zone | II |

| Sha-1 | 5# | 2965.7 | 2989.2 | 1.2 | 7.3 | 0.247 | Marginal Pay | III | |

| Sha-1 | 1# | 3078.7 | 3097.9 | 13.5 | 8.3 | 0.237 | Pay Zone | II | |

| X-2 | Sha-1 | 5# | 2929.4 | 2933.9 | 3.6 | 9.3 | 0.360 | Marginal Pay | III |

| Sha-1 | 4# total | 2961.0 | 4055.6 | 816.4 | 8.1 | 0.205 | Pay Zone | II |

| Proppant Types | Mesh | Roundness | Sphericity | Crush Resistance Pressure (MPa) | Apparent Density (g/cm3) | Crush Rate |

|---|---|---|---|---|---|---|

| Quartz Sand Proppant | 70/140 | 0.70 | 0.70 | 35 | 2.62 | ≤9% |

| Coated Quartz Sand Proppant | 40/70 | 0.70 | 0.80 | 52 | 2.57 | ≤9% |

| Fluid Type | Viscosity (mPa·s) | PH | Density (g/cm3) |

|---|---|---|---|

| Slickwater | 5.0 | 6.8 | 1.01 |

| Formation water | 1.15 | 8.3 | 1.02 |

| Confining Pressure (MPa) | Fluid Viscosity (mPa·s) | Core Type | Packing Method | Critical Velocity (m/s) |

|---|---|---|---|---|

| 60 | 1.15 | Formation core | Hybrid packing (4:1) | 0.0034 |

| 5 | Formation core | Hybrid packing (4:1) | 0.0101 | |

| 40 | 1.15 | Outcrop core | Hybrid packing (4:1) | 0.0075 |

| 1.15 | Formation core | Hybrid packing (4:1) | 0.0066 | |

| 20 | 1.15 | Formation core | Hybrid packing (4:1) | 0.0009 |

| 1.15 | Formation core | Layered packing (4:1) | 0.0017 | |

| 1.15 | Formation core | 100% Coated sand | 0.0027 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Q.; Zhang, X.; Du, C.; Di, K.; Xie, S.; Tang, H.; Luo, J.; Shu, R. Analysis of Sand Production Mechanisms in Tight Gas Reservoirs: A Case Study from the Wenxing Gas Area, Northwestern Sichuan Basin. Processes 2025, 13, 2278. https://doi.org/10.3390/pr13072278

Liu Q, Zhang X, Du C, Di K, Xie S, Tang H, Luo J, Shu R. Analysis of Sand Production Mechanisms in Tight Gas Reservoirs: A Case Study from the Wenxing Gas Area, Northwestern Sichuan Basin. Processes. 2025; 13(7):2278. https://doi.org/10.3390/pr13072278

Chicago/Turabian StyleLiu, Qilin, Xinyao Zhang, Cheng Du, Kaixiang Di, Shiyi Xie, Huiying Tang, Jing Luo, and Run Shu. 2025. "Analysis of Sand Production Mechanisms in Tight Gas Reservoirs: A Case Study from the Wenxing Gas Area, Northwestern Sichuan Basin" Processes 13, no. 7: 2278. https://doi.org/10.3390/pr13072278

APA StyleLiu, Q., Zhang, X., Du, C., Di, K., Xie, S., Tang, H., Luo, J., & Shu, R. (2025). Analysis of Sand Production Mechanisms in Tight Gas Reservoirs: A Case Study from the Wenxing Gas Area, Northwestern Sichuan Basin. Processes, 13(7), 2278. https://doi.org/10.3390/pr13072278