Abstract

To accommodate the extreme thermodynamic effects and erosion damage in throttling equipment for ultra-high-pressure natural gas wells (175 MPa), a coupled multiphase flow erosion numerical model for nozzles was established. This model incorporates a real gas compressibility factor correction and is based on the renormalized k-ε RNG (Renormalization Group k-epsilon model, a turbulence model that simulates the effects of vortices and rotation in the mean flow by modifying turbulent viscosity) turbulence model and the Discrete Phase Model (DPM, a multiphase flow model based on the Eulerian–Lagrangian framework). The study revealed that the nozzle flow characteristics follow an equal-percentage nonlinear regulation pattern. Choked flow occurs at the throttling orifice throat due to supersonic velocity (Ma ≈ 3.5), resulting in a mass flow rate governed solely by the upstream total pressure. The Joule–Thomson effect induces a drastic temperature drop of 273 K. The outlet temperature drops below the critical temperature for methane hydrate phase transition, thereby presenting a substantial risk of hydrate formation and ice blockage in the downstream outlet segment. Erosion analysis indicates that particles accumulate in the 180° backside region of the cage sleeve under the influence of secondary flow. At a 30% opening, micro-jet impact causes the maximum erosion rate to surge to 3.47 kg/(m2·s), while a minimum erosion rate is observed at a 50% opening. Across all opening levels, the maximum erosion rate consistently concentrates on the oblique section of the plunger front. Results demonstrate that removing the front chamfer of the plunger effectively improves the internal erosion profile. These findings provide a theoretical basis for the reliability design and risk prevention of surface equipment in deep ultra-high-pressure gas wells.

1. Introduction

In oil and gas well production technology, the nozzle assembly functions as a critical throttling device responsible for the core function of fluid regulation. To address the characteristic high-pressure and high-flowrate conditions of deep natural gas wells, the industry commonly employs multi-stage nozzle structures to achieve fluid throttling and pressure reduction. This equipment effectively prevents well kick incidents by controlling wellhead backpressure, playing an indispensable role in the safe production of gas wells [1,2,3]. Modern nozzle technology has evolved to incorporate diversified trim structures such as wedge valves, needle valves, and cage-type valves. Their operating principle is universally based on modulating the flow area via the axial displacement of the valve stem [4], achieving dual control of both flow rate and pressure. Notably, following the successful drilling of the 10,000-m-deep Teke-1 Well in the Tarim Oilfield in March 2024, deep-earth resource development presents new engineering challenges for surface equipment [5]. Under extreme operating conditions involving supercritical pressures (>105 MPa) and ultra-high flowrates (>1 × 106 m3/d), the substantial pressure differential across the nozzle causes significantly higher internal jet velocities compared to conventional operations. Due to the throttling cooling effect, natural gas hydrates readily form within the nozzle passage, posing a risk of ice blockage in both the nozzle and downstream piping. Furthermore, entrained rock cuttings within the produced high-pressure natural gas flow will induce significant erosion wear effects [6]. With the advancement of computational fluid dynamics (CFD), numerical simulation has become a powerful tool in valve design research, capable of intuitively revealing the internal flow characteristics of throttle valves. Currently, research on nozzles is predominantly based on conventional pressure conditions (<105 MPa) [7,8,9,10], with limited studies addressing ultra-high-pressure (inlet pressure up to 175 MPa) extreme conditions. Therefore, this study investigates the throttling effects and internal erosion characteristics of nozzles under the extreme field condition of 175 MPa, aiming to enhance the operational safety of throttle manifolds under ultra-high pressure.

2. Numerical Model

2.1. Turbulence Model

The nozzle operates across a wide pressure range from inlet to outlet. Combined with the complex trim structure (where the flow channels in the cage sleeve are interconnected via small-diameter orifices), the flow field exhibits sharp gradients as natural gas passes through. Therefore, the Renormalization Group k-epsilon (RNG) model [11], which simulates the effects of vortices and rotation in the mean flow by modifying the turbulent viscosity, was selected. For simulating the high-speed jets within the abrupt expansion and contraction flow paths during high-pressure natural gas throttling in nozzles, the k-epsilon RNG model demonstrates good accuracy [12]. The transport equations for turbulent kinetic energy k and its dissipation rate ε in this model are given as follows:

2.2. Discrete Phase Model

The nozzle is a fluid control device that operates with high-pressure natural gas containing rock cuttings as the working medium. During oil and gas production, this equipment withstands impacts from high-pressure gas–solid two-phase flow originating from the wellbore. The gas phase pressure can reach 175 MPa, accompanied by a significant volume of high-velocity rock cuttings, conforming to typical gas–solid two-phase flow dynamics [13]. Data indicate that the volume fraction of sand and gravel in natural gas typically ranges from 5% to 8%, remaining below 10% [14]. Given these flow characteristics, and after comparing the computational accuracy and resource consumption of multiphase flow models in Fluent, the Discrete Phase Model (DPM) based on the Eulerian–Lagrangian framework was adopted. This model accurately characterizes the particle–fluid interaction via a two-way coupling mechanism and can be integrated with an erosion model to reflect the erosion characteristics of particles on the structure [15].

2.3. Erosion Model

In Fluent software, the wall erosion model equation for particle-induced wall wear is given as follows [16]:

where is the particle diameter function, is the function of the impact angle between particles and the wall, and is the area of the wall mesh cell. During the simulation, based on the Forder equation [17], which reflects the influence of the particle impact angle on the erosion rate, this study implemented a user-defined function (UDF, a program in Fluent software used to extend the functionality of built-in models) modification to Fluent’s default erosion model. The wall normal restitution coefficient and tangential restitution coefficient are defined, respectively, as

2.4. Throttling Effect Mechanism

Under ultra-high-pressure conditions, the working fluid enters the throttling orifices on the cage sleeve from the nozzle inlet section. The flow area undergoes a sudden reduction, resulting in a pressure drop. As this process occurs extremely rapidly, it is generally regarded as an adiabatic process with no heat exchange with the external environment. The pressure change consequently induces a temperature variation in the internal fluid. This process is termed the Joule–Thomson effect, i.e., the throttling effect. The throttling coefficient is typically used to describe the temperature change during fluid throttling, as follows:

where is the specific heat capacity at constant pressure, is the specific internal energy, and , , and , denote gas pressure, temperature, and specific volume, respectively. When , the temperature difference across the throttling process increases with rising pressure drop. A throttling coefficient indicates a cooling effect, while signifies a heating effect.

3. Numerical Simulation

3.1. Computational Domain and Meshing

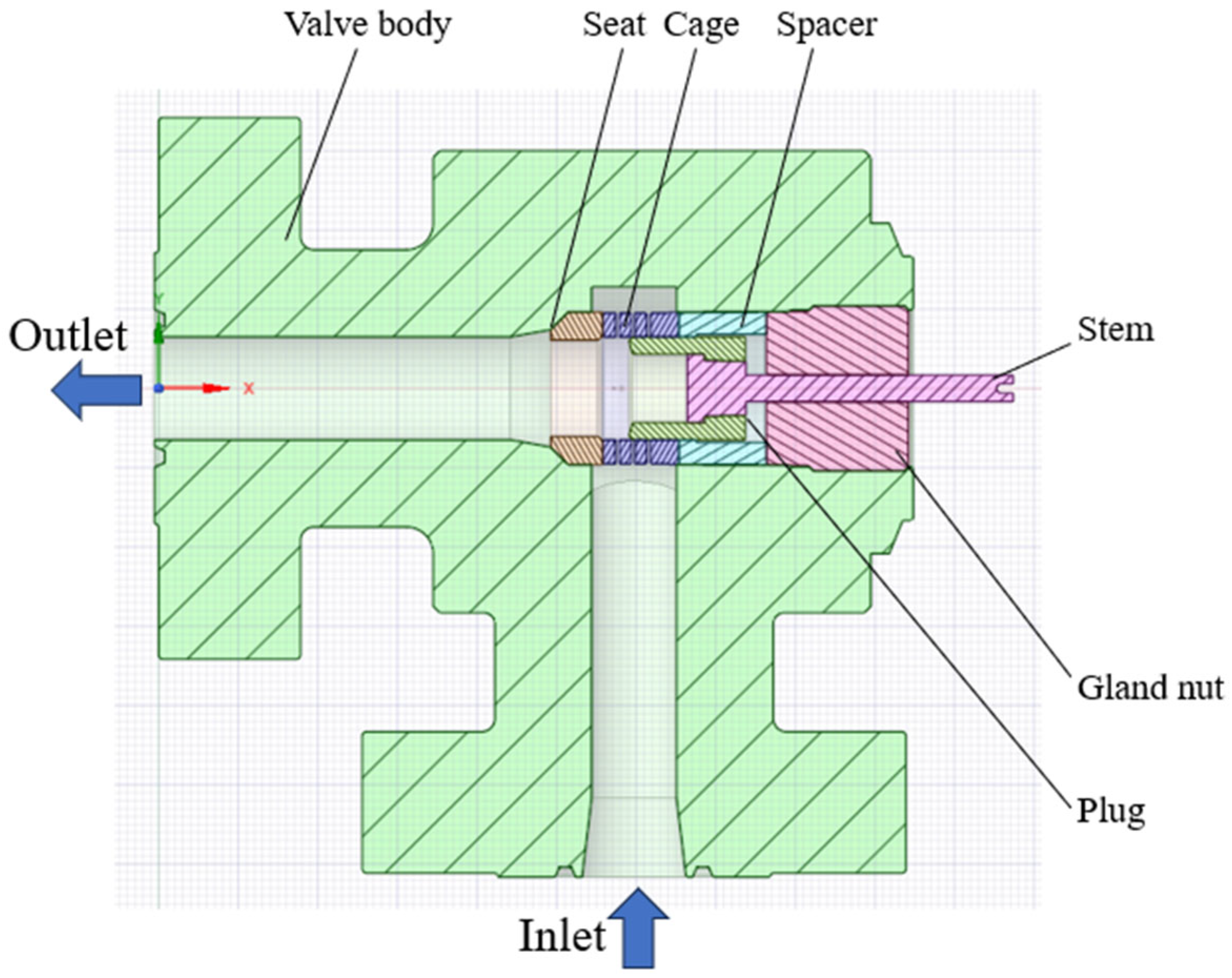

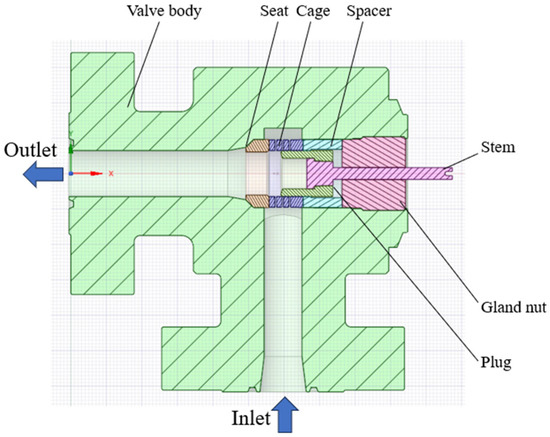

The throttling nozzle adopts an external cage sleeve structure (Figure 1), comprising components such as the valve body, base, cage sleeve, external gland, and valve stem. The plunger is connected to the valve stem via piston rings and a piston sleeve, with the valve stem linked to an electric actuator. The rotational motion of the actuator is converted into axial displacement through the threaded pair on the valve stem, driving the plunger to adjust the opening area of the throttling orifices on the cage sleeve. This device is characterized by low adjustment frequency and slow plunger movement speed.

Figure 1.

Schematic diagram of the cross-sectional structure of the nozzle assembly.

The nozzle inlet and outlet are connected to the Christmas tree via flanges. High-pressure natural gas from the formation enters the annular space between the valve body and cage sleeve through the inlet. The cage sleeve incorporates symmetrically arranged throttling orifices; when high-pressure gas flows through them, the flow area decreases abruptly and the flow rate increases significantly. The symmetrical orifice design causes the gas flow to converge at the center of the cage sleeve, where high-velocity gases mutually compress, impact, and dissipate energy, thereby achieving pressure reduction. By controlling the displacement of the valve stem via the actuator, the flow area of the throttling orifices can be regulated to control the natural gas flow rate.

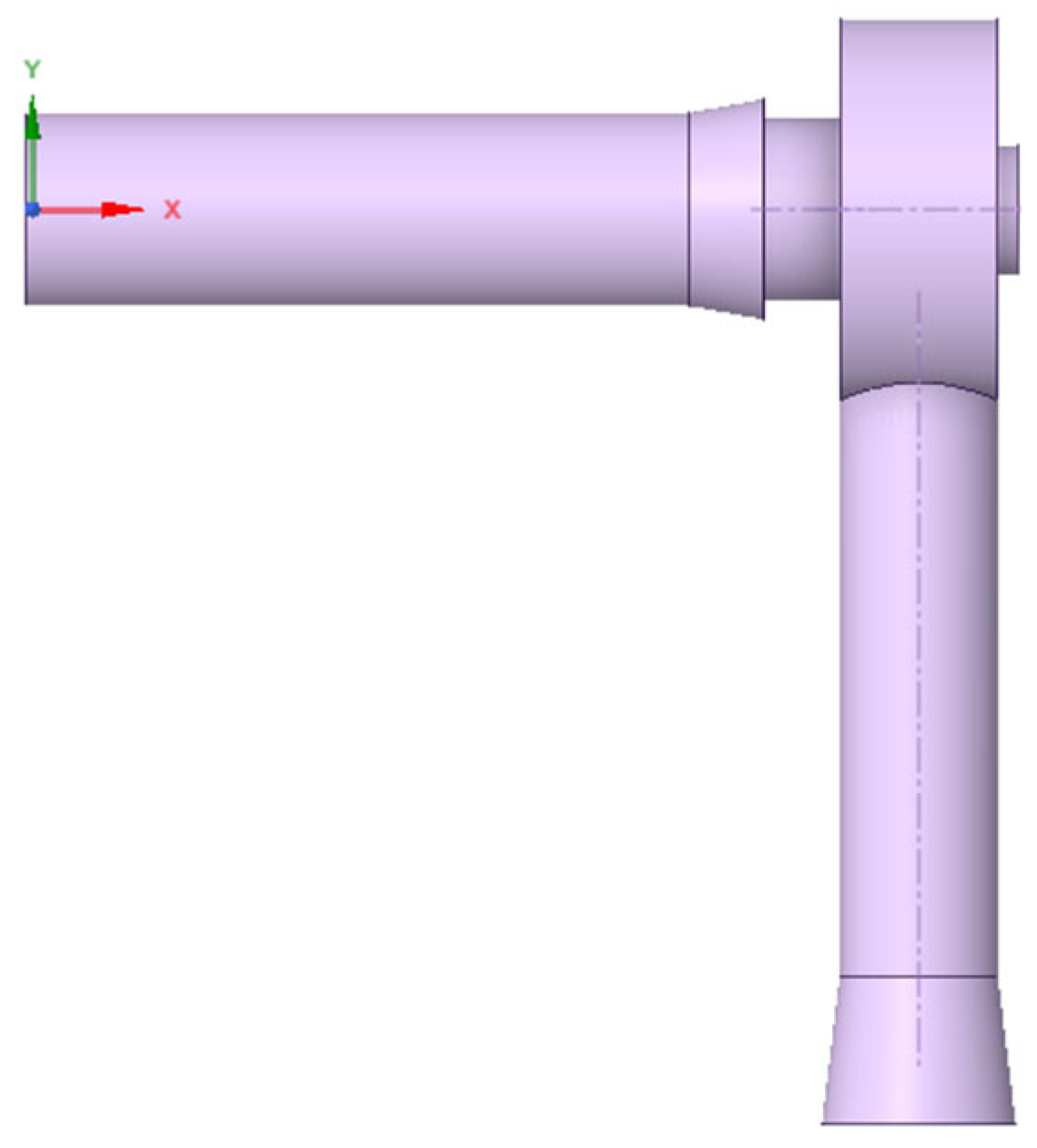

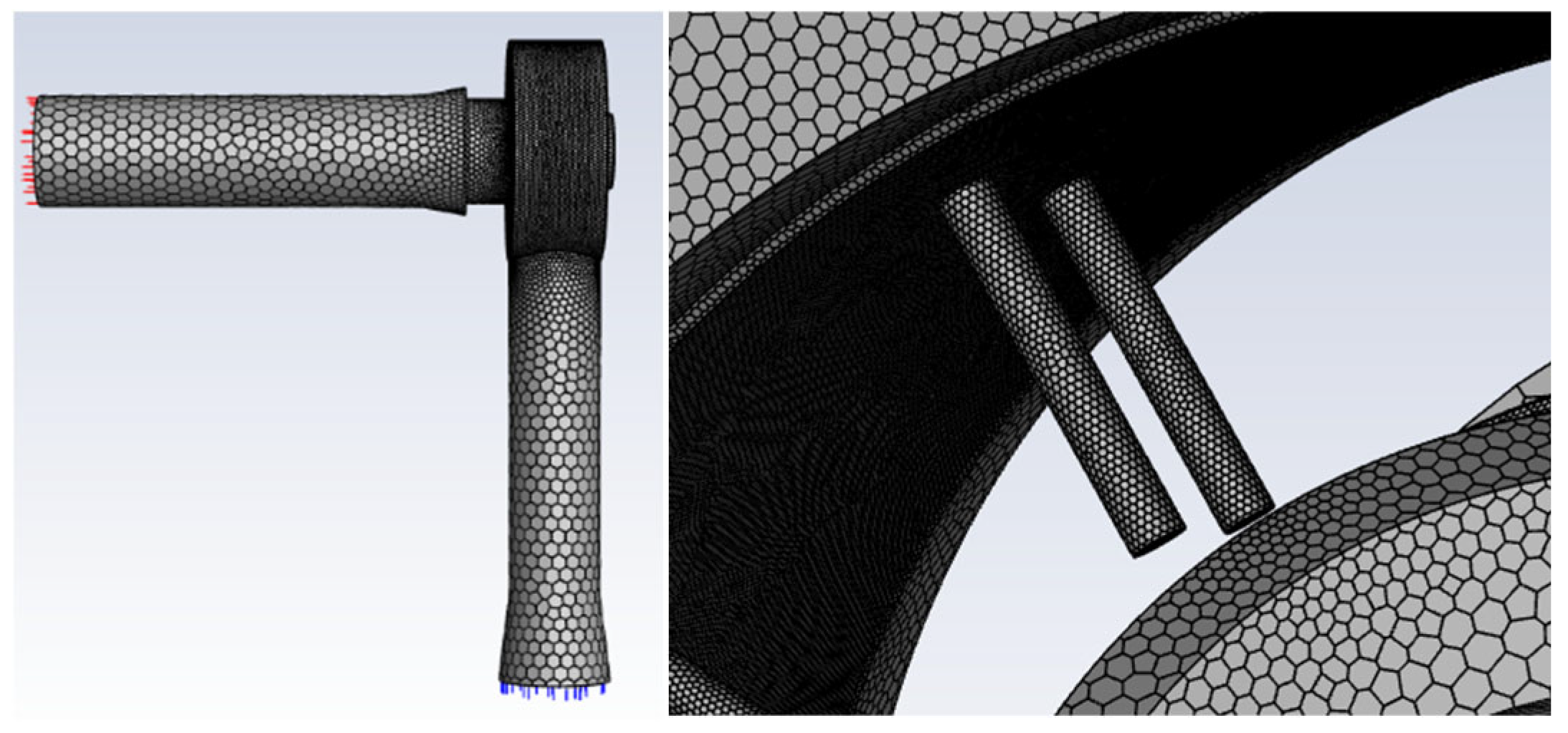

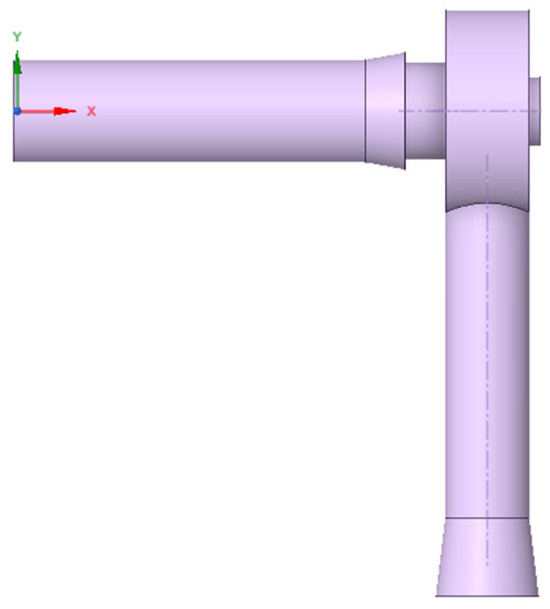

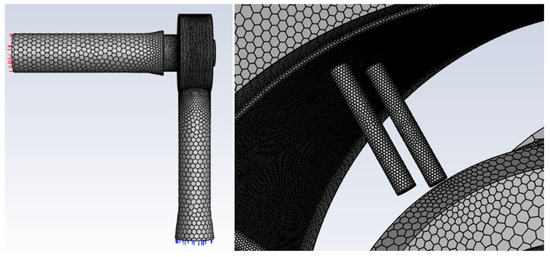

Different nozzle openings correspond to distinct internal flow rates. Consequently, the fluid domain model must be strictly extracted according to component dimensions. Figure 2 displays the extracted fluid domain model at a 50% opening. The quantity and quality of the mesh significantly affect the efficiency and accuracy of numerical simulations [18]. Given the relatively small geometric model of the studied nozzle, the flow region was meshed using the Fluent Meshing module. Due to the highly intense flow field variations near the orifices, local refinement was applied to these areas; the meshing results are shown in Figure 3.

Figure 2.

Computational fluid domain model.

Figure 3.

Grid division results and detailed processing.

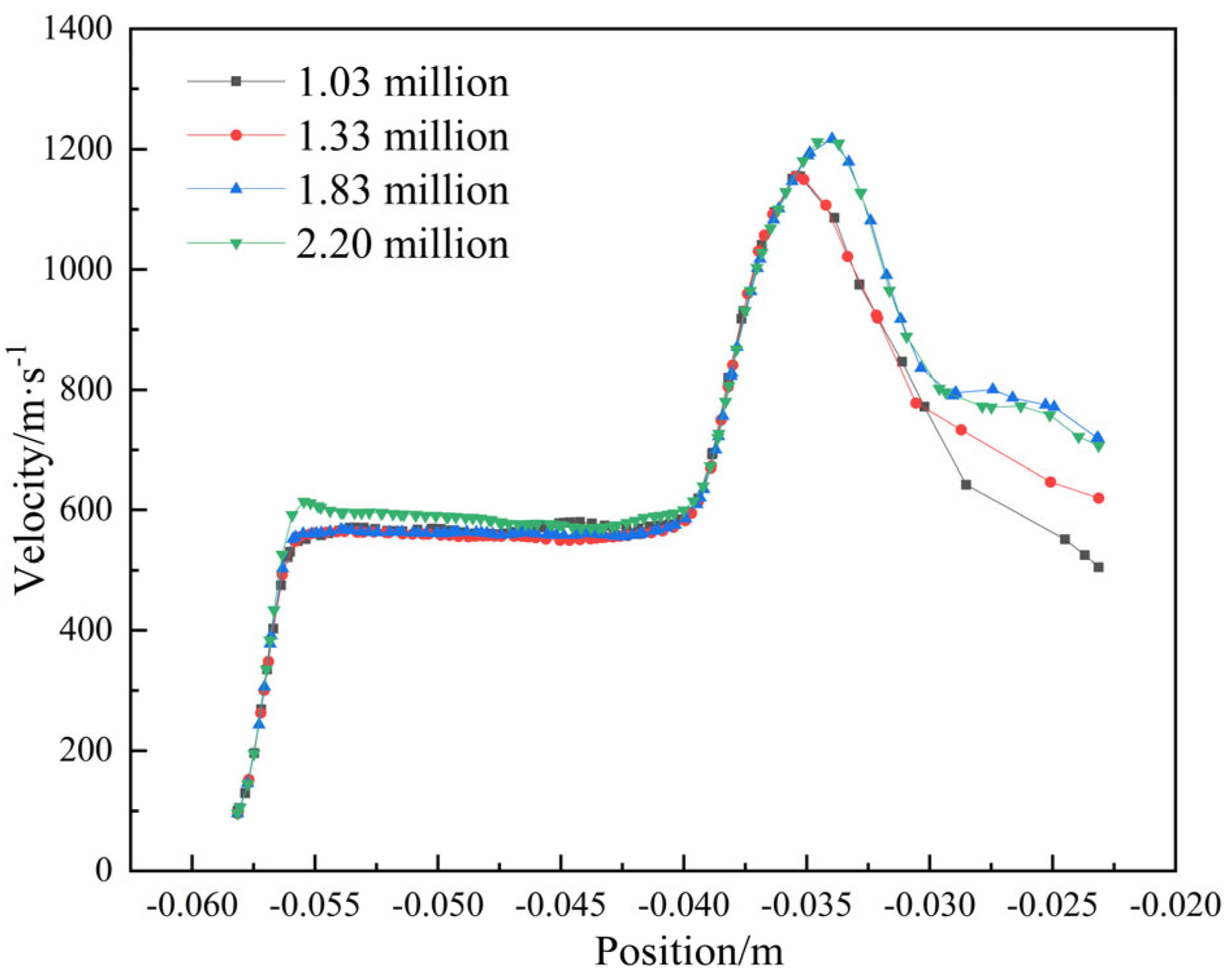

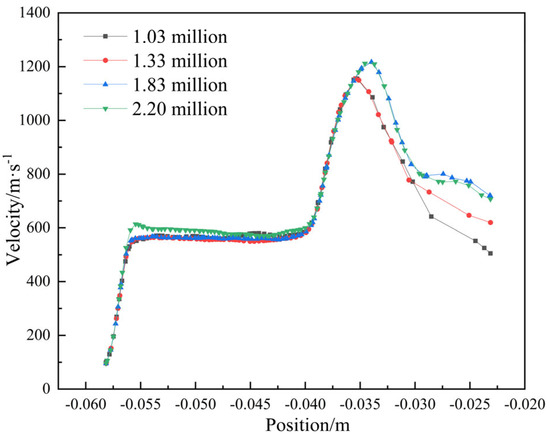

To ensure the accuracy of the numerical simulation results, a grid independence study was conducted. The condition at 50% opening (15.68 mm) was selected as the baseline. By monitoring the evolution of the velocity distribution along the flow direction at the first throttling orifice in the inlet region (Figure 4), the influence of grid resolution on the calculation results was systematically evaluated. The results indicate that, when the number of grid cells increases to 1.83 million and 2.23 million, the differences in the velocity field distribution within the throttling orifice become negligible, exhibiting favorable convergence characteristics. Based on the principle of optimizing the balance between computational accuracy and resource allocation, a mesh size of 1.83 million cells was ultimately adopted as the baseline discretization scheme for subsequent numerical studies.

Figure 4.

Grid independence verification.

3.2. Research Object and Material Properties

The research object is a cage-sleeved ultra-high-pressure grease nozzle, composed of components including a valve body, base, cage sleeve, and plunger. The cage sleeve is equipped with symmetrically distributed throttling orifices, and the plunger adjusts the opening degree through axial displacement. The nozzle is made of 4140 alloy steel. The solid particles are rock cuttings carried by natural gas. The gaseous working medium is methane. The operating conditions are as follows: inlet pressure of 175 MPa, outlet pressure of 12 MPa, and particle mass flow rate of 3.97 × 10−4 kg/s.

3.3. Boundary Conditions

Based on the extreme operating conditions encountered at the nozzle site, the following pressure boundary conditions were applied: the inlet pressure was set to 175 MPa, and the outlet pressure was controlled at 12 MPa. Given the coupled effects of high internal pressure and localized low temperatures within the nozzle, this study employed a real gas model with compressibility factor correction [19] instead of the ideal gas equation to accurately characterize the thermodynamic properties of methane (as a natural gas substitute). The wall boundary adopted a no-slip condition. The inner diameter of the nozzle inlet section is 78.5 mm, the outlet section inner diameter is 78 mm, and the characteristic diameter of the throttling orifices configured in the cage assembly is 2.7 mm. The turbulence intensity was calculated as 2.3% based on the characteristic inlet dimension of 78.5 mm. The device was installed in a vertically downward orientation; the gravitational acceleration vector was defined as acting along the negative Y-axis of the spatial coordinate system.

After the flow field calculation achieved convergence, the Discrete Phase Model (DPM) was introduced for erosion analysis. The particle phase was combined with the fluid motion. Particles were set with a diameter of 50 μm, density of 1600 kg/m3, and mass flow rate of 3.97 × 10−4 kg/s. This configuration enabled the investigation of the erosion effects induced by solid particles on structural surfaces within the supersonic flow field of the ultra-high-pressure nozzle.

3.4. Rationality Analysis of Boundary Conditions

For fully developed turbulent flows in industrial pipelines (with a Reynolds number Re > 104), the turbulence intensity typically ranges from 1% to 5% [20]. In this study, the inlet velocity of high-pressure methane (175 MPa) is estimated to exceed 100 m/s, corresponding to a Reynolds number of approximately 106 (calculated based on the physical properties of methane under high pressure), indicating that the flow is in a state of fully developed turbulence. A turbulence intensity of 2.3% falls within the recommended range for such operating conditions.

In similar studies on high-pressure gas throttling devices (e.g., choke valves and nozzles), the turbulence intensity for inlet boundary conditions is mostly set between 2% and 3%. For instance, Zhou et al. [19] adopted a turbulence intensity of 2.5% in the numerical simulation of downhole choke valves in coalbed methane wells, and their results showed good agreement with field data. This consistency further validates the rationality of the 2.3% setting in this study. The use of the inlet inner diameter (78.5 mm) as the characteristic length for turbulence intensity calculation conforms to the standard practice in CFD simulations of pipeline flows. For circular cross-sections, the hydraulic diameter (equal to the inner diameter) is the most representative dimension for characterizing turbulent development [21].

The ideal gas assumption is only valid under low-pressure and high-temperature conditions, where intermolecular forces and molecular volume are negligible. For methane at 175 MPa [22], the compressibility factor Z deviates significantly from 1 [23]. This means that the ideal gas law would overestimate the molar volume by approximately 10–15%, leading to prediction errors in density, velocity, and pressure drop. The real gas model used in this study incorporates Z-factor correction based on the Peng–Robinson equation of state [24], which has been widely validated in the simulation of high-pressure hydrocarbon fluids. The correction accounts for intermolecular attraction and repulsion, ensuring accurate calculation of thermodynamic parameters (density, enthalpy, and viscosity) during the throttling process. For example, studies by Zhu et al. [25] have shown that neglecting real gas effects in the simulation of subsea nozzles under 100 MPa can result in a temperature drop prediction error exceeding 30 K, which can be effectively mitigated by Z-factor correction. The target application scenario of this study is ultra-high-pressure natural gas wells (175 MPa), where methane accounts for more than 90% of the gas composition [5]. Field studies on deep gas wells in the Tarim Oilfield have confirmed that real gas behavior dominates under such conditions, and compressibility factor correction is crucial for reliable calculations of flow rate and pressure drop [26].

4. Result and Discussion

4.1. Nozzle Flow Characteristics

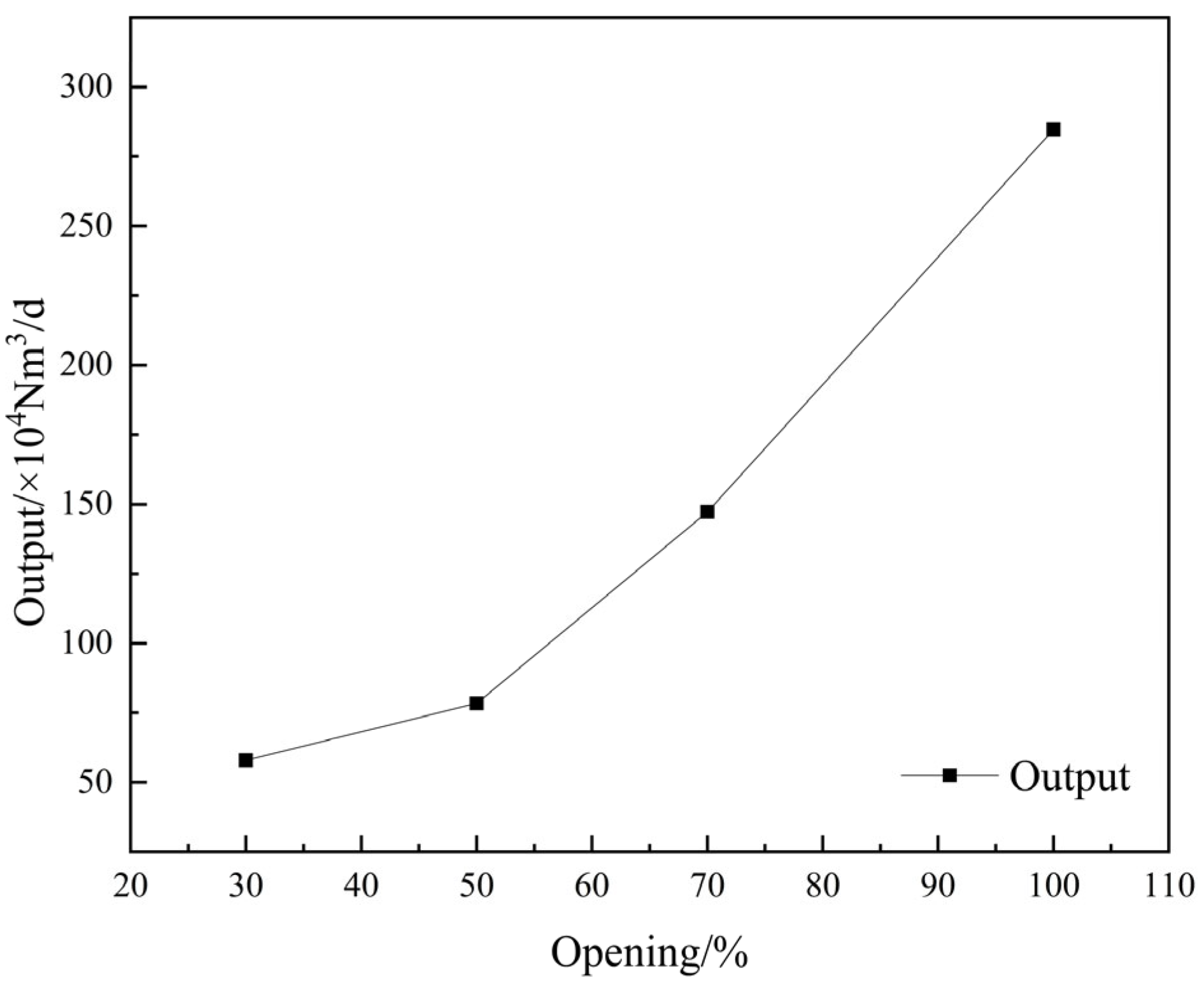

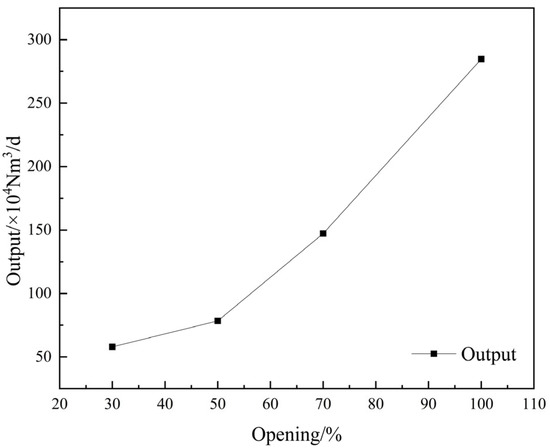

The flow characteristics of the nozzle refer to the relationship between the flow rate and the opening under fixed inlet and outlet pressures. To facilitate analysis of the relationship between opening and flow rate, the simulated flow rate results for different openings are summarized in Table 1 and plotted as an opening–flow rate curve in Figure 5.

Table 1.

Nozzle output at different openings.

Figure 5.

The variation curves of nozzle flow at different opening degrees.

Valve flow regulation characteristics primarily encompass four types: linear, equal-percentage, parabolic, and quick-opening. Based on the nozzle flow characteristic curve obtained from numerical simulations, the quantitative relationship between the flow rate and opening exhibits a typical equal-percentage regulation characteristic. Specifically, at smaller nozzle openings, the flow rate change is relatively gradual; as the opening increases, the flow rate change accelerates progressively. This nonlinear gain behavior provides disturbance rejection stability in the low opening range and maintains control sensitivity in the high opening range. This conclusion aligns with the field-measured nozzle flow characteristics under rated operating conditions, effectively demonstrating the engineering validity of the numerical methodology and real gas model.

4.2. Analysis of the Basic Flow Field Under Extreme Conditions

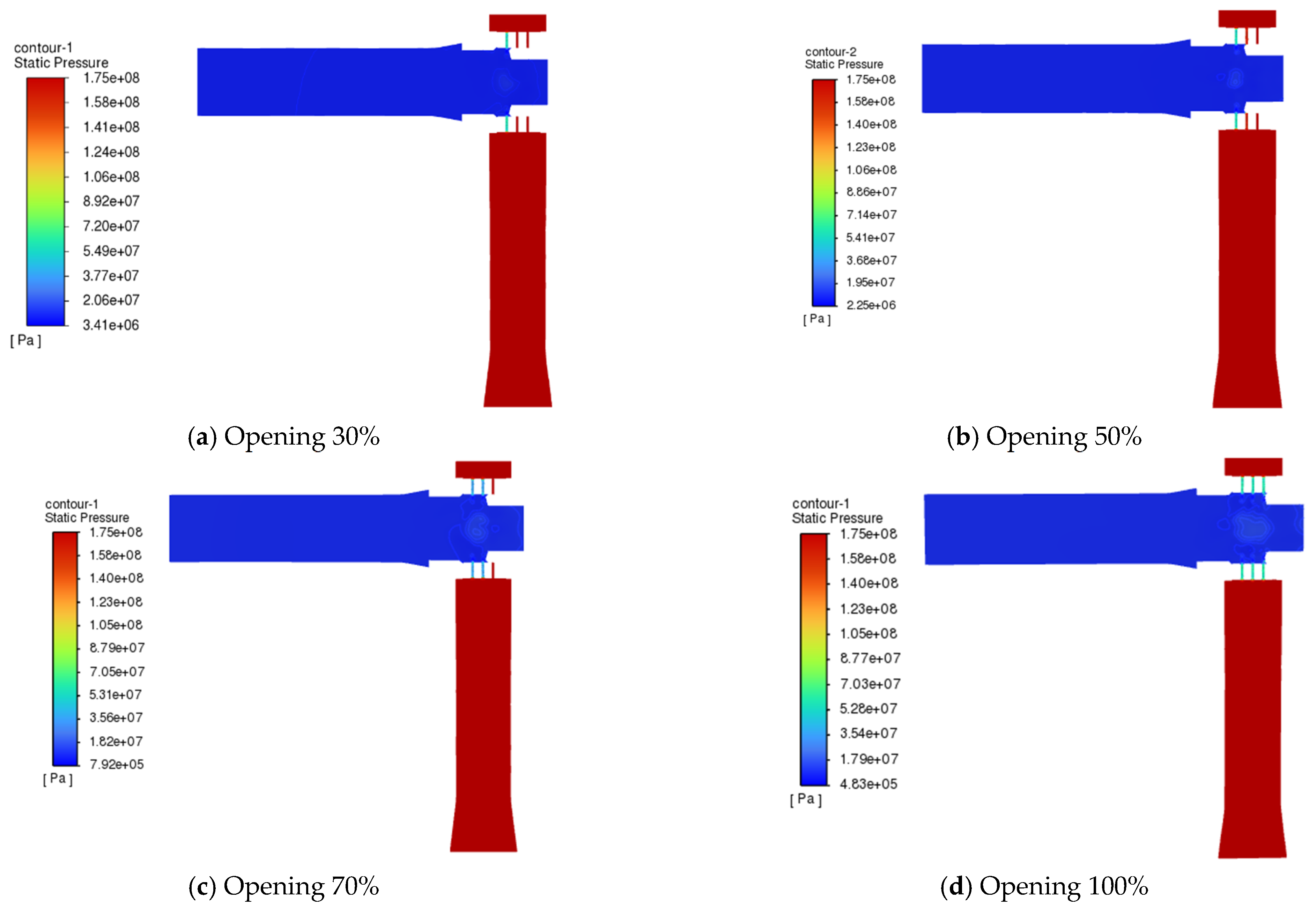

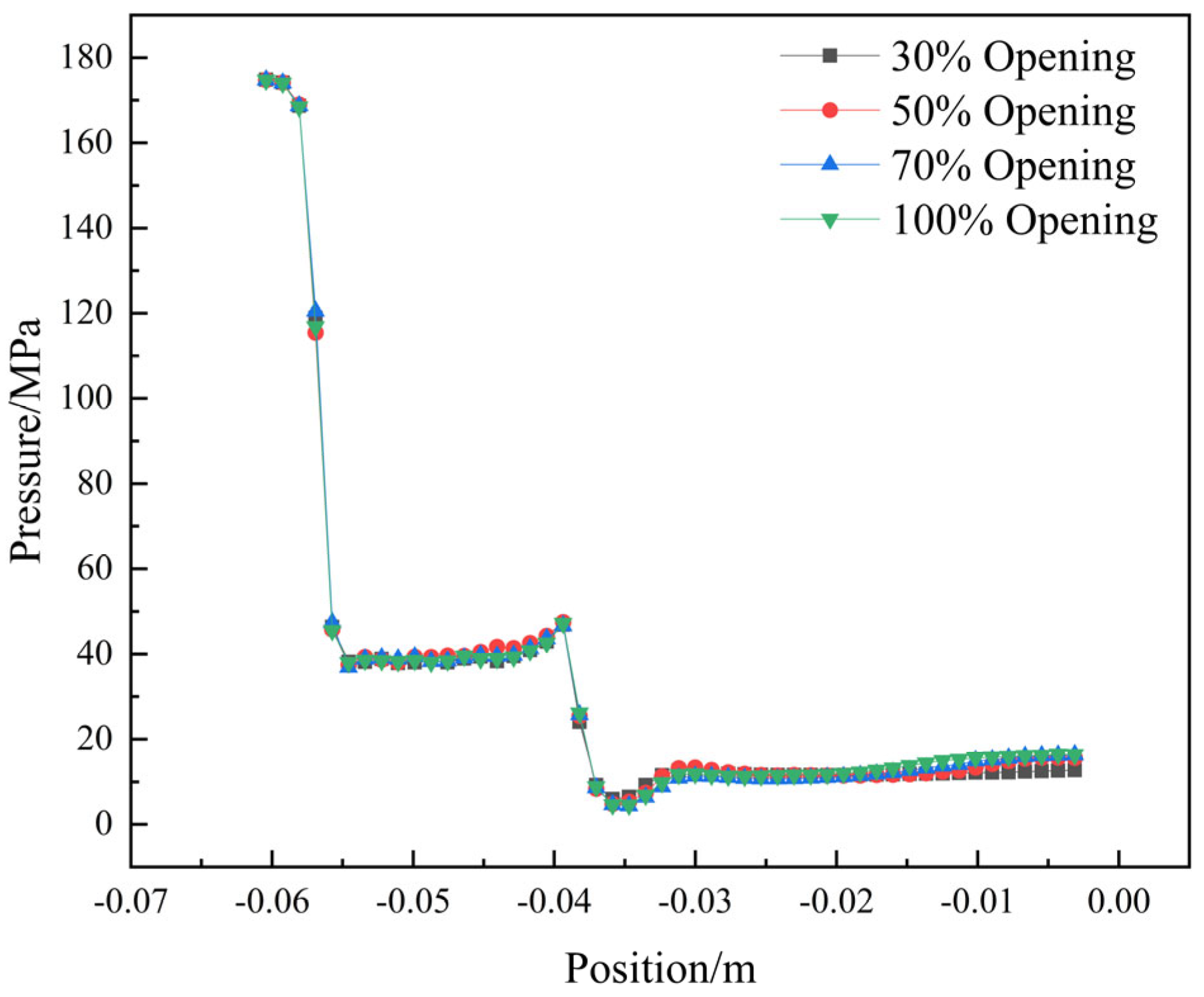

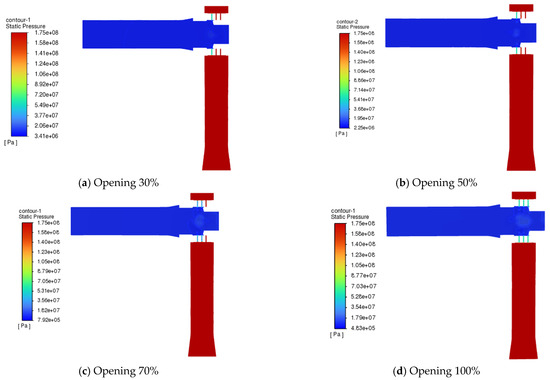

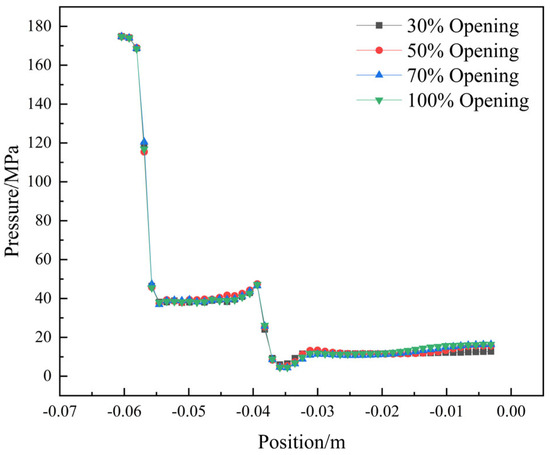

Based on the established numerical model, numerical simulations were first conducted for single-phase methane gas across multiple openings. The evolution of the flow field within the high-pressure nozzle was systematically investigated at four opening positions: 30%, 50%, 70%, and fully open (100%). The characteristic cross-section at Z = 0 m was selected to focus on analyzing the flow evolution in the passage of the first throttling orifice in the outlet region. This specifically targets the 18.75 mm flow-aligned length within the orifice, spanning the axial coordinate range from x = −57.40 mm to x = −38.65 mm.

Numerical analysis based on the pressure field distribution (Figure 6) reveals that a significant pressure gradient zone forms from the throttling orifice throat to the cage diffuser section, with a maximum pressure drop of 163 MPa. This aligns with the law of energy conservation for compressible fluids: high-velocity flow induces the conversion of pressure potential energy to kinetic energy. Notably, the static pressure at the throttling orifice throat remains relatively stable across different opening conditions (variation amplitude < 2.7%), as shown in Figure 7. This phenomenon originates from the critical pressure ratio theory: when the orifice throat velocity reaches the local speed of sound (Mach number Ma = 1), the flow enters a choked state. Under these conditions, the mass flow rate through a single throttling orifice depends solely on the upstream total pressure and temperature, with reduced dependence on downstream pressure.

Figure 6.

The pressure distribution characteristics of the nozzle at different opening degrees.

Figure 7.

Pressure variation curves under different nozzle openings.

Experimental data validate this theory: when the opening increases from 20% to 80%, despite a fourfold expansion of the flow area, the internal pressure within individual throttling orifices remains unchanged. This confirms the existence of the choked flow regime. Such self-adaptive flow characteristics ensure stable pressure regulation of the throttling device across a wide operating range.

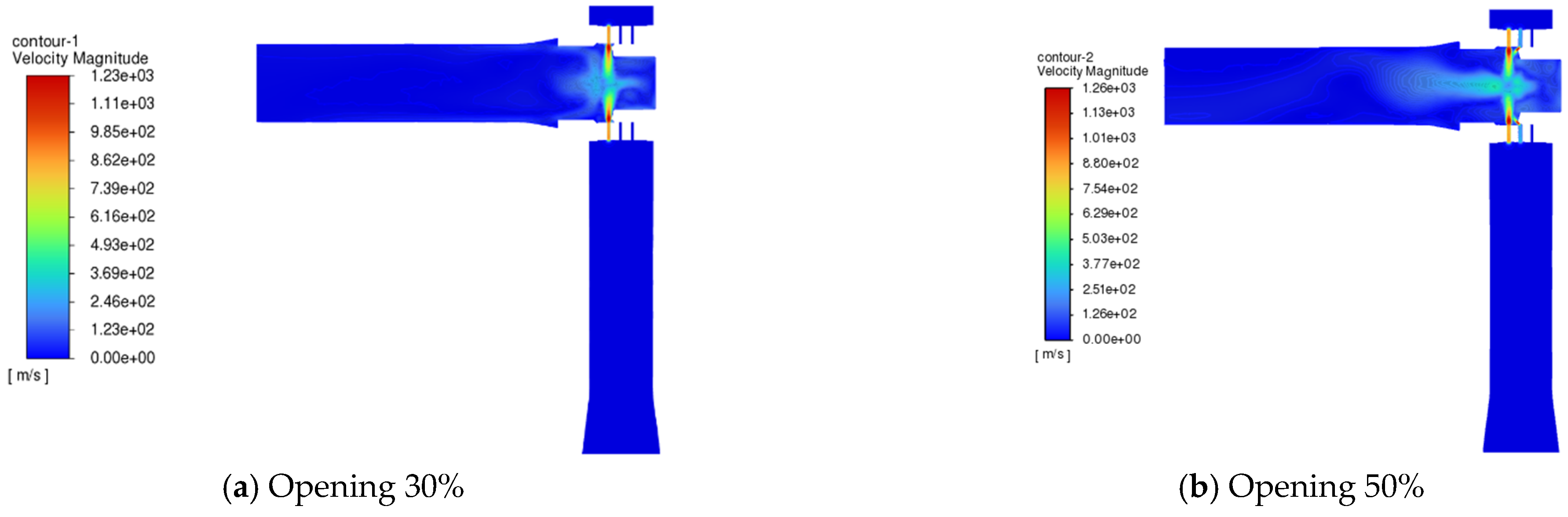

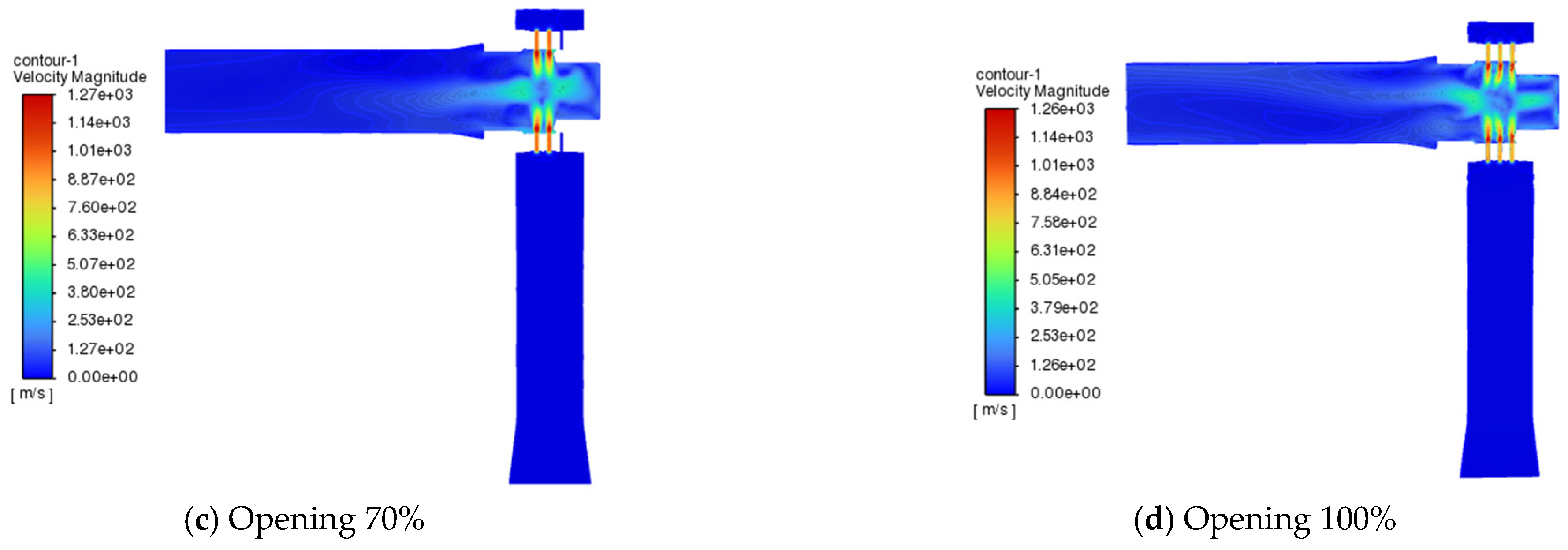

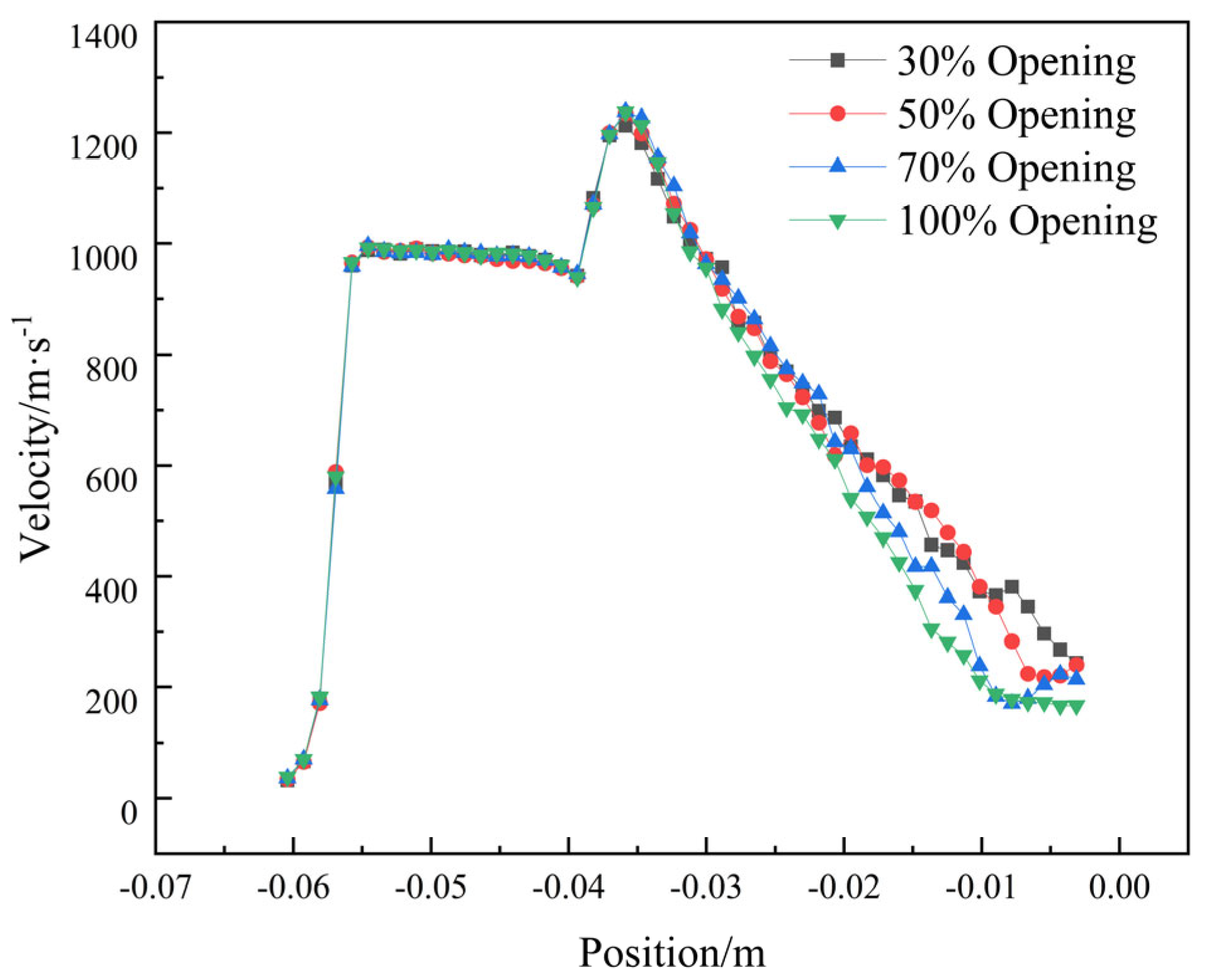

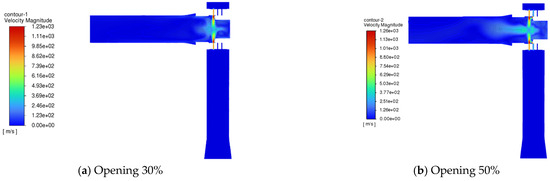

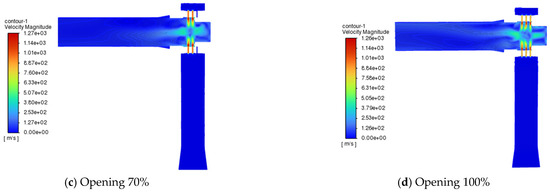

The velocity field distribution (Figure 8) exhibits characteristic features of compressible fluid dynamics in the throttle orifice throat region. As methane flows through the orifice, its velocity abruptly increases from subsonic at the inlet to supersonic (Ma ≈ 3.5), consistent with predictions from Prandtl–Meyer expansion wave theory. Numerical simulations reveal that the supersonic jet impinges within the expansion section, leading to the formation of a high-velocity stream (velocity > 800 m/s) downstream. Notably, as the opening increases from 25% to 75%, the time-averaged velocity at the orifice throat consistently remains within the range of 1150–1240 m/s (Figure 9), which aligns with the theoretical critical velocity under choked flow conditions. Further analysis indicates that, as the opening increases from 30% to 70%, the axial extent of the high-velocity stream increases by nearly 1.8 times. At 100% opening, a clear change in the direction of turbulent velocity fluctuations within the downstream high-speed flow becomes evident. This phenomenon arises because increased opening, accompanied by higher flow rates, intensifies jet impingement, resulting in vortex formation within the downstream outlet section. This vortex formation can induce alternating stresses on the nozzle components, warranting attention in practical operation.

Figure 8.

The velocity distribution characteristics of the nozzle at different opening degrees.

Figure 9.

Velocity variation curves under different nozzle openings.

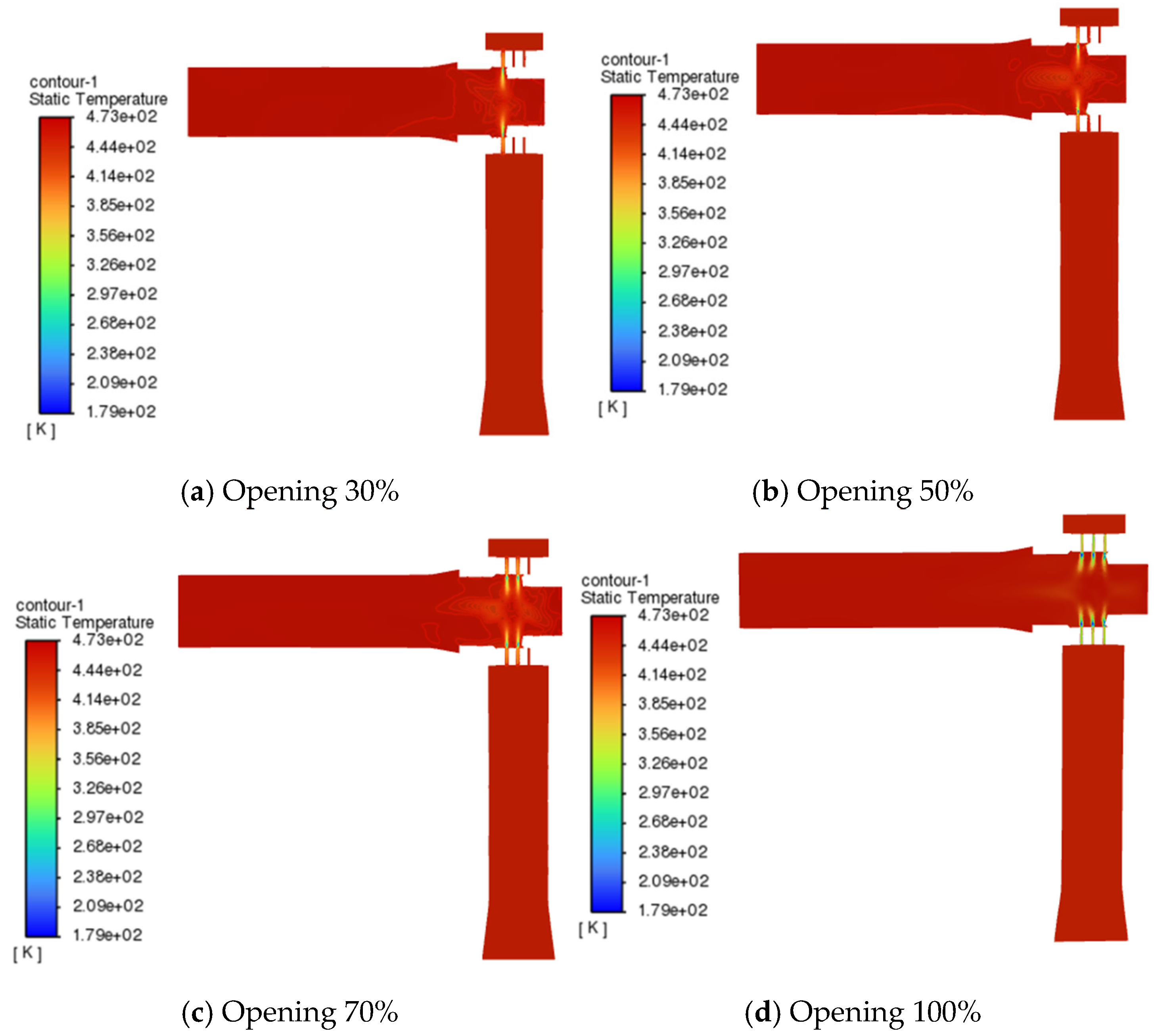

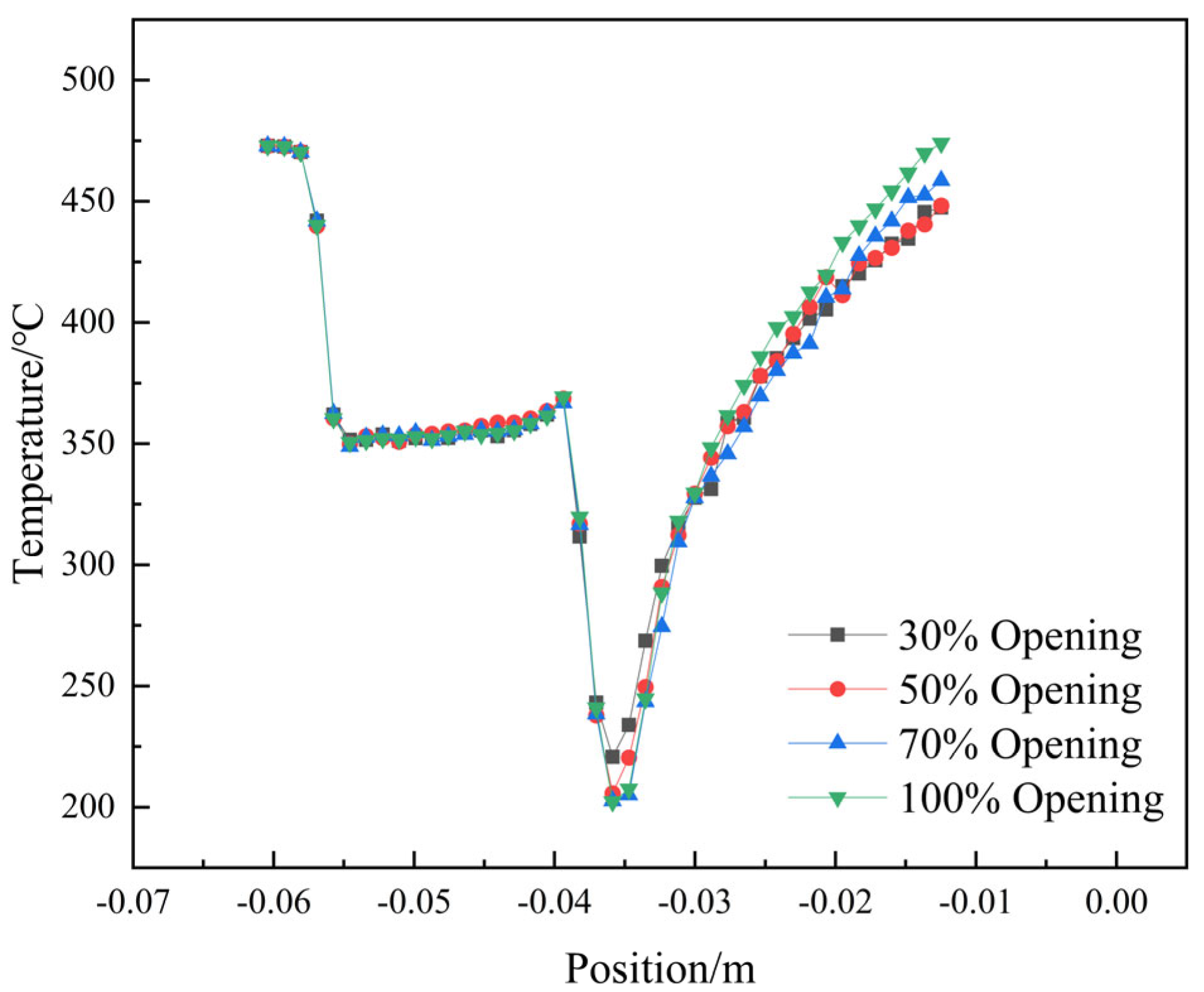

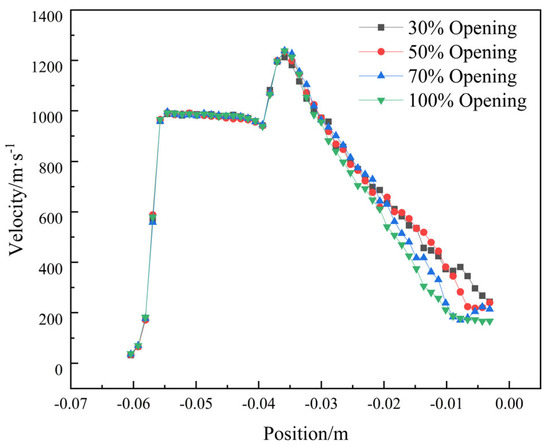

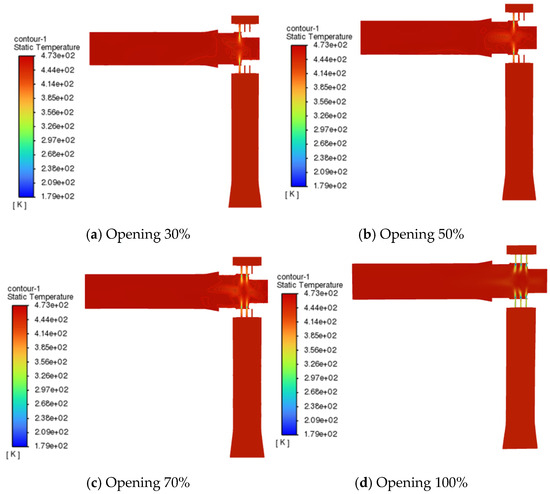

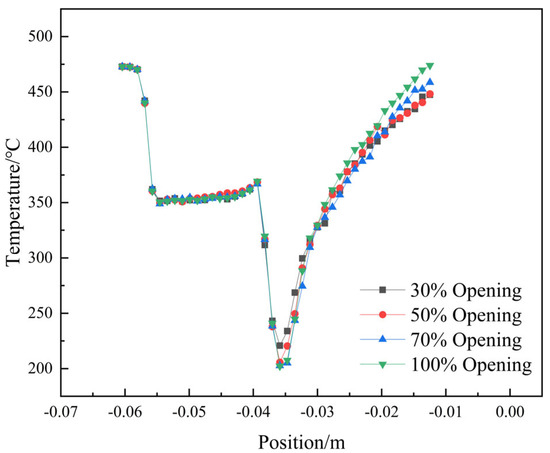

As shown in Figure 10, which depicts the temperature field distribution characteristics under different openings, the results reveal the non-equilibrium thermodynamic characteristics of the ultra-high-pressure throttling process. Figure 11 demonstrates that methane undergoes a drastic temperature drop (ΔT = 270.3 K) as it flows through the throttle orifice throat. The evolution of its temperature field conforms to the thermodynamic characteristics of the Joule–Thomson effect (throttling coefficient μJ = 1.7 K/MPa). A throttling coefficient greater than zero signifies a throttling cooling effect [25]. From a molecular dynamics standpoint, when a gas undergoes adiabatic expansion, the average distance between molecules abruptly increases. This causes the molecules to transition from a state of strong attraction to one of weaker attraction, resulting in an increase in molecular potential energy. This process adheres to the law of conservation of energy: the increase in total molecular potential energy corresponds to a decrease in total kinetic energy, meaning molecular motion slows down. This is directly reflected in a decrease in the medium’s temperature. Under all opening conditions, the lowest temperature consistently occurs at the throttle orifice outlet. Considering the natural gas hydrate formation criterion equation proposed by Ponomarev [27], the post-throttling methane pressure (12 MPa) significantly exceeds the critical curve inflection point pressure for hydrate formation (2.08 MPa). Consequently, natural gas hydrate will form in the downstream outlet section of the nozzle, potentially leading to ice blockage. For engineering protection purposes, increasing the inlet temperature or adding inhibitors can be considered to effectively suppress the phase transition.

Figure 10.

The temperature distribution characteristics of the nozzle at different opening degrees.

Figure 11.

Temperature variation curves under different nozzle openings.

4.3. Nozzle Erosion Analysis

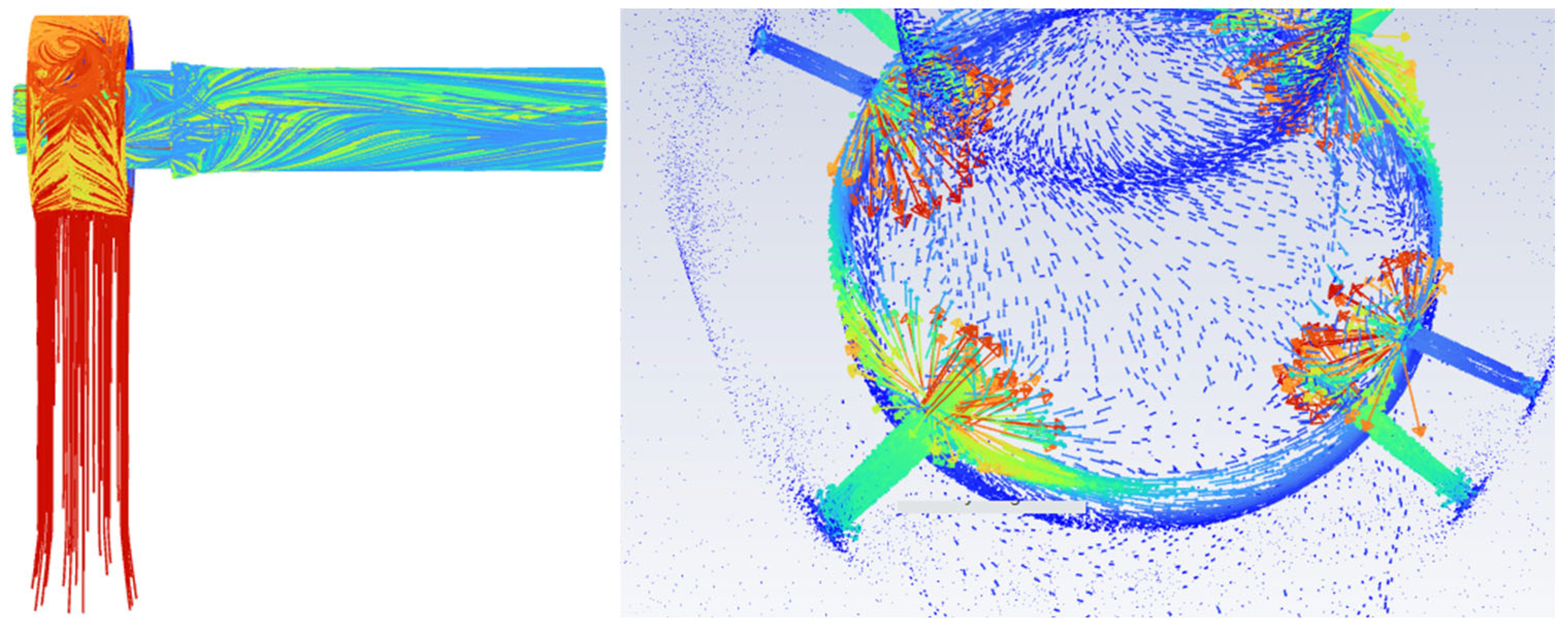

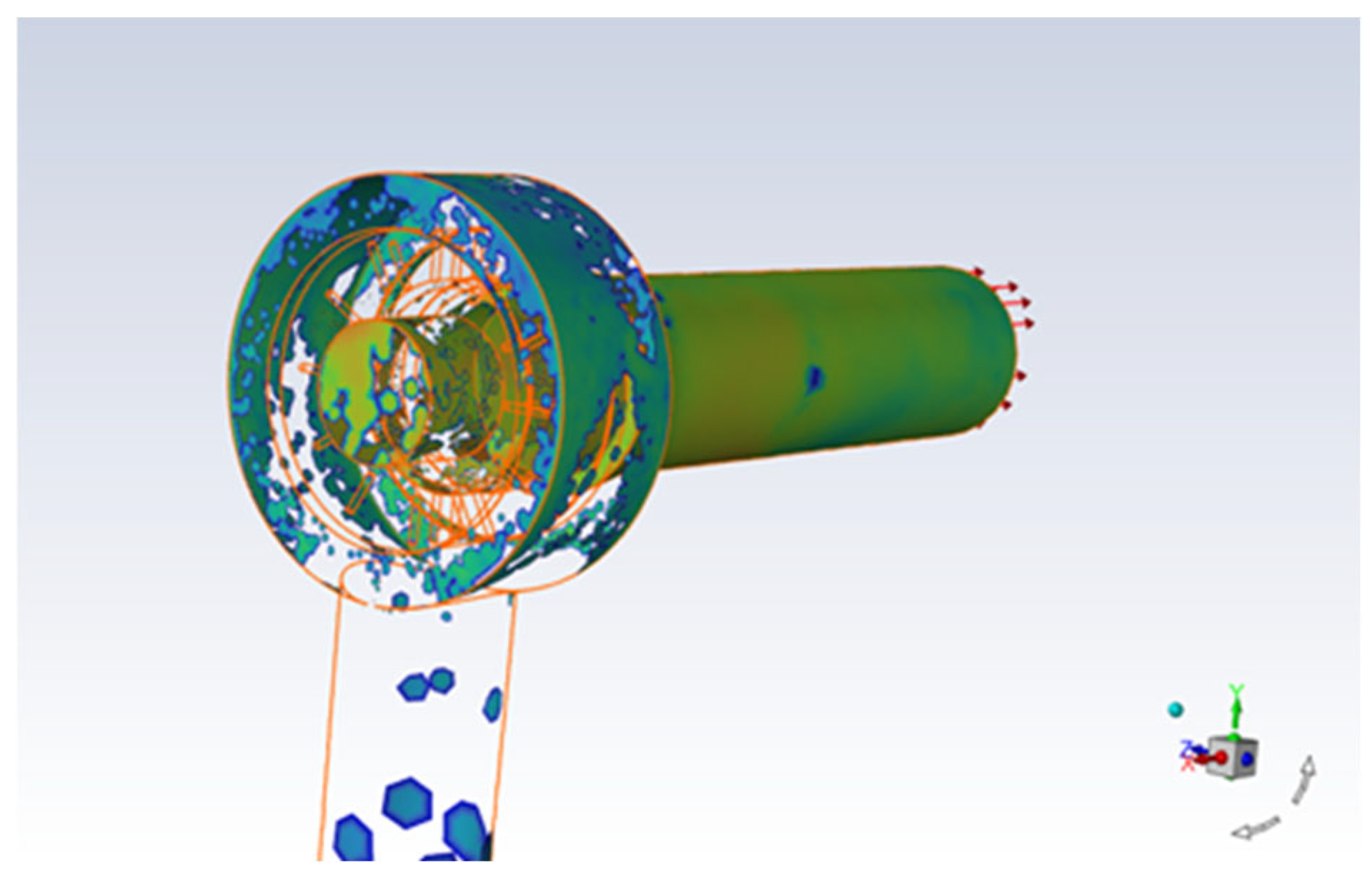

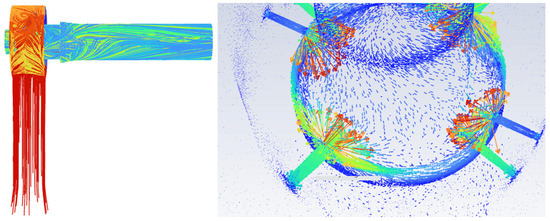

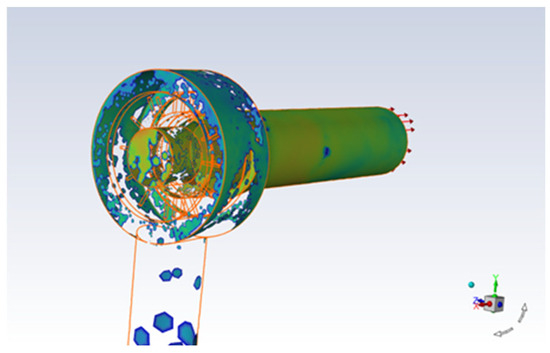

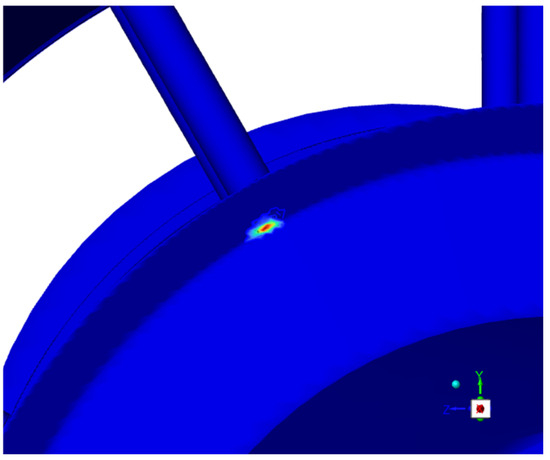

After the flow field is fully developed, solid particles are injected via the Discrete Phase Model (DPM). Particle trajectories are tracked using the stochastic trajectory model. Figure 12 illustrates, using the 100% opening case as an example, the particle trajectories within the nozzle and the velocity vector field at the orifice. The results demonstrate that, within the annular channel, particles exhibit spatial segregation due to secondary flow effects. Specifically, only a small fraction of particles passes through the axially symmetric orifice into the downstream region, while the majority migrate toward the 180° azimuthal region on the cage backside under the influence of centrifugal force. This non-uniform distribution subjects the annular channel wall in this area to sustained impact loading, forming an erosion hotspot region (Figure 13). Analysis of the velocity vector field reveals that the ultra-high inlet pressure generates a region of high-velocity gradient at the orifice outlet, thereby inducing intense anisotropic turbulence, which is also the root cause of downstream vortices. Consequently, in the downstream outlet section of the orifice, particles, influenced by the strong turbulence of the continuous phase, cause erosion damage to the downstream pipe wall.

Figure 12.

Particle motion path and pore velocity vector.

Figure 13.

Schematic diagram of the hot spot area of nozzle erosion.

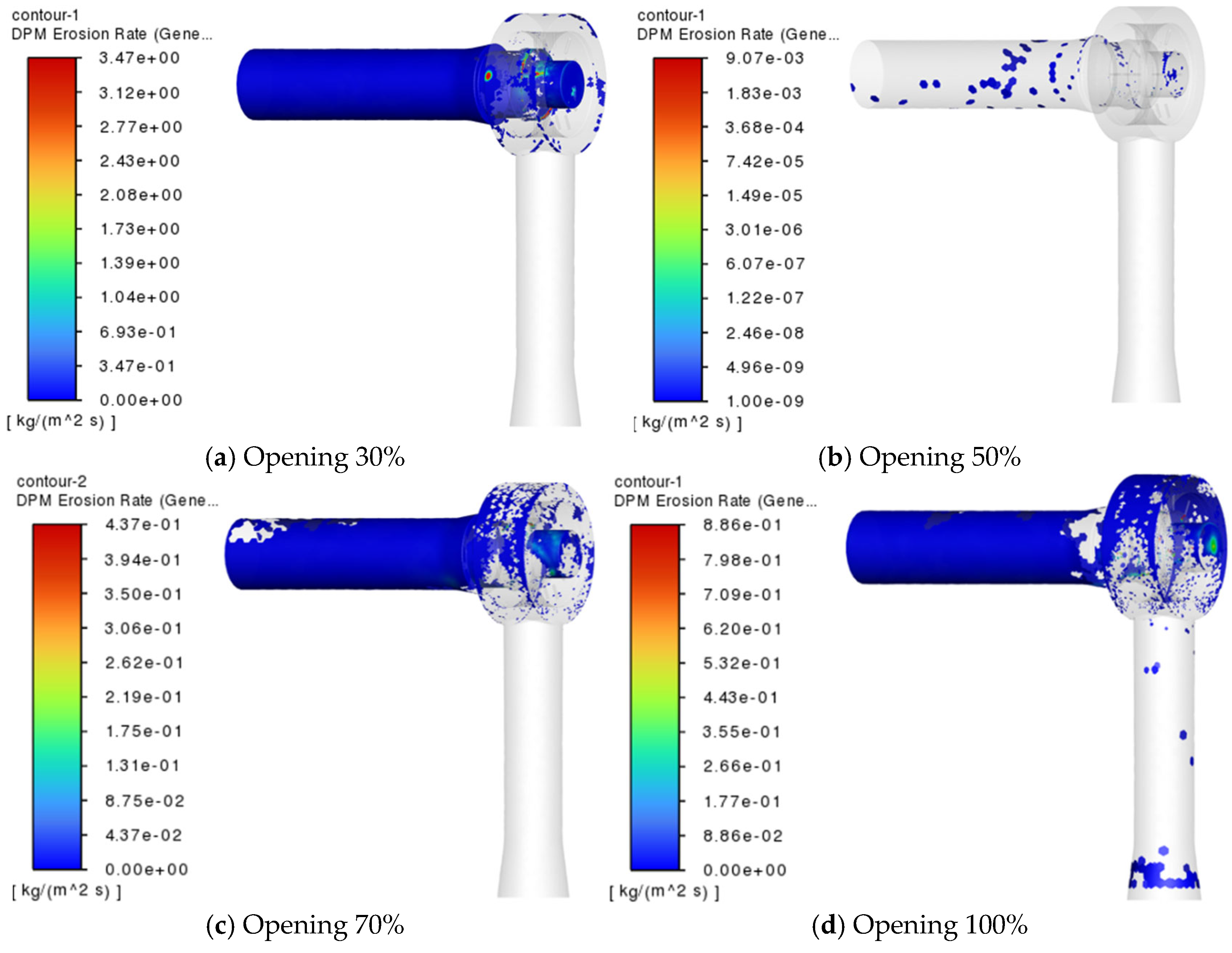

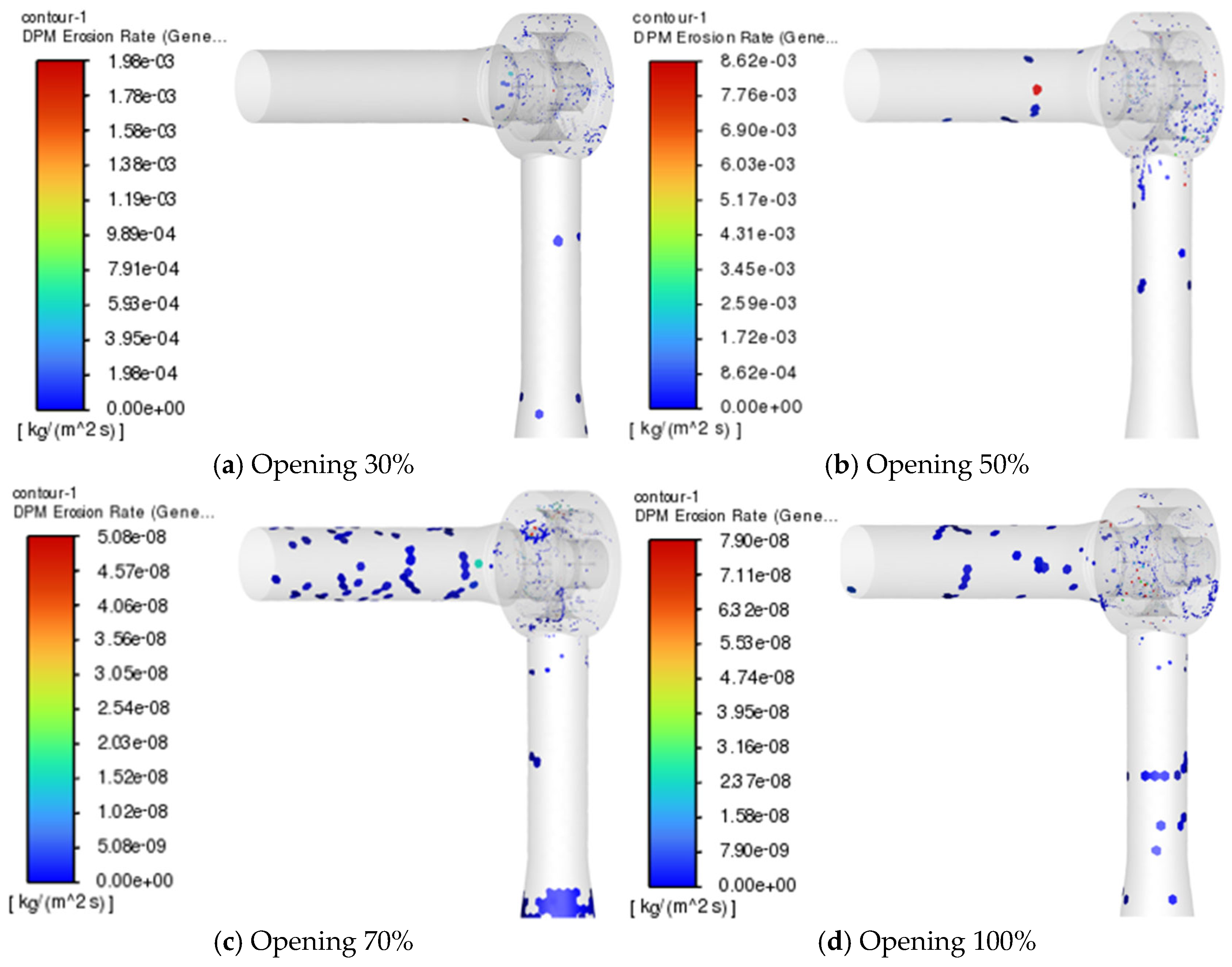

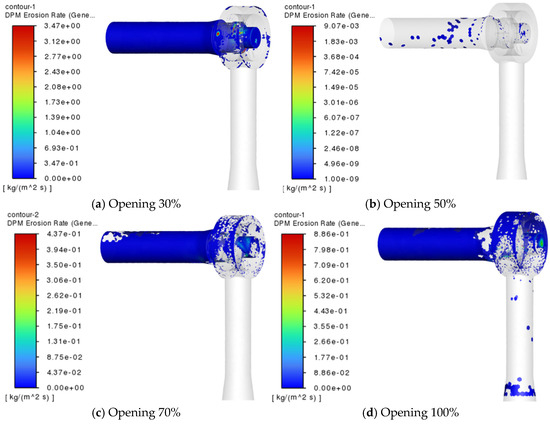

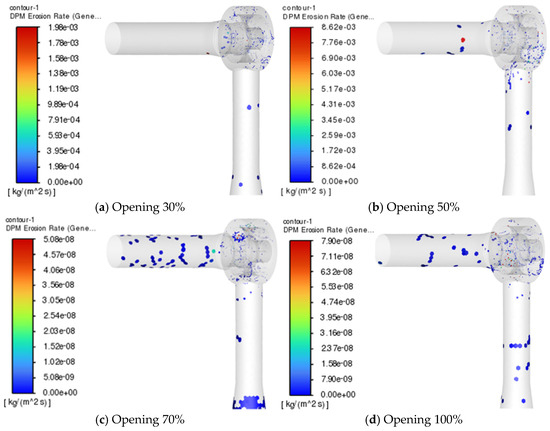

The erosion simulation results across different openings (Figure 14) reveal a nonlinear coupling relationship between the erosion rate and nozzle opening. At a 50% opening, the maximum erosion rate of the nozzle reaches its minimum value of 9.07 × 10−3 kg/(m2·s). However, due to ultra-high-pressure effects, this minimum value remains significantly higher than the erosion rates under conventional operating pressures (<105 MPa) [28]. When the opening decreases to 30% or increases to 70% from the 50% baseline, the erosion rate surges to 3.47 kg/(m2·s) and 4.37 × 10−1 kg/(m2·s), respectively. This phenomenon arises from the interaction of the following two mechanisms: (1) inlet flow velocity increases with opening, while particle kinetic energy is proportional to the square of the velocity; (2) the dynamic shielding effect of the plunger causes abrupt geometric changes in the flow path. The plunger may neither fully cover nor completely expose the orifices [29], forming a micro-jet structure at 30% opening that concentrates particle impact angles within the range most sensitive to material loss.

Figure 14.

Cloud images of nozzle erosion at different opening degrees.

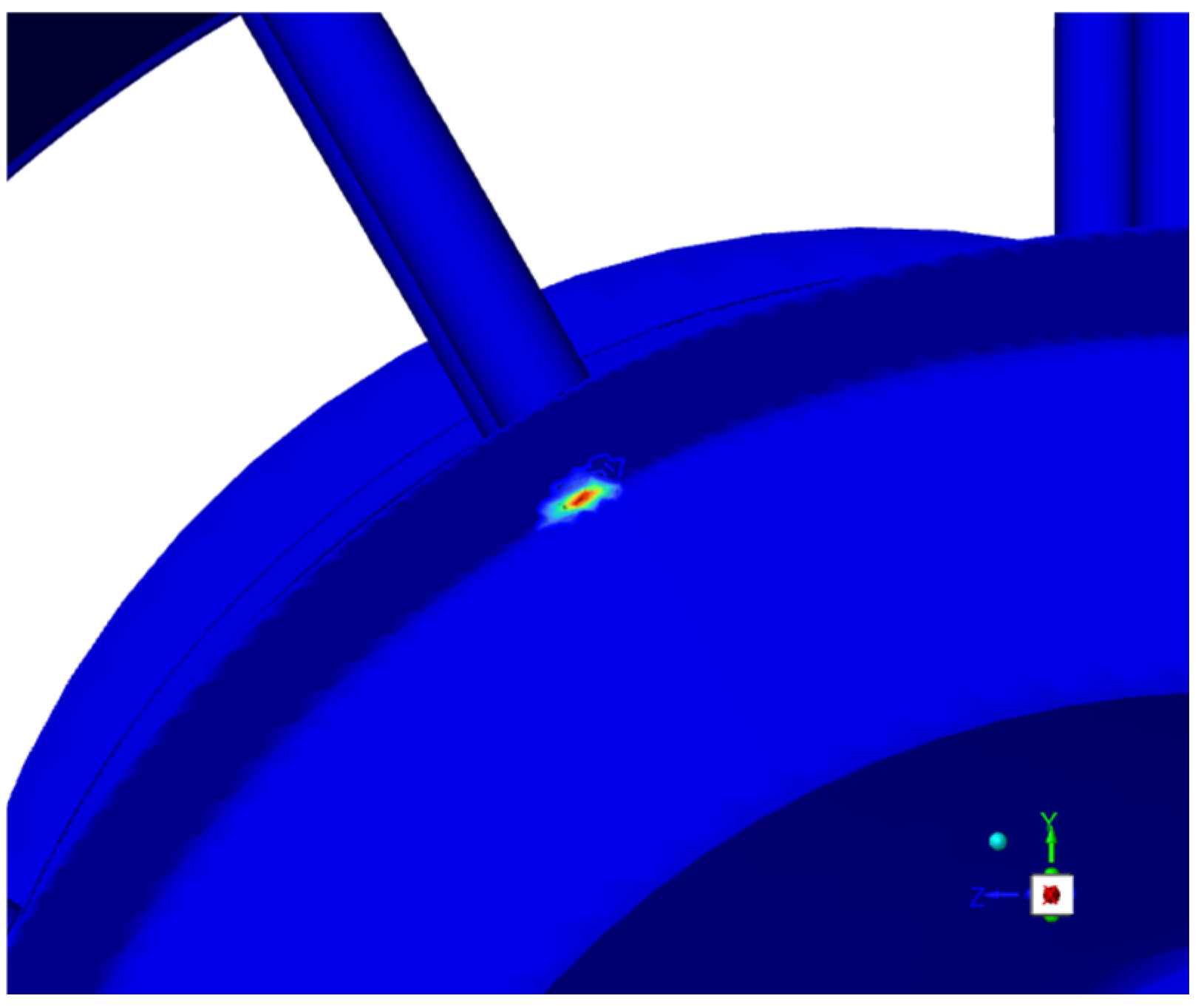

Additionally, the peak erosion rate consistently occurs at the oblique section of the throttling orifice outlet (Figure 15), corresponding to the chamfered region on the front oblique surface of the plunger. Figure 16 demonstrates that structural optimization by removing the plunger chamfer reduces erosion to some extent. Based on the erosion results, the following engineering optimization recommendations are proposed: The nozzle should avoid operating under low shading coefficients (defined as the ratio of effective flow area to geometric orifice area), i.e., avoid partially open/closed orifice conditions. Operating openings should be maintained near 50% to minimize erosion rates. Surface modification using a WC-10Co4Cr coating [30,31] can effectively suppress erosion rates.

Figure 15.

The position of the maximum erosion rate of the nozzle.

Figure 16.

Erosion variation with plunger chamfer.

5. Conclusions

By establishing a finite element analysis model of the choke, this study conducted numerical simulations on the throttling effects and erosion characteristics under the extreme operating condition of 175 MPa ultra-high-pressure natural gas wells. The main conclusions are as follows:

- (1)

- The relationship between the choke flow rate and opening exhibits a typical equal-percentage nonlinear regulation characteristic, with a gentle flow rate change at small openings and a significant increase at large openings, consistent with engineering practice.

- (2)

- The flow velocity at the throttling orifice throat reaches supersonic speeds (Ma ≈ 3.5), forming a choked flow regime where the mass flow rate depends solely on the upstream total pressure, independent of downstream pressure. The Joule–Thomson effect causes an abrupt temperature drop of 270.3 K (throttling coefficient: 1.7 K/MPa), with the outlet temperature falling below the critical formation temperature of methane hydrate, posing a risk of ice blockage.

- (3)

- Under the influence of secondary flow, particles accumulate in the 180° backside region of the cage, forming erosion hotspots. The maximum erosion rate reaches 3.47 kg/(m2·s) at 30% opening due to micro-jet impact, while the minimum erosion rate (9.07 × 10−3 kg/(m2·s)) occurs at 50% opening. Removing the plunger front chamfer can alleviate erosion. It is recommended to use WC-10Co4Cr coating and operate at approximately 50% opening to reduce risks.

Despite the insights gained, this study has several limitations, which provide opportunities for future research. Firstly, while the Renormalization Group k-epsilon (RNG k-ε) model employed demonstrates good accuracy in simulating high-speed jets, it is inherently a Reynolds-averaged turbulence model. Its capability to capture unsteady flow details such as intense rotational vortices and shock–turbulence interactions at the throttling orifice under extreme high pressure is limited, potentially leading to an underestimation of the impact of local turbulent fluctuations on erosion. Additionally, the Discrete Phase Model (DPM), based on the Euler–Lagrange framework, is suitable for scenarios with particle volume fractions < 10%. However, in this study, the particle diameter is assumed to be a fixed 50 μm with a density of 1600 kg/m3, failing to account for the effects of actual particle size distribution and shape in production processes. Additionally, the computational accuracy of the model under high particle concentrations has not been verified. Moreover, the grid independence study was conducted solely under the 50% opening condition, without validating the influence of grid resolution on results under other opening degrees. The turbulence intensity in the boundary conditions was set to 2.3%, derived from the inlet characteristic size, but this value has not been compared or validated against field-measured data or the turbulence intensity ranges reported in similar high-pressure flow studies.

Future research may consider extending simulations to a broader range of particle size distributions, particle shapes, and inlet mass flow rates to clarify the impacts of these variables on erosion patterns. Investigating the effects of upstream pressure variations on throttling effects and hydrate formation will help enhance model robustness. In addition, the current model does not account for fluid–structure interaction (FSI, a physical phenomenon describing the interaction between fluid motion and solid structure deformation) or hydrate formation kinetics. Incorporating FSI can include nozzle deformation under extreme pressure, which alters flow channels and erosion hotspots. Integrating hydrate kinetics models can further predict how hydrate deposition modifies flow resistance and erosion behavior, thereby enabling a more realistic assessment of ice blockage risks. Furthermore, extending plunger structure optimization to other components can further reduce erosion. Testing advanced materials in comparison with the proposed WC-10Co4Cr coating may identify more durable solutions for ultra-high-pressure environments.

Author Contributions

Conceptualization, S.F. and Z.X.; methodology, H.L.; software, B.Z.; validation, F.G.; formal analysis, F.G.; investigation, H.J.; resources, P.Y.; data curation, S.F.; writing—original draft preparation, S.F.; writing—review and editing, Z.X.; visualization, Z.X.; supervision, H.L.; project administration, H.L.; funding acquisition, S.F. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by [PetroChina Tarim Oilfield Company] grant number [201023063206], and the APC was funded by [PetroChina Tarim Oilfield Company].

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

Authors Shaobo Feng, Zhixiong Xu, Hongtao Liu, and Bao Zhang were employed by the PetroChina Tarim Oilfield Company, and R&D Center for Ultra-Deep Complex Reservoir Exploration and Development, CNPC, Korla. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Fan, H.; Ming, X.; Li, Y.; Sun, K.; Li, T. Simulation analysis and experimental study on erosion performance of throttle valve. Oil Field Equip. 2019, 48, 52–57. [Google Scholar]

- Li, G.; Wang, Y.; He, R.; Cao, X.; Lin, C.; Meng, T. Numerical simulation of predicting and reducing solid particle erosion of solid-liquid two-phase flow in a choke. Pet. Sci. 2009, 6, 91–97. [Google Scholar] [CrossRef][Green Version]

- Tong, W.; Wang, Y.; Ju, S.; Li, X.; Wang, X.; Wang, B.; Wei, Q. Erosion characteristics and life prediction of cage-type subsea throttle nozzle. Surf. Technol. 2025, 54, 116–127. [Google Scholar]

- Luo, Y.-X.; Zhou, Z.-N.; Liu, P.; Li, W.-Q.; Jin, Z.-J.; Qian, J.-Y. Flow rate adjustable ratio analysis of a novel control valve with double sleeve. Flow Meas. Instrum. 2024, 98, 102630. [Google Scholar] [CrossRef]

- Yang, P.; Liu, H.; Li, N.; Zhou, B.; Chen, L.; Wen, L. Drilling design and optimization technology for ultra-deep wells in Tarim Oilfield: A case study of Well Luntan 1, the deepest well in Asia. China Pet. Explor. 2021, 26, 126–135. [Google Scholar]

- Fu, Y.; Li, Y.; Guo, L.; Feng, C.; Zhou, R. Research on erosion wear of cage-type throttle nozzle core based on CFD. Hot Work. Technol. 2016, 45, 5. [Google Scholar]

- Hu, G.; Zhang, P.; Wang, G.; Zhu, H.; Li, Q.; Zhao, S.; Qiao, K.; Wang, T. Performance study of erosion resistance on throttle valve of managed pressure drilling. J. Pet. Sci. Eng. 2017, 156, 29–40. [Google Scholar] [CrossRef]

- Lisowski, E.; Filo, G. CFD analysis of the characteristics of a proportional flow control valve with an innovative opening shape. Energy Convers. Manag. 2016, 123, 15–28. [Google Scholar] [CrossRef]

- Mitra, H.; Gabel, T.; Williams, D.; Koeck, F.; Mónico, R.O.; Alba, K. Computational study of compressible flow through choke valve. J. Fluids Struct. 2022, 113, 103670. [Google Scholar] [CrossRef]

- Wallace, M.; Dempster, W.; Scanlon, T.; Peters, J.; McCulloch, S. Prediction of impact erosion in valve geometries. Wear 2004, 256, 927–936. [Google Scholar] [CrossRef]

- Fu, L. Study on Throttling Temperature Drop Characteristics of Throttle Valve in a Gas Gathering Station. Master’s Thesis, Southwest Petroleum University, Chengdu, China, 2018. [Google Scholar]

- Chattopadhyay, H.; Kundu, A.; Saha, B.K.; Gangopadhyay, T. Analysis of flow structure inside a spool type pressure regulating valve. Energy Convers. Manag. 2012, 53, 196–204. [Google Scholar] [CrossRef]

- Wang, J. Erosion Analysis and Structural Optimization of Large-Guide-Surface Plunger Throttle Valve Based on CFD. Master’s Thesis, Yangtze University, Jingzhou, China, 2023. [Google Scholar]

- Nie, T. Research on Multi-Stage Cage-Type Throttle Nozzle for Ultra-High Pressure Natural Gas Wellhead. Master’s Thesis, Chongqing University of Science and Technology, Chongqing, China, 2022. Available online: https://kns.cnki.net/kcms2/article/abstract?v=wOuTVkq58NnIRgNnyMD-ZAbs8Ff7mzeIgBeCf-Pc-_fjnCsj1WsrhIbNT9nex8f5SZsAaWSGtYdwHAYgGZbU3pEc1oB9yko_fQ5LWRtWiZYYGFhKE14vMcb0u5yyEoEW9c-hT1oiHi-p3Amh1Li4HcU2Slv1n-pOxO7Tar05yp_XY41hhPGwRw==&uniplatform=NZKPT (accessed on 17 June 2025).

- Wang, J.; Peng, X.; Liu, L.; Li, Y.; Wang, J. Analysis of multi-hole throttling effect and erosion characteristics of high-pressure natural gas. Acta Pet. Sin. 2018, 34, 521–529. [Google Scholar]

- Zhu, J. Study on Erosion of Subsea Throttle Nozzle Under Multi-Channel Flow Field Conditions. Master’s Thesis, China University of Petroleum (Beijing), Beijing, China, 2017. [Google Scholar]

- Chang, H. Design and Research of Throttle Valve for High-Pressure Gas Wells. Master’s Thesis, China University of Petroleum (East China), Qingdao, China, 2022. Available online: https://kns.cnki.net/kcms2/article/abstract?v=wOuTVkq58NnDucjgc0_itFyzqbaKe3o8wzfzGQs98pXbCd1RMM2L6bO-ors2aMLkmy_Tj6m3ZZiiUSGGGKJeYh_Kcu9Q09C8q6NAhO4RivYpVoJzrEeLGN2jjtK4a9jf3wEdz1BpCcY1yPdpin9eSU9uzHscNY-yzSAqQYOPqPujNc45_XQECA&uniplatform=NZKPT&language=CHS&captchaId=632706a6-ab0d-4853-b837-7594fdd2b152 (accessed on 17 June 2025).

- Forder, A.; Thew, M.; Harrison, D. A numerical investigation of solid particle erosion experienced within oilfield control valves. Wear 1998, 216, 184–193. [Google Scholar] [CrossRef]

- Zhou, J.; Zhang, Y.; Xiong, Z.; Shang, J. Numerical simulation of throttling effect of downhole throttle valve in coalbed methane well. J. China Univ. Pet. 2021, 45, 144–151. [Google Scholar]

- Pope, S.B. Turbulent Flows; Cambridge University Press: Cambridge, UK, 2000. [Google Scholar]

- Versteeg, H.K.; Malalasekera, W. An Introduction to Computational Fluid Dynamics: The Finite Volume Method, 2nd ed.; Pearson Education Limited: London, UK, 2007. [Google Scholar]

- Reid, R.C.; Prausnitz, J.M.; Poling, B.E. The Properties of Gases and Liquids, 4th ed.; McGraw-Hill: New York, NY, USA, 1987. [Google Scholar]

- Duan, Z.H.; Møller, S.L. Fredenslund Aa. Calculation of methane solubility in water under high pressures and temperatures. Fluid Phase Equilibria 1992, 78, 149–164. [Google Scholar]

- Peng, D.Y.; Robinson, D.B. A new two-constant equation of state. Ind. Eng. Chem. Fundam. 1976, 15, 59–64. [Google Scholar] [CrossRef]

- Zhu, J.L.; Li, Q.P.; Qin, R.; Yao, H.Y. Numerical simulation and law study on temperature drop of multiphase throttling in subsea nozzle. China Pet. Mach. 2022, 50, 65–71. [Google Scholar]

- Li, X.; Zhang, H.; Chen, G. Numerical simulation of high-pressure natural gas flow in gathering pipelines considering real gas effects. J. Nat. Gas Sci. Eng. 2018, 57, 312–321. [Google Scholar]

- Cao, F.; Wang, T.; Cao, L.; Wang, B. Prediction of natural gas hydrate formation conditions by numerical calculation. Guangzhou Chem. Ind. 2013, 41, 3. [Google Scholar]

- Meng, J. Multi-Parameter Erosion Analysis of Subsea Throttle Nozzle. Master’s Thesis, China University of Petroleum (Beijing), Beijing, China, 2022. [Google Scholar]

- Sun, R. Study on the relationship between opening degree and flow area of cage-type throttle nozzle. Pet. Chem. Equip. 2015, 18, 40–43. [Google Scholar]

- Murugan, K.; Ragupathy, A.; Balasubramanian, V.; Sridhar, K. Optimizing HVOF spray process parameters to attain minimum porosity and maximum hardness in WC–10Co–4Cr coatings. Surf. Coat. Technol. 2014, 247, 90–102. [Google Scholar] [CrossRef]

- Thakur, L.; Arora, N.; Jayaganthan, R.; Sood, R. An investigation on erosion behavior of HVOF sprayed WC–CoCr coatings. Appl. Surf. Sci. 2011, 258, 1225–1234. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).